The Immobilization of Lipases on Porous Support by Adsorption and Hydrophobic Interaction Method

Abstract

1. Introduction

2. Advantages of Enzymes Immobilization

3. Porous Carriers Used for the Immobilization of Lipase

3.1. Pore and Particle Sizes

3.2. Criteria

4. Types of Immobilization Methods on the Support/Carrier-Binding Method

5. Effect of a Solvent on a Porous Support

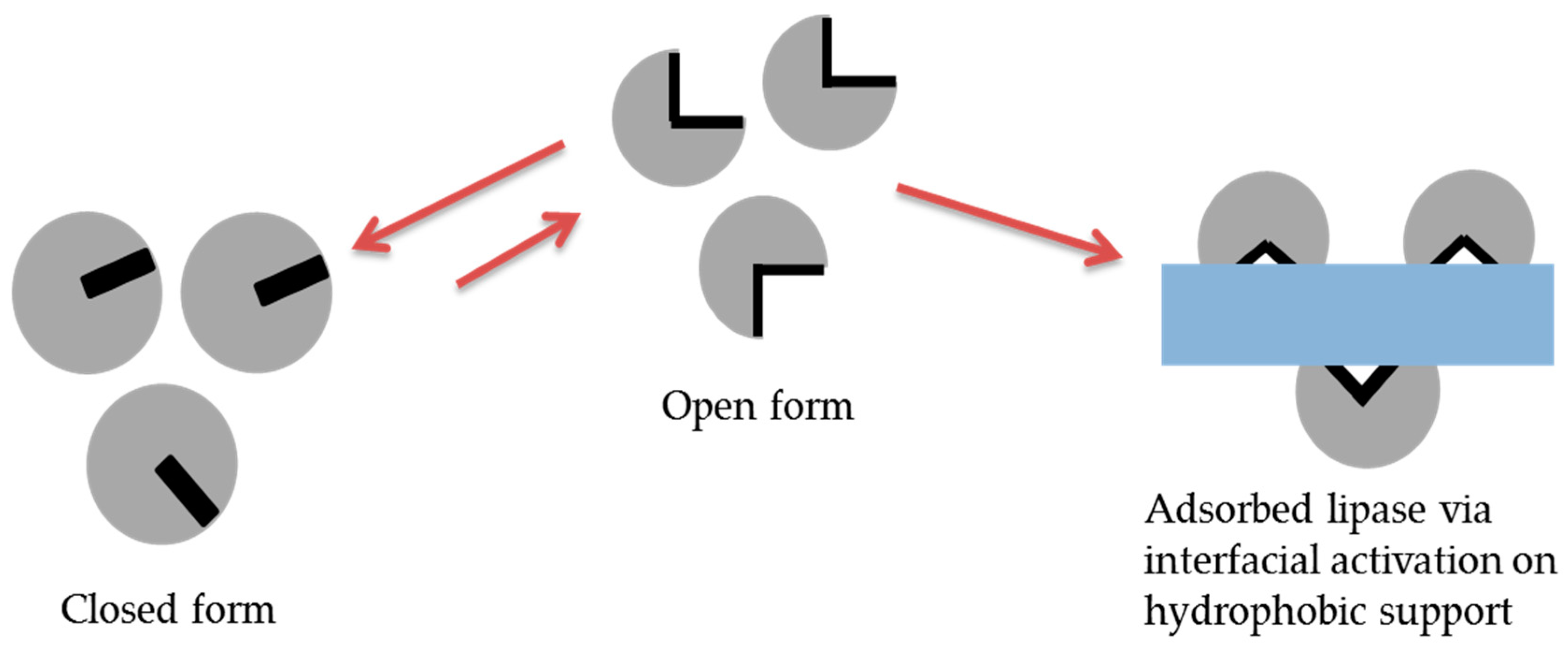

6. Interfacial Activation of Lipase on a Hydrophobic Porous Support

7. Application of Lipases Immobilized on a Porous Support

8. Conclusions and Expectation

9. Patents

Author Contributions

Funding

Conflicts of Interest

References

- Sheldon, R.A.; van Pelt, S. Enzyme Immobilisation in Biocatalysis: Why, What and How. Chem. Soc. Rev. 2013, 42, 6223–6235. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.D.; Yuwen, L.L.L.; Peng, L.L.L. Parameters Affecting the Performance of Immobilized Enzyme. J. Chem. Hindawi Publ. Corp. 2013. [CrossRef]

- Yang, T.; Zheng, Y.D. State and Trends of Oil Crops Production in China; State and Trends of Oil Crops Production in China. OCL 2016, 23. [Google Scholar]

- Villeneuve, P.; Muderhwa, J.M.; Graille, J.; Haas, M.J. Customizing lipases for biocatalysis:a survey of chemical, physical and molecular biological approaches. J. Mol. Catal. B Enzym. 2000, 9, 113–148. [Google Scholar] [CrossRef]

- Guo, Z.; Bai, S.; Sun, Y. Preparation and characterization of immobilized lipase on magnetic hydrophobic microspheres. Enzyme Microb. Technol. 2003, 32, 776–782. [Google Scholar] [CrossRef]

- Adlercreutz, P. Immobilisation and application of lipases in organic media. Chem. Soc. Rev. 2013, 42, 6406. [Google Scholar] [CrossRef] [PubMed]

- Flood, M.T.; Keller, M.K. Safety Evaluation of Lipase Produced from Rhizopus oryzae: Summary of Toxicological Data. Regul. Toxicol. Pharmacol. 2003, 37, 293–304. [Google Scholar] [CrossRef]

