A Review on Catalysts Development for Steam Reforming of Biodiesel Derived Glycerol; Promoters and Supports

Abstract

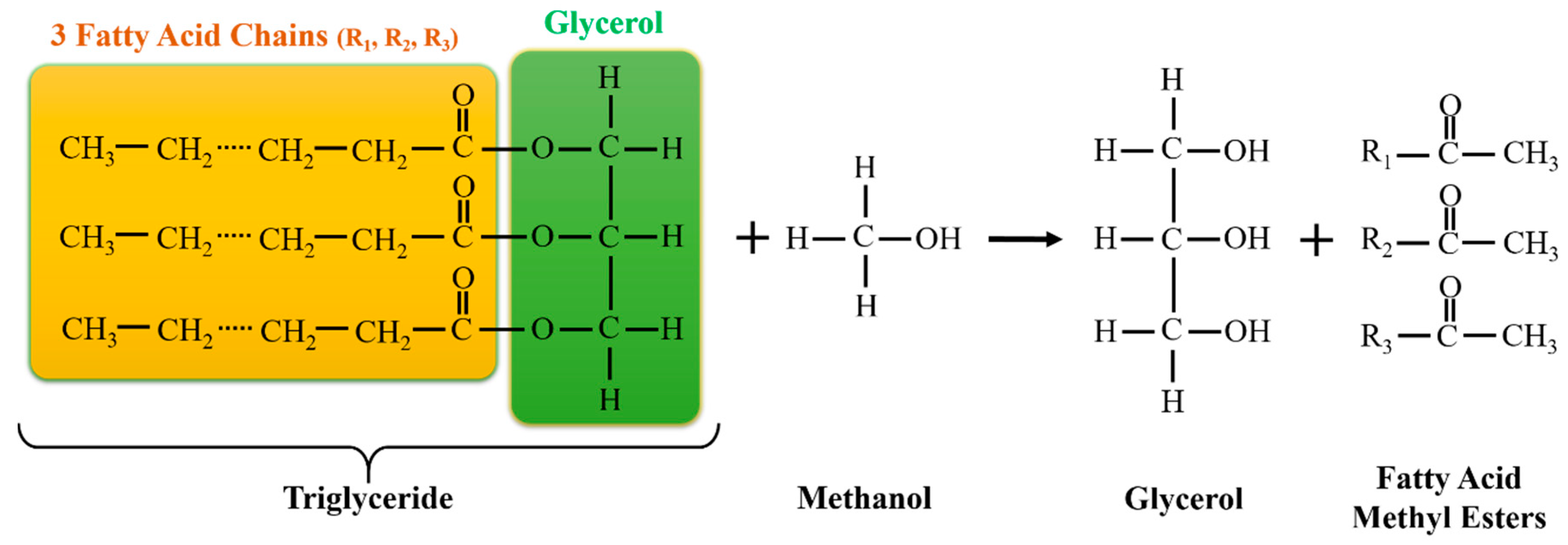

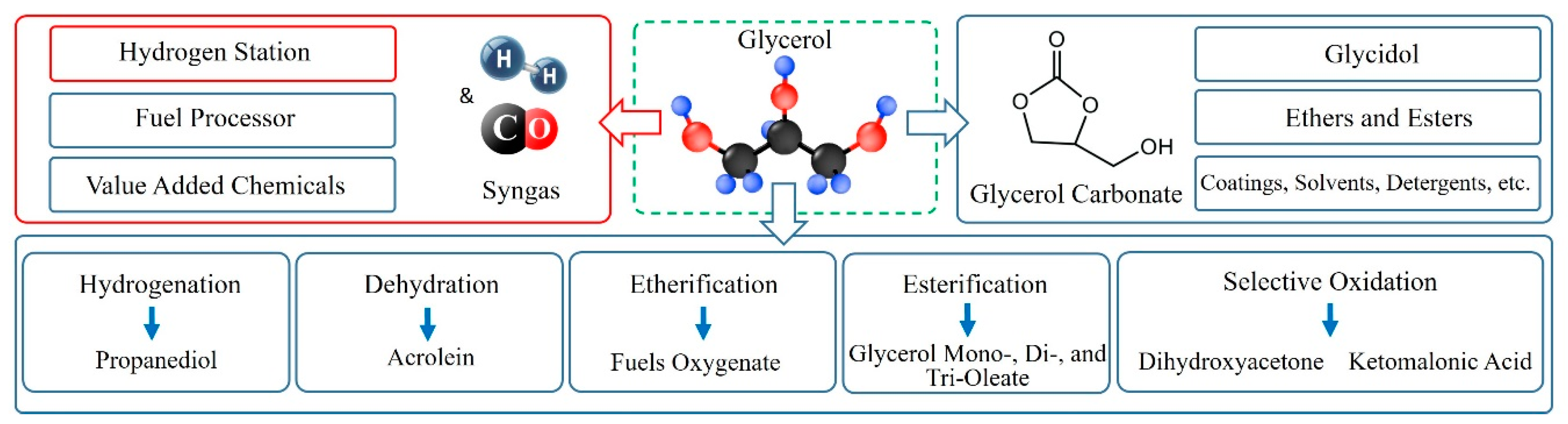

1. Introduction

2. Perspective of Catalysts

3. Steam Reforming of Glycerol

ΔH25 °C = 128 KJ/mol

ΔH25 °C = 251 KJ/mol

ΔH25 °C = −41 KJ/mol

(ΔH25 °C = −206 kJ)

(ΔH25 °C = −165 kJ)

(ΔH25 °C = 247 kJ)

(ΔH25 °C = −172 kJ)

(ΔH25 °C = 75 kJ)

(ΔH25 °C = −131 kJ)

(ΔH25 °C = 306 kJ)

