Process Diagnosis of Liquid Steel Flow in a Slab Mold Operated with a Slide Valve

Abstract

1. Introduction

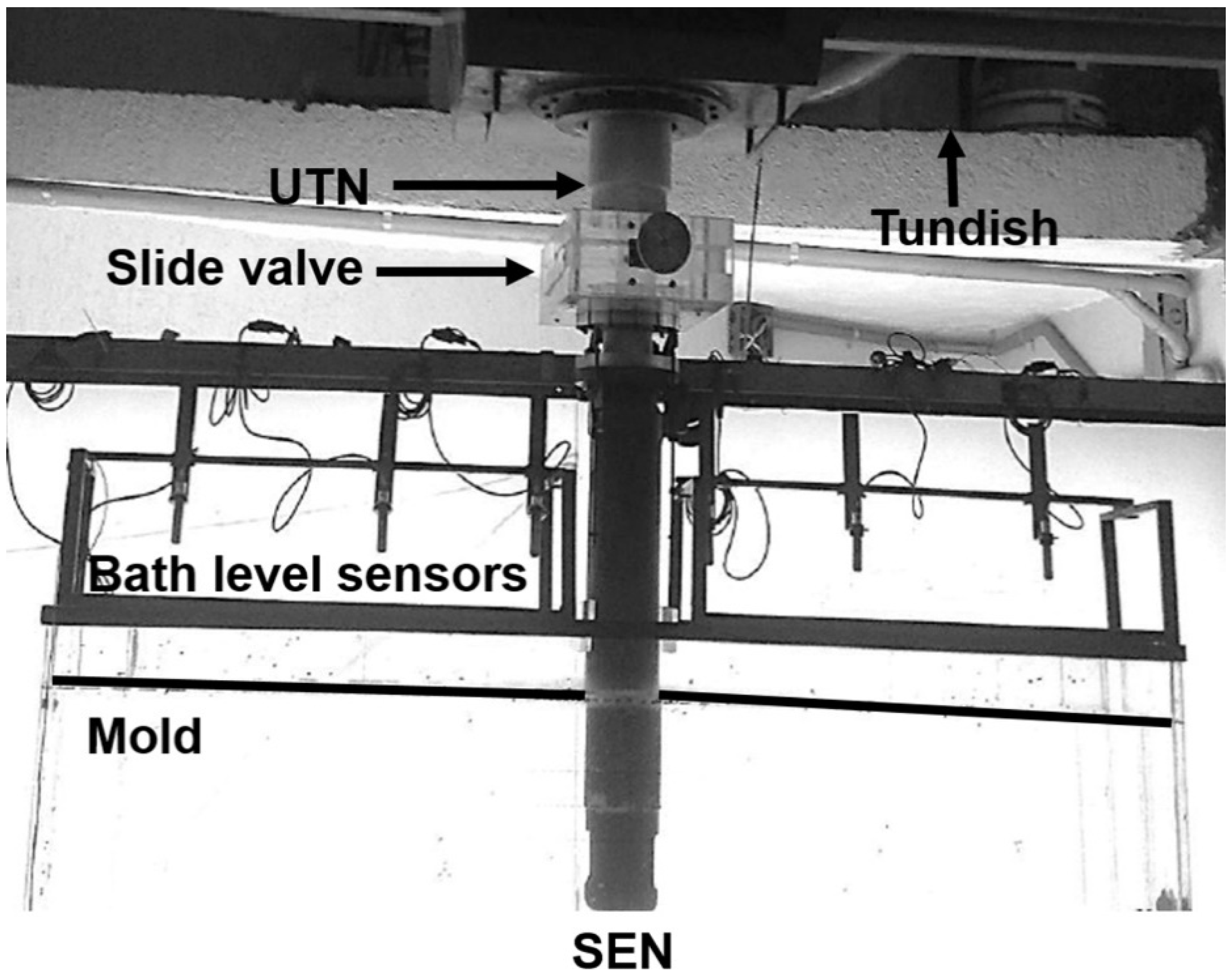

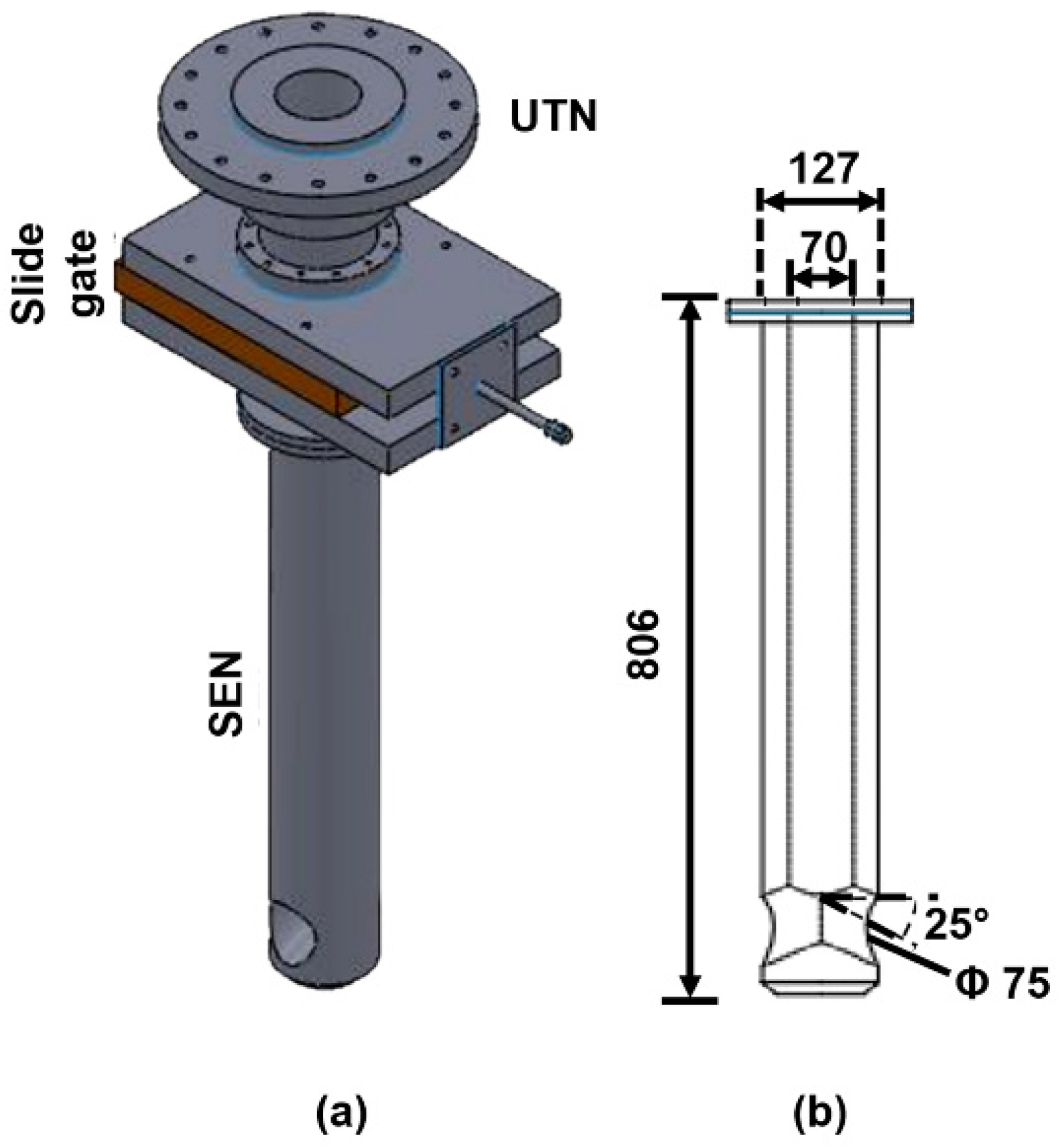

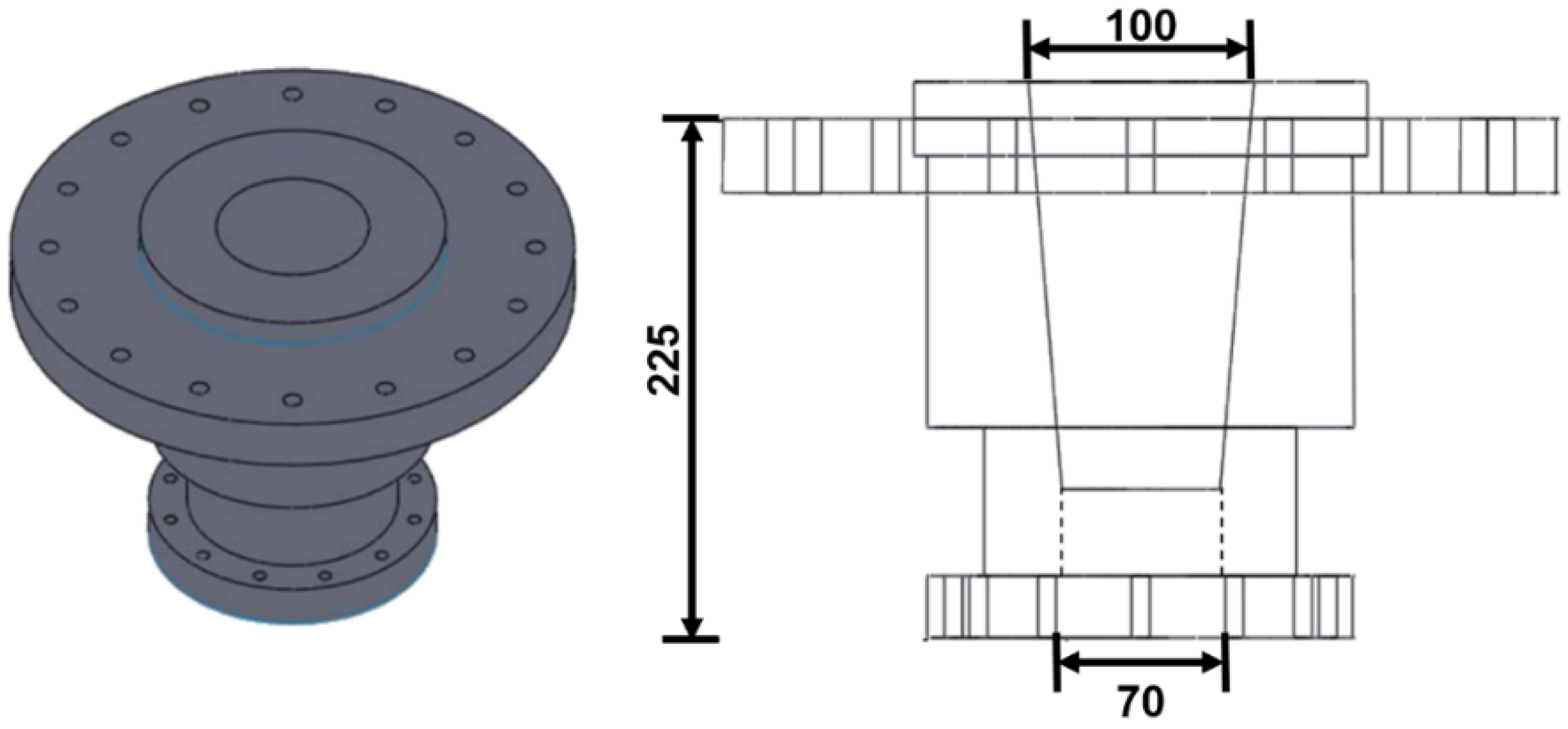

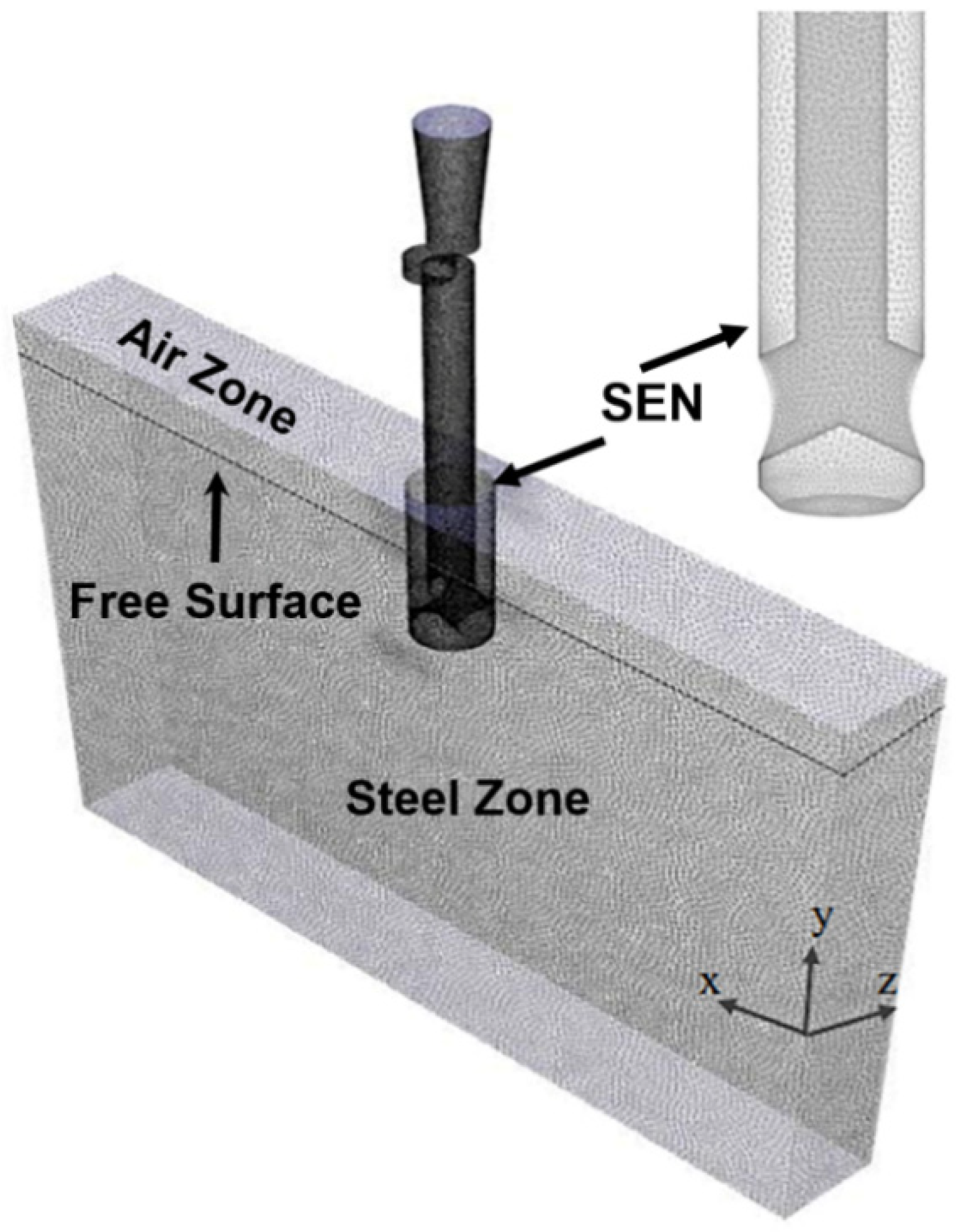

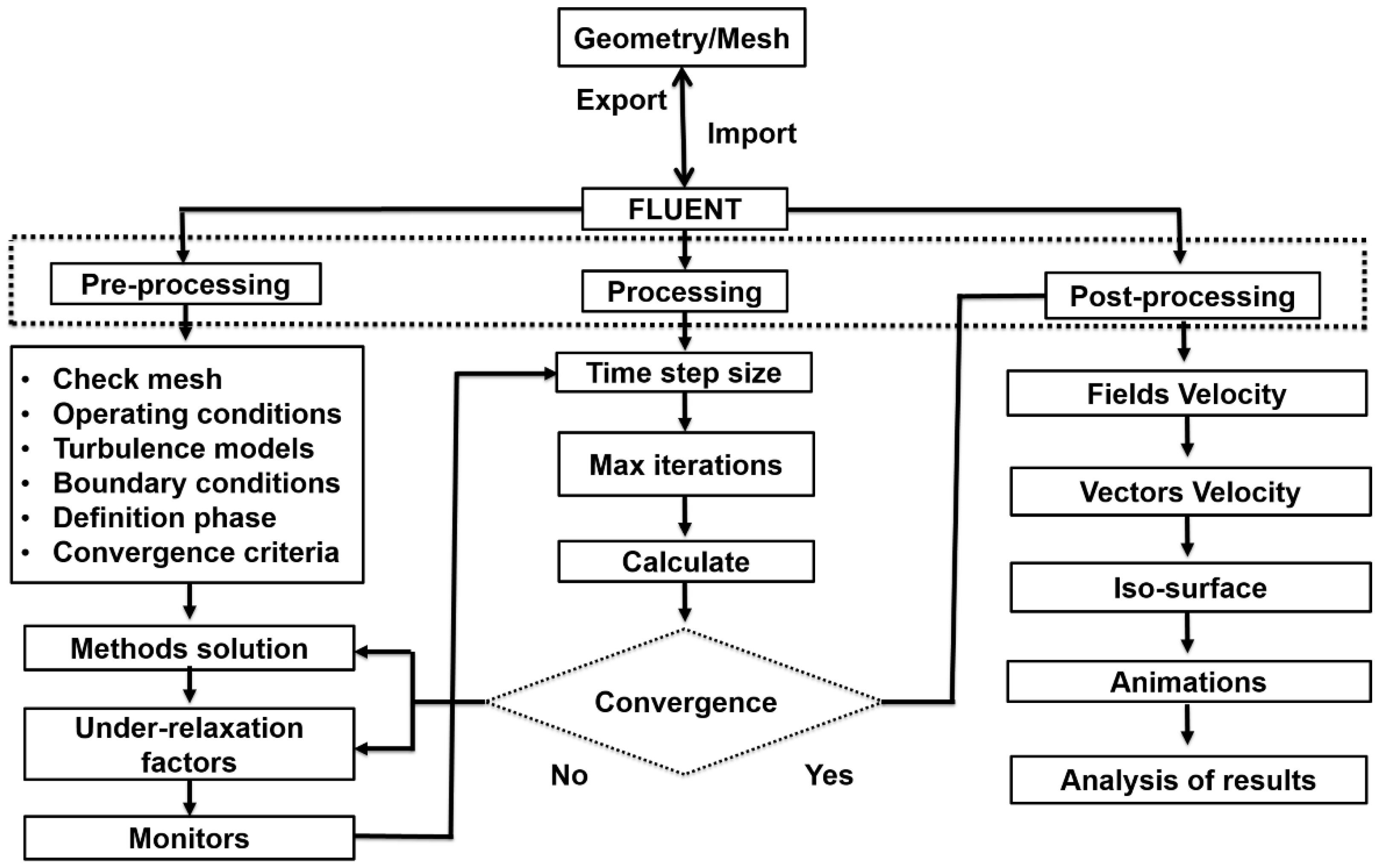

2. Experimental Techniques

3. The Mathematical Model

3.1. The Mathematical Models

- Kinetic energy

- Dissipation rate of kinetic energy

3.2. The LES Model

3.3. Numerical Schemes

4. Results and Discussion

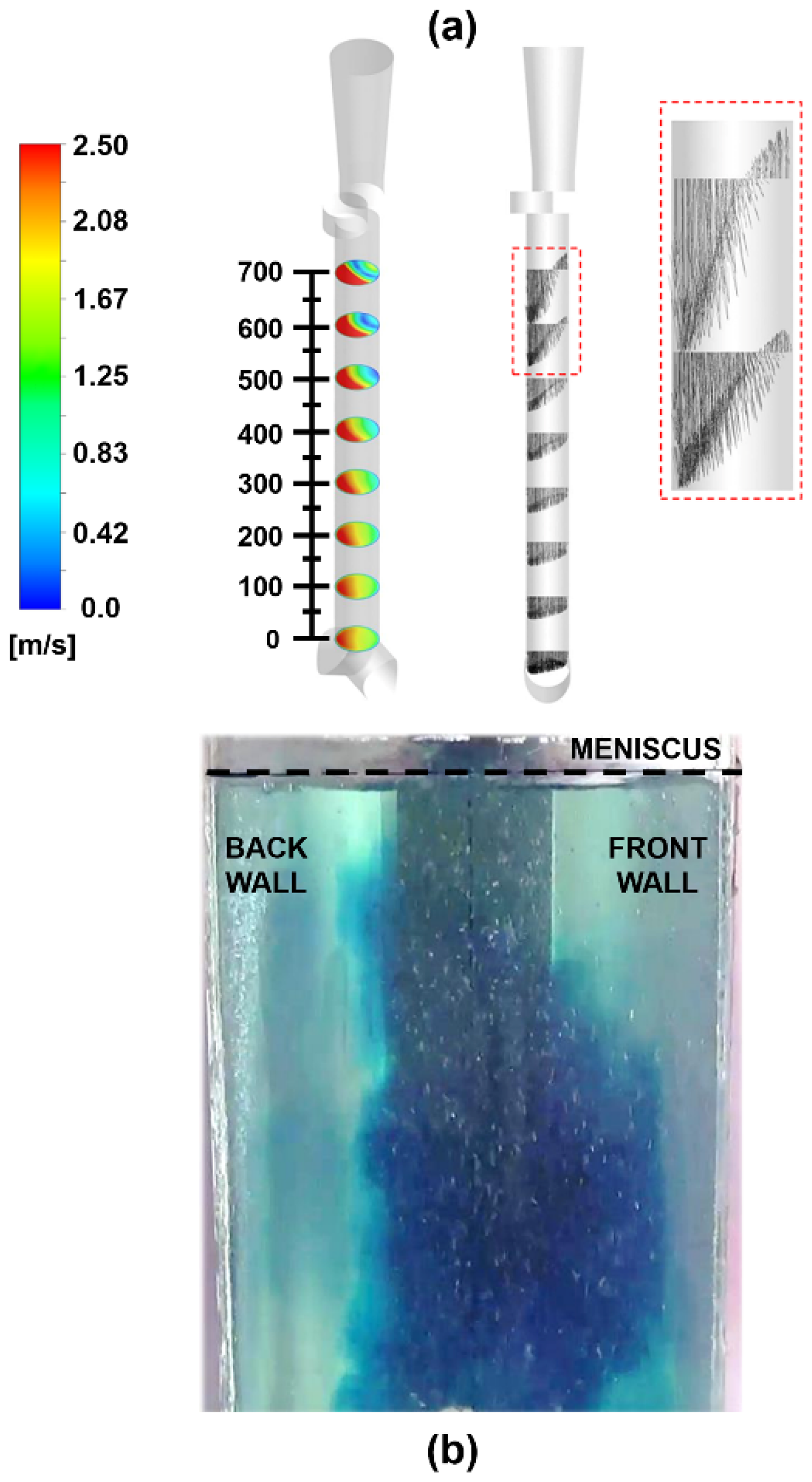

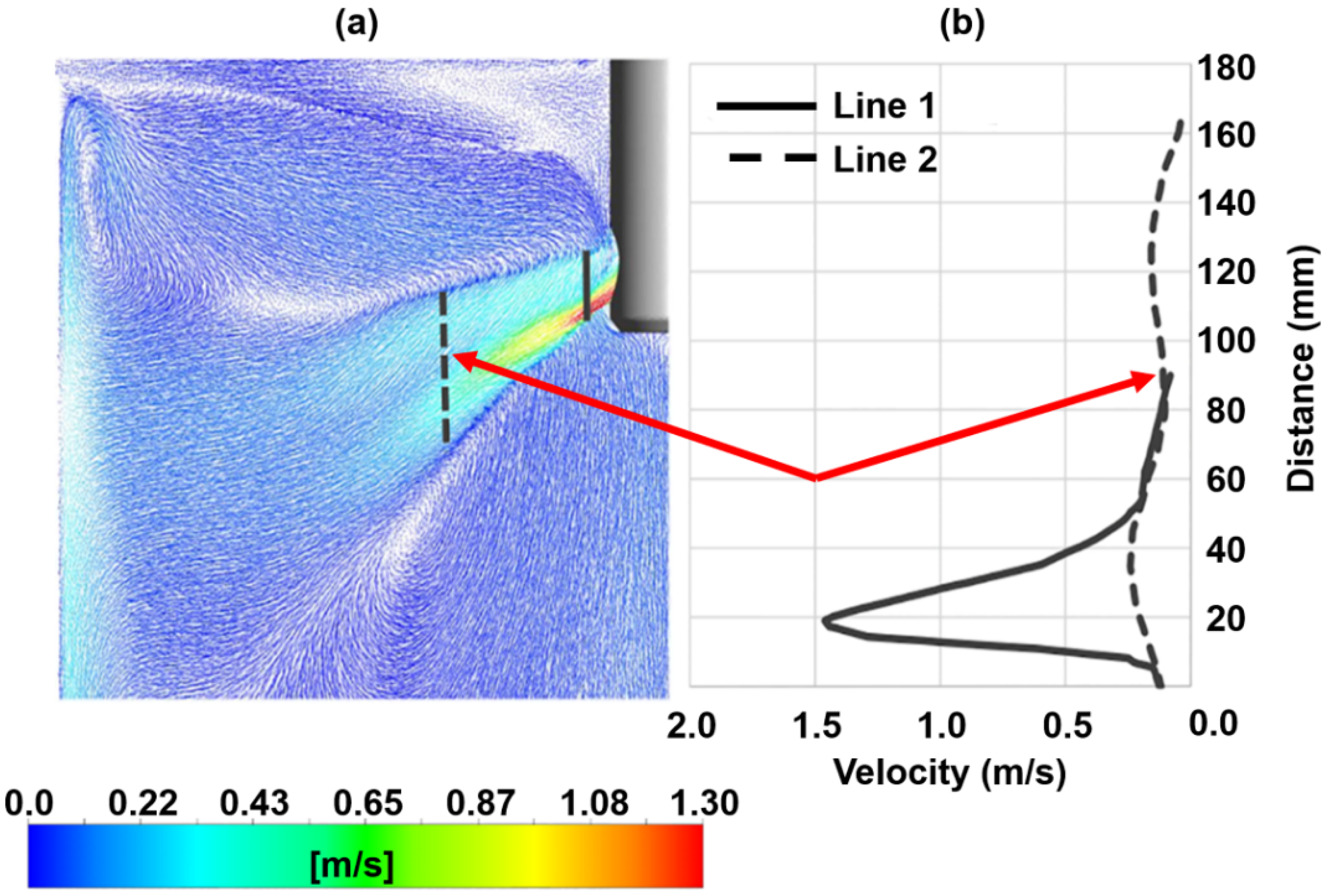

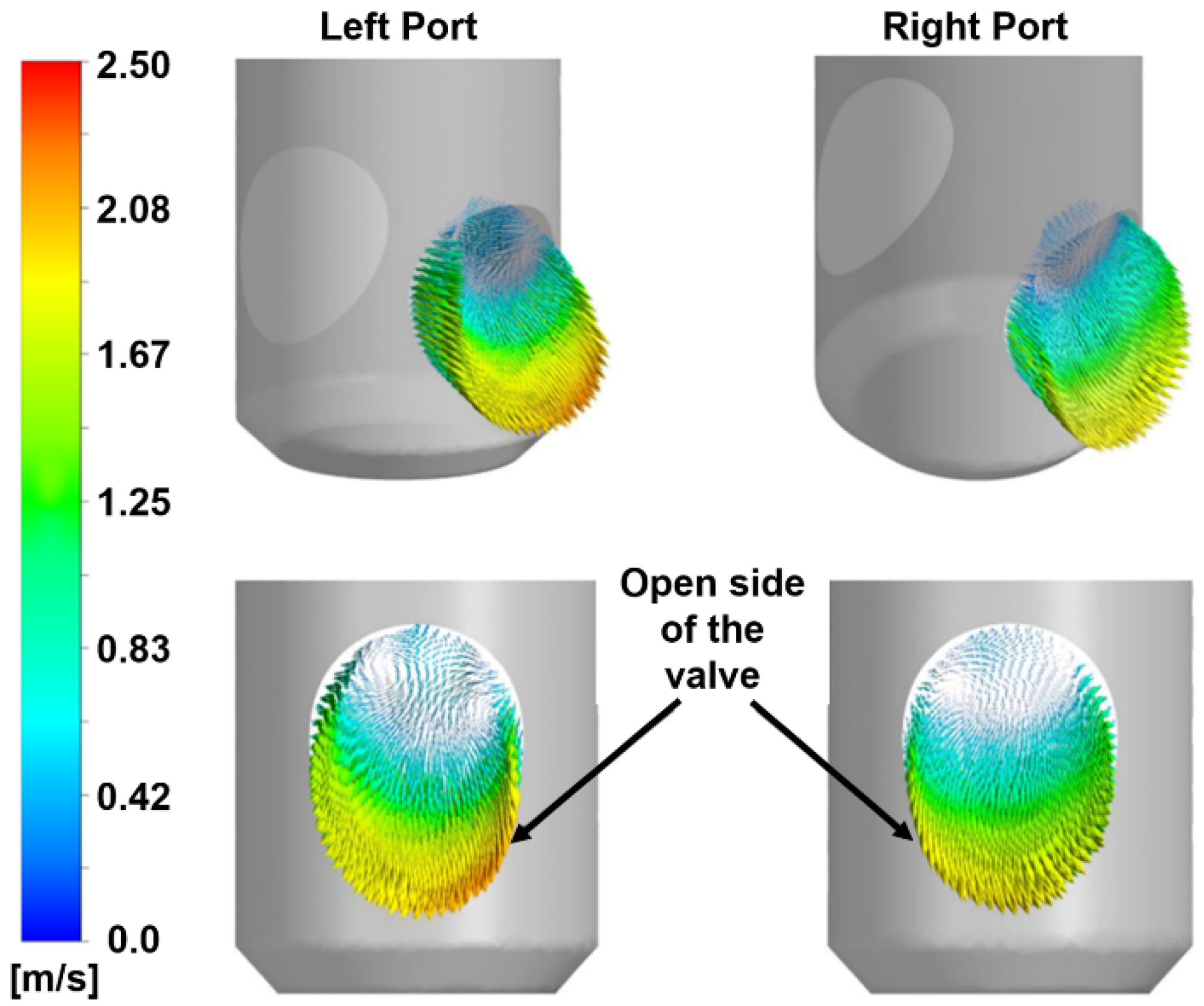

4.1. Fluid Flow through the Nozzle

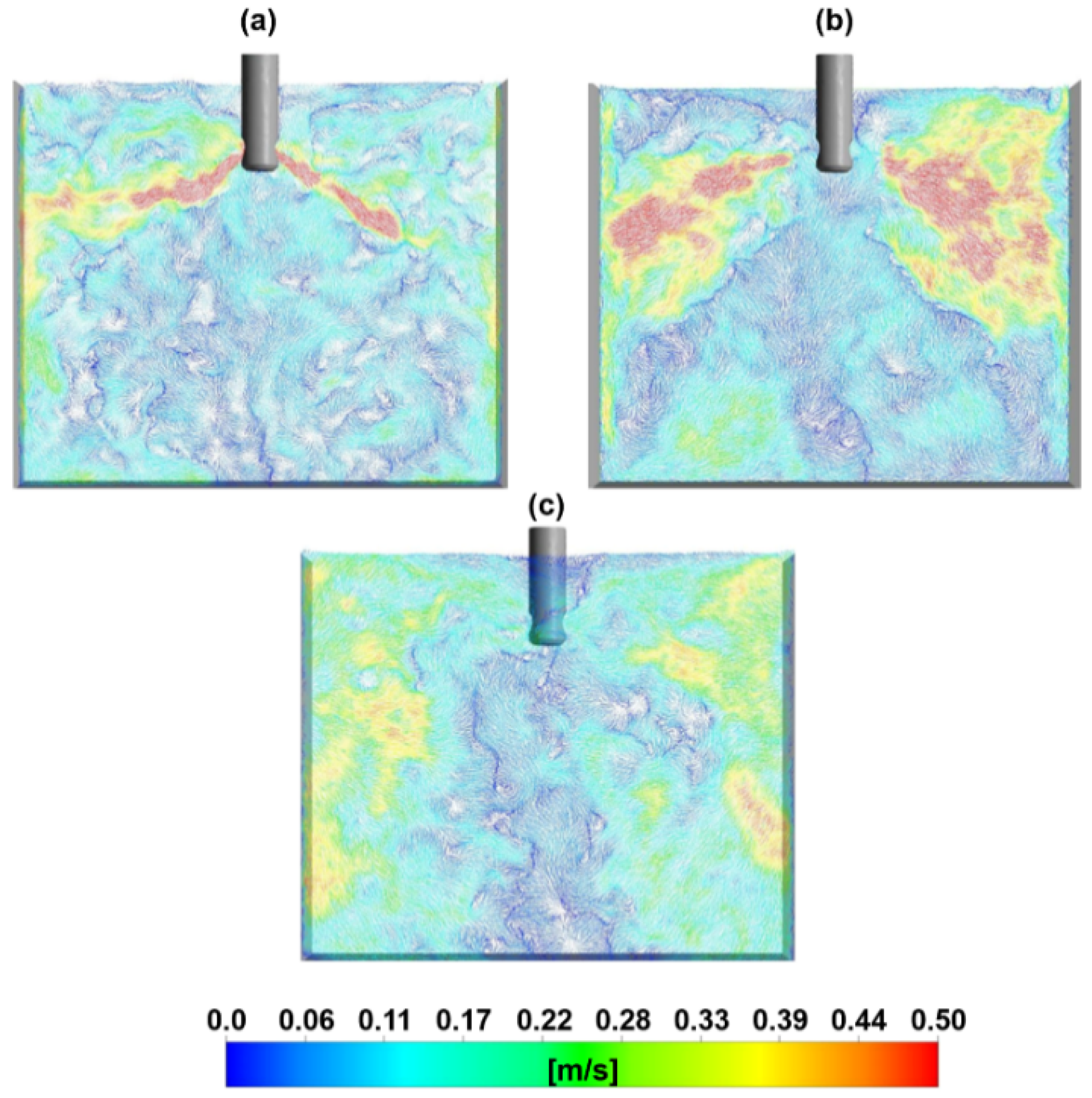

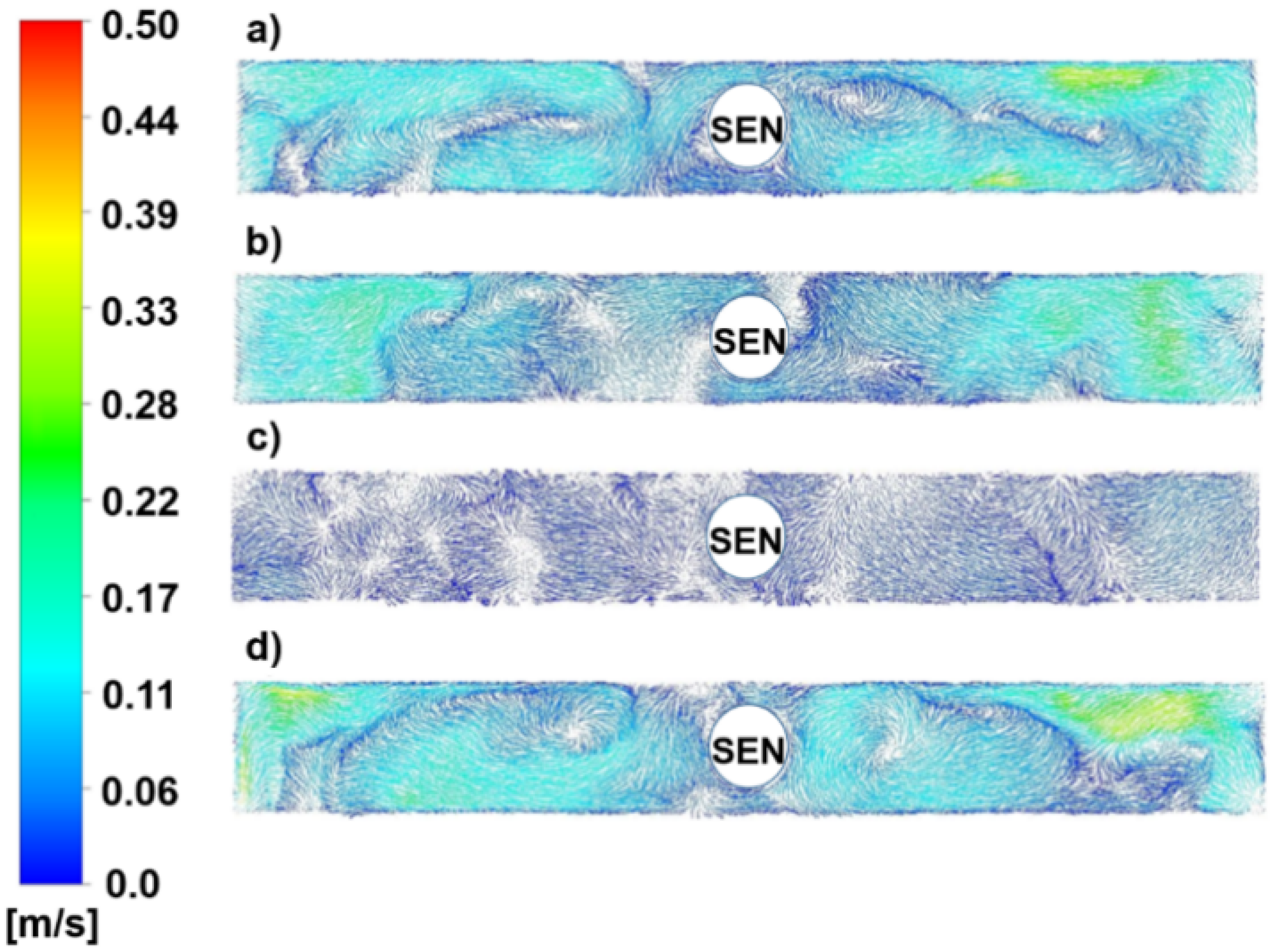

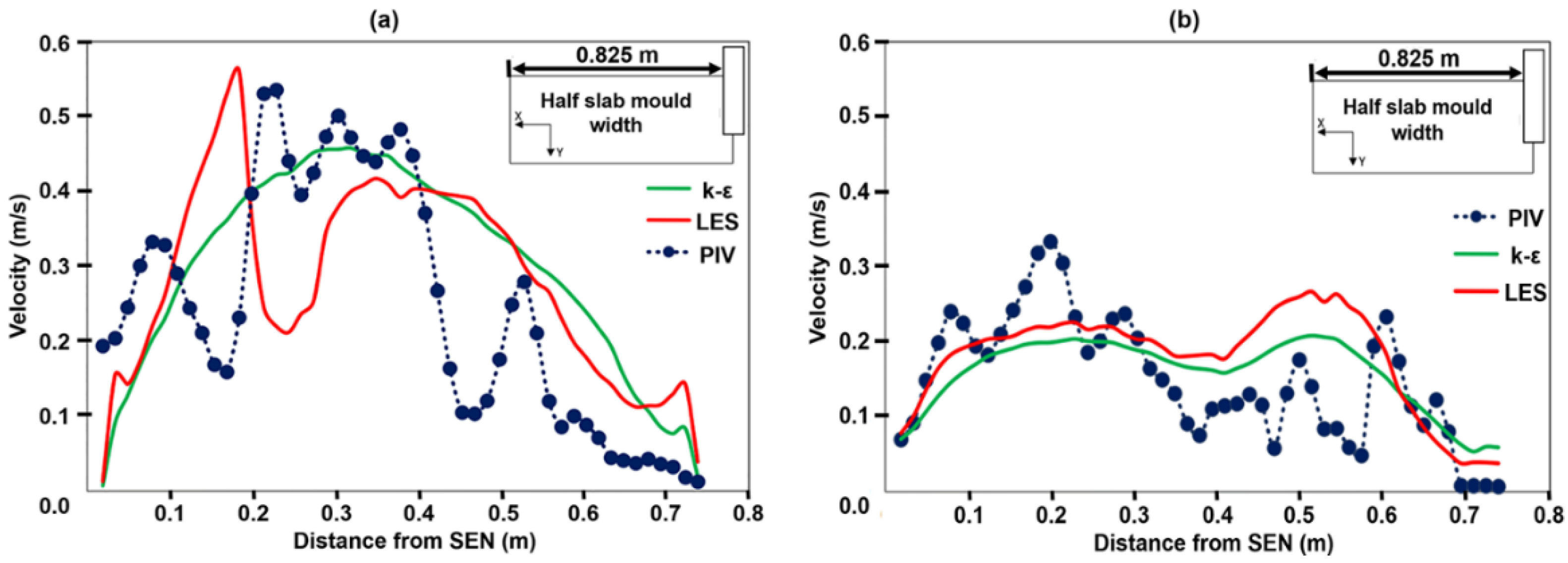

4.2. Velocity Fields by Mathematical Modeling

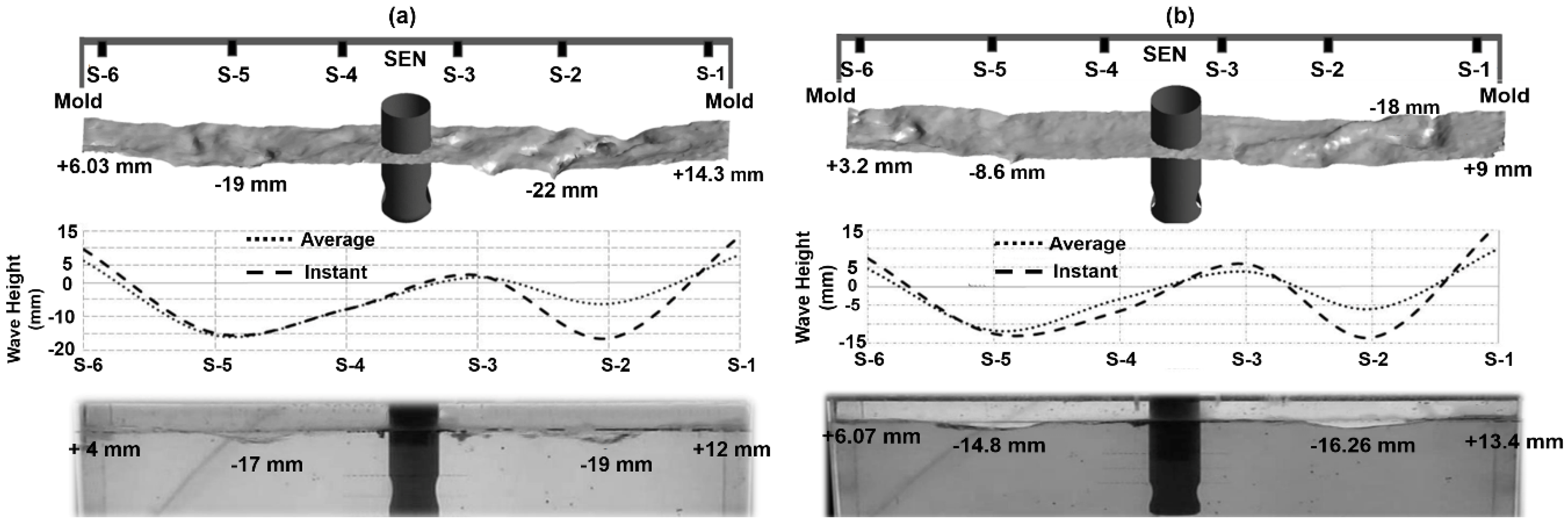

