Evolution of Char Structure During In-Situ Biomass Tar Reforming: Importance of the Coupling Effect Among the Physical-Chemical Structure of Char-Based Catalysts

Abstract

:1. Introduction

2. Results and Discussion

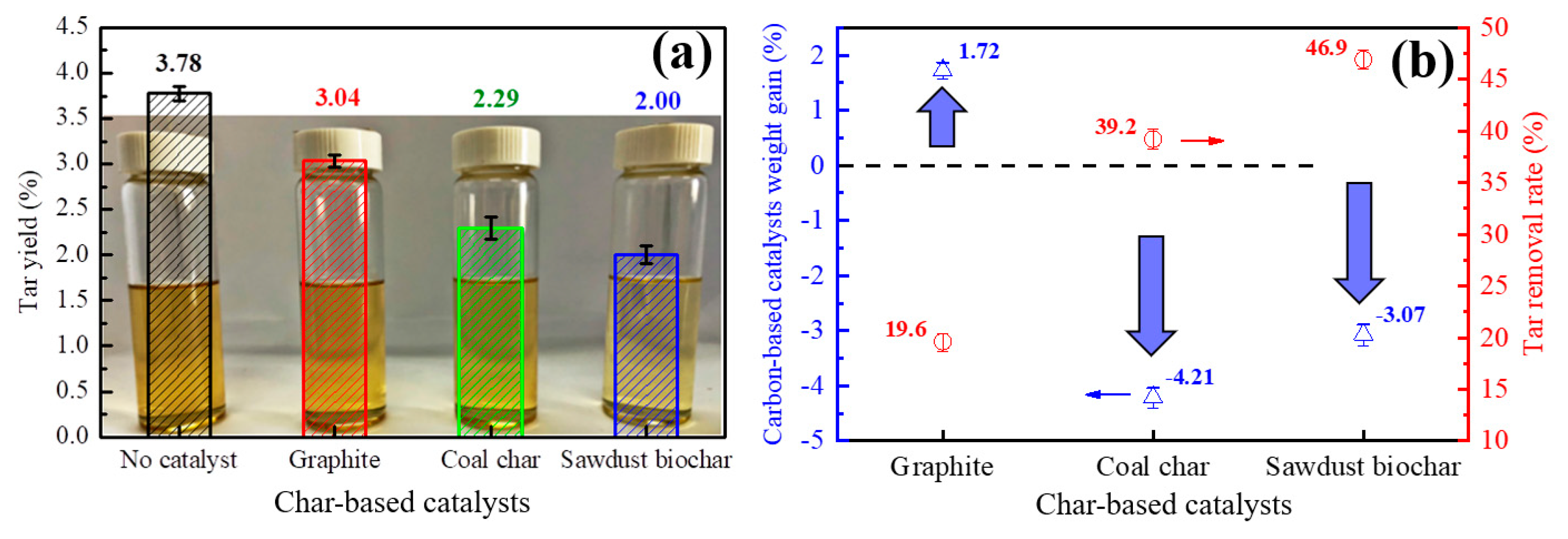

