Effect of Brazing Parameters on the Microstructure and Properties of SiC Ceramic Joint with Zr-Cu Filler Metal

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

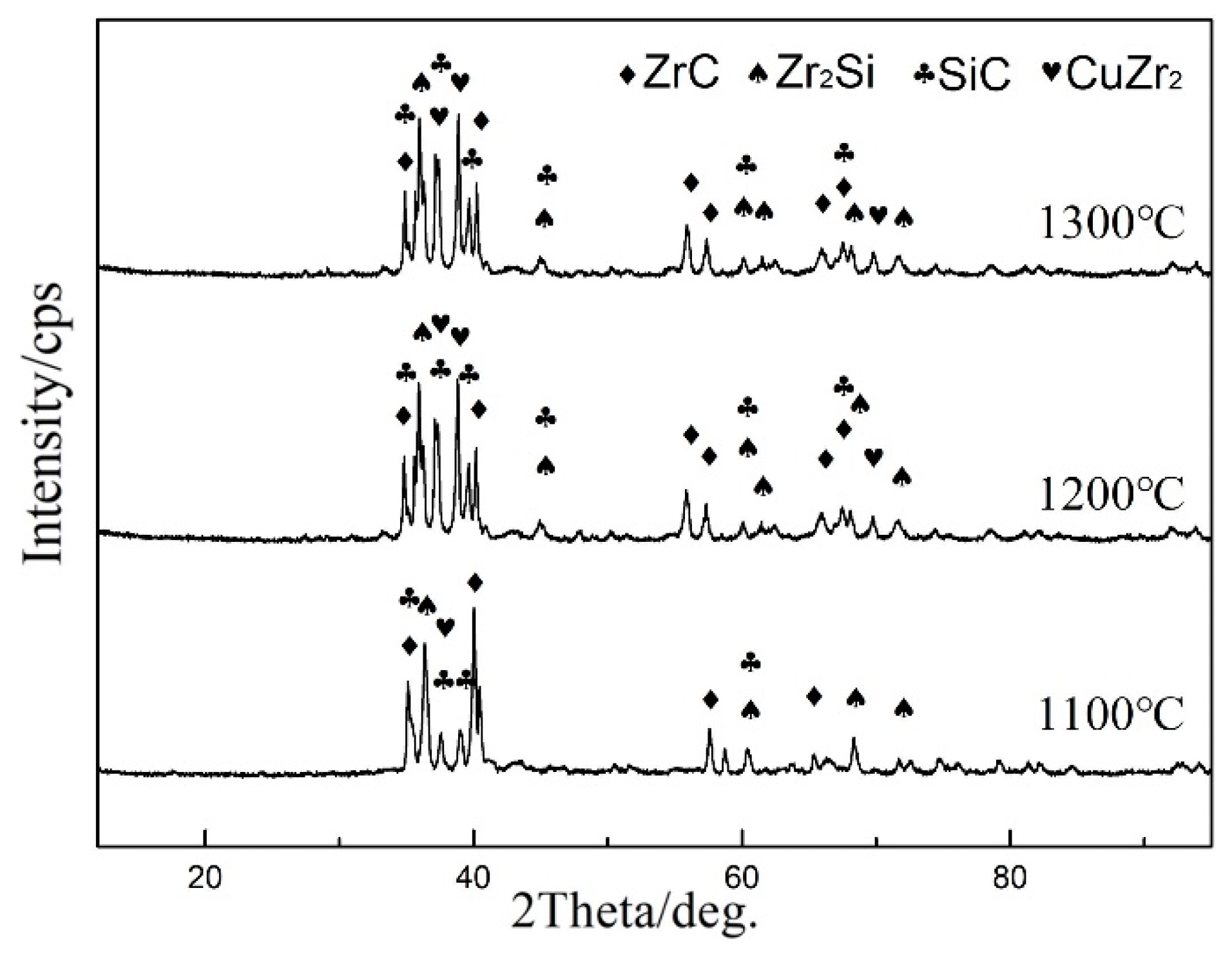

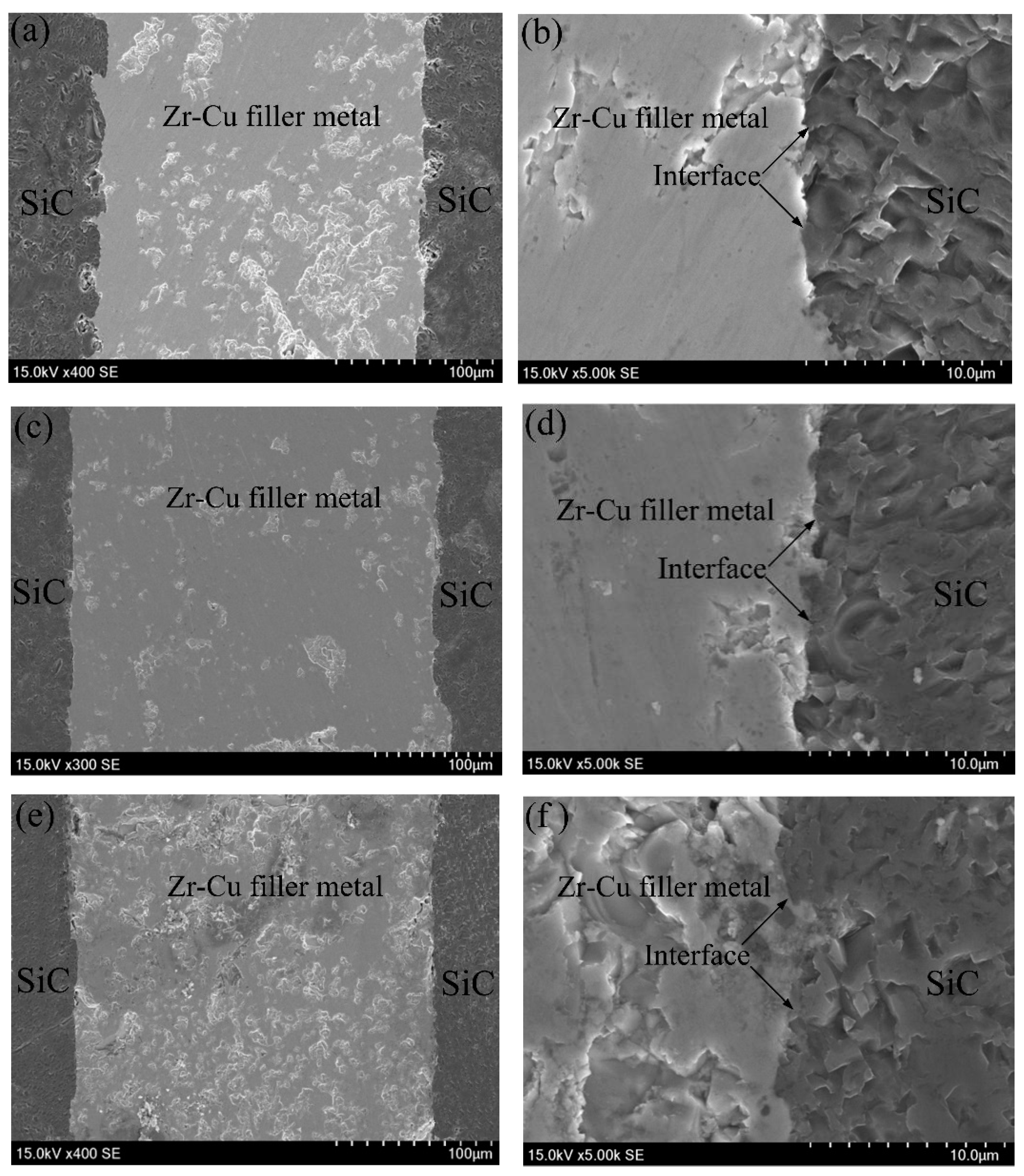

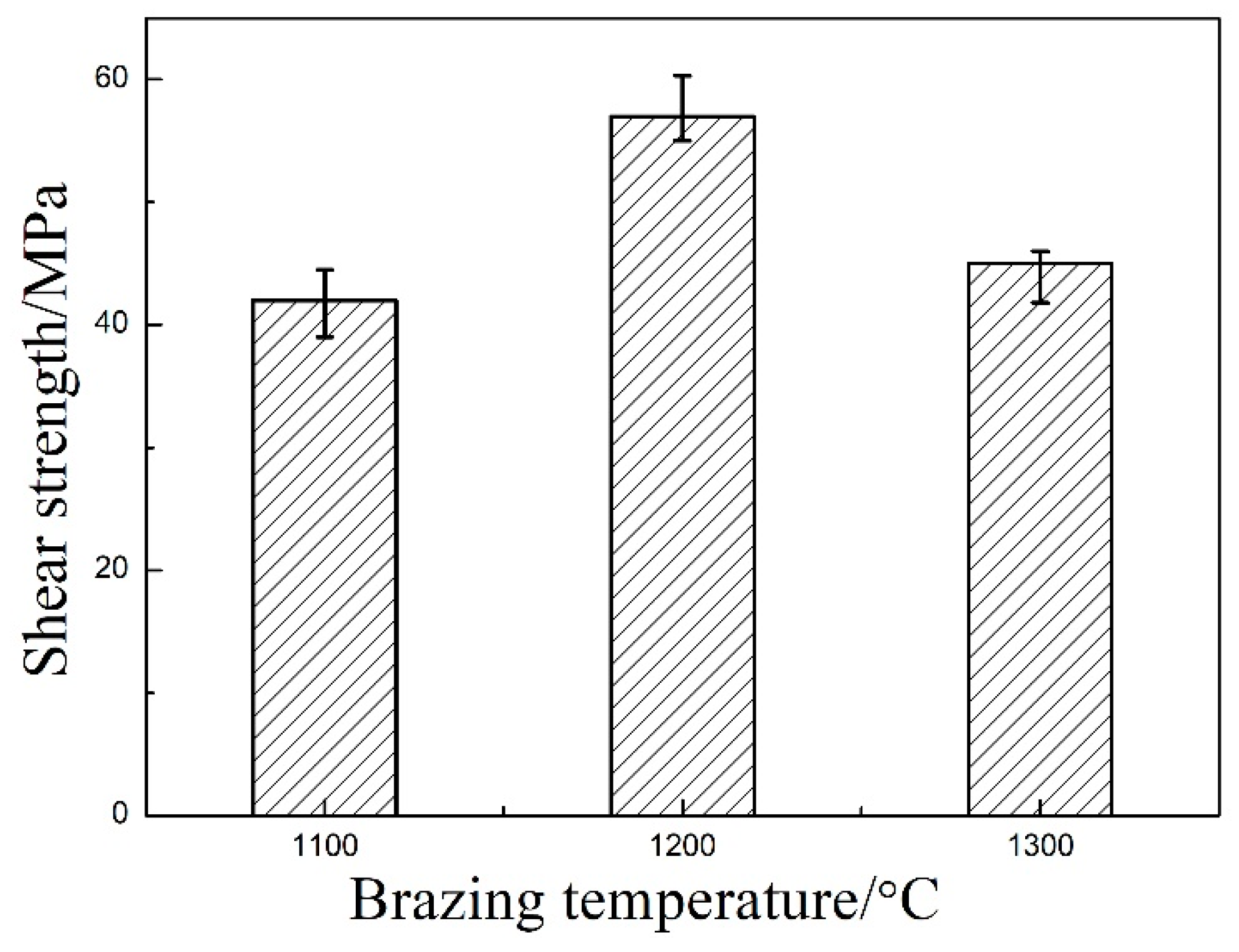

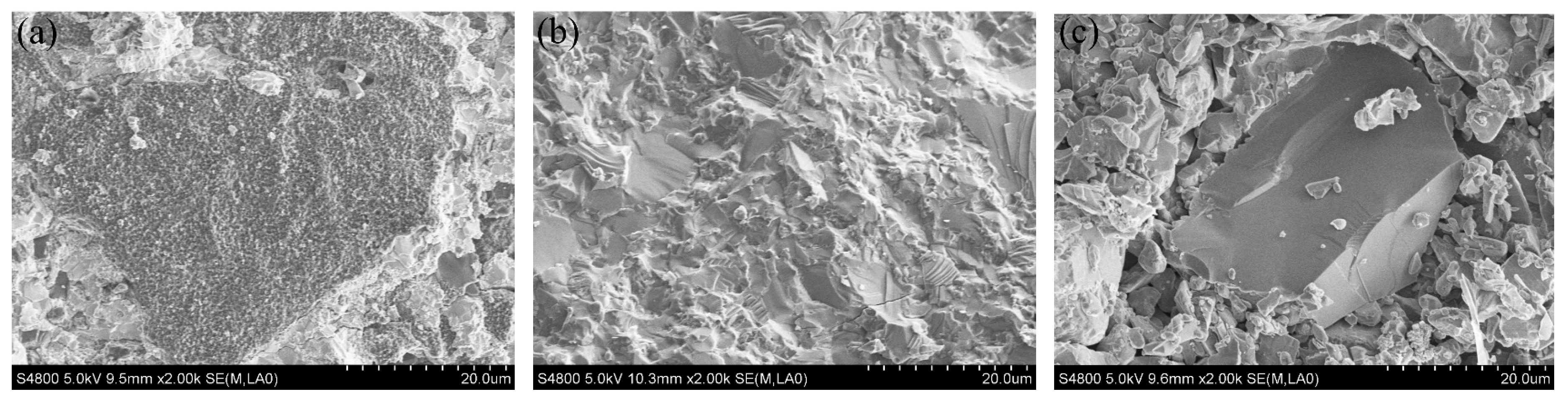

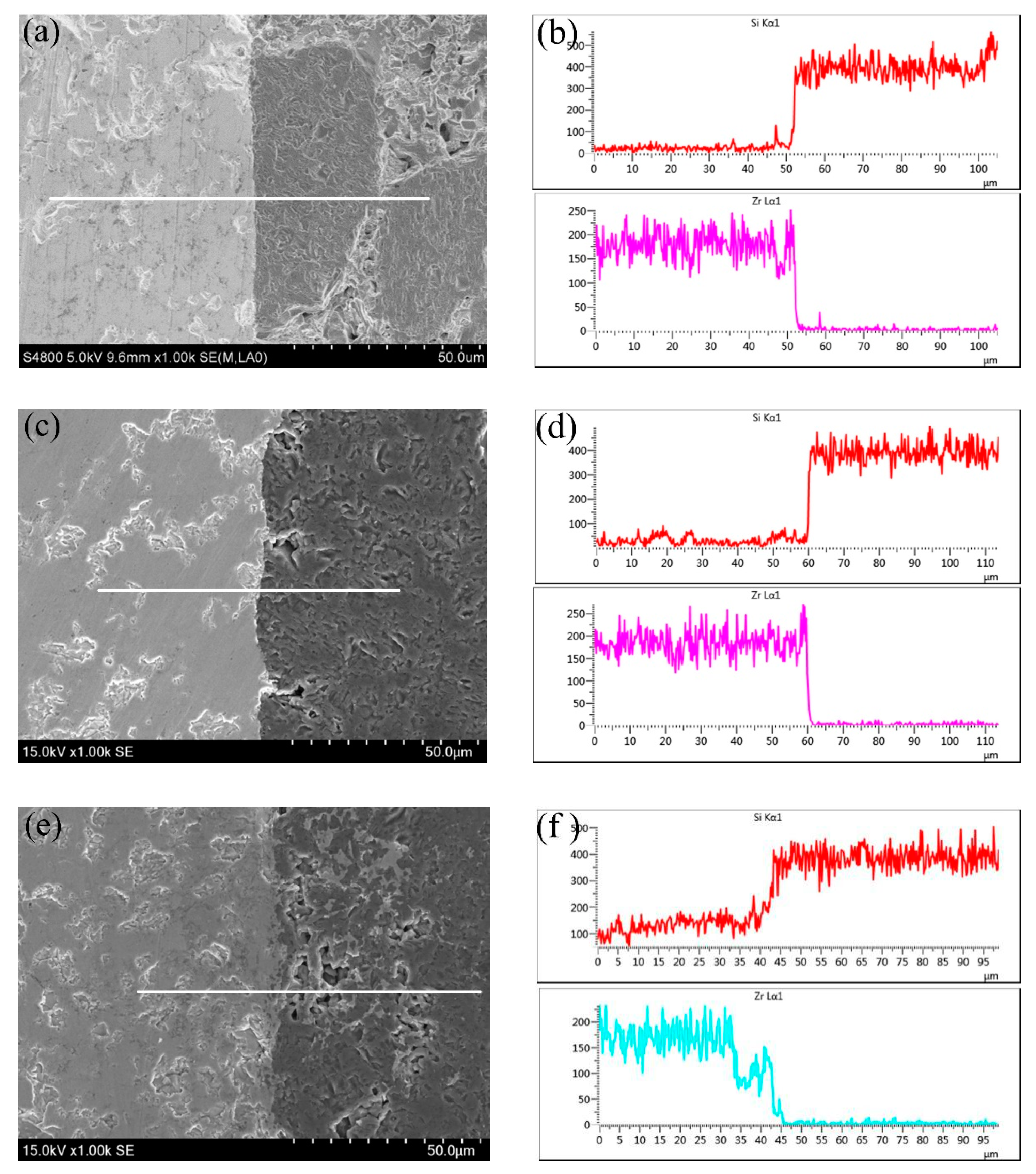

3.1. Brazing Temperature

3.2. Holding Time

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, Y.H.; Jiang, D.L.; Zhang, X.F. Enhancing toughness and strength of SiC ceramics