Biodegradation of Different Types of Bioplastics through Composting—A Recent Trend in Green Recycling

Abstract

1. Introduction

2. Types of Bioplastics

2.1. Starch-Based Bioplastic

2.2. PLA-Based Bioplastic

2.3. PHAs-Based Bioplastic

2.4. Cellulose-Based Bioplastic

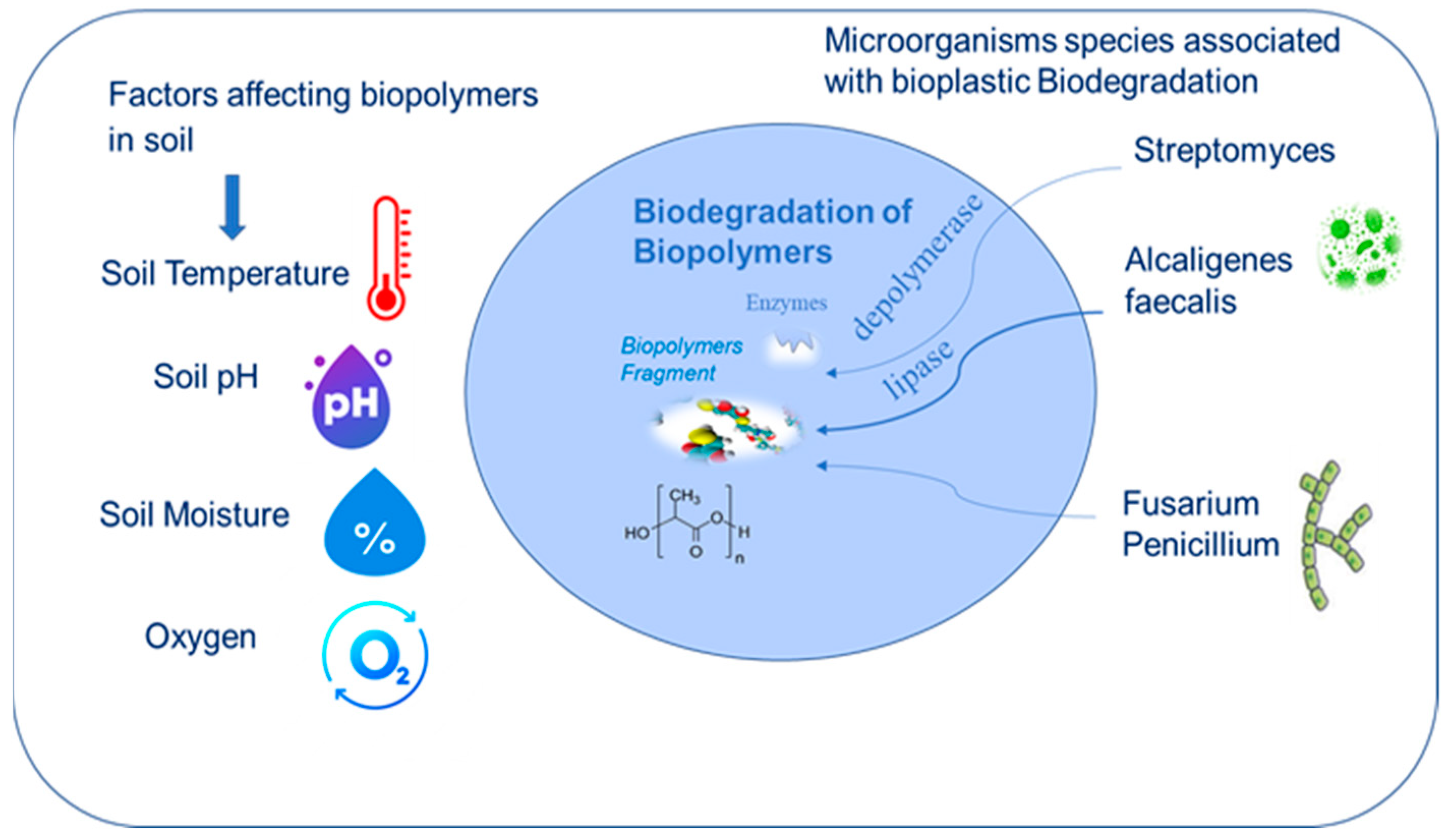

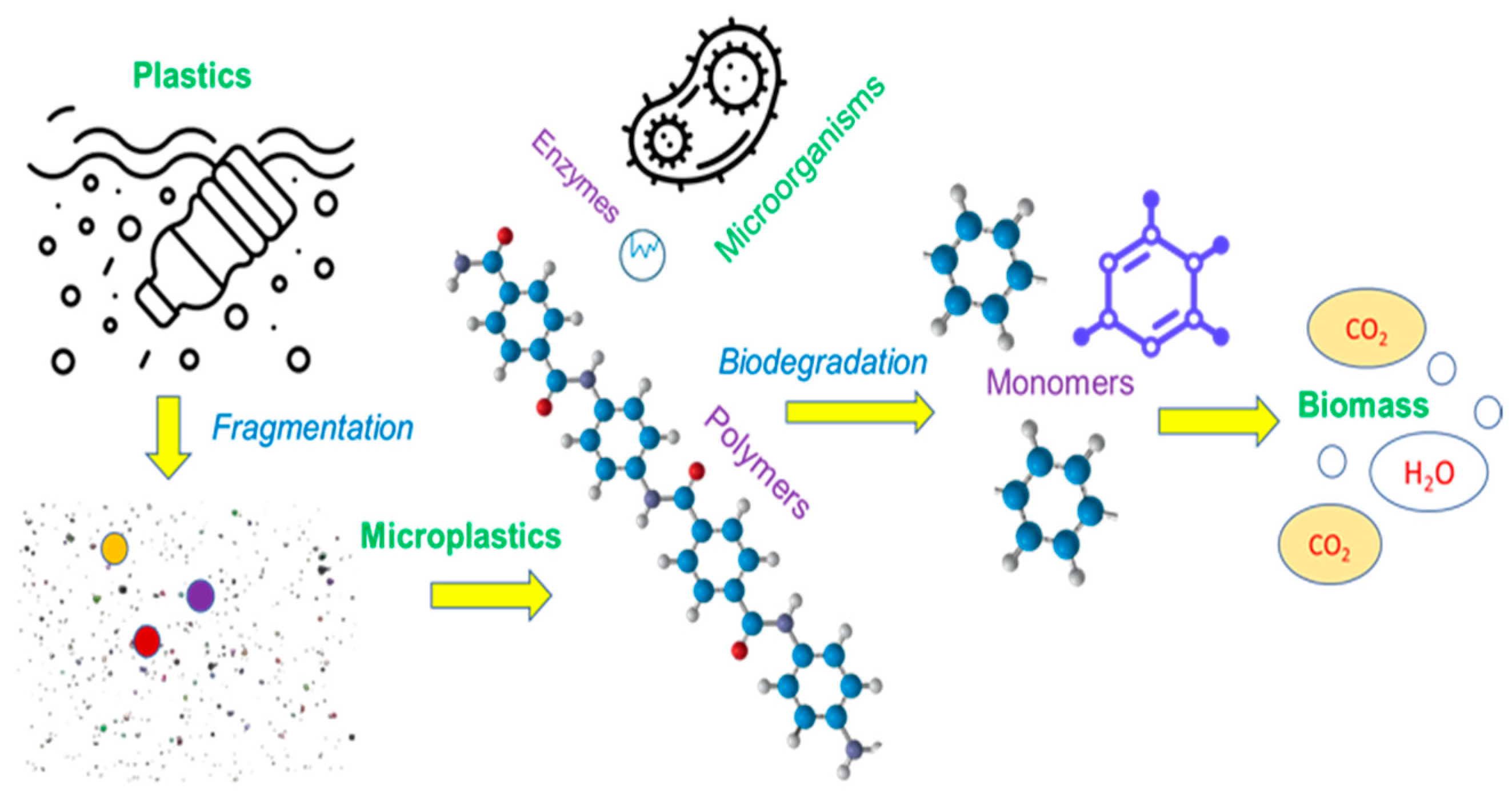

3. Biodegradation of Biopolymers in Soil and Aquatic Environments

Bioplastic Degradation in Soil

| Bioplastics | Environment | Temperature/Moisture/pH | Biodegradability | Days Taken for Biodegradation | References |

|---|---|---|---|---|---|

| Starch-based | Soil | 20 °C, 60% | 14.2% | 110 | [54] |

| Starch-based blends | Sea water | 25 °C | 1.5% | 90 | [65] |

| Starch/chitosan (35/65) | Soil | Soil burial test method | 96% | 28 | [66] |

| Starch-based | Sea water | Room temperature | 1.5% | 90 | [67] |

| PLA | Soil | 30% | 10% | 98 | [68] |

| PLA | Soil | 25 °C, 60% | 13.8% | 28 | [69] |

| PLA (powdered) | Soil | 25 °C, 60% | 13.8% | 28 | [66] |

| PLA | Sea water | 25 °C | 8.4% | 365 | [70] |

| PHA | Soil | 20 °C, 60% | 48.5% | 280 | [54] |

| PHA | Compost/Soil (10/90%) | 25 °C, 65% | 50% | 15 | [71] |

| PHA | Soil | 39% pH 6.8 | 75% | 80 | [72] |

| PHAs | Sea water | 25 °C | 8.5% | 365 | [73] |

| Cellulose | Soil | Undefined | 100% | 103 | [60] |

| Sponge fibers | Compost containing synthetic soil | Aerobic, 58 °C | >80% | 154 | [74] |