2.1. Tar Yield, Tar Removal Rate and Weight Change of Char-Based Catalysts

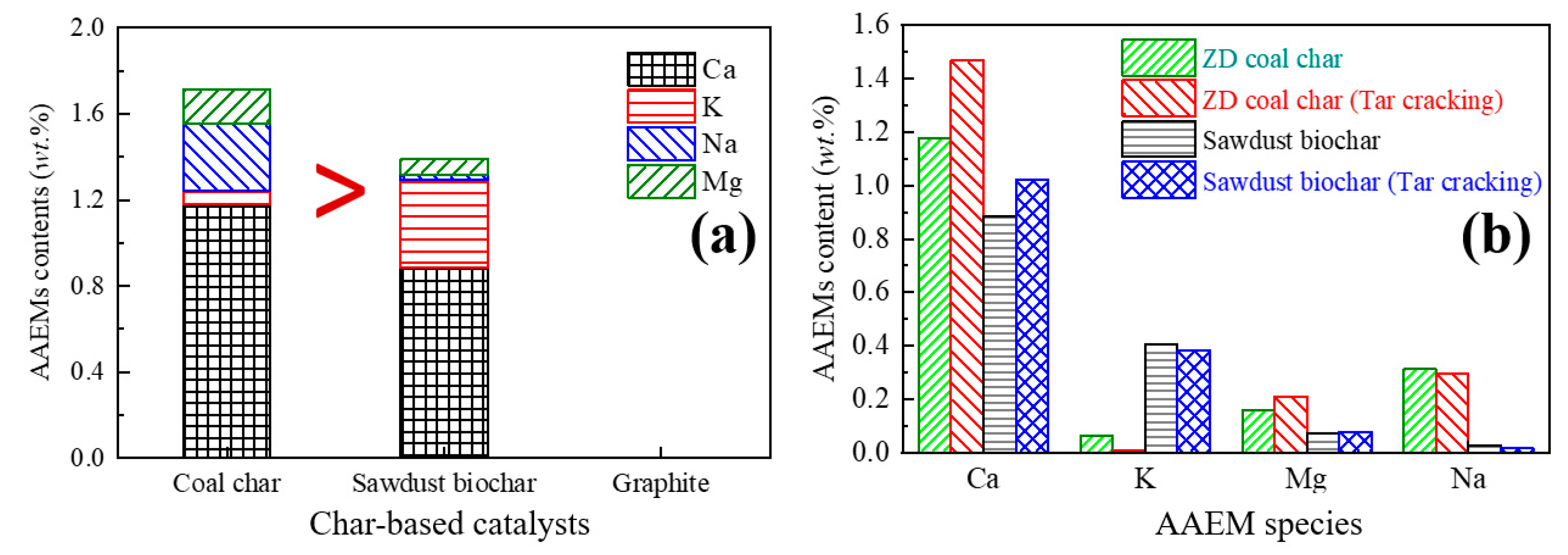

2.2. AAEMs Species in Char-Based Catalysts

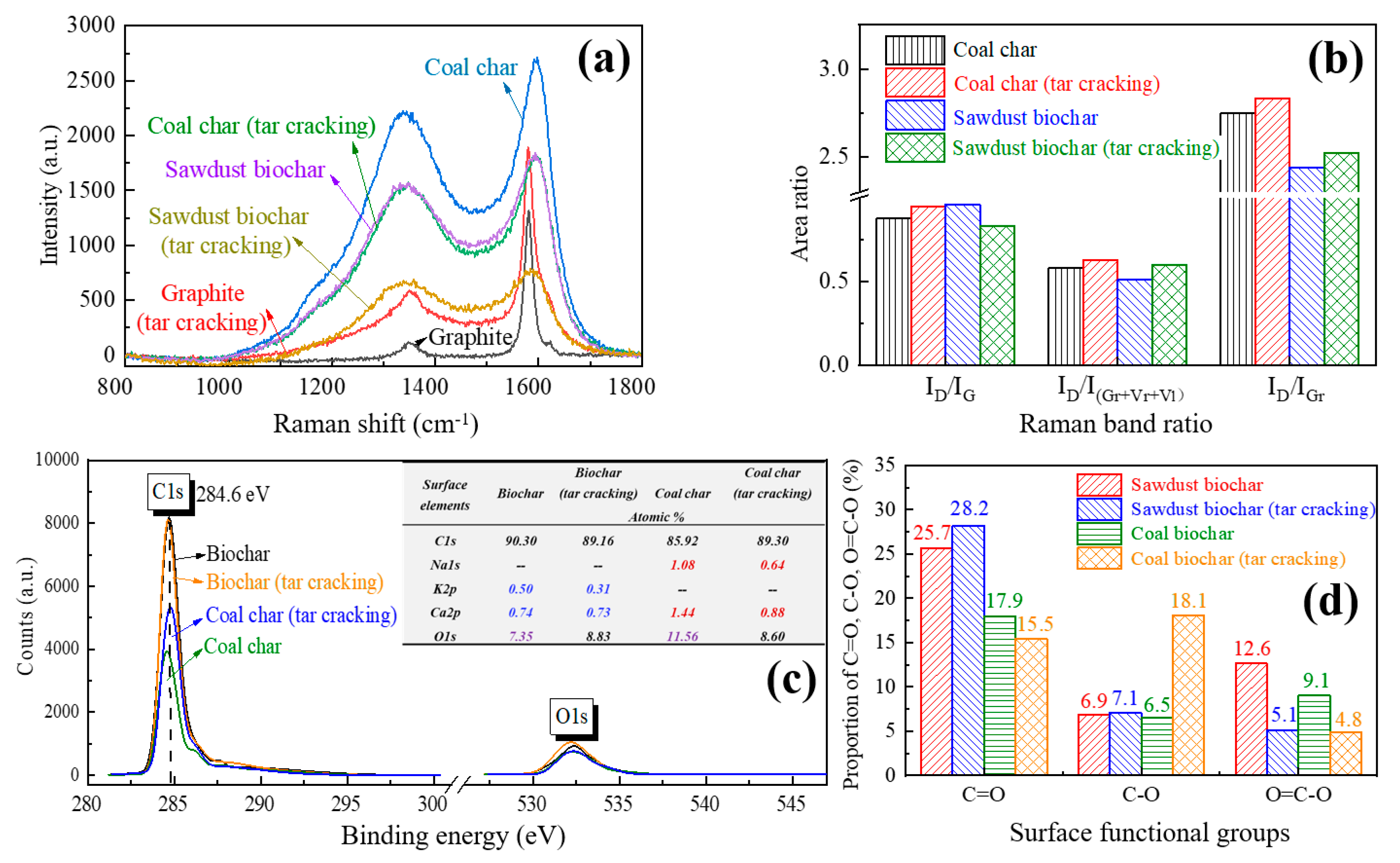

2.3. Chemical Structures of Char-Based Catalysts

2.4. Physical Structures of Char-Based Catalysts

