Enhancing Sustainable Production of Biodiesel from Xanthoceras sorbifolia Bunge Oil Using Bio-Based Heterogeneous Catalyst

Abstract

1. Introduction

2. Results and Discussion

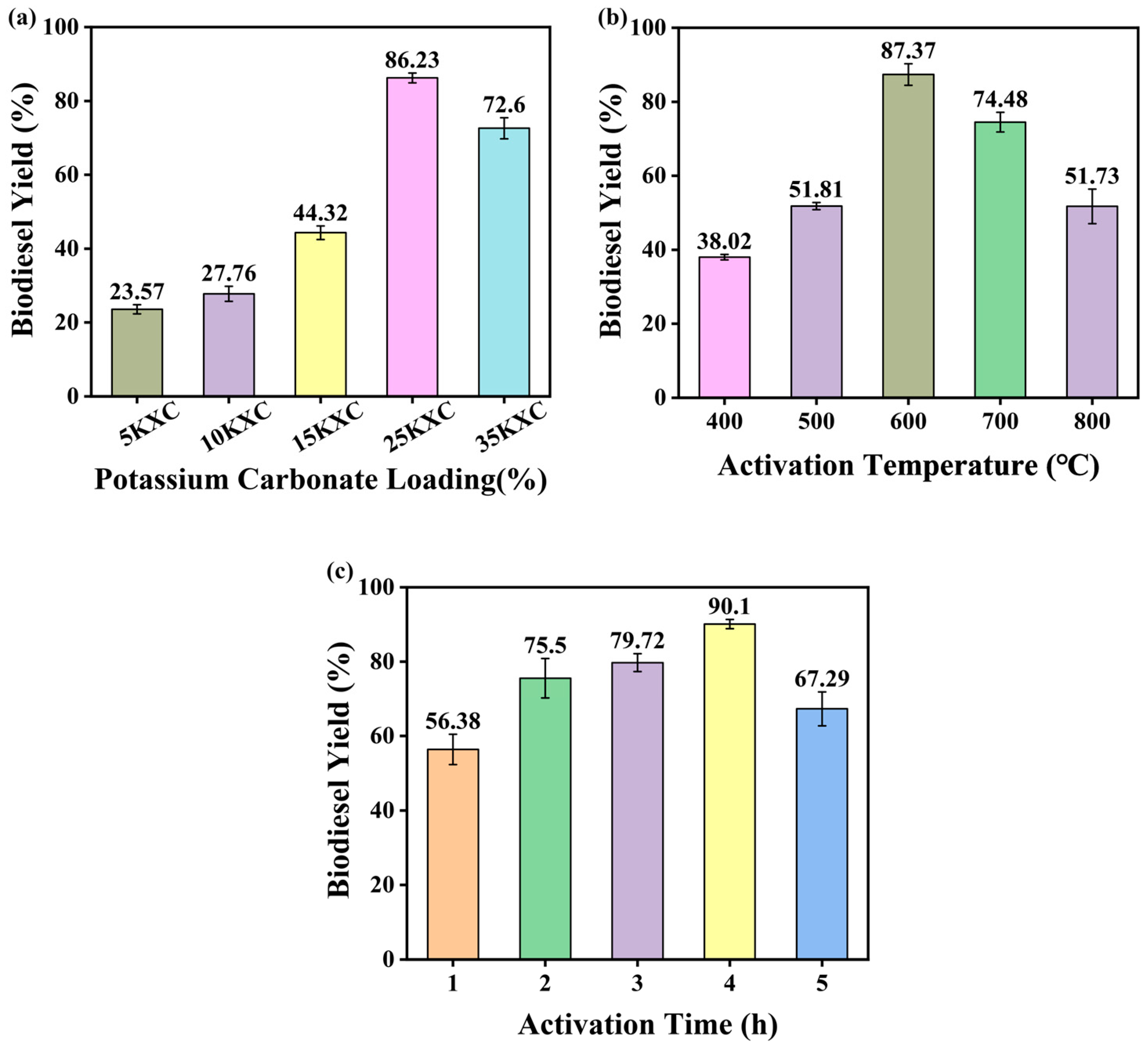

2.1. Influence of Potassium Percentage

2.2. XRD Analysis

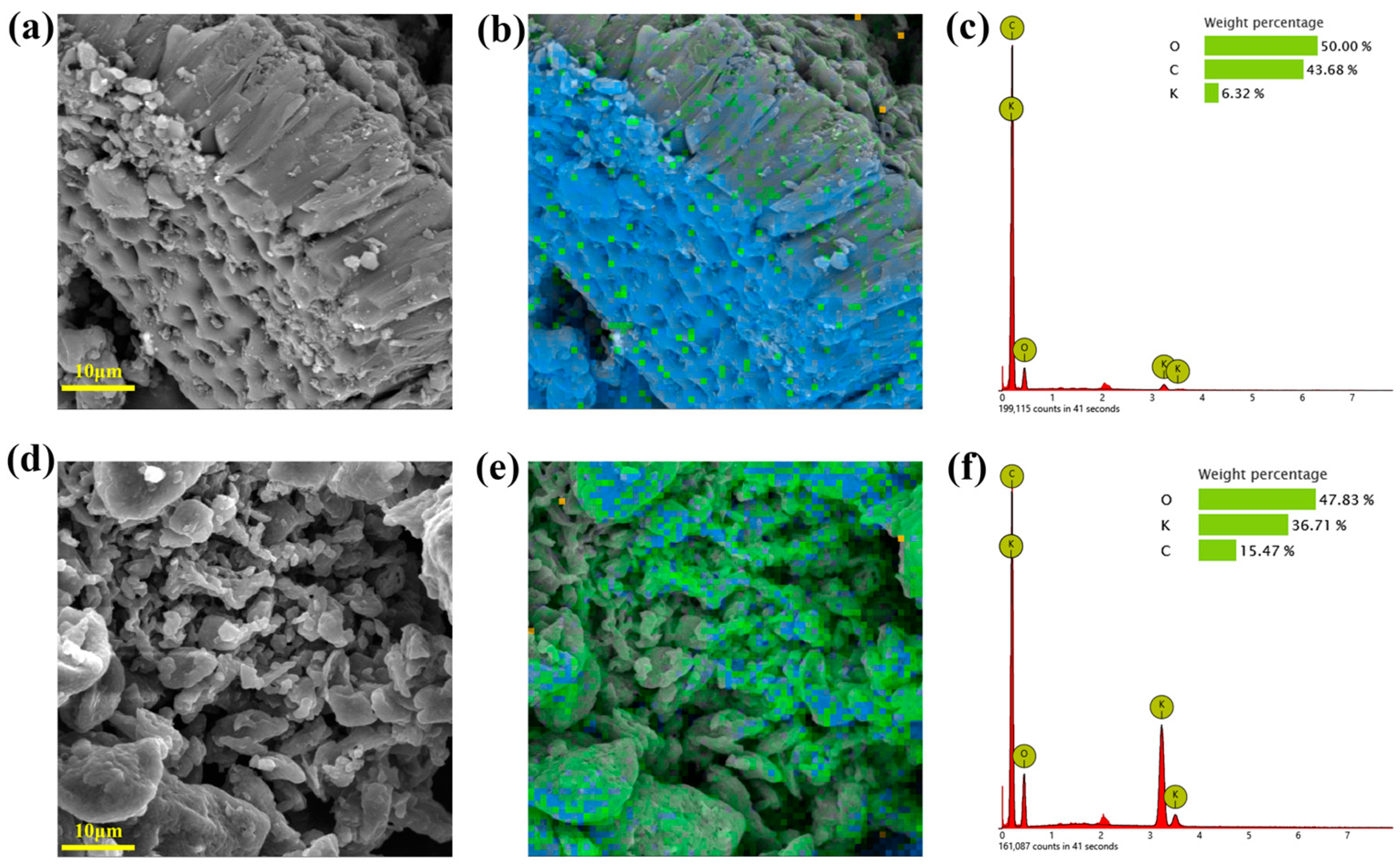

2.3. SEM-EDS Analysis

2.4. FTIR Analysis of Catalysts

