Abstract

The microstructural and magnetic properties of perpendicular anisotropic CoCrPt films deposited on Ru or RuCoCrX (X = Ti, Re) intermediate layers were studied. The c-axis of CoCrPt grains were promoted by (0002) textured RuCoCr, and RuCoCrX (X = Ti, Re) intermediate layers due to smaller lattice misfit as compared to Ru. The narrower rocking width (Δθ50 = 3.76°) in RuCoCrRe intermediate layer and CoCrPt shows higher out of plane coercivity (Hc = 6.2 kOe), magnetic anisotropy constant (Ku = 6.2 × 106 erg/cm3) and nucleation field (HN = −2.8kOe) as compared to the Ru intermediate layer (Hc = 5.4 kOe, Ku = 5.9 × 106 erg/cm3, HN = −1.6 kOe). The partial intergranular exchange decoupling of CoCrPt grains was observed. The grain boundaries oxides were formed by the residual oxygen in targets and sputtering processes. The minor Cr2O3, CoO, TiO2, ReO3 oxides were investigated by surface analysis. Due to the minor oxides and Cr segregation at grains boundaries, the CoCrPt films present high coercivity. Samples CoCrPt/RuCoCr and CoCrPt/RuCoCrTi present a minimum at 45° but the values are much higher than the ideal Stoner-Wohlfarth theoretical value 0.5 which could be due to fewer natural oxides for magnetic grains separation. In sample CoCrPt/RuCoCrRe, there is an increase of intergranular interaction as indicated by the large asymmetry and the shift of the minimum at lower angles.

1. Introduction

The CoCrPt (oxides) perpendicular magnetic anisotropy thin films have been applied in current perpendicular magnetic recording media for long periods of time but are still required to improve the properties in the near future [1,2,3,4,5,6,7,8,9,10,11,12,13,14]. Although ordered L10-FePt with higher perpendicular anisotropy has been promised for future ultra-high density heat-assisted magnetic recording media [15,16,17], improvements of the intermediate-, exchange coupling- and capping-layer are needed to optimize the magnetic properties and microstructure of CoCrPt-oxide granular films for next- generation devices.

Intergranular exchange decoupling in CoCrPt-based granular media is required to reduce the noise in media and to increase the SNR (signal to noise ratio) which is one of the essential issues for further increase of the area density [8]. The high and low melting amorphous oxides which do not dissolve in CoCrPt lattice have been utilized to segregate to the grain boundary area in granular media [8]. To further separate the CoCrPt grains in the initial growth stage, thinner nonmagnetic RuCoCr(Ti, Re)-oxide layer was deposited on the bump and trench of high-pressure Ru seed layer [8]. The grains separation and grain boundary thickness were clearly influenced by the kind and volume of oxides-materials. In this paper, we propose the nonmagnetic RuCoCrX (X = Ti, Re) to modify the crystallinity and microstructure of the current use Ru and RuCoCr intermediate layer. Replacement of Ru with RuCoCr provides more bulk and surface diffusion because of lower melting points. The c-axis of CoCrPt grains were promoted by (0002) textured RuCoCr, and RuCoCrX (X = Ti, Re) intermediate layers due to smaller lattice misfit as compared to Ru. The doping of multiple-oxides is important for magnetic grains separation and grain boundaries thickness. To control the oxide-content more precisely in magnetic- and intermediate-layer, we novelty discuss the native-oxide from metallic CoCrPt ferromagnetic- and RuCoCr and RuCoCrX (X = Ti, Re) intermediate-layers fundamentally. The minor native oxides (Cr2O3, CoO, TiO2, ReO3) were formed by the residual oxygen in targets and sputtering process. Due to the native-oxides segregation effect, the CoCrPt films deposited on RuCoCr(Ti, Re) intermediate layers show high perpendicular anisotropy and out-of-plane coercivity.