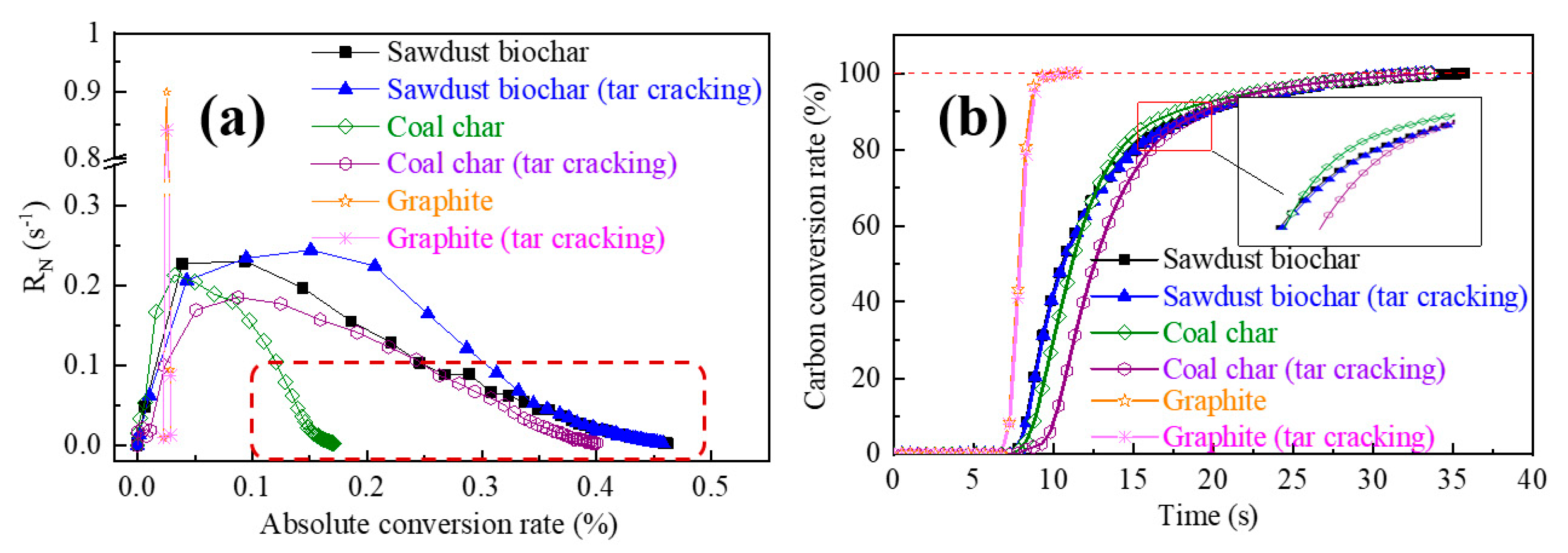

2.5. Reactivities of Char-Based Catalysts

3. Experimental

3.1. Preparation of Char-Based Catalysts

3.2. In-Situ Biomass Tar Reforming Over Char-Based Catalysts

3.3. Analysis of Physical-Chemical Structures of Char-Based Catalysts

4. Conclusions

- (1).