with reduced graphene oxide by HP sintering. J. Eur. Ceram. Soc. 2018, 38, 4329–4337. [Google Scholar] [CrossRef]

- Chen, M.W.; Xie, W.J.; Oiu, H.P. Recent progress in continuous SiC fiber SiC ceramic matrix composites. Adv. Appl. Ceram. 2016, 37, 393–402. [Google Scholar]

- Katoh, Y.; Snead, L.L.; Henager, C. Current status and recent research achievements in SiC/SiC composites. J. Nucl. Mater. 2014, 455, 387–397. [Google Scholar]

- Yu, Y.; Dong, H.Y.; Ma, B. Effect of different filler materials on the microstructure and mechanical properties of SiC/SiC joints joined by spark plasma sintering. J. Alloy. Compd. 2017, 708, 373–379. [Google Scholar] [CrossRef]

- Feinroth, H.; Ales, M.; Barringer, E. Mechanical strength of CTP triplex SiC fuel clad tubes after irradiation in MIT research reactor under PWR coolant conditions. Ceram. Eng. Sci. Process. 2009, 30, 47–55. [Google Scholar]

- Passerini, S.; Kazimi, M.S.; Shwageraus, E. A systematic approach to nuclear fuel cycle analysis and optimization. Nucl. Sci. Eng. 2014, 178, 186–201. [Google Scholar] [CrossRef]