2. Materials and Methods

CoCrPt thin films with a target composition of Co75Cr4Pt21 were direct current sputtered onto Ru, Ru50Co25Cr25 and Ru47Co25Cr25X3 (X = Ti, Re) intermediate layers with the NiW/NiTa seed layer and a base pressure of the magnetron sputtering system was 5 × 10−7 Torr. A 10 nm thick Ni-Ta amorphous layer was first sputtered on a glass substrate (Corning Eagle XG) using a Ni62.5Ta37.5 alloy target and the 10 nm thick Ni-W with (111) texture was sputtered on NiTa using Ni92W8 alloy target. The (0002) textured Ru, Ru50Co25Cr25 and Ru47Co25Cr25X3 (X = Ti, Re) intermediate layers with a thickness of 20 nm were grown on NiW(111) to be the epitaxial layer. Finally, the CoCrPt films with an optimal thickness of 18 nm were deposited on each intermediate layer.

To study the intermediate layer effect, the magnetic CoCrPt layer was deposited on RuCoCr, RuCoCrTi and RuCoCrRe. A CoCrPt/Ru/NiW/NiTa sample for reference was also deposited under the same sputtering parameters. All the layers were sputtered at room temperature, the deposition rates of each material being set to 0.053 nm/s (20W-DC) for NiTa, 0.044 nm/s (20W-DC) for NiW, 0.025 nm/s (60W-RF) for Ru, 0.034 nm/s for RuCoCr (60W-RF), 0.038 for RuCoCrTi (60W-RF), 0.042 for RuCoCrRe (60W-RF) and 0.213 nm/s (80W-DC) for CoCrPt.

The crystal structure was investigated by X-ray diffraction (XRD) using a BRUKER, D8 Discover diffractometer (D8 Discover, Bruker, Billerica, MA, USA) with Cu-Kα (λ = 0.1542 nm) radiation. The microstructure observation was carried out by transmission electron microscopy (TEM, JEOL JEM-2010, Tokyo, Japan). The magnetic hysteresis loops were measured at room temperature by vibrating sample magnetometer (VSM, DMS-1660, MicroSense, Lowell, USA). Angular dependence of switching field and DCD curves were measured by using a vector vibrating sample magnetometer (VSM, Microsense Model 10, Lowell, USA) equipped with a rotating electromagnet and two sets of pick-up coils perpendicular to each other that allow simultaneous collection of the component of the magnetization vector along with different directions. The compositions and chemical state of magnetic- and intermediate-layers were measured by x-ray photoelectron spectroscopy (XPS, ULVAC-PHI 5000, Kanagawa, Japan).

