Plasma Jet Sputtering as an Efficient Method for the Deposition of Nickel and Cobalt Mixed Oxides on Stainless-Steel Meshes: Application to VOC Oxidation

Abstract

1. Introduction

2. Results

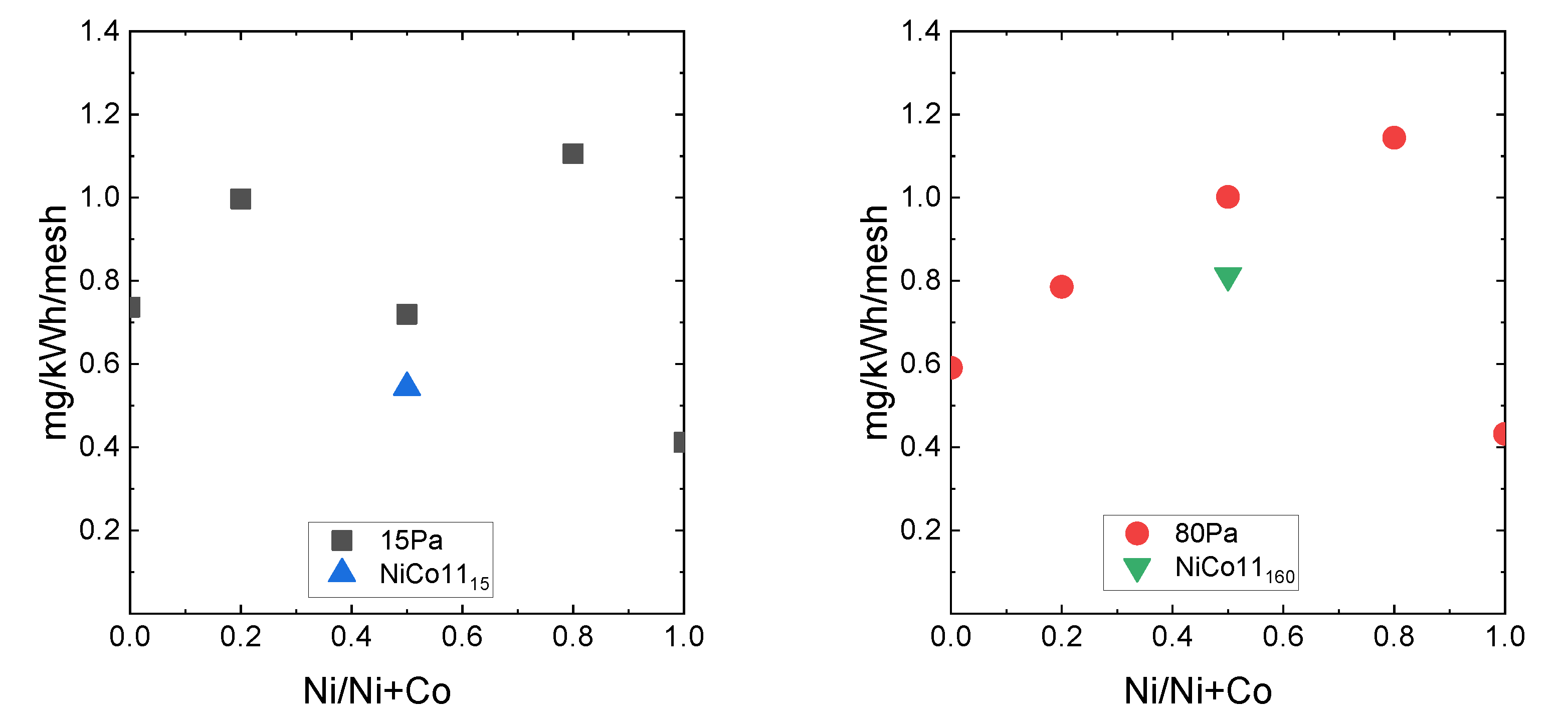

2.1. Plasma Jet Sputtering of Ni-Co Oxides on Stainless-Steel Meshes

2.2. Composition of the Catalysts

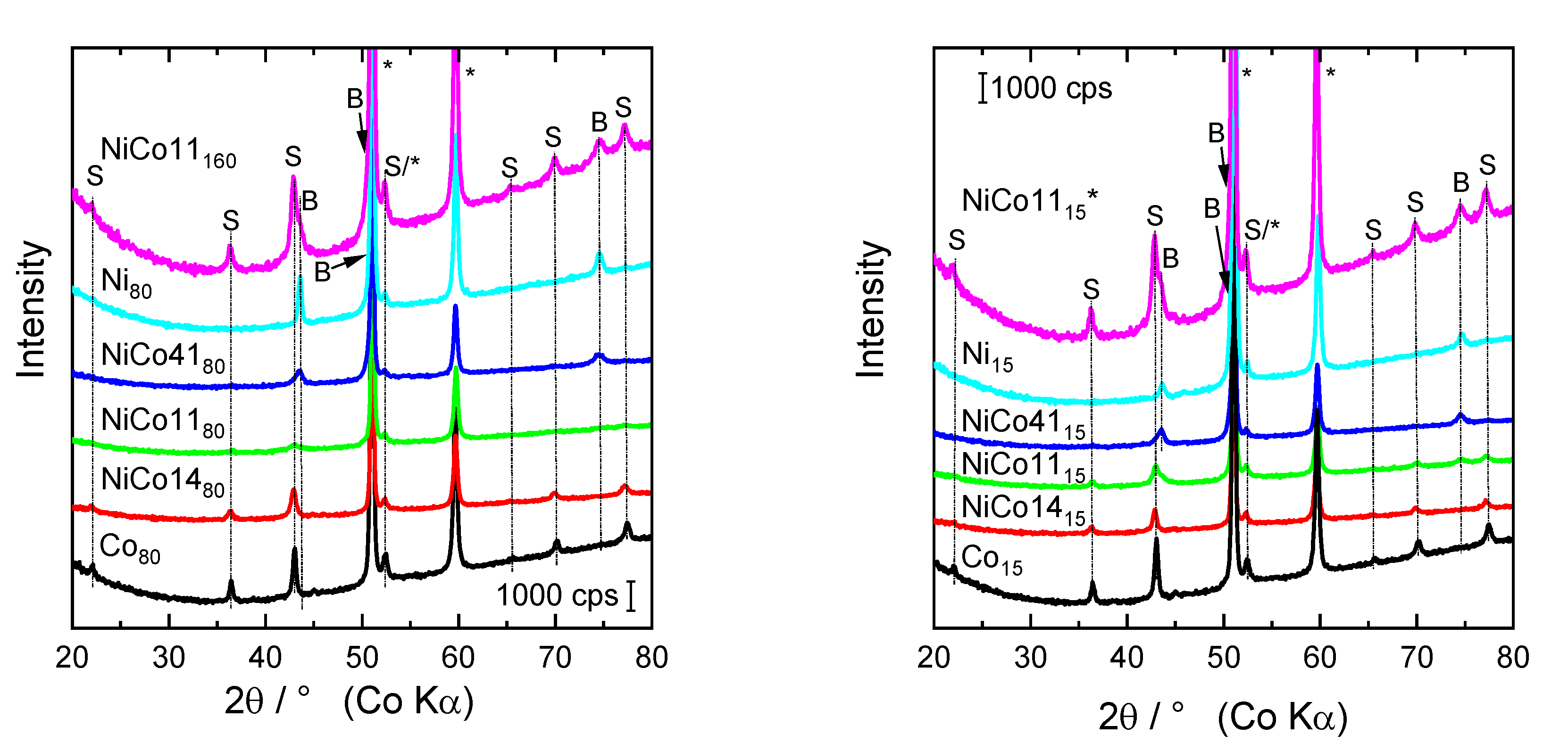

2.3. Powder X-ray Diffraction

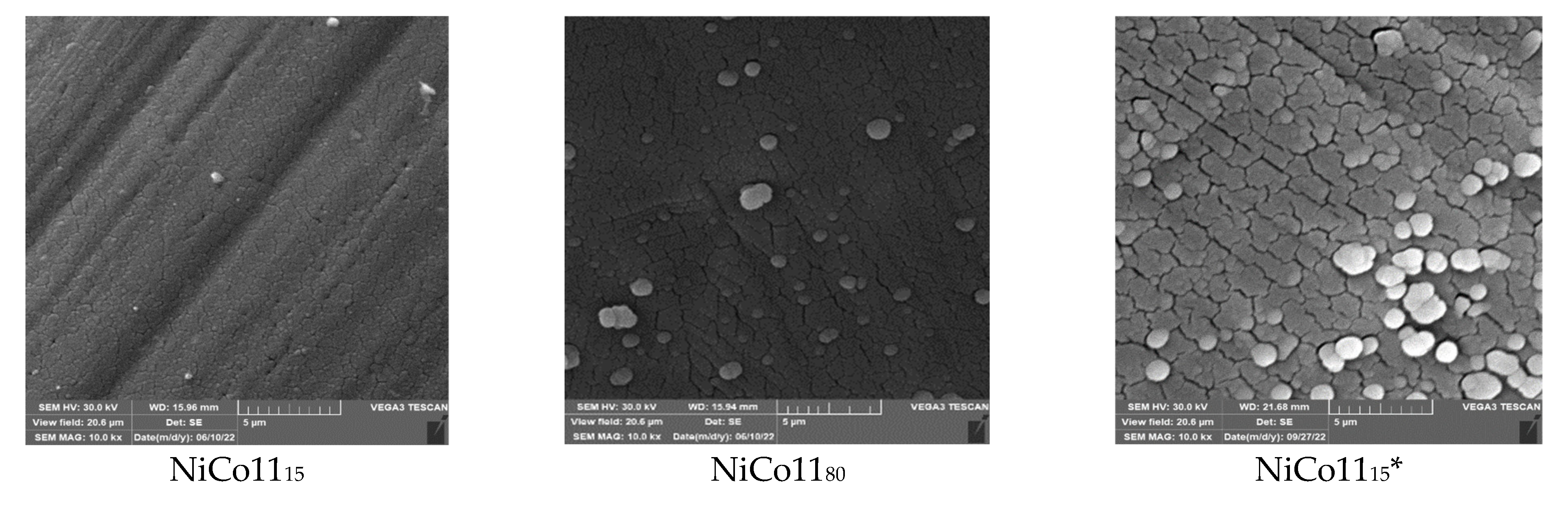

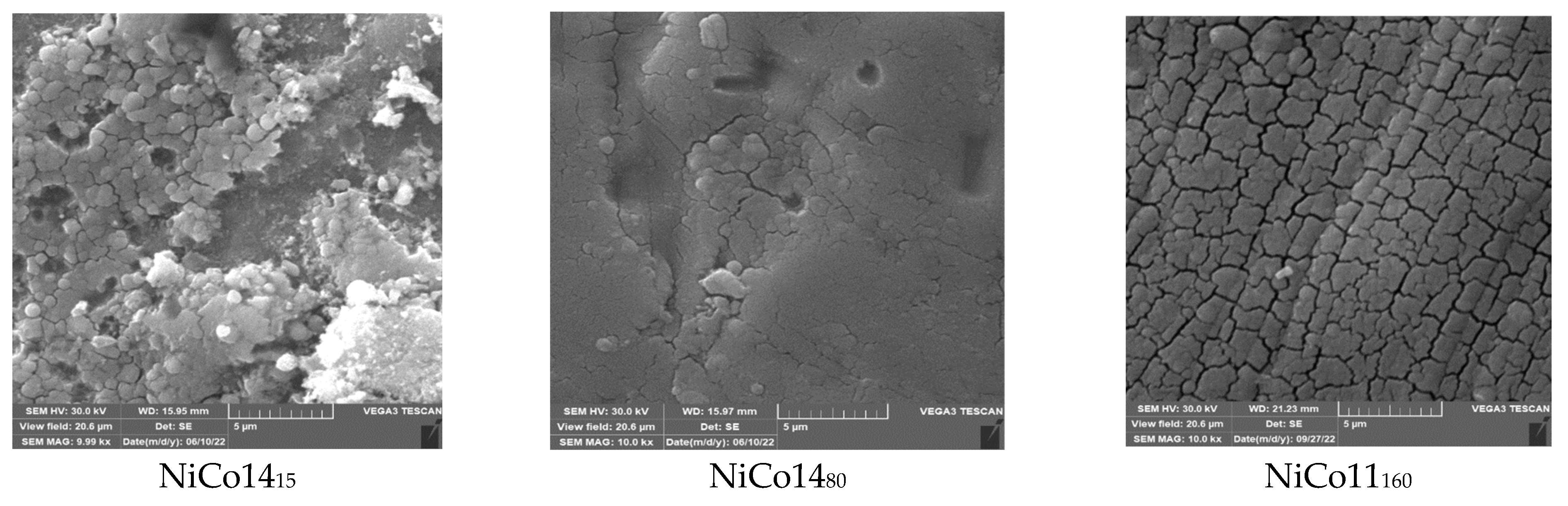

2.4. Surface Morphology and Textural Properties

2.5. Temperature-Programmed Reduction

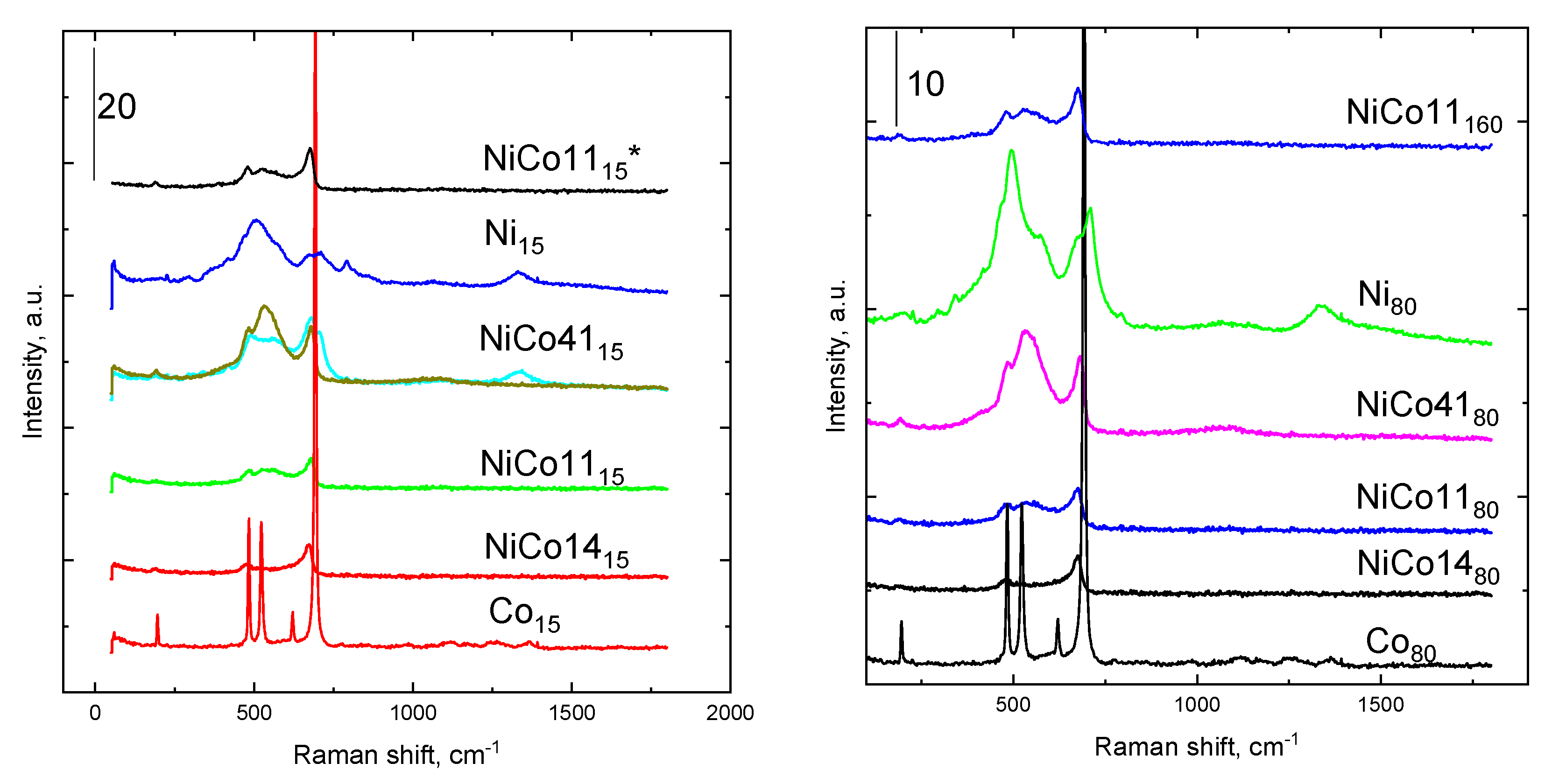

2.6. Raman Spectra

2.7. Surface Composition of the Catalysts

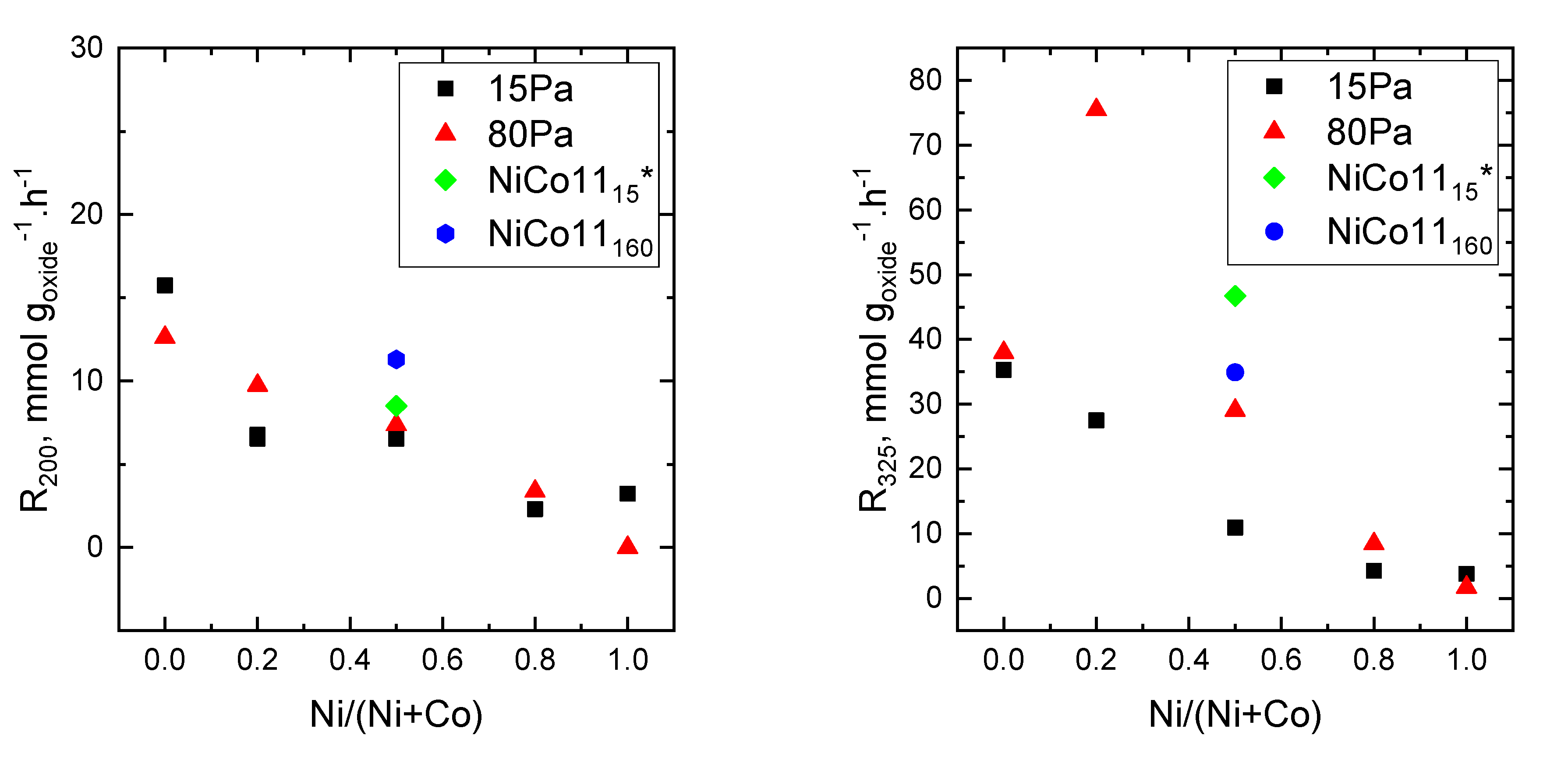

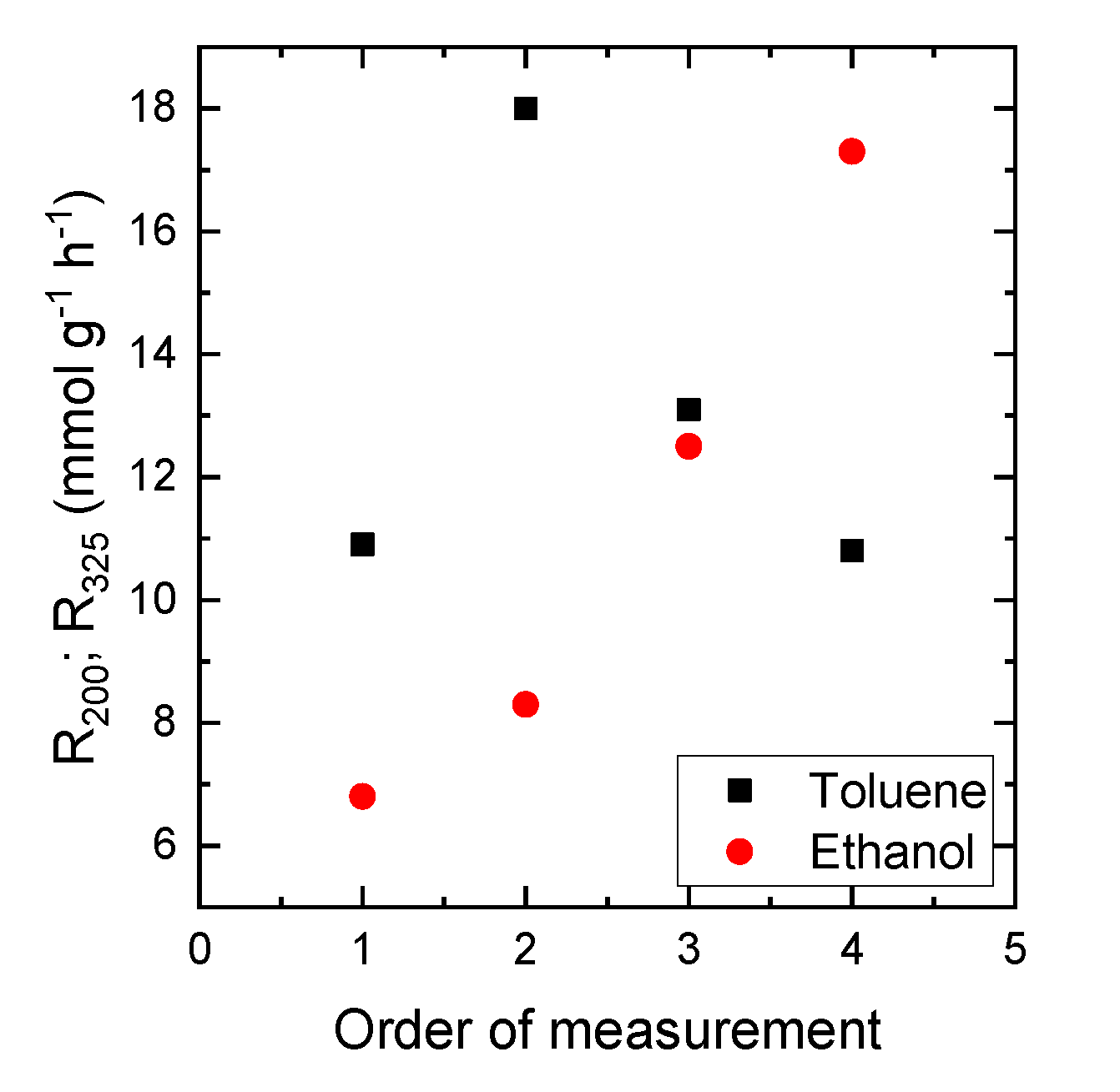

2.8. Catalytic Activity

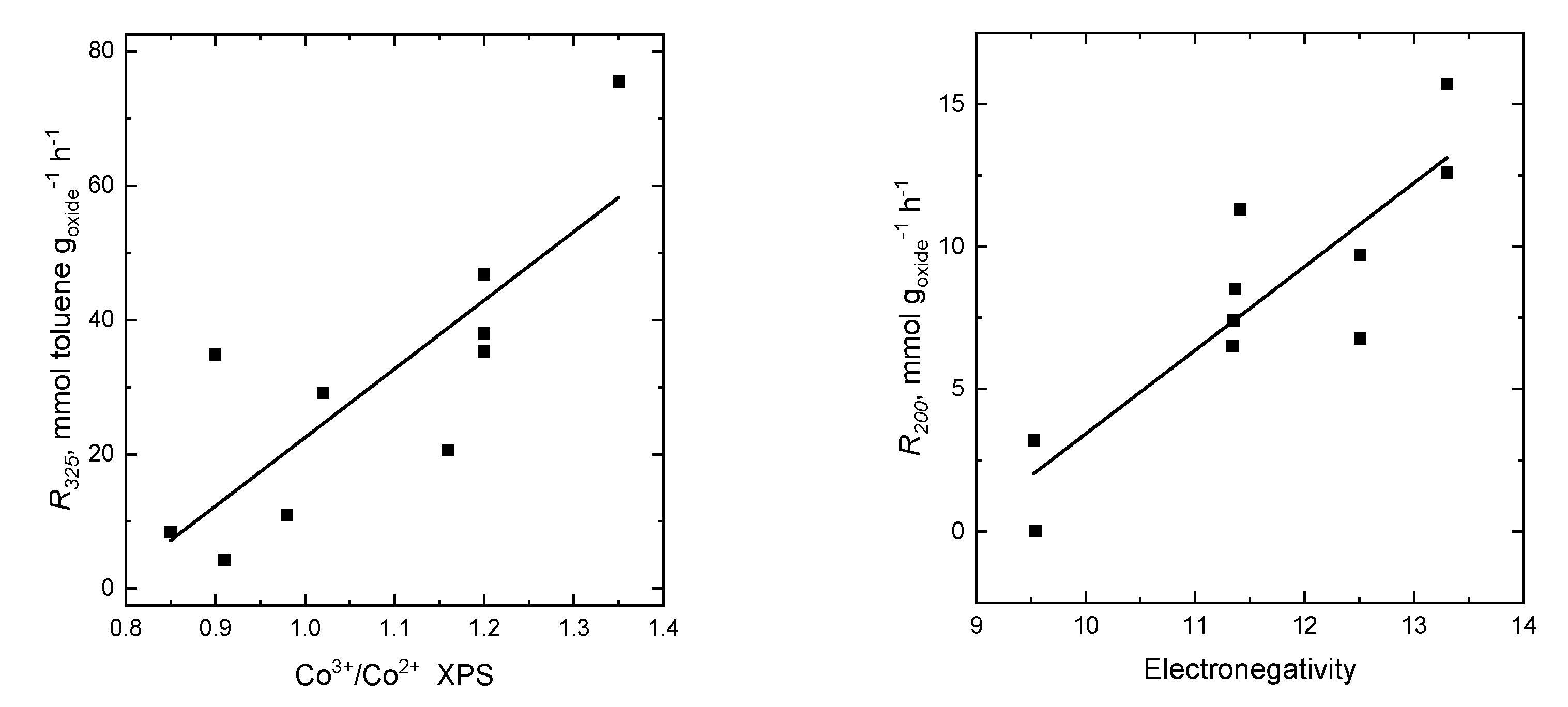

3. Discussion

4. Conclusions

5. Experimental

5.1. Preparation of Catalysts

