Impact of the Co/Ni-Ratio on Microstructure, Thermophysical Properties and Creep Performance of Multi-Component γ′-Strengthened Superalloys

Abstract

1. Introduction

- -

- The elemental segregation on the dendrite scale is lower on the Co-rich side of the system.

- -

- The γ′ solvus temperature decreases with an increase of the Co content.

- -

- Liquidus and solidus temperature remain largely unaffected.

- -

- The γ′ volume fraction exhibits a maximum in the alloy in which the Ni/Co-ratio is 1:3.

- -

- The oxidation resistance at 900 °C strongly and monotonously increases with the amount of Ni present.

- -

- The lattice misfit is negative on the Ni-rich side of the system (lattice parameter a0,γ′ < a0,γ) and positive on the Co-rich side (a0,γ′ > a0,γ), with a zero-transition between Ni/Co = 3:1 and 1:1.

- -

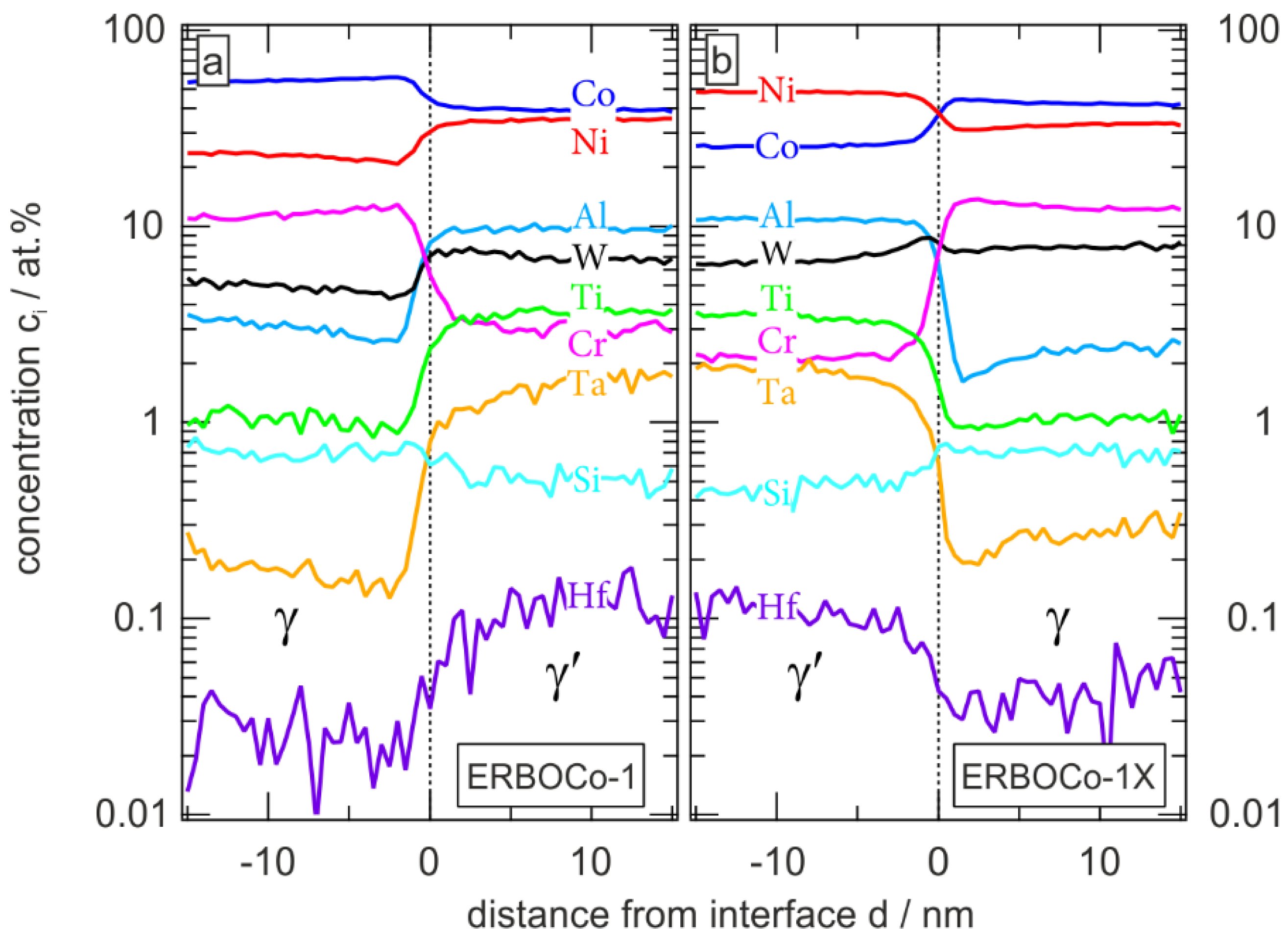

