Recent Developments on Processes for Recovery of Rhodium Metal from Spent Catalysts

Abstract

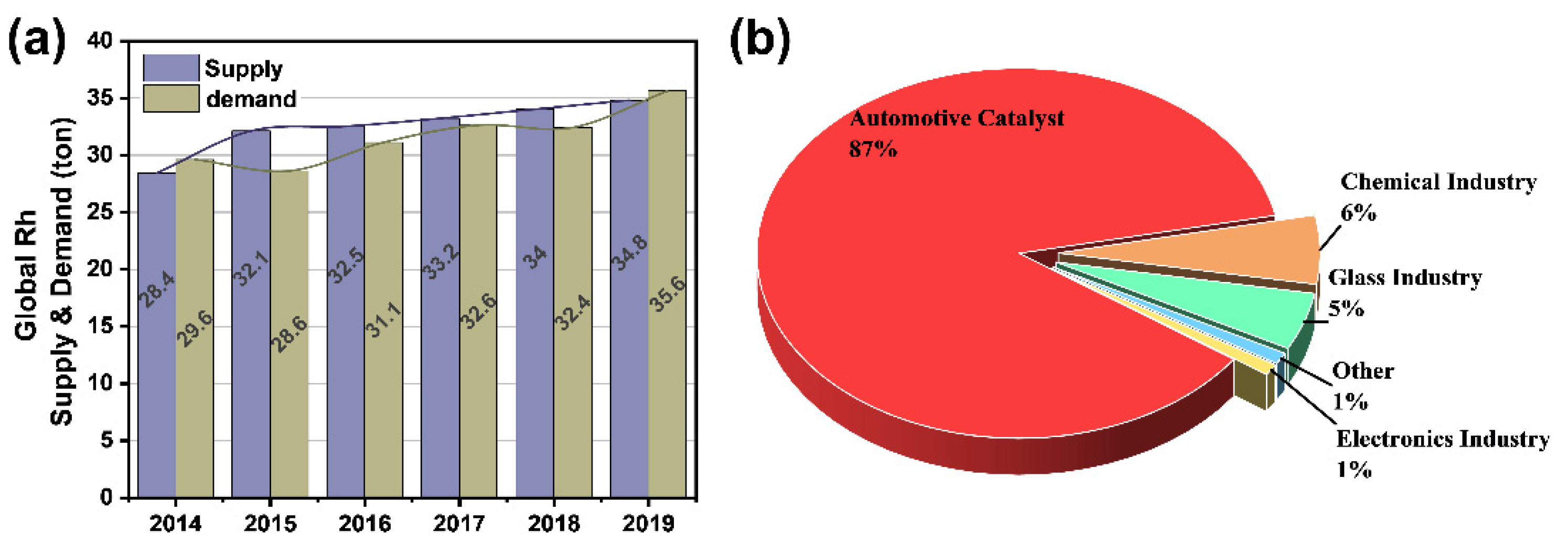

1. Introduction

2. Process of Rhodium Catalyst Recovery

2.1. Pyrometallurgical Process

2.1.1. Incineration

2.1.2. Plasma Melting Method

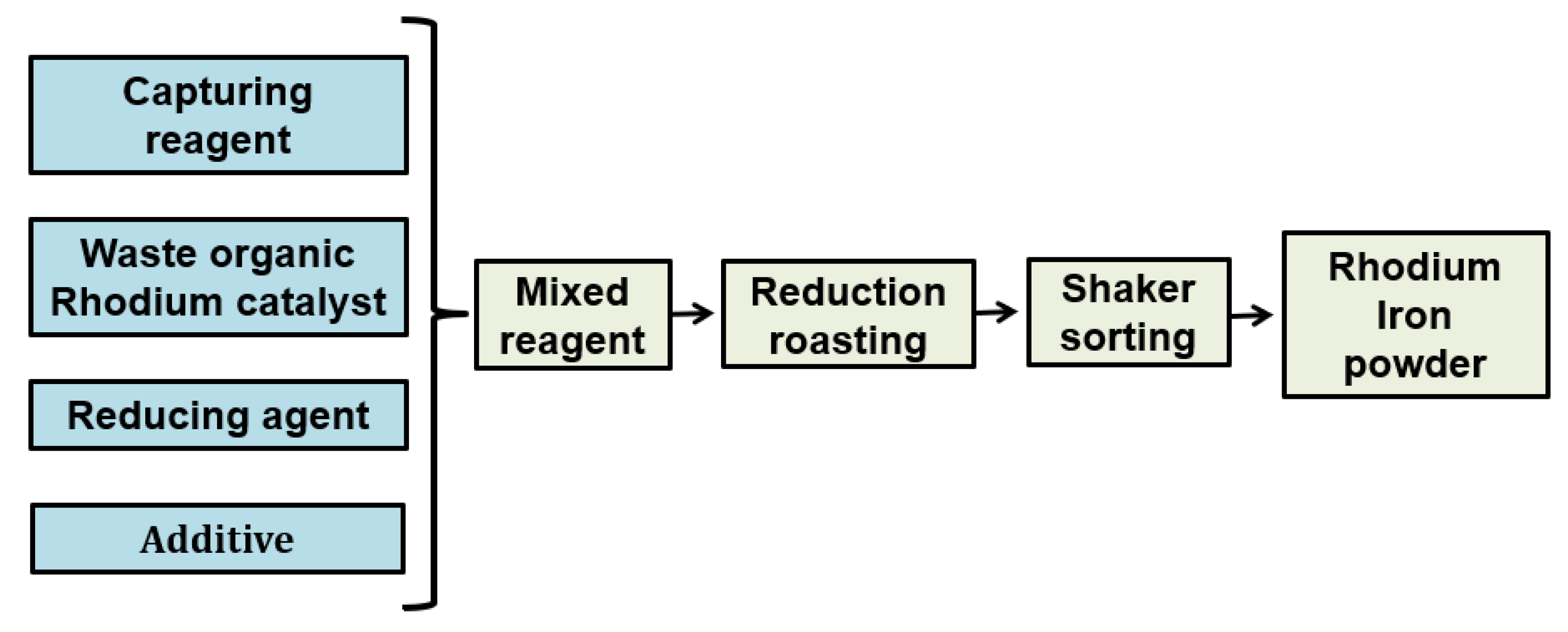

