2.1. Catalyst Characterization

This section shows the results of the characterization of the catalytic precursors Layered Double Hydroxides (LDH) identified as LDH1, LDH2, LDH3 and LDH4 corresponding to the ratio Co/Fe = 1, 2, 3 and 4 respectively, as well as the products of calcination of LDH identified as MO-LDH1, MO-LDH2, MO-LDH3 and MO-LDH4.

2.1.1. Thermal Evolution of Layered Double Hydroxides (LDH) to Co/Fe-Mixed Oxides (MO-LDH)

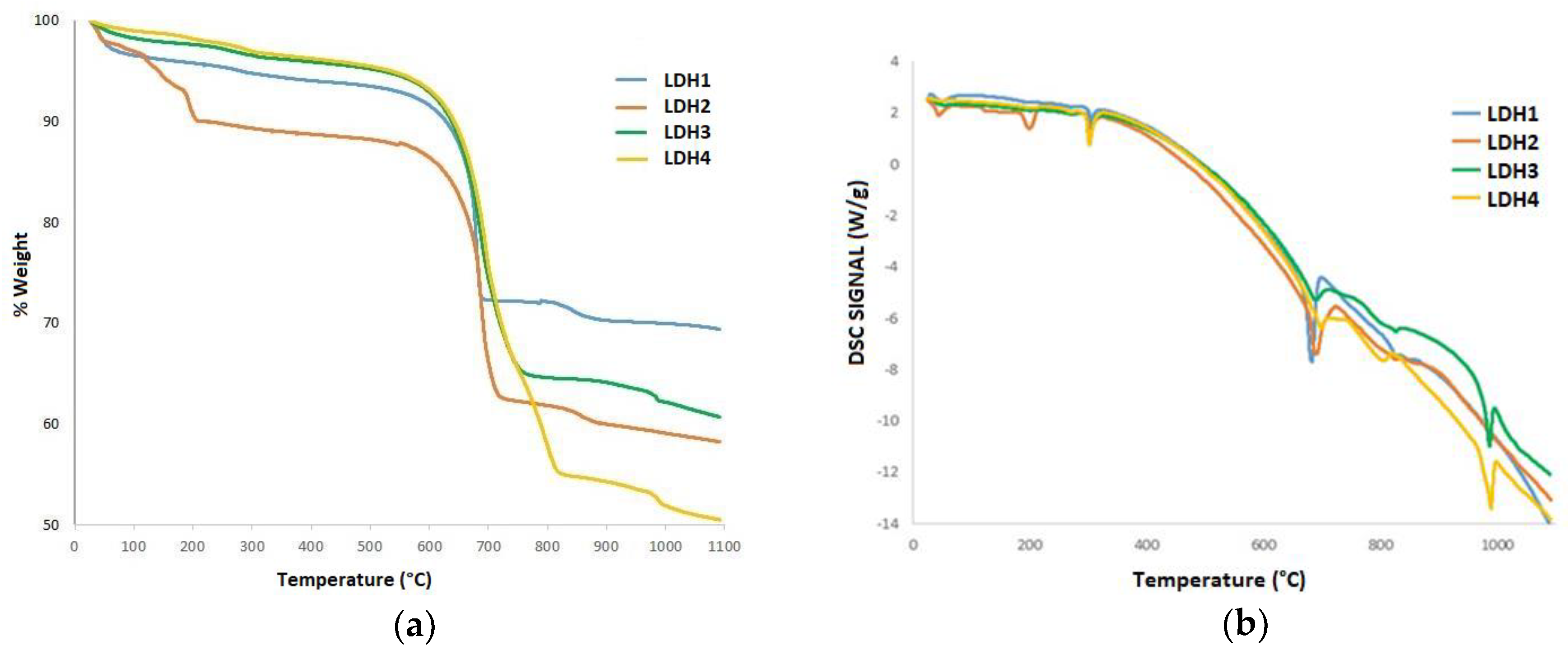

Figure 2a shows the thermogravimetric analysis (TGA) of the LDH, corresponding to the different precursors of the mixed Co/Fe oxides. As can be seen, the LDH2 precursor presents a first major weight loss associated with the elimination of water around 200 °C corresponding to 12% of its original weight, while the LDH3 and LDH4 precursors present a weight loss of only 3.5% in that same temperature range. The second weight loss occurs between 600 and 700 °C which for the solid LDH1 amounts to a loss of 22%, LDH2 of 33%, LDH3 of 34.5% and LDH4 of 46.5%, the latter being the highest total loss reached before losing 50% of its mass at 1100 °C. Thermograms by differential scanning calorimetry (DSC) are shown in

Figure 2b, where it can be seen that the different Co/Fe precursors synthesized present similar thermal evolutions. The main signals correspond to the dehydration of the molecules housed in the interlaminar at 300 °C and the decarbonation and dehydroxylation at 680 °C associated with the weight loss described in the TGA, which forms the crystalline and amorphous phases of the simple and mixed oxides. In the case of the LDH3 and LDH4 solids, an additional reaction can be seen at 998 °C associated with the sintering of the spinel of the cobalt ferrite (CoFe

2O

4).

The thermal stability of the LDH synthesized associated with the evolution of the crystalline phases allows us to determine the temperature at which the materials must be activated in order to be used as catalysts in the transesterification of triglycerides to biodiesel. This temperature was found to be 700 °C for the transition of the phases.