- Tecelão, C.; Guillén, M.; Valero, F.; Ferreira-Dias, S. Immobilized Heterologous Rhizopus oryzae Lipase: A Feasible Biocatalyst for the Production of Human Milk Fat Substitutes. Biochem. Eng. J. 2012, 67, 104–110. [Google Scholar] [CrossRef]

- Katchalski-Katzir, E.; Kraemer, D.M. Eupergit® C, a Carrier for Immobilization of Enzymes of Industrial Potential. J. Mol. Catal. B Enzym. 2000, 10, 157–176. [Google Scholar] [CrossRef]

- Talekar, S.; Chavare, S. Optimization of Immobilization of α-Amylase in Alginate Gel and Its Comparative Biochemical Studies with Free α-Amylase. Recent Res. Sci. Technol. 2012, 4, 1–5. [Google Scholar]

- Dwevedi, A. Enzyme Immobilization: Advances in Industry, Agriculture, Medicine, and the Environment; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–132. [Google Scholar]

- Iqbal, J.; Afaq, S. Immobilization and stabilization of papain on chelating sepharose: A metal chelate regenerable carrier. Electron. J. Biotechnol. 2001, 4, 1–2. [Google Scholar] [CrossRef]

- Rehman, S.; Bhatti, H.N.; Bilal, M.; Asgher, M. Cross-Linked Enzyme Aggregates (CLEAs) of Pencilluim Notatum Lipase Enzyme with Improved Activity, Stability and Reusability Characteristics. Int. J. Biol. Macromol. 2016, 91, 1161–1169. [Google Scholar] [CrossRef] [PubMed]

- Jesionowski, T.; Zdarta, J.; Krajewska, B.; Jakub, Z.; Krajewska, B. Enzyme immobilization by adsorption: A review. Adsorption 2014, 20, 801–821. [Google Scholar] [CrossRef]

- Shuai, W.; Das, R.K.; Naghdi, M.; Brar, S.K.; Verma, M. A review on the important aspects of lipase immobilization on nanomaterials. Appl. Biochem. Biotechnol. 2017, 64, 496–508. [Google Scholar] [CrossRef] [PubMed]

- Thangaraj, B.; Solomon, P.R. Immobilization of Lipases—A Review. Part I: Enzyme Immobilization. Chem. Biol. Eng. Rev. 2019, 6, 157–166. [Google Scholar] [CrossRef]

- Thangaraj, B.; Solomon, P.R. Immobilization of Lipases—A Review. Part II: Carrier Materials. Chem. Biol. Eng. Rev. 2019, 6, 167–194. [Google Scholar] [CrossRef]

- Fernandez-Lafuente, R.; Armisén, P.; Sabuquillo, P.; Fernández-Lorente, G.; Guisán, J.M. Immobilization of lipases by selective adsorption on hydrophobic supports. Chem. Phys. Lipids 1998, 93, 185–197. [Google Scholar] [CrossRef]

- Filho, D.G.; Silva, A.G.; Guidini, C.Z. Lipases: Sources, immobilization methods, and industrial applications. Appl. Microbiol. Biotechnol. 2019, 103, 7399–7423. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, R.C.; Virgen-Ortíz, J.J.; Santos, J.C.D.; Berenguer-Murcia, Á.; Alcantara, A.R.; Barbosa, O.; Fernandez-Lafuente, R. Immobilization of lipases on hydrophobic supports: Immobilization mechanism, advantages, problems, and solutions. Biotechnol. Adv. 2019, 37, 746–770. [Google Scholar] [CrossRef] [PubMed]

- Jegannathan, K.R.; Abang, S.; Poncelet, D.; Chan, E.S.; Ravindra, P. Production of Biodiesel Using Immobilized Lipase–A Critical Review. Crit. Rev. Biotechnol. 2008, 28, 253–264. [Google Scholar] [CrossRef] [PubMed]

- Karra-Châabouni, M.; Bouaziz, I.; Boufi, S.; Botelho do Rego, A.M.; Gargouri, Y. Physical immobilization of Rhizopus oryzae lipase onto cellulose substrate: Activity and stability studies. Colloids Surf. B 2008, 66, 168–177. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Ke, C.; Huang, Y.; Yan, Y. Immobilized Aspergillus niger Lipase with SiO2 Nanoparticles in Sol-Gel Materials. Catalysts 2016, 6, 149. [Google Scholar] [CrossRef]

- Ali, Z.; Tian, L.; Zhang, B.; Ali, N.; Khan, M.; Zhang, Q. Synthesis of fibrous and non-fibrous mesoporous silica magnetic yolk-shell microspheres as recyclable supports for immobilization of Candida rugosa lipase. Enzyme Microb. Technol. 2017, 103, 42–52. [Google Scholar] [CrossRef] [PubMed]

- Basri, M.; Yunus, W.M.Z.W.; Yoong, W.S.; Ampon, K.; Razak, C.N.A.; Salleh, A.B. Immobilization of Lipase from Candida rugosa on Synthetic Polymer Beads for Use in the Synthesis of Fatty Esters. J. Chem. Technol. Biotechnol. 1996, 66, 169–173. [Google Scholar] [CrossRef]

- Cesarini, S.; Pastor, F.I.J.; Diaz, P. Improvement of P.aeruginosa 42A2 lipase preparations for FAMEs production, both in immobilized and soluble form. J. Mol. Catal. B Enzym. 2014, 99, 1–7. [Google Scholar]

- Nawani, N.; Singh, R.; Kaur, J. Immobilization and stability studies of a lipase from thermophilic Bacillus sp: The effect of process parameters on immobilization of enzyme. Electron. J. Biotechnol. 2006, 9, 559–565. [Google Scholar]

