Abstract

The growing accumulation of waste from diverse human activities has intensified the search for sustainable strategies. Mechanochemistry offers a promising pathway, transforming residues into high-value products with reduced energy demand, shorter reaction times, and minimal use of solvents and reagents. Various wastes—including biomass, food residues, fly ash, used batteries, and halogenated polymers—can be converted into environmental adsorbents, industrial biopolymers, biocompatible compounds, electrodes, and catalysts. Unlike previous reviews that addressed specific waste streams, this study provides the first systematic and comparative analysis of mechanochemical valorization across multiple residues, following PRISMA guidelines (2000–2025). A total of 656 studies indexed in Scopus and Web of Science were evaluated. This integrative approach highlights recent advances, current challenges, and future prospects, offering a rigorous and transparent guide for scaling mechanochemistry toward circular and sustainable solutions.

Keywords:

wastes; valorization; mechanochemistry; fly ash; used batteries; biomass; polymer; chitosan 1. Introduction

Mechanochemistry, the science of reactions induced by mechanical force, dates back to ancient times with the grinding of pigments [1]. However, it gained notoriety in the 19th century with M. Carey Lea’s research on photomechanical and mechanochemical reactions, connecting early manual processes with modern mechanochemistry [2]. Recently, it has experienced a resurgence as a modern and sustainable approach to chemical synthesis. Today, mechanochemistry has enabled new chemical processes to create valuable compounds for pharmaceuticals [3,4,5], polymers [6], biopolymers [7,8], and others functional products in many industrial sectors. In this context, mechanochemistry emerges as a solution to the challenge of reducing the dependence on organic solvents in chemical processes, which can be harmful and represent the majority of a process’s composition. Thus, its importance lies in: (i) promoting green chemistry by minimizing or eliminating solvents; (ii) using recyclable raw materials (such as waste), aligning with fundamental sustainability principles [9,10].

Chemical methods used to generate desired products include thermochemical, electrochemical, photochemical, and mechanochemical approaches. All these methods require an energy source to overcome the natural energy barriers involved in breaking chemical bonds, thereby enabling new molecular arrangements and bond formation. Mechanochemical methods, in particular, have attracted increasing interest due to their simplicity, operating under varied conditions such as low temperatures, minimal solvent use, or entirely solid-state systems in inert or reactive environments. The objective of mechanochemical methods is to convert reactants into products through mechanical energy, applied via physical force with tools like crucibles and mortars [9,10]. The friction between components allows the direct absorption of energy, creating favorable conditions to overcome activation energy barriers. This process depends on the contact interfaces of the reactants, as reactions occur at the surface, promoting wear, fracture, and microstructural refinement [11].

Although this technique has employed specific tools since ancient times, its modern evolution is remarkable, as the milling process can now be carried out using ball mills equipped with jars made of resistant materials such as polytetrafluoroethylene (Teflon©), polymethylmethacrylate (PMMA), zirconia, and tungsten carbide. Therefore, the process can be conducted in both open and enclosed systems, using mills that protect the reaction from environmental interference. It can also be monitored in real time when transparent jars are used as reaction vessels. Analytical techniques such as synchrotron XRD (X-ray diffractometers) and Raman spectroscopy facilitate real-time monitoring of reaction kinetics [12,13]. Moreover, mechanochemical methods can incorporate small amounts of liquid additives in the form of “Liquid-Assisted Grinding” (LAG), thereby expanding their applications in pharmaceutical and biological research.

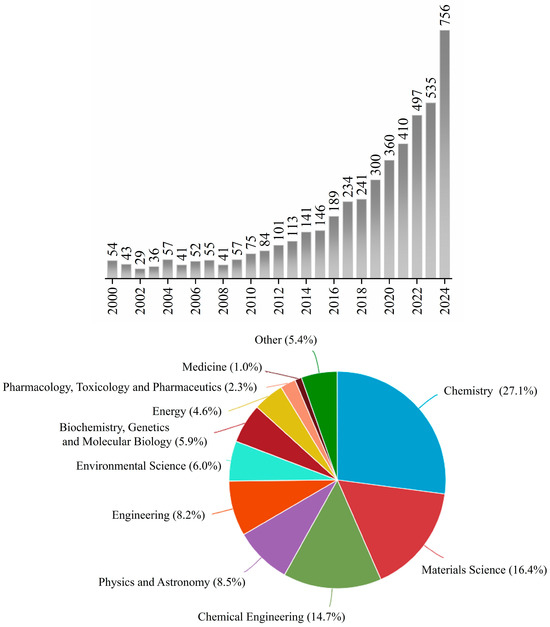

Thanks to its ease, versatility, and solvent-free conditions, mechanochemistry competes effectively with standard synthetic methods, offering efficient, single-step reactions without the need for traditional heating or toxic reagents. Mechanically assisted methods are increasingly recognized for their ability to synthesize a wide array of products. Despite its long history, mechanochemistry’s most significant developments in synthesis have taken place primarily over the past two decades [9,10,14,15]. As shown in Figure 1, studies related to the application of mechanically assisted protocols in organic chemistry and the preparation of new materials have increased considerably, especially over the last 14 years.

Figure 1.

The graphs show the evolution of research and thematic areas in mechanochemistry: the first presents the number of articles published annually on mechanochemistry, while the second is divided by thematic area of study on mechanochemistry by thematic area, in the period from 2000 to 2025 [16].

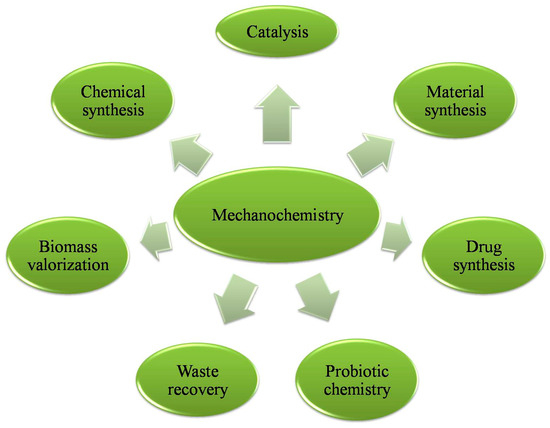

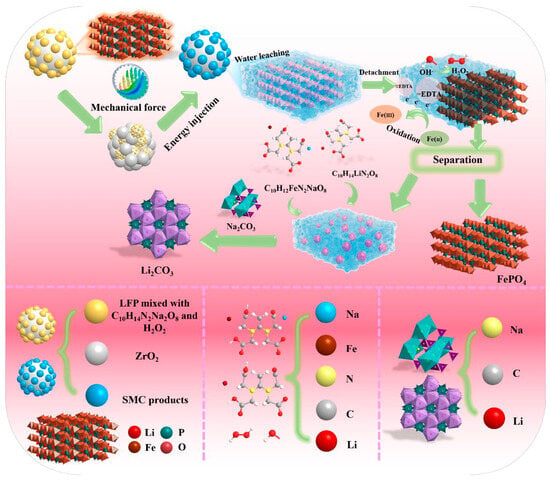

The applications of mechanochemical methods encompass catalytic processes such as Suzuki–Miyaura coupling [17,18], olefin metathesis, and C-H activation [12,19]. Other applications of mechanochemical reactions are in the synthesis of metal–organic materials such as MOFs and metal nanoparticles where the extensive use of solvents traditionally required to control particle size is avoided [20,21]. In general, mechanochemistry has found productive applications in the synthesis of porous materials [6]. These protocols have been used to prepare a wide range of products, as represented schematically in Figure 2.

Figure 2.

Schematic representation of the mechanochemical protocols used in the synthesis of highly useful and commercially valuable products.

Significantly reducing the solvent makes mechanochemical methods both cost-effective and broadly applicable. This aligns with the principles of green chemistry and broader environmental protection goals. In this context, waste recovery has emerged as a prominent application. Waste often presents challenges for industrial production, as it can constitute up to 50% of the total output and requires conversion into functional products. At the same time, many synthesis processes require precursors with specific chemical compositions to obtain functional materials, derived from both organic and inorganic sources, such as zeolites, mesoporous silica, biopolymers, nanoflowers, and biochar. These functional products typically undergo physicochemical processes, including hydrothermal reactions, sol–gel synthesis, or thermal treatments. Such precursors can be derived from various waste sources (e.g., minerals, biomass, ashes, and rice husk) [22]. Recent studies have highlighted the central role of mechanochemistry in waste transformation. Indeed, mechanochemistry-assisted techniques can be used for the preparation of new materials or value-added products from various industrial, agro-industrial, and urban wastes [23,24,25,26].

Fly ash is an abundant byproduct generated by various industries, including coal combustion and energy generation from agricultural byproducts such as sugarcane bagasse. In many cases, the incomplete carbonization of these materials results in fly ashes with a high content of unburned carbon [27]. Mechanochemical methods, such as high-energy milling and chemical activation, can be used to upcycle this type of waste. This approach has been applied in several studies, including enhancing adsorption characteristics for the effective removal of pollutants, such as dyes, from aqueous solutions. Furthermore, mechanochemically modified fly ash has shown potential in various applications, ranging from the stabilization of hazardous waste and contaminated soil to the synthesis of sustainable geopolymers and hydraulic cement. These innovations represent significant opportunities for the environmentally friendly utilization of fly ash and the valorization of this commonly overlooked industrial residue through mechanochemical methods [28,29].

The valorization of lignin residues has become an area of great interest, as lignin is one of the primary components of biomass and holds significant potential for the production of high-value chemicals and materials. Various mechanochemical methods have been explored to break lignin bonds and transform it into useful products. Some of these methods include the use of high-energy mills and readily available reagents, avoiding the need for expensive transition metals or solvents. Furthermore, the utilization of mechanochemical approaches has proven effective in producing a variety of products such as monomers, energy storage materials, and bioplastics. Research in this field continues to advance, and it is expected that mechanochemical strategies will play a crucial role in the sustainable valorization of lignin residues, thus contributing to the transition to a greener and more circular economy [30,31,32,33].

Plastic disposal, on both micro- and macro-scales, is a long-term environmental challenge. Sustainable practices are needed to reduce plastic waste, as global plastic production, reaching megatons annually, is heavily used in packaging (40%), construction (20%), and textiles (13%). In 2015, it was estimated that polyolefins, PVC (Polyvinyl Chloride), and PET (Polyethylene Terephthalate) comprised 79% of global plastic production, generating 69% of plastic waste. Besides the use in bottles, PET is included in the production of polyester fibers which has a production of 57 million tons by year that are discarded in landfills or incinerated [34,35]. Mechanochemical depolymerization offers a promising route for reducing plastic waste [36]. Applications include recycling automotive shredder residues through solid-state mechanochemical techniques [37], using mechanoenzymatic methods for polymerization and depolymerization [38], and filling PVC structures with eggshell additives, as described by Skórczewska [39]. These approaches could transform polymer production and waste management, reducing environmental pollution.