2.1.2. Modification of Functional Groups by Thermal Activation of the Catalyst

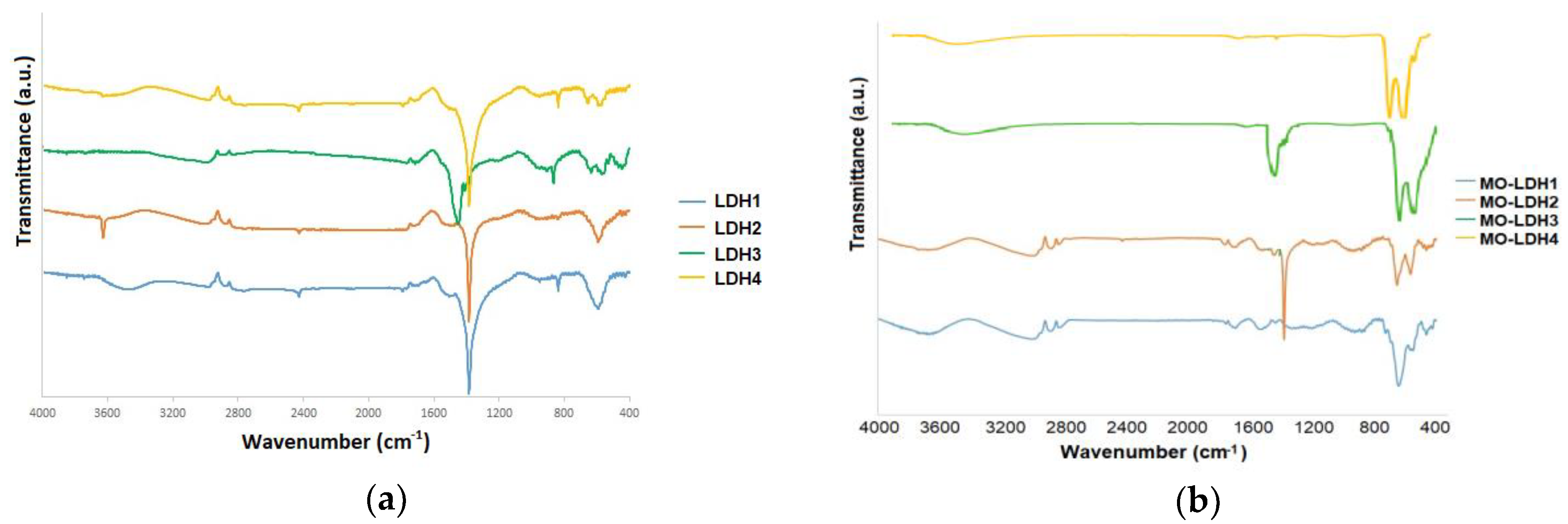

Figure 3 shows the FTIR spectra of the LDHs prior to activation (

Figure 3a) compared to the spectra of the catalysts obtained by calcination at 700 °C (

Figure 3b). As can be seen, the thermal decomposition profiles are correlated to the activation temperature of the catalysts. A broad band of low intensity close to 3300 cm

−1 can be observed in all spectra of

Figure 3b, which is associated with hydroxyl groups, where in the case of the catalysts MO-LDH1 and MO-LDH2 it is a double band associated with the interaction of hydroxyl and carbonates that could be reabsorbed on the surface given the precursor reconstruction effect. This signal attributed to the hydroxyl groups is of low intensity for the catalysts MO-LDH3 and MO-LDH4. With respect to the presence of carbonate groups, these signals are observed between 1200 and 1600 cm

−1. In the case of MO-LDH1 the band belonging to carbonates is not observed, for MO-LDH2 most of the carbonates are interlaminar, in the MO-LDH3 the carbonates are free, that is, they are adsorbed on the surface and the MO-LDH4 carbonates are not observed. For the case of the modifications in the interlaminar bonds of the metals when evolving from hydroxides to oxides, these signals can be identified in the region between 400 and 1000 cm

−1. For the catalyst MO-LDH3 and MO-LDH4, more intense bands can be observed that belong to the Fe–O, Co–O and Fe–O–Co bonds, these signals are characteristic of an infrared spectrum of the cobalt ferrite. which are less intense for the catalysts MO-LDH1 and MO-LDH2 given the over positioning some signals of simple and mixed oxides.

2.1.3. Identification of Crystalline Phases Present in the Catalysts

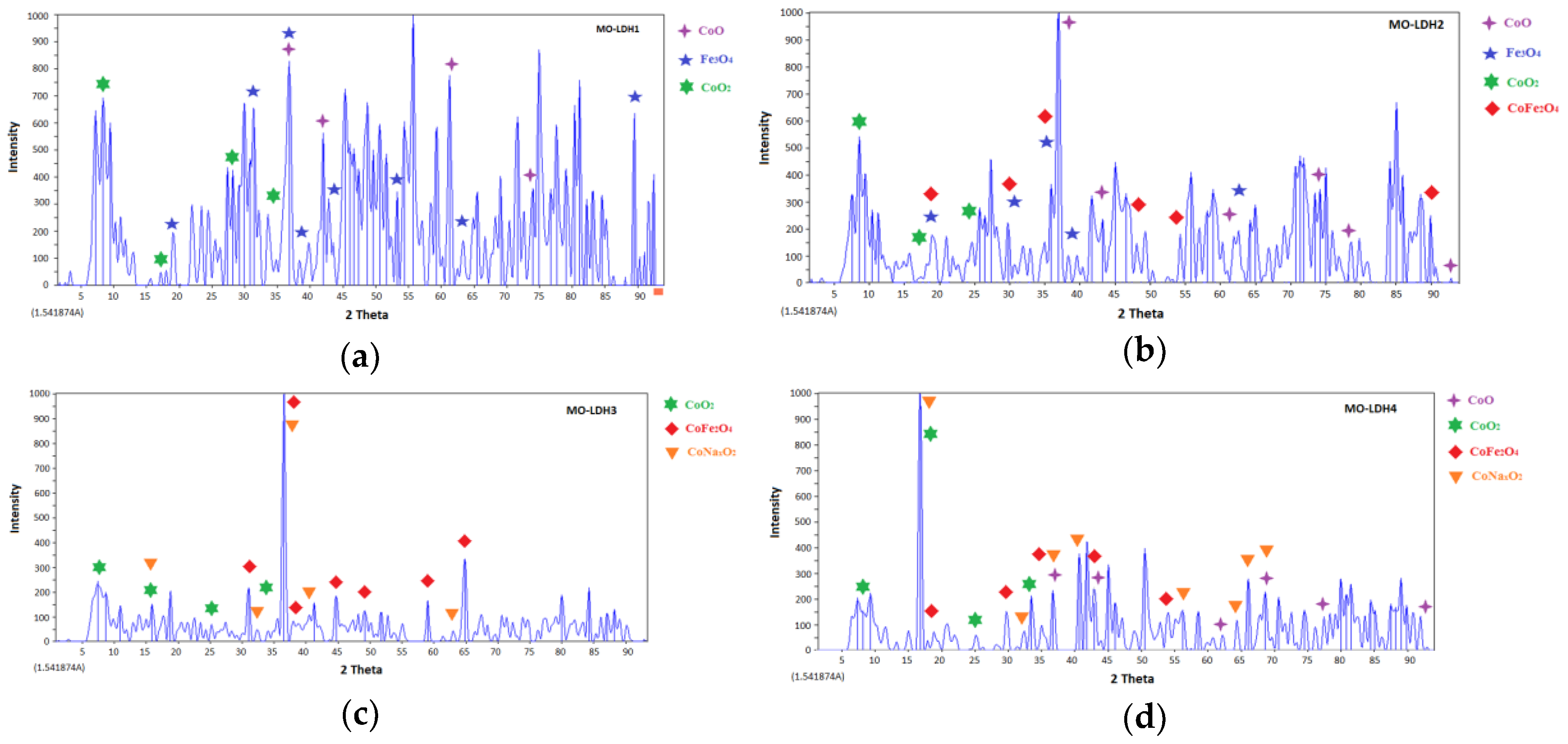

Figure 4 shows the X-ray diffraction patterns of the catalysts obtained by calcination at 700 °C. The solid MO-LDH1 does not present the crystalline phase of CoFe