- The elemental partitioning between the γ and γ′ phases is much more pronounced on the Ni-rich side of the system. Elements are generally distributed more homogeneously between the two-phase in the Co-rich alloys (with the exception of W).

- -

- The creep resistance (in terms of the minimum creep rate at 900 °C and 250 MPa) of the Ni-based alloy increases with the addition of Co, reaches an optimum at Ni/Co = 3:1, and strongly deteriorates over two orders of magnitude with a further addition of Co. However, the opposite effect was found for Cr-free Ni/Co-9Al-8W alloys.

2. Experimental Procedures

3. Results and Discussion

4. Summary and Conclusions

- -

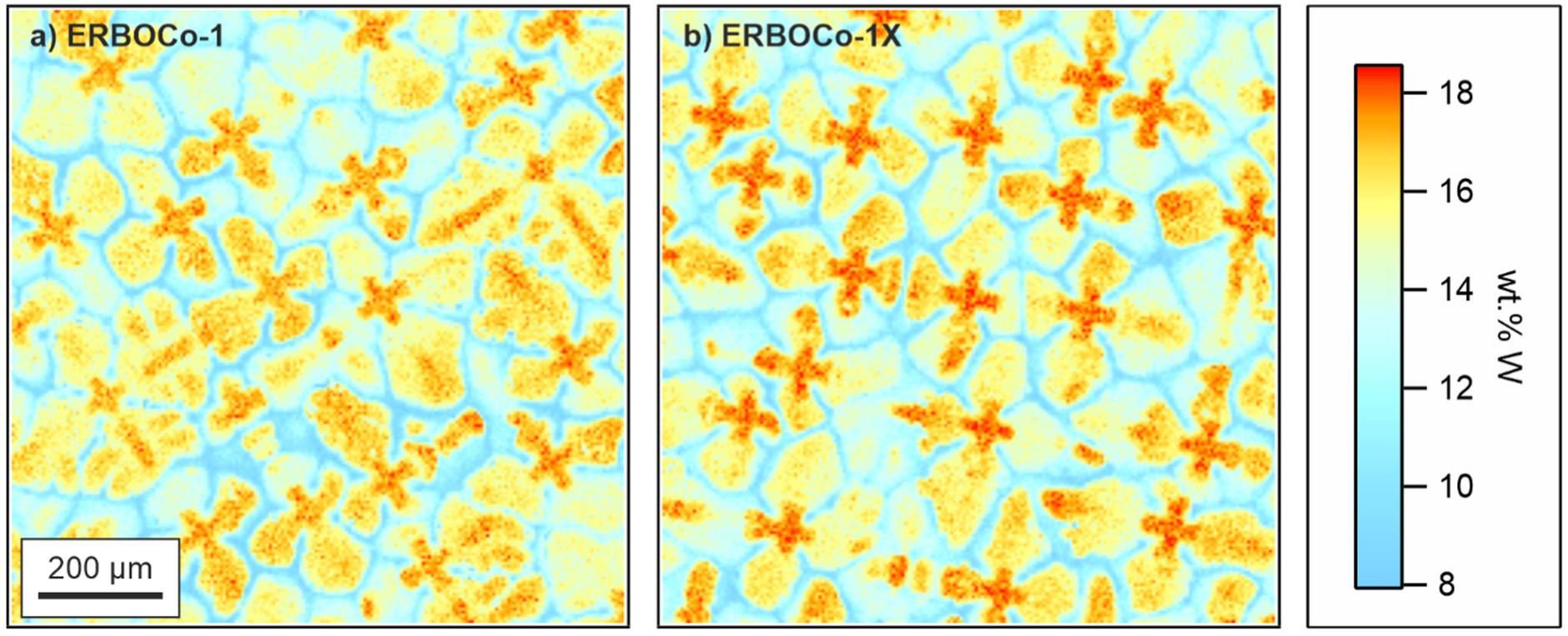

- Elemental segregation during casting was slightly more pronounced in the Ni-based alloy ERBOCo-1X, although the differences were marginal.