- Yang, D.; Rhee, J.S. Continuous hydrolysis of olive oil by immobilized lipase in organic solvent. Biotechnol. Bioeng. 1992, 40, 748–752. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhang, G.; Liu, N.; Liu, L. Preparation and Properties of Rhizopus oryzae Lipase Immobilized Using an Adsorption-Crosslinking Method. Int. J. Food Prop. 2016, 19, 1776–1785. [Google Scholar] [CrossRef]

- Biasutti, M.A.; Abuin, E.B.; Silber, J.J.; Correa, N.M.; Lissi, E.A. Kinetics of Reactions Catalyzed by Enzymes in Solutions of Surfactants. Adv. Colloid Interface Sci. 2008, 136, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Mihailović, M.; Stojanović, M.; Banjanac, K.; Carević, M.; Prlainović, N.; Milosavić, N.; Bezbradica, D. Immobilization of lipase on epoxy-activated Purolite® A109e®and its post-immobilization stabilization. Process Biochem. 2014, 49, 637–646. [Google Scholar] [CrossRef]

- Kharrat, N.; Ali, Y.B.; Marzouk, S.; Gargouri, Y.-T.; Karra-Châabouni, M. Immobilization of Rhizopus oryzae Lipase on Silica Aerogels by Adsorption: Comparison with the Free Enzyme. Process Biochem. 2011, 46, 1083–1089. [Google Scholar] [CrossRef]

- DiCosimo, R.; McAuliffe, J.; Poulose, A.J.; Bohlmann, G.; Kumar, H.; Satyanarayanan, T.; Langan, P. Industrial use of immobilized enzymes. Chem. Soc. Rev. 2013, 42, 6437–6474. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Dhar, K.; Kanwar, S.S.; Arora, P.K. Lipase catalysis in organic solvents: Advantages and applications. Biol. Proced. Online 2016, 18, 2. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.W.; Shaw, J.F.; Yang, K.H.; Chang, S.F.; Shieh, C.J. Studies of optimum conditions for covalent immobilization of Candida rugosa lipase on poly(γ-glutamic acid) by RSM. Bioresour. Technol. 2008, 99, 2800–2805. [Google Scholar] [CrossRef] [PubMed]

- Bayne, L.; Ulijn, R.V.; Halling, P.J. Effect of pore size on the performance of immobilized enzymes. Chem. Soc. Rev. 2013, 42, 9000–9010. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wu, J.-Q.; Long, N.-B.; Zhang, R.-F. Efficient immobilization of phospholipase D on novel polymer supports with hierarchical pore structures. Int. J. Biol. Macromol. 2019, 141, 60–67. [Google Scholar] [CrossRef] [PubMed]

- Taubert, M.; Beckmann, J.; Lange, A.; Enke, D.; Klepel, O. Attempts to design porous carbon monoliths using porous concrete as a template. Microporous Mesoporous Mater. 2014, 197, 58–62. [Google Scholar] [CrossRef]

- Samui, S.K.; Sahu, S.K. One-pot synthesis of microporous nanoscale metal organic frameworks conjugated with laccase as a promising biocatalyst. New J. Chem. 2018, 42, 4192–4200. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Y.; Wang, T.; Luo, G.; Dai, Y. Immobilization of lipase on methyl-modified silica aerogels by physical adsorption. Bioresour. Technol. 2009, 100, 996–999. [Google Scholar] [CrossRef] [PubMed]

- Mohamad, N.; Marzuki, N.; Buang, N.; Huyop, F.; Wahab, R. An overview of technologies for immobilization of enzymes and surface analysis techniques for immobilized enzymes. Biotechnol. Biotechnol. Equip. 2015, 29, 205–220. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.F.; Xu, L.Q.; Wen, X.H. Mesoporous silicas synthesis and application for lignin peroxidase immobilization by covalent binding method. J. Environ. Sci.-China 2013, 25, 181–187. [Google Scholar] [CrossRef]

- Ramachandran, P.; Narayanan, G.K.; Gandhi, S.; Sethuraman, S.; Krishnan, U.M. Rhizopus oryzae lipase immobilized on hierarchical mesoporous silica supports for transesterification of rice bran oil. Appl. Biochem. Biotechnol. 2015, 175, 2332–2346. [Google Scholar] [CrossRef] [PubMed]

- Pegah, S.; Nabavi, Z.; Björn, Å. Immobilization of enzymes in mesoporous silica particles: Protein concentration and rotationalmobility in the pores. J. Phys. Chem. B 2017, 121, 2575–2583. [Google Scholar]

- Lee, C.H.; Lin, T.S.; Mou, C.Y. Mesoporous materials for encapsulating enzymes. NanoToday 2009, 4, 165–179. [Google Scholar] [CrossRef]

- Carlsson, N.; Gustafsson, H.; Thörn, C.; Olsson, L.; Holmberg, K.; Åkerman, B. Enzymes immobilized in mesoporous silica: A physical-chemical perspective. Adv. Colloid Interface Sci. 2014, 205, 339–360. [Google Scholar] [CrossRef] [PubMed]

- Wen, L.Y.; Gao, A.C.; Cao, Y.; Frantisek, S.; Tan, T.W.; Lv, Y.Q. Layer-by-layer assembly of metal-organic frameworks in macroporous polymer monolith and their use for enzyme immobilization. Macromol. Rapid Commun. 2016, 37, 551–557. [Google Scholar] [CrossRef] [PubMed]

- Pavel, I.A.; Prazeres, S.F.; Montalvo, G.; Ruiz, C.G.; Nicolas, V.; Celzard, A.; Dehez, F.; Canabady-Rochelle, L.; Canilho, N.; Pasc, A. Effect of meso vs macro size of hierarchical porous silica on the adsorption and activity of immobilized β-galactosidase. Langmuir 2017, 33, 3333–3340. [Google Scholar] [CrossRef] [PubMed]

