Acetylene Abatement Over Micro/Mesoporous Active Carbon-Supported Low-Mercury Catalysts

Abstract

1. Introduction

2. Results and Discussion

2.1. Physicochemical Characterizations

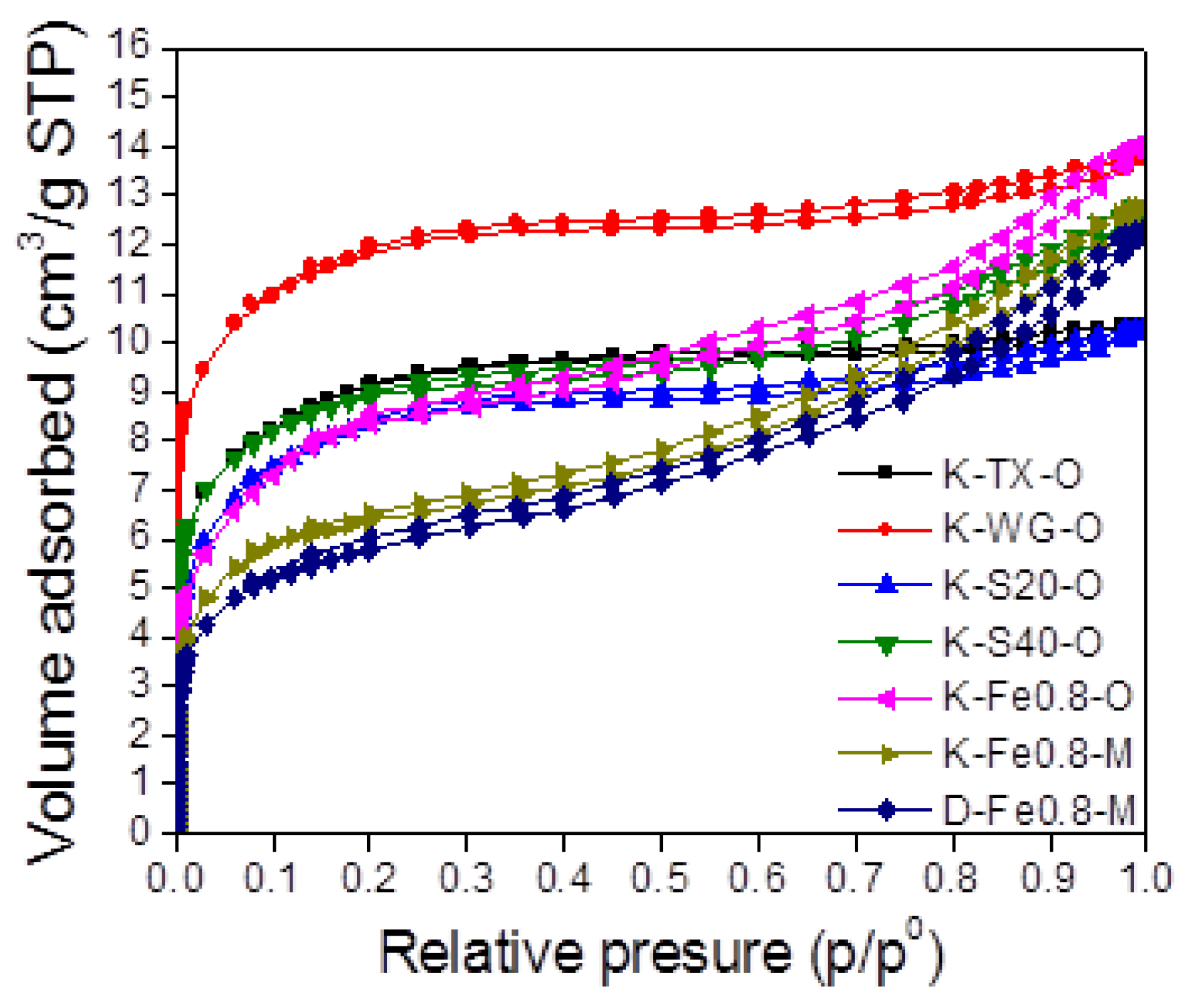

2.1.1. BET

2.1.2. XRD

2.1.3. SEM and Back Scattered Electron (BSE)

2.1.4. TG

2.2. Activity Measurement

2.2.1. Activity Test

2.2.2. Long-Term Reaction Stability Test

2.2.3. Deactivation and Reactivation of the D-Fe0.8-M

2.3. Correlation between Physicochemical Property and Activity Performance

3. Experimental

3.1. Catalyst Preparation

3.1.1. AC Substrate Preparation

3.1.2. Low-mercury AC-Supported Catalysts Preparation

3.2. Catalyst Characterization

3.3. Activity Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Wolfgang, A. Future semiconductor material requirements and innovations as projected in the ITRS 2005 roadmap. Mater. Sci. Eng. B 2006, 134, 104–108. [Google Scholar]

- Hitoshi, H.; Yasuaki, A.; Shoji, A.; Toru, O.; Wei, F.Q.; Manabu, S.; Kikuo, O. Chemical process of silicon epitaxial growth in a SiHCl3-H2 system. J. Cryst. Growth 1999, 207, 77–86. [Google Scholar]

- Tanimoto, Y. Hydrogen Chloride Manufacturing Method. CN Patent 107848799A, 27 March 2018. [Google Scholar]

- Tanimoto, Y. Hydrogen Chloride Manufacturing Method. CN Patent 107848798A, 27 March 2018. [Google Scholar]

- Zhang, J.R. Method and System for Preparing Hydrogen Chloride Gas with Moisture Content below 10 × 10−6. CN Patent 102838087A, 26 December 2012. [Google Scholar]

- Zhang, J.R. Method and System for Preparing Anhydrous Hydrogen Chloride Gas. CN Patent 101774543A, 14 July 2010. [Google Scholar]

- Zhang, J.R.; Song, W.M. Method for Preparing Electronic Grade Hydrogen Chloride. CN Patent 1511780, 14 July 2004. [Google Scholar]