Animal-derived feedstocks provide an eco-friendly source for producing functional products using mechanochemistry. Chitin, a polysaccharide of D-glucosamine derived from crustacean shells, is commonly transformed into chitosan, which has wide applications in papermaking, food, bioengineering, and agriculture [40]. Chitosan, synthesized by the deacetylation of chitin, is a biopolymer with high water solubility, biodegradability, and biocompatibility which makes it useful for the production of sustainable derivatives. In textiles, chitosan offers antimicrobial, antiviral, and anti-odor properties [41]. Mechanochemical milling of chitin from European green crabs yields eco-friendly biomaterials, replacing harmful inorganic acids with organic solid acids [33]. Mechanochemical and mechanoenzymatic methods are also applied to produce oligomers of N-acetyl-D-glucosamine and in fine chemistry for the production of 5-hydroxymethylfurfural (5-HMF) [42,43,44]. Thus, it is clear that mechanochemistry has wide applications and has become globally impactful, with research groups advancing its applications in various fields, such as catalyst preparation, depolymerization, geopolymerization, and the synthesis of high-value molecules from agro-industrial and urban biomass, fly ash, and other wastes [4,45,46,47,48,49,50,51,52,53].

Therefore, this systematic review aims to present the current landscape of waste valorization through ecologically sustainable mechanochemical processes, producing high-value functional products with diverse applications. The next section will describe mechanochemically assisted protocols for transforming low-cost, waste-based raw materials into value-added products.

2. Methods

This section describes the research and study selection process. It can be divided into subheadings to detail the search strategy, inclusion and exclusion criteria, and the data extraction and synthesis method.

2.1. Search Strategy

This systematic review was prepared in accordance with the recommendations described in the Preferred Reporting Items for Systematic Review 2020 (PRISMA 2020) methodology [54]. The literature was retrieved from Scopus and Web of Science to search for citations between 15 March 2025 and 30 April 2025 in the Scopus and Web of Science databases, using the keywords “mechanochemistry AND waste OR valorization OR reject OR processing OR waste recovery”, for studies published in the period from 2000 to 2025, limiting only research articles to the areas of chemistry, chemical engineering, materials engineering, materials science, and environmental science. In addition, the inclusion of additional literature was necessary, added from the Capes Journals platform.

2.2. Inclusion and Exclusion Criteria

All mechanochemistry articles that were related to the valorization or beneficiation of waste or rejects were included. The exclusion criteria were articles that did not address mechanochemistry, or mechanochemistry articles unrelated to waste or rejects, duplicate articles, review articles, and studies with insufficient data or low quality.

2.3. Study Selection

The selection of studies was carried out independently by two authors, using the Rayyan selection platform [55]. Initially, the articles were selected after reading the title and abstract, and those that met the eligibility criteria and that had consensus between the two authors were read in full for inclusion or exclusion in the review. Disagreements in the full reading phase were resolved by consensus by a third author [56].

3. Results

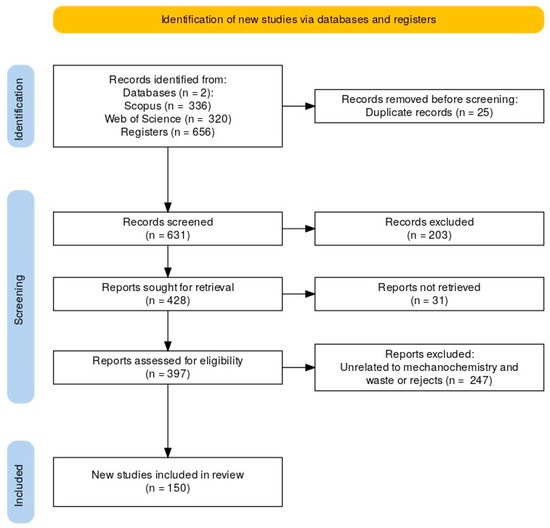

Initially, searching with keywords identified 656 potential articles: 336 from the Scopus database and 320 from the Web of Science database (Figure 3). Of the initial 656 articles, 25 were excluded for being duplicates files. The remaining 631 files were evaluated by title, abstract, and keywords, with 203 articles excluded for not being suitable for the scope of the study. There remaining 428 articles were selected for full-text evaluation, 31 of which were not retrieved, 62 were excluded because they were not related to mechanochemistry, 82 articles were not related to mechanochemistry applied to waste or rejects, and another 103 were reviewed articles. Therefore, 150 articles were selected from the Scopus and Web of Science databases and included in the review.

Figure 3.

This PRISMA flowchart illustrates the study selection process, specifying inclusion and exclusion criteria, from initial identification to final inclusion, showing the number of articles at each stagemay improve clarity.

3.1. Mechanochemistry: A Tool to Enhance Waste Valorization into Valuable Products

Mechanochemistry has proven itself as an established method across various research fields and has seen growing interest in recent years. This method contributes significantly to advancements in the utilization of waste in materials science, with a particular focus on catalysis, pretreatment of biomass, and preparation of active materials. Additionally, waste treatment has emerged as a compelling area for the mechanochemical community, with numerous studies employing mechanochemical techniques for waste processing [4,9,10,51,52,57]. In the following subsections, updates will be provided on publications that explore the reuse of various waste materials using a mechanochemical approach for the synthesis of catalytic materials, ceramics, polymers, valuable chemicals, and the degradation of halogenated organic pollutants.

These studies focus on both the synthesis and characterization of materials or products, aiming not only for the economic benefits derived from waste reuse but also for the significant environmental advantages it offers.

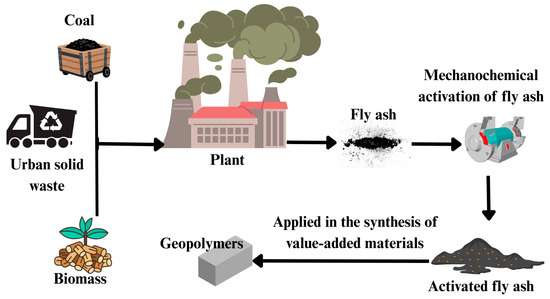

3.2. Fly Ashes Waste

Fly ash (FA) is a significant byproduct resulting from the combustion of coal, biomass, or municipal solid waste in power plants and industrial boilers, including those fueled by agricultural residues such as sugarcane bagasse [27]. It is typically defined as a fine, powdery residue composed of inorganic particles expelled from combustion chambers during high-temperature burning (see Figure 4). Based on the source material, fly ash can be classified into three main types: coal fly ash (CFA), biomass fly ash (BFA), and municipal solid waste fly ash (MSWFA) [48,49]. These categories represent the principal residues generated from both fossil fuel and renewable energy combustion processes. From an environmental perspective, fly ash presents considerable concern due to the presence of hazardous contaminants, including polycyclic aromatic hydrocarbons (PAHs), heavy metals, and dioxins [57]. Despite this, its unique physical and chemical properties render it a valuable raw material for environmental applications. Coal fly ash, in particular, has a complex composition, comprising a mixture of aluminosilicates, iron oxides, titanium dioxide, unburned carbon, and various inorganic oxides. Its morphological features, such as particle size distribution, surface area, and pore structure, vary significantly depending on its origin and combustion conditions. Additionally, it contains transition metals (often as oxides) and a range of functional groups that contribute to its reactivity. These properties make fly ash an attractive candidate for the synthesis of adsorbent materials, offering a low-cost and sustainable solution for pollutant removal from aqueous environments. Mechanochemical treatments have been shown to enhance these properties, improving its adsorption capacity and expanding its potential for use in environmental remediation strategies [58].

Figure 4.

The graphical diagram shows the process of incinerating coal, municipal solid waste, and biomass in thermoelectric plants. This process produces fly ash as a byproduct. Fly ash can undergo mechanochemical activation to produce active fly ash, which, in turn, is used in the production of highly useful and value-added functional materials.

Mechanochemical techniques have been explored as an effective approach to improve the properties of fly ash for pollutant removal. According to Geng et al. [58], mechanochemical activation—achieved by grinding solid reagents together, with or without solvents—induces surface defects and increases reactivity through frictional and shear forces. In their study, the authors utilized residual coal fly ash from power plants to produce low-cost adsorbents for mercury removal from wastewater. Mechanochemical bromination, performed using a planetary omnidirectional ball mill, was employed to modify the surface of the fly ash. This technique proved to be a cost-effective and efficient alternative to conventional solution-based functionalization, owing to the effective incorporation of bromine onto the adsorbent surface. The improved adsorption capacity was attributed to the formation of carbon–bromine (C–Br) bonds in carbon-rich domains and iron–bromine (Fe–Br) bonds in Fe2O3-containing phases. Based on Fourier-transform infrared spectroscopy (FTIR) and X-ray Photoelectron Spectroscopy (XPS) analyses, the proposed mechanism involved the generation of unsaturated carbon structures within the activated carbon matrix, which subsequently reacted with bromine radicals to form stable C–Br bonds. Overall, the study provides valuable insight into the mechanisms underlying the enhanced mercury adsorption performance of fly ash modified via mechanochemical bromination, reinforcing its potential for cost-effective wastewater treatment applications.

Chumpiboon et al. [27] reported that the use of mechanochemical methods can increase the adsorption capacity of fly ash, such as modifying fly ash through high-energy milling and chemical treatments with acidic and alkaline solutions. In this study, the authors investigated the treatment of sugarcane bagasse fly ash (BFA) with various acids and simultaneous carbonization under a nitrogen atmosphere to remove a cationic dye, methylene blue (MB), from aqueous solutions. This treatment significantly improved both the surface area and adsorption performance of the material. The resulting modified material—referred to as Treated BFA—achieved an MB adsorption capacity of 39.0 mg/g in 90 min, closely approaching that of commercial activated carbon (CAC), which showed a capacity of 42.1 mg/g but with a much larger surface area (1130 m2/g). Kinetic studies revealed that the adsorption process followed pseudo-second-order and intra-particle diffusion models, while equilibrium data were best fitted by the Langmuir isotherm model, with maximum MB adsorption capacities of 27.2 mg/g for untreated BFA, 39.0 mg/g for Treated BFA, and 42.1 mg/g for CAC. A comparative analysis demonstrated the high performance of the modified material relative to the commercial standard. These results highlight that, beyond surface area, surface functional groups and electrostatic interactions also play a critical role in dye adsorption efficiency.

Any material containing silica and alumina phases—whether primary (e.g., kaolinite, illite) [59] or secondary (e.g., fly ash, steel slag, red mud) [60]—is suitable for the production of geopolymers. Among these, fly ash stands out as a promising precursor for geopolymer synthesis through mechanochemical activation. Geopolymers are synthetic aluminosilicate binders formed by the reaction of silicon (Si) and aluminum (Al) oxides under alkaline conditions, resulting in an amorphous framework composed of interconnected SiO4 and AlO4 tetrahedra. Fly ash typically contains these oxides in both crystalline (e.g., mullite, quartz) and reactive amorphous forms. The effectiveness of geopolymerization depends largely on the reactivity of the aluminosilicate phases, which is influenced by factors such as the reactive content of SiO2 and Al2O3, and the particle fineness of the raw material. Insufficient reactivity leads to slower setting and poor mechanical strength in the final geopolymer [28,61]. Mechanochemical activation via high-energy milling plays a key role in enhancing this reactivity by increasing the specific surface area, generating structural defects, and inducing partial amorphization, which facilitates the dissolution of reactive species during alkali activation [29]. These effects have been shown to improve the mechanical performance of the resulting materials. In particular, the incorporation of mechanochemically activated fly ash into cementitious or geopolymeric matrices has led to significant increases in compressive strength, positioning this strategy as a viable route for both waste valorization and the development of sustainable construction materials [28].