- Morhardt, C.; Ketterer, B.; Heißler, S.; Franzreb, M. Direct quantification of immobilized enzymes by means of FTIR ATR spectroscopy—A process analytics tool for biotransformations applying non-porous magnetic enzyme carriers. J. Mol. Catal. B Enzym. 2014, 107, 55–63. [Google Scholar] [CrossRef]

- Valivety, R.H.; Halling, P.J.; Peilow, A.D.; Macrae, A.R. Relationship between water activity and catalytic activity of lipases in organic media: Effects of supports, loading and enzyme preparation. Eur. J. Biochem. 1994, 222, 461–466. [Google Scholar] [CrossRef] [PubMed]

- Pencreac’h, G.; Leullier, M.; Baratti, J.C. Properties of Free and Immobilized Lipase from Pseudomonas cepacia. Biotechnol. Bioeng. 1997, 56, 181–189. [Google Scholar] [CrossRef]

- Naya, M.; Imai, M. Impact of physicochemical character of hydrophobic porous carrier on reactivity of immobilized lipase progressing toward higher reaction rate and high yield in repeated use. Procedia Eng. 2012, 42, 1004–1015. [Google Scholar] [CrossRef][Green Version]

- Al-Duri, B.; Yong, Y.P. Characterisation of the equilibrium behaviour of lipase PS (from Pseudomonas) and lipolase 100 L (from Humicola) onto Accurel EP100. J. Mol. Catal. B Enzym. 1997, 3, 177–188. [Google Scholar] [CrossRef]

- Salis, A.; Sanjust, E.; Solinas, V.; Monduzzi, M. Characterisation of Accurel MP1004 polypropylene powder and its use as a support for lipase immobilization. J. Mol. Catal. B Enzym. 2003, 24, 75–82. [Google Scholar] [CrossRef]

- Manoel, E.A.; Ribeiro, M.F.P.; dos Santos, J.C.S.; Coelho, M.A.Z.; Simas, A.B.C.; Fernandez-Lafuente, R.; Freire, D.M.G. Accurel MP 1000 as a support for the immobilization of lipase from Burkholderia cepacia: Application to the kinetic resolution of myo -inositol derivatives. Process Biochem. 2015, 50, 1557–1564. [Google Scholar] [CrossRef]

- Foresti, M.L.; Ferreira, M.L. Ethanol pretreatment effect and particle diameter issues on the adsorption of Candida rugosa lipase onto polypropylene powder. Appl. Surf. Sci. 2004, 238, 86–90. [Google Scholar] [CrossRef]

- Cesarina, S.; Infanzon, B.; Pastor, F.I.J.; Diaz, P. Fast and economic immobilization methods described for non-commercial Pseudomonas lipases. BMC Biotechnol. 2014, 14, 1472–6750. [Google Scholar] [CrossRef] [PubMed]

- Silveira, E.A.; Moreno-Perez, S.; Basso, A.; Serban, S.; Pestana-Mamede, R.; Tardioli, P.W.; Sanchez-Farinas, C.; Castejon, N.; Fernandez-Lorente, G.; Rocha-Martin, J.; et al. Biocatalyst engineering of Thermomyces lanuginosus lipase adsorbed on hydrophobic supports: Modulation of enzyme properties for ethanolysis of oil in solvent-free systems. J. Biotechnol. 2019, 289, 126–134. [Google Scholar] [CrossRef] [PubMed]

- Séverac, E.; Galy, O.; Turon, F.; Pantel, C.A.; Condoret, J.S.; Monsan, P.; Marty, A. Selection of CalB immobilization method to be used in continuous oil transesterification: Analysis of the economical impact. Enzym. Microb. Technol. 2011, 48, 61–70. [Google Scholar] [CrossRef] [PubMed]

- Poppe, J.K.; Garcia-Galan, C.; Matte, C.R.; Fernandez-Lafuente, R.; Rodrigues, R.C.; Ayub, M.A.Z. Optimization of synthesis of fatty acid methyl esters catalyzed by lipase B from Candida antarctica immobilized in hydrophobic supports. J. Mol. Catal. B Enzym. 2013, 94, 51–56. [Google Scholar] [CrossRef]

- Chen, B.; Miller, E.M.; Miller, L.; Maikner, J.J.; Gross, R.A. Effects of Macroporous Resin Size on Candida antarctica Lipase B Adsorption, Fraction of Active Molecules, and Catalytic Activity for Polyester Synthesis. Langmuir 2007, 23, 1381–1387. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Miller, M.E.; Gross, R.A. Effects of Porous Polystyrene Resin Parameters on Candida antarctica Lipase B Adsorption, Distribution, and Polyester Synthesis Activity. Langmuir 2007, 23, 6467–6474. [Google Scholar] [CrossRef] [PubMed]

- Sankar, K.; Achary, A. Bio-ceramic, mesoporous cuttlebone of Sepia officinalis is an ideal support for the immobilization of Bacillus subtilis AKL13 lipase: Optimization, adsorption, thermodynamic and reaction kinetic studies. Chem. Papers 2019, 74, 459–470. [Google Scholar] [CrossRef]

- Anand, A.; Weatherley, L.R. The performance of microbial lipase immobilized onto polyolefin supports for hydrolysis of high oleate sunflower oil. Process Biochem. 2018, 68, 100–107. [Google Scholar] [CrossRef]

- Bassi, J.J.; Todero, L.M.; Lage, F.A.P.; Khedy, G.I.; Ducas, J.D.; Custódio, A.P.; Pinto, M.A.; Mendes, A.A. Interfacial activation of lipases on hydrophobic support and application in the synthesis of a lubricant ester. Int. J. Biol. Macromol. 2016, 92, 900–909. [Google Scholar] [CrossRef] [PubMed]