| Cellulose | Municipal solid waste | Room temperature | 44% | 14 | [75] |

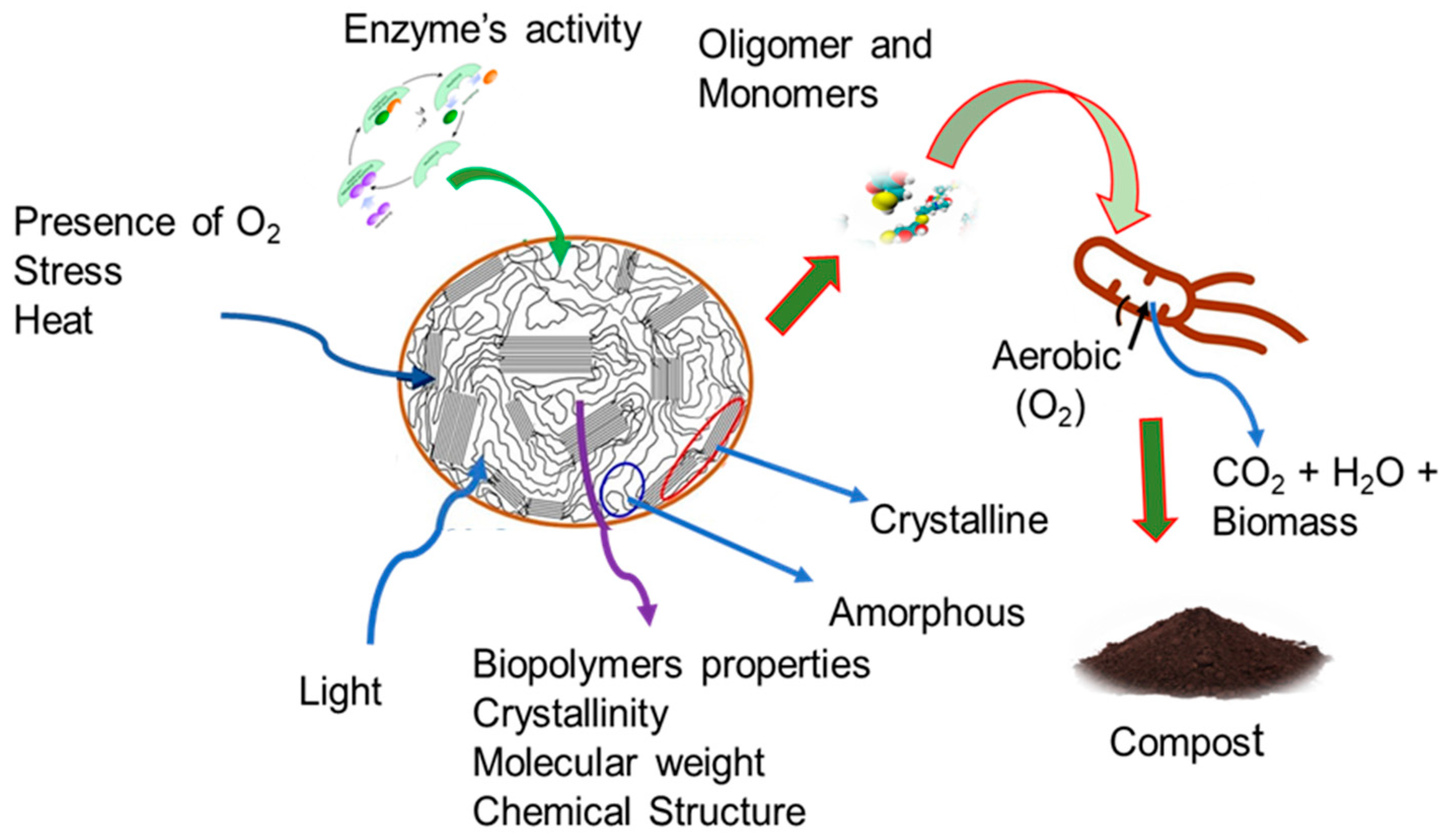

4. Biodegradation of Bioplastics in Compost

4.1. Degradation of PLA through Composting

4.2. Degradation of PHAs through Composting

4.3. Degradation of Starch-Based Bioplastic through Composting

4.4. Degradation of Cellulose-Based Bioplastic through Composting

| Bioplastics | Feedstock | Temperature/Moisture Contents | Biodegradability in Percentage | Composting Time Frame (Days) | References |

|---|---|---|---|---|---|

| Starch-based (potato almidon) | Compost | Aerobic, 58 °C | 85% | 90 | [107] |

| Plastarch | Compost | Aerobic, 55 °C, 60% | 50% | 85 | [54] |

| Starch-based blends | Compost/Food waste | 45–65 °C | 60% | 90 | [108] |

| PLA | Compost | 58 °C, 60% | 60% | 30 | [109] |

| PLA +Clay film | Compost | Aerobic, 58 °C, 55% | 34% | 130 | [110] |

| PLA | Compost | 65 °C, pH = 8.5, 63% | 84% | 58 | [111] |

| PHA-based | Compost | 55 °C, 70% | 80% | 28 | [112] |

| PHAs blends | Compost/Cow manure | 50 °C | 30% | 60 | [113] |

| Cellulose-based | Compost containing synthetic material | Aerobic, 58 °C | >80% | 154 | [74] |

| Sponge cloth (Cellulose-based) | Compost | Aerobic, 58 °C | 80% | 154 | [74] |

| Nylon4 (polyamides, bio-based) | Composted soil | 25 °C, pH 7.5–7.6, 80% | 100% | 120 | [61] |

5. Current Gaps and Future Research Directions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Polman, E.M.; Gruter, G.-J.M.; Parsons, J.R.; Tietema, A. Comparison of the aerobic biodegradation of biopolymers and the corresponding bioplastics: A review. Sci. Total Environ. 2021, 753, 141953. [Google Scholar] [CrossRef] [PubMed]

- Koch, D.; Mihalyi, B. Assessing the change in environmental impact categories when replacing conventional plastic with bioplastic in chosen application fields. Chem. Eng. Trans. 2018, 70, 853–858. [Google Scholar]

- Huang, J.; Veksha, A.; Chan, W.P.; Giannis, A.; Lisak, G. Chemical recycling of plastic waste for sustainable material management: A prospective review on catalysts and processes. Renew. Sustain. Energy Rev. 2022, 154, 111866. [Google Scholar] [CrossRef]

- Mellinas, C.; Valdés, A.; Ramos, M.; Burgos, N.; Garrigos, M.d.C.; Jiménez, A. Active edible films: Current state and future trends. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Mekonnen, T.; Mussone, P.; Khalil, H.; Bressler, D. Progress in bio-based plastics and plasticizing modifications. J. Mater. Chem. A 2013, 1, 13379–13398. [Google Scholar] [CrossRef]

- Suman, T.Y.; Li, W.-G.; Alif, S.; Faris, V.R.P.; Amarnath, D.J.; Ma, J.-G.; Pei, D.-S. Characterization of petroleum-based plastics and their absorbed trace metals from the sediments of the Marina Beach in Chennai, India. Environ. Sci. Eur. 2020, 32, 110. [Google Scholar] [CrossRef]

- Chae, Y.; An, Y.-J. Current research trends on plastic pollution and ecological impacts on the soil ecosystem: A review. Environ. Pollut. 2018, 240, 387–395. [Google Scholar] [CrossRef]