2.1.3. Metal Trapping Method

2.1.4. Volatilization

2.2. Hydrometallurgical Process

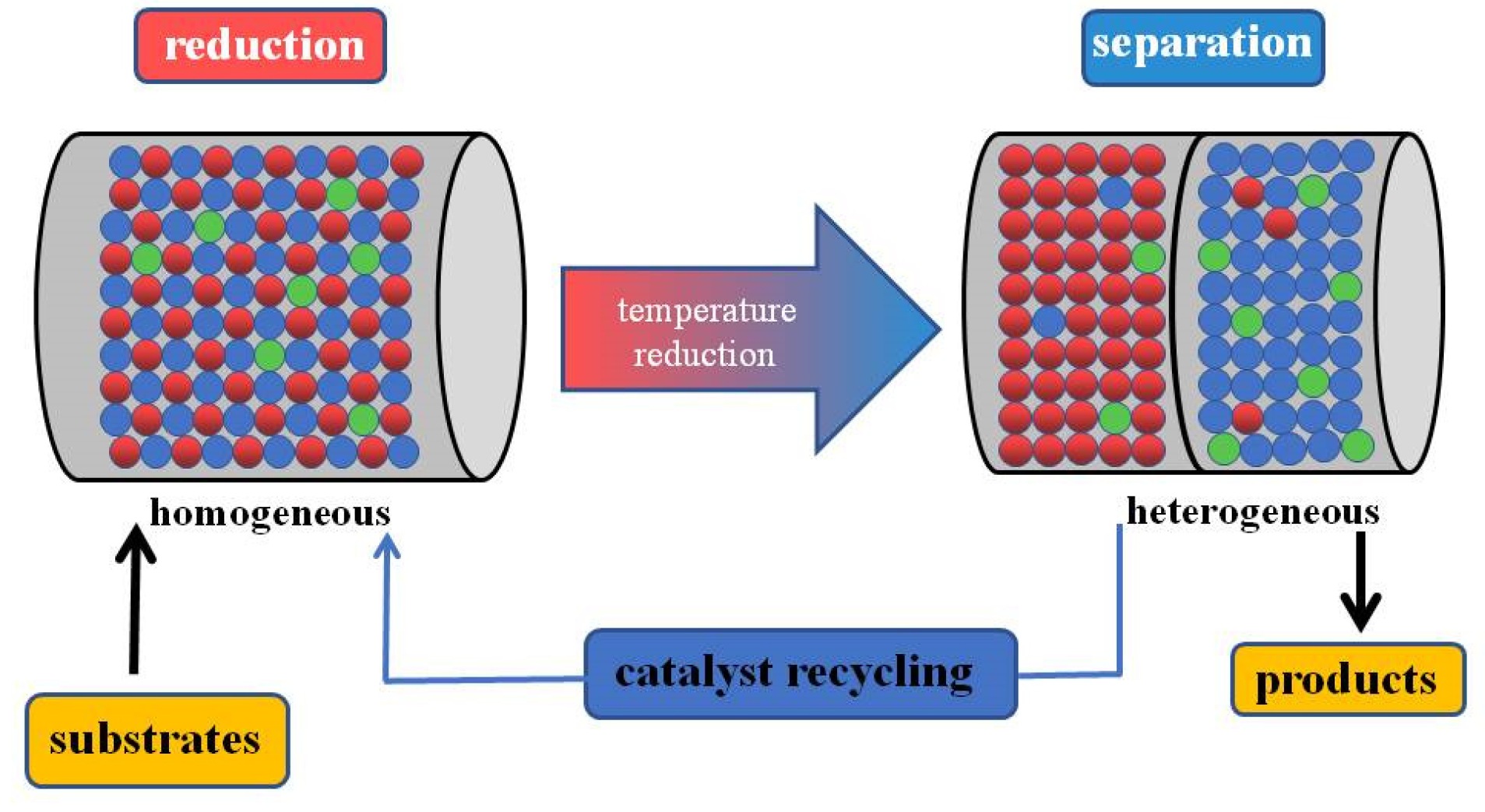

2.2.1. Extraction Method

2.2.2. Coprecipitation

- (1)

- Thiourea precipitation method

- (2)

- Sodium sulfide precipitation method

- (3)

- Sodium nitrite with hydrolysis precipitation method

- (4)