- Blugan, G.; Kuebler, J.; Bissig, V. Brazing of silicon nitride ceramic composite to steel using SiC-particle-reinforced active brazing alloy. Ceram. Int. 2007, 33, 1033–1039. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.X.; Zhong, Z.H. In-situ formation of fine-grained carbide composite interlayer during diffusion bonding of SiC ceramic. J. Alloy.Compd. 2018, 763, 875–882. [Google Scholar] [CrossRef]

- Tian, W.; Kita, H.; Hyuga, H. Reaction joining of SiC ceramics using TiB2-based composites. J. Eur. Ceram. Soc. 2010, 30, 3203–3208. [Google Scholar] [CrossRef]

- Zhou, B.F.; Feng, K.Q.; Zhou, H.L. Joining of SiC ceramic by using the liquid polyvinylphenylsiloxane. Adv. Appl. Ceram. 2018, 117, 212–216. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Z.R.; Liu, X.J. Joining of sintered silicon carbide using ternary Ag-Cu-Ti active brazing alloy. Ceram. Int. 2009, 35, 3479–3484. [Google Scholar] [CrossRef]

- Zhong, Z.H.; Hou, G.X.; Zhu, Z.X. Microstructure and mechanical strength of SiC joints brazed with Cr3C2 particulate reinforced Ag-Cu-Ti brazing alloy. Ceram. Int. 2018, 44, 11862–11868. [Google Scholar] [CrossRef]

