With respect to gas production, Futura-75 generally produced slightly lower gas yields compared to Fedora-17. For both cultivars, the absence of the fibre sheath tended to increase gas yields, although with some exceptions (e.g., Test 11). These differences, however, were relatively minor and fall within the range of experimental uncertainty. The catalyst amount appears to exert a stronger influence, with higher catalyst loadings leading to slightly reduced gas yields.

Product Analysis

The main properties of the biocrude oils obtained from HTU processing of Futura-75 and Fedora-17 are shown in

Table 2. For comparison, the elemental composition and higher heating value (HHV) of the feedstock are described in the Materials and Methods Section. The most significant difference is related to the oxygen content, which is lower in the bio-oils compared to the feedstock. The oxygen content of the oils ranged from 26–36 wt.%, whereas the raw hemp materials contained 46.8–47.5 wt.% oxygen. Herbaceous biomass generally contains more ash than woody biomass, primarily due to ash-forming minerals, and it also has higher levels of extractives and insoluble fibres such as lignin, hemicellulose, and cellulose [

19,

20]. As a result, the ash content in the produced bio-oils ranged from 2.8 to 6 wt.% (

Table 2).

The removal of oxygen significantly influenced the elemental composition of the produced bio-oils, increasing their hydrogen-to-carbon ratio. This in turn suggests an improvement in the calorific value of the products. The calculated higher heating values confirm this trend, as the second-highest HHV was observed for Test 7, which also exhibited the highest H/C ratio (

Table 2). A high H/C ratio is often associated with a greater energy density of liquid fuels, as it may reflect a higher proportion of hydrogen-rich compounds such as saturated hydrocarbons. However, in this study the detailed hydrocarbon composition (e.g., paraffins vs. aromatics) was not determined, and the observed correlation should therefore be regarded as indicative.

Analogous to the pure yields, the two highest HHVs (31.26 and 32.12 MJ/kg) were obtained for Fedora-17 with fibres, whereas the calorific values were lower when the same hemp was processed without fibres. An opposite trend was seen for Futura-75, where fibre-free samples gave slightly higher HHVs than their fibre-containing counterparts. Considering the hemp-waste material (fibre-free biomass), the HHVs ranged from 29.94 to 31.12 MJ/kg for both cultivars, which is only slightly below the maximum achieved value (32.12 MJ/kg) but markedly higher than the HHV of the raw feedstock (17.7–17.9 MJ/kg in this work; ~18.5 MJ/kg reported in the literature [

21].

Generally, the HHV increases with lower oxygen content. The relatively high HHV obtained for Test 10 (31.12 MJ/kg) can be explained by its high carbon content (63.1%) and the lowest oxygen fraction (27.02%) among the fibre-free samples, which favoured energy density despite the absence of fibres. In terms of product density, the highest value (902.17 kg/m3) was measured for Test 10 (Futura-75 without fibres), while the lowest (834.75 kg/m3) was obtained in Test 12 (Fedora-17 without fibres). This indicates that the impact of fibre removal on density depends on the cultivar: for Fedora-17, fibre-free oils generally had lower density compared to fibre-containing ones, while for Futura-75 the reverse was observed. The fibre sheath, composed mainly of cellulose, lignin, hemicellulose, pectin, wax, and ash, consists of large molecular structures that can influence product distribution and, in many cases, promote the formation of heavier fractions, though cultivar-specific effects were evident.

In a broader perspective, the HHVs obtained in this work (25.9–32.1 MJ/kg) fall within the ranges reported for bio-oils derived from lignocellulosic feedstocks processed by HTU/HTL (typically 16–25 MJ/kg [

22], 24.3 MJ/kg [

23]). Nevertheless, they remain below the values normally achieved after catalytic upgrading or hydrotreatment (≈34–41 MJ/kg [

24,

25]), underlining the need for further upgrading steps to enhance the energy density of hemp-derived bio-oils to the level of advanced biofuels.