3. Results and Discussion

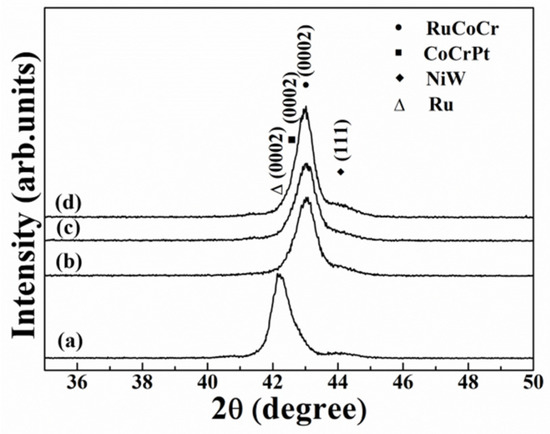

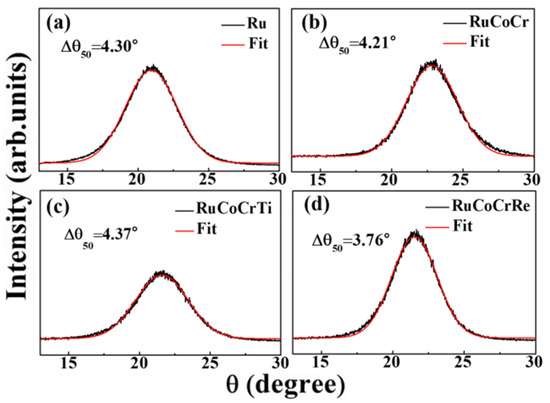

Figure 1 presents the X-ray diffraction patterns of CoCrPt/y/NiW/NiTa, here y is Ru, RuCoCr or RuCoCrX (X = Ti, Re) intermediate layer. The 10 nm thick NiW shows (111) texture on the amorphous NiTa layer. The Ru, RuCoCr, and RuCoCrX (X = Ti, Re) hcp (0002) main peaks were clearly identified and the CoCrPt hcp (0002) peaks were partially overlapped with the (0002) main peaks. The (0002) diffraction peaks were shifted to a higher angle when the Ru was alloyed by CoCr, CoCrTi, or CoCrRe. The c-axis in RuCoCr and RuCoCrX (X = Ti, Re) intermediate layers were contracted due to a smaller atomic radius of Co and Cr. The intermediate layers Ru, RuCoCr, RuCoCrX (X = Ti, Re) and CoCrPt presents a preferred orientation growth with the magnetic easy c-axis perpendicular to the substrate. The NiW buffer layer illustrates an fcc (111) crystallographic structure, which enhances the Ru, RuCoCr, and RuCoCrX (X = Ti, Re) (0002) texture. The preferential growth degree along the c-axis of the Ru, RuCoCr, RuCoCrX (X = Ti, Re) layers was measured by the full width at half maximum (FWHM) of the corresponding rocking curves (Figure 2). The rocking width (Δθ50) estimated by a Lorentzian interpolation of the peak (4.30°, 4.21°, 4.37° and 3.76° for samples with respective Ru, RuCoCr, RuCoCrTi, RuCoCrRe intermediate layers) shows a small angular dispersion of the c-axis as compare to the film normal. There is a significant reduction of Δθ50 as a RuCoCrRe layer is introduced; this result indicates the higher crystallinity in this intermediate film.

Figure 1.

X-ray diffraction (XRD) patterns of CoCrPt/y/NiW/NiTa, here y is (a) Ru, (b) RuCoCr, (c) RuCoCrTi and (d) RuCoCrRe intermediate layer.

Figure 2.

Rocking curves of (a) Ru, (b) RuCoCr, (c) RuCoCrTi, and (d) RuCoCrRe (0002) peaks.

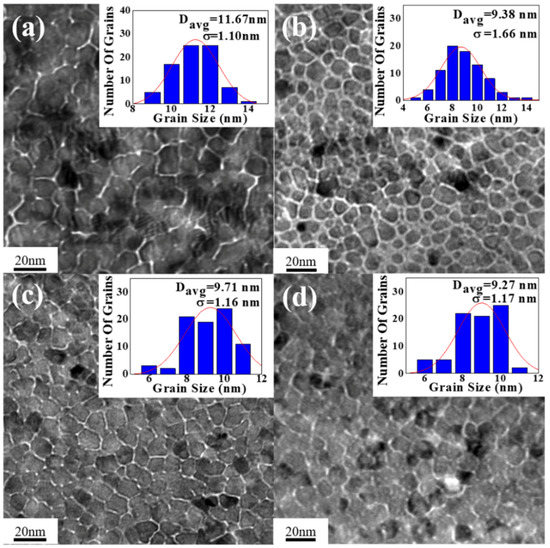

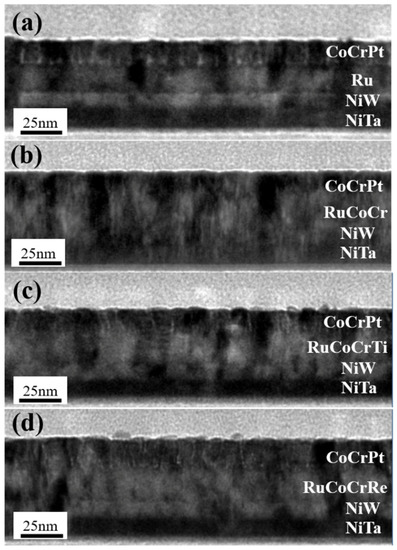

Figure 3 and Figure 4 illustrate the plane- and cross sectional-view TEM images of CoCrPt/y/NiW/NiTa, here y is Ru, RuCoCr or RuCoCrX (X = Ti, Re) intermediate layer. The CoCrPt layer presents in-plane granular structure which consisting columnar grains and an average grains size decreasing from 11.7 ± 1.10 nm for the sample with Ru intermediate layer to 9.38 ± 2.46, 9.71 ± 2.21 and 9.27 ± 2.14 nm for samples with RuCoCr, RuCoCrTi and RuCoCrRe intermediate layers, respectively.

Figure 3.

Plane view transmission electron microscopy (TEM) images of CoCrPt/y/NiW/NiTa, here y is (a) Ru, (b) RuCoCr, (c) RuCoCrTi, and (d) RuCoCrRe intermediate layer.

Figure 4.