- -

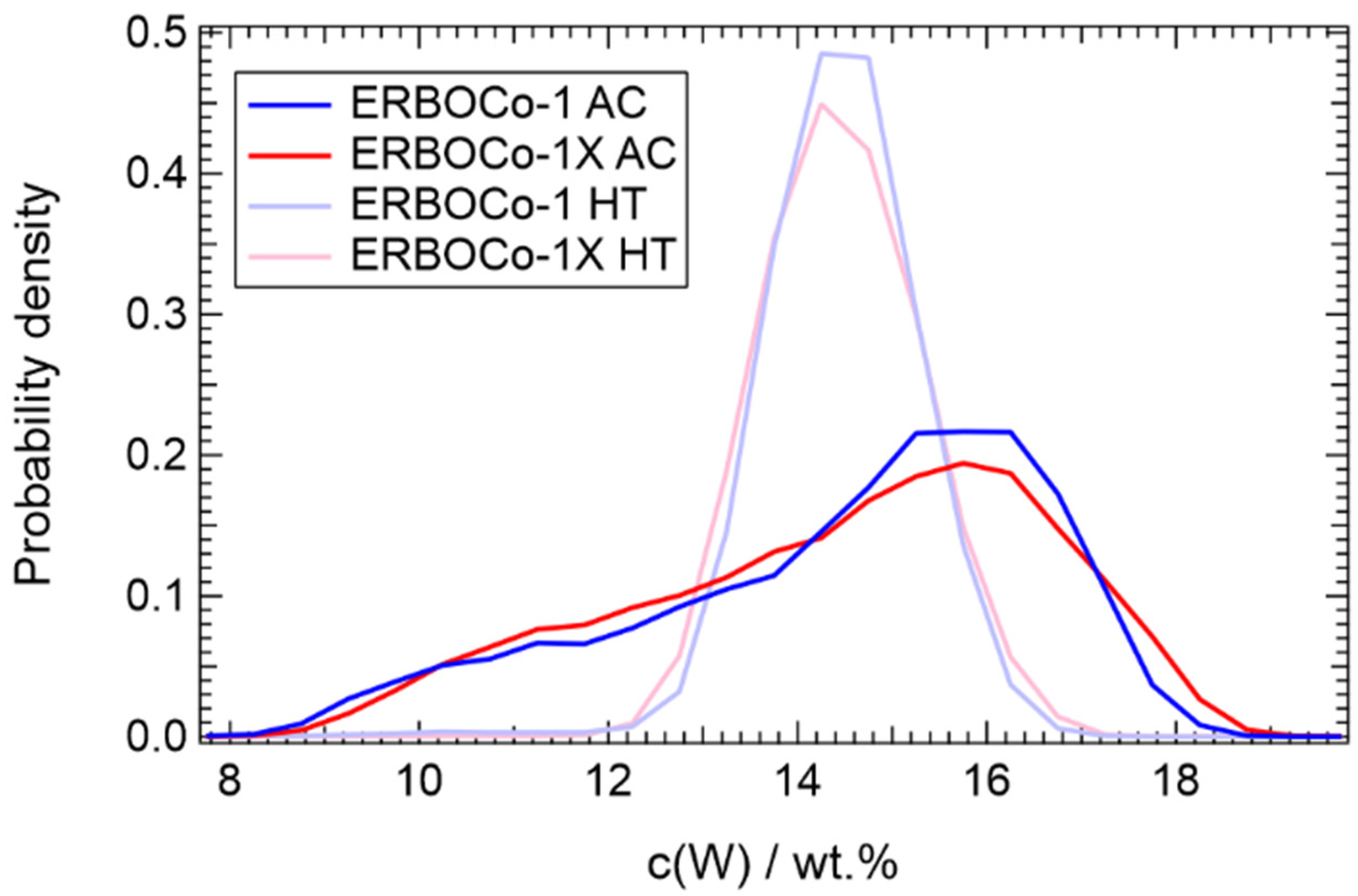

- The addition of Ni at the expense of Co did not significantly alter the liquidus and solidus temperatures but increased the γ′ solvus temperature by about ~50 °C.