4.3. Meniscus Topography

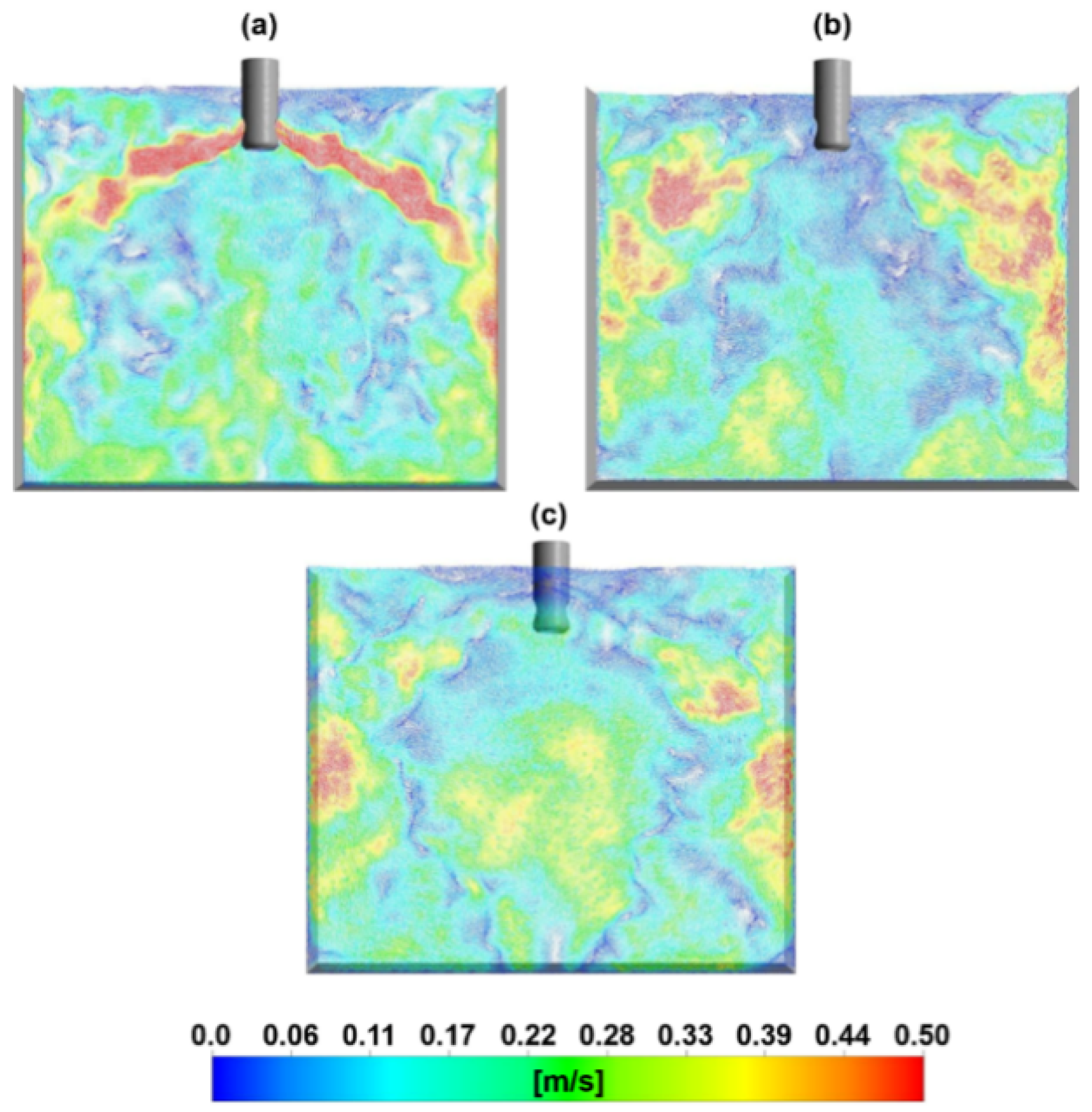

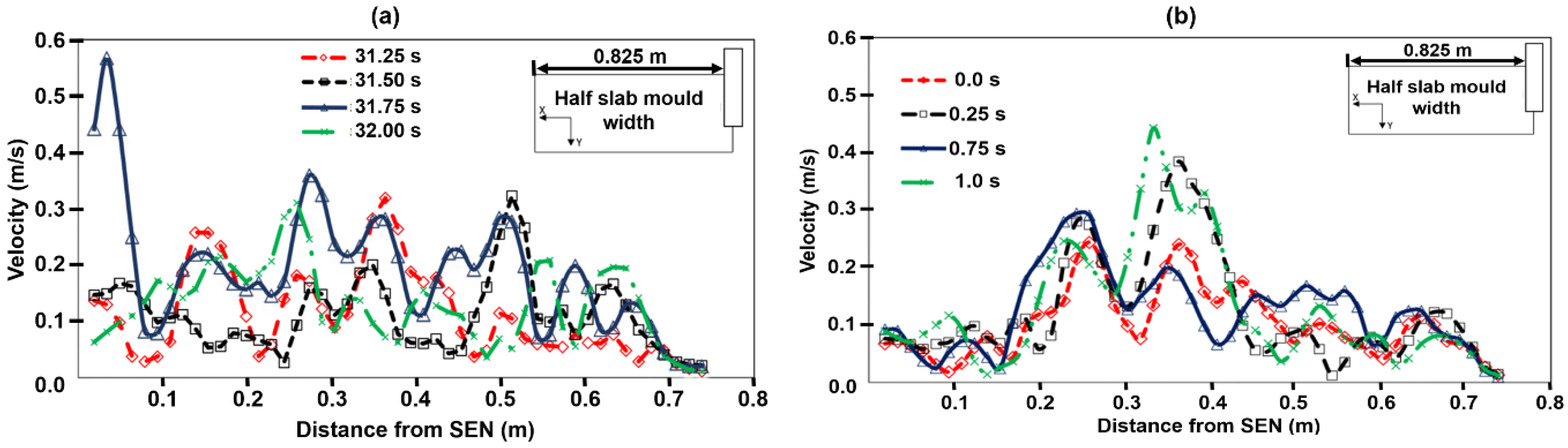

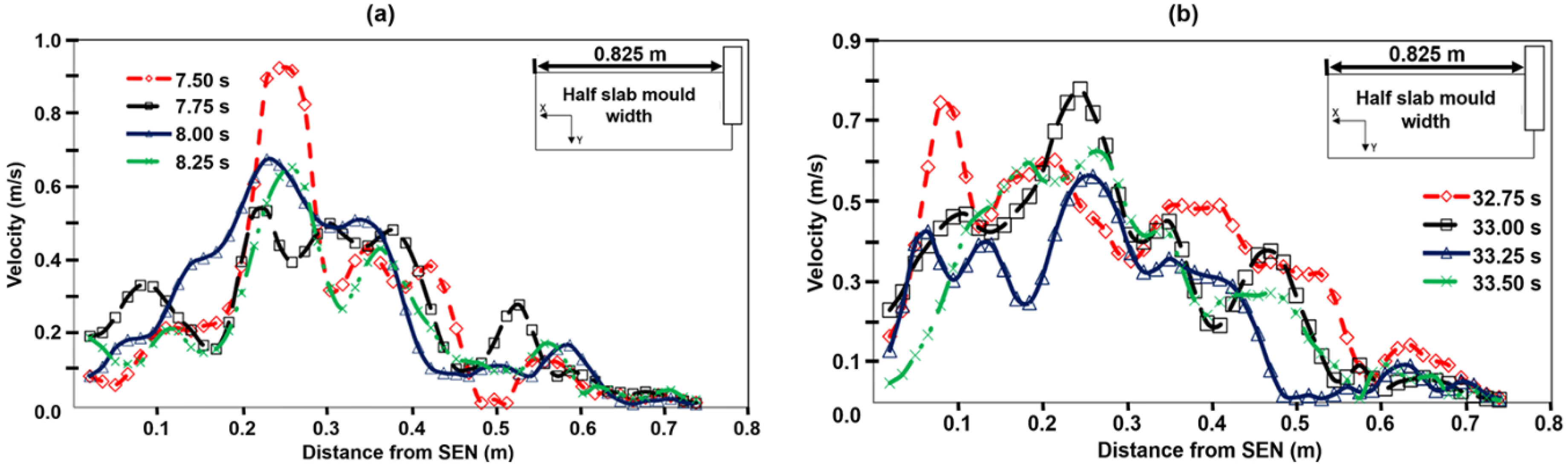

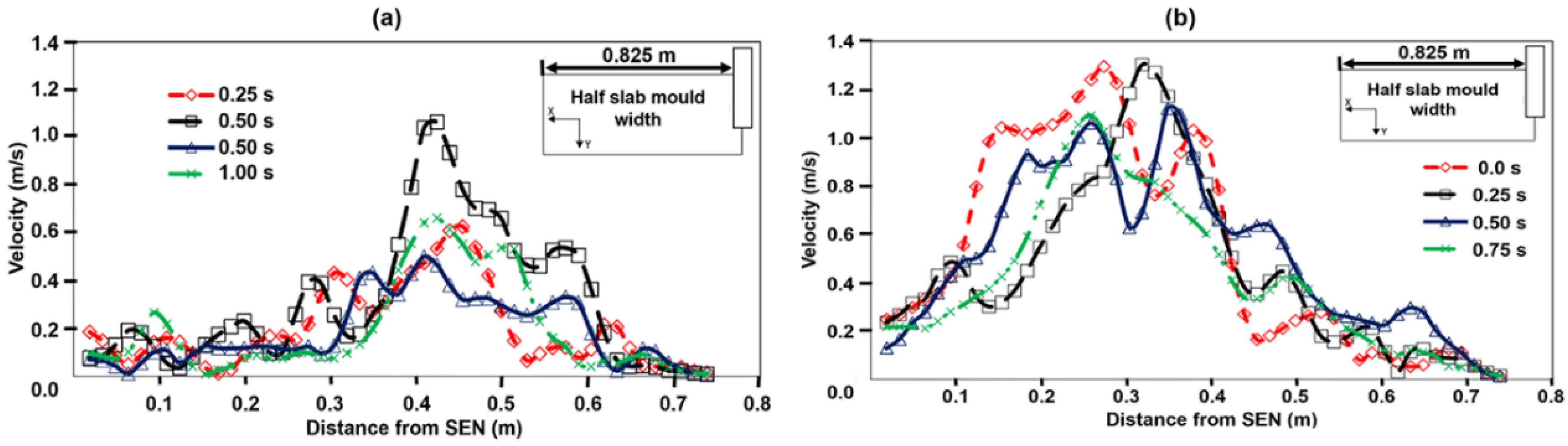

4.4. Dynamics of Sub-Meniscus Velocities

- At shallow immersions and low casting speeds, the flow behaves essentially as a single roll flow. The flow changes to a partial double roll flow at deep immersions.

- Increasing the casting speed at shallow immersions displaces the region of velocity peaks toward the nozzle, and deep immersions displace this region toward the narrow wall.

- The region yielding high-velocity peaks gets wider with deep immersions, and the region close to the nozzle remains quite for any case.

- The region close to the narrow wall observes high turbulence levels with deep immersions and high casting speeds.

5. Casting Diagnosis

6. Recommendations

7. Conclusions