As mentioned in the introduction, plant biomass typically produces mainly C

5–C

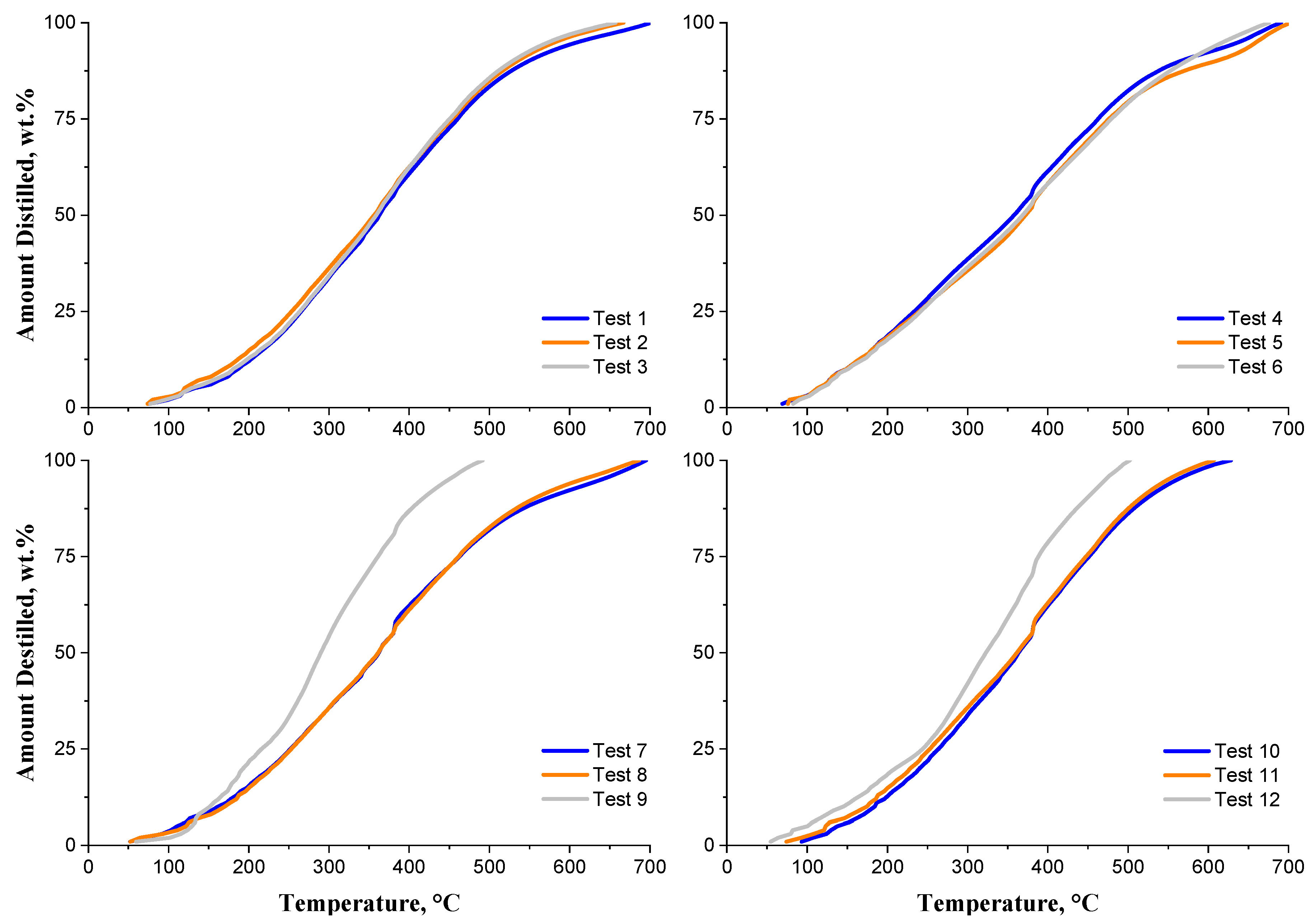

6 hydrocarbons through the hydrolysis of cellulose and hemicellulose in the presence of alkaline salts such as carbonates. During the HTU process, these short-chain compounds can undergo condensation, cyclization, and polymerization reactions, leading to the formation of larger molecules. This tendency is reflected in the SIMDIS results (

Figure 1), where the distillation curves of the obtained bio-oils extend up to 700 °C and show that, in most cases, more than half of the product fraction lies above 360 °C. Such high-boiling fractions are consistent with the presence of heavier compounds, indicating that molecular growth reactions occurred during the process.