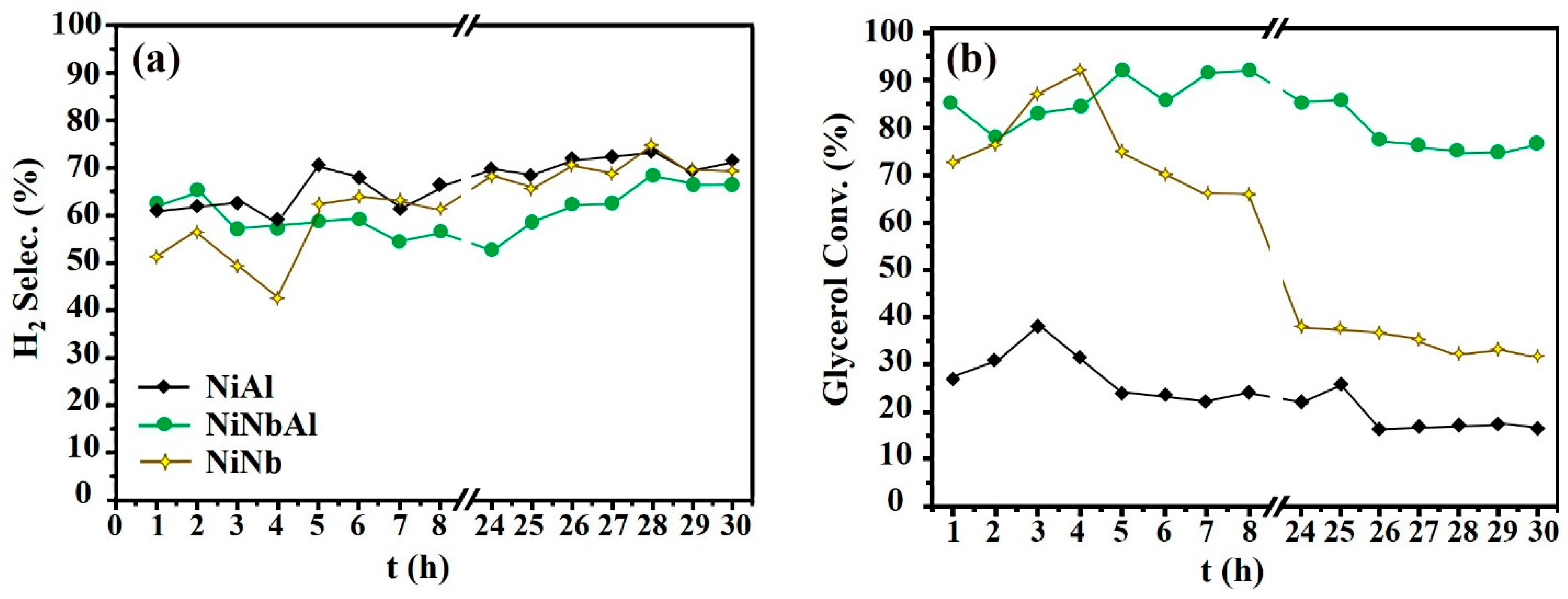

4. The Effect of Support in SR of Glycerol over Ni-Based Catalysts

5. The Effect of Promoters in SR of Glycerol over Ni-Based Catalyst

6. SR of Glycerol over the Perovskite-Based Catalyst

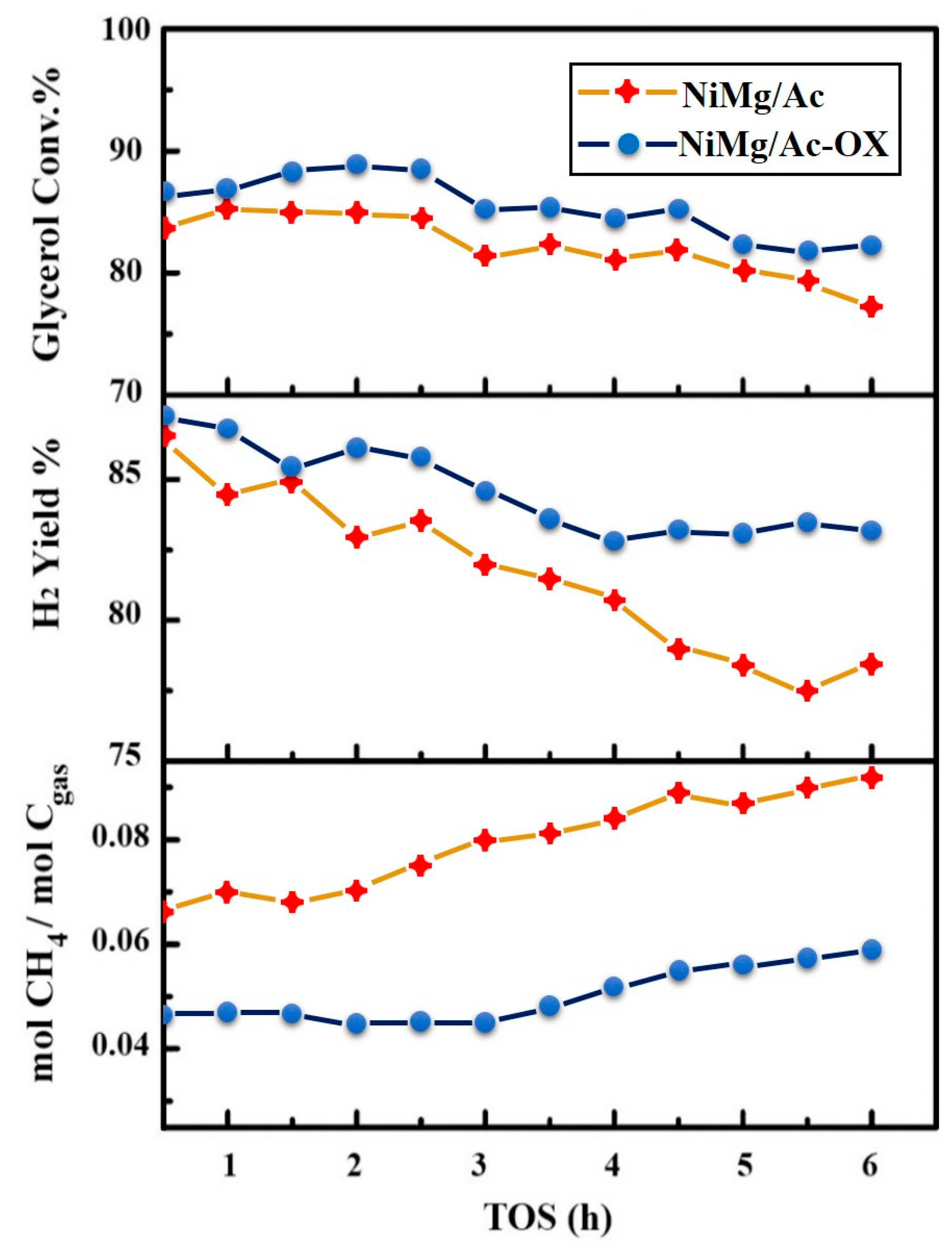

7. The SR of Glycerol over Hydrotalcite-Based Catalyst

8. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Chang, C.-J.; Lin, Y.-G.; Weng, H.-T.; Wei, Y.-H. Photocatalytic hydrogen production from glycerol solution at room temperature by ZnO-ZnS/graphene photocatalysts. Appl. Surf. Sci. 2018, 451, 198–206. [Google Scholar] [CrossRef]

- Rúa, D.; Hernández, L. Phenomenological evaluation of industrial reformers for glycerol steam reforming. Int. J. Hydrogen Energy 2016, 41, 13811–13819. [Google Scholar] [CrossRef]

- Song, J.H.; Han, S.J.; Song, I.K. Hydrogen Production by Steam Reforming of Ethanol Over Mesoporous Ni-Al2O3-ZrO2 Catalysts. Catal. Surv. Asia 2017, 21, 114–129. [Google Scholar] [CrossRef]

- Baykara, S.Z. Hydrogen: A brief overview on its sources, production and environmental impact. Int. J. Hydrogen Energy 2018, 43, 10605–10614. [Google Scholar] [CrossRef]

- Seo, J.; Youn, M.; Song, I. Mesoporous Nickel-Alumina Catalysts for Hydrogen Production by Steam Reforming of Liquefied Natural Gas (LNG). Catal. Surv. Asia 2009, 14, 1–10. [Google Scholar] [CrossRef]

- Sheikhbahaei, V.; Baniasadi, E.; Naterer, G. Experimental investigation of solar assisted hydrogen production from water and aluminum. Int. J. Hydrogen Energy 2018, 43, 9181–9191. [Google Scholar] [CrossRef]

- Arapova, M.V.; Pavlova, S.; Rogov, V.A.; Krieger, T.A.; Ishchenko, A.; Roger, A.-C. Ni(Co)-containing catalysts based on perovskite-like ferrites for steam reforming of ethanol. Catal. Sustain. Energy 2014, 2, 10–20. [Google Scholar] [CrossRef]

- Almind, M.R.; Vendelbo, S.B.; Hansen, M.F.; Vinum, M.G.; Frandsen, C.; Mortensen, P.M.; Engbaek, J.S. Improving performance of induction-heated steam methane reforming. Catal. Today 2020, 342, 13–20. [Google Scholar] [CrossRef]

- Choi, B.K.; Ok, H.J.; Moon, D.J.; Kim, J.H.; Park, N.C.; Kim, Y.C. Carbon deposition from the co2-steam reforming of methane over modified Ni/γ-Al2O3 catalysts. J. Nanosci. Nanotechnol. 2015, 15, 391–395. [Google Scholar] [CrossRef]

- Schwengber, C.A.; Alves, H.J.; Schaffner, R.A.; Da Silva, F.A.; Sequinel, R.; Bach, V.R.; Ferracin, R.J. Overview of glycerol reforming for hydrogen production. Renew. Sustain. Energy Rev. 2016, 58, 259–266. [Google Scholar] [CrossRef]

- Yang, E.-H.; Noh, Y.S.; Hong, G.H.; Moon, D.J. Combined steam and CO2 reforming of methane over La1-xSrxNiO3 perovskite oxides. Catal. Today 2018, 299, 242–250. [Google Scholar] [CrossRef]

- Tamošiūnas, A.; Valatkevičius, P.; Gimžauskaitė, D.; Valinčius, V.; Jeguirim, M. Glycerol steam reforming for hydrogen and synthesis gas production. Int. J. Hydrogen Energy 2017, 42, 12896–12904. [Google Scholar] [CrossRef]

- Ghoreishi, S.; Moein, P. Biodiesel synthesis from waste vegetable oil via transesterification reaction in supercritical methanol. J. Supercrit. Fluids 2013, 76, 24–31. [Google Scholar] [CrossRef]

- He, L.; Parra, J.M.S.; Blekkan, A.; Chen, D. Towards efficient hydrogen production from glycerol by sorption enhanced steam reforming. Energy Environ. Sci. 2010, 3, 1046–1056. [Google Scholar] [CrossRef]

- Wang, C.; Dou, B.; Chen, H.; Song, Y.; Xu, Y.; Du, X.; Luo, T.; Tan, C. Hydrogen production from steam reforming of glycerol by Ni-Mg-Al based catalysts in a fixed-bed reactor. Chem. Eng. J. 2013, 220, 133–142. [Google Scholar] [CrossRef]

- Pradima, J.; Kulkarni, M.R. Archna Review on enzymatic synthesis of value added products of glycerol, a by-product derived from biodiesel production. Res. Effic. Technol. 2017, 3, 394–405. [Google Scholar]

- Yang, F.; Hanna, M.A.; Sun, R. Value-added uses for crude glycerol—a byproduct of biodiesel production. Biotechnol. Biofuels 2012, 5, 13. [Google Scholar] [CrossRef]

- Valin, H.; Peters, D.; Berg, M.V.D.; Frank, S.; Havlik, P.; Forsell, N.; Hamelinck, C.; Pirker, J.; Mosnier, A.; Balkovic, J.; et al. The Land Use Change Impact of Biofuels Consumed in the Eu; ECOFYS: Utrecht, The Netherland, 2015. [Google Scholar]

- Dou, B.; Zhang, H.; Song, Y.; Zhao, L.; Jiang, B.; He, M.; Ruan, C.; Chen, H.; Xu, Y. Hydrogen production from the thermochemical conversion of biomass: Issues and challenges. Sustain. Energy Fuels 2019, 3, 314–342. [Google Scholar] [CrossRef]

- Kim, Y.C.; Moon, D.J. Sustainable Process for the Synthesis of Value-Added Products Using Glycerol as a Useful Raw Material. Catal. Surv. Asia 2019, 23, 10–22. [Google Scholar] [CrossRef]

- Iriondo, A.; Barrio, V.; Cambra, J.F.; Arias, P.L.; Güemez, B.; Sanchez-Sanchez, M.; Navarro, R.; Fierro, J.L.G. Glycerol steam reforming over Ni catalysts supported on ceria and ceria-promoted alumina. Int. J. Hydrogen Energy 2010, 35, 11622–11633. [Google Scholar] [CrossRef]

- Sad, M.; Duarte, H.A.; Vignatti, C.; Padró, C.; Apesteguia, C. Steam reforming of glycerol: Hydrogen production optimization. Int. J. Hydrogen Energy 2015, 40, 6097–6106. [Google Scholar] [CrossRef]

- Wu, G.; Zhang, C.; Li, S.; Han, Z.; Wang, T.; Ma, X.; Gong, J. Hydrogen Production via Glycerol Steam Reforming over Ni/Al2O3: Influence of Nickel Precursors. ACS Sustain. Chem. Eng. 2013, 1, 1052–1062. [Google Scholar] [CrossRef]