- Ammonium chloride precipitation method

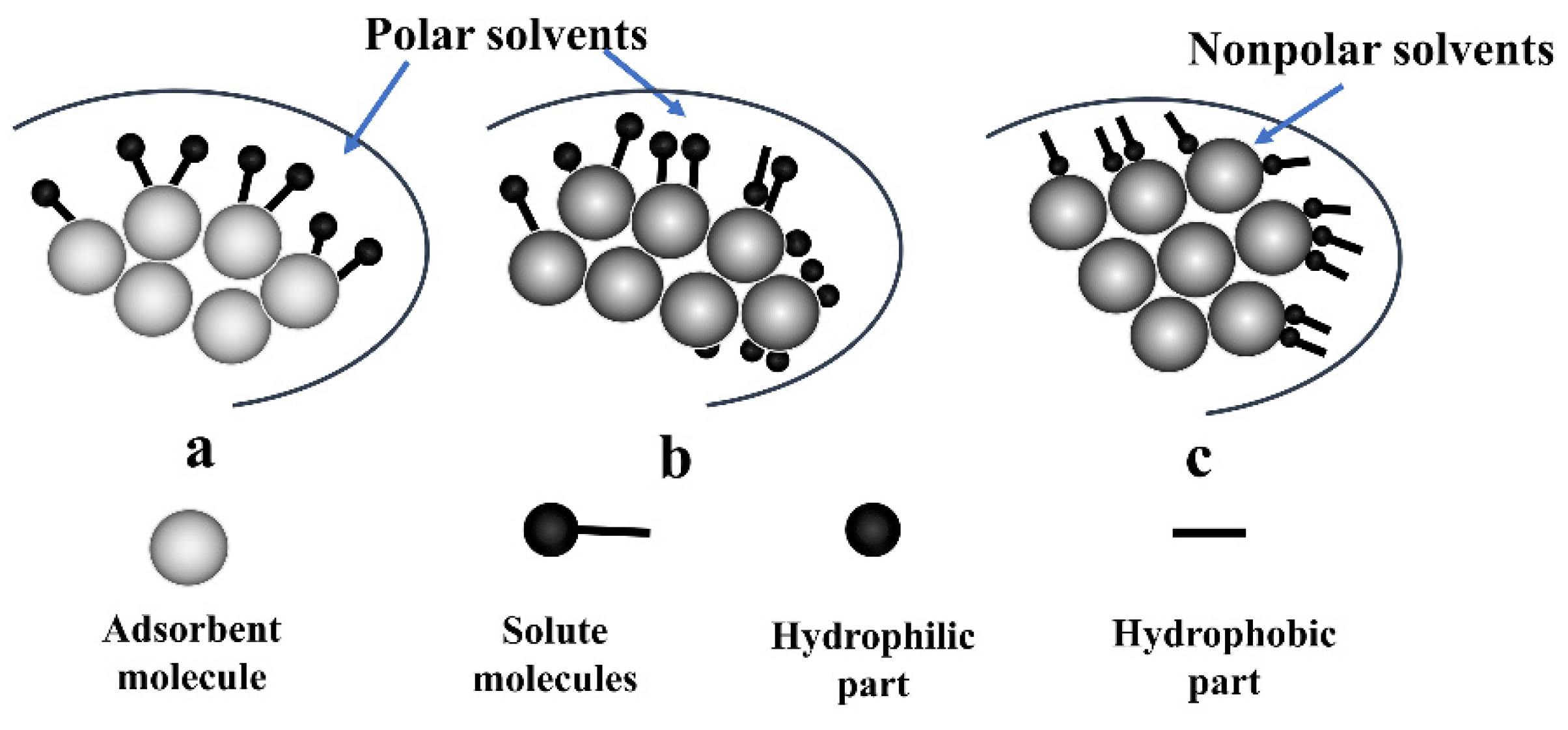

2.2.3. Adsorption Separation

2.2.4. Other Methods

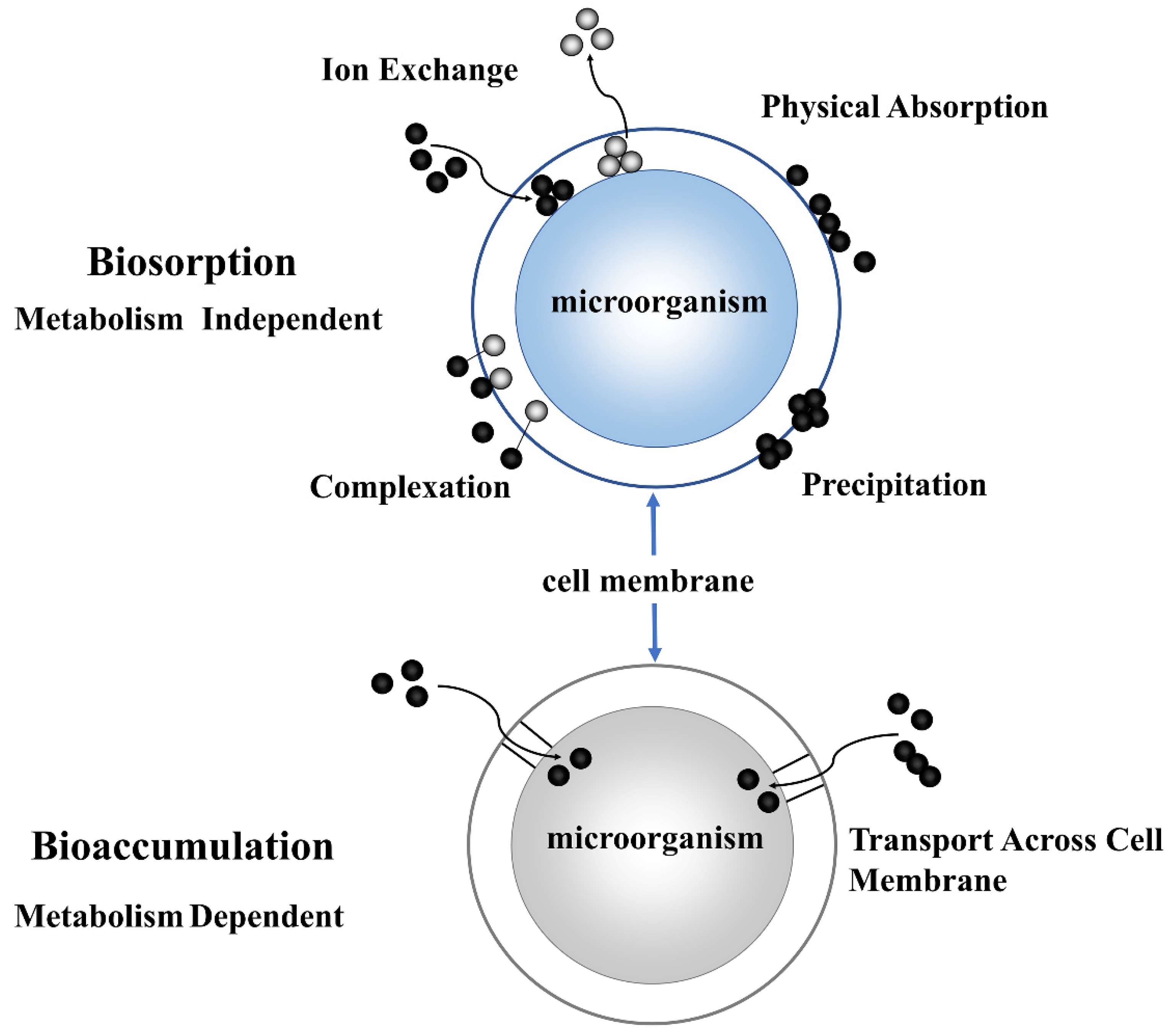

2.3. Biosorption

3. Conclusions and Prospect

Author Contributions

Funding

Conflicts of Interest

References

- Dong, H.; Zhao, J.; Chen, J.; Wu, Y.; Li, B. Recovery of platinum group metals from spent catalysts: A review. Int. J. Miner. Process. 2015, 145, 108–113. [Google Scholar] [CrossRef]

- Batten, J.A.; Ciner, C.; Lucey, B.M. The macroeconomic determinants of volatility in precious metals markets. Resour. Policy 2010, 35, 65–71. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, X.; Wei, W.; Wang, S.; Ni, B.J. Electrocatalysts for acidic oxygen evolution reaction: Achievements and perspectives. Nano Energy 2020, 78, 105392. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, X.; Wei, W.; Wang, S.; Ni, B.J. Iridium-based nanomaterials for electrochemical water splitting. Nano Energy 2020, 78, 105270. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, R.; Zou, W.; Wei, W.; Li, J.; Wei, W.; Ni, B.-J.; Chen, H. Integrating high-efficiency oxygen evolution catalysts featuring accelerated surface reconstruction from waste printed circuit boards via a boriding recycling strategy. Appl. Catal. B Environ. 2021, 298, 120583. [Google Scholar] [CrossRef]