2O

4 (cobalt ferrite) but many noise signals associated with amorphous phases. This confirms our observations of the infrared spectra, showing that when cobalt ferrite is present it is still amorphous, in addition to the presence of small crystalline phases secreted by Fe

3O

4, CoO and CoO

2. The solid MO-LDH2 can be observed in the presence of the crystalline phase of CoFe

2O

4 accompanied by segregated phases of Fe

3O

4, CoO

2 and CoO. In the case of solid MO-LDH3, a better crystallinity of CoFe

2O

4 is observed, as evidenced in the FTIR spectra, in addition to the presence of a segregated phase of CoO

2 and CoNa

xO

2. In the case of MO-LDH4, the CoFe

2O

4 phase is observed, combined with CoNaxO

2, CoO

2 and CoO [

43,

44].

For the solids MO-LDH3 and MO-LDH4, the presence of sodium in the crystalline networks is due to the fact that the amount of iron is less than cobalt, which allows cobalt to interact with sodium at the moment of synthesis in basic medium, favoring the integration of sodium in the crystalline network and modifying the properties of the catalysts.

Given the variation in the composition and segregation of the crystalline phases in the different catalysts obtained from the calcination products at 700 °C of the layered double hydroxides with different Co/Fe molar ratio, the effect of the presence may be analyzed of the different simple and mixed oxides of Co and Fe with respect to the catalytic activity.

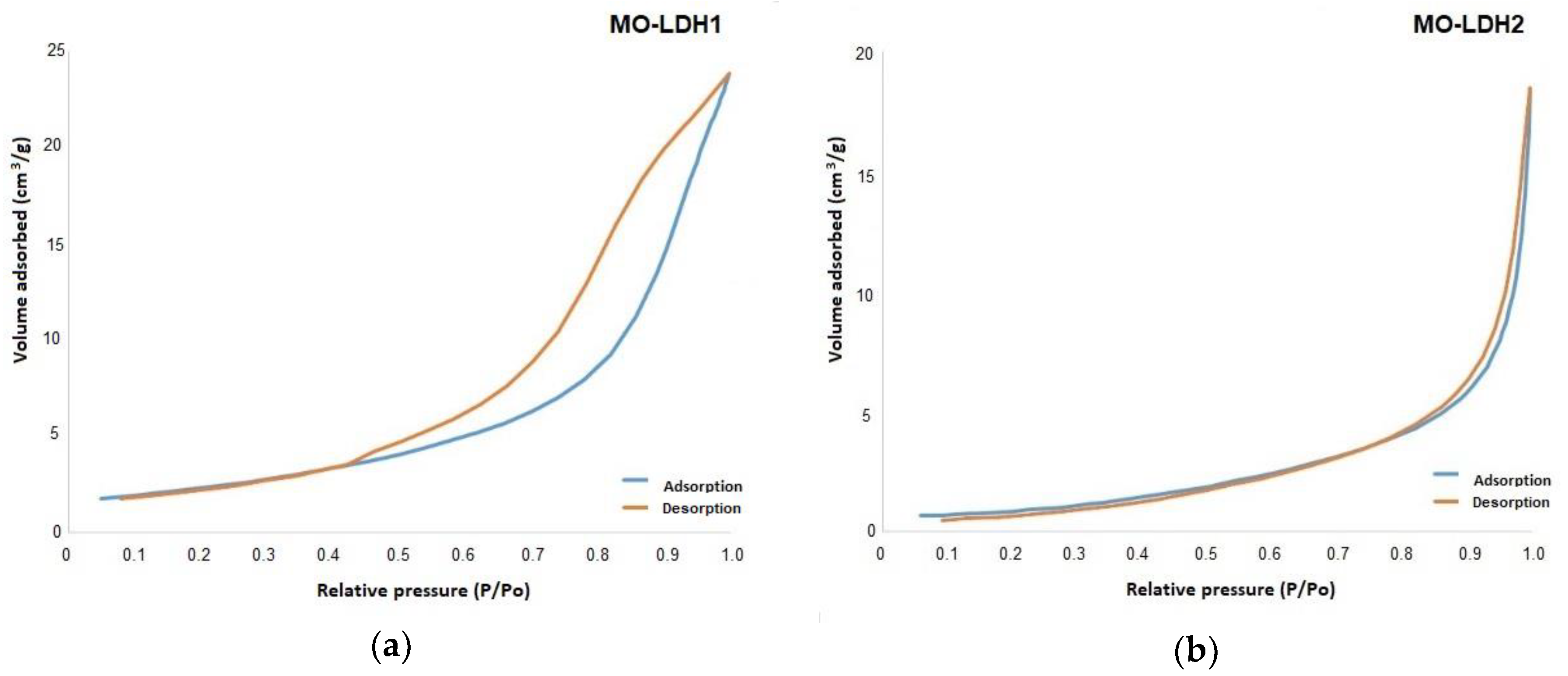

2.1.4. Determination of Textural Properties of the Catalysts

Figure 5 shows the physisorption isotherms of N

2 for the catalysts obtained by calcination at 700 °C. The adsorption isotherms for all solids belong to type III, corresponding to physical adsorption in multilayers by a free surface, which is characteristic of macroporous solids (pore size greater than 50 nm). However, a variation in the curl of hysteresis was observed, especially for the solid MO-LDH1. The reason why the solid MO-LDH1 presents a broad curl is associated with an incomplete thermal evolution so that it does not yet collapse the structure of the oxides. The rest of the catalysts show narrow curls, which reflect a collapse of the interlaminar spaces associated with a decrease in the specific area.