- Gustafsson, H.; Johansson, E.M.; Barrabino, A.; Odén, M.; Holmberg, K. Immobilization of lipase from Mucor miehei and Rhizopus oryzae into mesoporoussilica-The effect of varied particle size and morphology. Colloids Surf. B Biointerfaces 2012, 100, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Kalantari, M.; Yu, M.; Yang, Y.; Strounina, E.; Gu, Z.; Huang, X.; Zhang, J.; Song, H.; Yu, C. Tailoring mesoporous-silica nanoparticles for robust immobilization of lipase and biocatalysis. Nano Res. 2017, 10, 605–617. [Google Scholar] [CrossRef]

- Lage, F.A.P.; Bassi, J.J.; Corradini, M.C.C.; Todero, L.M.; Luiz, J.H.H.; Mendes, A.A. Preparation of a biocatalyst via physical adsorption of lipase from Thermomyces lanuginosus on hydrophobic support to catalyze biolubricant synthesis by esterification reaction in a solvent-free system. Enzym. Microb. Technol. 2016, 84, 56–67. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Liu, Y.; Wang, X.; Li, Q.; Wang, J.; Yan, Y. Improving catalytic performance of Burkholderia cepacia lipase immobilized on macroporous resin NKA. J. Mol. Catal. B Enzym. 2011, 71, 45–50. [Google Scholar] [CrossRef]

- Meng, X.; Xu, G.; Zhou, Q.L.; Wu, J.P.; Yang, L.R. Improvements of lipase performance in high-viscosity system by immobilization onto a novel kind of poly (me thylmethacrylate-co-divinylbenzene) encapsulated porous magnetic microspherecarrier. J. Mol. Catal. B Enzym. 2013, 89, 86–92. [Google Scholar] [CrossRef]

- Quirós, M.; García, A.B.; Montes-Morán, M.A. Influence of the support surface properties on the protein loading and activity of lipase/mesoporous carbon biocatalysts. Carbon N. Y. 2011, 49, 406–415. [Google Scholar] [CrossRef]

- Rios, N.S.; Pinheiro, M.P.; Lima, M.L.B.; Freire, D.M.G.; da Silva, I.J.; Rodríguez-Castellón, E.; de Sant’Ana, H.B.; Macedo, A.C.; Gonçalves, L.R.B. Pore-expanded SBA-15 for the immobilization of a recombinant Candida antarctica lipase B: Application in esterification and hydrolysis as model reactions. Chem. Eng. Res. Des. 2018, 129, 12–24. [Google Scholar] [CrossRef]

- Wang, B.; Li, W.; Wu, B.; He, B. Efficient resolution of 3-phenoxy-1, 2-propanediol by immobilized lipase on amphiphilic comb polymer modified TiO2. J. Mol. Catal. B Enzym. 2014, 106, 105–110. [Google Scholar] [CrossRef]

- Zheng, M.; Xiang, X.; Wang, S.; Shi, J.; Deng, Q.; Huang, F.; Cong, R. Lipase immobilized in ordered mesoporous silica: A powerful biocatalyst for ultrafast kinetic resolution of racemic secondary alcohols. Process Biochem. 2017, 53, 102–108. [Google Scholar] [CrossRef]

- Dong, Z.; Jiang, M.-Y.; Shi, J.; Zheng, M.-M.; Huang, F.-H. Preparation of Immobilized Lipase Based on Hollow Mesoporous Silica Spheres and Its Application in Ester Synthesis. Molecules 2019, 24, 395. [Google Scholar] [CrossRef] [PubMed]

- Malcata, F.X.; Reyes, H.R.; Garcia, H.S.; Hill, C.G.; Amundson, C.H. Immobilized Lipase Reactors for Modification of Fats and Oils-A Review. J. Am. Oil Chem. Soc. 1990, 67, 890–910. [Google Scholar] [CrossRef]

- Jun, L.Y.; Yon, L.S.; Mubarak, N.; Bing, C.H.; Pan, S.; Danquah, M.K.; Khalid, M. An overview of immobilized enzyme technologies for dye and phenolic removal from wastewater. J. Environ. Chem. Eng. 2019, 7, 102961. [Google Scholar] [CrossRef]

- Gotor-Fernández, V.; Busto, E.; Gotor, V. Candida antarctica lipase B: An ideal biocatalyst for the preparation of nitrogenated organic compounds. Adv. Synth. Catal. 2006, 348, 797–812. [Google Scholar] [CrossRef]

- Zhao, K.; Di, Q.; Cao, X.; Wang, M.; Deng, L.; Wang, F. Production of Biodiesel Using Immobilized Lipase and the Characterization of Different Co-Immobilizing Agents and Immobilization Methods. Sustainability 2016, 8, 764. [Google Scholar] [CrossRef]

- Brígida, A.I.S.; Pinheiro, A.D.T.; Ferreira, A.L.O.; Gonçalves, L.R.B. Immobilization of Candida antarctica lipase B byadsorption to green coconut fiber. Appl. Biochem. Biotechnol. 2008, 146, 173–187. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.M.; Chen, J.; Shi, Y.P. Advances on methods and easy separated support materials for enzymes immobilization. Trends Anal. Chem. 2018, 102, 332–342. [Google Scholar] [CrossRef]

- Tacias-Pascacio, V.G.; Peirce, S.; Torrestiana-Sanchez, B.; Yates, M.; Rosales-Quintero, A.; Virgen-Ortíz, J.J.; Fernandez-Lafuente, R. Evaluation of different commercial hydrophobic supports for the immobilization of lipases: Tuning their stability, activity and specificity. RSC Adv. 2016, 6, 100281–100294. [Google Scholar] [CrossRef]