5.2. Characterization of Catalysts

5.3. Catalytic Experiments

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| VOC | Volatile organic compound |

| XRD | X-ray diffraction |

| SEM | Scanning electron microscopy |

| TPR | Temperature-programmed reduction |

| XPS | X-ray photoelectron spectroscopy |

| EtOH | Ethanol |

References

- Zhang, K.; Ding, H.; Pan, W.; Mu, X.; Qiu, K.; Ma, J.; Zhao, Y.; Song, J.; Zhang, Z. Reserarch progress of a composite metal oxide catalyst for VOC degradation. Environ. Sci. Technol. 2022, 56, 9220–9236. [Google Scholar] [CrossRef] [PubMed]

- Jirátová, K.; Balabánová, J.; Kovanda, F.; Klegová, A.; Obalová, L.; Fajgar, R. Cobalt Oxides Supported Over Ceria–Zirconia Coated Cordierite Monoliths as Catalysts for Deep Oxidation of Ethanol and N2O Decomposition. Catal. Lett. 2017, 147, 1379–1391. [Google Scholar] [CrossRef]

- Topka, P.; Jirátová, K.; Dvořáková, M.; Balabánová, J.; Koštejn, M.; Kovanda, F. Hydrothermal deposition as a novel method for the preparation of Co–Mn mixed oxide catalysts supported on stainless steel meshes: Application to VOC oxidation. Environ. Sci. Pollut. 2022, 29, 5172–5183. [Google Scholar] [CrossRef]

- Kupková, K.; Topka, P.; Balabánová, J.; Koštejn, M.; Jirátová, K.; Lamonier, J.-F.; Maixner, J.; Kovanda, F. Co-Cu mixed oxide catalysts for VOC abatement: Effect of Co:Cu ratio on performance in ethanol oxidation. Catalysts 2023. submitted. [Google Scholar]

- Yentekakis, I.V.; Panagiotopoulou, P.; Artemakis, G. A Review of Recent Efforts to Promote Dry Reforming of Methane (DRM) to Syngas Production via Bimetallic Catalyst Formulations. Appl. Catal. B. Enviroment. 2021, 296, 120210. [Google Scholar] [CrossRef]

- Abdollahifar, M.; Haghighi, M.; Sharifi, M. Dry Reforming of Methane over Nanostructured Co/Y Catalyst for Hydrogen Production: Effect of Ultrasound Irradiation and Co Loading on Catalyst Properties and Performance. Energ. Convers Manag. 