- The char-based catalyst has a certain removal ability for in-situ biomass tar of corn straw in an inert atmosphere, which is as follows: sawdust biochar > ZD coal char > graphite.

- (2).

- During the in-situ tar reforming, the AAEM species act as adsorption/reaction sites, affecting the evolution of the aromatic ring structure and oxygen-containing functional groups of the char-based catalyst, and also its pore structure. AAEM species on the surface of char-based catalysts are the active sites for tar reforming, which promotes the increase of active intermediates (C–O bond and C–O–AAEMs), and enhances the interactions between char-based catalysts and biomass tar. The abundant AAEMs may lead to the conversion of O=C–O and C=O to C–O.

- (3).

- For tar reforming, the internal pore structure of the char-based catalyst is little changed, mainly with the carbon deposit forming on the surface pore structure. The carbon deposit from the reformation of straw tar on the char surface has better reactivity than the inherent carbon structure of ZD coal char and sawdust biochar.

- (4).

- There is a positive relationship between the MFBRA–MR specific reactivity and tar catalytic reforming ability of char-based catalysts, which can be used to determine the catalytic ability of char-based catalysts on tar reforming directly.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AAEMs | Alkali and alkaline earth metallic species |

| ZD coal | Zhundong coal |

| ICP-AES | Intrepid Inductively Coupled Plasma Atomic Emission Spectrometer |

| XPS | X-ray photoelectron spectroscopy |

| SEM-EDS | Scanning electron microscopy-energy dispersive spectrometer |

| BDDT | Brunauer, Deming, Deming, and Teller |

| MFBRA–MR | Micro fluidized bed reaction analyzer–MS reactor |

References

- Devi, L.; Ptasinski, K.J.; Janssen, F.J. A review of the primary measures for tar elimination in biomass gasification processes. Biomass Bioenergy 2003, 24, 125–140. [Google Scholar] [CrossRef]

- Sipra, A.T.; Gao, N.; Sarwar, H. Municipal solid waste (MSW) pyrolysis for bio-fuel production: A review of effects of MSW components and catalysts. Fuel Process. Technol. 2018, 175, 131–147. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, Z.; Zhang, H.; Wang, Y.; Xu, X.; Cheng, L.; Zhang, Y. The catalytic reforming of tar from pyrolysis and gasification of brown coal: Effects of parental carbon materials on the performance of char catalysts. Fuel Process. Technol. 2018, 174, 142–148. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, X.; Mourant, D.; Song, Y.; Zhang, L.; Lievens, C.; Xiang, J.; Li, C.-Z. Evolution of aromatic structures during the reforming of bio-oil: Importance of the interactions among bio-oil components. Fuel 2013, 111, 805–812. [Google Scholar] [CrossRef]

- Li, C.; Suzuki, K. Tar property, analysis, reforming mechanism and model for biomass gasification—An overview. Renew. Sustain. Energy Rev. 2009, 13, 594–604. [Google Scholar] [CrossRef]

- Coll, R.; Salvado, J.; Farriol, X.; Montane, D. Steam reforming model compounds of biomass gasification tars: Conversion at different operating conditions and tendency towards coke formation. Fuel Process. Technol. 2001, 74, 19–31. [Google Scholar] [CrossRef]

- Kurkela, E.; Ståhlberg, P. Air gasification of peat, wood and brown coal in a pressurized fluidized-bed reactor. I. Carbon conversion, gas yields and tar formation. Fuel Process. Technol. 1992, 31, 1–21. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, Y.; Brown, R.C. Steam reforming of tar compounds over Ni/olivine catalysts doped with CeO2. Energy Convers. Manag. 2007, 48, 68–77. [Google Scholar] [CrossRef]

- Kinoshita, C.; Wang, Y.; Zhou, J. Tar formation under different biomass gasification conditions. J. Anal. Appl. Pyrolysis 1994, 29, 169–181. [Google Scholar] [CrossRef]