- Kousi, K.; Kondarides, D.; Verykios, X.; Papadopoulou, C. Glycerol steam reforming over modified Ru/Al2O3 catalysts. Appl. Catal. A Gen. 2017, 542, 201–211. [Google Scholar] [CrossRef]

- Senseni, A.Z.; Rezaei, M.; Meshkani, F. Glycerol steam reforming over noble metal nanocatalysts. Chem. Eng. Res. Des. 2017, 123, 360–366. [Google Scholar] [CrossRef]

- Zamzuri, N.H.; Mat, R.; Amin, N.A.S.; Talebian-Kiakalaieh, A. Hydrogen production from catalytic steam reforming of glycerol over various supported nickel catalysts. Int. J. Hydrogen Energy 2017, 42, 9087–9098. [Google Scholar] [CrossRef]

- Goula, M.; Charisiou, N.; Papageridis, K.; Siakavelas, G. Influence of the synthesis method parameters used to prepare nickel-based catalysts on the catalytic performance for the glycerol steam reforming reaction. Chin. J. Catal. 2016, 37, 1949–1965. [Google Scholar] [CrossRef]

- Veiga, S.; Bussi, J. Steam reforming of crude glycerol over nickel supported on activated carbon. Energy Convers. Manag. 2017, 141, 79–84. [Google Scholar] [CrossRef]

- Kamonsuangkasem, K.; Therdthianwong, S.; Therdthianwong, A.; Thammajak, N. Remarkable activity and stability of Ni catalyst supported on CeO2-Al2O3 via CeAlO3 perovskite towards glycerol steam reforming for hydrogen production. Appl. Catal. B Environ. 2017, 218, 650–663. [Google Scholar] [CrossRef]

- Dębek, R.; Motak, M.; Grzybek, T.; Gálvez, M.E.; Da Costa, P. A Short Review on the Catalytic Activity of Hydrotalcite-Derived Materials for Dry Reforming of Methane. Catalysts 2017, 7, 32. [Google Scholar] [CrossRef]

- Shekoohi, K.; Hosseini, F.S.; Haghighi, A.H.; Sahrayian, A. Synthesis of some Mg/Co-Al type nano hydrotalcites and characterization. MethodsX 2017, 4, 86–94. [Google Scholar] [CrossRef]

- Sikander, U.; Sufian, S.; Salam, M.A. A review of hydrotalcite based catalysts for hydrogen production systems. Int. J. Hydrogen Energy 2017, 42, 19851–19868. [Google Scholar] [CrossRef]

- Silva, J.M.; Soria, M.A.; Madeira, L.M. Challenges and strategies for optimization of glycerol steam reforming process. Renew. Sust. Energ. Rev. 2015, 42, 1187–1213. [Google Scholar] [CrossRef]

- Dang, C.; Yu, H.; Wang, H.; Peng, F.; Yang, Y. A bi-functional Co-CaO-Ca12Al14O33 catalyst for sorption-enhanced steam reforming of glycerol to high-purity hydrogen. Chem. Eng. J. 2016, 286, 329–338. [Google Scholar] [CrossRef]

- Lima, D.S.; Calgaro, C.O.; Perez-Lopez, O.W. Hydrogen production by glycerol steam reforming over Ni based catalysts prepared by different methods. Biomass Bioenerg. 2019, 130, 105358. [Google Scholar] [CrossRef]

- Zhang, B.; Tang, X.; Li, Y.; Xu, Y.; Shen, W. Hydrogen production from steam reforming of ethanol and glycerol over ceria-supported metal catalysts. Int. J. Hydrogen Energy 2007, 32, 2367–2373. [Google Scholar] [CrossRef]

- Koc, S.; Avci, A.K. Reforming of glycerol to hydrogen over Ni-based catalysts in a microchannel reactor. Fuel Process. Technol. 2017, 156, 357–365. [Google Scholar] [CrossRef]

- Shao, S.; Shi, A.-W.; Liu, C.-L.; Yang, R.-Z.; Dong, W.-S. Hydrogen production from steam reforming of glycerol over ni/cezro catalysts. Fuel Process. Technol. 2014, 125, 1–7. [Google Scholar] [CrossRef]

- Ebshish, A.; Yaakob, Z.; Narayanan, B.; Bshish, A.; Daud, W.R.W. Steam reforming of glycerol over Ni supported alumina xerogel for hydrogen production. Energy Procedia. 2012, 18, 552–559. [Google Scholar] [CrossRef]

- Sahraei, O.A.Z.; Luo, Y.; Abatzoglou, N.; Iliuta, M. Hydrogen production by glycerol steam reforming catalyzed by Ni-promoted Fe/Mg-bearing metallurgical wastes. Appl. Catal. B Environ. 2017, 219, 183–193. [Google Scholar] [CrossRef]

- Nichele, V.; Signoretto, M.; Menegazzo, F.; Gallo, A.; Dal Santo, V.; Cruciani, G.; Cerrato, G. Glycerol steam reforming for hydrogen production: Design of Ni supported catalysts. Appl. Catal. B Environ. 2012, 111, 225–232. [Google Scholar] [CrossRef]

- Rossetti, I.; Gallo, A.; Dal Santo, V.; Bianchi, C.L.; Nichele, V.; Signoretto, M.; Finocchio, E.; Ramis, G.; Di Michele, A. Nickel Catalysts Supported Over TiO2, SiO2 and ZrO2 for the Steam Reforming of Glycerol. ChemCatChem 2012, 5, 294–306. [Google Scholar] [CrossRef]

- Ming, F.; Qingli, X.; Wei, Q.; Zhikai, Z.; Suping, Z.; Yongjie, Y. Hydrogen production from glycerol steam reforming over Ni/La/Co/Al2O3 catalyst. Energy Sources Part A Recover. Util. Environ. Eff. 2016, 38, 2128–2134. [Google Scholar] [CrossRef]

- Kousi, K.; Chourdakis, N.; Matralis, H.; Kontarides, D.; Papadopoulou, C.; Verykios, X. Glycerol steam reforming over modified Ni-based catalysts. Appl. Catal. A Gen. 2016, 518, 129–141. [Google Scholar] [CrossRef]

- Veiga, S.; Faccio, R.; Romero, M.; Bussi, J. Utilization of waste crude glycerol for hydrogen production via steam reforming over Ni-La-Zr catalysts. Biomass Bioenergy 2020, 135, 105508. [Google Scholar] [CrossRef]

- Feng, P.; Huang, K.; Xu, Q.; Qi, W.; Xin, S.; Wei, T.; Liao, L.; Yan, Y. Ni supported on the CaO modified attapulgite as catalysts for hydrogen production from glycerol steam reforming. Int. J. Hydrogen Energy 2020, 45, 8223–8233. [Google Scholar] [CrossRef]

- Veiga, S.; Romero, M.; Faccio, R.; Segobia, D.; Duarte, H.; Apesteguía, C.; Bussi, J. Hydrogen-rich gas production by steam and oxidative steam reforming of crude glycerol over Ni-La-Me mixed oxide catalysts (Me = Ce and/or Zr). Catal. Today 2020, 344, 190–198. [Google Scholar] [CrossRef]

- Chen, D.; Wang, W.; Liu, C. Hydrogen production through glycerol steam reforming over beehive-biomimetic graphene-encapsulated nickel catalysts. Renew. Energy 2020, 145, 2647–2657. [Google Scholar] [CrossRef]

- Suffredini, D.F.; Thyssen, V.V.; De Almeida, P.M.; Gomes, R.S.; Borges, M.C.; De Farias, A.M.D.; Assaf, E.M.; Fraga, M.A.; Brandão, S.T. Renewable hydrogen from glycerol reforming over nickel aluminate-based catalysts. Catal. Today 2017, 289, 96–104. [Google Scholar] [CrossRef]

- Bepari, S.; Pradhan, N.C.; Dalai, A.K. Selective production of hydrogen by steam reforming of glycerol over Ni/Fly ash catalyst. Catal. Today 2017, 291, 36–46. [Google Scholar] [CrossRef]

- Charisiou, N.D.; Siakavelas, G.; Papageridis, K.N.; Baklavaridis, A.; Tzounis, L.; Polychronopoulou, K.; Goula, M.A. Hydrogen production via the glycerol steam reforming reaction over nickel supported on alumina and lanthana-alumina catalysts. Int. J. Hydrogen Energy 2017, 42, 13039–13060. [Google Scholar] [CrossRef]

- Veiga, S.; Faccio, R.; Segobia, D.; Apesteguía, C.; Bussi, J. Hydrogen production by crude glycerol steam reforming over Ni-La-Ti mixed oxide catalysts. Int. J. Hydrogen Energy 2017, 42, 30525–30534. [Google Scholar] [CrossRef]

- Jiang, B.; Li, L.; Bian, Z.; Li, Z.; Sun, Y.; Sun, Z.; Tang, D.; Kawi, S.; Dou, B.; Goula, M.A. Chemical looping glycerol reforming for hydrogen production by Ni@ZrO2 nanocomposite oxygen carriers. Int. J. Hydrogen Energy 2018, 43, 13200–13211. [Google Scholar] [CrossRef]

- Parlar Karakoc, O.; Kibar, M.E.; Akin, A.N.; Yildiz, M. Nickel-based catalysts for hydrogen production by steam reforming of glycerol. Int. J. Environ. Sci. Technol. 2019, 16, 5117–5124. [Google Scholar] [CrossRef]

- Thyssen, V.V.; Sartore, D.M.; Assaf, E.M. Effect of preparation method on the performance of Ni/MgOSiO2 catalysts for glycerol steam reforming. J. Energy Inst. 2019, 92, 947–958. [Google Scholar] [CrossRef]