- Severin, P.J.; Poodt, G.J. Capacitance-Voltage Measurements with a Mercury-Silicon Diode. J. Electrochem. Soc. 1972, 119, 1384–1388. [Google Scholar] [CrossRef]

- Lima, F.G.D.C.; Mescheder, U.; Katona, G.; Leiste, H.; Özel, E.; Müller, C. Influence of silicon doping type on the adhesion of seedless electrodeposited copper layers. Surf. Coat. Technol. 2018, 349, 208–216. [Google Scholar] [CrossRef]

- Tsai, C.C.; Jan, H.R.; Huang, C.H. Influence of surfactant addition for the texture etching process on multi-crystalline silicon wafer. J. Chin. Inst. Eng. 2012, 35, 69–77. [Google Scholar] [CrossRef]

- Dai, B.; Chen, K.; Wang, Y.; Kang, L.; Zhu, M. Boron and nitrogen doping in graphene for the catalysis of acetylene hydrochlorination. ACS Catal. 2015, 5, 2541–2547. [Google Scholar] [CrossRef]

- Li, P.; Li, H.; Pan, X.; Kai, T.; Cui, T.T.; Ding, M.Z.; Bao, X.H. Catalytically active boron nitride in acetylene hydrochlorination. ACS Catal. 2017, 7, 8572–8577. [Google Scholar] [CrossRef]

- Lin, R.; Kaiser, S.K.; Hauert, R.; Perezramirez, J. Descriptors for high-performance nitrogen-doped carbon catalysts in acetylene hydrochlorination. ACS Catal. 2018, 8, 1114–1121. [Google Scholar] [CrossRef]

- Zhi, L.; Li, Y.; Tang, H.; Liu, H.; Pei, W. Deactivation mechanism of low-mercury catalyst for acetylene hydrochlorination. Chem. React. Eng. Technol. 2015, 31, 343–353. [Google Scholar]

- Xu, X.L.; He, H.H.; Zhao, J.; Wang, B.L.; Gu, S.C.; Li, X.N. The ligand coordination approach for improving the stability of low-mercury catalyst in the hydrochlorination of acetylene. Chin. J. Chem. Eng. 2017, 25, 1217–1221. [Google Scholar] [CrossRef]

