In Situ Neutron Diffraction Study of Phase Transformation of High Mn Steel with Different Carbon Content

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

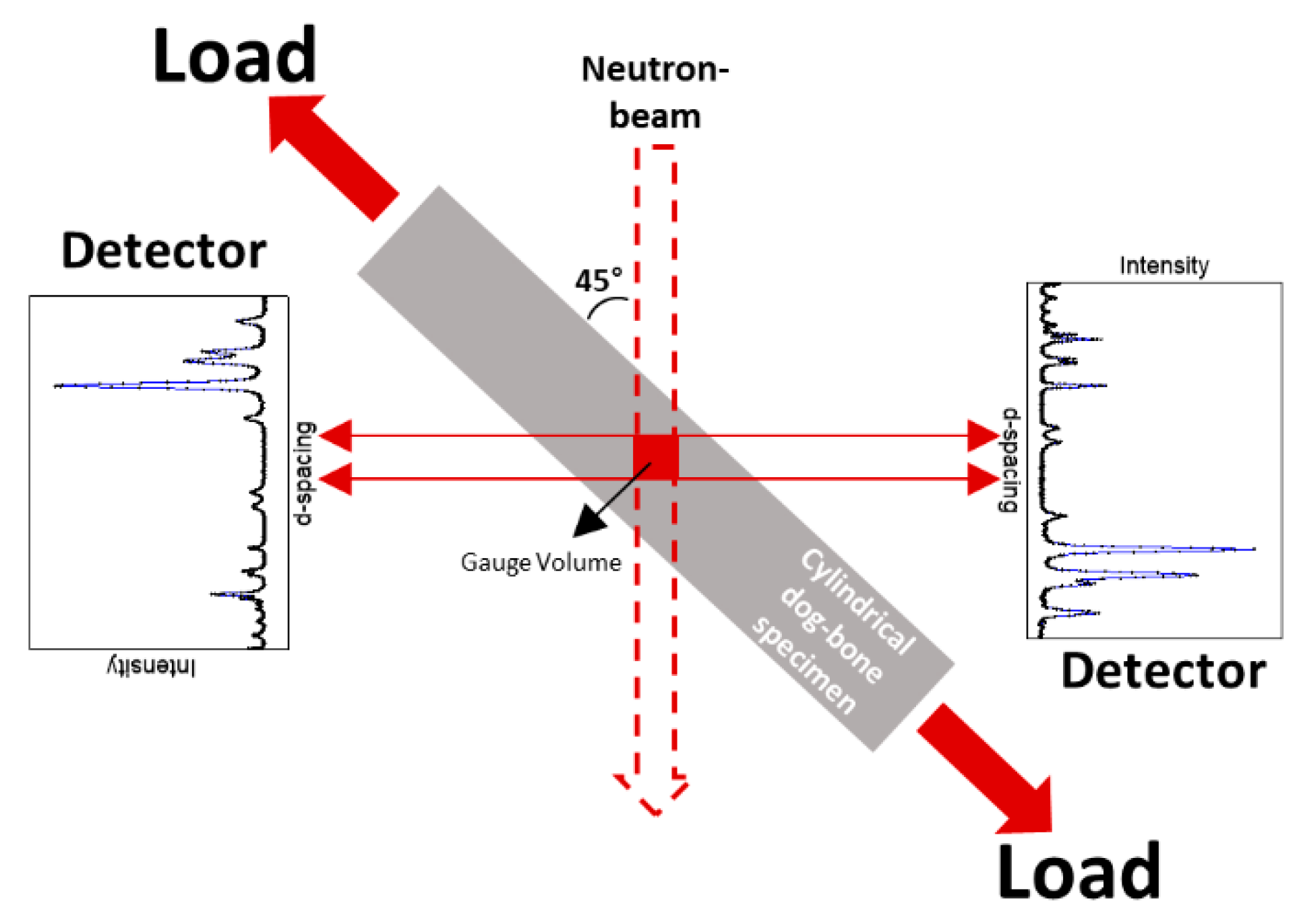

2.2. In situ Neutron Diffraction

3. Results

3.1. Microstructure and Stacking Fault Energies

3.2. Macroscopic Stress-Strain Responses

3.3. Phase Transformation During in Situ Loading

3.4. Lattice Strain Evolution

3.5. Stress Contribution from Each Phase

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Tomota, Y.; Strum, M.; Morris, J.W., Jr. Microstructural dependence of Fe-high Mn tensile behavior. Mater. Trans. A 1986, 17, 537–547. [Google Scholar] [CrossRef]