Table 2 shows the results of the textural characterization of mixed oxides of different molar ratios: Brunauer, Emmett and Teller (BET)-area, diameter and pore volume.

As can be seen, the catalysts show a trend of the value of the specific area in correlation with the metal molar ratio Co/Fe and with the thermal decomposition profile of the catalysts. For all cases the areas are less than 10 m2/g, which suggests the degree of collapse of the laminar structure associated with thermal evolution to simple and mixed metal oxides. In relation to the pore diameter, only the MO-LDH2 catalyst has mesoporous size, and the rest exhibit a larger size corresponding to macropores.

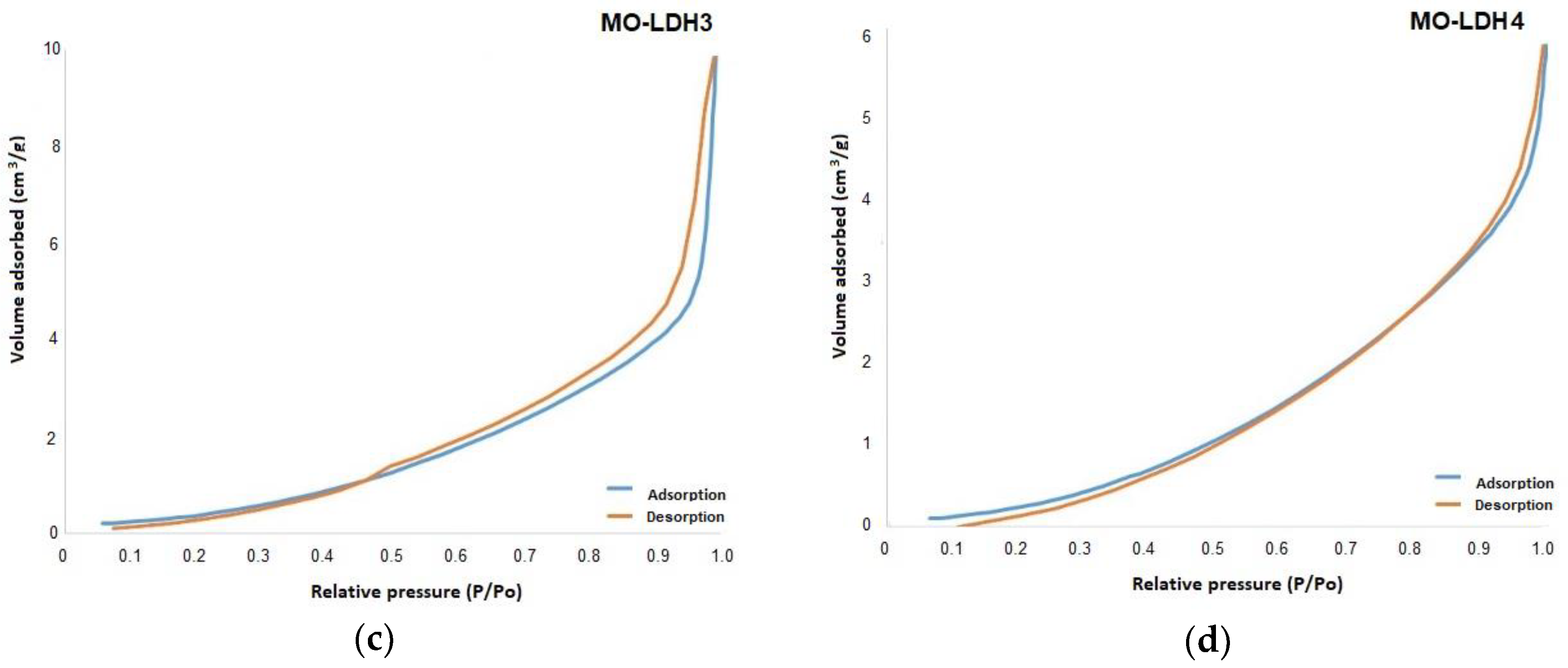

2.1.5. Surface Analysis of the Particles of the Catalysts

Figure 6 shows the photographs obtained by scanning electron microscopy of the catalysts. As can be observed, the solid MO-LDH1 and MO-LDH2 show an amorphous texture with the presence of few hexagonal crystalline structures, which is because the crystallization by thermal evolution has not concluded for all the crystalline phases of the mixed and simple oxides. For the solids MO-LDH3 and MO-LDH4, the presence of hexagonal particles in cumulus and in the form of thin, defined sheets increases markedly. The hexagonal sheets form due to the large amount of mixed oxide Co/Fe present in the different catalysts, mainly in the MO-LDH3 catalyst. In the case of the MO-LDH4 catalyst, very large hexagonal prisms resulting from the ordering of the catalyst sheets can be clearly observed.