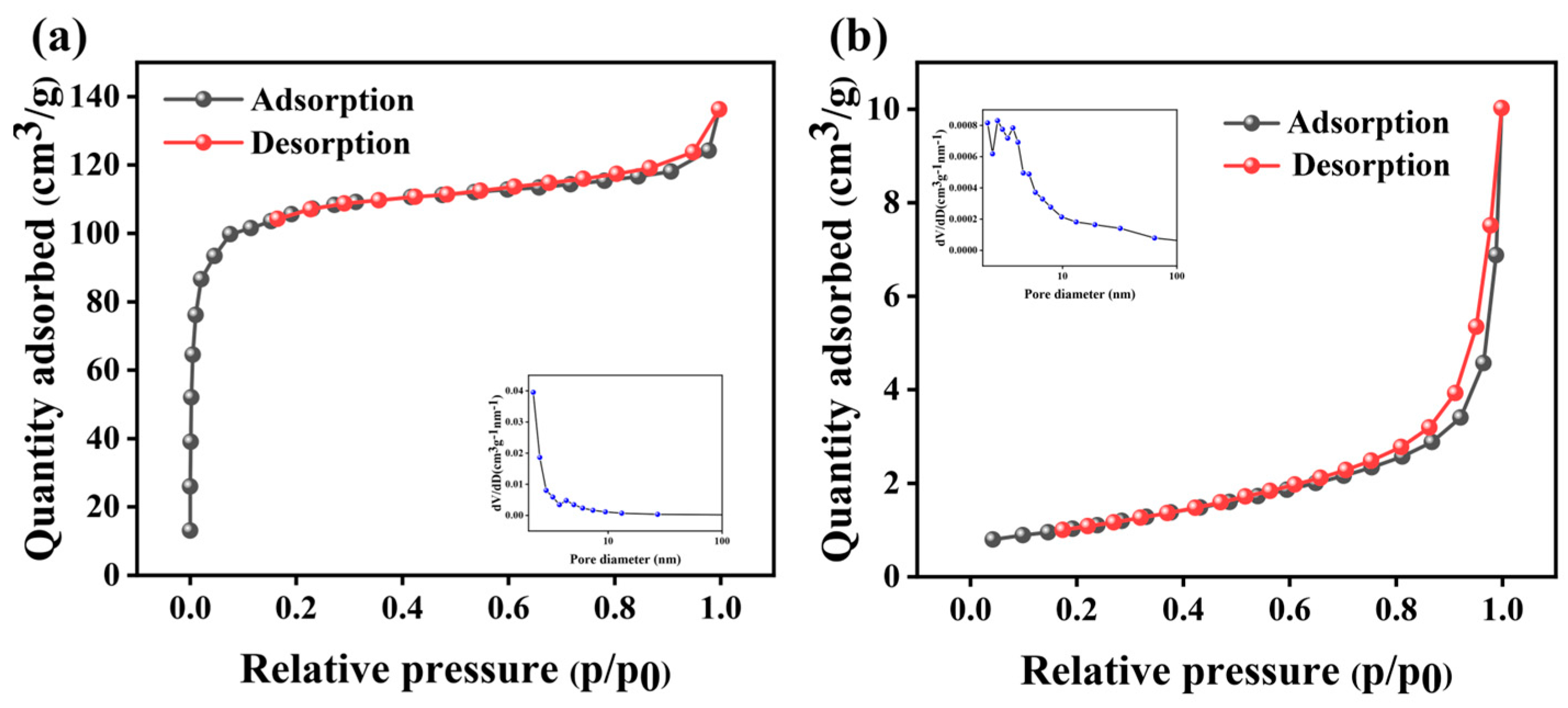

2.5. BET Surface Area Analysis

2.6. TG Analysis

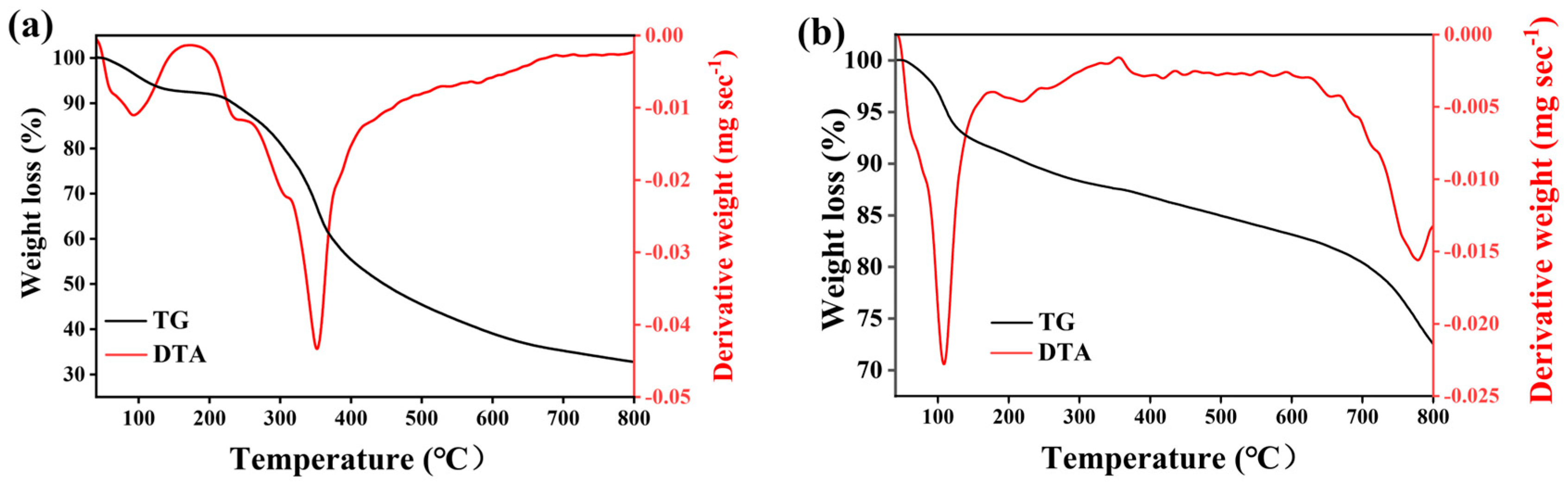

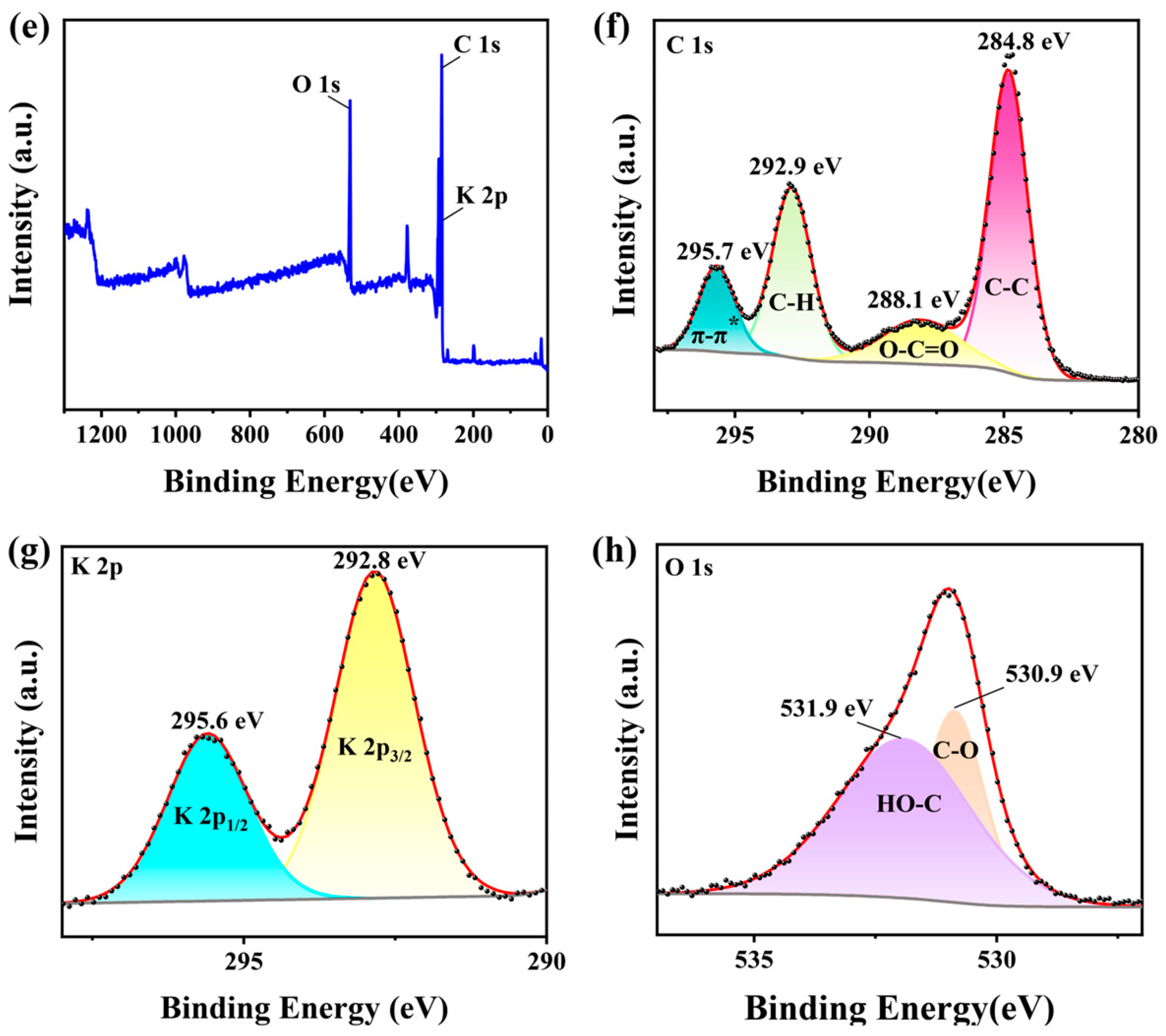

2.7. XPS Analysis

2.8. Study of the Influence of Reaction Parameters for Biodiesel Synthesis

2.8.1. Effect of Methanol–Oil Molar Ratio (MOMR) on the Reaction