- Chen, Z.; Zou, W.; Zheng, R.; Wei, W.; Wei, W.; Ni, B.J.; Chen, H. Synergistic recycling and conversion of spent Li-ion battery leachate into highly efficient oxygen evolution catalysts. Green Chem. 2021, 23, 6538–6547. [Google Scholar] [CrossRef]

- Hou, J.; Yang, M.; Ke, C.; Wei, G.; Priest, C.; Qiao, Z.; Wu, G.; Zhang, J. Platinum-group-metal catalysts for proton exchange membrane fuel cells: From catalyst design to electrode structure optimization. EnergyChem 2020, 2, 100023. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Wei, W.; Ni, B.J. Recent advances in electrocatalysts for halogenated organic pollutant degradation. Environ. Sci-Nano 2019, 6, 2332–2366. [Google Scholar] [CrossRef]

- Chaudhari, N.K.; Joo, J.; Kwon, H.-b.; Kim, B.; Kim, H.Y.; Joo, S.H.; Lee, K. Nanodendrites of platinum-group metals for electrocatalytic applications. Nano Res. 2018, 11, 6111–6140. [Google Scholar] [CrossRef]

- Franz, D.; Schroder, U.; Shayduk, R.; Arndt, B.; Noei, H.; Vonk, V.; Michely, T.; Stierle, A. Hydrogen solubility and atomic structure of graphene supported Pd nanoclusters. ACS Nano 2021, 15, 15771–15780. [Google Scholar] [CrossRef]

- Wang, H.; Rao, H.; Luo, M.; Xue, X.; Xue, Z.; Lu, X. Noble metal nanoparticles growth-based colorimetric strategies: From monocolorimetric to multicolorimetric sensors. Coord. Chem. Rev. 2019, 398, 113003. [Google Scholar] [CrossRef]

- Bernardis, F.L.; Grant, R.A.; Sherrington, D.C. A review of methods of separation of the platinum-group metals through their chloro-complexes. React. Funct. Polym. 2005, 65, 205–217. [Google Scholar] [CrossRef]

- Duclos, L.; Chattot, R.; Dubau, L.; Thivel, P.X.; Mandil, G.; Laforest, V.; Bolloli, M.; Vincent, R.; Svecova, L. Closing the loop: Life cycle assessment and optimization of a PEMFC platinum-based catalyst recycling process. Green Chem. 2020, 22, 1919–1933. [Google Scholar] [CrossRef]

- Jha, M.K.; Lee, J.c.; Kim, M.s.; Jeong, J.; Kim, B.S.; Kumar, V. Hydrometallurgical recovery/recycling of platinum by the leaching of spent catalysts: A review. Hydrometallurgy 2013, 133, 23–32. [Google Scholar] [CrossRef]

- Mudd, G.M. Key trends in the resource sustainability of platinum group elements. Ore Geol. Rev. 2012, 46, 106–117. [Google Scholar] [CrossRef]

- Tao, M.; Lu, D.; Shi, Y.; Wu, C. Utilization and life cycle assessment of low activity solid waste as cementitious materials: A case study of titanium slag and granulated blast furnace slag. Sci. Total Environ. 2022, 849, 157797. [Google Scholar] [CrossRef] [PubMed]

- Hoang, A.T.; Varbanov, P.S.; Nižetić, S.; Sirohi, R.; Pandey, A.; Luque, R.; Ng, K.H.; Pham, V.V. Perspective review on municipal solid waste-to-energy route: Characteristics, management strategy, and role in circular economy. J. Clean. Prod. 2022, 359, 131897. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, W.; Chen, H.; Ni, B.J. Recent advances in waste-derived functional materials for wastewater remediation. Eco-Environ. Health 2022, 1, 86–104. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, R.; Wei, W.; Wei, W.; Zou, W.; Li, J.; Ni, B.-J.; Chen, H. Recycling spent water treatment adsorbents for efficient electrocatalytic water oxidation reaction. Resour. Conserv. Recycl. 2022, 178, 106037. [Google Scholar] [CrossRef]

- Nakahiro, Y. Recycling of precious metals. In Ecomaterials; Yamamoto, R., Furubayashi, E., Doi, Y., Fang, R., Liu, B., Otsuka, K., Liu, C.T., Shimizu, K., Suzuki, Y., Van Humbeeck, J., et al., Eds.; Elsevier: Amsterdam, The Netherlands, 1994; pp. 167–170. [Google Scholar]

- Morris, R.H. Exploiting metal–ligand bifunctional reactions in the design of iron asymmetric hydrogenation catalysts. Acc. Chem. Res. 2015, 48, 1494–1502. [Google Scholar] [CrossRef]

- Foubelo, F.; Nájera, C.; Yus, M. Catalytic asymmetric transfer hydrogenation of ketones: Recent advances. Tetrahedron Asymmetry 2015, 26, 769–790. [Google Scholar] [CrossRef]

- Taylor, K.C. Nitric oxide catalysis in automotive exhaust systems. Catal. Rev.-Sci. Eng. 1993, 35, 457–481. [Google Scholar] [CrossRef]

- Yoneda, N.; Kusano, S.; Yasui, M.; Pujado, P.; Wilcher, S. Recent advances in processes and catalysts for the production of acetic acid. Appl. Catal. A Gen. 2001, 221, 253–265. [Google Scholar] [CrossRef]

- Arambasic, M.; Hooper, J.F.; Willis, M.C. Activating group recycling in action: A rhodium-catalyzed carbothiolation route to substituted isoquinolines. Org. Lett. 2013, 15, 5162–5165. [Google Scholar] [CrossRef] [PubMed]

- Liu, S. Metallurgy of Platinum Group Metals; Central South University Press: Changsha, China, 2013; pp. 24–76. [Google Scholar]

- Wilburn, D.R.; Bleiwas, D.I. Platinum-Group Metals--World Supply and Demand; US geological survey open-file report, 2004-1224; U.S. Department of the Interior: Washington, DC, USA, 2005.