Nevertheless, raw bio-oil cannot be directly applied as a transport fuel due to its high viscosity, high oxygen content, and corrosiveness. Therefore, producing heavier bio-crude for subsequent refining—such as cracking or deep oxygen removal—is advantageous [

25]. From the distillation curves, it can be observed that, except for Tests 9 and 12, more than 50% of the bio-oils consist of fractions boiling above 360 °C. This finding is further supported by the fractionation data presented in

Table 3.

Table 3 shows that the dominant fractions of raw bio-oil are the residual fraction (>360 °C), and diesel-cut equivalent (180–360 °C), which is a desirable finding considering the current diesel fuel shortage in Europe. The results for the differences between hemp cultivars are rather comparable. Regarding the diesel fraction of the tests using Futura-75, processing the material with fibres results in slightly higher yields of the diesel fraction and seems to confirm the previous finding related to the higher density of the products of those tests.

This trend is less apparent in Fedora-17, except in Tests 9 and 12, which stand out for their unusually high diesel fraction (58 wt.% and 47 wt.%, respectively) combined with a markedly reduced residual fraction (26 wt.% and 38 wt.%). This deviation from the general pattern, where residual fractions typically exceeded 50 wt.%, makes these two cases particularly notable.

Generally, for Futura-75 with fibres, the gasoline, jet fuel, and diesel fraction yields were in the range of 8–10 wt.%, 27–28 wt.%, and 39–41 wt.%, respectively. While processing Futura-75 without fibres, the fraction yields were 13 wt.%, 28–31 wt.%, and 32–36 wt.% for gasoline, jet fuel, and diesel fractions, respectively. For the tests processing Fedora-17 with fibre sheath, the fractionation results were in a range of 11–16 wt.% for gasoline, 28–47 wt.%, for jet-fuel, and 37–58 wt.% for the diesel fraction equivalent. In the case of Fedora-17 without fibres, the corresponding ranges were 9–15 wt.%, 29–31 wt.%, and 38–47 wt.%.

Comparable trends have been reported for hydrothermally processed algal oils, where the crude products were largely composed of heavy fractions boiling above 330 °C, with lighter fractions becoming significant only after additional thermal upgrading [

26]. In contrast, the hemp-derived oils in this study already contained considerable proportions of diesel-range products (up to 32–58 wt.%), underscoring the positive influence of catalytic HTU conditions compared to purely thermal treatments.

Since the raw bio-oils obtained from hemp stalks (with or without the fibre sheath) contain significant residual fractions, nearly all products required further refining. Residual fractions were typically 51–55 wt.%, with the sole exception being Test 12, where the residual fraction was 38 wt.%.