2.8.2. Effect of Temperature on the Reaction

2.8.3. Effect of Time on the Reaction

2.8.4. Effect of Catalyst Loading

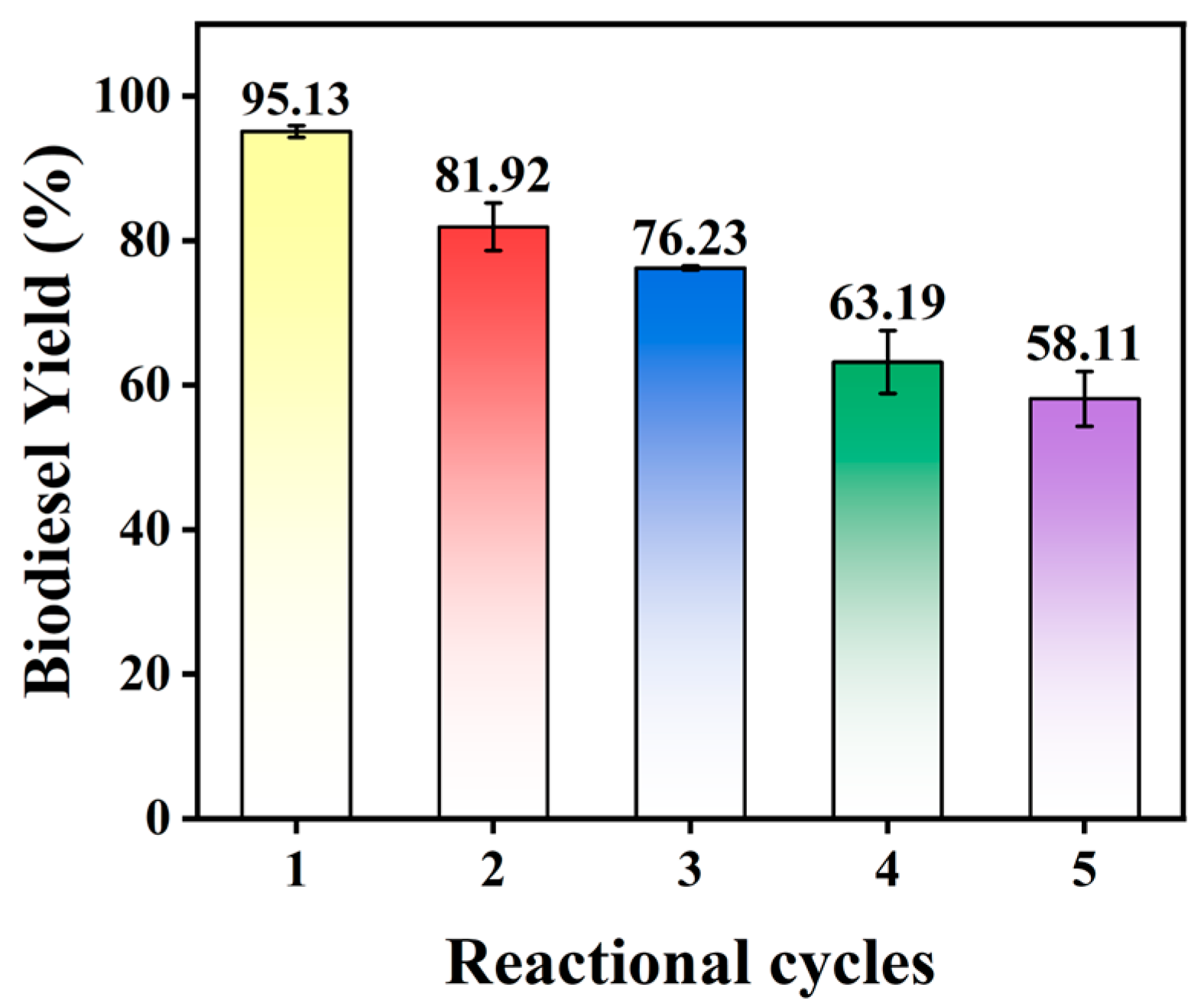

2.8.5. Investigation of Catalyst Reusability

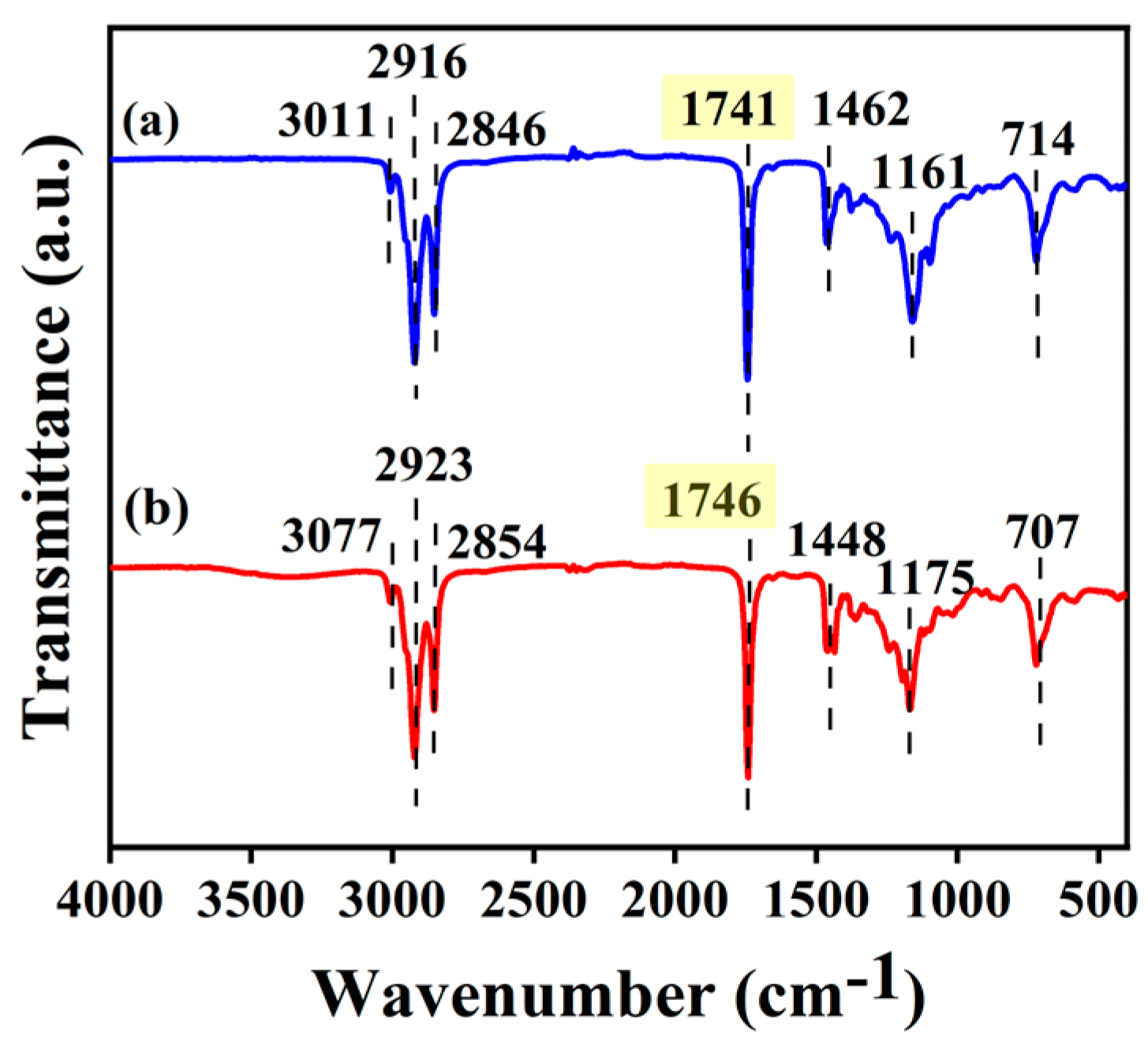

2.9. Characterization of Xanthoceras sorbifolia Biodiesel

2.9.1. FTIR Analysis Xanthoceras sorbifolia Biodiesel