- Bridgwater, A. The technical and economic feasibility of biomass gasification for power generation. Fuel 1995, 74, 631–653. [Google Scholar] [CrossRef]

- Liu, Q.; Xiong, Z.; Syed-Hassan, S.S.A.; Deng, Z.; Zhao, X.; Su, S.; Xiang, J.; Wang, Y.; Hu, S. Effect of the pre-reforming by Fe/bio-char catalyst on a two-stage catalytic steam reforming of bio-oil. Fuel 2019, 239, 282–289. [Google Scholar] [CrossRef]

- Zhang, S.; Asadullah, M.; Dong, L.; Tay, H.L.; Li, C.Z. An advanced biomass gasification technology with integrated catalytic hot gas cleaning. Part II: Tar reforming using char as a catalyst or as a catalyst support. Fuel 2013, 112, 646–653. [Google Scholar] [CrossRef]

- Hosokai, S.; Norinaga, K.; Kimura, T.; Nakano, M.; Li, C.Z.; Hayashi, J.I. Reforming of Volatiles from the Biomass Pyrolysis over Charcoal in a Sequence of Coke Deposition and Steam Gasification of Coke. Energy Fuels 2011, 25, 5387–5393. [Google Scholar] [CrossRef]

- Shao, S.; Zhang, H.; Xiao, R.; Li, X.; Cai, Y. Evolution of coke in the catalytic conversion of biomass-derivates by combined in-situ DRIFTS and ex-situ approach: Effect of functional structure. Fuel Process. Technol. 2018, 178, 88–97. [Google Scholar] [CrossRef]

- Li, C.-Z. Importance of volatile–char interactions during the pyrolysis and gasification of low-rank fuels—A review. Fuel 2013, 112, 609–623. [Google Scholar] [CrossRef]

- Hu, C.; Zhang, H.; Xiao, R. Effects of nascent char on ex-situ catalytic fast pyrolysis of wheat straw. Energy Convers. Manag. 2018, 177, 765–772. [Google Scholar] [CrossRef]

- Xu, C.C.; Hamilton, S.; Ghosh, M. Hydro-treatment of Athabasca vacuum tower bottoms in supercritical toluene with microporous activated carbons and metal–carbon composite. Fuel 2009, 88, 2097–2105. [Google Scholar] [CrossRef]

- Bhandari, P.N.; Kumar, A.; Bellmer, D.D.; Huhnke, R.L. Synthesis and evaluation of biochar-derived catalysts for removal of toluene (model tar) from biomass-generated producer gas. Renew. Energy 2014, 66, 346–353. [Google Scholar] [CrossRef]

- Feng, D.; Zhao, Y.; Zhang, Y.; Sun, S.; Meng, S.; Guo, Y.; Huang, Y. Effects of K and Ca on reforming of model tar compounds with pyrolysis biochar under H2O or CO2. Chem. Eng. J. 2016, 306, 422–432. [Google Scholar] [CrossRef]

- Zhang, Y.; Kajitani, S.; Ashizawa, M.; Oki, Y. Tar destruction and coke formation during rapid pyrolysis and gasification of biomass in a drop-tube furnace. Fuel 2010, 89, 302–309. [Google Scholar] [CrossRef]

- Wang, F.-J.; Zhang, S.; Chen, Z.-D.; Liu, C.; Wang, Y.-G. Tar reforming using char as catalyst during pyrolysis and gasification of Shengli brown coal. J. Anal. Appl. Pyrolysis 2014, 105, 269–275. [Google Scholar] [CrossRef]

- Li, X.; Hayashi, J.I.; Li, C.Z. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part VII. Raman spectroscopic study on the changes in char structure during the catalytic gasification in air. Fuel 2006, 85, 1509–1517. [Google Scholar] [CrossRef]

- El-Rub, Z.A.; Bramer, E.A.; Brem, G. Experimental comparison of biomass chars with other catalysts for tar reduction. Fuel 2008, 87, 2243–2252. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Y.; Hu, X.; Xiang, J.; Hu, S.; Mourant, D.; Li, T.; Wu, L.; Li, C.-Z. Effects of volatile–char interactions on in-situ destruction of nascent tar during the pyrolysis and gasification of biomass. Part II. Roles of steam. Fuel 2015, 143, 555–562. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Y.; Hu, X.; Hu, S.; Xiang, J.; Zhang, L.; Zhang, S.; Min, Z.; Li, C.-Z. Effects of volatile–char interactions on in situ destruction of nascent tar during the pyrolysis and gasification of biomass. Part I. Roles of nascent char. Fuel 2014, 122, 60–66. [Google Scholar] [CrossRef]