2015, 103, 1101–1112. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, H.; Li, H. NiCo@SiO2 core-shell catalyst with high activity and long lifetime for CO2 conversion through DRM reaction. Nano Energy 2018, 45, 4101–4108. [Google Scholar] [CrossRef]

- Xiang, J.F.; Wen, X.; Zhang, F.Z. Supported Nickel-Cobalt Bimetallic Catalysts Derived from Layered Double Hydroxide Precursors for Selective Hydrogenation of Pyrolysis Gasoline. Ind. Eng. Chem. Res. 2014, 53, 5600–15610. [Google Scholar] [CrossRef]

- Ashok, A.; Kumar, A.; Ponraj, J.; Mansour, S.A.; Tarlochan, F. Effect of Ni incorporation in cobalt oxide lattice on carbon formation during ethanol decomposition reaction. Appl. Catal. B. Environ. 2019, 254, 300–311. [Google Scholar] [CrossRef]

- Horlyck, J.; Lawrey, C.; Lovell, C.E.; Amal, R.; Scott, J. Elucidating the impact of Ni and Co loading on the selectivity of bimetallic NiCo catalysts for dry reforming of methane. Chem. Eng. J. 2018, 352, 572–580. [Google Scholar] [CrossRef]

- Niu, J.; Liu, H.; Zhang, Y.; Wang, X.; Han, J.; Yue, Z.; Duan, E. NiCo2O4 spinel for efficient toluene oxidation: The effect of crystal plane and solvent. Chemosphere 2020, 259, 127427. [Google Scholar] [CrossRef]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing; Elsevier: Boston, MA, USA, 2010; pp. 2–6. [Google Scholar]

- Lin, J.; Sproul, W.D.; Moore, J.J. Tribological behavior of thick CrN coatings deposited by modulated pulsed power magnetron sputtering. Surf. Coat. Technol. 2012, 206, 2474–2483. [Google Scholar] [CrossRef]

- Wiatrowski, A.; Obstarczyk, A.; Mazur, M.; Kaczmarek, D.; Wojcieszak, D. Characterization of HfO2 Optical Coatings Deposited by MF Magnetron Sputtering. Coatings 2019, 9, 106. [Google Scholar] [CrossRef]