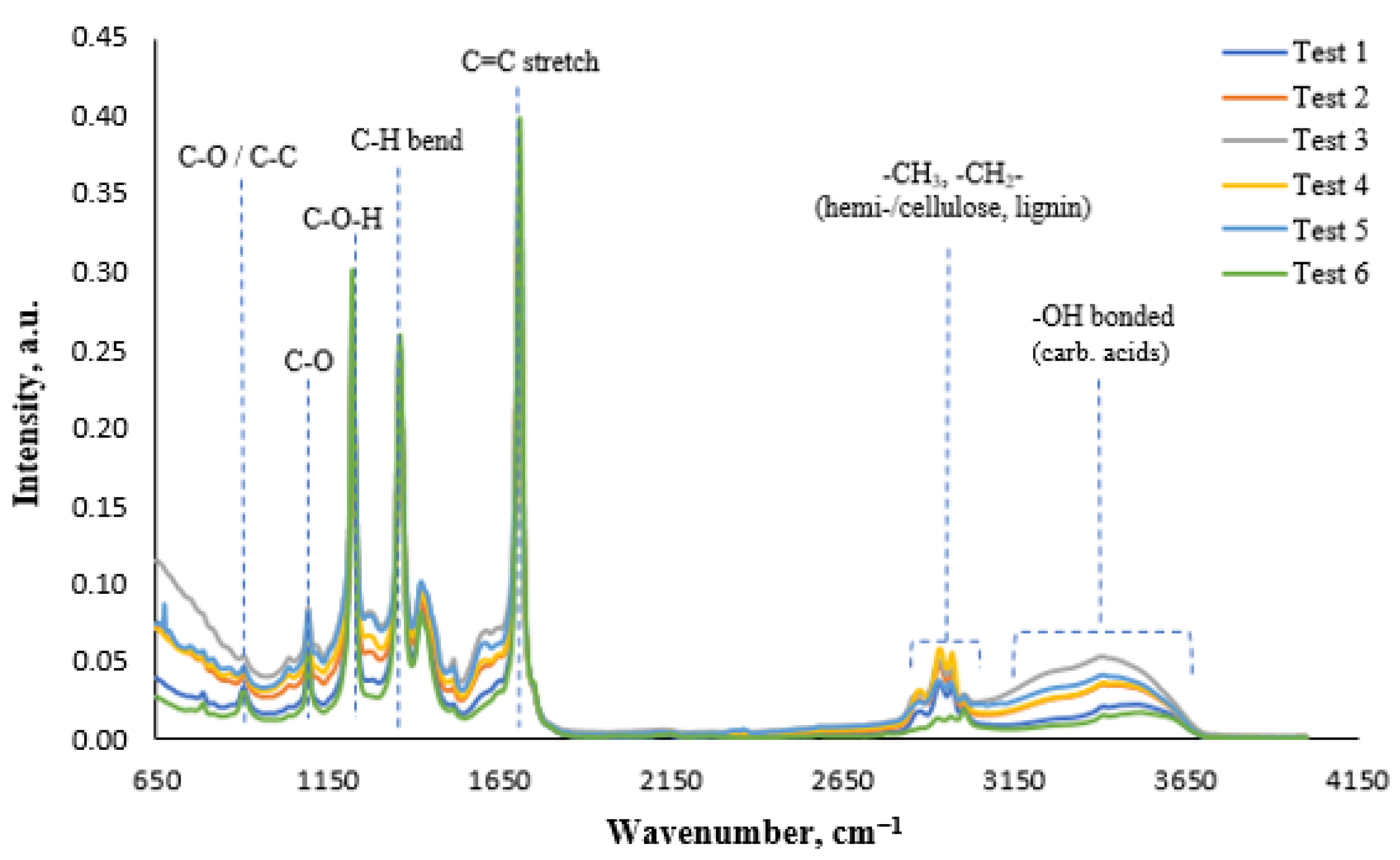

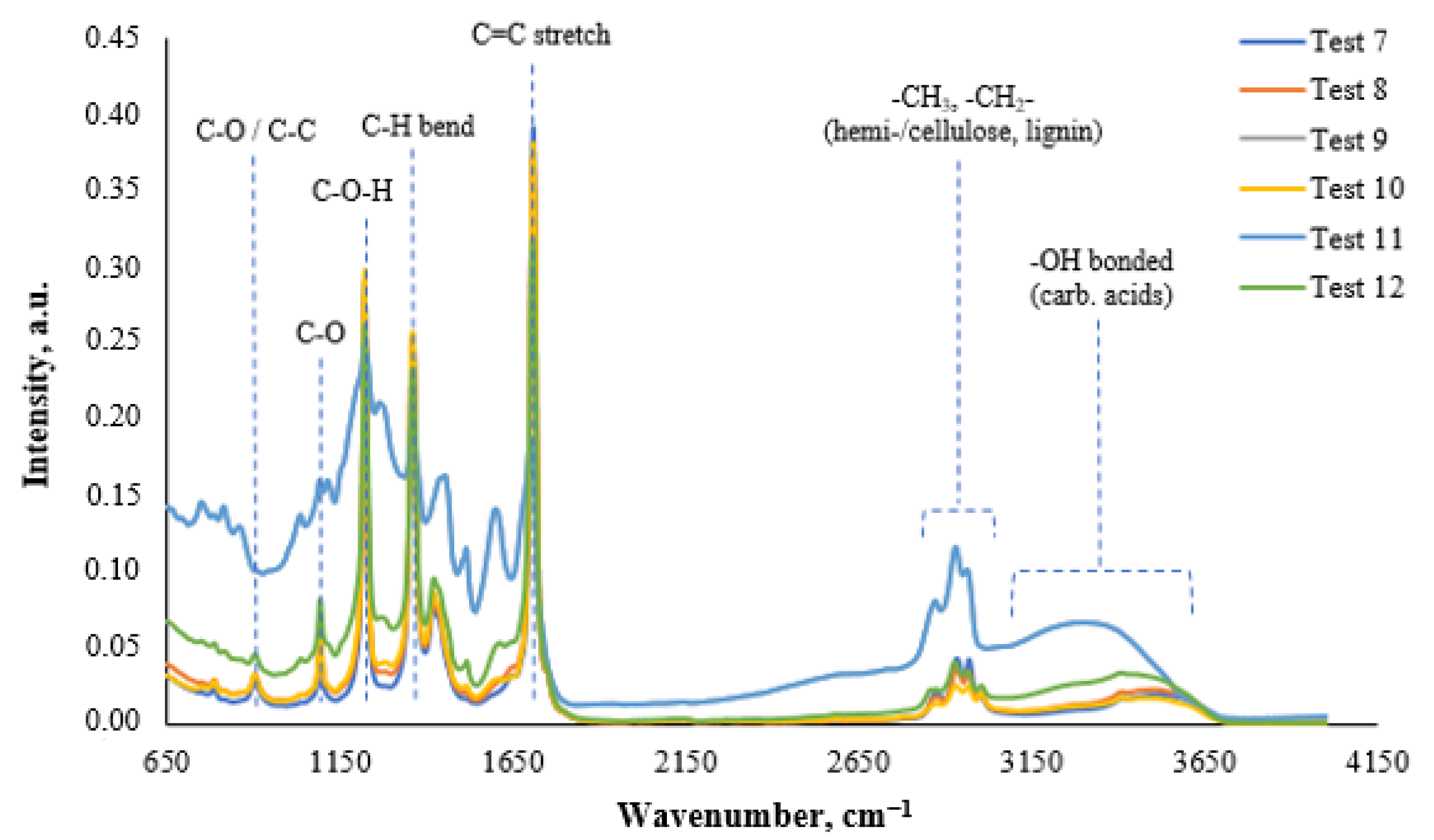

The attenuated total reflectance (ATR) technique was applied to the bio-oil samples to identify their characteristic absorption signals (

Figure 2 and

Figure 3).

The spectra show a band from 3110 to 3690 cm

−1 corresponding to OH groups and bands from 2820 to 3110 cm

−1 typical of the methylene and methyl groups derived from cellulose, hemicellulose, and lignin [

27]. Signals at 1709 cm

−1, 1361 cm

−1, and 1221 cm

−1 indicate the presence of lignin derivatives, with the first attributed to C=C stretch, the second to aromatic C-H deformation [

28], and the third to the C-O-H band, confirming the existence of the CH

2OH groups from hexose units [

29]. A peak at 1093 cm

−1 confirms the presence of di- or oligosaccharides associated with glycoside linkages [

28]. ATR results for the Fedora-17 cultivar were nearly identical, with only slight differences in signal intensity. Overall, the spectra confirm the presence of biomass-derived compounds in the bio-oil.

As mentioned in the introduction, oxygen is removed during the HTU process in the form of water and carbon dioxide through deoxygenation and decarboxylation of carboxylic acids. This is supported by the gas composition of all collected products presented in

Table 4, where CO

2 is dominant, ranging from 89.21 to 96.61 wt.%