Oyun-Erdene and Temuujin [29], investigated the effect of mechanochemical activation of fluidized bed coal fly ash (CFA) on the mechanical performance of geopolymers. In this study, geopolymer samples were prepared from both raw and mechanically activated CFA using alkaline solutions composed of 10 mol/L sodium hydroxide (NaOH) and mixtures of sodium silicate (Na2SiO3) and sodium hydroxide at a 2:1 weight ratio. After 30 min of vibratory milling, the Brunauer–Emmett–Teller (BET) method surface area of CFA increased from 4.8 m2/g to 9.2 m2/g, attributed to particle size reduction and the amorphization of crystalline phases, as confirmed by X-ray Diffraction (XRD), Scanning Electron Microscopy (SEM), and FTIR analyses. The incorporation of sodium silicate into the alkaline solution increased the compressive strength of raw CFA-based geopolymers from 6.03 MPa to 16.23 MPa, while the mechanically activated CFA-based geopolymers exhibited an increase from 27.6 MPa to 32.4 MPa. In addition, geopolymers derived from mechanically treated CFA showed a denser and more homogeneous microstructure. These results demonstrate that mechanochemical activation is an effective strategy to enhance the reactivity of fluidized bed fly ash, thereby improving the geopolymerization process and the resulting mechanical properties of the final material.

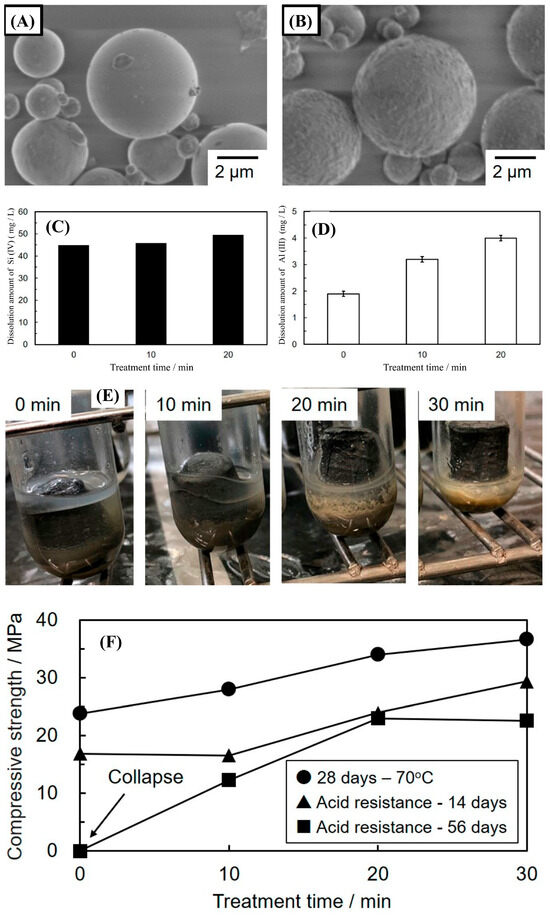

In another study, Matsuoka et al. [62] studied the effect of mechanochemical activation on the surface of coal fly ash particles. The article reports that mechanochemical activation modifies the surface morphology and the crystalline phase of the fly ash particles using a friction-type mill (Figure 5A,B). Consequently, an increased dissolution of Si (IV) and Al (III) species in 10 mol/L NaOH for 3 h solution is observed (Figure 5C,D). This increase results in an increased reactivity of the mechanochemical-activated CFA allowing the use of milder geopolymerization conditions (28 days at 70 °C, 7 days at 70 °C, and 28 days at room temperature). Mechanochemical activation of CFA results in improved compressive strength (45.2 MPa for 30 min of treatment after 28 days at 70 °C) of the corresponding geopolymer, along with an increased acid resistance by densification of the hardened body (Figure 5E). The compressive strength of geopolymers after an acid resistance test is shown in Figure 5F. Thus, with these results, it is clearly demonstrated that mechanochemical activation is effective for producing geopolymers with beneficial mechanical properties under milder curing conditions.

Figure 5.

SEM images of coal fly ash (A) before, (B) after mechanical treatment, Dissolution amount of (C) Si (IV) and (D) Al (III) ions from coal fly ash, (E) appearance of geopolymers after 56 days of the acid resistance test: room temperature curing for 28 days. From left to right, mechanical treatment times are 0, 10, 20, and 30 min, respectively, and (F) Compressive strength of geopolymers (28 days, 70 °C cured) from mechanically treated coal fly ash after acid resistant test (14 and 56 days). Reprinted with permission from Matsuoka et al. [62]. Copyright 2019 MDPI and under the Creative Commons CC BY license.

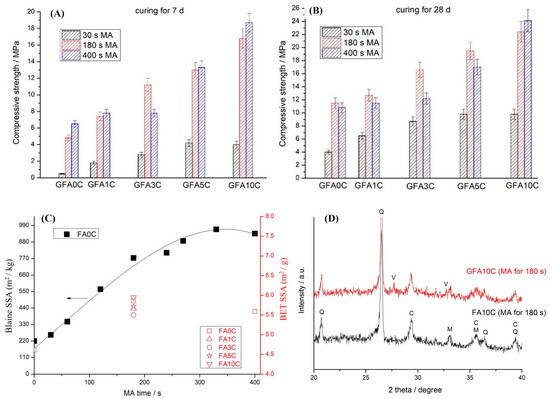

In another subsequent study, Kalinkin and collaborators [15] examined the synthesis of geopolymers at room temperature using mechanically activated fly ash (FA) milled for 30 s, 180 s, and 400 s, combined with varying contents of natural calcite (0–10 wt%) (Calcium carbonate, CaCO3) and activated with an 8.3 mol/L sodium hydroxide solution. The incorporation of 10 wt% calcite into 90 wt% FA (denoted as GFA10C) resulted in compressive strength values that were 8.0, 3.5, and 2.9 times higher, respectively, than those of the calcite-free geopolymer (GFA0C) for the same milling times, particularly after 7 days of curing (Figure 6A,B). According to specific surface area data (Figure 6C), milling for 180 s led to a substantial strength improvement compared to 30 s, whereas the additional milling from 180 to 400 s yielded only marginal or even negative effects. Furthermore, the main calcite diffraction peak, observed at 2θ ≈ 29.4° in the XRD pattern of GFA10C, showed a slight decrease in intensity relative to the unreacted FA10C blend (Figure 6D), suggesting partial interaction between calcite and the geopolymeric matrix.

Figure 6.

(A) Effect of calcite content and MA time on the 7-day compressive strength of geopolymers. (B) Effect of calcite content and MA time on the 28-day compressive strength of geopolymers. (C) The X-ray diffraction patterns of the blend containing 10% CaCO3 (FA10C) milled for 180 s and of the geopolymer prepared using this blend after 28 d of curing (GFA10C). Phases marked: Q—quartz; M—mullite; C—calcite; V—vaterite. (D) Blaine-specific surface area (SSA) of the fly ash (black symbols) and Brunauer–Emmett–Teller (BET) SSA of the FA + CaCO3 blends milled for 180 s (red open symbols) vs. mechanochemical activation (MA) time. One Reprinted with permission from Kalinkin et al. [15]. Copyright 2020 MDPI and Adapted from Kalinkin et al. (2020) under the Creative Commons CC BY license.

Research in this field has focused on synthesizing geopolymers from waste and by-products, with fly ash standing out due to its aluminosilicate composition, flow ability, and large waste volume. Geopolymer samples synthesized at a temperature of 27 °C using fly ash mechanically activated for different periods (60–90 min) in an eccentric vibrating mill (EVM) were reported by Kumar et al. [28]. The study also analyzed the effect of MA on the geopolymerization reaction using an isothermal conduction calorimeter. FTIR analysis justified the formation of the new band at 1080–1096 cm−1 in MA samples which is related to the highly polymerized sheet structure corresponding to SiQn (n = 3–4) which is related to the restructuring of quartz, also corroborated by the results from QXRD (Quantitative X-ray Diffraction).

Nikolić et al. [63] investigated the effectiveness of geopolymers derived from FA (initial FA) or mechanically activated FA in lead immobilization. To simulate the ability to use these FAs to trap and immobilize toxic Pb2+ ions during the geopolymerization process, they were mixed, at room temperature, with the geopolymerizing agent (alkali solution) in the presence of Pb(NO3)2. The results of the studies indicated that geopolymers based on mechanically activated FA were more effective in immobilizing lead compared to geopolymers based on initial FA, showing a reduction in the leaching of Pb2+ present in the geopolymers. The greater effectiveness of Pb2+ immobilization was attributed to the decrease in the pore sizes (from 18.8 to 6.9 nm) of the geopolymers based on mechanically activated FA compared to those based on the initial FA. In addition, the mechanically activated FA led to a geopolymer with a significantly increased compressive strength (58.46 N/mm2, with 1% Pb after 28 days of aging). The study reports that mechanochemical activation of FA can replace thermal activation which is of great importance for practical applications of geopolymers.

Regarding mechanical treatment and the presence of heavy metals in FA, studies have focused on the mechanochemical stabilization of Pb. In this sense, Li et al. [64] associated the Pb stabilization mechanism in ground fly ash with the entrapment of Pb in a process of particle re-agglomeration. Interestingly the authors reported a counterintuitive trend of the particle size vs. the mechanochemical process time. Indeed, the size decreases at low treating times while increasing again due to a re-agglomeration process occurring at higher times, to arrive at the size of the starting non-treated particles. In terms of leaching, the results show that 93.11% of Pb was partitioned into the ground ash, and the leaching of Pb was inhibited after short-term grinding (from 5.2 to 1.2 mg/L after 1 h of grinding) and further reduced by around 96% after 96 h of ball milling. This can be attributed to the formation of water-insoluble species, upon interaction with the higher surface energy the freshly ground particles exhibited. Nomura et al. [65] also reported that through mechanochemical treatment of FA, the Pb leaching was reduced by 92.8% due to the formation of water-insoluble species. Among these, is the formation of Pb3O4. Chen et al. [25] also noted that mechanochemical treatment of FA decreases the concentration of leached Pb, Cr, and Cu, while water prewashing effectively increases stabilization efficiency through the removal of soluble salts.

In another study reported by Li et al. [66] red mud (RM) was used as an additive for the stabilization of heavy metals in mechanochemical-treated FA. The results of this study demonstrated that the addition of RM under the optimized conditions of 30% by weight of red mud, 0.1 g/L solid–liquid ratio, and 24 h ball milling time significantly decreased the leaching of Pb, Cr and Zn from FA, in 99%, 81.18% and 100%, respectively. Even in this case, a re-agglomeration phenomenon was reported: FA was broken into small particles and then agglomerated into larger particles after mechanochemical treatment. It was evident that the main reasons responsible for the entrapment of heavy metals were attributed to precipitation and sealing by fine particles, captured by new phases which RM contributed to form.