- Remy, L.; Pineau, A. Twinning and strain-induced FCC→HCP transformation in the Fe-Mn-Cr-C system. Mater. Sci. Eng. 1977, 28, 99–107. [Google Scholar] [CrossRef]

- Sato, K.; Ichinose, M.; Hirotsu, Y.; Inoue, Y. Effects of deformation induced phase transformation and twinning on the mechanical properties of austenitic Fe–Mn–Al alloys. ISIJ Int. 1989, 29, 868–877. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.-P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Choi, C.-S. Effects of thermal cycling on the kinetics of the γ → ε martensitic transformation in an Fe-17 wt pct Mn alloy. Metall. Mater. Trans. A 2000, 31, 355–360. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and variation in composition-dependent stacking fault energy maps based on subregular solution model in high-manganese steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Andrews, K.W. The calculation of transformation temperatures and austenite-ferrite equilibria in steels. J. Iron. Steel. Inst. 1956, 184, 414–427. [Google Scholar]

- Hutchings, M.T.; Withers, P.J.; Holden, T.M.; Lorentzen, T. Introduction to the Characterization of Residual Stress by Neutron Diffraction; Taylor & Francis Group: Boca Raton, FL, USA, 2005; pp. 160–192. [Google Scholar]

- Kwon, K.H.; Suh, B.-C.; Baik, S.-I.; Kim, Y.-W.; Choi, J.-K.; Kim, N.J. Deformation behavior of duplex austenite and ε-martensite high-Mn steel. Sci. Technol. Adv. Mater. 2013, 14, 014204. [Google Scholar] [CrossRef]

- Kwon, K.H.; Jeong, J.S.; Choi, J.-K.; Koo, Y.M.; Tomota, Y.; Kim, N.J. In situ neutron diffraction analysis on deformation behavior of duplex high Mn steel containing austenite and ε-Martensite. Met. Mater. Int. 2012, 18, 751–755. [Google Scholar] [CrossRef]

- An, K. VDRIVE- Data Reduction and Interactive Visualization Software for Event Mode Neutron Diffraction; ORNL Report ORNL-TM-2012-621; Oak Ridge National Laboratory: Tennessee, TN, USA, 2012.

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part II. FCC→BCC and other martensitic transformations. Metall. Trans. A 1976, 7, 1905–1914. [Google Scholar] [CrossRef]

- Dumay, A.; Chateau, J.-P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an austenitic Fe–Mn–C steel. Mater. Sci. Eng. A 2008, 483–484, 184–187. [Google Scholar] [CrossRef]

- Dew-Hughes, D.; Kaufman, L. Ternary phase diagrams of the manganese-titanium-iron and the aluminum-titanium-iron systems: A comparison of computer calculations with experiment. Calphad 1979, 3, 175–203. [Google Scholar] [CrossRef]

- Breedis, J.F.; Kaufman, L. The formation of Hcp and Bcc phases in austenitic iron alloys. Metall. Trans. 1971, 2, 2359–2371. [Google Scholar] [CrossRef]

- Yang, W.S.; Wan, C.M. The influence of aluminium content to the stacking fault energy in Fe-Mn-Al-C alloy system. J. Mater. Sci. 1990, 25, 1821–1823. [Google Scholar] [CrossRef]

- Lee, Y.-K. Relationship between austenite dislocation density introduced during thermal cycling and M s temperature in an Fe-17 wt pct Mn alloy. Metall. Mater. Trans. A 2002, 33, 1913–1917. [Google Scholar] [CrossRef]

- Larson, A.C.; Von Dreele, R.B. General Structure Analysis System (GSAS); Los Alamos National Laboratory Report LAUR: California, CA, USA, 2000.