- Bizkarra, K.; Barrio, V.L.; Gartzia-Rivero, L.; Bañuelos, J.; López-Arbeloa, I.; Cambra, J.F. Hydrogen production from a model bio-oil/bio-glycerol mixture through steam reforming using zeolite l supported catalysts. Int. J. Hydrogen Energy 2019, 44, 1492–1504. [Google Scholar] [CrossRef]

- Dahdah, E.; Estephane, J.; Gennequin, C.; Aboukaïs, A.; Abi-Aad, E.; Aouad, S. Zirconia supported nickel catalysts for glycerol steam reforming: Effect of zirconia structure on the catalytic performance. Int. J. Hydrogen Energy 2020, 45, 4457–4467. [Google Scholar] [CrossRef]

- Shokrollahi Yancheshmeh, M.; Alizadeh Sahraei, O.; Aissaoui, M.; Iliuta, M.C. A novel synthesis of NiAl2O4 spinel from a Ni-Al mixed-metal alkoxide as a highly efficient catalyst for hydrogen production by glycerol steam reforming. Appl. Catal. B Environ. 2020, 265, 118535. [Google Scholar] [CrossRef]

- Menezes, J.P.d.S.Q.; Jácome, F.C.; Manfro, R.L.; Souza, M.M.V.M. Effect of cao addition on nickel catalysts supported on alumina for glycerol steam reforming. Catal. Lett. 2019, 149, 1991–2003. [Google Scholar] [CrossRef]

- Adhikari, S.; Fernando, S.D.; To, S.D.F.; Bricka, R.M.; Steele, P.H.; Haryanto, A. Conversion of glycerol to hydrogen via a steam reforming process over nickel catalysts. Energy Fuels 2008, 22, 1220–1226. [Google Scholar] [CrossRef]

- Buffoni, I.N.; Pompeo, F.; Santori, G.F.; Nichio, N.N. Nickel catalysts applied in steam reforming of glycerol for hydrogen production. Catal. Commun. 2009, 10, 1656–1660. [Google Scholar] [CrossRef]

- Choi, G.Y. Steam Reforming of Glycerol for Hydrogen Production on Ni-Supported Catalysts. Master’s Thesis, Chonnam National University, Gwangju, Korea, 2012. [Google Scholar]

- Menezes, J.P.d.S.Q.; Manfro, R.L.; Souza, M.M.V.M. Hydrogen production from glycerol steam reforming over nickel catalysts supported on alumina and niobia: Deactivation process, effect of reaction conditions and kinetic modeling. Int. J. Hydrogen Energy 2018, 43, 15064–15082. [Google Scholar] [CrossRef]

- Bastan, F.; Kazemeini, M.; Larimi, A.; Maleki, H. Production of renewable hydrogen through aqueous-phase reforming of glycerol over Ni/Al2O3MgO nano-catalyst. Int. J. Hydrogen Energy 2018, 43, 614–621. [Google Scholar] [CrossRef]

- Liu, S.; Yan, Z.; Zhang, Y.; Wang, R.; Luo, S.-Z.; Jing, F.; Chu, W. Carbon nanotubes supported nickel as the highly efficient catalyst for hydrogen production through glycerol steam reforming. ACS Sustain. Chem. Eng. 2018, 6, 14403–14413. [Google Scholar] [CrossRef]

- Prasongthum, N.; Xiao, R.; Zhang, H.; Tsubaki, N.; Natewong, P.; Reubroycharoen, P. Highly active and stable Ni supported on CNTs-SiO2 fiber catalysts for steam reforming of ethanol. Process. Technol. 2017, 160, 185–195. [Google Scholar] [CrossRef]

- Rahman, M.M. H2 production from aqueous-phase reforming of glycerol over Cu-Ni bimetallic catalysts supported on carbon nanotubes. Int. J. Hydrogen Energy 2015, 40, 14833–14844. [Google Scholar] [CrossRef]

- Yan, Y.; Miao, J.; Yang, Z.; Xiao, F.-X.; Yang, H.B.; Liu, B.; Yang, Y. Carbon nanotube catalysts: Recent advances in synthesis, characterization and applications. Chem. Soc. Rev. 2015, 44, 3295–3346. [Google Scholar] [CrossRef]

- Dal Santo, V.; Gallo, A.; Naldoni, A.; Guidotti, M.; Psaro, R. Bimetallic heterogeneous catalysts for hydrogen production. Catal. Today 2012, 197, 190–205. [Google Scholar] [CrossRef]

- Araque, M.; Martínez, T.L.M.; Vargas, J.C.; Centeno, M.A.; Roger, A.C. Effect of the active metals on the selective H2 production in glycerol steam reforming. Appl. Catal. B Environ. 2012, 125, 556–566. [Google Scholar] [CrossRef]

- Frusteri, F.; Freni, S.; Chiodo, V.; Spadaro, L.; Di Blasi, O.; Bonura, G.; Cavallaro, S. Steam reforming of bio-ethanol on alkali-doped Ni/MgO catalysts: Hydrogen production for MC fuel cell. Appl. Catal. A Gen. 2004, 270, 1–7. [Google Scholar] [CrossRef]

- Iriondo, A.; Barrio, V.L.; Cambra, J.F.; Arias, P.L.; Guemez, M.B.; Navarro, R.M.; Sanchez-Sanchez, M.; Fierro, J.L.G.; Yerga, R.M.N. Hydrogen Production from Glycerol Over Nickel Catalysts Supported on Al2O3 Modified by Mg, Zr, Ce or La. Top. Catal. 2008, 49, 46–58. [Google Scholar] [CrossRef]

- Gallegos-Suarez, E.; Guerrero-Ruiz, A.; Fernández-García, M.; Rodríguez-Ramos, I.; Kubacka, A. Efficient and stable Ni-Ce glycerol reforming catalysts: Chemical imaging using X-ray electron and scanning transmission microscopy. Appl. Catal. B Environ. 2015, 165, 139–148. [Google Scholar] [CrossRef]

- Demsash, H.D.; Mohan, R. Steam reforming of glycerol to hydrogen over ceria promoted nickel-alumina catalysts. Int. J. Hydrogen Energy 2016, 41, 22732–22742. [Google Scholar] [CrossRef]

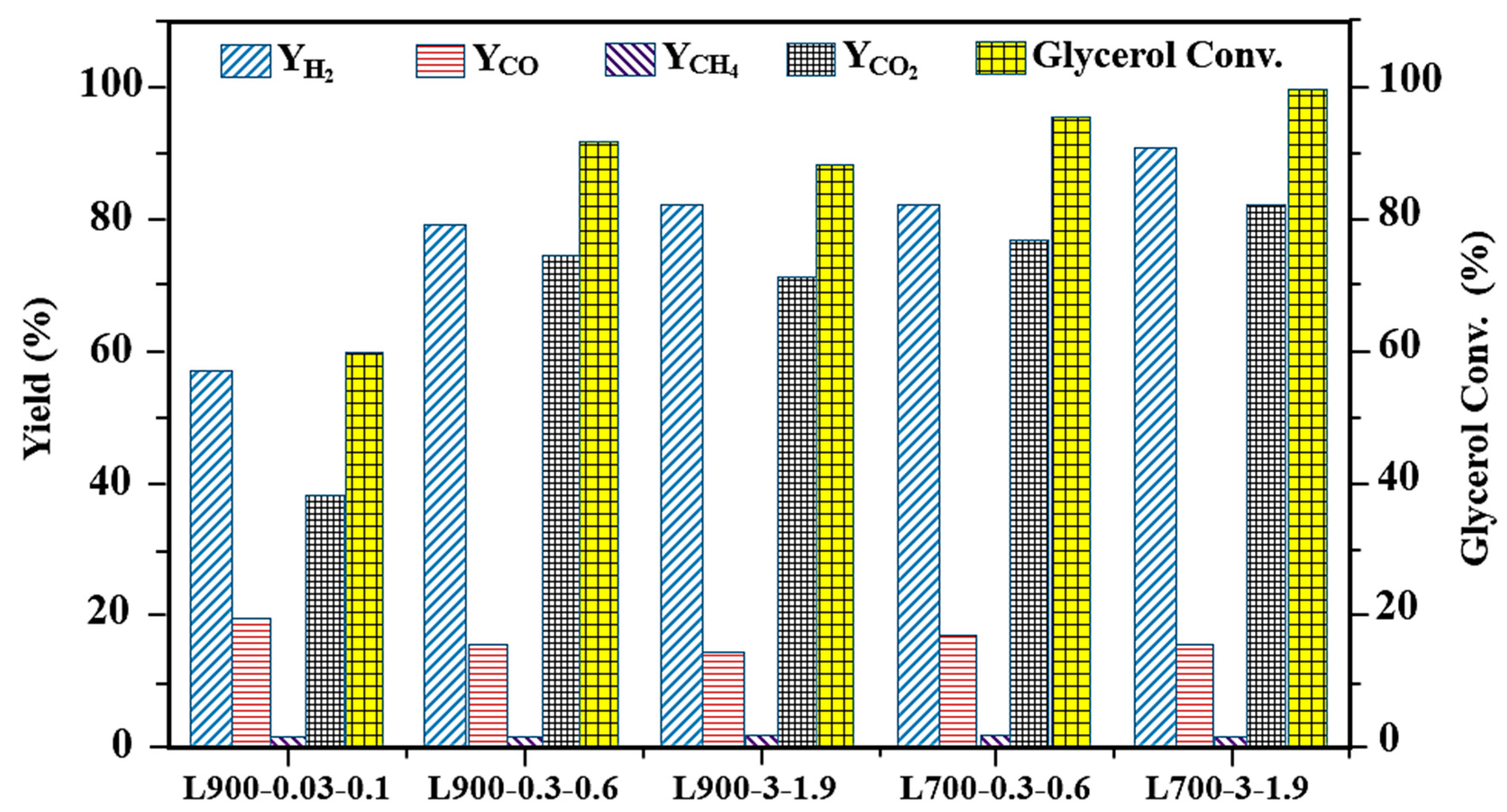

- Go, G.-S. Catalytic Activity and Kinetics in Glycerol Steam Reforming over Ni-Based Catalyst. Master’s Thesis, Department of Chemical Engineering Graduate School, Chonnam National University, Seoul, Korea, 2016. [Google Scholar]