- The use of a slide valve inherently delivers biased flows through the bifurcated ports of a nozzle.

- A shallow nozzle immersion, such as 95 mm, is not recommended, as this condition induces a single roll flow pattern that has a propensity to drag flux in the metal bulk.

- Casting speeds like 1.65 m/min raise the liquid velocity at the meniscus level to magnitudes as high as 1.1–1.3 m/min. These velocities will drag flux in the metal bulk.

- This caster’s operating conditions demand a nozzle with a different design that must guarantee unbiased flows and stabilize the meniscus.

- The application of the k-ε, VOF, and LES models, combined with experimental techniques for current operating casters, proved suitable for process diagnosis.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| instantaneous velocity | |

| mean velocity | |

| fluctuant velocity | |

| averaged deformation-rate tensor | |

| turbulent kinetic energy | |

| normal Reynolds stresses tensor | |

| constants model k-ε | |

| average velocity of the mixture | |

| gravity constant | |

| casting speed | |

| filtered three-velocity components | |

| filtered pressure | |

| Greek Symbols | |

| density | |

| viscosity and turbulent viscosity | |

| strain-stress tensor | |

| dissipation rate of turbulent kinetic energy | |

| surface tension | |

| volume fraction | |

| curvature radius | |

| residual stress term | |

| Sub-Indexes | |

| tensor notation | |

| phase q | |

| normal | |

| mixture | |

References

- Stemple, D.K.; Zulueta, E.N.; Flemings, M.C. Effect of Wave Motion on Chill Casting Surfaces. Metall. Mater. Trans. B 1982, 13, 503–509. [Google Scholar] [CrossRef]

- Segupta, J.; Shin, H.-J.; Thomas, B.G.; Kim, S.-H. Micrograph evidence of meniscus solidification and sub-surface microstructure evolution in continuous-cast ultralow-carbon steels. Acta Mater. 2006, 54, 1165–1173. [Google Scholar] [CrossRef]