- Hutchings, G.J.; Haruta, M. A golden age of catalysis: A perspective. Appl. Catal. A 2005, 291, 2–5. [Google Scholar] [CrossRef]

- Mitchenko, S.A.; Krasnyakova, T.V.; Mitchenko, R.S.; Korduban, A.N. Acetylene catalytic hydrochlorination over powder catalyst prepared by pre-milling of K2PtCl4 salt. J. Mol. Catal. A Chem. 2007, 275, 101–108. [Google Scholar] [CrossRef]

- Hutchings, G.J. Gole catalysis in chemical processing. Catal. Today 2002, 72, 11–17. [Google Scholar] [CrossRef]

- Oliver-Meseguer, J.; Domenech-Carbo, A.; Boronat, M.; Leyva-Perez, A.; Corma, A. Partial reduction and selective transfer of hydrogen chloride on catalytic gold nanoparticles. Angew. Chem. Int. Ed. 2017, 56, 6435–6439. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, Q.; Chen, K.; Wang, Y.; Huang, C.; Dai, H.; Yu, F.; Kang, L.; Dai, B. Development of a heterogeneous non-mercury catalyst for acetylene hydrochlorination. ACS Catal. 2015, 5, 5306–5316. [Google Scholar] [CrossRef]

- Conte, M.; Davies, C.J.; Morgan, D.J.; Davies, T.E.; Elias, D.J.; Carley, A.F.; Johnston, P.; Hutchings, G.J. Aqua regia activated Au/C catalysts for the hydrochlorination of acetylene. J. Catal. 2013, 297, 128–136. [Google Scholar] [CrossRef]

- Zhou, K.; Jia, J.; Li, C.; Xu, H.; Zhou, J.; Luo, G.H.; Wei, F. Low content Au-based catalyst for hydrochlorination of C2H2 and its industrial scale-up for future PVC process. Green Chem. 2014, 17, 356–364. [Google Scholar] [CrossRef]

- Wang, Y.J.; Tian, Y.; Zang, W.C.; Jian, X.D. Study on treatment and recycling of mercury from waste mercury catalysts in China. Procedia Environ. Sci. 2016, 31, 432–439. [Google Scholar] [CrossRef]

- Chen, M.; Kui, X.; Liao, J.; Chen, X. Effects of Cd cocatalytic mechanism in maltielement catalytic system on performance of low-level mercury catalysts. Polyvinyl Chloride 2014, 42, 26–29. [Google Scholar]

- Xu, X.L.; Zhao, J.; Lu, C.S.; Zhang, T.T.; Di, X.X.; Gu, S.C.; Li, X.N. Improvement of the stability of Hg/AC catalysts by CsCl for the high-temperature hydrochlorination of acetylene. Chin. Chem. Lett. 2016, 27, 822–826. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Q.; Luo, Q.; Jiang, W.W. Preparation and optimization of a new-type low-mercury catalyst for hydrochlorination of acetylene. Appl. Chem. Ind. 2011, 40, 2147. [Google Scholar]

- Dong, X.B.; Chao, S.L.; Wan, F.F.; Guan, Q.X.; Wang, G.C.; Li, W. Sulfur and nitrogen co-doped mesoporous carbon with enhanced performance for acetylene hydrochlorination. J. Catal. 2018, 359, 161–170. [Google Scholar] [CrossRef]

- Liu, Z.; Ling, L.; Qiao, W.; Lu, C.; Dong, W.; Lang, L. Effects of various metals and their loading methods on the mesopore formation in pitch-based spherical activated carbon. Carbon 1999, 37, 1333–1335. [Google Scholar] [CrossRef]

- Liu, Z.; Ling, L.; Qiao, W.; Liu, L. Preparation of pitch-based spherical activated carbon with developed mesopore by the aid of ferrocene. Carbon 1999, 37, 663–667. [Google Scholar] [CrossRef]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Springer: Dordrecht, The Netherlands, 2005; Volume 16, p. 1620. [Google Scholar]