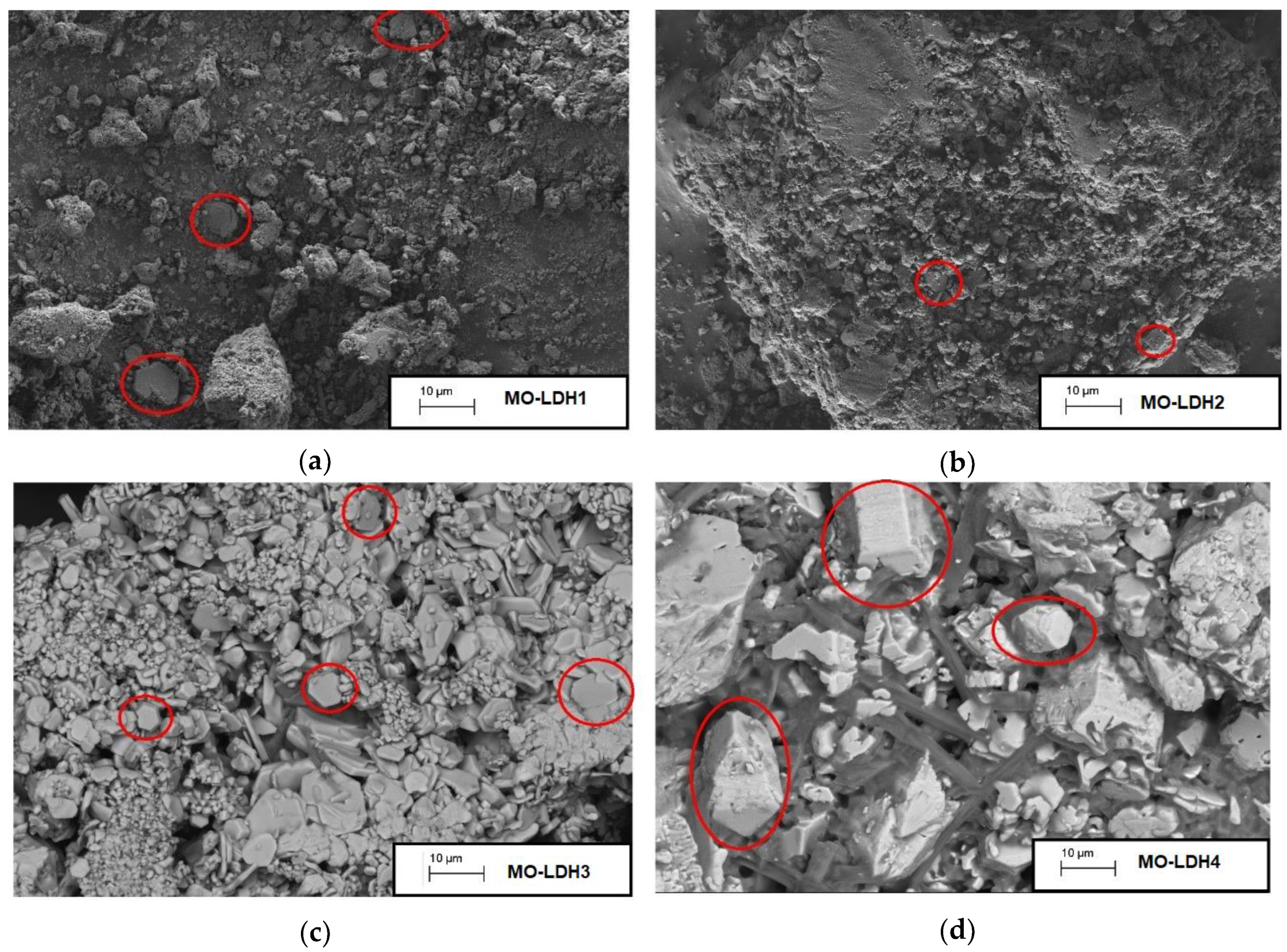

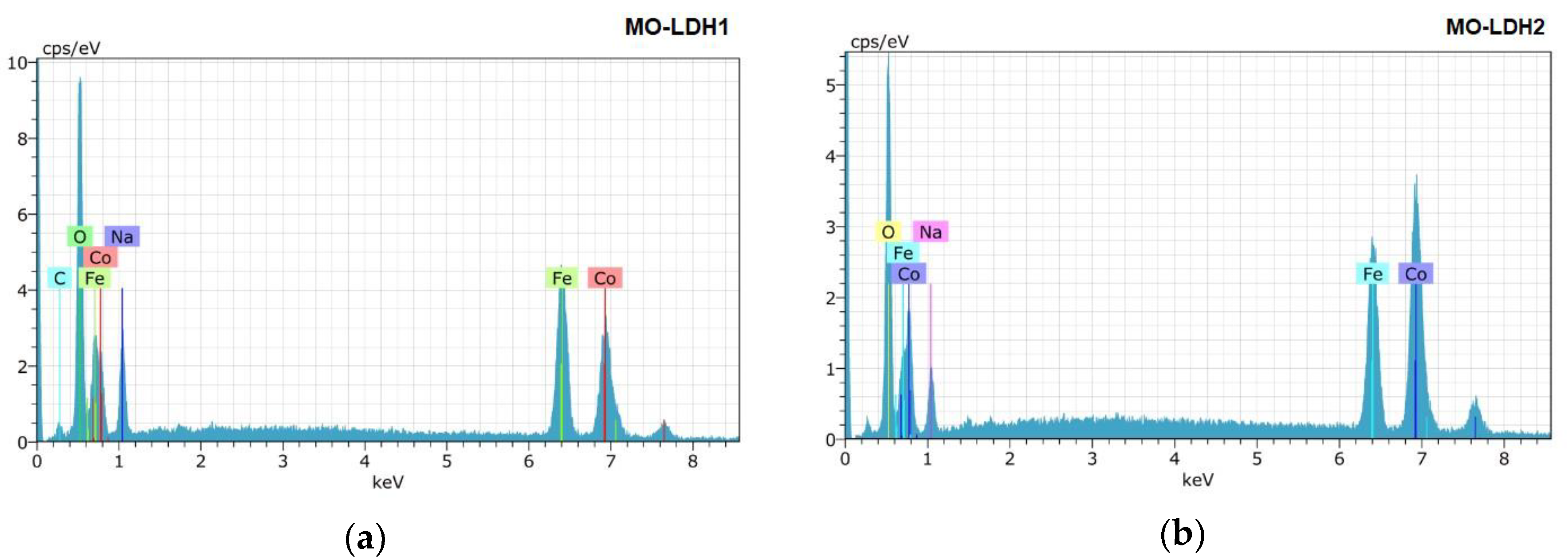

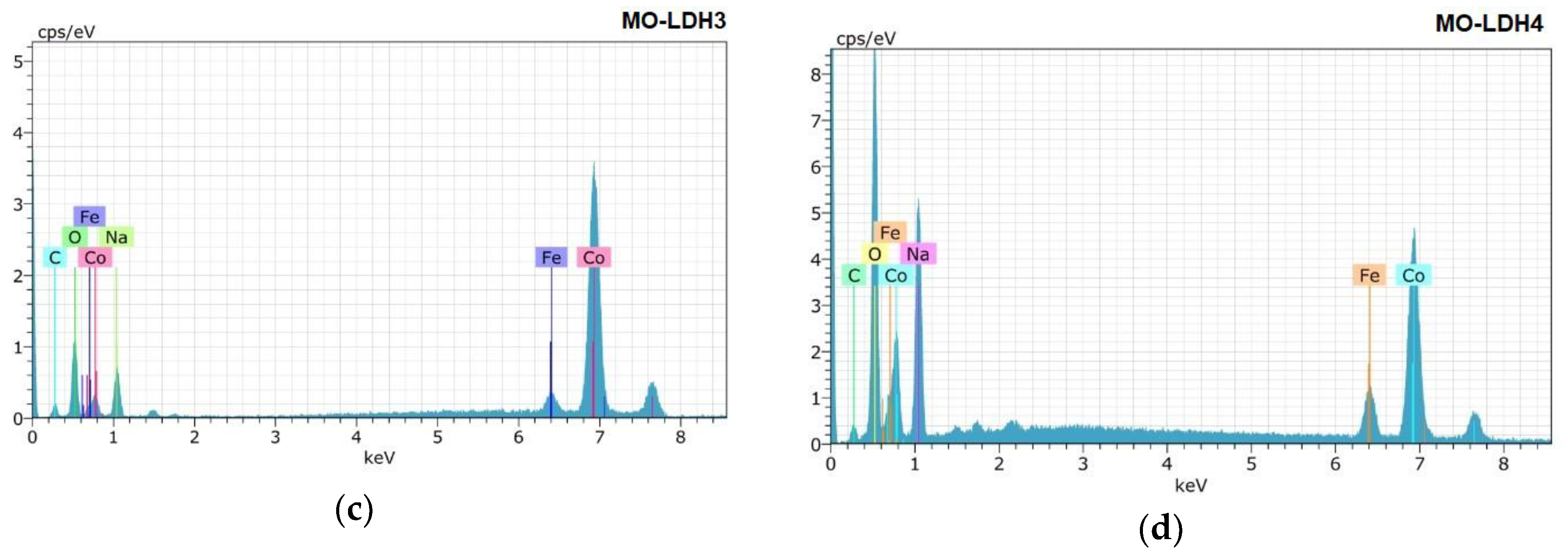

2.1.6. Elemental Composition on the Surface of the Particles

Finally, in

Figure 7 is shown an elemental analysis performed on the catalysts obtained by calcination at 700 °C. As can be seen, the general composition of the mixed oxides is similar for all the catalysts, which was to be expected because they were synthesized with the same methodology. The variation between the catalysts lies in the variation in the metallic Co/Fe ratio in the synthesis of the catalytic precursors, as well as in the proportion of the simple and mixed metal oxides present in the catalyst. The elements present in the catalysts are: cobalt, iron, sodium, oxygen and carbon, where by correlation with the diffractograms are in the form of metal oxides for the case of cobalt, iron and sodium; whereas the carbon by confirmation of the FTIR spectra corresponds to the CO

2 physisorbed on the surface of the catalysts.

Table 3 shows the results of the determination of the Co/Fe molar ratio in the catalytic precursors compared with that of the catalysts.

As can be seen, for the case of catalytic precursors, the theoretical molar ratio of Co/Fe is very close to the values of the molar ratio calculated from the average quantification on the surface of the particles. After the heat treatment, it can be seen that for the case of the MO-LDH1 and MO-LDH2 solids the Co/Fe ratio varies very little, which can be attributed to the homogeneity of the dispersion of metals in the particles. These solids were also homogeneous after thermal evolution. In the case of the MO-LDH3 and MO-LDH4 catalysts, a decrease in the Co/Fe molar ratio is observed, which can be attributed to the fact that the particles are more crystalline with defined edges, which concentrate the iron in the crystalline network, thus decreasing the amount of iron on the surface.

2.2. Evaluation of Biodiesel Quality