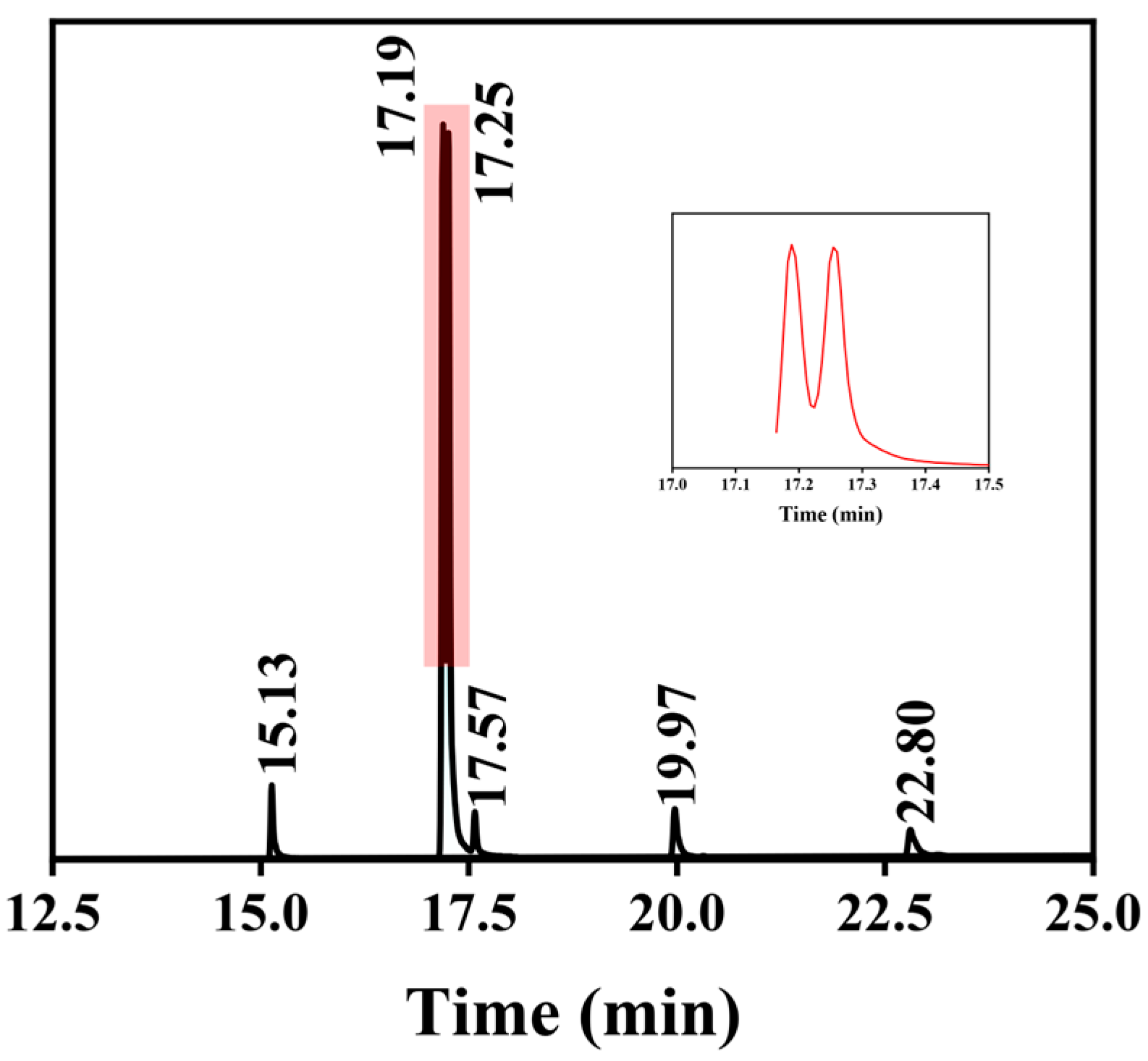

2.9.2. GC-MS Analysis

2.9.3. Xanthoceras sorbifolia Bunge Oil Biodiesel Properties

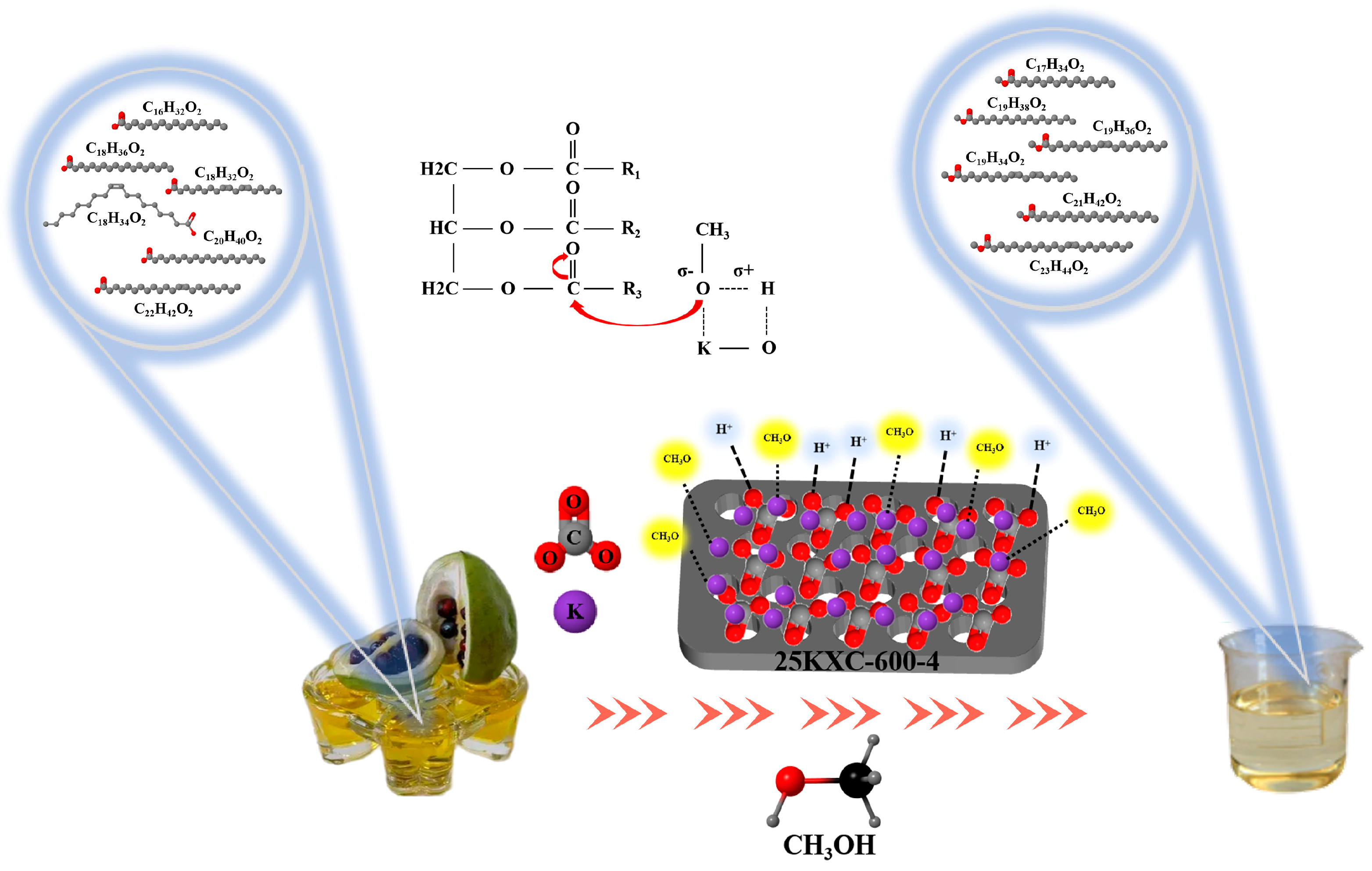

2.10. Proposed Reaction Mechanisms

3. Materials and Methods

3.1. Materials

3.2. Preparation of the Catalysts

3.3. Catalyst Characterization

3.4. Transesterification and Characterization of Biodiesel

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karkal, S.S.; Rathod, D.R.; Jamadar, A.S.; Mamatha, S.S.; Kudre, T.G. Production optimization, scale-up, and characterization of biodiesel from marine fishmeal plant oil using Portunus sanguinolentus crab shell derived heterogeneous catalyst. Biocatal. Agric. Biotechnol. 2023, 47, 102571. [Google Scholar] [CrossRef]