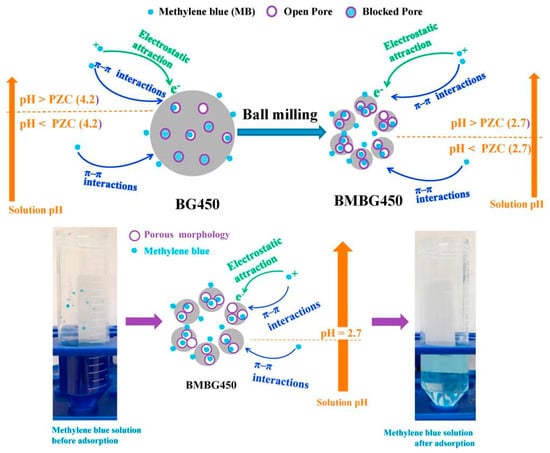

On the other hand, Li et al. [67] investigate the adsorption properties of methylene blue (MB) on mechanochemically modified FA. The results showed that the modification of the grinding process increased the MB adsorption capacity of FA, with the adsorption capacity value increasing from 5.06 to 7.97 mg/g for raw FA and ground FA, respectively. Kinetic modeling revealed that the adsorption follows a pseudo-second-order reaction rate. Furthermore, the authors mentioned that some assessment of environmental pollution caused by FA should be carried out before application.

Modification of fly ash was carried out by dry grinding in a planetary ball mill was reported by Sundum et al. [68] and studied its efficiency in preparing thermoplastic starch composites (TPS) containing different amounts of unmodified (UFA) or modified (MFA) fly ash powder. It was found that the UFA particle size decreased from 59.60 μm to 13.17 μm while the surface area increased from 3.68 m2/g (UFA) to 4.44 m2/g (MFA), after grinding for 1 h at 400 rpm. Both UFA and MFA powders were incorporated into thermoplastic starch. The high maximum tensile strength (7.78 MPa) was obtained in a composite with 2.50% MFA, which is about 9 times higher than TPS (0.86 MPa) and 2 times higher than the TPS/UFA composite. According to this study, composites with MFA showed better water resistance and delayed degradation compared to TPS and composites with UFA. While the presence of UFA or MFA had a slight effect on the thermal stability of the samples, it promoted the final phase of the thermal decomposition. This property can be exploited for their thermal degradation as waste.

Resuming, the use of mechanochemically treated FA in geopolymers presents several advantages, including transforming waste into a value-added material, improving the mechanical properties of geopolymers, and reducing environmental impact. These and the other results presented in this section are schematically resumed in Table 1.

Table 1.

General summary of studies on mechanochemical activation of fly ash and its applications.

3.3. Biomass

In recent years, concerns about the severity of environmental problems and the growing energy shortage have led to the exploration of renewable resources as a viable alternative. Biomass is the most abundant renewable source globally, with approximately 130 billion tons produced annually. Lignocellulosic biomass, derived from agricultural residues, bioenergy crops, and biomass waste, is composed of three biopolymers: cellulose (38–50%), hemicellulose (20–35%), and lignin (15–25%), varying by species and biomass sources [31,33]. While cellulose and hemicellulose are primarily exploited for conversion into various products such as pentoses, xyloligosaccharides, and liquid fuels, lignin can be employed in the production of aromatic compounds. However, the recalcitrance of biomass and the complexity of its structures pose significant challenges in the efficient separation and utilization of its components [30,31,33,73,74,75,76].

The pre-treatment to isolate lignin from other components is a crucial step in biorefinery operations, presenting a challenge to achieve maximum production efficiency. Various technologies of mechanochemical and biological pre-treatment have been developed for the effective separation of this biomass. Among them, mechanochemical activation is a sustainable approach compared to techniques involving toxic solvents during pre-treatment. This technique disrupts the biomass structure, reducing cellulose crystallinity and enhancing reactive activity [77].

Mechanochemical methods applied in lignin depolymerization, enable the breaking of bonds and the production of economically valuable aromatic compounds. This is because mechanochemistry can fasten reactions and create high-energy microenvironments through localized pressures and friction-induced heating [30,33]. According to Scimmi et al. [31], lignin depolymerization to recover fine chemicals involves hydrogenolysis and oxidation methods, with the latter being more commonly used due to milder conditions and cleaner final product production. Traditional oxidation processes using chlorine and nitrate are considered environmentally unfriendly, posing environmental and health risks. In pursuit of more sustainable alternatives, new oxidative methods have been optimized, replacing oxidants with hydrogen peroxide and molecular oxygen. Additionally, the application of heterogeneous catalysts, following green chemistry principles, aims to improve recoverability, reusability, and waste reduction.

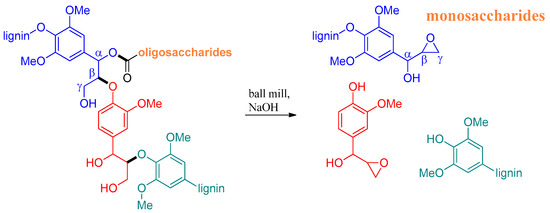

The work of Kleine et al. [74] was a pioneer in reporting the use of mechanochemistry for biomass degradation, demonstrating that with this methodology the use of solvents and metal catalysts can be avoided. This study developed a base-assisted ball milling process, demonstrating its potential as a mechanochemical technique for wood degradation. NMR spectroscopy indicated that cellulose and hemicellulose in beech wood were degraded into low molecular weight compounds, mainly breaking the β-O-4 linkage and hydrolyzing oligosaccharides (Scheme 1). Overall, these observations supported the authors’ initial hypothesis that base-assisted milling can also be applied to the degradation of untreated natural wood.

Scheme 1.

Schematic representation of the suggested course of mechanochemical degradation of hemicellulose and lignin in the original wood structure based on spectroscopic results [74].

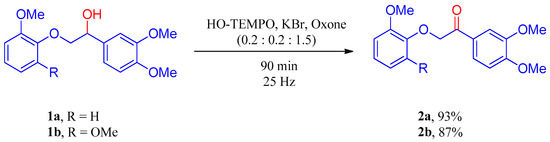

On the other hand, Dabral et al. [78] reported a mechanochemically activated oxidation of beech lignin using HO–TEMPO, KBr, and Oxone® in the ratio 0.2:0.2:1.5 and using tungsten carbide (WC) as grinding medium. In this study, mechanochemical oxidation of model compounds, methoxy-substituted monolignol derivatives, 1a and 1b proved to be successful, as it provided the corresponding ketones 2a and 2b in 93% and 87% yields, respectively, after purification by column chromatography (Scheme 2).

Scheme 2.

Oxidation of Lignin Model Compounds in the Ball Mill using WC Milling Media; Yields after Column Chromatography [78].

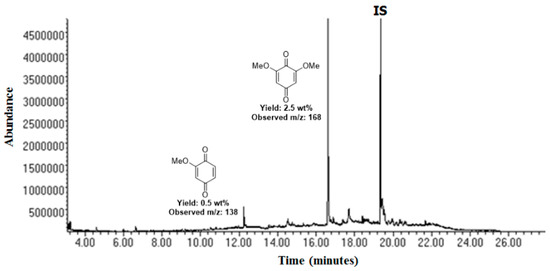

The same methodology was applied to a beechwood lignin. The Gas Chromatography coupled to Mass Spectrometry (GC-MS) analysis highlighted the formation of 3,5-dimethoxyquinone as the major monomer (2.5 wt%), along with 2-methoxybenzoquinone (0.5 wt%) (Figure 7). Furthermore, when the reaction was carried out on 10 g of beechwood lignin, gel permeation chromatography showed a strong reduction in molecular weight, demonstrating that the lignin was successfully depolymerized. Overall, this study demonstrates that this oxidative protocol can be applied on a large scale to biomass.

Figure 7.

GC-FID trace of the organic-soluble fraction (diethyl ether filtration) after the mechanochemical oxidation of Organosolv beechwood lignin with HO–TEMPO/KBr/Oxone® in a WC jar at 30 Hz for 90 min in a mixer mill (MM). Quantification performed using n-octadecane as an internal standard (SI). Identification of the major products was achieved by comparing the major products with commercial samples. Reprinted with permission from Dabral et al. [78] Copyright 2018 American Chemical Society.

Another successful solvent-free and environmentally friendly oxidative depolymerization protocol of model lignin (ligninox) was developed by Sun et al. [79], and the results showed successful depolymerization with some selectivity in syringate production (72.7% in weight). Zakaria et al. [80] used lignocellulosic oil palm residues, namely empty fruit bunches (OPEFB) and palm leaf fiber (OPFF), to produce glucose and xylose through enzymatic hydrolysis after ball milling pretreatment. The pretreatment of OPFF for 60 min of ball milling followed by OPEFB for 120 min demonstrated high glucose recovery with yields of 80.3 and 67.5%, respectively. Meanwhile, the highest xylose yield was obtained from OPEFB (80.1%), followed by OPFF (78.6%). The total sugar conversion yield of OPEFB and OPFF was 71.9 and 79.8%, respectively. The BM-treated OPEFB and OPFF produced 4 times more glucose and 4 to 16 times more xylose, respectively, compared to untreated oil palm biomass. The study further showed that higher recoveries of xylose (80.35 and 84.23%), glucose (62.4 and 78.69%) and total conversion (68.1 to 81.5%) were obtained from OPEFB and OPFF samples, respectively, when they were hydrolyzed at different loadings (30 and 40 FPU/g) of acremonium cellulase substrate. This suggested that BM effectively increased the surface area to enhance enzymatic hydrolysis.

Ball milling pretreatment was considered by Pang et al. [81] an efficient method to promote the catalytic conversion of lignocellulosic biomass into ethylene glycol. According to the report, Miscanthus subjected to dry grinding for 6 h at 450 rpm using a planetary ball mill, was converted by a binary catalyst of tungstic acid and Ru/AC into water. The maximum ethylene glycol yield from Miscanthus reached 52.4%, much higher when compared to untreated Miscanthus (22.5%). The study by Schneider et al. [82] describes a procedure for converting lignocellulosic barley straw into total reducing sugars (ATR) by mechanocatalytic pretreatment. Under optimized conditions, it resulted in high ATR release (42%) using oxalic acid dihydrate as catalyst. This study revealed that acid strength plays an important role in the depolymerization of barley straw and furthermore, it showed that the reaction catalyzed by oxalic acid generates low levels of the degradation product 5-hydroxymethylfurfural (HMF).

The ball mill has provided many relevant advantages compared to other lignocellulosic biomass pretreatment techniques, such as easy operation and avoidance of solvents and post-treatments. Zhang et al. [83] compared the feasibility and effectiveness of different biomass pretreatment methods, including microwave-assisted alkali (MAP), ultrasound-assisted alkali (UAP), and ball milling (BMP) to pretreat digested waste (2.5%-DR and 10%-DR) of rice straw, with 2.5% and 10.0% solids, for ethanol production. The result of this study revealed that BMP was found to be the best method to increase ethanol production from 116.65 and 147.42 mg/g to 2.5%-DR and 10%-DR, respectively. Digestion of ruminal fluid from rice straw with 2.5% solids content, combined with ethanol fermentation, produced a total energy production of 7.010 kJ/g, higher than the 5.464 kJ/g with 10% solids content. Overall, the integrated system was an effective biorefinement process with high energy output and reaction time savings.