- Hakim, L.; Sari, R.; Daud, W.R.W.; Yaakob, Z.; Ismail, M. Hydrogen production by steam reforming of glycerol over Ni/Ce/Cu hydroxyapatite-supported catalysts. Chem. Pap. 2013, 67, 703–712. [Google Scholar] [CrossRef]

- Sánchez, N.; Encinar, J.M.; Nogales-Delgado, S.; González, J.F. Lanthanum Effect on Ni/Al2O3 as a Catalyst Applied in Steam Reforming of Glycerol for Hydrogen Production. Processes 2019, 7, 449. [Google Scholar] [CrossRef]

- Wang, C.; Dou, B.; Jiang, B.; Song, Y.; Du, B.; Zhang, C.; Wang, K.; Chen, H.; Xu, Y. Sorption-enhanced steam reforming of glycerol on Ni-based multifunctional catalysts. Int. J. Hydrogen Energy 2015, 40, 7037–7044. [Google Scholar] [CrossRef]

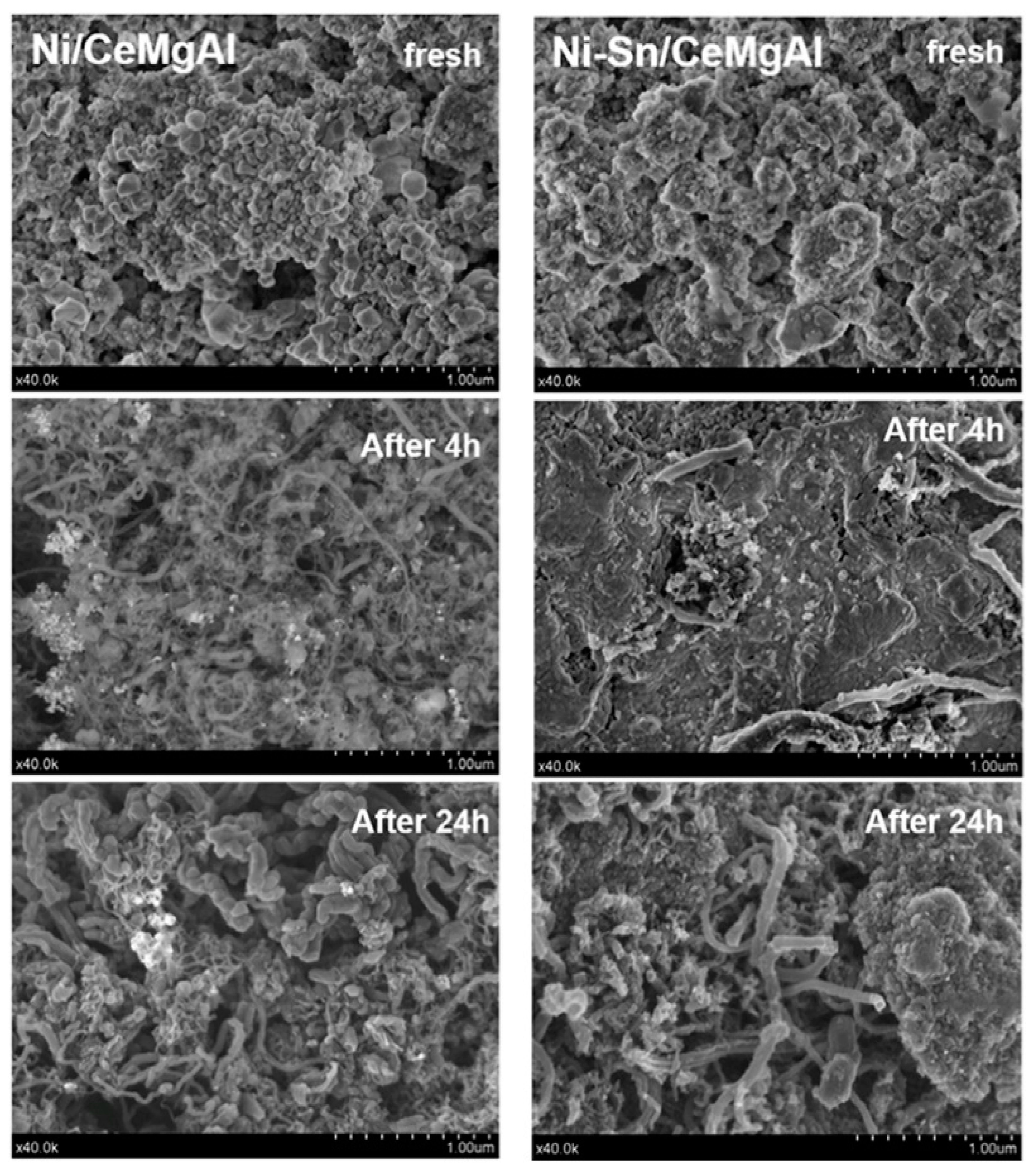

- Bobadilla, L.; Romero-Sarria, F.; Centeno, M.Á.; Odriozola, J.A. Promoting effect of Sn on supported Ni catalyst during steam reforming of glycerol. Int. J. Hydrogen Energy 2016, 41, 9234–9244. [Google Scholar] [CrossRef]

- Oemar, U.; Ang, M.L.; Hidajat, K.; Kawi, S. Enhancing performance of Ni/La2O3 catalyst by Sr-modification for steam reforming of toluene as model compound of biomass tar. RSC Adv. 2015, 5, 17834–17842. [Google Scholar] [CrossRef]

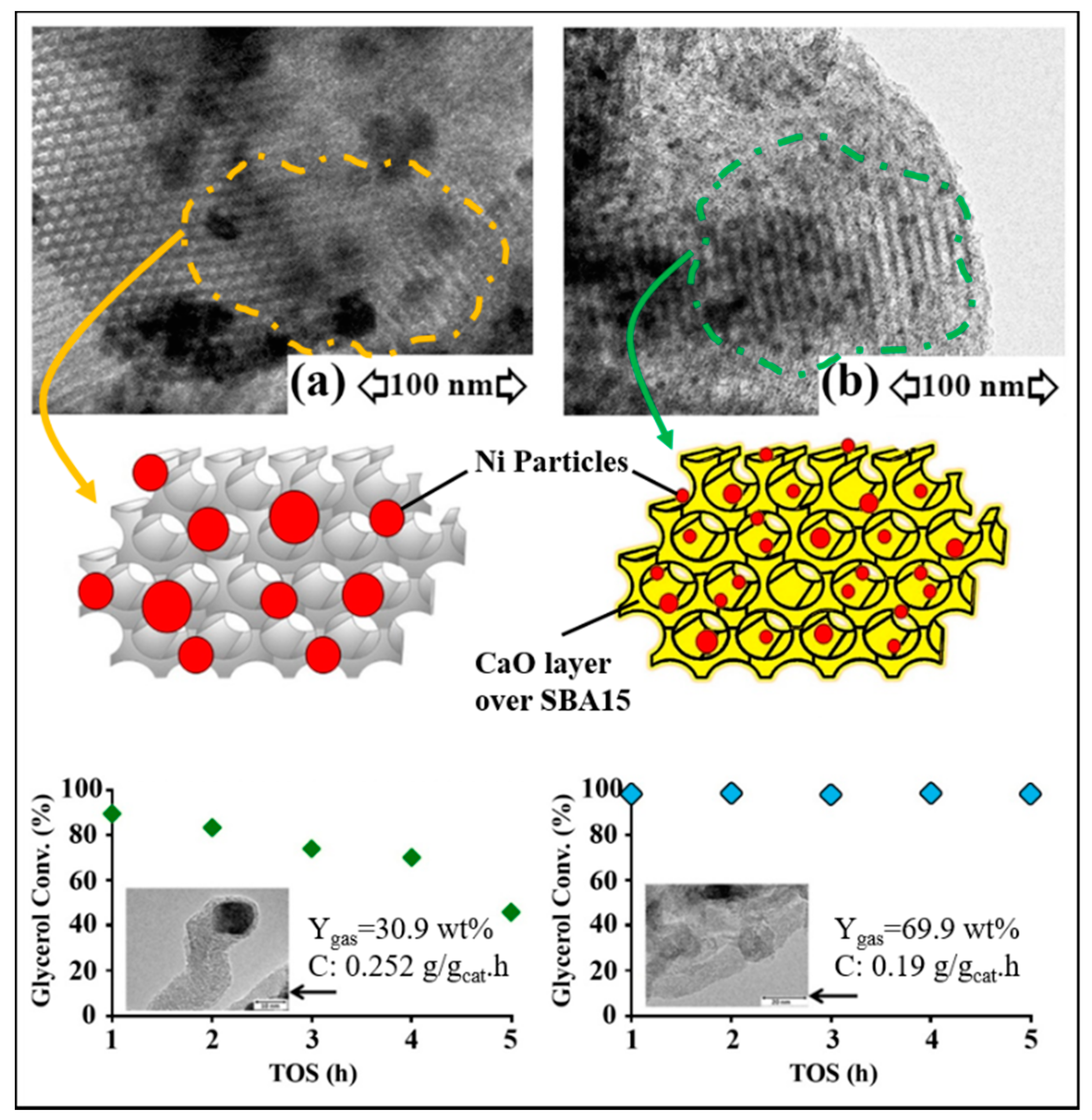

- Calles, J.; Carrero, A.; Vizcaíno, A.; Garcia-Moreno, L. Hydrogen production by glycerol steam reforming over SBA-15-supported nickel catalysts: Effect of alkaline earth promoters on activity and stability. Catal. Today 2014, 227, 198–206. [Google Scholar] [CrossRef]