- Ducousso, M.; Weiss-Hortala, E.; Nzihou, A.; Castaldi, M.J. Reactivity enhancement of gasification biochars for catalytic applications. Fuel 2015, 159, 491–499. [Google Scholar] [CrossRef] [Green Version]

- Feng, D.; Zhao, Y.; Zhang, Y.; Gao, J.; Sun, S. Changes of biochar physiochemical structures during tar H2O and CO2 heterogeneous reforming with biochar. Fuel Process. Technol. 2017, 165, 72–79. [Google Scholar] [CrossRef]

- Shen, Y. Chars as carbonaceous adsorbents/catalysts for tar elimination during biomass pyrolysis or gasification. Renew. Sustain. Energy Rev. 2015, 43, 281–295. [Google Scholar] [CrossRef]

- Fushimi, C.; Wada, T.; Tsutsumi, A. Inhibition of steam gasification of biomass char by hydrogen and tar. Biomass Bioenergy 2011, 35, 179–185. [Google Scholar] [CrossRef]

- Tay, H.-L.; Kajitani, S.; Zhang, S.; Li, C.-Z. Inhibiting and other effects of hydrogen during gasification: Further insights from FT-Raman spectroscopy. Fuel 2014, 116, 1–6. [Google Scholar] [CrossRef]

- Feng, D.; Zhao, Y.; Zhang, Y.; Xu, H.; Zhang, L.; Sun, S. Catalytic mechanism of ion-exchanging alkali and alkaline earth metallic species on biochar reactivity during CO2/H2O gasification. Fuel 2018, 212 (Suppl. C), 523–532. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, C.; Hu, S.; Wang, Y.; Xu, K.; Su, S.; Xiang, J. Catalytic behaviors of alkali metal salt involved in homogeneous volatile and heterogeneous char reforming in steam gasification of cellulose. Energy Convers. Manag. 2018, 158, 147–155. [Google Scholar] [CrossRef]

- Zhou, W.; Bai, B.; Chen, G.; Ma, L.; Jing, D.; Yan, B. Study on catalytic properties of potassium carbonate during the process of sawdust pyrolysis. Int. J. Hydrog. Energy 2018, 43, 13829–13841. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, D.; Zhang, Y.; Huang, Y.; Sun, S. Effect of pyrolysis temperature on char structure and chemical speciation of alkali and alkaline earth metallic species in biochar. Fuel Process. Technol. 2016, 141, 54–60. [Google Scholar] [CrossRef]

- Feng, D.; Zhao, Y.; Zhang, Y.; Sun, S. Effects of H2O and CO2 on the homogeneous conversion and heterogeneous reforming of biomass tar over biochar. Int. J. Hydrog. Energy 2017, 42, 13070–13084. [Google Scholar] [CrossRef]

- Feng, D.; Zhao, Y.; Zhang, Y.; Zhang, Z.; Sun, S. Roles and fates of K and Ca species on biochar structure during in-situ tar H2O reforming over nascent biochar. Int. J. Hydrog. Energy 2017, 42, 21686–21696. [Google Scholar] [CrossRef]

- Mun, T.Y.; Kim, J.W.; Kim, J.S. Air gasification of dried sewage sludge in a two-stage gasifier: Part 1. The effects and reusability of additives on the removal of tar and hydrogen production. Int. J. Hydrog. Energy 2013, 38, 5226–5234. [Google Scholar] [CrossRef]

- Klinghoffer, N.B.; Castaldi, M.J.; Nzihou, A. Catalyst Properties and Catalytic Performance of Char from Biomass Gasification. Ind. Eng. Chem. Res. 2012, 51, 13113–13122. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Provisional). Pure Appl. Chem. 1982, 54, 2201–2218. [Google Scholar] [CrossRef]