A combined pretreatment of ball milling and ultrasound (MU) was investigated by Li et al. [77], corn cob with solid acid catalyst (/SiO2−Al2O3/La3+) for the conversion selectively catalytic hydrothermal processing of corncob into furfural. It was evident from this study that combined combination of ball milling and MU pretreatment was an efficient mechanocatalytic approach to destroy the complex structure of corn cob. So much so that the highest furfural yield of 197.76 mg/g corresponding to 82.90% of theoretical productivity was obtained at 190 °C for 30 min.

The work reported by Jiang et al. [76] compared the effects of ionic liquid and ball milling pretreatment on glucose yield from cellulose. According to the report, the glucose yield from untreated cellulose was only 20.9%, while both ball mill and ionic liquid pretreated cellulose exhibited remarkably higher cellulose digestibility for efficient enzymatic hydrolysis. The results proved that the yield of cellulose pretreated by ball milling (84.5%) was higher than that of cellulose pretreated with ionic liquid (78.0%).

Studies prove that ball mill pretreatment is a simple operation with high efficiency and is environmentally friendly. Powders, ball milling is a physical process that eliminates the use of potentially dangerous chemical reagents. The pretreated sample could be used directly without washing and filtration steps. For example, Kim et al. [84] reported that conventional pretreatment processes with sodium hydroxide and aqueous ammonia showed a rice straw loss of 34.2% and 14.8%, respectively. Comparatively, no biomass loss was observed with ball milling. Furthermore, milling produced significantly lower concentrations of soluble phenolics than alkaline treatments.

A solid cellulase acid catalyst (SA-SO3H) prepared without the use of sulfuric acid (H2SO4) was prepared by Shen et al. [85] and applied it to the conversion of microcrystalline cellulose. According to the report, cellulose can be effectively converted to levulinic acid in pure water at 180 °C in 12 h without additives with a maximum yield of 51.5% double SA-SO3H. However, cellulose pretreatment by ball milling improved levulinic acid yields by only a few percent (52.2%), showing that the cellulose binding sites (-Cl) and catalytic sites (-SO3H) of the catalyst are fundamental to the activity of the catalyst. A greater recycling efficiency of 95% is reported in the 5th round, and that the spent catalyst was regenerated with hydrogen peroxide (H2O2) solution. The study investigated the use of glucose as a starting material under the same reaction conditions and with the catalyst it promoted a yield of 61.5% of levulinic acid. The route of converting carbohydrates to levulinic acid in pure water with the biomimetic catalyst prepared with an H2SO4 free method provides an environmentally friendly method for producing bio-based platform chemicals from renewable resources.

Su et al. [86] successfully obtained a solid acid catalyst, notable for its absence of strong sulfonic acid (-SO3H) functional groups. Instead, the material, prepared from cow dung, exhibits the presence of weak acidic groups, namely carboxylic and phenolic. The synthesis process involved the initial carbonization of the dung at 400 °C for 2 h, followed by an activation step at 600 °C under a nitrogen (N2) atmosphere for 2 h, using potassium hydroxide (KOH) in a 1:2 weight ratio (substrate/activator).

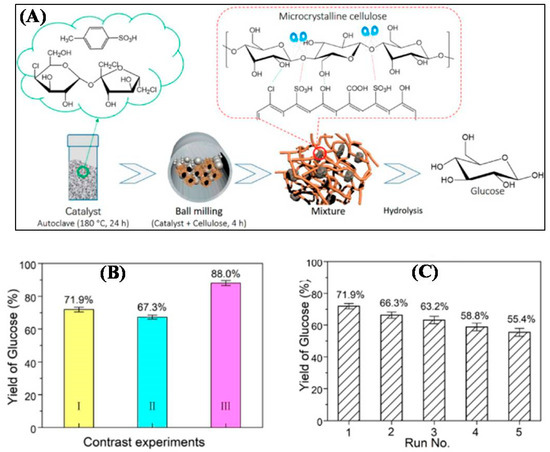

A solid carbonaceous acid catalyst functionalized with -SO3H group by co-carbonization of sucralose was synthesized by Qiu et al. [87] and studied its efficiency in converting cellulose to glucose in pure water (Figure 8A). It was established by the study that the mixture of cellulose with the catalyst prepared by ball milling, used in the cellulose hydrolysis process provided a glucose yield of 52.8% in pure water at 200 °C in 1 h, and the glucose yields increased to 71.9% and 88.0% when it was diluted in 0.02% by weight of H2SO4 and hydrochloric acid (HCl) (with the same proton content) aqueous solutions, respectively, (Figure 8B). Furthermore, the prepared solid carbonaceous acid catalyst exhibited relatively stable catalytic activity over five cycles (Figure 8C). According to this study, the excellent catalytic activity for the production of glucose from cellulose was attributed to the reduced degree of crystallinity of cellulose and the improved contact between the active sites and the β-1,4-glycosidic bonds in cellulose during the cellulose and solid acid milling process. The work provided a promising strategy for high-yield glucose production from cellulose hydrolysis in aqueous solutions and offers broad application for transforming lignocellulosic biomass into valuable chemicals.

Figure 8.

(A) Hydrolysis of cellulose into glucose by mechanochemical process. (B) Glucose yields obtained under standard conditions for (I) the sucralose-derived catalyst in a 0.02 wt% H2SO4 aqueous solution, (II) the sucrose-derived catalyst in a 0.02 wt% H2SO4 aqueous solution, and (III) the sucralose-derived catalyst in a 0.02 wt% HCl aqueous. solution. (C) Recycling performance of the sucralose-derived catalyst in a 0.02 wt% H2SO4 aqueous solution under standard conditions. Reprinted with permission from Qiu et al. [87]. Copyright 2018 American Chemical Society.

Research conducted by Qi et al. [88], demonstrated a promising method for the synthesis of weakly acidic carbon catalysts from biomass byproducts. The team used black liquor, a substance generated from rice straw pretreated with an aqueous potassium hydroxide (KOH) solution, as the main raw material. These innovative catalysts demonstrated excellent catalytic performance in hydrolysis processes, efficiently converting cellulose and alkali-pretreated rice straw into valuable sugars. The study highlighted remarkable results: cellulose hydrolysis achieved an impressive 76.3% glucose yield. For rice straw, the process resulted in high yields of 52.1% glucose and 66.5% xylose when the reaction was conducted in a 0.015% (by weight) HCl solution at 200 °C for 60 min. In addition to high activity, the carbon catalysts exhibited remarkable stability and recyclability in the aqueous reaction system. One specific catalyst, BC-600, provided a glucose yield of 84.6% and maintained this yield after three recycling cycles, highlighting its robustness and potential for industrial use. In summary, this work not only offers an innovative strategy for the efficient hydrolysis of lignocellulose using catalysts derived from the biomass itself but also represents a significant advance in the comprehensive utilization of lignocellulosic biomass.

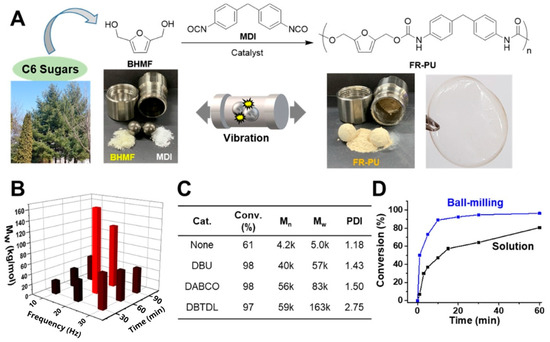

The valorization of compounds derived from biomass can benefit from mechanochemical techniques as well. The research group of Oh et al. [89], developed a simple and sustainable mechanochemical technique for the production of polyurethanes (PUs). The method, which does not require the use of solvents and operates at room temperature, uses 2,5-bis(hydroxymethyl)furan (BHMF), a biomass-derived compound, in combination with a vibratory milling process (Figure 9). This approach, in addition to being fast and straightforward, produced PUs with a maximum molecular weight of 163 kJ. The resulting polymers are flexible, with a glass transition temperature (Tg) of 96 °C, and thermally stable, with a decomposition temperature (Td) of 197 °C. The ball milling technique also proved versatile, enabling the synthesis of PU copolymers with different diols and diamines, which allows varying the final properties of the polymer, such as its Tg.

Figure 9.

Schematic illustration of PU synthesis using diols derived from biomass (A). Screening of ball-milling polymerization with BHMF and MDI (B) by controlling frequency and reaction time, and (C) with several catalysts. The reaction with the DBTDL catalyst at 20 Hz for 60 min yielded the highest Mw PU. (D) Comparison of conversion achieved with ball-milling vs. solution synthesis of PU as a function of the reaction time. Reprinted with permission from Oh et al. [89]. Copyright 2020 American Chemical Society.

In summary, mechanochemistry has proven to be a promising tool in transforming biomass, including lignin, into sustainable chemicals and materials. This approach contributes to the search for environmentally friendly solutions for the efficient use of renewable resources and addresses the challenges in biomass separation. As research advances in this field, it is expected that new developments will lead to more effective and sustainable processes for biomass valorization. Table 2 summarizes the effect of ball milling pretreatment on the conversion of lignocellulosic biomass into different chemicals.

Table 2.

Mechanical milling pretreatment on the product yields from different types of biomass.

3.4. Polymer Waste

Polymers are one of the main materials developed in the XX century with the growth of petroleum exploitation, to supply the demand of an extensive range of industrial activities making them ubiquitous. It is estimated that the production of plastics in the world was almost 368 million tons in 2019, with over 80% being waste. In 2020 the production of fibers included polymers such as polyester and polyamide, representing 109 million tons together with natural fibers. In this scenario, polyester is responsible for 52% of fiber production with only polyethylene terephthalate contributing with 57 million tons [34,101].

Plastic waste treatment includes incineration, landfill, mechanical recycling, and chemical upcycling. Among these, chemical upcycling offers a path to obtain highly valuable monomers and oligomers. An example is the reported selective depolymerization of PET and other polymers to originate useful compounds [36,101,102]. The process of chemical upcycling demands the application of heating and the use of chemicals besides catalysts. In addition, classical methods are more time-consuming and less cost-effective than mechanochemical methods which also avoid the use of solvents and additives and offer fewer risks in downgrading the properties of the recycled polymer [102].