The physical and rapid qualitative parameter that was used to determine whether transesterification was performed for the conversion of triglycerides to biodiesel was the kinematic viscosity, starting from the fact that the oil prior to transesterification had a viscosity of 32 cp, while biodiesel with a high percentage of conversion presents values below 6 cp according to ASTMD6751, implying that a decrease in viscosity is associated with the transesterification of the fatty acids present in the oil [

45].

Once it was confirmed that the viscosity had been reduced to values close to the norm, we proceeded to the quantification and confirmation of the conversion by diffuse reflectance infrared Fourier-transform spectroscopy (DRIFTS) and

1H-Nuclear magnetic resonance (NMR) spectroscopy [

46], as well as the verification of the international parameters of density, corrosion of the copper foil and turbidity. These parameters can be used to verify the feasibility of the products’ application as biofuels in internal combustion engines.

Table 4 shows the best conversion percentages obtained in the shortest reaction times tested for obtaining biodiesel using a 3% catalyst, a molar oil/methanol ratio of 1:12, a reaction temperature of 65 °C and constant agitation at 1400 rpm.

It can be seen that the four catalysts achieved a conversion of triglycerides to biodiesel by lowering the viscosity of the 32 cp oil to values lower than 7 cp. In the case of the MO-LDH1 and MO-LDH2 catalysts, at a reaction time of 30 min, the viscosities were 14.24 and 15.27 cp, respectively, which indicated that the conversion had not yet finished. When the reaction time was extended to 60 min, a decrease in viscosity values close to 7 cp was observed, associated with conversion values greater than 70%. On the other hand, for the case of the MO-LDH3 and MO-LDH4 catalysts, at 30 min they had already reached viscosities below 4 cp and achieved conversions greater than 90%.