- Abreu, C.S.; Matos, J.; Cavaleiro, A.; Alves, E.; Barradas, N.P.; Vaz, F.; Torrell, M.; Gomes, J.R. Tribological characterization of TiO2/Au decorative thin films obtained by PVD magnetron sputtering technology. Wear 2015, 330, 419–428. [Google Scholar] [CrossRef]

- Hubička, Z. Hollow Cathodes and Plasma Jets for Thin Film Deposition in Low Temperature Plasmas; Wiley-VCH: Weinheim, Germany, 2008. [Google Scholar]

- Perekrestov, R.; Kudrna, P.; Tichý, M. The deposition of titanium dioxide nanoparticles by means of a hollow cathode plasma jet in dc regime. Plasma Sources Sci. Technol. 2015, 24, 035025. [Google Scholar] [CrossRef]

- Tichý, M.; Hubička, Z.; Šícha, M.; Čada, M.; Olejníček, J.; Churpita, O.; Jastrabík, L.; Virostko, P.; Adámek, P.; Kudrna, P.; et al. Langmuir probe diagnostics of a plasma jet system. Plasma Sources Sci. Technol. 2009, 18, 014009. [Google Scholar] [CrossRef]

- Čada, M.; Hubička, Z.; Adámek, P.; Ptáček, P.; Šíchová, H.; Šícha, M.; Jastrabík, L. Investigation of RF and DC plasma jet system during deposition of highly oriented ZnO thin films. Surf. Coat. Technol. 2003, 174, 627–631. [Google Scholar] [CrossRef]

- Hubička, Z.; Přibil, G.; Soukup, R.J.; Ianno, N.J. Investigation of the rf and dc hollow cathode plasma-jet sputtering systems for the deposition of silicon thin films. Surf. Coat. Technol. 2002, 160, 114–123. [Google Scholar] [CrossRef]

- Olejníček, J.; Šmíd, J.; Perekrestov, R.; Kšírová, P.; Rathouský, J.; Kohout, M.; Dvořáková, M.; Kment, Š.; Jurek, K.; Čada, M. Co3O4 thin films prepared by hollow cathode discharge. Surf. Coat. Technol. 2019, 366, 303–310. [Google Scholar] [CrossRef]

- Hubicka, Z.; Cada, M.; Adamek, P.; Virostko, P.; Olejnicek, J.; Deyneka, A.; Jastrabik, L.; Jurek, K.; Suchaneck, G.; Guenther, M.; et al. Investigation of the RF pulse modulated plasma jet system during the deposition of Pb(ZrxTi(1-x))O3 thin films on polymer substrates. Surf. Coat. Technol. 2005, 200, 940–946. [Google Scholar] [CrossRef]

- Hubička, Z.; Kment, Š.; Olejníček, J.; Čada, M.; Kubart, T.; Brunclíková, M.; Kšírová, P.; Adámek, P.; Remeš, Z. Deposition of hematite Fe2O3 thin film by DC pulsed magnetron and DC pulsed hollow cathode sputtering system. Thin Solid Films 2013, 549, 184–191. [Google Scholar] [CrossRef]

- Fedorov, A.V.; Kukushkin, R.G.; Yeletsky, P.M.; Bulavchenko, O.A.; Chesalov, Y.A.; Yakovlev, V.A. Temperature-programmed reduction of model CuO, NiO and mixed CuO-NiO catalysts with hydrogen. J. Alloy. Compds. 2020, 844, 156135. [Google Scholar] [CrossRef]

- Hurst, N.W.; Gentry, S.J.; Jones, A.; McNicol, B.D. Temperature Programmed Reduction. Catal. Rev. Sci. Eng. 1982, 24, 233–309. [Google Scholar] [CrossRef]

- Jirátová, K.; Perekrestov, R.; Dvořáková, M.; Balabánová, J.; Koštejn, M.; Veselý, M.; Čada, M.; Topka, P.; Pokorná, D.; Hubička, Z.; et al. Modification of Cobalt Oxide Electrochemically Deposited on Stainless Steel Meshes with Co-Mn Thin Films Prepared by Magnetron Sputtering: Effect of Preparation Method and Application to Ethanol Oxidation. Catalysts 2021, 11, 1453. [Google Scholar] [CrossRef]

- Lin, H.-Y.; Chen, Y.-W. The mechanism of reduction of cobalt by hydrogen. Mater. Chem. Phys. 2004, 85, 171–175. [Google Scholar] [CrossRef]

- Richardson, J.T.; Lei, M.; Turk, B.; Forster, K.; Twigg, M.V. Reduction of model steam reforming catalysts: NiO/α-Al2O3. Appl. Catal. General 1994, 110, 217–237. [Google Scholar] [CrossRef]

- Garces, L.J.; Hincapie, B.; Zerger, R.; Suib, S.L. The Effect of Temperature and Support on the Reduction of Cobalt Oxide: An in Situ X-ray Diffraction Study. J. Phys. Chem. C 2015, 119, 5484–5490. [Google Scholar] [CrossRef]

- Goncalves, V.O.O.; Talon, W.H.S.M.; Kartnaller, V.; Venancio, F.; Cajaiba, J.; Cabioc’h, T.; Clacens, J.M.; Richard, F. Hydrodeoxygenation of m-cresol as a depolymerized lignin probe molecule: Synergistic effect of NiCo supported alloys. Catal. Today 2021, 377, 135–144. [Google Scholar] [CrossRef]

- Hadjiev, V.G.; Iliev, M.N.; Vergilov, I.V. The Raman spectra of Co3O4. J. Phys. C: Solid State Phys. 1988, 21, L199–L201. [Google Scholar] [CrossRef]

- Tang, C.-W.; Wang, C.-B.; Chien, S.-H. Characterization of cobalt oxides studied by FT-IR, Raman, TPR and TG-MS. Thermochim. Acta 2008, 473, 68–73. [Google Scholar] [CrossRef]

- Mironova-Ulmane, N.; Kuzmin, A.; Steins, I.; Grabis, J.; Sildos, I.; Pärs, M. Raman scattering in nanosized nickel oxide NiO. J. Phys. Conf. Ser. 2007, 93, 012039. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Y.; Xu, C.; Zheng, C.; Wang, G. Synthesis of NiO nanorods by a novel simple precursor thermal decomposition approach. Chem. Phys. Lett. 2002, 362, 119–122. [Google Scholar] [CrossRef]

- Bala, N.; Singh, H.K.; Verma, S.; Rath, S. Magnetic-order induced effects in nanocrystalline NiO probed by Raman spectroscopy. Phys. Rev. B 2020, 102, 024423. [Google Scholar] [CrossRef]

- NIST X-ray Photoelectron Spectroscopy Database, NIST Standard Reference Database 20, Version 3.5. Available online: http://srdata.nist. [CrossRef]