- Burgos, N.; Valdés, A.; Jiménez, A. Valorization of agricultural wastes for the production of protein-based biopolymers. J. Renew. Mater. 2016, 4, 165–177. [Google Scholar] [CrossRef]

- Ali, S.S.; Elsamahy, T.; Abdelkarim, E.A.; Al-Tohamy, R.; Kornaros, M.; Ruiz, H.A.; Zhao, T.; Li, F.; Sun, J. Biowastes for biodegradable bioplastics production and end-of-life scenarios in circular bioeconomy and biorefinery concept. Bioresour. Technol. 2022, 363, 127869. [Google Scholar] [CrossRef]

- Yasin, N.M.; Akkermans, S.; Van Impe, J.F. Enhancing the biodegradation of (bio) plastic through pretreatments: A critical review. Waste Manag. 2022, 150, 1–12. [Google Scholar] [CrossRef]

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.-A.T. Environmental impact of bioplastic use: A review. Heliyon 2021, 7, e07918. [Google Scholar] [CrossRef] [PubMed]

- Garrison, T.F.; Murawski, A.; Quirino, R.L. Bio-based polymers with potential for biodegradability. Polymers 2016, 8, 262. [Google Scholar] [CrossRef] [PubMed]

- Wicaksono, J.A.; Purwadaria, T.; Yulandi, A.; Tan, W.A. Bacterial dynamics during the burial of starch-based bioplastic and oxo-low-density-polyethylene in compost soil. BMC Microbiol. 2022, 22, 309. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.; Chaudhary, J.; Sharma, B.; Verma, A.; Tamulevicius, S.; Thakur, V.K. Sustainability of bioplastics: Opportunities and challenges. Curr. Opin. Green Sustain. Chem. 2018, 13, 68–75. [Google Scholar] [CrossRef]

- Endres, H.-J. Bioplastics. In Biorefineries; Springer: Cham, Switzerland, 2017; pp. 427–468. [Google Scholar]

- Cucina, M.; de Nisi, P.; Tambone, F.; Adani, F. The role of waste management in reducing bioplastics’ leakage into the environment: A review. Bioresour. Technol. 2021, 337, 125459. [Google Scholar] [CrossRef]

- Sánchez, Ó.J.; Ospina, D.A.; Montoya, S. Compost supplementation with nutrients and microorganisms in composting process. Waste Manag. 2017, 69, 136–153. [Google Scholar] [CrossRef]

- Tiquia, S. Evolution of extracellular enzyme activities during manure composting. J. Appl. Microbiol. 2002, 92, 764–775. [Google Scholar] [CrossRef]

- Báreková, A.; Demovičová, M.; Tátošová, L.; Danišová, L.; Medlenová, E.; Hlaváčiková, S. Decomposition of Single-Use Products Made of Bioplastic under Real Conditions of Urban Composting Facility. J. Ecol. Eng. 2021, 22, 265–272. [Google Scholar] [CrossRef]

- Tran, H.-T.; Lin, C.; Bui, X.-T.; Ngo, H.-H.; Cheruiyot, N.K.; Hoang, H.-G.; Vu, C.-T. Aerobic composting remediation of petroleum hydrocarbon-contaminated soil. Current and future perspectives. Sci. Total Environ. 2021, 753, 142250. [Google Scholar] [CrossRef]

- Megías-Sayago, C.; Navarro-Jaén, S.; Drault, F.; Ivanova, S. Recent Advances in the Brønsted/Lewis Acid Catalyzed Conversion of Glucose to HMF and Lactic Acid: Pathways toward Bio-Based Plastics. Catalysts 2021, 11, 1395. [Google Scholar] [CrossRef]

- de Freitas Batista, G.; Roman, F.F.; de Tuesta, J.L.D.; Mambrini, R.V.; Praça, P.; Gomes, H.T. Assessment of pretreatments for highly concentrated leachate waters to enhance the performance of catalytic wet peroxide oxidation with sustainable low-cost catalysts. Catalysts 2022, 12, 238. [Google Scholar] [CrossRef]

- Diaz de Tuesta, J.L.; Pantuzza, G.F.; Silva, A.M.T.; Praça, P.; Faria, J.L.; Gomes, H.T. Catalysts prepared with matured compost derived from mechanical-biological treatment plants for the wet peroxide oxidation of pollutants with different lipophilicity. Catalysts 2020, 10, 1243. [Google Scholar] [CrossRef]

- Zainudin, M.H.M.; Zulkarnain, A.; Azmi, A.S.; Muniandy, S.; Sakai, K.; Shirai, Y.; Hassan, M.A. Enhancement of agro-industrial waste composting process via the microbial inoculation: A brief review. Agronomy 2022, 12, 198. [Google Scholar] [CrossRef]

- Sikorska, W.; Musiol, M.; Nowak, B.; Pajak, J.; Labuzek, S.; Kowalczuk, M.; Adamus, G. Degradability of polylactide and its blend with poly [(R, S)-3-hydroxybutyrate] in industrial composting and compost extract. Int. Biodeterior. Biodegrad. 2015, 101, 32–41. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N. Environmental performance comparison of bioplastics and petrochemical plastics: A review of life cycle assessment (LCA) methodological decisions. Resour. Conserv. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Lucas, N.; Bienaime, C.; Belloy, C.; Queneudec, M.; Silvestre, F.; Nava-Saucedo, J.-E. Polymer biodegradation: Mechanisms and estimation techniques—A review. Chemosphere 2008, 73, 429–442. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly (lactic acid)(PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef]

- Kaur, H.; Banipal, T.S.; Thakur, S.; Bakshi, M.S.; Kaur, G.; Singh, N. Novel biodegradable films with extraordinary tensile strength and flexibility provided by nanoparticles. ACS Sustain. Chem. Eng. 2013, 1, 127–136. [Google Scholar] [CrossRef]