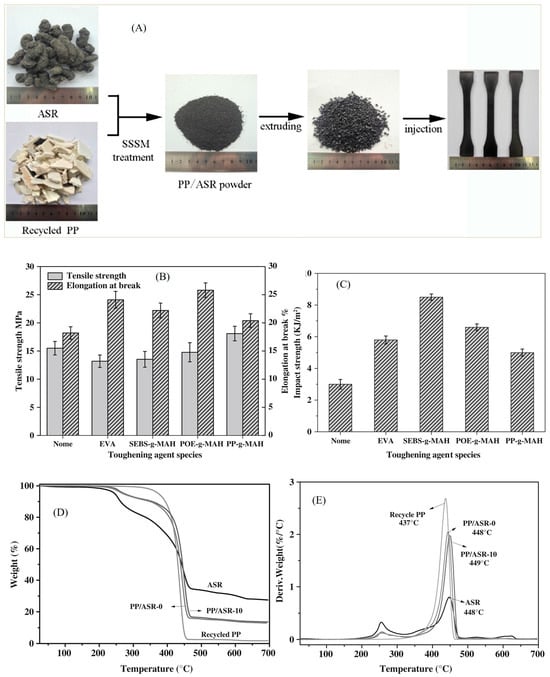

The mechanochemical treatment of polymers and their wastes makes the use of mills for the generation of new structures, such as the method called Solid State Shear Milling (SSSM) that allows the formation of ultrafine powder polymer with the application of strong force. Polypropylene (PP) waste and automotive shredder residue (ASR) have been used with this technique to produce a composite with good toughness [37]. The authors fabricated a PP/ASR composite that exhibited robust mechanical performance due to the excellent dispersion of ASR particles and in situ compatibility between the ASR matrix and PP (Figure 10A). The results of this study showed that the 50/50 wt% PP/ASR-10 composite presented excellent mechanical performance combined with good processability and high thermal stability (Figure 10B–E).

Figure 10.

(A) Schematic of practical processing of PP/ASR composites, Mechanical properties of 50/50 wt% PP/ASR composites with various toughening agents: (B) tensile properties; (C) impact toughness. (D) Thermogravimetric Analysis (TGA) and (E) Derivative Thermogravimetry (DTG) curves of ASR, PP and 50/50 wt% composites with and without SSSM process. Reprinted from Yang et al. [37]. Copyright 2018 with permission from John Wiley and Sons.

Access to new polymer structures based on mechanochemistry methods for recycling polymer waste demands some considerations about experimental parameters such as crushing speed, crushing time, and the knowledge of feed amount. In polyurethane processing for recycling, the action of mechanochemical forces decomposes chemical groups such as methyl and aldehyde groups, generating a material with strong reactivity and plasticity. Improved thermomechanical features are reached in this process [101].

In this scenario, polyurethane thermoset waste recycling is a challenge. A process of milling and grinding in the presence of an organocatalyst, triazabicyclodecene, followed by molding, has been applied to promote a vitrimerization process. This results in a vitrimerized polymer that can relax stress quickly, mainly by a carbamate exchange reaction, allowing the material to be reprocessed by simple techniques such as extrusion and injection molding [103]. Plastic wastes of polyolefins from domestic sources have the potential to be transformed into materials with improved properties by high-energy mechanochemical processes using planetary ball milling [104].

The prospects for eco-friendly methods involving mechanochemical treatments highlight the urgent need to address the disposal of massive amounts of plastic waste. These methods aim to avoid traditional recycling procedures such as incineration and landfill storage, which, while reducing polymer waste, contribute significantly to global pollution. One significant source of waste is car tires, composed of thermosetting polymer materials that can persist in the environment for hundreds of years. The cross-linking in polymer structures has great occurrence [105,106,107,108] and increases their stability. Mechanochemical processing breaks the cross-linking, increasing the surface area and roughness of rubber from tires [109].

The production of polymer blends involves the bonding of a polymer structure to another one. In this process, the mechanochemical technique is applied to split the polymers, with disproportionation or recombination reactions, forming a copolymer block in conditions of high shear. The formation of these structures allows the improvement of mechanical properties in the final material [110]. Mechanochemical ball milling plays a key role in the development of these materials. For example, the formation of polylactic acid (PLA) with improved mechanical properties demonstrates the high efficiency of this method. The high-energy collisions between reactants enable the synthesis of new compounds without the need for solvents. Additionally, mechanochemical processes offer advantages such as shorter polymer degradation times and the ability to avoid C-C bond cleavage. This makes them a versatile route for the synthesis of polymers like polyphenylene/vinylene, polyphenylene, polyazomethine, polylactides, and polyurethane [111].

Polyurethane copolymers can be synthesized via ball milling through the polyaddition of diisocyanates in the presence of a catalyst. To obtain a high molecular weight product, it is crucial to control factors such as reaction time and energy input [89]. In this context, few studies have investigated the kinetics of copolymer formation, such as the melting process of two polymers to produce a copolymer. The mechanical force applied during the process yields a product with an architecture similar to the primary structures involved, often with the addition of a multifunctional reagent that interacts with both polymers. Radical-radical coupling frequently occurs in these reactions. Ball milling, used to pulverize shredded recycled plastic, affects polymer size and has been applied in the treatment of polyolefins, such as in the formation of the polypropylene–low-density polyethylene (PP-LDPE) copolymer. This process acts as a compatibilizer, reducing interfacial tension and improving interfacial bonding [51].

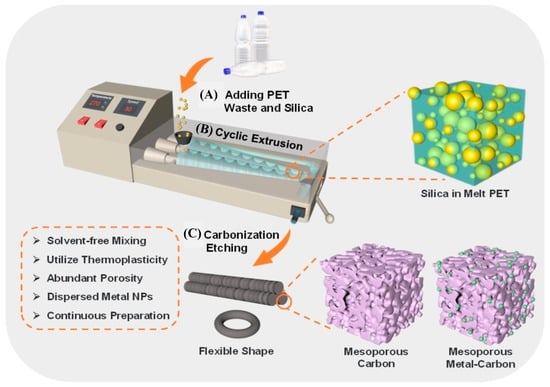

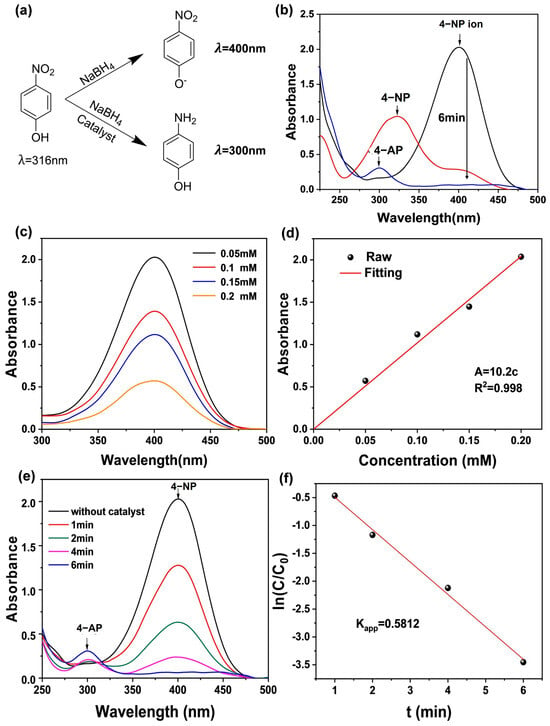

The development of functional materials through the mechanochemical treatment of polymer waste is driving the growth of this research area, offering new concepts for waste management across various industries. In this context, the production of mesoporous carbon materials is particularly attractive for polymer waste-based synthesis, as these materials serve as effective catalyst supports due to their inert nature. They are widely used in reactions such as hydrodeoxygenation, nitrogen reduction, hydrogen evolution, and oxygen evolution. Carbon-based structures can be synthesized from PET waste, as reported by Xu et al. [112]. In this study, functional porous carbons with variable shapes formed in situ and with high surface areas (up to 1001 m2/g) were obtained after carbonization and chemical attack (Figure 11). Furthermore, metallic Mo species were impregnated in a well-dispersed form into the porous carbons through solvent-free extrusion to support solid catalyst design particles (Mo2C@MC). The results indicated that Mo2C@MC not only has good catalytic performance in the reduction reaction of 4-nitrophenol (4-NP) to 4-aminophenol (4-AP), but also the linearity of ln(C/C0) over time was consistent with pseudo-first-order kinetics with an apparent rate constant (Kapp) of 0.5812 min−1 (Figure 12).

Figure 11.

Schematic illustration of the mechanochemical extrusion processes. (A) Adding PET waste and silica into the extruder. (B) Cyclic extrusion for 60 min. (C) Carbonization at 500–800 °C followed by silica removal. Reprinted from Xu et al. [112]. Copyright 2022 with the permission from John Wiley and Sons.

Figure 12.

(a) Maximum UV absorption wavelength of 4-NP, 4-NP ion, and 4-AP. (b) Evolution of UV/Vis absorption spectra for the reduction of 4-NP in 6 min with Mo2C@MC as a catalyst. (c) UV/Vis absorption of 4-NP ion under different concentrations. (d) Variation in absorbance with different solution concentrations of 4-NP ion. (e) UV/Vis spectra of the reaction solution during catalytic reduction by Mo2C@MC. (f) Curves of ln(C/C0) as a function of time. Reaction conditions: C4-NP = 0.2 mm, CNaBH4 = 0.32 m, room temperature, mcat = 10 mg. Reprinted from Xu et al. [112]. Copyright 2022 with the permission from John Wiley and Sons.

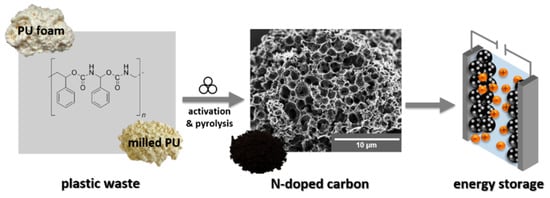

Another polymer with potential application in the synthesis of functional materials is polyurethane. Wastes generated from this material are estimated to accumulate at about 19 million tons annually. This is a precursor for N-doped porous carbon materials, used in supercapacitor applications, provided with high surface area and electrical conductivity. The modification with heteroatoms improves features of the carbonous structures in terms of energy storage, being nitrogen incorporated in the carbon skeleton by immersion of it in a liquid medium such as urea or by post-treatment in the gas phase using ammonia (NH3) or nitrogen (N2) at high temperatures [113]. Schneidermann and his collaborators [113] developed a polyurethane upcycling process obtaining porous carbon materials already doped with nitrogen that were applied to supercapacitor electrodes (Figure 13). In this study, polyurethane residues served as a source of carbon (and nitrogen) that were converted via mechanochemistry with K2CO3 and, optionally, urea. Finally, optimized carbon materials with excellent properties were obtained, such as a high specific surface area of 2.150 m2/g and a total pore volume of 0.9 cm3/g (PUUPC-800-1). Furthermore, such N-doped carbon materials performed similarly to commercial carbon material supercapacitors such as YP-50F, showing a specific capacitance of up to 99 F/g in Li2SO4, as well as stable performance in TEA-BF4 with 83 F/g. By mechanochemical upcycling with additional urea, the rate capacity of the supercapacitor was increased and the obtained device exhibits 80% of its capacitance at a high specific current of 10 A/g in aqueous electrolyte. The authors report that such materials have the possibility of being applied to other energy storage systems, such as lithium-ion batteries or wastewater purification, whenever materials with a high surface area and better wettability are required. This study presents a broader perspective, aiming to extend the process described here to other challenging polymeric waste streams, thereby further reducing waste generation.

Figure 13.