- Biesinger, M.C.; Payne, B.G.P.; Lau, L.W.M.; Gerson, A.; Smart, R.S.C. X-ray photoelectron spectroscopic chemical state quantification of mixed nickel metal, oxide and hydroxide systems. Surf. Interface Anal. 2009, 41, 324–332. [Google Scholar] [CrossRef]

- Yamamura, Y.; Tawara, H. Energy dependence of ion-induced sputtering yields from monoatomic solids at normal incidence. At. Data Nucl. Data Tables 1996, 62, 149–253. [Google Scholar] [CrossRef]

- Bielanski, A.; Haber, J. Oxygen in Catalysis; Marcel Dekker, Inc.: New York, NY, USA, 1990. [Google Scholar]

- Shibata, K.; Kioyma, T.; Kitagawa, J.; Sumiyoshi, T.; Tanabe, K.K. Acidic properties of binary metal oxides. Bull. Chem. Soc. Japan 1973, 46, 2985–2988. [Google Scholar] [CrossRef]

- Tanaka, K.; Ozaki, A. Acid-base properties and catalytic activity of solid surfaces. J. Catal. 1967, 8, 1–7. [Google Scholar] [CrossRef]

- Idriss, H.; Seebauer, E.G. Reactions of ethanol over metal oxides. J. Mol. Catal. A Chem. 1999, 152, 201–212. [Google Scholar] [CrossRef]

- Matějová, L.; Topka, P.; Jirátová, K.; Šolcová, O. Total oxidation of model volatile organic compounds over some commercial catalysts. Appl. Catal. A 2012, 443, 40–49. [Google Scholar] [CrossRef]

- Topka, P.; Jirátová, K.; Soukup, K.; Goliáš, J. Device for Measuring Specific Surface of Large Samples, Method of Measurement and Its Use. Czech Patent CZ308606, 30 December 2020. [Google Scholar]

| Sample | Nia at. % | Co at. % | Ni/(Ni+Co)EDX mol mol−1 | Ni:CoEDX mol mol−1 |

|---|---|---|---|---|

| Co15 | 0.0 | 31.5 | 0 | 1:0 |

| NiCo1415 | 7.5 | 28.5 | 0.21 | 1:3.80 |

| NiCo1115 | 15.6 | 14.7 | 0.52 | 1:0.92 |

| NiCo4115 | 27.2 | 6.8 | 0.80 | 4:1 |

| Ni15 | 29.8 | 0.2 | 1 | 0:1 |

| NiCo1115 * | 20.2 | 19.5 | 0.50 | 1:0.97 |

| Co80 | 0.0 | 28.1 | 0 | 1:0 |

| NiCo1480 | 6.3 | 24.0 | 0.21 | 1:3.80 |

| NiCo1180 | 18.5 | 17.6 | 0.51 | 1:0.96 |

| NiCo4180 | 28.1 | 7.2 | 0.80 | 4:1 |

| Ni80 | 27.2 | 0.3 | 1 | 0:1 |

| NiCo11160 | 19.0 | 19.2 | 0.50 | 1:1.01 |

| Sample | NiO | Ni-Co Spinel | ||

|---|---|---|---|---|

| D (nm) | a (Å) | D (nm) | a (Å) | |

| NiCo1415 | - | - | 20.3 | 8.119 |

| NiCo1115 | - | - | 19.6 | 8.104 |

| NiCo4115 | 17.5 | 4.180 | - | - |

| NiCo1115 * | 15.4 | 4.175 | 17.1 | 8.120 |

| NiCo1480 | - | - | 24.2 | 8.122 |

| NiCo1180 | 18.7 | 4.171 | 15.8 | 8.109 |

| NiCo4180 | 14.2 | 4.179 | 11.4 | 8.104 |

| NiCo11160 | 15.3 | 4.181 | 17.3 | 8.129 |

| Sample | SBET m2 goxide−1 | Tonset °C | Tmax °C | mmol H2 goxide−1 |

|---|---|---|---|---|

| Co15 | 2.6 | 242 | 359 | 16.4 |

| NiCo1415 | 8.1 | 163 | 323 | 17.6 |

| NiCo1115 | 7.9 | 147 | 315 | 19.8 |

| NiCo4115 | 8.8 | 190 | 339 | 14.2 |

| Ni15 | 2.2 | 314 | 371 | 15.7 |

| NiCo1115 * | 2.9 | 240 | 314 | 15.1 |

| Co80 | 2.8 | 162 | 376 | 20.0 |

| NiCo1480 | 9.4 | 195 | 328; 346; (512) | 18.4 |

| NiCo1180 | 10.0 | 137 | 301; 316 | 22.8 |

| NiCo4180 | 9.4 | 199 | 328; 356 | 12.4 |

| Ni80 | 4.1 | 342 | 364 | 13.1 |

| NiCo11160 | 2.8 | 245 | 320 | 12.5 |

| Sample | C 1s | O 1s | Co 2p | Ni 2p | Ni/(Ni + Co)nom | Ni/(Ni + Co)EDX | Ni/(Ni + Co)XPS |

|---|---|---|---|---|---|---|---|

| At.% | At.% | At.% | At.% | mol/mol | mol/mol | mol/mol | |

| Co15 | 50.79 | 38.02 | 11.19 | 0 | 0 | 0 | - |

| NiCo1415 | 54.62 | 32.94 | 8.07 | 4.38 | 0.2 | 0.21 | 0.35 |

| NiCo1115 | 50.47 | 34.42 | 6.63 | 8.48 | 0.5 | 0.52 | 0.56 |

| NiCo4115 | 45.61 | 33.28 | 2.34 | 18.78 | 0.8 | 0.8 | 0.89 |

| Ni15 | 47.94 | 34.71 | 0 | 17.35 | 1 | 1 | - |

| NiCo1115 * | 50.66 | 32.75 | 5.34 | 11.24 | 0.5 | 0.50 | 0.68 |

| Co80 | 52.27 | 36.74 | 10.99 | 0 | 0 | 0 | - |

| NiCo1480 | 53.57 | 34.36 | 8.32 | 3.75 | 0.2 | 0.21 | 0.31 |

| NiCo1180 | 42.64 | 36.00 | 5.53 | 15.83 | 0.5 | 0.51 | 0.74 |

| NiCo4180 | 49.22 | 31.92 | 2.14 | 16.71 | 0.8 | 0.80 | 0.89 |

| Ni80 | 52.95 | 30.97 | 0 | 16.08 | 1 | 1 | - |

| NiCo11160 | 49.43 | 36.05 | 5.32 | 9.2 | 0.5 | 0.50 | 0.63 |

| Sample | Co3+ | Co2+ | Co2+ | Co3+/Co2+ | Ol | Ov | Ow | Ov/(Ni+Co) |

|---|---|---|---|---|---|---|---|---|

| BE, eV | 779.5 ± 0.1 | 781.0 | 783.1 | Peak 1/(2 + 3) | 529.0–529.9 | 530.5–531.0 | 531.7–533.0 | |