- Song, X.; Bian, Z.; Hui, Y.; Wang, H.; Liu, F.; Yu, S. Zn-Acetate-Containing ionic liquid as highly active catalyst for fast and mild methanolysis of Poly (lactic acid). Polym. Degrad. Stab. 2019, 168, 108937. [Google Scholar] [CrossRef]

- Itävaara, M.; Karjomaa, S.; Selin, J.-F. Biodegradation of polylactide in aerobic and anaerobic thermophilic conditions. Chemosphere 2002, 46, 879–885. [Google Scholar] [CrossRef] [PubMed]

- Devahasdin, S.; Fan Jr, C.; Li, K.; Chen, D.H. TiO2 photocatalytic oxidation of nitric oxide: Transient behavior and reaction kinetics. J. Photochem. Photobiol. A Chem. 2003, 156, 161–170. [Google Scholar] [CrossRef]

- Degli-Innocenti, F.; Tosin, M.; Bastioli, C. Evaluation of the biodegradation of starch and cellulose under controlled composting conditions. J. Environ. Polym. Degrad. 1998, 6, 197–202. [Google Scholar] [CrossRef]

- Agarwal, S.; Singhal, S.; Godiya, C.B.; Kumar, S. Prospects and Applications of Starch based Biopolymers. Int. J. Environ. Anal. Chem. 2021. [Google Scholar] [CrossRef]

- Hernandez-Carmona, F.; Morales-Matos, Y.; Lambis-Miranda, H.; Pasqualino, J. Starch extraction potential from plantain peel wastes. J. Environ. Chem. Eng. 2017, 5, 4980–4985. [Google Scholar] [CrossRef]

- Dang, K.M.; Yoksan, R. Development of thermoplastic starch blown film by incorporating plasticized chitosan. Carbohydr. Polym. 2015, 115, 575–581. [Google Scholar] [CrossRef]

- Helanto, K.E.; Matikainen, L.; Talja, R.; Rojas, O.J. Bio-based polymers for sustainable packaging and biobarriers: A critical review. BioResources 2019, 14, 4902–4951. [Google Scholar]

- Giordano, G. Making Packaging Pop: Film Packaging Gets Personal: Film packaging must now do double duty, protecting perishables and catching the attention of busy consumers. Plast. Eng. 2018, 74, 38–42. [Google Scholar] [CrossRef]

- Jiménez-Rosado, M.; Zarate-Ramírez, L.; Romero, A.; Bengoechea, C.; Partal, P.; Guerrero, A. Bioplastics based on wheat gluten processed by extrusion. J. Clean. Prod. 2019, 239, 117994. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly (lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef]

- Geueke, B. Dossier—Bioplastics as Food Contact Materials; Food Packaging Forum: Zurich, Switzerland, 2014. [Google Scholar]

- Kim, G.M.; Chang, W.-S.; Kim, Y.-K. Biocomposites Using Whole or Valuable Component-Extracted Microalgae Blended with Polymers: A Review. Catalysts 2021, 12, 25. [Google Scholar] [CrossRef]

- Dietrich, K.; Dumont, M.-J.; Del Rio, L.F.; Orsat, V. Sustainable PHA production in integrated lignocellulose biorefineries. New Biotechnol. 2019, 49, 161–168. [Google Scholar] [CrossRef]

- Mal, N.; Satpati, G.; Raghunathan, S.; Davoodbasha, M. Current strategies on algae-based biopolymer production and scale-up. Chemosphere 2022, 289, 133178. [Google Scholar] [CrossRef] [PubMed]

- Peelman, N.; Ragaert, P.; De Meulenaer, B.; Adons, D.; Peeters, R.; Cardon, L.; Van Impe, F.; Devlieghere, F. Application of bioplastics for food packaging. Trends Food Sci. Technol. 2013, 32, 128–141. [Google Scholar] [CrossRef]

- Asgher, M.; Arshad, S.; Qamar, S.A.; Khalid, N. Improved biosurfactant production from Aspergillus niger through chemical mutagenesis: Characterization and RSM optimization. SN Appl. Sci. 2020, 2, 1–11. [Google Scholar] [CrossRef]

- Imam, S.; Gordon, S.; Shogren, R.; Tosteson, T.; Govind, N.; Greene, R. Degradation of starch–poly (β-hydroxybutyrate-co-β-hydroxyvalerate) bioplastic in tropical coastal waters. Appl. Environ. Microbiol. 1999, 65, 431–437. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Tajeddin, B. Cellulose-based polymers for packaging applications. Lignocellul. Polym. Compos. 2014, 477–498. [Google Scholar] [CrossRef]

- Qasim, U.; Osman, A.I.; Al-Muhtaseb, A.a.H.; Farrell, C.; Al-Abri, M.; Ali, M.; Vo, D.-V.N.; Jamil, F.; Rooney, D.W. Renewable cellulosic nanocomposites for food packaging to avoid fossil fuel plastic pollution: A review. Environ. Chem. Lett. 2021, 19, 613–641. [Google Scholar] [CrossRef]

- Okolie, J.A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Chemistry and specialty industrial applications of lignocellulosic biomass. Waste Biomass Valorization 2021, 12, 2145–2169. [Google Scholar] [CrossRef]

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Gómez, E.F.; Michel, F.C., Jr. Biodegradability of conventional and bio-based plastics and natural fiber composites during composting, anaerobic digestion and long-term soil incubation. Polym. Degrad. Stab. 2013, 98, 2583–2591. [Google Scholar] [CrossRef]