- Fernandez-Lorente, G.; Rocha-Martín, J.; Guisan, J.M. Immobilization of Lipases by Adsorption on Hydrophobic Supports: Modulation of Enzyme Properties in Biotransformations in Anhydrous Media. Methods Mol. Biol. 2020, 143–158. [Google Scholar]

- Bosley, J.A.; Peilow, A.D. Immobilization of lipases on porous polypropylene: Reduction in esterification efficiency at low loading. J. Am. Oil Chem. Soc. 1997, 74, 107–111. [Google Scholar] [CrossRef]

- Gitlesen, T.; Bauer, M.; Adlercreutz, P. Adsorption of lipase on polypropylene powder. Biochim. Biophys. Acta 1997, 1345, 188–196. [Google Scholar] [CrossRef]

- Al-Duri, B.; Yong, Y.P. Lipase immobilization: An equilibrium study of lipases immobilized on hydrophobic and hydrophilic/hydrophobic supports. Biochem. Eng. J. 2000, 4, 207–215. [Google Scholar] [CrossRef]

- Lin, H.-Y.; Tsai, S.-W. Dynamic kinetic resolution of (RS)-naproxen 2, 2, 2-trifluoroethyl ester via lipase-catalyzed hydrolysis in micro-aqueous isooctane. J. Mol. Catal. B Enzym. 2003, 24–25, 111–120. [Google Scholar] [CrossRef]

- Peirce, S.; Tacias-Pascacio, V.; Russo, M.; Marzocchella, A.; Virgen-Ortíz, J.; Fernandez-Lafuente, R. Stabilization of Candida antarctica Lipase B (CALB) Immobilized on Octyl Agarose by Treatment with Polyethyleneimine (PEI). Molecules 2016, 21, 751. [Google Scholar] [CrossRef] [PubMed]

- Mateo, C.; Palomo, J.M.; Fernandez-Lorente, G.; Guisan, J.M.; Fernandez-Lafuente, R. Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzym. Microb. Technol. 2007, 40, 1451–1463. [Google Scholar] [CrossRef]

- Xue, P.; Hu, C.-M.; Yan, X.-H.; Fang, G.-L.; Shen, H.-F. Enhancement of activity and reusability of lipase immobilized on magnetic mesoporous silica for the resolution of racemic secondary alcohols. J. Chin. Chem. Soc. 2018, 66, 427–433. [Google Scholar] [CrossRef]

- Ghamgui, H.; Miled, N.; Karra-chaâbouni, M.; Gargouri, Y. Immobilization Studies and Biochemical Properties of Free and Immobilized Rhizopus oryzae Lipase onto CaCO3: A Comparative Study. Biochem. Eng. J. 2007, 37, 34–41. [Google Scholar] [CrossRef]

- Hirata, D.B.; Albuquerque, T.L.; Rueda, N.; Sánchez-Montero, J.M.; Garcia-Verdugo, E.; Porcar, R.; Fernandez-Lafuente, R. Advantages of Heterofunctional Octyl Supports: Production of 1, 2-Dibutyrin by Specific and Selective Hydrolysis of Tributyrin Catalyzed by Immobilized Lipases. ChemistrySelect 2016, 1, 3259–3270. [Google Scholar] [CrossRef]

- Brady, D.; Jordaan, J. Advances in enzyme immobilization. Biotechnol. Lett. 2009, 31, 1639–1650. [Google Scholar] [CrossRef] [PubMed]

- Gerday, C.; Aittaleb, M.; Bentahir, M.; Chessa, J.-P.; Claverie, P.; Collins, T.; Feller, G. Cold-adapted enzymes: From fundamentals to biotechnology. Trends Biotechnol. 2000, 18, 103–107. [Google Scholar] [CrossRef]

- Pereira, S.E.; Fernandes, K.F.; Ulhoa, C.J. Immobilization of Cryptococcus flavus α-amylase on glass tubes and its application in starch hydrolysis. Starch-Stärke 2016, 69, 1600189. [Google Scholar] [CrossRef]

- Cavalcanti, E.D.C.; Aguieiras, É.C.G.; da Silva, P.R.; Duarte, J.G.; Cipolatti, E.P.; Fernandez-Lafuente, R.; da Silva, J.A.C.; Freire, D.M.G. Improved production of biolubricants from soybean oil and different polyols via esterification reaction catalyzed by immobilized lipase from Candida rugosa. Fuel 2018, 215, 705–713. [Google Scholar] [CrossRef]

- de Abreu, L.; Fernandez-Lafuente, R.; Rodrigues, R.C.; Volpato, G.; Ayub, M.A.Z. Efficient purification-immobilization of an organic solvent-tolerant lipase from Staphylococcus warneri EX17 on porous styrene-divinylbenzene beads. J. Mol. Catal. B Enzym. 2014, 99, 51–55. [Google Scholar] [CrossRef]

- Gao, Z.; Chu, J.; Jiang, T.; Xu, T.; Wu, B.; He, B. Lipase immobilization on functionalized mesoporous TiO2: Specific adsorption, hyperactivation and application in cinnamyl acetate synthesis. Process Biochem. 2018, 64, 152–159. [Google Scholar] [CrossRef]

- Liu, N.; Wang, Y.; Zhao, Q.; Cui, C.; Fu, M.; Zhao, M. Immobilisation of Lecitase®Ultra for production of diacylglycerols by glycerolysis of soybean oil. Food Chem. 2012, 134, 301–307. [Google Scholar] [CrossRef]

- Guerrand, D. Lipases industrial applications: Focus on food and agroindustries. OCL 2017, 24. [Google Scholar] [CrossRef]

- Choudhury, P. Industrial application of lipase: A review. Biopharm. J. 2015, 11, 41–47. [Google Scholar]

- Gao, Y.; Tan, T.; Nie, K.; Wang, F. Immobilization of Lipase on Macroporous Resin and Its Application in Synthesis of Biodiesel in Low Aqueous Media. Chin. J. Biotechnol. 2006, 22, 114–118. [Google Scholar] [CrossRef]

- Sun, J.; Chen, Y.; Sheng, J.; Sun, M. Immobilization of Yarrowia lipolytica Lipase on Macroporous Resin Using Different Methods: Characterization of the Biocatalysts in Hydrolysis Reaction. BioMed Res. Int. 2015.