- Bradi, A.; Natarajan, T.T.; Snyder, C.C.; Powders, K.D.; Mannion, F.J.; Byrne, M.; Cramb, A.W. Mold Simulator for Continuous Casting of Steel: Part II.The Formation of Oscillation Marks during the ContinuousCasting of Low Carbon Steel. Metall. Mater. Trans. B 2005, 36, 373–383. [Google Scholar]

- Knoepke, J.; Hubbard, M.; Kelly, J.; Kittridge, R.; Lucas, J. Pencil blister reduction at inland steel company. In Proceedings of the 77th Steelmaking Conference, Iron and Steel Society, Chicago, IL, USA, 20–23 March 1994; pp. 381–388. [Google Scholar]

- Emling, W.H.; Waugaman, T.A.; Feldbauer, S.L.; Cramb, A.W. Subsurface mold slag entrainment in ultra-low carbon steels. In Proceedings of the 77th Steelmaking Conference, Iron and Steel Society, Chicago, IL, USA, 20–23 March 1994; pp. 371–379. [Google Scholar]

- Bai, H.; Thomas, B.G. Turbulent flow of liquid steel and argon bubbles in slide-gate tundish nozzles: Part I. Model development and validation. Metall. Mater. Trans. B 2001, 32, 253–267. [Google Scholar] [CrossRef]

- Bai, H.; Thomas, B.G. Turbulent flow of liquid steel and argon bubbles in slide-gate tundish nozzles: Part II. Effect of operation conditions and nozzle design. Metall. Mater. Trans. B 2001, 32, 269–284. [Google Scholar] [CrossRef]

- Thomas, B.G. Modeling of continuous casting. In Proceedings of the 3rd International Congress on Science and Technology of Steelmaking, AISTech, Charlotte, NC, USA, 9–12 May 2005; pp. 847–861. [Google Scholar]

- Liu, Z.; Li, B.; Jiang, M. Transient asymmetric flow and bubble transport inside a slab continuous-casting mold. Metall. Mater. Trans. B 2014, 45, 675–697. [Google Scholar] [CrossRef]

- Takatani, K. Effects of electromagnetic brake and meniscus electromagnetic stirrer on transient molten steel flow at meniscus in a continuous casting mold. ISIJ Int. 2003, 43, 915–922. [Google Scholar] [CrossRef]

- Liu, R.; Sengupta, J.; Crosbie, D.; Yavuz, M.M.; Thomas, B.G. Effects of stopper rod movement on mold fluid flow at Arcelor Mittal Dofasco’s No. 1 continuous caster. In Proceedings of the Iron and Steel Technology Conference and Exposition, AISTech, Indianapolis, IN, USA, 2–5 May 2011; pp. 1–13. [Google Scholar]

- Greis, B.; Bahrmann, R.; Ruckert, A.; Pfeifer, H. Investigations of flow pattern in the SEN regarding different stopper rod geometries. Steel Res. Int. 2015, 86, 1469–1479. [Google Scholar] [CrossRef]

- Otsuka, A.; Harada, K.; Haruyuki, O.; Tsuneoka, A. New slide gate system for flow control. In Proceedings of the Iron and Steel Technology Conference, AISTech, Nashville, TN, USA, 15–17 September 2004; pp. 985–991. [Google Scholar]