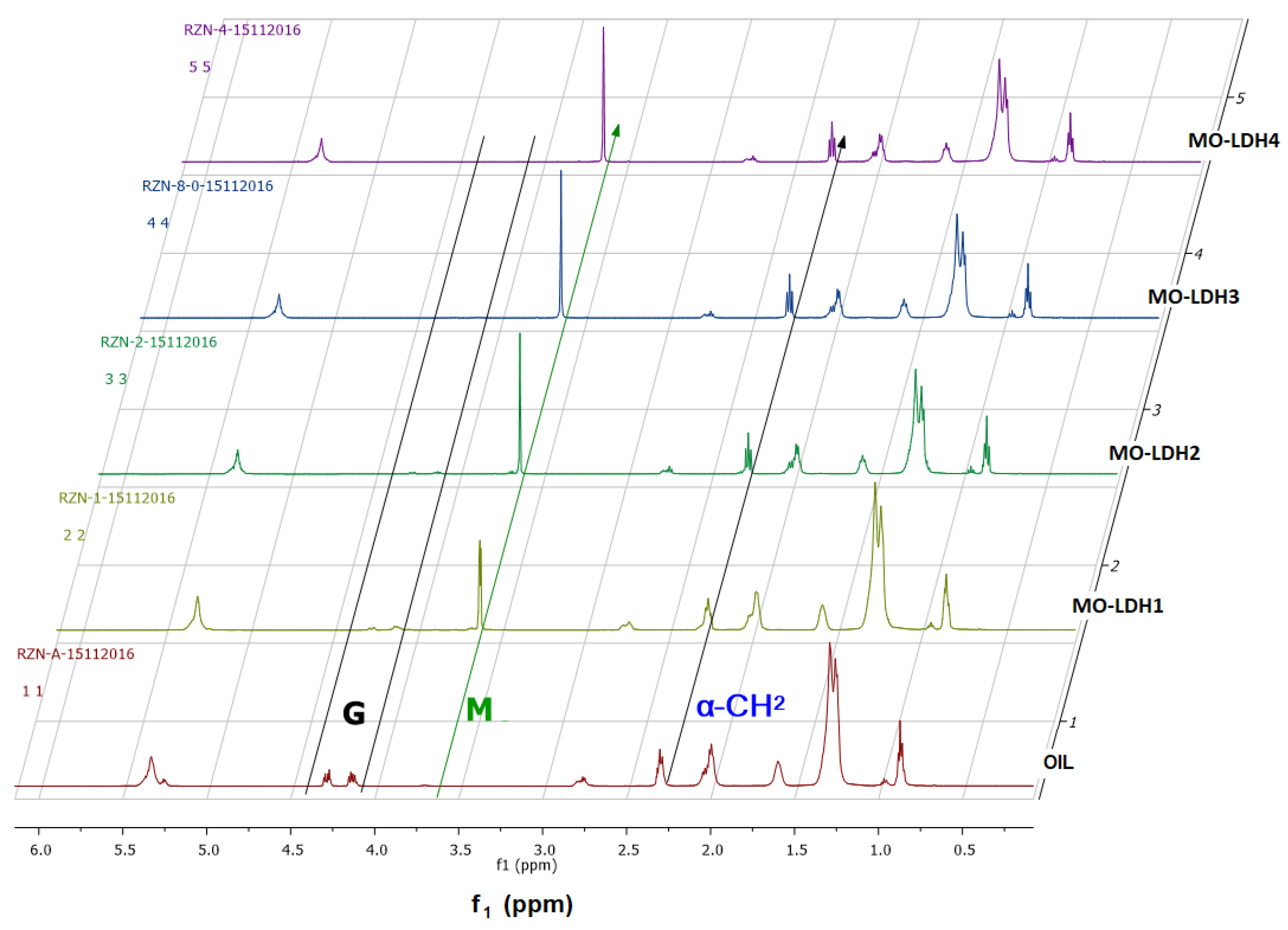

Figure 8 shows the

1H-NMR spectra which were used to calculate the % conversion to biodiesel from the M signal corresponding to the methyl group of the biodiesel methylesters that is formed as the reaction is carried out. Associated with the M signal is the G zone corresponding to the monoglycerides, diglycerides and triglycerides of the oil, which disappear in the conversion to methylesters.

With this analysis it can be verified that at 60 min the MO-LDH1 and MO-LDH2 catalysts have not yet been able to complete the transesterification reaction of all triglycerides in the oil, but there is a high percentage of conversion greater than 60%. It can be observed that in the case of the MO-LDH1 catalyst, the activity reached at 60 min was 63.3%, which can be attributed to the fact that it consists of particles of amorphous material with a small amount of simple CoO, CoO2 and Fe3O4, which provide a greater specific area than the rest of the catalysts, but with fewer active sites for catalytic conversion. The MO-LDH2 catalyst has a better conversion capacity, reaching 82% in 60 min, because the catalyst contains the mixed oxide CoFe2O4 in addition to the segregated phases of Fe3O4, CoO2 and CoO. For the case of the MO-LDH3 and MO-LDH4 catalysts, a high conversion to biodiesel with values of 92.7 and 96%, respectively, can be observed. In the NMR spectra it can be observed that there are no signals in the G zone, which implies that they have already completed the transesterification reaction for the formation of the methyl esters when a high intensity of the corresponding M signal is observed. This is associated with better conversion capacity of the MO-LDH3 and MO-LDH4 catalysts, attributed to the presence of crystalline particles of the mixed oxides CoFe2O4 and CoNaxO2.

With respect to the complementary quality parameters shown in

Table 4, related to the acidity index, corrosion of the sheet and turbidity of the biodiesels obtained with the MO-LDH3 and MO-LDH4 catalysts, it can be seen that these parameters are within the standard ranges. Thus, it is confirmed that the biodiesel obtained with these catalysts can be used in an internal combustion engine.

As the MO-LDH4 catalyst exhibits a better conversion capacity, reaching 96% and presenting a viscosity decrease to 3.66 cp, this catalyst was used to correlate and improve the reaction conditions for obtaining biodiesel with respect to the decrease of the reaction time, the amount of catalyst and the aomount of methanol used in the synthesis.

In relation to the reaction time, a study of the conversion capacity of the catalyst as a function of time was carried out, from 5 to 30 min, while maintaining the reaction conditions of 3% catalyst, a molar ratio of oil/methanol of 1:12, a reaction temperature of 65 °C and constant stirring at 1400 rpm.

Table 5 shows the results of the biodiesel conversion values quantified by

1H-NMR obtained with the catalyst MO-LDH4 at times below 30 min, also indicating the viscosity values as a quality parameter of the biodiesel.

It can be seen that the MO-LDH4 catalyst has the capacity to convert the oil to biodiesel in only 5 min with viscosity values that comply with the norm, reaching a conversion of 81%. These results exceed the capacity found for the MO-LDH2 catalyst, which required 60 min to reach the same conversion capacity, thus confirming the fast selectivity and conversion capacity of the catalyst as well as the important role of mixed oxides in the process. After 5 min, the biodiesel complies with the viscosity quality parameter. With respect to the variation of the conversion% as a function of time, it can be seen that from 5 to 30 min the values of the conversion increase gradually from 81.3% to 96%. The activity of the MO-LDH4 catalyst, attributed to the presence of particles of the mixed oxides CoFe2O4 and CoNaxO2 and of the simple oxides CoO2 and CoO, is favored by the crystalline structure of the catalyst particles, as well as by the macroporosity that allows access to active sites. An advantage of the catalyst is that the formation of catalytically active sites is favored by the formation of mixed crystalline structures.

The combination of the different particles containing Co species with different oxidation states in both the simple oxides and in the mixed with Fe and Na, as a catalytic composition, allows the formation of different acidic and basic sites for the esterification of the free fatty acids present in the oil, as well as for the transesterification of the fatty acids from triglycerides to biodiesel. The process that could be developing in the catalyst is proposed based on the recent kinetic model of transesterification in two sites of the Eley–Rideal type, where the mechanism has three important steps, the first step is the adsorption of both methanol and oil on the surface of the catalyst, in the second step a tetrahedral intermediate is produced from the alkoxide group which attacks the positively polarized carbon of the triacylglyceride in both the liquid phase and the catalyst surface, and the third step involves the production of a fatty acid ester and the release of a diacylglycerides. this procedure is repeated with the following two fatty acids bound to the glycerol [

47].