Cross-section TEM images of CoCrPt/y/NiW/NiTa, here y is (a) Ru, (b) RuCoCr, (c) RuCoCrTi, and (d) RuCoCrRe intermediate layer.

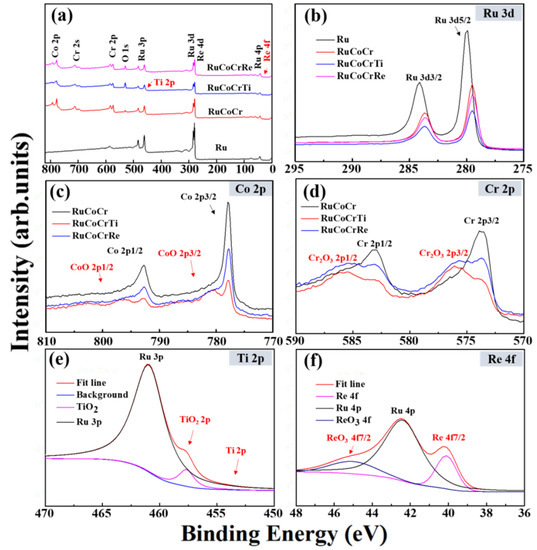

The metallic CoCrPt/[Ru, RuCoCr, RuCoCr(Ti, Re)] bilayers show granular structure which could be due to the formation of native oxides as indicated by the XPS analysis (Figure 5). The full XPS spectra of Ru, RuCoCr, and RuCoCr(Ti, Re) intermediate layers are illustrated in Figure 5a. After fitting, the Ru element is in metallic Ru for all the samples and the off-set values are 0.8 eV and 1.3 eV for samples with Ru and RuCoCr series intermediate layers as indicated in Figure 5b. The reference binding energy of Ru element is 280.2 for 3d5/2, and 282.4 eV for 3d3/2. After fitting, the Co and Cr elements are almost present in metallic (Co, Cr) but slight CoO, Cr2O3 oxides are indexed in Figure 5c,d. The off-set values are both 1.2 eV for Co and CoO, and 1.0 eV for Cr and Cr2O3. The reference binding energy of Co element is 778.5 eV for 2p3/2 and 793.3 eV for 2p1/2, respectively. The CoO oxide has higher reference binding energy at 781.2 eV for 2p3/2 and 796.5 eV for 2p1/2. In Figure 5e, the Ti and Re elements show metallic (Ti, Re) and oxides form (TiO2, ReO3) in both respective RuCoCrTi and RuCoCrRe intermediate layers.

Figure 5.

X-ray photoelectron spectroscopy (XPS) spectra of intermediate layers, (a) full spectra, (b) Ru, (c) Co, (d) Cr, (e) Ti, (f) Re.

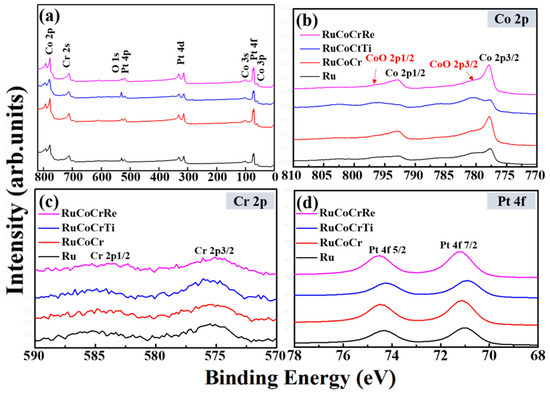

Figure 6 shows the XPS spectra of CoCrPt magnetic layer. The Co, Cr, Pt elements are in the metallic state but slight CoO oxide is present. The granular structure observed in the TEM images can be explained by the formation of CoO, Cr2O3, TiO2, and ReO3 at the grains boundaries of magnetic and intermediate layers.

Figure 6.

XPS spectras of CoCrPt magnetic layer, (a) full spectra, (b) Co, (c) Cr, (d) Pt.