- Heinrich, B.; Stopinc, A.G.; Hackl, G.; Marshall, U. Adavantages of optimised flow control from ladle to tundish. In Proceedings of the METEC and 2nd ESTAD, Dusseldorf, Germany, 15–19 June 2015. [Google Scholar]

- Najjar, F.M.; Thomas, B.G.; Hershey, D.E. Numerical study of steady turbulent flow through bifurcated nozzle in continuous casting. Metall. Mater. Trans. B 1995, 26, 749–765. [Google Scholar] [CrossRef]

- Mills, K.C.; Fox, A.B.; Thackray, R.P.; Li, Z. Continuos casting mould powder and castind process interaction: Why powders do not always wok as expected. In VII International Conference on Molten Slags Fluxes and Salts; The South African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2004; pp. 713–722. [Google Scholar]

- Mills, K.C.; Sridhar, S. Viscosities of ironmaking and steelmaking slags. Ironmak. Steelmak. 1999, 26, 262–268. [Google Scholar] [CrossRef]

- Milanovic, I.M.; Hammad, K.J. PIV study of the near field region of a turbulent round jet. In Proceedings of the 3rd Joint US-European Fluids Engineering Summer Meeting and the 8th International Conference on Nanochannels, Microchannels and Mini-channels, ASME, Montreal, QC, Canada, 1–5 August 2010; pp. 1–9. [Google Scholar]

- Morales, R.D.; Palafox-Ramos, J.; García-Demedices, L.; Sanchez-Perez, R. A DPIV study of liqud steel flow in a wide thin slab caster using four ports submerged entry nozzles. ISIJ Int. 2004, 44, 1384–1392. [Google Scholar] [CrossRef][Green Version]

- Wilcox, D.C. Turbulence Modeling for CFD; DCW Industries: La Cañada, CA, USA, 2000; pp. 103–104. [Google Scholar]

- Tennekes, H.; Lumley, J.L. A First Course on Turbulence; The MIT Press: Cambridge/London, UK, 1972; pp. 27–30. [Google Scholar]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. Comp. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Yeoh, G.H.; Tu, J. Computational Techniques for Multiphase Flows; Butterworth-Heinemann: Oxford, London, UK, 2010; p. 215. [Google Scholar]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. Comp. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Sagaut, P. Large Eddy Simulation for Incompressible Flows; Springer-Verlag: Berlin/Heidelberg, Germany, 2000; pp. 1–291. [Google Scholar]

- Pope, S. Turbulent Flows; Cambridge University Press, Cambridge Press: London, UK, 2000; pp. 558–638. [Google Scholar]

- Smagorinsky, J. General Circulation Experiments with the Primitive Equations. I the Basic Experiment. Month. Weather Rev. 1963, 91, 99–164. [Google Scholar] [CrossRef]

- Smirnov, A.; Shi, S.; Celik, I. Random flow generation technique for large eddy simulations and particle-dynamics modeling. J. Fluids Eng. 2001, 123, 359–371. [Google Scholar] [CrossRef]

- Ferziger, J.H.; Peric, M. Computational Methods for Fluid Dynamics; Springer: New York, NY, USA; Berlin, Germany, 2002; p. 72. [Google Scholar]

- Chung, T.J. Computational Fluid Dynamics; Cambridge University Press: London, UK; New York, NY, USA, 2002; pp. 106–119. [Google Scholar]

- Issa, R.I. Solution of the implicitly discretized fluid flow equations by operator-splitting. Comp. Phys. 1986, 62, 40–65. [Google Scholar] [CrossRef]

- ANSYS, Inc. Available online: www.Ansys.com (accessed on 10 April 2019).

- Calderón-Ramos, I.; Morales, R.D. Influence of turbulent flows in the nozzle on melt flow within a slab mold and stability of the metal-flux interface. Metall. Mater. Trans. B 2016, 47, 1866–1881. [Google Scholar] [CrossRef]

- González-Solórzano, M.G.; Morales, R.D.; Gutiérrez, E.; Guarneros-Guarneros, J.; Chattopadhyay, K. Analysis of Fluid Flow of Liquid Steel through Clogged Nozzles: Thermodynamic Analysis and Flow Simulations. Steel Res. Int. 2020, 91. [Google Scholar] [CrossRef]

- Cedillo, V.; Morales, R.D. Biased flows in slab molds induced by slide gates. Part I: Experimental measurements and flow simulation. Ironmak. Steelmak. 2018, 45, 204–214. [Google Scholar] [CrossRef]

| Orientation of the SV Opening (Degrees) | Effects on the Flow |

|---|---|

| 0 toward one of the narrow mold faces | Produces a biased and swirling jets toward one of the narrow faces |

| 90 oriented to one of the broad faces of the mold | orientation generates jets with strong swirl and asymmetry in the horizontal plane, |

| 45 oriented in between the two precedent directions | Poor choice. Generation of instable flows |

| Parameter | Value | ||

|---|---|---|---|

| Casting speed (m/min) | 0.9, 1.3 and 1.65 | ||

| Casting speed (m/s) | 0.015, 0.0216667 and 0.0275 | ||

| Water flow rate (L/s) | 5.41, 7.81 and 9.92 | ||

| Physical properties of water (20 °C) | |||

| Density (kg/m3) | Kinematic viscosity (m2/s) | Surface tension (N/m) | |

| 1000 | 1 × 10−6 | 0.073 | |

| Physical properties of liquid steel (1550 °C) | |||

| Density (kg/m3) | Kinematic viscosity (m2/s) | Surface tension (N/m) | |

| 7014 | 0.913 × 10−6 | 1.6 | |

| Concept | Implementation | Observations |

|---|---|---|

| Discretization of the computing mesh | Fisrst upwind shifted to second upwind | RANS model uses 1st upwid and LES model uses 2nd upwind |

| Iteration | Iterative Time Advancemnet | |

| Mesh geometry | Tetraedral | 1 853 907 cells |

| Input turbulence | Turbulence generator [28] | Generation of turbulent field in the input |

| Interpolation | Gradient method [29] | |

| Pressure-velocity algorithm | SIMPLE [30] and PISO [31] | Simple for RANS-LES and PISO for VOF |

| Near wall velocities | Wall function and WALE | Wall function for RANS and VOF. WALE for LES [32] |

| Velocities in the walls | Velocities are zero | |

| Fluid velocities at the inlet | Use liquid throghput | Throghputs calculated using the Bernoulli equation. |

| Pressure abiove the system | 101 325 Pa | |

| Convergence criterion | Sum of all residuals < 10−4 | Time step 0.001−0.05 swith 500 hundred iterations as average |

| Casting Speed (m/min) | Nozzle Immersion (mm) | Effects on Quality of Steel Sheets |

|---|---|---|

| 0.9 | 95 | A single flow roll causes flux entrainment particles, which become inclusions in steel sheets. However, it can keep a hot meniscus to melt the flux and forming thin shells. |

| 1.3 | 95 | This condition yields a single roll flow pattern. Higher liquid velocities cause flux entrainment, forming exogeneous inclusions in the final steel sheet. |

| 0.9 | 185 | The discharging jets barely impact the mold´s narrow faces leaving a stagnant meniscus. This condition will lead to excessive shell thicknesses deriving of longitudinal cracks. |

| 1.3 | 185 | Flow maintains a hotter steel due to the larger fluid velocities in the meniscus. Rapid melting of the mold flux. The probability for the formation of hook cracks decreases. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Ávila, J.; Muñiz-Valdés, C.R.; Morales-Dávila, R.; Nàjera-Bastida, A. Process Diagnosis of Liquid Steel Flow in a Slab Mold Operated with a Slide Valve. Crystals 2020, 10, 1035. https://doi.org/10.3390/cryst10111035

Rodríguez-Ávila J, Muñiz-Valdés CR, Morales-Dávila R, Nàjera-Bastida A. Process Diagnosis of Liquid Steel Flow in a Slab Mold Operated with a Slide Valve. Crystals. 2020; 10(11):1035. https://doi.org/10.3390/cryst10111035

Chicago/Turabian StyleRodríguez-Ávila, Jafeth, Carlos Rodrigo Muñiz-Valdés, Rodolfo Morales-Dávila, and Alfonso Nàjera-Bastida. 2020. "Process Diagnosis of Liquid Steel Flow in a Slab Mold Operated with a Slide Valve" Crystals 10, no. 11: 1035. https://doi.org/10.3390/cryst10111035

APA StyleRodríguez-Ávila, J., Muñiz-Valdés, C. R., Morales-Dávila, R., & Nàjera-Bastida, A. (2020). Process Diagnosis of Liquid Steel Flow in a Slab Mold Operated with a Slide Valve. Crystals, 10(11), 1035. https://doi.org/10.3390/cryst10111035