- He, X.; Guo, J.; Wang, H.; Li, Y.; Wu, X.; Zhao, Y.; Han, S.; Li, K.; Tan, W.; Liu, W. Reviews of platinum group metals secondary resource and recycling industries in China. Precious Met. 2013, 34, 82–89. [Google Scholar]

- Zhang, R.; Chen, Q.; Liu, Q.; Yu, W.; Tan, H. World demand and analysis of supply and demand of platinum-group metals. Resour. Sci. 2015, 37, 1018–1029. [Google Scholar]

- Kim, C.-H.; Woo, S.I.; Jeon, S.H. Recovery of platinum-group metals from recycled automotive catalytic converters by carbochlorination. Ind. Eng. Chem. Res. 2000, 39, 1185–1192. [Google Scholar] [CrossRef]

- Kasuya, R.; Miki, T.; Morikawa, H.; Tai, Y. Dissolution of platinum in catalyst materials using hydrochloric acid: A new method based on the use of complex oxides. Miner. Eng. 2016, 87, 25–31. [Google Scholar] [CrossRef]

- Pérez-Ramírez, J.; Kapteijn, F.; Schöffel, K.; Moulijn, J.A. Formation and control of N2O in nitric acid production: Where do we stand today? Appl. Catal. B Environ. 2003, 44, 117–151. [Google Scholar] [CrossRef]

- Horn, R.; Mestl, G.; Thiede, M.; Jentoft, F.C.; Schmidt, P.M.; Bewersdorf, M.; Weber, R.; Schlögl, R. Gas phase contributions to the catalytic formation of HCN from CH4 and NH3 over Pt: An in situ study by molecular beam mass spectrometry with threshold ionization. Phys. Chem. Chem. Phys. 2004, 6, 4514–4521. [Google Scholar] [CrossRef]

- Brown, A.C.R.; Pearce, R.; Reynolds, G. Method for recovery of metals by incineration of metal contg. basic ion exchange resin. Patent CN1452605A, 29 October 2003. [Google Scholar]

- Steinhoff, B.A.; Fix, S.R.; Stahl, S.S. Mechanistic study of alcohol oxidation by the Pd(OAc)2/O2/DMSO catalyst system and implications for the development of improved aerobic oxidation catalysts. J. Am. Chem. Soc. 2002, 124, 766–767. [Google Scholar] [CrossRef] [PubMed]

- Hagelüken, C. Precious metals process catalysts: Material flows and recycling. Chim. Oggi 2006, 24, 14–17. [Google Scholar]

- Adámek, J.; Bartuška, P.; Lejček, P.; Baretzky, B. Grain boundary segregation and brittle fracture in a Pt-Rh base alloy. Scr. Mater. 1999, 40, 485–489. [Google Scholar] [CrossRef]

- Peng, Z.; Li, Z.; Lin, X.; Tang, H.; Ye, L.; Ma, Y.; Rao, M.; Zhang, Y.; Li, G.; Jiang, T. Pyrometallurgical recovery of platinum group metals from spent catalysts. JOM 2017, 69, 1553–1562. [Google Scholar] [CrossRef]

- He, X.; Wang, H.; Wu, X.; Li, Y.; Zhao, Y.; Han, S.; Li, K.; Guo, J. Study on the recovery of rhodium from spent organic rhodium catalysts of acetic acid industry using pyrometallurgical process. Precious Met. 2012, 33, 24–27. [Google Scholar]

- Byrd, A.J.; Pant, K.K.; Gupta, R.B. Hydrogen production from glycerol by reforming in supercritical water over Ru/Al2O3 catalyst. Fuel 2008, 87, 2956–2960. [Google Scholar] [CrossRef]

- Mark, M.F.; Maier, W.F. CO2-reforming of methane on supported Rh and Ir catalysts. J. Catal. 1996, 164, 122–130. [Google Scholar] [CrossRef]

- Samel, U.R.; Bieg, W.; Broellos, K.; Irnich, R. Process for the recovery and recycling of nickel, cobalt and rhodium from mixtures comprising aliphatic carboxylic acids. Patent EP0337262, 18 October 1989. [Google Scholar]

- Liu, H.; Duarte, A.; Meihack, W.; Ratchev, I.P. Production of ferro-nickel or nickel matte by a combined hydrometallurgical and pyrometallurgical process. Patent US7597738B2, 06 October 2009. [Google Scholar]

- Rossini, G.; Bernardes, A.M. Galvanic sludge metals recovery by pyrometallurgical and hydrometallurgical treatment. J. Hazard. Mater. 2006, 131, 210–216. [Google Scholar] [CrossRef]

- Birloaga, I.; Veglio, F. An innovative hybrid hydrometallurgical approach for precious metals recovery from secondary resources. J. Environ. Manag. 2022, 307, 114567. [Google Scholar] [CrossRef]

- Chen, Z.; Ren, Z.; Zheng, R.; Gao, H.; Ni, B.J. Migration behavior of impurities during the purification of waste graphite powders. J. Environ. Manag. 2022, 315, 115150. [Google Scholar] [CrossRef]

- Choubey, P.K.; Singh, N.; Panda, R.; Jyothi, R.K.; Yoo, K.; Park, I.; Jha, M.K. Development of hydrometallurgical process for recovery of rare earth metals (Nd, Pr, and Dy) from Nd-Fe-B magnets. Metals 2021, 11, 1987. [Google Scholar] [CrossRef]

- ÖZer, A.; Özer, D.; İbrahim Ekİz, H. The equilibrium and kinetic modelling of the biosorption of copper(ii) ions on cladophora crispata. Adsorption 2005, 10, 317–326. [Google Scholar] [CrossRef]

- Buhling, A.; Elgersma, J.W.; Nkrumah, S.; Kamer, P.C.J.; van Leeuwen, P.W.N.M. Novel amphiphilic diphosphines: Synthesis, rhodium complexes, use in hydroformylation and rhodium recycling. J. Chem. Soc. Dalton Trans. 1996, 10, 2143–2154. [Google Scholar] [CrossRef]

- Candeias, N.R.; Afonso, C.A.M.; Gois, P.M.P. Making expensive dirhodium(ii) catalysts cheaper: Rh(ii) recycling methods. Org. Biomol. Chem. 2012, 10, 3357–3378. [Google Scholar] [CrossRef]

- Gurung, M.; Adhikari, B.B.; Alam, S.; Kawakita, H.; Ohto, K.; Inoue, K. Persimmon tannin-based new sorption material for resource recycling and recovery of precious metals. Chem. Eng. J. 2013, 228, 405–414. [Google Scholar] [CrossRef]