- Masera, K.; Hossain, A.K. Advancement of biodiesel fuel quality and NOx emission control techniques. Renew. Sustain. Energy Rev. 2023, 178, 113235. [Google Scholar] [CrossRef]

- Bahadorizadeh, O.; Sobati, M.A.; Shahnazari, S. Emission characteristics of a semi-industrial boiler fueled by waste cooking oil biodiesel containing different metal oxide nanoparticles. Process Saf. Environ. Prot. 2022, 158, 199–209. [Google Scholar] [CrossRef]

- Shokrani, R.; Haghighi, M. Textural evolution of hierarchical nanostructured ZSM-5 via sono-hydrothermal design by various carbon shapes for efficient biodiesel production. Appl. Catal. B Environ. 2020, 271, 118940. [Google Scholar] [CrossRef]

- Mierczynski, P.; Szkudlarek, L.; Chalupka, K.; Maniukiewicz, W.; Wahono, S.K.; Vasilev, K.; Szynkowska-Jozwik, M.I. The Effect of the Activation Process and Metal Oxide Addition (CaO, MgO, SrO) on the Catalytic and Physicochemical Properties of Natural Zeolite in Transesterification Reaction. Materials 2021, 14, 2415. [Google Scholar] [CrossRef]

- Basumatary, B.; Basumatary, S.; Das, B.; Nath, B.; Kalita, P. Waste Musa paradisiaca plant: An efficient heterogeneous base catalyst for fast production of biodiesel. J. Clean. Prod. 2021, 305, 127089. [Google Scholar] [CrossRef]

- Das, A.; Shi, D.; Halder, G.; Lalthazuala Rokhum, S. Microwave-assisted synthesis of glycerol carbonate by transesterification of glycerol using Mangifera indica peel calcined ash as catalyst. Fuel 2022, 330, 125511. [Google Scholar] [CrossRef]

- Rhithuparna, D.; Ghosh, N.; Khatoon, R.; Rokhum, S.L.; Halder, G. Evaluating the commercial potential of Cocos nucifera derived biochar catalyst in biodiesel synthesis from Kanuga oil: Optimization, kinetics, thermodynamics, and process cost analysis. Process Saf. Environ. Prot. 2024, 183, 859–874. [Google Scholar] [CrossRef]

- Adepoju, T.F.; Olatunbosun, B.E.; Olatunji, O.M.; Ibeh, M.A. Brette Pearl Spar Mable (BPSM): A potential recoverable catalyst as a renewable source of biodiesel from Thevetia peruviana seed oil for the benefit of sustainable development in West Africa. Energ. Sustain. Soc. 2018, 8, 23. [Google Scholar] [CrossRef]

- Eldiehy, K.S.H.; Gohain, M.; Daimary, N.; Borah, D.; Mandal, M.; Deka, D. Radish (Raphanus sativus L.) leaves: A novel source for a highly efficient heterogeneous base catalyst for biodiesel production using waste soybean cooking oil and Scenedesmus obliquus oil. Renew. Energy 2022, 191, 888–901. [Google Scholar] [CrossRef]

- Asuquo, A.J.; Zhang, X.; Lin, L.; Li, J. Green heterogeneous catalysts derived from fermented kola nut pod husk for sustainable biodiesel production. Int. J. Green Energy 2024, 21, 2218–2227. [Google Scholar] [CrossRef]

- Mulkan, A.; Zulkifli, N.W.M.; Husin, H.; Ahmadi; Dahlan, I.; Syafiie, S. Development of jackfruit (Artocarpus heterophyllus) peel waste as a new solid catalyst: Biodiesel synthesis, optimization and characterization. Process Saf. Environ. Prot. 2023, 177, 152–168. [Google Scholar] [CrossRef]

- Elendu, C.C.; Liu, C.; Aleem, R.D.; Shan, Y.; Cao, C.; Ramzan, N.; Duan, P.-G. Optimization and Deep Learning Modeling of the Yield and Properties of Baobab-Derived Biodiesel Catalyzed by Waste Banana Bunch Stalk Biochar. ACS Omega 2024, 9, 12941–12955. [Google Scholar] [CrossRef] [PubMed]

- Saetiao, P.; Kongrit, N.; Jitjamnong, J.; Direksilp, C.; Cheng, C.K.; Khantikulanon, N. Enhancing Sustainable Production of Fatty Acid Methyl Ester from Palm Oil Using Bio-Based Heterogeneous Catalyst: Process Simulation and Techno-Economic AnaK2CO3lysis. ACS Omega 2023, 8, 30598–30611. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Lv, P.; Yang, L.; Xing, S.; Luo, W.; Wang, Z. Biodiesel synthesis over biochar-based catalyst from biomass waste pomelo peel. Energy Convers. Manag. 2018, 160, 477–485. [Google Scholar] [CrossRef]

- Foroutan, R.; Mohammadi, R.; Razeghi, J.; Ramavandi, B. Biodiesel production from edible oils using algal biochar/CaO/ as a heterogeneous and recyclable catalyst. Renew. Energy 2021, 168, 1207–1216. [Google Scholar] [CrossRef]

- Haghighi, M.; Zare, L.B.; Ghiasi, M. Biodiesel production from Spirulina algae oil over [Cu(H2PDC)(H2O)2] complex using transesterification reaction: Experimental study and DFT approach. Chem. Eng. J. 2022, 430, 132777. [Google Scholar] [CrossRef]

- Amadine, O.; Essamlali, Y.; Fihri, A.; Larzek, M.; Zahouily, M. Effect of calcination temperature on the structure and catalytic performance of copper–ceria mixed oxide catalysts in phenol hydroxylation. RSC Adv. 2017, 7, 12586–12597. [Google Scholar] [CrossRef]