- Volova, T.; Boyandin, A.; Vasiliev, A.; Karpov, V.; Prudnikova, S.; Mishukova, O.; Boyarskikh, U.; Filipenko, M.; Rudnev, V.; Xuân, B.B. Biodegradation of polyhydroxyalkanoates (PHAs) in tropical coastal waters and identification of PHA-degrading bacteria. Polym. Degrad. Stab. 2010, 95, 2350–2359. [Google Scholar] [CrossRef]

- Maran, J.P.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Degradation behavior of biocomposites based on cassava starch buried under indoor soil conditions. Carbohydr. Polym. 2014, 101, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Rudnik, E.; Briassoulis, D. Degradation behaviour of poly (lactic acid) films and fibres in soil under Mediterranean field conditions and laboratory simulations testing. Ind. Crops Prod. 2011, 33, 648–658. [Google Scholar] [CrossRef]

- Kale, G.; Kijchavengkul, T.; Auras, R.; Rubino, M.; Selke, S.E.; Singh, S.P. Compostability of bioplastic packaging materials: An overview. Macromol. Biosci. 2007, 7, 255–277. [Google Scholar] [CrossRef]

- Kawashima, N.; Yagi, T.; Kojima, K. How Do Bioplastics and Fossil-Based Plastics Play in a Circular Economy? Macromol. Mater. Eng. 2019, 304, 1900383. [Google Scholar] [CrossRef]

- Bilo, F.; Pandini, S.; Sartore, L.; Depero, L.E.; Gargiulo, G.; Bonassi, A.; Federici, S.; Bontempi, E. A sustainable bioplastic obtained from rice straw. J. Clean. Prod. 2018, 200, 357–368. [Google Scholar] [CrossRef]

- Hashimoto, K.; Sudo, M.; Ohta, K.; Sugimura, T.; Yamada, H.; Aoki, T. Biodegradation of nylon4 and its blend with nylon6. J. Appl. Polym. Sci. 2002, 86, 2307–2311. [Google Scholar] [CrossRef]

- Kalita, N.K.; Hazarika, D.; Kalamdhad, A.; Katiyar, V. Biodegradation of biopolymeric composites and blends under different environmental conditions: Approach towards end-of-life panacea for crop sustainability. Bioresour. Technol. Rep. 2021, 15, 100705. [Google Scholar] [CrossRef]

- Setti, L.; Francia, E.; Pulvirenti, A.; De Leo, R.; Martinelli, S.; Maistrello, L.; Macavei, L.I.; Montorsi, M.; Barbi, S.; Ronga, D. Bioplastic film from black soldier fly prepupae proteins used as mulch: Preliminary results. Agronomy 2020, 10, 933. [Google Scholar] [CrossRef]

- Ong, S.Y.; Sudesh, K. Effects of polyhydroxyalkanoate degradation on soil microbial community. Polym. Degrad. Stab. 2016, 131, 9–19. [Google Scholar] [CrossRef]

- Accinelli, C.; Saccà, M.L.; Mencarelli, M.; Vicari, A. Deterioration of bioplastic carrier bags in the environment and assessment of a new recycling alternative. Chemosphere 2012, 89, 136–143. [Google Scholar] [CrossRef]

- Jangong, O.; Gareso, P.; Mutmainna, I.; Tahir, D. Fabrication and characterization starch/chitosan reinforced polypropylene as biodegradable. J. Phys. Conf. Ser. 2019, 1341, 082022. [Google Scholar] [CrossRef]

- Tosin, M.; Weber, M.; Siotto, M.; Lott, C.; Degli Innocenti, F. Laboratory test methods to determine the degradation of plastics in marine environmental conditions. Front. Microbiol. 2012, 3, 225. [Google Scholar] [CrossRef]

- Wu, C.S. Preparation, characterization, and biodegradability of renewable resource-based composites from recycled polylactide bioplastic and sisal fibers. J. Appl. Polym. Sci. 2012, 123, 347–355. [Google Scholar] [CrossRef]

- Adhikari, D.; Mukai, M.; Kubota, K.; Kai, T.; Kaneko, N.; Araki, K.S.; Kubo, M. Degradation of bioplastics in soil and their degradation effects on environmental microorganisms. J. Agric. Chem. Environ. 2016, 5, 23. [Google Scholar] [CrossRef]

- Greene, J. Marine Biodegradation of PLA, PHA, and Bio-Additive Polyethylene Based on ASTM D7081; ACADEMIA: San Francisco, CA, USA, 2012. [Google Scholar]

- Arcos-Hernandez, M.V.; Laycock, B.; Pratt, S.; Donose, B.C.; Nikolić, M.A.; Luckman, P.; Werker, A.; Lant, P.A. Biodegradation in a soil environment of activated sludge derived polyhydroxyalkanoate (PHBV). Polym. Degrad. Stab. 2012, 97, 2301–2312. [Google Scholar] [CrossRef]

- Pérez-Arauz, A.; Aguilar-Rabiela, A.; Vargas-Torres, A.; Rodríguez-Hernández, A.-I.; Chavarría-Hernández, N.; Vergara-Porras, B.; López-Cuellar, M. Production and characterization of biodegradable films of a novel polyhydroxyalkanoate (PHA) synthesized from peanut oil. Food Packag. Shelf Life 2019, 20, 100297. [Google Scholar] [CrossRef]

- Bagheri, A.R.; Laforsch, C.; Greiner, A.; Agarwal, S. Fate of so-called biodegradable polymers in seawater and freshwater. Glob. Chall. 2017, 1, 1700048. [Google Scholar] [CrossRef]

- Vaverková, M.D.; Adamcová, D. Biodegrability of bioplastic materials in a controlled composting environment. J. Ecol. Eng. 2015, 16. [Google Scholar] [CrossRef]