- Choong, C.K.; Zhong, Z.; Huang, L.; Wang, Z.; Ang, T.P.; Borgna, A.; Lin, J.; Hong, L.; Chen, L. Effect of calcium addition on catalytic ethanol steam reforming of Ni/Al2O3: I. Catalytic stability, electronic properties and coking mechanism. Appl. Catal. A Gen. 2011, 407, 145–154. [Google Scholar] [CrossRef]

- Seung-Hoon, K.; Jae-Sun, J.; Eun-Hyeok, Y.; Kwan-Young, L.; Ju, M.D. Hydrogen production by steam reforming of biomass-derived glycerol over Ni-based catalysts. Catal. Today 2014, 228, 145–151. [Google Scholar] [CrossRef]

- Kitamura, S.; Su-Enaga, T.; Ikenaga, N.-O.; Miyake, T.; Suzuki, T. Steam Reforming of Glycerin Using Ni-based Catalysts Loaded on CaO-ZrO2 Solid Solution. Catal. Lett. 2011, 141, 895–905. [Google Scholar] [CrossRef]

- Go, Y.-J.; Go, G.-S.; Lee, H.-J.; Moon, D.J.; Park, N.-C.; Kim, Y.C. The relation between carbon deposition and hydrogen production in glycerol steam reforming. Int. J. Hydrogen Energy 2015, 40, 11840–11847. [Google Scholar] [CrossRef]

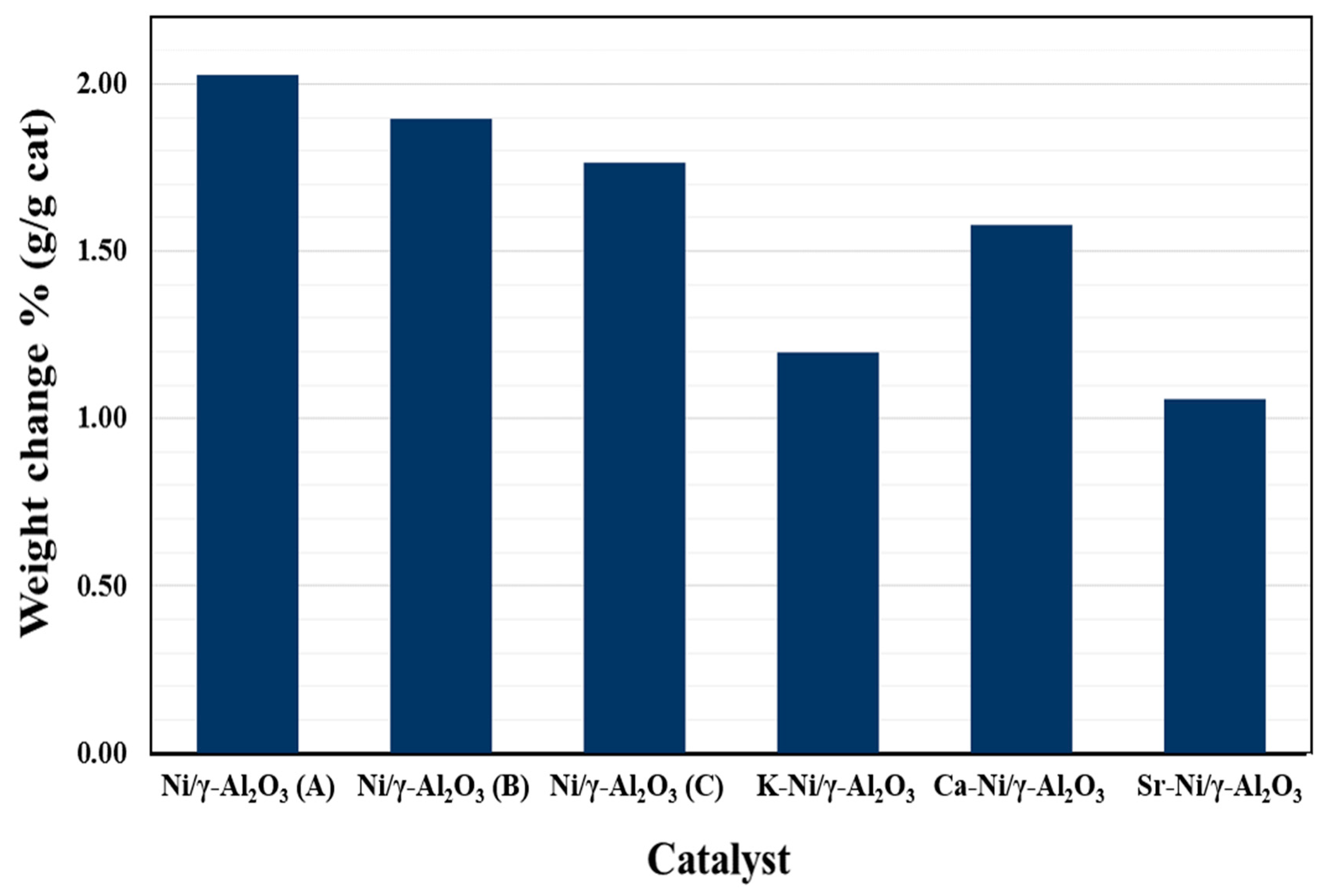

- Huang, Z.-Y.; Xu, C.-H.; Liu, C.-Q.; Xiao, H.-W.; Chen, J.; Zhang, Y.-X.; Lei, Y.-C. Glycerol steam reforming over Ni/γ-Al2O3 catalysts modified by metal oxides. Korean J. Chem. Eng. 2013, 30, 587–592. [Google Scholar] [CrossRef]

- Guerin, S.; Hayden, B.E. ABO3 and A1−xCxB1−yDy(O1−zEz)3: Review of experimental optimisation of thin film perovskites by high-throughput evaporative physical vapour deposition. Chem. Commun. 2019, 55, 10047–10055. [Google Scholar] [CrossRef] [PubMed]

- Aman, D.; Radwan, D.; Ebaid, M.; Mikhail, S.; Van Steen, E. Comparing nickel and cobalt perovskites for steam reforming of glycerol. Mol. Catal. 2018, 452, 60–67. [Google Scholar] [CrossRef]

- Chen, S.; Wang, H.; Liu, Y. Perovskite La-St-Fe-O (St = Ca, Sr) supported nickel catalysts for steam reforming of ethanol: The effect of the A site substitution. Int. J. Hydrogen Energy 2009, 34, 7995–8005. [Google Scholar] [CrossRef]

- Glisenti, A.; Galenda, A.; Natile, M.M. Steam reforming and oxidative steam reforming of methanol and ethanol: The behaviour of LaCo0.7Cu0.3O3. Appl. Catal. A Gen. 2013, 453, 102–112. [Google Scholar] [CrossRef]

- Pereñíguez, R.; Gonzalez-Delacruz, V.M.; Holgado, J.P.; Caballero, A. Synthesis and characterization of a LaNiO3 perovskite as precursor for methane reforming reactions catalysts. Appl. Catal. B Environ. 2010, 93, 346–353. [Google Scholar] [CrossRef]

- Franchini, C.A.; Aranzaez, W.; De Farias, A.M.D.; Pecchi, G.; Fraga, M. Ce-substituted LaNiO3 mixed oxides as catalyst precursors for glycerol steam reforming. Appl. Catal. B Environ. 2014, 147, 193–202. [Google Scholar] [CrossRef]

- Xie, S.; Zhang, X.; Tu, Q.; Shi, B.; Cui, Y.; Chen, C. Influence of Preparation Conditions on the Performance of Ni-Based Catalysts for Glycerol Steam Reforming. ACS Omega 2018, 3, 13335–13342. [Google Scholar] [CrossRef]

- Ramesh, S.; Yang, E.-H.; Jung, J.-S.; Moon, D.J. Copper decorated perovskite an efficient catalyst for low temperature hydrogen production by steam reforming of glycerol. Int. J. Hydrogen Energy 2015, 40, 11428–11435. [Google Scholar] [CrossRef]

- Ramesh, S.; Venkatesha, N.J. Template Free Synthesis of Ni-Perovskite: An Efficient Catalyst for Hydrogen Production by Steam Reforming of Bioglycerol. ACS Sustain. Chem. Eng. 2017, 5, 1339–1346. [Google Scholar] [CrossRef]

- Wu, G.; Li, S.; Zhang, C.; Wang, T.; Gong, J. Glycerol steam reforming over perovskite-derived nickel-based catalysts. Appl. Catal. B Environ. 2014, 144, 277–285. [Google Scholar] [CrossRef]

- Dębek, R.; Motak, M.; Duraczynska, D.; Launay, F.; Galvez, M.E.; Grzybek, T.; Da Costa, P. Methane dry reforming over hydrotalcite-derived Ni-Mg-Al mixed oxides: The influence of Ni content on catalytic activity, selectivity and stability. Catal. Sci. Technol. 2016, 6, 6705–6715. [Google Scholar] [CrossRef]

- Dębek, R.; Motak, M.; Gálvez, M.E.; Grzybek, T.; Da Costa, P. Promotion effect of zirconia on Mg(Ni,Al)O mixed oxides derived from hydrotalcites in CO2 methane reforming. Appl. Catal. B Environ. 2018, 223, 36–46. [Google Scholar] [CrossRef]

- Nawfal, M.; Gennequin, C.; Labaki, M.; Nsouli, B.; Aboukaïs, A.; Abi-Aad, E. Hydrogen production by methane steam reforming over Ru supported on Ni-Mg-Al mixed oxides prepared via hydrotalcite route. Int. J. Hydrogen Energy 2015, 40, 1269–1277. [Google Scholar] [CrossRef]