- -

- The γ′ volume fraction remained largely unaffected by altering the Ni/Co-ratio and was found to be ~70%.

- -

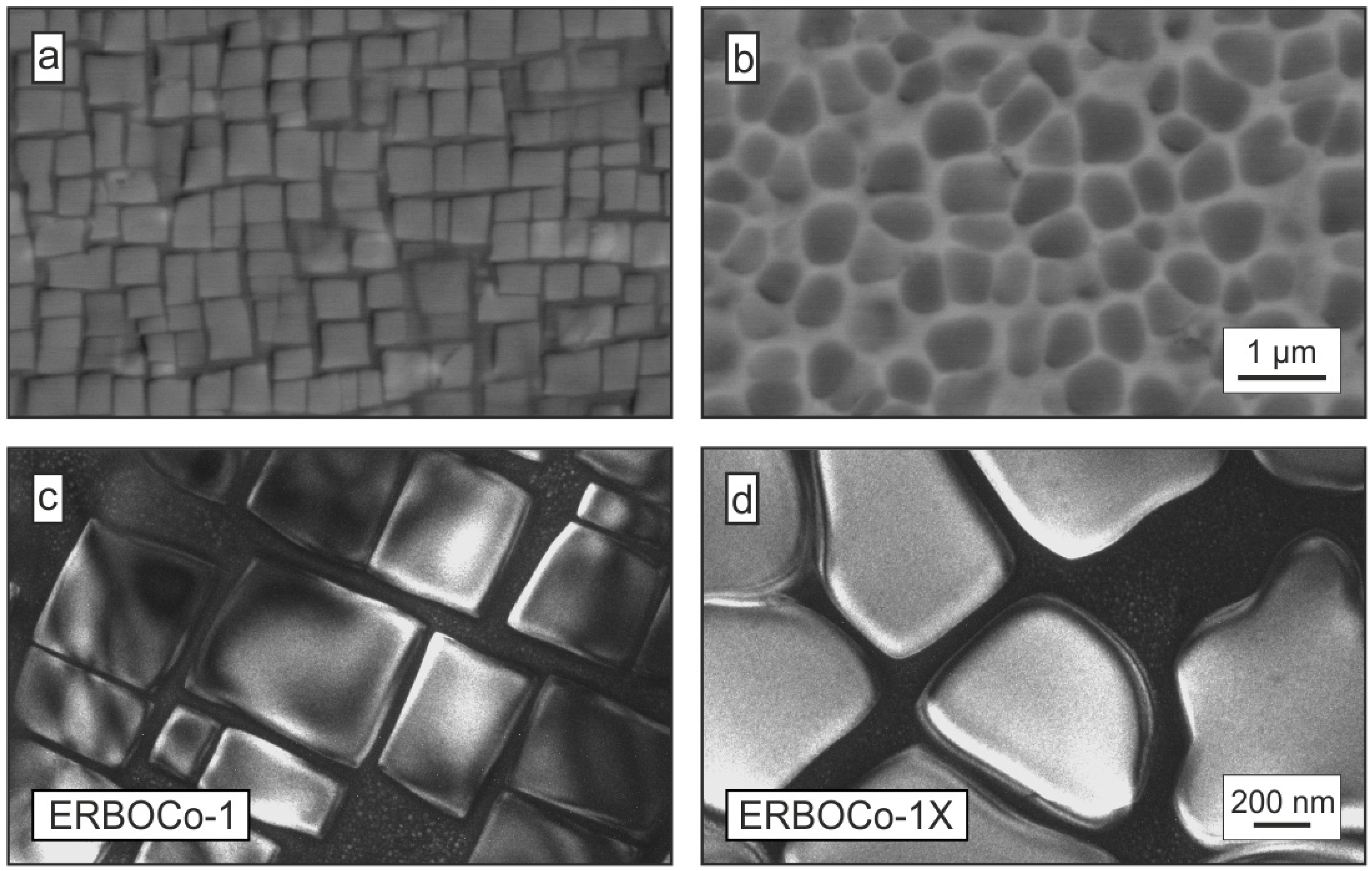

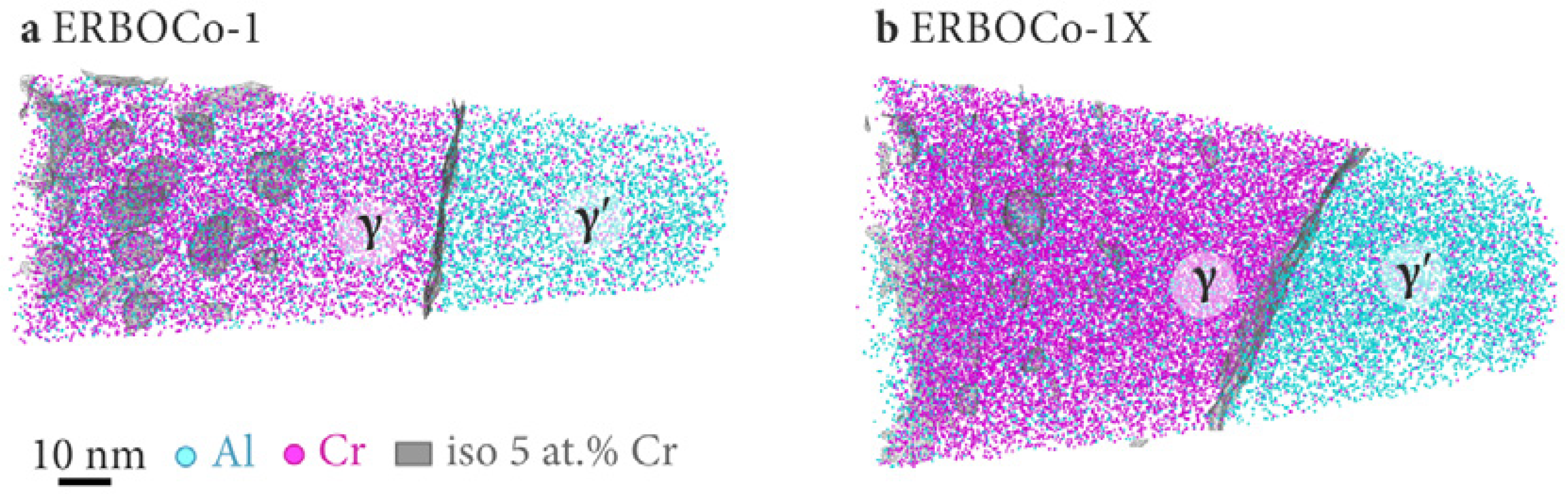

- The precipitate morphology was cubic in ERBOCo-1 and spherical in ERBOCo-1X, indicating a decrease of the positive lattice misfit with the addition of Ni.

- -

- A reversion of the W partitioning (to γ′ in ERBOCo-1 and γ in ERBOCo-1X) was identified as the major reason for the change in lattice misfit.

- -

- The partitioning behavior of Al (to γ′) and Cr (to γ) to their respective phases becomes more pronounced as the Ni-content was increased. Contrarily, Ta, Ti and Hf were more enriched in γ′ in the Co-rich alloy ERBOCo-1.

- -

- The Ni and Co partitioning of ERBOCo-1X caused the precipitates to be Ni-based whereas the matrix was Co-based.

- -

- The shape of the compressive creep curves differed significantly, indicating a change of deformation mechanisms.