- Mostafa, N.; Farag, A.A.; Abo-dief, H.M.; Tayeb, A.M. Production of biodegradable plastic from agricultural wastes. Arab. J. Chem. 2018, 11, 546–553. [Google Scholar] [CrossRef]

- Volova, T.; Gladyshev, M.; Trusova, M.Y.; Zhila, N. Degradation of polyhydroxyalkanoates in eutrophic reservoir. Polym. Degrad. Stab. 2007, 92, 580–586. [Google Scholar] [CrossRef]

- Wei, Y.; Wei, Z.; Zhang, F.; Li, X.; Tan, W.; Xi, B. Role of humic acid chemical structure derived from different biomass feedstocks on Fe (III) bioreduction activity: Implication for sustainable use of bioresources. Catalysts 2019, 9, 450. [Google Scholar] [CrossRef]

- Giangeri, G.; Morlino, M.S.; De Bernardini, N.; Ji, M.; Bosaro, M.; Pirillo, V.; Antoniali, P.; Molla, G.; Raga, R.; Treu, L. Preliminary investigation of microorganisms potentially involved in microplastics degradation using an integrated metagenomic and biochemical approach. Sci. Total Environ. 2022, 843, 157017. [Google Scholar] [CrossRef]

- Kim, D.-W.; Ahn, J.-H.; Cha, C.-J. Biodegradation of plastics: Mining of plastic-degrading microorganisms and enzymes using metagenomics approaches. J. Microbiol. 2022, 60, 969–976. [Google Scholar] [CrossRef]

- 6400-04; Standard Specification for Compostable Plastics. ASTM International: West Conshohocken, PA, USA, 2004.

- Kolstad, J.J.; Vink, E.T.; De Wilde, B.; Debeer, L. Assessment of anaerobic degradation of Ingeo™ polylactides under accelerated landfill conditions. Polym. Degrad. Stab. 2012, 97, 1131–1141. [Google Scholar] [CrossRef]

- Albertsson, A.-C.; Hakkarainen, M. Designed to degrade. Science 2017, 358, 872–873. [Google Scholar] [CrossRef]

- Vink, E.T.; Rábago, K.R.; Glassner, D.A.; Springs, B.; O’Connor, R.P.; Kolstad, J.; Gruber, P.R. The sustainability of NatureWorks™ polylactide polymers and Ingeo™ polylactide fibers: An update of the future. Macromol. Biosci. 2004, 4, 551–564. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of polyesters. J. Polym. Environ. 2007, 15, 259–267. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iniguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly (lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Hajighasemi, M.; Nocek, B.P.; Tchigvintsev, A.; Brown, G.; Flick, R.; Xu, X.; Cui, H.; Hai, T.; Joachimiak, A.; Golyshin, P.N. Biochemical and structural insights into enzymatic depolymerization of polylactic acid and other polyesters by microbial carboxylesterases. Biomacromolecules 2016, 17, 2027–2039. [Google Scholar] [CrossRef] [PubMed]

- Kawai, F. Polylactic acid (PLA)-degrading microorganisms and PLA depolymerases. In Green Polymer Chemistry: Biocatalysis and Biomaterials; ACS Publications: Washington, DC, USA, 2010; pp. 405–414. [Google Scholar]

- Bandini, F.; Misci, C.; Taskin, E.; Cocconcelli, P.S.; Puglisi, E. Biopolymers modulate microbial communities in municipal organic waste digestion. FEMS Microbiol. Ecol. 2020, 96, fiaa183. [Google Scholar] [CrossRef] [PubMed]

- Mohanan, N.; Montazer, Z.; Sharma, P.K.; Levin, D.B. Microbial and enzymatic degradation of synthetic plastics. Front. Microbiol. 2020, 11, 580709. [Google Scholar] [CrossRef] [PubMed]

- Ghorpade, V.M.; Gennadios, A.; Hanna, M.A. Laboratory composting of extruded poly (lactic acid) sheets. Bioresour. Technol. 2001, 76, 57–61. [Google Scholar] [CrossRef] [PubMed]

- Chidambarampadmavathy, K.; Karthikeyan, O.P.; Heimann, K. Sustainable bio-plastic production through landfill methane recycling. Renew. Sustain. Energy Rev. 2017, 71, 555–562. [Google Scholar] [CrossRef]

- Ho, K.-L.G.; Pometto, A.L.; Hinz, P.N. Effects of temperature and relative humidity on polylactic acid plastic degradation. J. Environ. Polym. Degrad. 1999, 7, 83–92. [Google Scholar] [CrossRef]

- Nandakumar, A.; Chuah, J.-A.; Sudesh, K. Bioplastics: A boon or bane? Renew. Sustain. Energy Rev. 2021, 147, 111237. [Google Scholar] [CrossRef]

- Gioia, C.; Giacobazzi, G.; Vannini, M.; Totaro, G.; Sisti, L.; Colonna, M.; Marchese, P.; Celli, A. End of life of biodegradable plastics: Composting versus Re/upcycling. ChemSusChem 2021, 14, 4167–4175. [Google Scholar] [CrossRef]

- Mergaert, J.; Anderson, C.; Wouters, A.; Swings, J.; Kersters, K. Biodegradation of polyhydroxyalkanoates. FEMS Microbiol. Rev. 1992, 9, 317–321. [Google Scholar] [CrossRef]

- Volova, T.; Boyandin, A.; Vasil’ev, A.; Karpov, V.; Kozhevnikov, I.; Prudnikova, S.; Rudnev, V.; Xuån, B.B.; Dũng, V.V.; Gitel’Zon, I. Biodegradation of polyhydroxyalkanoates (PHAs) in the South China Sea and identification of PHA-degrading bacteria. Microbiology 2011, 80, 252–260. [Google Scholar] [CrossRef]