Among the detected gaseous components, CO was present at concentrations of 1.69–6.83 wt.% traces of hydrogen and methane were also detected in all cases. No clear trends were detected between hemp cultivars or the presence of fibre sheath. However, the amount of catalyst appeared to influence the formation of unsaturated hydrocarbons, as higher catalyst loadings resulted in a lower proportion of alkenes. The detection of heavier hydrocarbons in the gas phase most likely arose from incomplete condensation during sampling, since the thermo-probe measures the heating mantle temperature rather than the actual temperature inside the reaction vessel, which can prevent full condensation of higher-boiling compounds.

In addition to liquid and gaseous products, the HTU process also generates a small amount of solid residue, primarily originating from lignin-rich and mineral components of hemp feedstock. Although not quantified in this study, such residue could potentially be valorized as a low-grade fuel or as a precursor for activated carbon, thereby reducing waste and improving the sustainability of the process. These aspects emphasize that HTU not only produces liquid bio-oil but also provides opportunities for comprehensive utilization of hemp biomass.

Thus, industrial hemp biomass emerges as a promising feedstock for bio-oil production. Despite its high oxygen content, the HTU process produces bio-oil with significantly improved characteristics for subsequent upgrading into motor fuels. Moreover, it allows the conversion of hemp waste into a more valuable product in an environmentally friendly way, making this pathway particularly attractive from both technological and ecological perspectives. Overall, these results highlight the relevance of HTU in advancing renewable fuel production and support its potential role in addressing current energy challenges.