- Buhling, A.; Kamer, P.C.J.; van Leeuwen, P.W.N.M.; Elgersma, J.W.; Goubitz, K.; Fraanje, J. Novel amphiphilic diphosphines: synthesis, X-ray structure, rhodium complexes, use in hydroformylation, and rhodium recycling. Organometallics 1997, 16, 3027–3037. [Google Scholar] [CrossRef]

- De Wolf, E.; Speets, E.A.; Deelman, B.J.; van Koten, G. Recycling of rhodium-based hydrosilylation catalysts; A fluorous approach. Organometallics 2001, 20, 3686–3690. [Google Scholar] [CrossRef]

- Lei, X. Review on the development of precious metal recovery industry in china. World Nonferrous Met. 2007, 42, 163–175. [Google Scholar]

- Cui, J.; Zhang, L. Metallurgical recovery of metals from electronic waste: A review. J. Hazard. Mater. 2008, 158, 228–256. [Google Scholar] [CrossRef]

- Chang, F.Y.; Chen, J.C.; Wey, M.-Y. Catalytic removal of NO in waste incineration processes over Rh/Al2O3 and Rh–Na/Al2O3: Effects of particulates, heavy metals, SO2 and HCl. Fuel Process. Technol. 2009, 90, 576–582. [Google Scholar] [CrossRef]

- Sakamoto, M.; Mori, T.; Tsuboi, A. Recovery method of rhodium. US Patent 5364445A, 15 November 1994. [Google Scholar]

- Wang, R.; Zhao, X.; Zhang, W.; Gao, C.; Liu, G. Process for recovering metal rhodium from residual liquid of waste rhodium catalyst. Patent CN1273278A, 15 November 2000. [Google Scholar]

- Yong, L.I.; Tang, H.X.; Xiong, Q.F.; Yao, Y.; Xiao, X.; Wang, H.; Zhao, Y.; Ning, X.X. Recovery of platinum group metals from spent auto-catalysts by smelting. Nonferrous Met. 2017, 145, 40–43. [Google Scholar]

- Zhou, L.; Dong, H.; Zhao, J.; Yuedong, W.U.; Bojie, L.I.; Yang, H.; Bao, S.; Tong, W. Recovery of Rh from spent organic catalyst by solid state reduction iron collection. Precious Met. 2015, 36, 17–20. [Google Scholar]

- Zhao, J.; Cui, H.; Bao, S.; Tong, W.; Dong, H. Recovery of Pt, Pd and Rh from spent auto catalysts by copper collection method. Precious Met. 2018, 39, 56–59. [Google Scholar]

- Toru, S. Method for recovering platinum group metal. Patent JPH01225729A, 8 September 1989. [Google Scholar]

- Ferracin, L.C.; Chácon-Sanhueza, A.E.; Davoglio, R.A.; Rocha, L.O.; Caffeu, D.J.; Fontanetti, A.R.; Rocha-Filho, R.C.; Biaggio, S.R.; Bocchi, N. Lead recovery from a typical brazilian sludge of exhausted lead-acid batteries using an electrohydrometallurgical process. Hydrometallurgy 2002, 65, 137–144. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, W.; Zou, W.; Li, J.; Zheng, R.; Wei, W.; Ni, B.J.; Chen, H. Integrating electrodeposition with electrolysis for closed-loop resource utilization of battery industrial wastewater. Green Chem. 2022, 24, 3208–3217. [Google Scholar] [CrossRef]

- Syed, S. A green technology for recovery of gold from non-metallic secondary sources. Hydrometallurgy 2006, 82, 48–53. [Google Scholar] [CrossRef]

- Huang, K.; Chen, J.; Chen, Y.R.; Zhao, J.C.; Yang, Q.X. Recovery of precious metals from spent auto-catalysts by method of pressure alkaline treatment-cyanide leaching. Chin. J. Nonferrous Met. 2006, 16, 363–369. [Google Scholar]

- Demopoulos, G.P. Solvent extraction in precious metals refining. JOM 1986, 38, 13–17. [Google Scholar] [CrossRef]

- Barnes, R.L. Process for recovery of rhodium values. Patent US4364907A, 21 December 1982. [Google Scholar]

- Fuchs, S.; Steffen, M.; Dobrowolski, A.; Rösler, T.; Johnen, L.; Meier, G.; Strutz, H.; Behr, A.; Vorholt, A.J. Secondary diamines as a monomer from bis-hydroaminomethylation of industrial cyclic dienes. Catal. Sci. Technol. 2017, 7, 5120–5127. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, J.; Wang, Y.; Liu, C.; Jin, Z. A new thermoregulated PEG biphasic system and its application for hydroformylation of 1-dodecene. J. Mol. Catal. A Chem. 2007, 261, 288–292. [Google Scholar] [CrossRef]

- Miceli, M.; Frontera, P.; Macario, A.; Malara, A. Recovery/reuse of heterogeneous supported spent catalysts. Catalysts 2021, 11, 591. [Google Scholar] [CrossRef]

- Yu, P.; Huang, K.; Zhang, C.; Xie, K.; He, X.; Liu, H. One-step separation of platinum, palladium, and rhodium: A three-liquid-phase extraction approach. Ind. Eng. Chem. Res. 2011, 50, 9368–9376. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, Q.; Xiang, Z.; Yang, Y. Separation of Pt(IV), Pd(II), Ru(III), and Rh(III) from chloride medium using liquid–liquid extraction with mixed imidazolium-based ionic liquids. Sep. Sci. Technol. 2018, 53, 2064–2073. [Google Scholar] [CrossRef]

- Brunsch, Y.; Behr, A. Temperature-controlled catalyst recycling in homogeneous transition-metal catalysis: Minimization of catalyst leaching. Angew. Chem. Int. Ed. 2013, 52, 1586–1589. [Google Scholar] [CrossRef]

- Behr, A.; Brunsch, Y.; Lux, A. Rhodium nanoparticles as catalysts in the hydroformylation of 1-dodecene and their recycling in thermomorphic solvent systems. Tetrahedron Lett. 2012, 53, 2680–2683. [Google Scholar] [CrossRef]

- Mc George, B.; Gaylard, P.G.; Lewis, A.E. Mechanism of rhodium(III) co-precipitation with copper sulfide (at low Rh concentrations) incorporating a new cationic substitution reaction path. Hydrometallurgy 2009, 96, 235–245. [Google Scholar] [CrossRef]

- Chen, G.; Yuan, Z.; Jiang, S.; Gong, H. Advances in technologies for recovering precious metal rhodium from spent catalysts. Sino-Glob. Energy 2021, 26, 65–69. [Google Scholar]