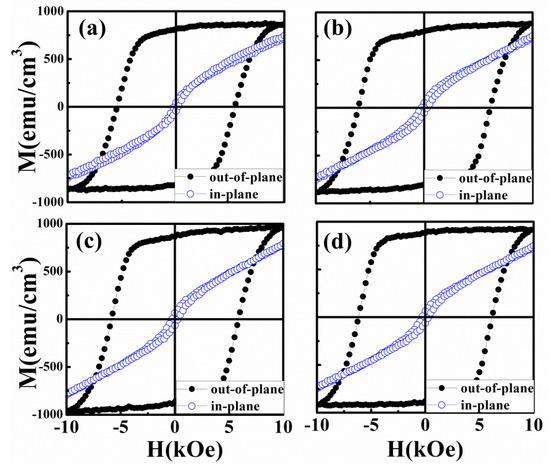

Figure 7 illustrates the room temperature out of the plane and in-plane magnetic hysteresis loops of CoCrPt/y/NiW/NiTa films, here y is Ru, RuCoCr or RuCoCrX (X = Ti, Re) intermediate layer. Total samples have a strong perpendicular magnetization and an almost neglect weak in-plane (hard axis) hysteresis. To compare properties between the films, the values of the saturation of magnetization (Ms), out-of-plane coercivity (HC⊥), nucleation field (HN) (here the nucleation field is defined as the reversed field that causes the saturation magnetization (Ms) to drop to 0.95), anisotropy constant (Ku) and lattice misfit (f) were evaluated and summarized in Table 1.

Figure 7.

Out-of-plane and in-plane field-dependent magnetization loops of CoCrPt/y/NiW/NiTa, here y is (a) Ru, (b) RuCoCr, (c) RuCoCrTi, and (d) RuCoCrRe intermediate layer.

Table 1.

Magnetic parameters obtained from room temperature out-of-plane field dependent magnetization loops. Ms saturation of magnetization; HC⊥: out-of-plane coercivity; HN: nucleation filed; Ku: anisotropy constant; f: lattice misfit.

The anisotropy constant was determined as Ku = HkMs/2, where Hk is the anisotropy field measured by the merge point of the in-plane (IP) and out-of-plane (OOP) magnetization loops. The intersection point of the IP and OOP loop was fitted approximately by extending the magnetization curve linearly. When the RuCoCr or RuCoCrX (X = Ti, Re) intermediate layer is used, the nucleation field is significantly promoted and the out-of-plane coercivity and anisotropy the of CoCrPt increases slightly as consequences of improvement of microstructure and smaller lattice misfit of the RuCoCr- and CoCrPt layers, as indicated by the TEM and XRD results.

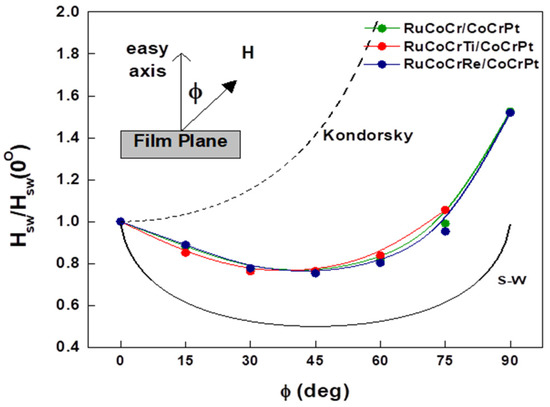

To investigate in detail the effect of intermediate layers on the magnetic grains coupling, the magnetization reversal of CoCrPt/y/NiW/NiTa, y = Ru, RuCoCr, and RuCoCrX (X = Ti, Re) intermediate layers were studied by measuring the angular dependence of the switching field, Hsw vs. ϕ, (Figure 8), where ϕ is the angle between the applied field H and the easy axis of magnetization (see inset in Figure 8). The measured curves were compared with the theoretical Kondorsky (incoherent switching by domain wall motion in highly exchange coupled systems) [18] and Stoner-Wohlfarth (S-W, coherent rotation for isolated particles) models [19]. A series of magnetic easy axis Direct Current Demagnetization (DCD) curves were measured at different ϕ values (ranging between 0° and 90°), using a non-conventional procedure that allows an explanation between experimental results and model [20,21]. The sample was first saturated at an out-of-plane field of −19.5 kOe, and the DCD curves were measured at each angle ϕ and the remanent magnetization (Mre) along the magnetic easy axis direction was obtained. The remanent curves were used to determine the remanent coercivity Hcr (defined as the field where the remanence is equal to zero), which well represents the switching field Hsw. All the samples present a similar trend [11].

Figure 8.