- Gunning, M.A.; Geever, L.M.; Killion, J.A.; Lyons, J.G.; Higginbotham, C.L. Mechanical and biodegradation performance of short natural fibre polyhydroxybutyrate composites. Polym. Test. 2013, 32, 1603–1611. [Google Scholar] [CrossRef]

- Wang, S.; Lydon, K.A.; White, E.M.; Grubbs III, J.B.; Lipp, E.K.; Locklin, J.; Jambeck, J.R. Biodegradation of poly (3-hydroxybutyrate-co-3-hydroxyhexanoate) plastic under anaerobic sludge and aerobic seawater conditions: Gas evolution and microbial diversity. Environ. Sci. Technol. 2018, 52, 5700–5709. [Google Scholar] [CrossRef] [PubMed]

- Nafchi, A.M.; Moradpour, M.; Saeidi, M.A.A.K. Thermoplsatic Starches: Properties, Challenges and Prospects; Islamic Azad University: Tehran, Iran; Food Biopolymer Research Group, University Sains Malaysia: George Town, Malaysia, 2013. [Google Scholar]

- Tang, X.; Alavi, S. Recent advances in starch, polyvinyl alcohol based polymer blends, nanocomposites and their biodegradability. Carbohydr. Polym. 2011, 85, 7–16. [Google Scholar] [CrossRef]

- Torres, F.; Troncoso, O.; Torres, C.; Díaz, D.; Amaya, E. Biodegradability and mechanical properties of starch films from Andean crops. Int. J. Biol. Macromol. 2011, 48, 603–606. [Google Scholar] [CrossRef]

- Czaja-Jagielska, N.; Melski, K. Biodegradation of starch-based films in conditions of nonindustrial composting. Pol. J. Environ. Stud. 2013, 22, 1039. [Google Scholar]

- Hillis, D.M.; Heller, H.C.; Hacker, S.D.; Hall, D.W.; Laskowski, M.J.; Sadava, D.E. Life: The Science of Biology; Macmillan Higher Education: New York, NY, USA, 2020. [Google Scholar]

- Vikman, M.; Vartiainen, J.; Tsitko, I.; Korhonen, P. Biodegradability and compostability of nanofibrillar cellulose-based products. J. Polym. Environ. 2015, 23, 206–215. [Google Scholar] [CrossRef]

- Amin, M.R.; Chowdhury, M.A.; Kowser, M.A. Characterization and performance analysis of composite bioplastics synthesized using titanium dioxide nanoparticles with corn starch. Heliyon 2019, 5, e02009. [Google Scholar] [CrossRef]

- Goto, T.; Kishita, M.; Sun, Y.; Sako, T.; Okajima, I. Degradation of polylactic acid using sub-critical water for compost. Polymers 2020, 12, 2434. [Google Scholar] [CrossRef]

- Javierre, C.; Sarasa, J.; Claveria, I.; Fernandez, A. Study of the biodisintegration on a painted bioplastic material waste. Mater. Plast. 2015, 52, 116–121. [Google Scholar]

- Cafiero, L.M.; Canditelli, M.; Musmeci, F.; Sagnotti, G.; Tuffi, R. Assessment of disintegration of compostable bioplastic bags by management of electromechanical and static home composters. Sustainability 2020, 13, 263. [Google Scholar] [CrossRef]

- Mihai, M.; Legros, N.; Alemdar, A. Formulation-properties versatility of wood fiber biocomposites based on polylactide and polylactide/thermoplastic starch blends. Polym. Eng. Sci. 2014, 54, 1325–1340. [Google Scholar] [CrossRef]

- Balaguer, M.P.; Aliaga, C.; Fito, C.; Hortal, M. Compostability assessment of nano-reinforced poly (lactic acid) films. Waste Manag. 2016, 48, 143–155. [Google Scholar] [CrossRef] [PubMed]

- Kale, G.; Auras, R.; Singh, S.P.; Narayan, R. Biodegradability of polylactide bottles in real and simulated composting conditions. Polym. Test. 2007, 26, 1049–1061. [Google Scholar] [CrossRef]

- Tabasi, R.Y.; Ajji, A. Selective degradation of biodegradable blends in simulated laboratory composting. Polym. Degrad. Stab. 2015, 120, 435–442. [Google Scholar] [CrossRef]

- Sun, Y.; Ren, X.; Rene, E.R.; Wang, Z.; Zhou, L.; Zhang, Z.; Wang, Q. The degradation performance of different microplastics and their effect on microbial community during composting process. Bioresour. Technol. 2021, 332, 125133. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahsan, W.A.; Hussain, A.; Lin, C.; Nguyen, M.K. Biodegradation of Different Types of Bioplastics through Composting—A Recent Trend in Green Recycling. Catalysts 2023, 13, 294. https://doi.org/10.3390/catal13020294

Ahsan WA, Hussain A, Lin C, Nguyen MK. Biodegradation of Different Types of Bioplastics through Composting—A Recent Trend in Green Recycling. Catalysts. 2023; 13(2):294. https://doi.org/10.3390/catal13020294

Chicago/Turabian StyleAhsan, Wazir Aitizaz, Adnan Hussain, Chitsan Lin, and Minh Ky Nguyen. 2023. "Biodegradation of Different Types of Bioplastics through Composting—A Recent Trend in Green Recycling" Catalysts 13, no. 2: 294. https://doi.org/10.3390/catal13020294

APA StyleAhsan, W. A., Hussain, A., Lin, C., & Nguyen, M. K. (2023). Biodegradation of Different Types of Bioplastics through Composting—A Recent Trend in Green Recycling. Catalysts, 13(2), 294. https://doi.org/10.3390/catal13020294