Table 6 shows the viscosity values obtained by decreasing the amount of methanol used in the synthesis while preserving the synthesis conditions of 3% catalyst, a reaction temperature of 65 °C, constant agitation at 1400 rpm and a reaction time of 30 min. It can be seen that the efficiency of the catalyst is not significantly affected by decreasing the oil/methanol ratio from 1:12 to 1:9 and to 1:6. This represents an operational advantage since an excess of methanol as a reagent is not required to displace the reaction to products, as in most procedures reported by heterogeneous catalysis [

8,

22]. In this case, the conversion capacity is even slightly improved by decreasing the volume of methanol in the reaction.

The effect of the decrease of the amount of the catalyst used in the transesterification reaction was tested, while maintaining the conditions of a reaction temperature of 65 °C, an oil/ethanol molar ratio of 1:12, constant agitation at 1400 rpm and a reaction time of 30 min.

Table 7 shows that the efficiency of the process is not significantly affected by decreasing the amount of the catalyst from 3 to 2%, allowing a reduction of up to one third of the catalyst.

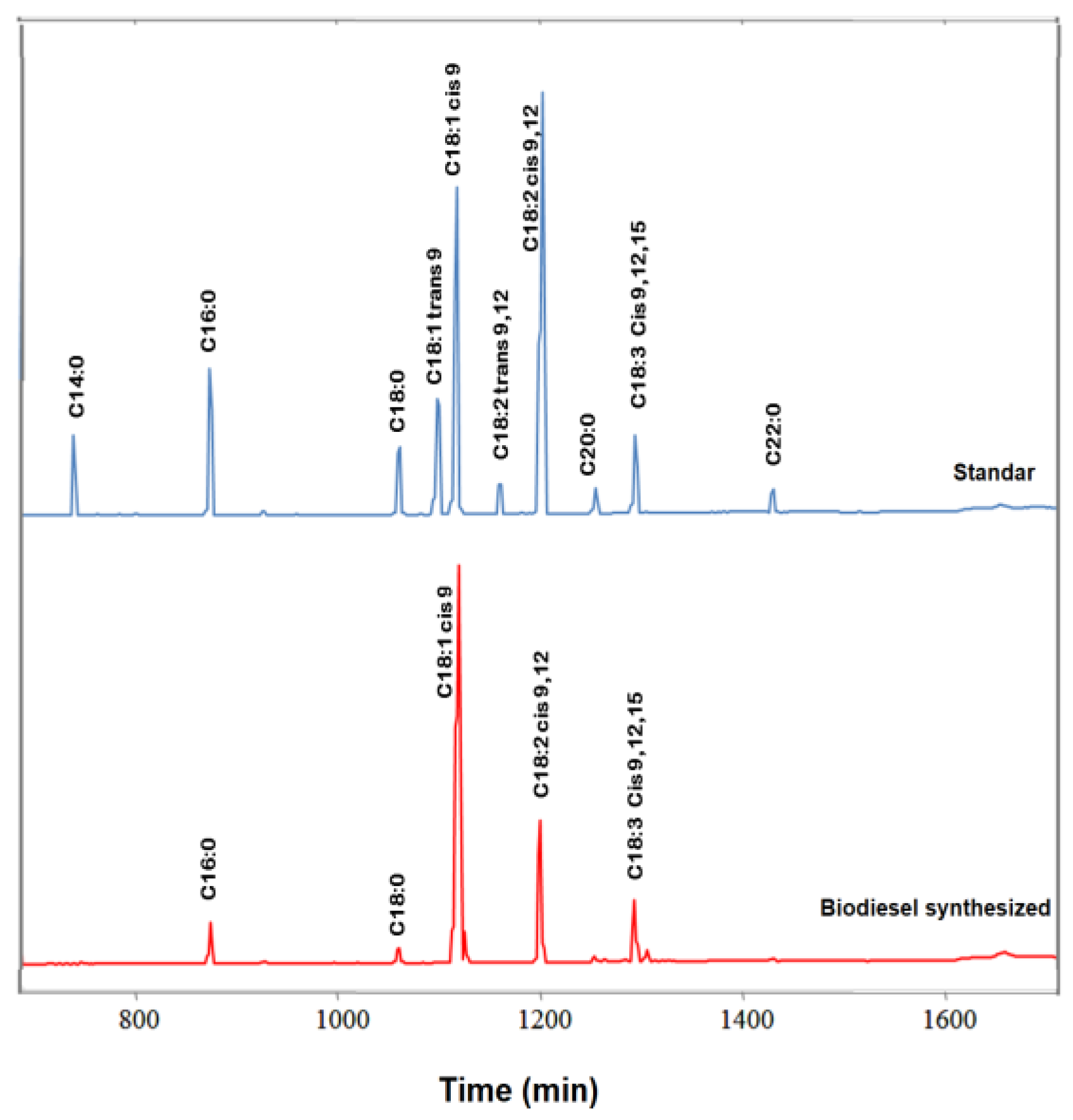

Finally, to verify the best synthesis conditions considering the simultaneous decrease of the catalyst, methanol and reaction time, biodiesel was obtained with 2% catalyst, a oil/methanol molar ratio of 1:6 and a reaction time of 20 min. Thus, we achieved a biodiesel with quality parameters that comply with the ASTM standards, as reported in

Table 8.

It can be seen that the biodiesel obtained by Gas Chromatography-Flame Ionization Detector (CG-FID) is mainly composed of the methyl esters of oleic acid (C18: 1 cis-9), linoleic acid (C18: 2 cis-9,12) and linolenic acid (C18: 3 cis-9,12,15), and in a lower proportion of palmitic acid (C16: 0) and stearic acid (C18: 0), which were identified according to the chromatograms shown in

Figure 9. These results confirm the high selectivity of MO-LDH4 towards unsaturated fatty acids.

The results of the analysis of the biodiesel composition obtained confirm the formation of the methyl esters of the respective fatty acids that formed the oil used as raw material in the transesterification reaction. The biodiesel obtained complies with the quality standards set by the ASTM international standards. The quality of the biodiesel was improved by the selectivity and high conversion capacity of the catalyst.