- -

- The Ni-based superalloy ERBOCo-1X exhibited a lower secondary creep rate despite a less favorable microstructure.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Reed, R.C. The Superalloys; Cambridge University Press: Cambridge, UK, 2006; ISBN 9780511541285. [Google Scholar]

- Beltran, A.M. Co-base alloys. In Superalloys II; Sims, C.T., Stoloff, N.S., Hagel, W.C., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1987; pp. 135–164. ISBN 0471011479. [Google Scholar]

- Sato, J.; Omori, T.; Oikawa, K.; Ohnuma, I.; Kainuma, R.; Ishida, K. Cobalt-base high-temperature alloys. Science 2006, 312, 90–91. [Google Scholar] [CrossRef] [PubMed]

- Miura, S.; Ohkubo, K.; Mohri, T. Mechanical properties of co-based L12 intermetallic compound Co3(Al,W). Mater. Trans. 2007, 48, 2403–2408. [Google Scholar] [CrossRef]

- Suzuki, A.; Pollock, T.M. High-temperature strength and deformation of γ/γ′ two-phase Co–Al–W-base alloys. Acta Mater. 2008, 56, 1288–1297. [Google Scholar] [CrossRef]

- Shinagawa, K.; Omori, T.; Sato, J.; Oikawa, K.; Ohnuma, I.; Kainuma, R.; Ishida, K. Phase Equilibria and Microstructure on γ’ Phase in Co-Ni-Al-W System. Mater. Trans. 2008, 49, 1474–1479. [Google Scholar] [CrossRef]

- Ooshima, M.; Tanaka, K.; Okamoto, N.L.; Kishida, K.; Inui, H. Effects of quaternary alloying elements on the γ′ solvus temperature of Co–Al–W based alloys with fcc/L12 two-phase microstructures. J. Alloys Compd. 2010, 508, 71–78. [Google Scholar] [CrossRef]

- Zhu, J.; Titus, M.S.; Pollock, T.M. Experimental Investigation and Thermodynamic Modeling of the Co-Rich Region in the Co-Al-Ni-W Quaternary System. J. Phase Equilibria Diffus. 2014. [Google Scholar] [CrossRef]

- Zenk, C.H.; Neumeier, S.; Stone, H.J.; Göken, M. Mechanical properties and lattice misfit of γ/γ’ strengthened Co-base superalloys in the Co–W–Al–Ti quaternary system. Intermetallics 2014, 55, 28–39. [Google Scholar] [CrossRef]

- Eggeler, Y.M.; Titus, M.S.; Suzuki, A.; Pollock, T.M. Creep deformation-induced antiphase boundaries in L12-containing single-crystal cobalt-base superalloys. Acta Mater. 2014, 77, 352–359. [Google Scholar] [CrossRef]

- Titus, M.S.; Eggeler, Y.M.; Suzuki, A.; Pollock, T.M. Creep-induced planar defects in L12-containing Co- and CoNi-base single-crystal superalloys. Acta Mater. 2015, 82, 530–539. [Google Scholar] [CrossRef]

- Zenk, C.H.; Neumeier, S.; Engl, N.M.; Fries, S.G.; Dolotko, O.; Weiser, M.; Virtanen, S.; Göken, M. Intermediate Co/Ni-base model superalloys—Thermophysical properties, creep and oxidation. Scr. Mater. 2016, 112, 83–86. [Google Scholar] [CrossRef]

- Zenk, C.H.; Neumeier, S.; Kolb, M.; Volz, N.; Fries, S.G.; Dolotko, O.; Povstugar, I.; Raabe, D.; Göken, M. The role of the base element in γ′ strengthened cobalt/nickel-base superalloys. In Proceedings of the Superalloys 2016; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; Volume 2016-Janua, pp. 969–980. [Google Scholar]

- Volz, N.; Zenk, C.H.; Halvaci, T.; Matuszewska, K.; Neumeier, S.; Göken, M. Castability and Recrystallization Behavior of γ′-Strengthened Co-Base Superalloys. In Superalloys; Springer: Cham, Switzerland, 2020; pp. 901–908. [Google Scholar]

- Weiser, M.; Galetz, M.C.; Zschau, H.E.; Zenk, C.H.; Neumeier, S.; Göken, M.; Virtanen, S. Influence of Co to Ni ratio in γ′-strengthened model alloys on oxidation resistance and the efficacy of the halogen effect at 900 °C. Corros. Sci. 2019, 156, 84–95. [Google Scholar] [CrossRef]

- Volz, N.; Zenk, C.H.; Cherukuri, R.; Kalfhaus, T.; Weiser, M.; Makineni, S.K.; Betzing, C.; Lenz, M.; Gault, B.; Fries, S.G.; et al. Thermophysical and Mechanical Properties of Advanced Single Crystalline Co-base Superalloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 4099–4109. [Google Scholar] [CrossRef]