- Cai, X.; Zhang, M.; Wei, W.; Zhang, Y.; Wang, Z.; Zheng, J. The Immobilization of Candida antarctica lipase B by ZIF-8 encapsulation and macroporous resin adsorption: Preparation and characterizations. Biotechnol. Lett. 2019, 42, 269–276. [Google Scholar] [CrossRef] [PubMed]

- Hernandez, K.; Fernandez-Lafuente, R. Lipase B from Candida antarctica immobilized on octadecyl sepabeads: A very stable biocatalyst in the presence of hydrogen peroxide. Process Biochem. 2011, 46, 873–878. [Google Scholar] [CrossRef]

- Martins, A.B.; Friedrich, J.L.R.; Cavalheiro, J.C.; Garcia-Galan, C.; Barbosa, O.; Ayub, M.A.Z.; Fernandez-Lafuente, R.; Rodrigues, R.C. Improved production of butyl butyrate with lipase from Thermomyces lanuginosus immobilized on styrene-divinylbenzene beads. Bioresour. Technol. 2013, 134, 417–422. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Fan, M.; Zeng, J.; Du, W.; Liu, C.; Liu, D. Kinetics of lipase recovery from the aqueous phase of biodiesel production by macroporous resin adsorption and reuse of the adsorbed lipase for biodiesel preparation. Enzym. Microb. Technol. 2013, 52, 226–233. [Google Scholar] [CrossRef] [PubMed]

| Lipase Source | Support | Surface Area | Particle Size | Pore Size | Reference |

|---|---|---|---|---|---|

| Phospholipase D from Streptomyces sp. | Novel epoxy resin-based hierarchical porous polymers (HPSs) | 225–156 m2/g | Ultramacropore (5–50 μm); Macropore (0.1–5 μm); Mesopore (10–50 μm) | - | [37] |

| Lipase B from Candida antarctica (CALB) | Methyl methacrylate resins | 500 m2/g | 560–710 µm | 250 Å | [61] |

| CALB | Polystyrene resins | - | 350–600 µm | 300–1000 Å | [62] |

| AKL 13 lipase from Bacillus subtilis (BsL) | Mesoporous cuttlebone powder of Sepia officinalis (CBP) | 1.631 m2/g | 89.95 µm | - | [63] |

| Candida rugosa (OF360) | Polyolefin (Accurel) | EP100: 50–90 m2/g | <200 µm | 0.1–1.0 µm | [64] |

| EP400: 20–40 m2/g | <400 µm | 0.1–0.5 µm | |||

| Thermomyces lanuginosus lipase (TLL) | Poly-methacrylate particles (PMA) | 500 m2/g | 300–700 µm | 170 Å | [65] |

| Mucor miehei and Rhizopus oryzae | Mesoporous silica (MPS) | MPS-1000: 502 m2/g | 1000 nm | 9.3 nm | [66] |

| MPS-300: 606 m2/g | 300 nm | 9.4 nm | |||

| MPS-40: 463 m2/g | 40 nm | 9.1 nm | |||

| Candida rugosa | Octadecylalkyl-modified mesoporous silica nanoparticles (C18-MSNs) | 219–486 m2/g | 37–45 nm | 1.6–5.4 nm | [67] |

| Thermomyces lanuginosus | -Mesoporous hydrophobic poly-methacrylate particles (Diaion® HP 2-MG) -Mesoporous PMA particles (Diaion®HP 2-MG) | 500 m2/g | 300–700 µm | 170 Å | [68] |

| Burkholderia cepacia | Macroporous resin NKA (polystyrene) | 570 m2/g | 300 µm | 200 Å | [69] |

| Mucor javanicus lipase | Poly(methylmethacrylate-co divinylbenzene)-encapsulated porous magnetic microspheres | 12 m2/g | - | 170 nm | [70] |

| Candida sp. L3170 | Purolite® A109, polystyrenic macroporous resin | - | 400 µm | - | [31] |

| CALB | Styrene-divinylbenzene MCI GEL CHP20P porous support | >500 m2/g | 75–150 µm | 400–600 Å | [60] |

| Lipases A and B from Candida antarctica | Mesoporous carbon beads | >800 m2/g | 0.5–1 mm | - | [71] |

| CALB | Pore-expanded mesoporous silica (SBA-15) | 526 m2/g | - | 14 nm | [72] |

| CALB | Accurel MP (a macroporous propylene) | 78.92 cm2/g | MP1000: <1500 µm | 10 nm | [59] |

| MP1001: <1000 µm | 8 µm | ||||

| Thermomyces lanuginosus | Macroporous Purolite C-18 mesoporous Sepabeads C-18 | 116 m2/g | - | 616 Å | [58] |

| 60–80 m2/g | 100–200 Å | ||||

| Heterologous Rhizopus oryzae | Accurel MP 1000 (polypropylene) Lewatit® VP OC 1600 | 70 m2/g | 50–1000 µm | 2000 Å | [8] |