Angular dependence of the normalized switching field (Hsw/Hsw,0°) as a function of the CoCrPt/y/NiW/NiTa, y = RuCoCrX (X = Ti, Re) films; the curve of the reference sample (RuCoCr intermediate layer) is also reported together with the theoretical curves corresponding to the Stoner-Wohlfarth and Kondorsky switching models.

Samples CoCrPt/RuCoCr and CoCrPt/RuCoCrTi present a minimum at 45° but the values are much higher than the ideal Stoner-Wohlfarth theoretical value 0.5 which could be due to fewer natural oxides for magnetic grains separation. The origin of the observed asymmetry (without a shift of the minimum) could be due to the coexistence of coherent and incoherent reversal processes. In sample CoCrPt/y/NiW/NiTa, y = RuCoCrRe there is an increase of intergranular interaction, as indicated by the large asymmetry and the shift of the minimum of angular dependence curve at lower angles.

4. Conclusions

The RuCoCr alloy doped with less Re shows better crystallinity which was evidenced in lower rocking width value and higher (002) texture. The perpendicular magnetic anisotropy, nucleation field, and out-of-plane coercivity were enhanced when the CoCrPt deposited on the RuCoCrRe intermediate layer. From the microstructure, smaller magnetic CoCrPt grains were obtained in the early growth stage by the nonmagnetic RuCoCrRe intermediate layers.

Author Contributions

J.-L.T. was designed the experiments, analyzed the data and paper writing; J.-Y.C. were performed the sample preparation experiments; T.-W.H., C.D., and S.-M.W. were performed the microstructure and surface investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Science and Technology, Taiwan, the grant number [MOST 108-2221-E-005-031.], Solar Applied Materials Technology Corp., Taiwan, the grant number [107D520].

Acknowledgments

The authors would like to thank for Solar Applied Materials Technology Corp. for sputtering targets support. Also we would like to thank for Gaspare Varvaro for providing VSM measurement (VSM, Microsense Model 10) and discussion.

Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Ball, D.K.; Günther, S.; Fritzsche, M.; Lenz, K.; Varvaro, G.; Laureti, S.; Makarow, D.; Mücklich, A.; Facsko, S.; Albrecht, M.; et al. Out-of-plane magnetized cone-shaped magnetic nanoshells. J. Phys. D Appl. Phys. 2017, 50, 115004. [Google Scholar] [CrossRef]

- Watanabe, D.; Mizukami, S.; Oogane, M.; Naganuma, H.; Ando, Y.; Miyazaki, T. Fabrication of MgO-based magnetic tunnel junctions with CoCrPt perpendicularly magnetized electrodes. J. Appl. Phys. 2009, 105, 07C911. [Google Scholar] [CrossRef]

- Varvaro, G.; Agostinelli, E.; Laureti, S.; Testa, A.M.; Garc´-ıa-Martin, J.M.; Briones, F.; Fiorani, D. Magnetic anisotropy and intergrain interactions in L10 CoPt(111)/Pt(111)/MgO(100) PLD granular films with tilted easy axes. J. Phys. D Appl. Phys. 2008, 41, 134017. [Google Scholar] [CrossRef][Green Version]

- Beaujour, J.M.; Tran, C.; Weller, D.; York, B.; Gurney, B. Anomalous Enhancement of the Magnetic Anisotropy of CoCrPt Alloy Thin Film with Ultrathin Pt Interface. IEEE Trans. Magn. 2016, 52, 2100104. [Google Scholar] [CrossRef]

- Albrecht, T.R.; Arora, H.; Vitikkate, V.A.; Beaujour, J.M.; Bedau, D.; Berman, D.; Bogdanov, A.L.; Chapuis, Y.A.; Elizabeth, J.C.; Dobisz, E.; et al. Bit-Patterned Magnetic Recording: Theory, Media Fabrication, and Recording Performance. IEEE Trans. Magn. 2015, 51, 0800342. [Google Scholar] [CrossRef]

- Elphick, K.; Vallejo-Fernandez, G.; Klemmer, T.J.; Thiele, J.-U.; O’Grady, K. HAMR media based on exchange bias. Appl. Phys. Lett. 2016, 109, 052402. [Google Scholar] [CrossRef]