- Moszner, F.; Mata-Osoro, G.; Chiodi, M. Mechanical behavior of SiC joints brazed using an active Ag-Cu-In-Ti braze at elevated temperatures. Int. J. Appl. Ceram. Technol. 2017, 14, 703–711. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Huang, J.H.; Zhang, H. Microstructures of Si/SiC ceramic and invar alloy brazing joint. Rare Met. Mater. Eng. 2009, 38, 493–496. [Google Scholar]

- Riccardi, B.; Nannetti, C.A.; Woltersdorf, J. Brazing of SiC and SiCf/SiC composites performed with 84Si-16Ti eutectic alloy: Microstructure and strength. J. Mater. Sci. 2002, 37, 5029–5039. [Google Scholar] [CrossRef]

- Mao, Y.W.; Li, S.J.; Han, W.B. Joining of SiC by high temperature brazing with Ni-51Cr filler. Rare Met. Mater. Eng. 2006, 35, 312–315. [Google Scholar]

- Tian, W.B.; Sun, Z.M.; Zhang, P. Brazing of silicon carbide ceramics with Ni-Si-Ti powder mixtures. J. Aust. Ceram. Soc. 2017, 53, 511–516. [Google Scholar] [CrossRef]

- Zhou, B.F.; Feng, K.Q. Zr-Cu alloy filler metal for brazing SiC ceramic. RSC Adv. 2018, 8, 26251–26254. [Google Scholar] [CrossRef]

- Zhou, B.F.; Zeng, Z.C.; Cai, Y.C. FEM simulation and verification of brazing SiC ceramic with novel Zr-Cu filler metal. Materials 2019, 12, 3380. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Zhang, L.X.; Liu, C.B. Brazing C/SiC composites and Nb with TiNiNb active filler metal. Sci. Technol. Weld. Join. 2011, 16, 193–198. [Google Scholar] [CrossRef]

- Riccardi, B.; Nannetti, C.A.; Petrisor, T. Low activation brazing materials and techniques for SiC/SiC composite. J. Nucl. Mater. 2002, 307, 1237–1241. [Google Scholar] [CrossRef]

| Properties | Maximum Temperature of Application | Density | Open Porosity | Bending Strength | Modulus of Elasticity | Thermal Conductivity | Coefficient of Thermal Expansion |

|---|---|---|---|---|---|---|---|

| RBSiC | 1380 °C | >3.02 g/cm3 | <0.1% | 280 MPa | 300 GPa | 74 W/mK | 4.5 × 10−6 K−1 |

| Brazing Experiment | Heating Rate (°C /min) | Brazing Temperature (°C) | Holding Time (min) | Cooling Rate (°C /min) |

|---|---|---|---|---|

| Brazing temperature | 4 | 1100~1300 | 20 | 4 |

| Holding time | 4 | 1200 | 5~60 | 4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, B.; Wang, J.; Feng, K.; Cai, Y.; Chen, S. Effect of Brazing Parameters on the Microstructure and Properties of SiC Ceramic Joint with Zr-Cu Filler Metal. Crystals 2020, 10, 93. https://doi.org/10.3390/cryst10020093

Zhou B, Wang J, Feng K, Cai Y, Chen S. Effect of Brazing Parameters on the Microstructure and Properties of SiC Ceramic Joint with Zr-Cu Filler Metal. Crystals. 2020; 10(2):93. https://doi.org/10.3390/cryst10020093

Chicago/Turabian StyleZhou, Bofang, Jinfeng Wang, Keqin Feng, Yuchen Cai, and Sitan Chen. 2020. "Effect of Brazing Parameters on the Microstructure and Properties of SiC Ceramic Joint with Zr-Cu Filler Metal" Crystals 10, no. 2: 93. https://doi.org/10.3390/cryst10020093

APA StyleZhou, B., Wang, J., Feng, K., Cai, Y., & Chen, S. (2020). Effect of Brazing Parameters on the Microstructure and Properties of SiC Ceramic Joint with Zr-Cu Filler Metal. Crystals, 10(2), 93. https://doi.org/10.3390/cryst10020093