- He, J.; Zenk, C.H.; Zhou, X.; Neumeier, S.; Raabe, D.; Gault, B.; Makineni, S.K. On the atomic solute diffusional mechanisms during compressive creep deformation of a Co-Al-W-Ta single crystal superalloy. Acta Mater. 2020, 184, 86–99. [Google Scholar] [CrossRef]

- Neumeier, S.; Freund, L.P.P.; Göken, M. Novel wrought γ/γ′ cobalt base superalloys with high strength and improved oxidation resistance. Scr. Mater. 2015, 109, 104–107. [Google Scholar] [CrossRef]

- Freund, L.P.; Messé, O.M.D.M.; Barnard, J.S.; Göken, M.; Neumeier, S.; Rae, C.M.F. Segregation assisted microtwinning during creep of a polycrystalline L12-hardened Co-base superalloy. Acta Mater. 2017, 123, 295–304. [Google Scholar] [CrossRef]

- Freund, L.P.; Giese, S.; Schwimmer, D.; Höppel, H.W.; Neumeier, S.; Göken, M. High temperature properties and fatigue strength of novel wrought γ/γ′ Co-base superalloys. J. Mater. Res. 2017, 32, 4475–4482. [Google Scholar] [CrossRef]

- Freund, L.P.; Stark, A.; Pyczak, F.; Schell, N.; Göken, M.; Neumeier, S. The grain boundary pinning effect of the μ phase in an advanced polycrystalline γ/γ′ Co-base superalloy. J. Alloys Compd. 2018, 753, 333–342. [Google Scholar] [CrossRef]

- Tsunekane, M.; Suzuki, A.; Pollock, T.M. Single-crystal solidification of new Co-Al-W-base alloys. Intermetallics 2011, 19, 636–643. [Google Scholar] [CrossRef]

- Koßmann, J.; Zenk, C.H.; Lopez-Galilea, I.; Neumeier, S.; Kostka, A.; Huth, S.; Theisen, W.; Göken, M.; Drautz, R.; Hammerschmidt, T. Microsegregation and precipitates of an as-cast Co-based superalloy—Microstructural characterization and phase stability modelling. J. Mater. Sci. 2015, 50, 6329–6338. [Google Scholar] [CrossRef]

- Povstugar, I.; Choi, P.-P.; Neumeier, S.; Bauer, A.; Zenk, C.H.; Göken, M.; Raabe, D. Elemental partitioning and mechanical properties of Ti- and Ta-containing Co-Al-W-base superalloys studied by atom probe tomography and nanoindentation. Acta Mater. 2014, 78, 78–85. [Google Scholar] [CrossRef]

- Sherby, O.D.; Burke, P.M. Mechanical behavior of crystalline solids at elevated temperature. Prog. Mater. Sci. 1968, 13, 323–390. [Google Scholar] [CrossRef]

- Mukherjee, A.K.; Bird, J.E.; Dorn, J.E. Experimental Correlations for High-Temperature Creep. 1968. Available online: https://escholarship.org/uc/item/31p4z5v2 (accessed on 20 November 2020).

- Mohamed, F.A.; Langdon, T.G. The transition from dislocation climb to viscous glide in creep of solid solution alloys. Acta Metall. 1974, 22, 779–788. [Google Scholar] [CrossRef]

- Gallagher, P.C.J. The influence of alloying, temperature, and related effects on the stacking fault energy. Metall. Trans. 1970, 1, 2429–2461. [Google Scholar] [CrossRef]

- Neumeier, S.; Rehman, H.U.; Neuner, J.; Zenk, C.H.; Michel, S.; Schuwalow, S.; Rogal, J.; Drautz, R.; Göken, M. Diffusion of solutes in fcc cobalt investigated by diffusion couples and first principles kinetic Monte Carlo. Acta Mater. 2016, 106, 304–312. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Directional coarsening in Nickel-base single crystals with high volume fractions of coherent precipitates. Acta Met. Mater. 1994, 42, 1859–1874. [Google Scholar] [CrossRef]