- Nakayama, Y.; Kusanagi, Y.; Shimatsu, T.; Kikuchi, N.; Okamoto, S.; Kitakami, O. Microwave-Assistance Effect on Magnetization Switching in Antiferro-magnetically Coupled CoCrPt Granular Media. IEEE Trans. Magn. 2016, 52, 3201203. [Google Scholar] [CrossRef]

- Jung, H.-J. Conventional Perpendicular Magnetic Recording Media. In Ultrahigh-Density Magnetic Recording; Varvaro, G., Casoli, F., Eds.; Pan Stanford Publishing: Singapore, 2016; pp. 133–194. [Google Scholar]

- Tham, K.K.; Kushibiki1, R.; Kamada, T.; Hinata, S.; Saito, S. Reduction of Intergranular Exchange Coupling for CoPt–B2O3 Granular Media by Employing a RuCoCr-Oxide Buffer Layer With Oxide of Various Melting Points. IEEE Trans. Magn. 2018, 54, 3201004. [Google Scholar]

- Kushibiki, R.; Tham, K.K.; Hinata, S.; Saito, S. High Ku and small grain size Co80Pt20 granular media with double oxide grain boundary materials consisting of B2O3. AIP Adv. 2017, 7, 056512. [Google Scholar] [CrossRef]

- Tsai, J.L.; Pi, C.; Chang, Y.S.; Wu, Y.T.; Chen, Y.R.; Chang, C.W.; Varvaro, G. Effect of Pd Buffer and Interlayer on the Magnetic Properties of CoCrPt-Oxide Granular Thin Films. IEEE Trans. Magn. 2018, 54, 3200705. [Google Scholar] [CrossRef]

- Tamai, I.; Araki, R.; Tanahashi, K. Magnetic and Recording Characteristics of CoCrPt-Oxide Media with a Mixture of SiO2 and TiO2. IEEE Trans. Magn. 2008, 44, 3492. [Google Scholar] [CrossRef]

- Kikuchi, N.; Kitakami, O.; Okamoto, S.; Shimada, Y.; Sakuma, A.; Otani, Y.; Fukamichi, K. Influence of 5d transition elements on the magnetocrystalline anisotropy of hcp-Co. J. Phys. Condens. Matter 1999, 11, L485. [Google Scholar] [CrossRef]

- Piramanayagam, S.N. Perpendicular recording media for hard disk drives. J. Appl. Phys. 2007, 102, 011301. [Google Scholar] [CrossRef]

- Weller, D.; Parker, G.; Mosendz, O.; Lyberatos, A.; Mitin, D.; Safonova, N.Y.; Albrecht, M. FePt heat assisted magnetic recording media. J. Vac. Sci. Technol. B 2016, 34, 060801. [Google Scholar] [CrossRef]

- Hono, K.; Takahashi, Y.K. L10-FePt granular films for heat-assisted magnetic recording media. In Ultrahigh Density Magnetic Recording; Varvaro, G., Casoli, F., Eds.; Pan Stanford Publishing: Singapore, 2016; pp. 246–277. [Google Scholar]

- Tsai, J.L.; Weng, S.M.; Dai, C.; Chen, J.Y.; Huang, L.C.; Hsu, T.W. Surface modification of FePt(Ag, C) granular film by ultrathin B4C capping layer. Appl. Surf. Sci. 2020, 509, 145337. [Google Scholar] [CrossRef]

- Kondorsky, E. On hysteresis in ferromagnetics. J. Phys. 1940, 2, 161–181. [Google Scholar]

- Stoner, E.C.; Wohlfarth, E.P. A mechanism of magnetic hysteresis in heterogeneous alloys. IEEE Trans. Magn. 1991, 27, 3475–3518. [Google Scholar] [CrossRef]

- Varvaro, G.; Testa, A.M.; Agostinelli, E.; Fiorani, D.; Laureti, S.; Springer, F.; Brombacher, C.; Albrecht, M.; del Bianco, L.; Barucca, G.; et al. Study of microstructure and magnetization reversal mechanism in granular CoCrPt:SiO2 films of variable thickness. Mater. Chem. Phys. 2013, 141, 790–796. [Google Scholar] [CrossRef]

- Coffey, K.R.; Thomson, T.; Thiele, J.U. Angular dependence of the switching field of thin-film longitudinal and perpendicular magnetic recording media. J. Appl. Phys. 2002, 92, 4553–4559. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).