- Toby, B.H.; Von Dreele, R.B. GSAS-II: The genesis of a modern open-source all purpose crystallography software package. J. Appl. Crystallogr. 2013, 46, 544–549. [Google Scholar] [CrossRef]

- Bracke, L.; Kestens, L.; Penning, J. Transformation mechanism of α′-martensite in an austenitic Fe–Mn–C–N alloy. Scripta Mater. 2007, 57, 385–388. [Google Scholar] [CrossRef]

- Seol, J.-B.; Jung, J.E.; Jang, Y.W.; Park, C.G. Influence of carbon content on the microstructure, martensitic transformation and mechanical properties in austenite/ε-martensite dual-phase Fe–Mn–C steels. Acta Mater. 2013, 61, 558–578. [Google Scholar] [CrossRef]

- Harjo, S.; Tsuchida, N.; Abe, J.; Gong, W. Martensite phase stress and the strengthening mechanism in TRIP steel by neutron diffraction. Sci. Rep. 2017, 7, 15149. [Google Scholar] [CrossRef]

- Reed, R.P.; Schramm, R.E. Relationship between stacking fault energy and x-ray measurements of stacking fault probability and microstrain. J. Appl. Phys. 1974, 45, 4705–4711. [Google Scholar] [CrossRef]

- Kang, M.; Woo, W.; Lee, Y.K.; Seong, B.S. Neutron diffraction analysis of stacking fault energy in Fe–18Mn–2Al–0.6C twinning-induced plasticity steels. Mater. Lett. 2012, 76, 93–95. [Google Scholar] [CrossRef]

- Gutiérrez-Urrutia, I.; Raabe, D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe–Mn–Al–C steel. Acta Mater. 2012, 60, 5791–5802. [Google Scholar] [CrossRef]

- Tian, X.; Li, H.; Zhang, Y. Effect of Al content on stacking fault energy in austenitic Fe–Mn–Al–C alloys. J. Mater. Sci. 2008, 43, 6214–6222. [Google Scholar] [CrossRef]

- Huang, B.X.; Wang, X.D.; Wang, L.; Rong, Y.H. Effect of nitrogen on stacking fault formation probability and mechanical properties of twinning-induced plasticity steels. Metall. Mater. Trans. A 2008, 39, 717–724. [Google Scholar] [CrossRef]

| (wt.%) | Fe | Mn | C | Cu | Cr | Ni | Zn | P | S |

|---|---|---|---|---|---|---|---|---|---|

| 0.1 C | Bal. | 16.40 | 0.109 | 0.47 | 0.19 | 0.26 | 0.15 | 0.02 | 0.01 |

| 0.3 C | Bal. | 16.35 | 0.372 | 0.59 | 0.20 | 0.30 | 0.32 | 0.01 | 0.05 |

| 0.5 C | Bal. | 16.78 | 0.535 | 0.52 | 0.14 | 0.14 | 0.33 | 0.02 | 0.04 |

| SFE(mJ/m2) | TRIP | TWIP | |

|---|---|---|---|

| 0.1 C steel | 0.5–0.8 | ○ | - |

| 0.3 C steel | 9.9–11.6 | ○ | △ |

| 0.5 C steel | 15.2–17.8 | ○ | ○ |

| ○: Measured in EBSD image △: Measured only in OM image -: Not observed | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Choi, W.; Choo, H.; An, K.; Choi, H.-S.; Lee, S.Y. In Situ Neutron Diffraction Study of Phase Transformation of High Mn Steel with Different Carbon Content. Crystals 2020, 10, 101. https://doi.org/10.3390/cryst10020101

Kim Y, Choi W, Choo H, An K, Choi H-S, Lee SY. In Situ Neutron Diffraction Study of Phase Transformation of High Mn Steel with Different Carbon Content. Crystals. 2020; 10(2):101. https://doi.org/10.3390/cryst10020101

Chicago/Turabian StyleKim, Youngsu, Wookjin Choi, Hahn Choo, Ke An, Ho-Suk Choi, and Soo Yeol Lee. 2020. "In Situ Neutron Diffraction Study of Phase Transformation of High Mn Steel with Different Carbon Content" Crystals 10, no. 2: 101. https://doi.org/10.3390/cryst10020101

APA StyleKim, Y., Choi, W., Choo, H., An, K., Choi, H.-S., & Lee, S. Y. (2020). In Situ Neutron Diffraction Study of Phase Transformation of High Mn Steel with Different Carbon Content. Crystals, 10(2), 101. https://doi.org/10.3390/cryst10020101