- Ojeda-Niño, O.H.; Gracia, F.; Daza, C. Role of Pr on Ni-Mg-Al Mixed Oxides Synthesized by Microwave-Assisted Self-Combustion for Dry Reforming of Methane. Ind. Eng. Chem. Res. 2019, 58, 7909–7921. [Google Scholar] [CrossRef]

- Bepari, S.; Basu, S.; Pradhan, N.C.; Dalai, A.K. Steam reforming of ethanol over cerium-promoted Ni-Mg-Al hydrotalcite catalysts. Catal. Today 2017, 291, 47–57. [Google Scholar] [CrossRef]

- Coleman, L.J.I.; Epling, W.; Hudgins, R.R.; Croiset, E. Ni/Mg-Al mixed oxide catalyst for the steam reforming of ethanol. Appl. Catal. A Gen. 2009, 363, 52–63. [Google Scholar] [CrossRef]

- Li, M.; Wang, X.; Li, S.; Wang, S.; Ma, X. Hydrogen production from ethanol steam reforming over nickel based catalyst derived from Ni/Mg/Al hydrotalcite-like compounds. Int. J. Hydrogen Energy 2010, 35, 6699–6708. [Google Scholar] [CrossRef]

- Vizcaíno, A.J.; Lindo, M.; Carrero, A.; Calles, J.A. Hydrogen production by steam reforming of ethanol using Ni catalysts based on ternary mixed oxides prepared by coprecipitation. Int. J. Hydrogen Energy 2012, 37, 1985–1992. [Google Scholar] [CrossRef]

- Ferreira, K.A.; Ribeiro, N.F.P.; Souza, M.M.V.M.; Schmal, M. Structural transformation of Cu-Mg-Al mixed oxide catalysts derived from hydrotalcites during shift reaction. Catal. Lett. 2009, 132, 58–63. [Google Scholar] [CrossRef]

- Furtado, A.C.; Alonso, C.G.; Cantão, M.P.; Fernandes-Machado, N.R.C. Bimetallic catalysts performance during ethanol steam reforming: Influence of support materials. Int. J. Hydrogen Energy 2009, 34, 7189–7196. [Google Scholar] [CrossRef]

- Vizcaíno, A.J.; Carrero, A.; Calles, J.A. Hydrogen production by ethanol steam reforming over Cu-Ni supported catalysts. Int. J. Hydrogen Energy 2007, 32, 1450–1461. [Google Scholar] [CrossRef]

- Wang, F.; Li, Y.; Cai, W.; Zhan, E.; Mu, X.; Shen, W. Ethanol steam reforming over Ni and Ni-Cu catalysts. Catal. Today 2009, 146, 31–36. [Google Scholar] [CrossRef]

- Manfro, R.L.; Souza, M.M.V.M. Production of renewable hydrogen by glycerol steam reforming using Ni-Cu-Mg-Al mixed oxides obtained from hydrotalcite-like compounds. Catal. Lett. 2014, 144, 867–877. [Google Scholar] [CrossRef]

- Dahdah, E.; Aouad, S.; Gennequin, C.; Estephane, J.; Nsouli, B.; Aboukaïs, A.; Abi-Aad, E. Glycerol steam reforming over Ru-Mg-Al hydrotalcite-derived mixed oxides: Role of the preparation method in catalytic activity. Int. J. Hydrogen Energy 2018, 43, 19864–19872. [Google Scholar] [CrossRef]

- De Rezende, S.M.; Franchini, C.A.; Dieuzeide, M.L.; Duarte de Farias, A.M.; Amadeo, N.; Fraga, M.A. Glycerol steam reforming over layered double hydroxide-supported Pt catalysts. Chem. Eng. J. 2015, 272, 108–118. [Google Scholar] [CrossRef]

- Hur, E.; Moon, D.J. Steam reforming of glycerol into hydrogen over nano-size Ni-based hydrotalcite-like catalysts. J. Nanosci. Nanotechnol. 2011, 11, 7394–7398. [Google Scholar] [CrossRef]

| T (°C) | P (Bar) | H2O/C3H8O3 Molar Ratio | Support | Promoters | Ni Content wt% | Glycerol Conversion (%) | Ref. |

|---|---|---|---|---|---|---|---|

| 500,650 | 1 | 3.7 | La2O3-ZrO2 | - | 15 | 99.9 | [45] |

| 400~800 | 3 | CaO-ATP * | - | 10 | 93.7 | [46] | |

| 650 | 1 | 3.7 | CeO2–ZrO2 | La | 12 | 99.9 | [47] |

| 550~650 | - | 9 | Graphene | - | 13~14.7 | 95.1 | [48] |

| 600 | 1 | 12 | Al2O3/Al2O4 | - | 15 | 99.0 | [49] |

| 450~550 | 1 | 8~14 | Fly ash | - | 2.5,5,7.5,10 | 96.0 | [50] |

| 400~750 | 1 | 2.6 | Al2O3,La2O3 | 8 | 70~92.0 | [51] | |

| 500~650 | 1 | 3.7 | TiO2 | La | 15 | 99.7 | [52] |

| 650 | - | 3 | ZrO2 | Pr,Ce,La,Yb | 20 | 90 | [53] |

| 650 | 1 | 6~15 | CeO2,Al2O3,SiO2 | - | 15 | 92 | [54] |

| 650 | - | 12 | SiO2 | Mg | 10 | 91~97.0 | [55] |

| 700 | 1 | 5 | Zeolite Y/CeO2 | Cs or Na | 13 | 99.0 | [56] |

| 400~700 | - | 9 | ZrO2 | - | 5 | 98.0 | [57] |

| 630 | 1 | 9 | NiAl2O4 | - | - | 88.2 | [58] |

| 500 | - | 4 | Al2O3, AlCeO3 | CaO | 20 | 95.0 | [59] |

| Catalyst | T (°C) | Glycerol Conversion (%) | H2 Selectivity (%) | C1 Electivity (%) | ||

|---|---|---|---|---|---|---|

| CO | CH4 | CO2 | ||||

| Ni/Al2O3 | 350 | 74.1 | 33.5 | 77.8 | 0.2 | 21.9 |

| 450 | 99.2 | 83.2 | 28.6 | 2.3 | 69.1 | |

| 550 | 100 | 87.3 | 20.6 | 6.7 | 72.7 | |

| Ni/SiO2(5)-Al2O3 | 350 | 82.7 | 39.7 | 79.1 | 0.9 | 20.0 |

| 450 | 91.9 | 83.4 | 25.4 | 3.5 | 71.2 | |

| 550 | 100 | 85.9 | 21.3 | 6.9 | 71.8 | |

| Ni/SiO2(70)-Al2O3 | 350 | 99.7 | 36.6 | 89.4 | 1.4 | 9.3 |

| 450 | 100 | 58.7 | 45.1 | 13.1 | 41.9 | |

| 550 | 100 | 75.3 | 19.4 | 13.9 | 66.6 | |

| Catalyst | Glycerol Conversion (%) | H2 Selectivity (%) | C1 Product Selectivity (%) | ||

|---|---|---|---|---|---|

| CO | CH4 | CO2 | |||

| NiAl | 81 | 63 | 2.3 | 2.7 | 31.8 |

| NiFeAl | 89 | 63 | 2.0 | 2.2 | 32.1 |

| NiFeCeAl | 94 | 64 | 1.3 | 2.2 | 32.5 |

| Catalyst | Calcination Temp. (°C) | Pore Volume (cc/g) | Particle Size (nm) | BET Surface Area (m2/g) | Pore Size (nm) | |

|---|---|---|---|---|---|---|

| XRD | TEM | |||||

| Ni/Al2O4 | 750 | 0.29 | 15.0 | - | 46 | 7.0 |

| Ni/Al2O3 (A) | 750 | 0.32 | 4.4 | 6.8 | 111 | 11.8 |

| Ni/Al2O3 (B) | 850 | 0.32 | 5.5 | 7.7 | 106 | 12.1 |

| Ni/Al2O3 (C) | 950 | 0.29 | 6.6 | 8.1 | 87 | 13.2 |

| K-Ni/Al2O3 | 950 | 0.30 | 19.2 | 24.5 | 88 | 13.3 |

| Ca-Ni/Al2O3 | 950 | 0.30 | 18.3 | 24.7 | 86 | 13.8 |

| Sr-Ni/Al2O3 | 950 | 0.30 | 19.1 | 24.6 | 90 | 13.2 |

| Catalyst | Reaction Temp. (°C) | Reaction Time (h) | Glycerol Conversion (%) | Selectivity (%) | Coke Formation (g/g cat·h) | |