Upcycling approach consisting of high-energy ball milling and carbonization of a mixture of PU foam as the carbon source and potassium carbonate (K2CO3) as an activation reagent to form nitrogen-doped porous carbon as an electrode material for supercapacitors. Reproduced from Schneidermann et al. [113] under the Creative Commons CC BY license.

The presence of halogenated organics in plastic waste complicates chemical recycling. Therefore, recycling methods for these polymeric wastes focus on developing mechanochemical processes with dehalogenation, such as the removal of bromine, chlorine, and fluorine from polypropylene after ball milling for a certain period [114].

Mechanochemistry has proven to be an effective method for mineralizing halogenated organic pollutants. Balema et al. [115] reported the mechanochemical depolymerization of polystyrene to styrene monomer via ball milling. After the milling process, the molecular weight of polystyrene dropped from 88 kDa to 7–8 kDa, and 7 wt% styrene monomer was detected, as characterized by 1H NMR (hydrogen-1 proton nuclear magnetic resonance) and GC-MS (Gas Chromatography with Mass Spectrometry). Although the depolymerization yield is low, this work showed promise for depolymerizing polystyrene in an economical and scalable manner.

The recycling process for this material involves the use of a solvent (benzyl alcohol) under high-pressure conditions. It was observed that extended soaking periods resulted in less undissolved resin in the final product, improving the quality of the recovered fibers. However, the deposition of the catalyst on the surface may compromise this quality [116]. Some additives such as flame retardants, that use halogens in composition, are present in plastic from vehicle components, that in the end-of-life cycle turn to waste. Hexabromocycledodecane (HBCD) is one of the additives. Plastic components made of ABS (acryl nitrile-butadiene-styrene) and PP/PE (polypropylene/polyethylene) have undergone a mechanochemical dehalogenation process using ball milling with the addition of Al- and Si-based additives. This process is particularly relevant since HBCDs were listed as potential pollutants under the Stockholm Convention on Persistent Organic Pollutants in 2013 [117].

In a previous study, Grause et al. [118] performed the almost complete debromination (98%) of decabromodiphenyl ethane (DBDPE) in high impact polystyrene (HIPS) through 24 h wet grinding with an agitated ball mill. In this study, NaOH in ethylene glycol was used as dehalogenation reagent at a relatively high temperature (90 °C). The diffusion-controlled activation energy was about 205 kJ/mol. The strong reagent, high temperature, and long treatment highlight the weak reactivity of brominated compounds in polymer matrices. However, the ball mill had the advantage of deforming and flattening the plastic particles. Therefore, the thermal stability of treated HIPS was also improved after mechanochemical treatment, according to Thermogravimetric analysis (TGA).

Cagnetta et al. [114] studied the mechanochemical treatment of commercial polypropylene (PP) pellets, which contain 15.4 wt% DBDPE, through high-energy planetary grinding for 8 h. The highest debromination efficiency of 90% was achieved with Fe-SiO2 additives, due to the redox activity of Fe, which reduces DBDPE and facilitates the debromination/degradation. The report estimated the energy consumption, assessing that the polymer matrix absorbed about 85% of the milling energy, while only about 15% was used for effective debromination, approximately proportional to the mass proportion of DBDPE. Furthermore, the proposed mechanochemical process carried out in dry conditions at room temperature with cheap reagents, is significantly faster than previously studied [118].

On the other hand, Wang and collaborators [119] investigated the mechanochemical degradation of polybrominated diphenyl ethers (PBDEs) contained in Waste Printed Circuit Boards (WPCBs). The results showed that a degradation conversion of 65.2% for PBDEs was achieved, with PBDEs with higher bromination being reduced with increasing grinding time, and PBDEs with lower bromination being generated.

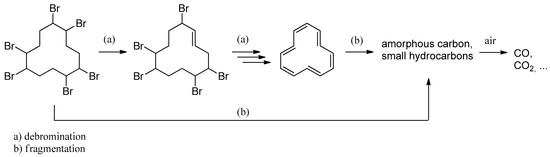

Considering the strong need for disposal of waste containing HBCD, mechanochemical pretreatment technology as a dehalogenation method was investigated by Lu et al. [117] to destroy brominated flame retardants (BFRs). In this study, the results showed that HBCD was effectively degraded during mechanochemical treatment with the aid of Si-Al-based additives in the ratio SiO2/Al = 7:2 with a reagent ratio of 15:1. With the optimized additive system, 4 h of ball milling treatment was sufficient to degrade HBCD. According to the experimental and characteristic results, the possible degradation pathway of HBCD was proposed, as shown in Scheme 3. There are two reactions: (a) debromination and (b) fragmentation. Both reactions occur at the same time, but debromination is the dominant reaction. As it is only a qualitative and not a quantitative result, more in-depth research must be carried out on the mechanism.

Scheme 3.

The proposed degradation pathways of HBCD in the milling process [117].

The application of recycling techniques enables the exploration of methods beyond ball milling, such as solid-state shear milling, which has been reported as a useful approach for recycling epoxy resin waste with potential applications in coatings and functional materials [120]. To conclude this section, it is important to highlight that mechanochemical methods are as environmentally friendly as other methods of recycling polymeric waste. Giving new life to these materials offers alternatives to obtain composites, blends, catalyst supports, electrodes, and electric components, all products which are essential for many human activities. The mechanochemical processes offer many positive features, e.g., the problem of contaminant presence that can be ignored because contaminants may act as milling assistants. This process can be combined with chemical processing for the recycling of a variety of wastes and for the synthesis of new materials [121], which have already been and will be mentioned throughout this review. It is proven that the mechanochemical method has a certain degradation effect on brominated organic matter. The charge ratio (i.e., ball-to-powder ratio) and the rotation speed are considered fundamental parameters in dehalogenation reactions. These control the specific energy density within the matrix. Essential information on the most effective operating parameters of mechanochemical treatment of the chlorinated, brominated, and fluorinated compounds described in the reviewed papers is reported in Table 3.

Table 3.

Summary of experimental conditions utilized in reviewed papers that achieved best dehalogenation/degradation results.

3.5. Crustaceans

As large amounts of residual shells still remain underexploited, the concept of shell biorefinery is developing rapidly and has attracted increasing attention in recent years. Fractionating crustacean shells into their main components and processing each component into value-added chemicals and materials can bring ecological and economic benefits [164].

Chitosan (CS), a biopolysaccharide composed of glucosamine units linked together by β-1,4 linkages, is generally produced by deacetylation of chitin, which is mainly extracted from crustacean shells, insect cuticles, or other microorganisms such as bacteria, fungi, and others. In particular, low molecular weight chitosan (LMWC) between 2 and 10 kDa exhibits enhanced solubility that can be dissolved in neutral water for direct use under physiological conditions. Furthermore, LMWC is specifically suited for DNA delivery, showing more enhancement in biological, antibacterial, antitumor, and immunostimulatory activities than chitin and high molecular weight chitosan (HMWC), making it attractive in biomedical and pharmaceutical applications. LMWC is also superior compared to HMWC and chitin in materials synthesis due to remarkably improved reactivity in grafting, crosslinking, and other types of modifications [165,166]. Both chitin and chitosan are biocompatible, biodegradable, non-toxic, and quite valuable due to their lower mineral content. However, the deacetylation of chitin into chitosan is still an expensive, difficult process and is usually accompanied by depolymerization, providing low molecular weight chitosan [167].

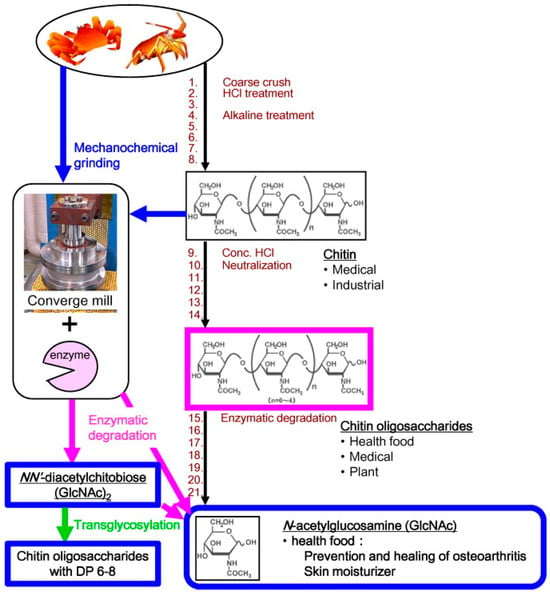

The first report of a chitinolytic system using combinations of mechanochemical grinding and direct enzymatic degradation of crustacean shells was by Nakagawa and colleagues [168]. This study developed an intensive “convergence” ball mill for rapid mechanochemical conversion of chitin and crustacean shells (crab or shrimp) into amorphous microparticles sensitive to chitinase (Figure 14). The mechanochemical pre-treatment allowed a complete degradation of crab shells into N-acetylglucosamine (GlcNAc).

Figure 14.

The traditional method of manufacturing N-acetylglucosamine and decrease the environmental burdens by the innovative technology Left side shows industrially applied process to make chitin, chitin oligomers and GlcNAc from crustacean shells. Using converge mill for pre-treatment, it is possible to decrease 2/3 steps from traditional method. While the traditional method requires many steps (1-21) including acid and alkaline treatments, neutralization to be able to start the enzymatic degradation step to obtain GlcNAc Reprinted from Nakagawa et al. [168]. Copyright 2011, with permission from Elsevier.

Chen et al. [169] transformed shrimp shells into LMWC in the presence of NaOH by single-step mechanochemistry. The results showed that raw shrimp shells were successfully transformed into LMWC (7.9 kDa) with a high purity of 90% under NaOH-catalyzed grinding conditions (8 cycles, 700 rpm). The FTIR spectra of the product demonstrate the formation of chitosan-like compounds, as well as the weak bands at 1536 cm−1 and 1395 cm−1 which suggest the presence of residual CaCO3 and proteins. The content of protein residues in the final product was analyzed using the Bradford method, while analysis by ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry) revealed a CaCO3 content of 6.7% in weight. This new simple, solvent-free approach avoids the generation of wastewater and the use of oxidants, acids, or other environmentally harmful reagents. Furthermore, the work not only emphasizes that base usage has been drastically reduced to 1/10 compared to traditional methods but also inhibits side reactions under ball milling conditions.

Di Nardo and colleagues [170] reported a new method, to produce high molecular weight chitosan with minimal energy and solvent consumption, based on the combination of mechanochemistry and aging. The results showed that the method was versatile and applicable to a range of chitin sources, including crude crustaceans and insect shells, allowing a deacetylation degree of up to 98% and remarkably high molecular weights. According to reports, this process provides chitosan in a safer way and with lower consumption of materials and energy compared to the classic hydrothermal process. It minimizes material dependency (achieving excellent results with NaOH: chitin ratios of 4 or 5), eliminates the need for solvents during the reaction, and significantly lowers energy consumption, particularly in pure aging experiments. This article describes an innovative methodology for producing chitosan-based materials resistant to dissolution in water. This opens up the possibility of using them in new areas, such as environmental remediation or food packaging production. Because this methodology is remarkably simple to implement, requiring minimal technical equipment, it is highly adaptable to the challenge of bark biorefinery. Overall, this approach offers solutions for the local production of high-value-added products, especially in locations close to fishing areas and insect farms.