- Mawlid, O.A.; Abdelhady, H.H.; Abd El-Moghny, M.G.; Hamada, A.; Abdelnaby, F.; Kased, M.; Al-Bajouri, S.; Elbohy, R.A.; El-Deab, M.S. Clean approach for catalytic biodiesel production from waste frying oil utilizing K2CO3/Orange peel derived hydrochar via RSM Optimization. J. Clean. Prod. 2024, 442, 140947. [Google Scholar] [CrossRef]

- Sharma, M.; Khan, A.A.; Puri, S.K.; Tuli, D.K. Wood ash as a potential heterogeneous catalyst for biodiesel synthesis. Biomass Bioenergy 2012, 41, 94–106. [Google Scholar] [CrossRef]

- Betiku, E.; Etim, A.O.; Pereao, O.; Ojumu, T.V. Two-Step Conversion of Neem (Azadirachta indica) Seed Oil into Fatty Methyl Esters Using a Heterogeneous Biomass-Based Catalyst: An Example of Cocoa Pod Husk. Energy Fuels 2017, 31, 6182–6193. [Google Scholar] [CrossRef]

- Dehkhoda, A.M.; Ellis, N. Biochar-based catalyst for simultaneous reactions of esterification and transesterification. Catal. Today 2013, 207, 86–92. [Google Scholar] [CrossRef]

- Devaraj, K.; Veerasamy, M.; Aathika, S.; Mani, Y.; Thanarasu, A.; Dhanasekaran, A.; Subramanian, S. Study on effectiveness of activated calcium oxide in pilot plant biodiesel production. J. Clean. Prod. 2019, 225, 18–26. [Google Scholar] [CrossRef]

- Joshi, G.; Rawat, D.S.; Lamba, B.Y.; Bisht, K.K.; Kumar, P.; Kumar, N.; Kumar, S. Transesterification of Jatropha and Karanja oils by using waste egg shell derived calcium based mixed metal oxides. Energy Convers. Manag. 2015, 96, 258–267. [Google Scholar] [CrossRef]

- Kresge, C.T.; Leonowicz, M.E.; Roth, W.J.; Vartuli, J.C.; Beck, J.C. Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature 1992, 359, 710–712. [Google Scholar] [CrossRef]

- Al-Hamamre, Z. Biodiesel production from waste cooking oil using heterogeneous KNO3/Oil shale ash catalyst. Renew. Energy 2023, 211, 470–483. [Google Scholar] [CrossRef]

- Betiku, E.; Okeleye, A.A.; Ishola, N.B.; Osunleke, A.S.; Ojumu, T.V. Development of a Novel Mesoporous Biocatalyst Derived from Kola Nut Pod Husk for Conversion of Kariya Seed Oil to Methyl Esters: A Case of Synthesis, Modeling and Optimization Studies. Catal. Lett. 2019, 149, 1772–1787. [Google Scholar] [CrossRef]

- Naghipour, A.; Ghorbani-Choghamarani, A.; Taherinia, Z. Novel hybrid materials based on mesoporous Gamma-Alumina@ Riboflavin@ vanadium for biodiesel production. Fuel 2023, 334, 126674. [Google Scholar] [CrossRef]

- Wang, S. A novel peat biochar supported catalyst for the transesterification reaction. Energy Convers. Manag. 2017, 139, 89–96. [Google Scholar] [CrossRef]

- Nath, B.; Basumatary, B.; Wary, N.; Basumatary, U.R.; Basumatary, J.; Rokhum, S.L.; Azam, M.; Min, K.; Basumatary, S. Agricultural Waste-Based Heterogeneous Catalyst for the Production of Biodiesel: A Ranking Study via the VIKOR Method. Int. J. Energy Res. 2023, 2023, 1–23. [Google Scholar] [CrossRef]

- Abu-Ghazala, A.H.; Abdelhady, H.H.; Mazhar, A.A.; El-Deab, M.S. Exceptional room temperature catalytic transesterification of waste cooking oil to biodiesel using environmentally-benign K2CO3/γ-Al2O3 nano-catalyst. Chem. Eng. J. 2023, 474, 145784. [Google Scholar] [CrossRef]

- Lu, S.; Cui, W.; Wang, R.; Zhang, C.; Yan, P. Biomimetic mineralization and characterization of hierarchically structured hydrated magnesium carbonates: The effects of sodium alginate. J. CO2 Util. 2022, 56, 101848. [Google Scholar] [CrossRef]

- Lu, S.; Cui, W.; Zhang, C.; Yan, P. Controllable biomimetic mineralization and characterization of hydrated magnesium carbonates using sodium carboxymethyl cellulose. J. Cryst. Growth 2022, 589, 126693. [Google Scholar] [CrossRef]

- Abdelrahim, A.M.; Abd El-Moghny, M.G.; El-Shakre, M.E.; El-Deab, M.S. Robust electrolytic oxygen evolution at nanostructured NiFe LDH@ in-situ functionalized graphite felt. J. Alloys Compd. 2023, 967, 171771. [Google Scholar] [CrossRef]

- Kaur, N.; Ali, A. Biodiesel production via ethanolysis of jatropha oil using molybdenum impregnated calcium oxide as solid catalyst. RSC Adv. 2015, 5, 13285–13295. [Google Scholar] [CrossRef]

- Nath, B.; Das, B.; Kalita, P.; Basumatary, S. Waste to value addition: Utilization of waste Brassica nigra plant derived novel green heterogeneous base catalyst for effective synthesis of biodiesel. J. Clean. Prod. 2019, 239, 118112. [Google Scholar] [CrossRef]

- Gohain, M.; Devi, A.; Deka, D. Musa balbisiana Colla peel as highly effective renewable heterogeneous base catalyst for biodiesel production. Ind. Crops Prod. 2017, 109, 8–18. [Google Scholar] [CrossRef]

- Miladinović, M.R.; Zdujić, M.V.; Veljović, D.N.; Krstić, J.B.; Banković-Ilić, I.B.; Veljković, V.B.; Stamenković, O.S. Valorization of walnut shell ash as a catalyst for biodiesel production. Renew. Energy 2020, 147, 1033–1043. [Google Scholar] [CrossRef]

- Saeed, A.M.M.; Sharma, S.; Hassan, S.Z.; Ghaleb, A.M.; Cao, G.-P. Intensification and Optimization of FAME Synthesis via Acid-Catalyzed Esterification Using Central Composite Design (CCD). ACS Omega 2023, 8, 26206–26217. [Google Scholar] [CrossRef]

- Laskar, I.B.; Gupta, R.; Chatterjee, S.; Vanlalveni, C.; Rokhum, S.L. Taming waste: Waste Mangifera indica peel as a sustainable catalyst for biodiesel production at room temperature. Renew. Energy 2020, 161, 207–220. [Google Scholar] [CrossRef]

- Abu-Jrai, A.M.; Jamil, F.; Al-Muhtaseb, A.H.; Baawain, M.; Al-Haj, L.; Al-Hinai, M.; Al-Abri, M.; Rafiq, S. Valorization of waste Date pits biomass for biodiesel production in presence of green carbon catalyst. Energy Convers. Manag. 2017, 135, 236–243. [Google Scholar] [CrossRef]