|---|---|---|---|---|---|---|

| H2 | CH4 | |||||

| NiAl2O4 | 800 | 24 | 75 | 60 | 8.2 | 0.521 |

| Ni/Al2O3(A) | 800 | 24 | 94 | 65 | 6.2 | 0.157 |

| Ni/Al2O3(B) | 800 | 24 | 94 | 64 | 5.9 | 0.149 |

| Ni/Al2O3(C) | 800 | 24 | 95 | 65 | 5.7 | 0.104 |

| Ni/Al2O3(A) | 600 | 24 | 86 | 64 | 4.1 | 0.356 |

| Ni/Al2O3(B) | 600 | 24 | 88 | 64 | 4.1 | 0.284 |

| Ni/Al2O3(C) | 600 | 24 | 90 | 64 | 2.1 | 0.188 |

| K-Ni/Al2O3 | 800 | 100 | 93 | 60 | 4.6 | 0.008 |

| Ca-Ni/Al2O3 | 800 | 100 | 94 | 60 | 4.1 | 0.043 |

| Sr-Ni/Al2O3 | 800 | 100 | 94 | 65 | 0.4 | 0.001 |

| K-Ni/Al2O3 | 600 | 24 | 84 | 63 | 4.2 | 0.217 |

| Ca-Ni/Al2O3 | 600 | 24 | 85 | 63 | 3.9 | 0.148 |

| Sr-Ni/Al2O3 | 600 | 24 | 87 | 63 | 3.7 | 0.136 |

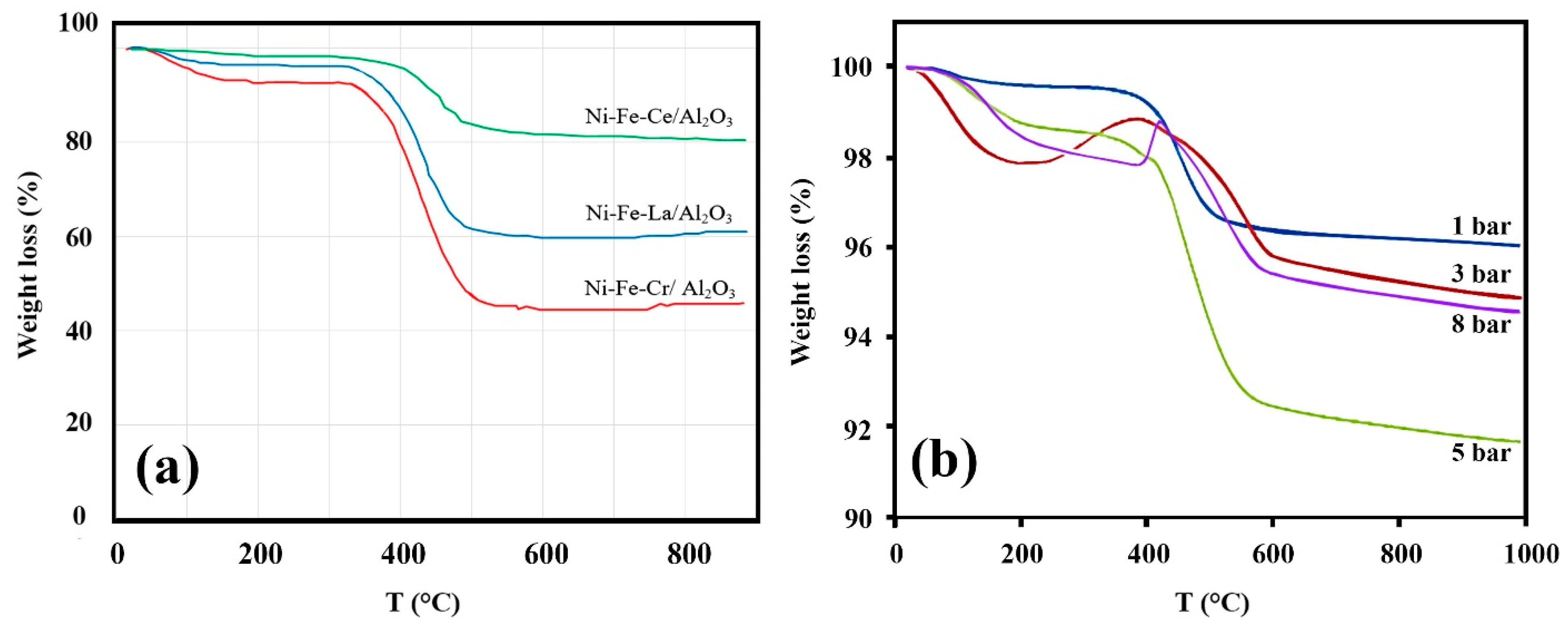

| Catalyst | Composition (wt%) | BET Surface Area (m2/g) * | Metal Dispersion (%) ** | ||||

|---|---|---|---|---|---|---|---|

| Ni | Fe | Ce | La | Cr | |||

| Ni-Fe-Ce/Al2O3 | 15 | 3 | 1 | - | - | 136 | 0.22 |

| Ni-Fe-La/Al2O3 | 15 | 3 | - | 1 | - | 129 | 0.17 |

| Ni-Fe-Cr/Al2O3 | 15 | 3 | - | - | 1 | 125 | 0.08 |

| Catalyst | Glycerol Conversion (%) | H2 Selectivity (%) | C1 Selectivity (%) | ||

|---|---|---|---|---|---|

| CO | CH4 | CO2 | |||

| Ni-Fe-Ce/Al2O3 | 94.1 | 64.0 | 1.3 | 2.7 | 32.0 |

| Ni-Fe-La/Al2O3 | 82.8 | 63.5 | 2.4 | 2.5 | 31.6 |

| Ni-Fe-Cr/Al2O3 | 59.0 | 63.3 | 4.5 | 1.5 | 30.7 |

| Catalysts | Glycerol Conversion (mol%) | Conversion to Gaseous Products | Gas Vol. Produced in 2 h (L) | Production Ratio (L/gG) ** | Gas Product Distribution (mol%) | |||

|---|---|---|---|---|---|---|---|---|

| H2 | CO | CO2 | CH4 | |||||

| Ni/γAl2O3 | 63.9 | 54.1 | 34.4 | 1.17 | 74.1 | 6.4 | 17.9 | 1.6 |

| NiCa/γAl2O3 | 90.6 | 60.1 | 38.2 | 1.30 | 74.8 | 6.5 | 16.9 | 1.7 |

| NiMg/γAl2O3 | 83.7 | 58.1 | 36.9 | 1.26 | 74.8 | 6.4 | 16.6 | 2.2 |

| Ni/CMA *** | 84.6 | 68.4 | 43.5 | 1.48 | 67.9 | 9.2 | 20.6 | 2.3 |

| NiLa/CMA | 84.0 | 66.2 | 42.1 | 1.43 | 71.8 | 8.1 | 17.3 | 2.7 |

| NiCe/CMA | 48.2 | 29.6 | 18.9 | 0.64 | 69.0 | 10.3 | 16.4 | 4.1 |

| NiY/CMA | 67.3 | 43.4 | 27.6 | 0.94 | 68.5 | 9.9 | 17.4 | 4.1 |

| NiZr/CMA | 63.1 | 38.1 | 24.2 | 0.82 | 68.2 | 9.4 | 19.2 | 3.2 |

| NiMo/CMA | 93.4 | 93.0 | 57.3 | 1.95 | 65.2 | 10.5 | 19.9 | 4.4 |

| NiMoLa/CMA | 99.1 | 99.0 | 60.0 | 1.98 | 63.2 | 17.7 | 14.1 | 4.9 |

| T (°C) | Catalyst | Glycerol Conversion (%) | Selectivity (%) | |||

|---|---|---|---|---|---|---|

| H2 | CO | CH4 | CO2 | |||

| 550 | LaNiO3 | 35 | 69 | 0.3 | 1.3 | 30 |

| LaNi0.9Cu0.1O3 | 36 | 68 | 2.7 | 1.0 | 28 | |

| LaNi0.5Cu0.5O3 | 38 | 68 | 1.1 | 0.6 | 30 | |

| 650 | LaNiO3 | 58 | 66 | 2.7 | 3.5 | 28 |

| LaNi0.9Cu0.1O3 | 73 | 67 | 2.6 | 2.6 | 27 | |

| LaNi0.5Cu0.5O3 | 57 | 67 | 2.8 | 2.8 | 27 | |

| T (°C) | Catalyst | BET Surface Area (m2/g) | Glycerol Conversion (%) | Selectivity (%) | |||

|---|---|---|---|---|---|---|---|

| H2 | CO | CH4 | CO2 | ||||

| 550 | LaNiO3 * | 10.7 | 48 | 70 | 0.3 | 0.8 | 28 |

| LaNiO3 | 15.0 | 41 | 69 | 2.7 | 1.3 | 30 | |

| NiAl2O3 | 110 | 5 | 67 | 1.1 | 1.4 | 20 | |

| 650 | LaNiO3 * | 10.7 | 72 | 70 | 2.7 | 2.4 | 24 |

| LaNiO3 | 15.0 | 68 | 66 | 2.6 | 3.5 | 28 | |

| NiAl2O3 | 110 | 56 | 68 | 2.8 | 2.8 | 25 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghaffari Saeidabad, N.; Noh, Y.S.; Alizadeh Eslami, A.; Song, H.T.; Kim, H.D.; Fazeli, A.; Moon, D.J. A Review on Catalysts Development for Steam Reforming of Biodiesel Derived Glycerol; Promoters and Supports. Catalysts 2020, 10, 910. https://doi.org/10.3390/catal10080910

Ghaffari Saeidabad N, Noh YS, Alizadeh Eslami A, Song HT, Kim HD, Fazeli A, Moon DJ. A Review on Catalysts Development for Steam Reforming of Biodiesel Derived Glycerol; Promoters and Supports. Catalysts. 2020; 10(8):910. https://doi.org/10.3390/catal10080910

Chicago/Turabian StyleGhaffari Saeidabad, Nasim, Young Su Noh, Ali Alizadeh Eslami, Hyun Tae Song, Hyun Dong Kim, Ali Fazeli, and Dong Ju Moon. 2020. "A Review on Catalysts Development for Steam Reforming of Biodiesel Derived Glycerol; Promoters and Supports" Catalysts 10, no. 8: 910. https://doi.org/10.3390/catal10080910

APA StyleGhaffari Saeidabad, N., Noh, Y. S., Alizadeh Eslami, A., Song, H. T., Kim, H. D., Fazeli, A., & Moon, D. J. (2020). A Review on Catalysts Development for Steam Reforming of Biodiesel Derived Glycerol; Promoters and Supports. Catalysts, 10(8), 910. https://doi.org/10.3390/catal10080910