Su et al. [171] also developed a contemporary method for reusing shrimp shell waste, transforming it into new value-added materials. This process, called mechanochemistry, is considered gentle and waste-free. One of the main advantages of this method is that it eliminates the use of harsh chemicals such as strong acids and bases, as well as oxidants. It also does not require extreme temperature or pressure conditions and consumes less energy than traditional methods (Table 4). According to the authors, the aim of the study is to contribute to the circular economy by promoting the sustainable use of crustacean waste. With this approach, they aim to achieve United Nations (UN) Sustainable Development Goals (SDG) 3, 6, 12, and 14 [172] proposing a method of economical and sustainable reuse of crustacean waste.

Table 4.

The types, quantities, and energy consumption of chemical reagents required to treat each ton of shrimp shells [171].

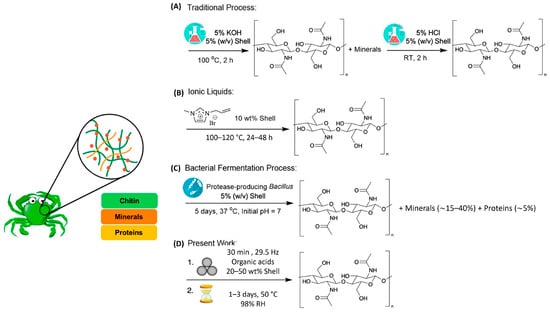

Hajiali et al. [33] described a sustainable approach based on mechanochemistry and aging for extracting chitin directly from crab shells using a commercial blender (Figure 15). According to the results, different solid acids (i.e., citric, ascorbic, malic, salicylic, and succinic acids) promoted chitin extraction with yields reaching 27% and low ash contents (0.9%). Using citric acid, chitin from 200 g of crab shells could be extracted using a commercial blender, achieving low values of 190 and 18 kJ/g for process mass intensity (PMI) and energy consumption, respectively. Although 30 min of grinding can provide high-quality materials, yields could be increased further by decreasing the grinding time to 10 min. These results showed viability when compared with other traditional chitin extraction methods and alternative strategies, which is summarized in Figure 16.

Figure 15.

Photos of the whole GC (European Green Crabs) as received by Parks Canada, GC shells after boiling and defleshing, GC shells powder after homogenization using a commercial blender, and chitin extracted after the mechanochemical process developed and proposed. Reprinted from Hajiali et al. [33]. Copyright 2022 with permission from American Chemical Society.

Figure 16.

Comparison between the extraction of chitin from crab shells using (A) the traditional solution-based process, (B) ionic liquids, (C) bacterial fermentation, and (D) the work of Hajiali et al., based on mechanochemistry and aging. Reprinted from Hajiali et al. [33]. Copyright 2022 with permission from American Chemical Society.

Recently, Fatika et al. [173] successfully synthesized chitosan Schiff bases (ChSB) from shrimp shells through a consecutive process involving demineralization, deproteinization, and deacetylation at room temperature, followed by solvent-free mechanochemical grafting using an environmentally friendly method. The resulting ChSB was found to be more amorphous and exhibited increased thermostability compared to chitosan. Notably, solvent-free mechanochemical grafting enabled ChSB synthesis in just 10 min, significantly reducing the processing time compared to conventional methods (>3 h). The authors highlighted the need for further studies to explore this approach for generating ChSB from other raw materials and to investigate its biological activity.

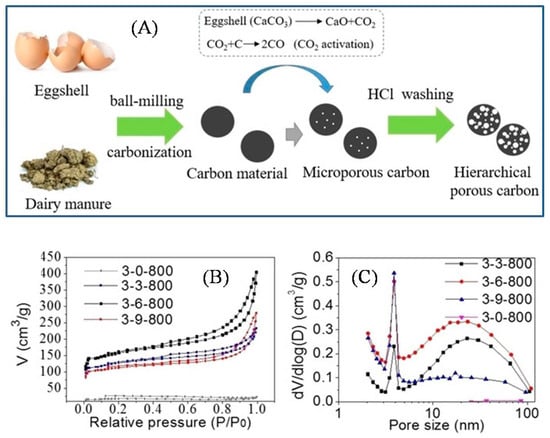

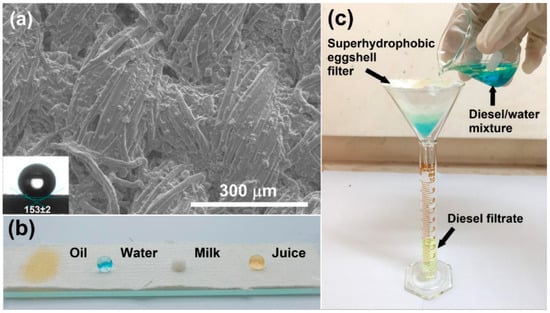

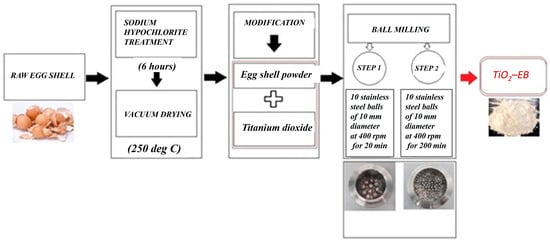

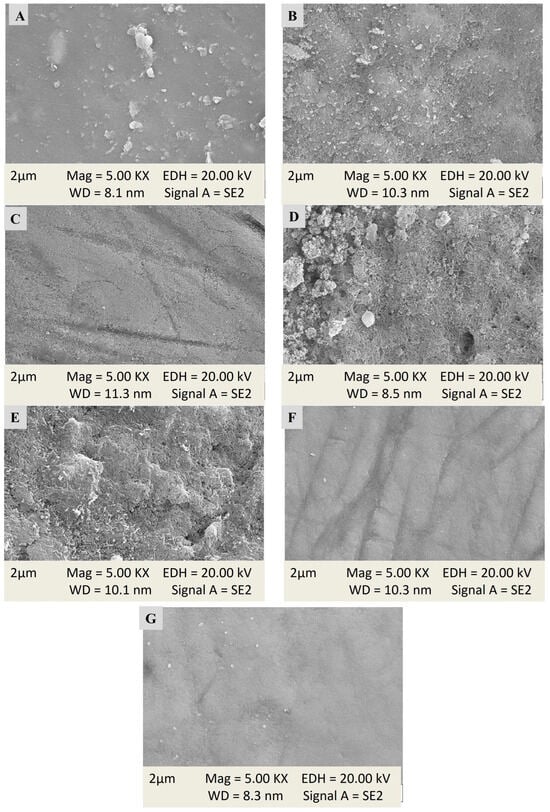

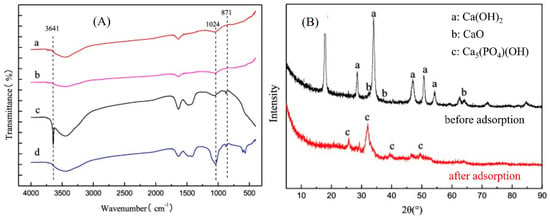

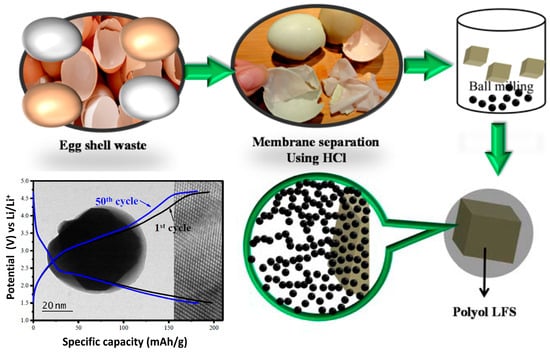

3.6. Synthesis of Materials

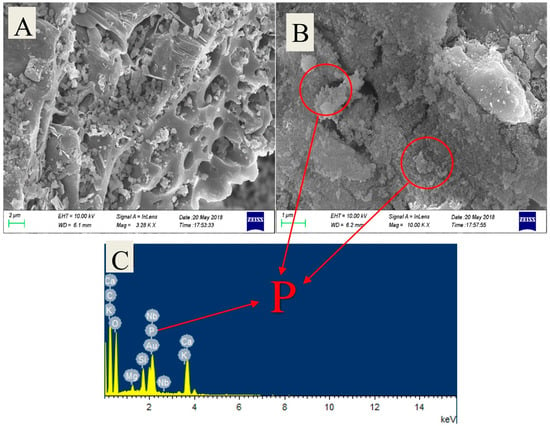

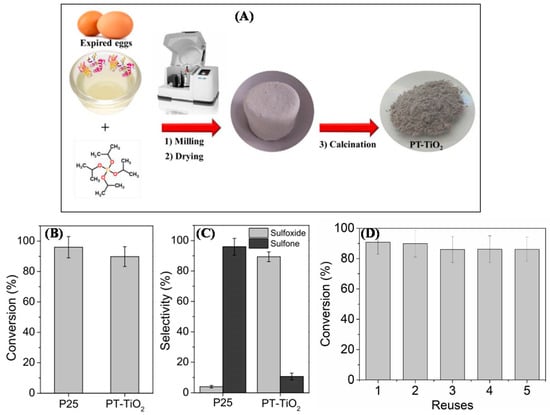

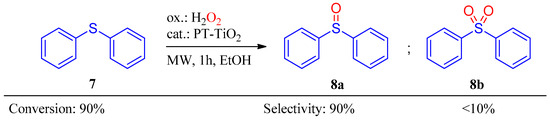

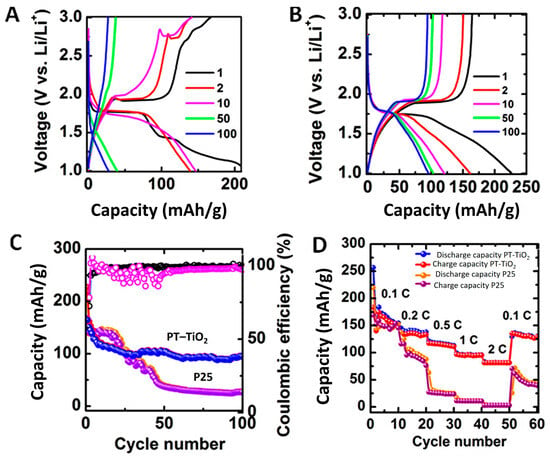

Eggs, a widely consumed natural food source, provide essential amino acids, vitamins, and minerals. As a result, chicken eggshells are a common byproduct of food waste. These residues are fully biodegradable, recyclable, and biocompatible [174]. The primary chemical component of eggshells is calcium carbonate (CaCO3) in the form of calcite, comprising approximately 94–97% of their composition. Other constituents include calcium phosphate (Ca3(PO4)2) at 1%, magnesium carbonate (MgCO3) at 1%, and organic matter at 4% [4]. Studies highlight the significance of CaCO3 as the main component of natural waste materials such as oyster and eggshells, both of which have been successfully employed in mechanochemical dechlorination processes [175,176,177]. This review provides an updated overview of recent publications utilizing a mechanochemical approach for eggshell waste treatment, summarizing key applications and findings.