- Usui, S.; Ito, Y.; Okajima, N.; Swkine, K. Method for Recovering Rhodium. Patent CN101045959A, 3 October 2007. [Google Scholar]

- Renner, H.; Kleiss, K.; Schlodder, R. Process for the Recovery of Noble Metals from Solutions. Patent US4687514 A, 18 August 1987. [Google Scholar]

- Kleinwachter, I.; Kleiss, K.; Gerner, R. Process for the separation of rhodium from organic solutions. Patent US5256188 A, 26 October 1993. [Google Scholar]

- Du, X.; Zhang, X.; Zhou, Y.; Yang, J.; Lv, J. Hydrometallurgical processes of platinum group metals recovery from exhaust catalysts. China Min. Mag. 2009, 18, 82–85. [Google Scholar]

- Els, E.R.; Lorenzen, L.; Aldrich, C. The adsorption of precious metals and base metals on a quaternary ammonium group ion exchange resin. Miner. Eng. 2000, 13, 401–414. [Google Scholar] [CrossRef]

- Iglesias, M.; Anticó, E.; Salvadó, V. Recovery of palladium(II) and gold(III) from diluted liquors using the resin duolite GT-73. Anal. Chim. Acta 1999, 381, 61–67. [Google Scholar] [CrossRef]

- Rovira, M.; Hurtado, L.; Cortina, J.L.; Arnaldos, J.; Sastre, A.M. Recovery of palladium(II) from hydrochloric acid solutions using impregnated resins containing Alamine 336. React. Funct. Polym. 1998, 38, 279–287. [Google Scholar] [CrossRef]

- Kakoi, T.; Goto, M.; Nakashio, F. Separation of platinum and palladium by liquid surfactant membranes utilizing a novel bi-functional surfactant. J. Membr. Sci. 1996, 120, 77–88. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, J.; Zhou, Z.; Yu, X.; Yao, B. A study of Pt4+ adsorption and its reduction by bacillus megaterium. Chem. Res. Chin. Univ. 2000, 16, 246–249. [Google Scholar]

- Veglio, F.; Beolchini, F. Removal of metals by biosorption: A review. Hydrometallurgy 1997, 44, 301–316. [Google Scholar] [CrossRef]

- Berunhalt, F. Recovery method of rhodium-phosphine complex catalyst. Patent 51-048519, 26 April 1976. [Google Scholar]

- Ibrahim, M.Y.S.; Denmark, S.E. Selective extraction of supported Rh nanoparticles under mild, non-acidic conditions with carbon monoxide. J. Mater. Chem. A 2018, 6, 18075–18083. [Google Scholar] [CrossRef]

- Panster, P.; Wieland, S.; Buding, H.; Obrecht, W. Recovery of hydrogenation catalysts from solutions of hydrogenated nitrile rubber. Patent US5403566, 4 April 1995. [Google Scholar]

- Zhang, L.; Yao, M.; Xu, R.; Kuei-Hsien, H.; Zhong, Y. Adsorption of rhodium and ruthenium from hydrogenated nitrile rubbersolution by macroporousion exchange resin. China Synth. Rubber Ind. 2006, 3, 197–199. [Google Scholar]

- Jiang, L.; Yu, H.; Li, J.; Li, C.; Li, J.; Hao, T. Method for preparing rhodium chloride hydrate by recovering rhodium from dead rhodium catalyst of oxo synthesis. Patent CN102923796A, 13 February 2013. [Google Scholar]

- Jiang, L.; Li, C.; Li, J.; Hao, T.; Wang, P.; Wang, B. Study on preparing high-purity rhodium chloride by using digestion solution produced in dispelling waste catalyst containing rhodium from butyl octanol unit. Inorg. Chem. Ind. 2017, 49, 76–78. [Google Scholar]

- Li, C.; Yu, H.; Jiang, L.; Li, J.; Li, J.; Hao, T. Method for recovering rhodium from dead catalysts containing rhodium of hydroformylation reaction through treatment of hydrogen peroxide. Patent CN102925699A, 13 February 2013. [Google Scholar]

- Chun, Y.; Gui, W.; Yu, L. Method of recovering rhodium from spent rhodium catalyst in carbonyl group synthesis reaction. Patent CN1414125A, 30 April 2003. [Google Scholar]

- Chen, Y.; Xu, M.; Wen, J.; Wan, Y.; Zhao, Q.; Cao, X.; Ding, Y.; Wang, Z.L.; Li, H.; Bian, Z. Selective recovery of precious metals through photocatalysis. Nat. Sustain. 2021, 4, 618–626. [Google Scholar] [CrossRef]

- Godlewska-Żyłkiewicz, B.; Malejko, J. Appraisal of biosorption for recovery, separation and determination of platinum, palladium and rhodium in environmental samples. In Platinum Metals in the Environment; Zereini, F., Wiseman, C.L.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 33–52. [Google Scholar]

- Kwak, I.S.; Won, S.W.; Chung, Y.S.; Yun, Y.-S. Ruthenium recovery from acetic acid waste water through sorption with bacterial biosorbent fibers. Bioresour. Technol. 2013, 128, 30–35. [Google Scholar] [CrossRef]

- Das, N. Recovery of precious metals through biosorption—A review. Hydrometallurgy 2010, 103, 180–189. [Google Scholar] [CrossRef]

- Esposito, A.; Pagnanelli, F.; Vegliò, F. pH-related equilibria models for biosorption in single metal systems. Chem. Eng. Sci. 2002, 57, 307–313. [Google Scholar] [CrossRef]

- Bashir, A.; Malik, L.A.; Ahad, S.; Manzoor, T.; Bhat, M.A.; Dar, G.N.; Pandith, A.H. Removal of heavy metal ions from aqueous system by ion-exchange and biosorption methods. Environ. Chem. Lett. 2019, 17, 729–754. [Google Scholar] [CrossRef]

- Liu, S. Preparation of four microbial adsorbents and their removal characteristics and mechanisms for heavy metals from wastewater. Ph.D. Thesis, Kunming University of Science and Technology, Kunming, China, 2019. [Google Scholar]

- Li, W.W.; Yu, H.Q. Insight into the roles of microbial extracellular polymer substances in metal biosorption. Bioresour. Technol. 2014, 160, 15–23. [Google Scholar] [CrossRef]

- Minoda, A.; Miyashita, S.i.; Fujii, S.i.; Inagaki, K.; Takahashi, Y. Cell population behavior of the unicellular red alga Galdieria sulphuraria during precious metal biosorption. J. Hazard. Mater. 2022, 432, 128576. [Google Scholar] [CrossRef] [PubMed]