- Karunaratne, M.S.A.; Carter, P.; Reed, R.C. Interdiffusion in the face-centred cubic phase of the Ni-Re, Ni-Ta and Ni-W systems between 900 and 1300\°C. Mater. Sci. Eng. A 2000, 281, 229–233. [Google Scholar] [CrossRef]

- Eggeler, Y.M.; Müller, J.; Titus, M.S.; Suzuki, A.; Pollock, T.M.; Spiecker, E. Planar defect formation in the γ’ phase during high temperature creep in single crystal CoNi-base superalloys. Acta Mater. 2016, 113, 335–349. [Google Scholar] [CrossRef]

- Lenz, M.; Wu, M.; He, J.; Makineni, S.K.; Gault, B.; Raabe, D.; Neumeier, S.; Spiecker, E. Atomic Structure and Chemical Composition of Planar Fault Structures in Co-Base Superalloys. In Superalloys; Springer: Cham, Switzerland, 2020; pp. 920–928. [Google Scholar]

| Co | Ni | Al | Cr | W | Ti | Ta | Si | Hf | |

|---|---|---|---|---|---|---|---|---|---|

| ERBOCo-1 | 44.5 | 32 | 8 | 8 | 5 | 2.5 | 1.5 | 0.4 | 0.1 |

| ERBOCo-1X | 32 | 44.5 |

| Liquidus | Solidus | γ′ Solvus | |

|---|---|---|---|

| ERBOCo-1 AC | 1420 | 1278 | - |

| ERBOCo-1X AC | 1417 | 1287 | - |

| ERBOCo-1 HT | 1423 | 1357 | 1145 |

| ERBOCo-1X HT | 1417 | 1355 | 1195 |

| ERBOCo-1 | ERBOCo-1X | |||||

|---|---|---|---|---|---|---|

| γ | γ′ | kγ/γ′ | γ | γ′ | kγ/γ′ | |

| Co | 55.48 | 39.26 | 0.71 | 42.29 | 26.65 | 0.61 |

| Ni | 23.02 | 23.02 | 1.53 | 33.02 | 48.74 | 1.48 |

| Al | 3.11 | 9.76 | 3.13 | 2.34 | 10.91 | 4.65 |

| Cr | 11.47 | 3.01 | 0.26 | 12.45 | 2.14 | 0.17 |

| W | 4.95 | 6.78 | 1.37 | 7.84 | 6.57 | 0.84 |

| Ti | 1.05 | 3.68 | 3.50 | 1.04 | 3.52 | 3.37 |

| Ta | 0.18 | 1.64 | 9.17 | 0.28 | 1.90 | 6.86 |

| Si | 0.70 | 0.52 | 0.73 | 0.71 | 0.47 | 0.66 |

| Hf | 0.03 | 0.13 | 4.58 | 0.04 | 0.12 | 2.63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zenk, C.H.; Volz, N.; Zenk, C.; Felfer, P.J.; Neumeier, S. Impact of the Co/Ni-Ratio on Microstructure, Thermophysical Properties and Creep Performance of Multi-Component γ′-Strengthened Superalloys. Crystals 2020, 10, 1058. https://doi.org/10.3390/cryst10111058

Zenk CH, Volz N, Zenk C, Felfer PJ, Neumeier S. Impact of the Co/Ni-Ratio on Microstructure, Thermophysical Properties and Creep Performance of Multi-Component γ′-Strengthened Superalloys. Crystals. 2020; 10(11):1058. https://doi.org/10.3390/cryst10111058

Chicago/Turabian StyleZenk, Christopher H., Nicklas Volz, Carolin Zenk, Peter J. Felfer, and Steffen Neumeier. 2020. "Impact of the Co/Ni-Ratio on Microstructure, Thermophysical Properties and Creep Performance of Multi-Component γ′-Strengthened Superalloys" Crystals 10, no. 11: 1058. https://doi.org/10.3390/cryst10111058

APA StyleZenk, C. H., Volz, N., Zenk, C., Felfer, P. J., & Neumeier, S. (2020). Impact of the Co/Ni-Ratio on Microstructure, Thermophysical Properties and Creep Performance of Multi-Component γ′-Strengthened Superalloys. Crystals, 10(11), 1058. https://doi.org/10.3390/cryst10111058