- Suuberg, E.M.; Deevi, S.C.; Yun, Y. Elastic behaviour of coals studied by mercury porosimetry. Fuel 1995, 74, 1522–1530. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, D.; Li, B.; Sun, S.; Zhang, S. Combustion characteristics of char from pyrolysis of Zhundong sub-bituminous coal under O2/steam atmosphere: Effects of mineral matter. Int. J. Greenh. Gas Control 2019, 80, 54–60. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, D.; Li, B.; Wang, P.; Tan, H.; Sun, S. Effects of flue gases (CO/CO2/SO2/H2O/O2) on NO-Char interaction at high temperatures. Energy 2019, 174, 519–525. [Google Scholar] [CrossRef]

- Du, C.; Liu, L.; Qiu, P. Importance of volatile AAEM species to char reactivity during volatile–char interactions. RSC Adv. 2017, 7, 10397–10406. [Google Scholar] [CrossRef]

- Liu, P.; Zhao, Y.; Guo, Y.; Feng, D.; Wu, J.; Wang, P.; Sun, S. Effects of volatile-char interactions on char during pyrolysis of rice husk at mild temperatures. Bioresour. Technol. 2016, 219, 702–709. [Google Scholar] [CrossRef] [PubMed]

| Conditions | BET Surface Area | Pore Volume | Micropore Area <2 nm | Large Hole Area >2 nm | SMic./SExt. |

|---|---|---|---|---|---|

| (m2/g) | (cm3/g) | (m2/g) | (m2/g) | ||

| Graphite | 0.29 | 0.0029 | 3.18 | - - | - - |

| Coal char | 13.73 | 0.0107 | 10.42 | 3.31 | 3.15 |

| Sawdust biochar | 188.86 | 0.1069 | 139.68 | 49.18 | 2.84 |

| Graphite (tar reforming) | 0.04 | 0.0018 | 3.15 | - - | - - |

| Coal char (tar reforming) | 1.77 | 0.0040 | 1.28 | 0.48 | 2.67 |

| Sawdust biochar (tar reforming) | 89.66 | 0.0845 | 11.89 | 77.77 | 0.15 |

| Sample Name | Proximate Analysis (ad., %) | Ultimate Analysis (daf., %) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Moisture | Volatile | Ash | Fixed Carbon | C | H | N | S | Odiff. | |

| ZD coal | 9.63 | 40.30 | 5.50 | 44.57 | 61.40 | 4.41 | 0.89 | 0.48 | 17.69 |

| Sawdust | 9.49 | 77.13 | 0.96 | 12.42 | 43.72 | 5.31 | 0.12 | 0.01 | 40.39 |

| Corn stalk | 6.17 | 71.20 | 6.52 | 16.11 | 40.39 | 5.14 | 1.12 | 0.16 | 39.91 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Feng, D.; Zhao, Y.; Dong, H.; Chang, G.; Quan, C.; Sun, S.; Qin, Y. Evolution of Char Structure During In-Situ Biomass Tar Reforming: Importance of the Coupling Effect Among the Physical-Chemical Structure of Char-Based Catalysts. Catalysts 2019, 9, 711. https://doi.org/10.3390/catal9090711

Zhang Y, Feng D, Zhao Y, Dong H, Chang G, Quan C, Sun S, Qin Y. Evolution of Char Structure During In-Situ Biomass Tar Reforming: Importance of the Coupling Effect Among the Physical-Chemical Structure of Char-Based Catalysts. Catalysts. 2019; 9(9):711. https://doi.org/10.3390/catal9090711

Chicago/Turabian StyleZhang, Yu, Dongdong Feng, Yijun Zhao, Heming Dong, Guozhang Chang, Cui Quan, Shaozeng Sun, and Yukun Qin. 2019. "Evolution of Char Structure During In-Situ Biomass Tar Reforming: Importance of the Coupling Effect Among the Physical-Chemical Structure of Char-Based Catalysts" Catalysts 9, no. 9: 711. https://doi.org/10.3390/catal9090711

APA StyleZhang, Y., Feng, D., Zhao, Y., Dong, H., Chang, G., Quan, C., Sun, S., & Qin, Y. (2019). Evolution of Char Structure During In-Situ Biomass Tar Reforming: Importance of the Coupling Effect Among the Physical-Chemical Structure of Char-Based Catalysts. Catalysts, 9(9), 711. https://doi.org/10.3390/catal9090711