- Dhawane, S.H.; Kumar, T.; Halder, G. Biodiesel synthesis from Hevea brasiliensis oil employing carbon supported heterogeneous catalyst: Optimization by Taguchi method. Renew. Energy 2016, 89, 506–514. [Google Scholar] [CrossRef]

- Buasri, A.; Ksapabutr, B.; Panapoy, M.; Chaiyut, N. Biodiesel production from waste cooking palm oil using calcium oxide supported on activated carbon as catalyst in a fixed bed reactor. Korean J. Chem. Eng. 2012, 29, 1708–1712. [Google Scholar] [CrossRef]

- Betiku, E.; Oraegbunam, J.C.; Falowo, O.A.; Ojumu, T.V.; Latinwo, L.M. Sustainable microwave-supported biodiesel production using sandbox oil and its waste shell as a nanoparticle green alkali heterogeneous catalyst. Process Biochem. 2024, 142, 1–12. [Google Scholar] [CrossRef]

- Fadara, O.A.; Falowo, O.A.; Ojumu, T.V.; Betiku, E. Process optimization of microwave irradiation-aided transesterification of kariya seed oil by Taguchi orthogonal array: Pawpaw trunk as a novel biocatalyst. Biofuels Bioprod. Biorefin. 2021, 15, 1006–1020. [Google Scholar] [CrossRef]

- Falowo, O.A.; Betiku, E. A novel heterogeneous catalyst synthesis from agrowastes mixture and application in transesterification of yellow oleander-rubber oil: Optimization by Taguchi approach. Fuel 2022, 312, 122999. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of Infrared Spectra, A Practical Approach. In Encyclopedia of Analytical Chemistry, 1st ed.; Meyers, R.A., Ed.; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar] [CrossRef]

- Basumatary, S.F.; Brahma, S.; Das, B.; Basumatary, S. A mixture of three agrowastes-K2CO3 as a solid catalyst for biodiesel synthesis from a binary blend of two non-edible oils. J. Indian Chem. Soc. 2024, 101, 101195. [Google Scholar] [CrossRef]

- Prajapati, P.; Shrivastava, S.; Sharma, V.; Srivastava, P.; Shankhwar, V.; Sharma, A.; Srivastava, S.; Agarwal, D. Karanja seed shell ash: A sustainable green heterogeneous catalyst for biodiesel production. Results Eng. 2023, 18, 101063. [Google Scholar] [CrossRef]

- Chutia, G.P.; Phukan, K. Jute leaves ash@Fe3O4 as efficient nanocatalyst for sustainable biodiesel production: Characterization, optimization and kinetic investigation. J. Ind. Eng. Chem. 2024, 131, 288–304. [Google Scholar] [CrossRef]

- ASTM D6751; Standard Specification for Biodiesel Fuel Blendstock(B100) for Middle Distillate Fuels. ASTM international: West Conshohocken, PA, USA, 2023.

- Ambat, I.; Srivastava, V.; Sillanpää, M. Recent advancement in biodiesel production methodologies using various feedstock: A review. Renew. Sustain. Energy Rev. 2018, 90, 356–369. [Google Scholar] [CrossRef]

- Jitjamnong, J.; Thunyaratchatanon, C.; Luengnaruemitchai, A.; Kongrit, N.; Kasetsomboon, N.; Sopajarn, A.; Chuaykarn, N.; Khantikulanon, N. Response surface optimization of biodiesel synthesis over a novel biochar-based heterogeneous catalyst from cultivated (Musa sapientum) banana peels. Biomass Conv. Bioref. 2021, 11, 2795–2811. [Google Scholar] [CrossRef]

- Bekele, D.T.; Shibeshi, N.T.; Reshad, A.S. Heterogeneous Catalysts from Metallic Oxides and Lignocellulosic Biomasses Ash for the Valorization of Feedstocks into Biodiesel: An Overview. Bioenerg. Res. 2023, 16, 1361–1379. [Google Scholar] [CrossRef]

- Alsaiari, R.A.; Musa, E.M.; Rizk, M.A. Biodiesel production from date seed oil using hydroxyapatite-derived catalyst from waste camel bone. Heliyon 2023, 9, e15606. [Google Scholar] [CrossRef] [PubMed]

| Sl no. | R.T. | Identified Compounds | Corresponding Acid | Total |

|---|---|---|---|---|

| 1 | 15.13 | Methyl palmitate | C17:0 | 4.33% |

| 2 | 17.19 | Methyl linoleate | C19:2 | 37.86% |

| 3 | 17.25 | Methyl oleate | C19:1 | 46.28% |

| 4 | 17.57 | Methyl stearate | C19:0 | 2.60% |

| 5 | 19.97 | Methyl cis-11-eicosenoate | C21:1 | 4.95% |

| 6 | 22.80 | Methyl cis-13-docosenoate | C23:1 | 3.99% |

| Properties | Unit | ASTM D6751 | This Study |

|---|---|---|---|

| Density | kg/m3 | 860–900 | 881 |

| Cold filter plugging point | °C | - | 2 |

| Flash point | °C | ≥93 | 175 |

| Sulfur content | mg/kg | - | 35.4 |

| Acid value | mg KOH/g | 0.5 max | 0.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Sheng, J.; Zhang, K.; Li, M.; Duan, R.; Li, Z.; Hao, Y.; Wang, X. Enhancing Sustainable Production of Biodiesel from Xanthoceras sorbifolia Bunge Oil Using Bio-Based Heterogeneous Catalyst. Catalysts 2024, 14, 753. https://doi.org/10.3390/catal14110753

Wang J, Sheng J, Zhang K, Li M, Duan R, Li Z, Hao Y, Wang X. Enhancing Sustainable Production of Biodiesel from Xanthoceras sorbifolia Bunge Oil Using Bio-Based Heterogeneous Catalyst. Catalysts. 2024; 14(11):753. https://doi.org/10.3390/catal14110753

Chicago/Turabian StyleWang, Jingwen, Jian Sheng, Kai Zhang, Mengyao Li, Rao Duan, Zexin Li, Yinan Hao, and Ximing Wang. 2024. "Enhancing Sustainable Production of Biodiesel from Xanthoceras sorbifolia Bunge Oil Using Bio-Based Heterogeneous Catalyst" Catalysts 14, no. 11: 753. https://doi.org/10.3390/catal14110753

APA StyleWang, J., Sheng, J., Zhang, K., Li, M., Duan, R., Li, Z., Hao, Y., & Wang, X. (2024). Enhancing Sustainable Production of Biodiesel from Xanthoceras sorbifolia Bunge Oil Using Bio-Based Heterogeneous Catalyst. Catalysts, 14(11), 753. https://doi.org/10.3390/catal14110753