| Co15 | 34.44 | 25.99 | 2.83 | 1.2 | 34.5 | 0.0 | 65.5 | 0.0 |

| NiCo1415 | 33.39 | 23.44 | 5.42 | 1.16 | 41.3 | 24.2 | 34.5 | 1.9 |

| NiCo1115 | 30.79 | 25.24 | 6.04 | 0.98 | 42.5 | 22.3 | 35.2 | 1.5 |

| NiCo4115 | 25.81 | 21.76 | 6.53 | 0.91 | 50.5 | 25.5 | 24.0 | 1.2 |

| Ni15 | - | - | - | - | 44.5 | 23.3 | 32.3 | 1.3 |

| NiCo1115 * | 32.07 | 23.87 | 3.03 | 1.2 | 46.3 | 19.3 | 34.4 | 1.2 |

| Co80 | 33.95 | 25.15 | 2.3 | 1.2 | 34.0 | 0.0 | 66.0 | 0.0 |

| NiCo1480 | 35.70 | 24.01 | 2.4 | 1.35 | 42.1 | 25.6 | 32.3 | 2.1 |

| NiCo1180 | 31.29 | 26.4 | 4.4 | 1.02 | 52.0 | 29.3 | 18.8 | 1.4 |

| NiCo4180 | 22.87 | 21.62 | 5.36 | 0.85 | 45.3 | 24.4 | 30.3 | 1.3 |

| Ni80 | - | - | - | - | 38.9 | 18.5 | 42.6 | 1.2 |

| NiCo11160 | 28.33 | 25.56 | 6.2 | 0.9 | 32.4 | 3.8 | 63.8 | 0.3 |

| Catalyst | Ni/(Ni + Co) | Ethanol | Toluene | ||

|---|---|---|---|---|---|

| mol mol−1 | T50, °C | T90CO2, °C | T50, °C | T90CO2, °C | |

| Co15 | 0 | 260 | 324 | 345 | 402 |

| NiCo1415 | 0.2 | 265 | 335 | 334 | 359 |

| NiCo1115 | 0.5 | 274 | 329 | 364 | 355 |

| NiCo4115 | 0.8 | 269 | 332 | 363 | 396 |

| Ni15 | 1 | 296 | 402 | 455 | >480 |

| NiCo1115 * | 0.5 | 249 | 301 | 343 | 342 |

| Co80 | 0 | 258 | 324 | 343 | 379 |

| NiCo1480 | 0.2 | 252 | 329 | 328 | 356 |

| NiCo1180 | 0.5 | 274 | 324 | 338 | 382 |

| NiCo4180 | 0.8 | 270 | 329 | 356 | 389 |

| Ni80 | 1 | 296 | 402 | 430 | >450 |

| NiCo11160 | 0.5 | 247 | 294 | 314 | 346 |

| Sample | Hollow Cathode Material | Ni/(Ni+Co) Molar Ratio | Cathode Voltage (V) | Discharge Current (A) | Absorbed Power in Plasma (W) | Deposition Pressure (Pa) | Deposition Time (min) | Average Thin Film Weight (mg) |

|---|---|---|---|---|---|---|---|---|

| Co15 | Co | 0 | −312 | 1.6 | 499 | 15 | 120 | 1.47 |

| NiCo1415 | Ni20Co80 | 0.2 | −312 | 1.6 | 499 | 15 | 120 | 1.99 |

| NiCo1115 | Ni50Co50 | 0.5 | −306 | 1.6 | 490 | 15 | 120 | 1.41 |

| NiCo4115 | Ni80Co20 | 0.8 | −314 | 1.6 | 502 | 15 | 120 | 2.22 |

| Ni15 | Ni | 1 | −318 | 1.05 | 334 | 15 | 240 | 1.10 |

| NiCo1115 * | Ni50Co50 | 0.5 | −336 | 1.5 | 504 | 15 | 370 | 3.38 |

| Co80 | Co | 0 | −356 | 1.6 | 567 | 80 | 120 | 1.34 |

| NiCo1480 | Ni20Co80 | 0.2 | −336 | 1.6 | 538 | 80 | 120 | 1.69 |

| NiCo1180 | Ni50Co50 | 0.5 | −340 | 1.6 | 544 | 80 | 120 | 2.18 |

| NiCo4180 | Ni80Co20 | 0.8 | −354 | 1.6 | 566 | 80 | 120 | 2.59 |

| Ni80 | Ni | 1 | −345 | 1.05 | 362 | 80 | 240 | 1.25 |

| NiCo11160 | Ni50Co50 | 0.5 | −320 | 1.5 | 480 | 160 | 200 | 2.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jirátová, K.; Čada, M.; Naiko, I.; Ostapenko, A.; Balabánová, J.; Koštejn, M.; Maixner, J.; Babii, T.; Topka, P.; Soukup, K.; et al. Plasma Jet Sputtering as an Efficient Method for the Deposition of Nickel and Cobalt Mixed Oxides on Stainless-Steel Meshes: Application to VOC Oxidation. Catalysts 2023, 13, 79. https://doi.org/10.3390/catal13010079

Jirátová K, Čada M, Naiko I, Ostapenko A, Balabánová J, Koštejn M, Maixner J, Babii T, Topka P, Soukup K, et al. Plasma Jet Sputtering as an Efficient Method for the Deposition of Nickel and Cobalt Mixed Oxides on Stainless-Steel Meshes: Application to VOC Oxidation. Catalysts. 2023; 13(1):79. https://doi.org/10.3390/catal13010079

Chicago/Turabian StyleJirátová, Květa, Martin Čada, Iryna Naiko, Alina Ostapenko, Jana Balabánová, Martin Koštejn, Jaroslav Maixner, Timur Babii, Pavel Topka, Karel Soukup, and et al. 2023. "Plasma Jet Sputtering as an Efficient Method for the Deposition of Nickel and Cobalt Mixed Oxides on Stainless-Steel Meshes: Application to VOC Oxidation" Catalysts 13, no. 1: 79. https://doi.org/10.3390/catal13010079

APA StyleJirátová, K., Čada, M., Naiko, I., Ostapenko, A., Balabánová, J., Koštejn, M., Maixner, J., Babii, T., Topka, P., Soukup, K., Hubička, Z., & Kovanda, F. (2023). Plasma Jet Sputtering as an Efficient Method for the Deposition of Nickel and Cobalt Mixed Oxides on Stainless-Steel Meshes: Application to VOC Oxidation. Catalysts, 13(1), 79. https://doi.org/10.3390/catal13010079