- Ohata, J.; Ball, Z.T. A hexa-rhodium metallopeptide catalyst for site-specific functionalization of natural antibodies. J. Am. Chem. Soc. 2017, 139, 12617–12622. [Google Scholar] [CrossRef]

- Garcia, A.; Deyris, P.A.; Adler, P.; Pelissier, F.; Dumas, T.; Legrand, Y.M.; Grison, C.I. Ecologically responsible and efficient recycling of Pd from aqueous effluents using biosorption on biomass feedstock. J. Clean. Prod. 2021, 299, 126895. [Google Scholar] [CrossRef]

- Gao, M.; Zhou, Y.; Yan, J.; Zhu, L.; Li, Z.; Hu, X.; Zhan, X. Efficient precious metal Rh(III) adsorption by waste P. pastoris and P. pastoris surface display from high-density culture. J. Hazard. Mater. 2022, 427, 128140. [Google Scholar] [CrossRef] [PubMed]

- Ngwenya, N.; Whiteley, C.G. Recovery of rhodium (iii) from solutions and industrial wastewaters by a sulfate-reducing bacteria consortium. Biotechnol. Prog. 2006, 22, 1604–1611. [Google Scholar] [CrossRef]

- Yousif, A.M. Rapid and selective adsorption of rh(iii) from its solutions using cellulose-based biosorbent containing iminodiacetate functionality. Sep. Sci. Technol. 2011, 46, 2341–2347. [Google Scholar] [CrossRef]

- Mahamadi, C. Will nano-biosorbents break the achilles’ heel of biosorption technology? Environ. Chem. Lett. 2019, 17, 1753–1768. [Google Scholar] [CrossRef]

- Hong, H.J.; Yu, H.; Hong, S.; Hwang, J.Y.; Kim, S.M.; Park, M.S.; Jeong, H.S. Modified tunicate nanocellulose liquid crystalline fiber as closed loop for recycling platinum-group metals. Carbohydr. Polym. 2020, 228, 115424. [Google Scholar] [CrossRef] [PubMed]

| Application Fields | Catalyst Carrier | PGMs | Content/wt.% | References | |

|---|---|---|---|---|---|

| Automotive industry | Catalysts | Cordierite monolith ceramic | Pt/Rh; Pt-Pd-Rh; Pt, | 0.1–0.5 | [1,30] |

| Metallic monolith | Pt; Rh | [31] | |||

| Bulk and specialties | Nitric acid | Gauzes | Pt-Rh | 100 | [32] |

| HCN | Al2O3, gauzes | Pt/Rh | 0.1, 100 | [1,33] | |

| Fine Chemicals | Hydrogenation | Activated carbon Al2O3, SiO2 | Pd; Pd/Pt, Ru; Rh; Ir | 0.5–10 | [34] |

| Oxidation | Activated carbon | Pd; Pd/Pt, Ru; Rh; Ir | [35] | ||

| Debenzylation | Activated carbon | Pd; Pd/Pt, Ru; Rh; Ir | [36] | ||

| Glass industry | Glass fiber | Pt-Rh alloy | Pt-Rh | 100 | [37,38] |

| Homogeneous products | Acetic acid | SiO2, Metallic monolith | Rh; Ir/Ru | 0.01–5 | [39] |

| Oil refining industry | Reforming | Al2O3 | Ru; Rh/Ir | 0.02–1.2 | [40,41] |

| Method | Advantage | Disadvantage | |

|---|---|---|---|

| Pyrometallurgical process | Incineration | Simple process; no chemical additives required; high recovery rate. | The need to control the rate of incineration; prevent loss of fugitive material. |

| Plasma melting | Short process flow; high efficiency; no wastewater and waste gas generation; high platinum enrichment. | Not very suitable for materials containing SiO2; short service life of plasma guns at high temperatures. | |

| Metal trapping method | High adaptability of raw materials; low operating costs; weak reduction atmosphere; high capture efficiency; large production scale. | Rh recovery is low (65% to 70%); number of factors to consider when selecting a metal trap. | |

| Volatilization | Simple process; low reagent consumption; low energy consumption. | Corrosive; high equipment requirements; toxic gases to be handled. | |

| Hydrometallurgical process | Extraction method | Good separation effect; simple operation; high safety; low energy consumption. | Requires large amounts of extractant and diluent; ingredients are mostly toxic reagents. |

| Coprecipitation | Simple equipment; low investment; large processing capacity. | Inconvenient to operate; slow reaction speed; introduction of other elements; easy to produce secondary pollution. | |

| Adsorption separation | High separation efficiency; low cost; simple equipment and operation. | Rhodium is difficult to separate in resin; high cost of resin incineration; serious secondary contamination. | |

| Biosorption | Cheap; easy to obtain; flexibility. | Immobilization of biomaterials, distribution of biosorbents; regeneration and recycling are also important issues to be solved. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, M.; Jiang, G.; Chen, H.; Pang, Y.; Yuan, F.; Zhang, Z.; Miao, N.; Zheng, C.; Song, J.; Li, Y.; et al. Recent Developments on Processes for Recovery of Rhodium Metal from Spent Catalysts. Catalysts 2022, 12, 1415. https://doi.org/10.3390/catal12111415

Jia M, Jiang G, Chen H, Pang Y, Yuan F, Zhang Z, Miao N, Zheng C, Song J, Li Y, et al. Recent Developments on Processes for Recovery of Rhodium Metal from Spent Catalysts. Catalysts. 2022; 12(11):1415. https://doi.org/10.3390/catal12111415

Chicago/Turabian StyleJia, Mingqi, Guangshen Jiang, Hanchu Chen, Yue Pang, Fei Yuan, Zhen Zhang, Naiqian Miao, Chengzhuo Zheng, Jianhui Song, Yanyan Li, and et al. 2022. "Recent Developments on Processes for Recovery of Rhodium Metal from Spent Catalysts" Catalysts 12, no. 11: 1415. https://doi.org/10.3390/catal12111415

APA StyleJia, M., Jiang, G., Chen, H., Pang, Y., Yuan, F., Zhang, Z., Miao, N., Zheng, C., Song, J., Li, Y., & Wang, H. (2022). Recent Developments on Processes for Recovery of Rhodium Metal from Spent Catalysts. Catalysts, 12(11), 1415. https://doi.org/10.3390/catal12111415