- Zhu, X.; Yu, S.; Xu, K.; Zhang, Y.; Zhang, L.; Lou, G. Sustainable activated carbons from dead ginkgo leaves for supercapacitor electrode active materials. Chem. Eng. Sci. 2018, 181, 36–45. [Google Scholar] [CrossRef]

- Wade, C.B.; Thurman, C.; Freas, W.; Student, J.; Matty, D.; Mohantya, D.K. Preparation and characterization of high efficiency modified activated carbon for the capture of mercury from flue gas in coal-fired power plants. Fuel Process. Technol. 2012, 97, 107–117. [Google Scholar] [CrossRef]

- Xie, Y.C.; Yang, N.F.; Liu, Y.J.; Tang, Y.Q. Spontaneous dispersion of some active components onto the surfaces of carriers. Sci. China Ser. B 1983, 26, 337–350. [Google Scholar]

- Jiang, L.; Chen, B.H.; Zhang, J.R.; Fu, J.Q. Effect of activated carbon pore size distribution on low-mercury catalyst performance for acetylene hydrochlorination. J. Chem. Ind. Eng. 2018, 69, 423–428. [Google Scholar]

- Wood, J.; Alldrick, M.J.; Winterbottom, J.M. Diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) study of ethyne hydrogenation on Pd/Al2O3. Catal. Today 2007, 128, 52–62. [Google Scholar] [CrossRef]

- Wei, H.; William, P.; Raul, F.L. Selective hydrogenation of acetylene in the presence of ethylene on K+-β-zeolite supported Pd and Pd/Ag catalysts. J. Catal. 2007, 246, 40–51. [Google Scholar]

| Samples | a SBET/m2 g−1 | b Vtotal/cm3 g−1 | c Vmicro/cm3 g−1 | d Vmeso/cm3 g−1 | Vmeso (Vtotal)−1/% | e D/nm |

|---|---|---|---|---|---|---|

| K-TX-O | 1545 | 0.81 | 0.58 | 0.23 | 28.3 | 1.16 |

| K-WG-O | 2137 | 1.31 | 0.97 | 0.35 | 26.3 | 0.96 |

| K-S20-O | 1619 | 0.78 | 0.40 | 0.38 | 49.1 | 2.01 |

| K-S40-O | 1943 | 1.18 | 0.44 | 0.74 | 62.8 | 4.34 |

| K-Fe0.8-O | 2019 | 1.34 | 0.40 | 0.94 | 70.3 | 5.21 |

| K-Fe0.8-M | 1802 | 1.17 | 0.26 | 0.91 | 77.6 | 5.45 |

| D-Fe0.8-M | 1723 | 1.03 | 0.25 | 0.78 | 75.5 | 5.12 |

| SD1-Fe0.8-M | 1215 | 0.71 | 0.11 | 0.60 | 84.8 | 6.36 |

| ZS-SD1-Fe0.8-M | 1498 | 0.82 | 0.116 | 0.704 | 85.8 | 7.11 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Liu, N.; Dai, C.; Xu, R.; Chen, B.; Zhang, J. Acetylene Abatement Over Micro/Mesoporous Active Carbon-Supported Low-Mercury Catalysts. Catalysts 2018, 8, 610. https://doi.org/10.3390/catal8120610

Jiang L, Liu N, Dai C, Xu R, Chen B, Zhang J. Acetylene Abatement Over Micro/Mesoporous Active Carbon-Supported Low-Mercury Catalysts. Catalysts. 2018; 8(12):610. https://doi.org/10.3390/catal8120610

Chicago/Turabian StyleJiang, Luo, Ning Liu, Chengna Dai, Ruinian Xu, Biaohua Chen, and Jirui Zhang. 2018. "Acetylene Abatement Over Micro/Mesoporous Active Carbon-Supported Low-Mercury Catalysts" Catalysts 8, no. 12: 610. https://doi.org/10.3390/catal8120610

APA StyleJiang, L., Liu, N., Dai, C., Xu, R., Chen, B., & Zhang, J. (2018). Acetylene Abatement Over Micro/Mesoporous Active Carbon-Supported Low-Mercury Catalysts. Catalysts, 8(12), 610. https://doi.org/10.3390/catal8120610