| 130 m2/g | 315–100 µm | 15 Å | |||

| Burkholderia ambifaria (YCJ01) | Mesoporous TiO2 modified with an comb polymer—poly(sodium acrylate)-g-methoxy poly(ethylene oxide) | 38.02 m2/g | - | 16.25 nm | [73] |

| Burkholderia cepacia | Phenyl-modified ordered mesoporous silica | 152 m2/g | 8–10 µm | 21.3 nm | [74] |

| Candida rugosa | Modified hollow mesoporous silica (HMSS) | 399 m2/g | - | 12 nm | [75] |

| Physical Method | Chemical Method | Support Material |

|---|---|---|

| Adsorption | Covalent attachment | Magnetic nanoparticles |

| Entrapment (gel/fiber entrapping, microencapsulation, and metal-organic frameworks (MOFS) embedding) | Crosslinking (crosslinking to a support matrix, CLEAs) | Membranes |

| Ionic bonding | Capillary columns | |

| Conjugation by affinity ligands | Polymer |

| Source | Temperature (°C) | pH | Reusability | Stability | Application | Reference |

|---|---|---|---|---|---|---|

| Heterologous Rhizopus oryzae | 60 | 7 | 2 batches | - | Synthesis of human milk fat substitutes | [8] |

| Candida sp. (L3170) | 25 | 7 | - | Free lipase: 1–1.4 h; Immobilized lipase: 2.4 h | Hydrolysis of p-nitrophenyl butyrate | [31] |

| Rhizopus oryzae | 37 | wide | 12 | 4 months | n-butyl oleate synthesis by esterification of oleic acid with n-butanol | [32] |

| Phospholipase D (Streptomyces sp.) | Free lipase: 40 Immobilized lipase: 45 | Free lipase: 6; Immobilized lipase: 6.5 | 12 | After 28 days, Free lipase: 25%; Immobilized lipase: 80% | Catalysis of the transphosphatidylation from phosphatidylcholine PC to phosphatidylserine PS | [37] |

| Thermomyces lanuginosus | 40 | 7 | - | 20 days | Hydrolysis of 0.4 mM p-nitrophenyl butyrate (pNPB) -ethanolysis of sunflower oil | [58] |

| CALB | 60 | 7.2 | - | - | Continuous oil transesterification | [59] |

| CALB | 20–25 | 7.8 | - | - | Polyester synthesis | [61] |

| Bacillus subtilis AKL 13 lipase (BsL) | 50 | - | 15 | - | p-nitrophenol palmitate hydrolysis | [63] |

| Fungal yeast Candida rugosa OF360 | 30 45 | 7–9 | - | Free enzyme: 310.03 h; EP400: 2100.71 h; EG100: 1008.16 h | Catalytic hydrolysis of triglyceride esters -hydrolysis of high oleate sunflower oil | [64] |

| TLL | 45 | 8 | 12 | - | n-Octyl oleate was synthesized by enzymatic esterification reaction of oleic acid and n-octanol -used as a lubricant in industrial processes | [65] |

| Candida rugosa | 40 | 7.4 | 5 | - | Hydrolysis of 4-nitrophenyl palmitate | [67] |

| Thermomyces lanuginosus | 55–60 | 9 | 22 | - | Hydrolysis of olive oil emulsion -synthesis of isoamyl oleate (biolubricant) by esterification reaction. | [68] |

| Burkholderia cepacia | 37 | 7 | 50 | - | Synthesis of methyl esters | [69] |

| Mucor javanicus | 8 | Free lipase: 5; Immobilized lipase: 30 | - | Esterification of glycerol and oleic acid | [70] | |

| Lipases A and B from Candida antarctica | 29.85 | Free lipase: 7 CALA/MB: 5 CALA/MB: 1500–4 CALA/MB: LTA-5 CALB/MB: 5 CALB/MB: 1500–6 CALB/MB-LTA: 5 and 7 | 10 | - | Kinetic resolution of (±)-1-phenylethanol | [71] |

| Recombinant CALB | 25 | 5 | 5 | - | Production of methyl and ethyl butyrate, hydrolysis of ethyl hexanoate | [72] |

| Burkholderia ambifaria (YCJ01) | 40 | 7.5 | 6 | - | Resolution of 3-phenoxy-1,2-propanediol | [73] |

| Burkholderia cepacia | 35 | 7 | 50 cycles | - | Resolution of 1-phenylethanol | [74] |

| Candida rugosa lipase (CRL) | 37 | 7 | 21 | After 120 min, Free lipase: 30%; Immobilized lipase: 90% | Esterification of phytosterols with polyunsaturated fatty acid (PUFA) | [75] |

| Burkholderia cepacia | 25 | 6.5 | >5 | - | Transesterification resolution of racemic aromatic secondary alcohols to synthesize chiral intermediates | [90] |

| Lipomod 34MDP (free lipase from Candida rugosa) | 40 | 7 | 6 | - | Esterification of free fatty acids obtained from soybean-oil hydrolysis and different polyols (neopentyl glycol, NPG; trimethylolpropane, TMP; and pentaerythritol | [96] |

| Staphylococcus warneri lipase (EX17) | 30–45 | 7 | - | - | Catalysis of the synthesis of ethyl butyrate a short-chain ester, which has a fruity flavor similar to the pineapple and can find applications in the food industry. | [97] |

| Burkholderia ambifaria lipase (YCJ01) | 50 | Free lipase: 7.5 Immobilized lipase: 7 | 10 | - | Cinnamyl acetate synthesis -an essential ingredient, which is widely used in the synthesis of flavors, fragrances, and fine chemicals | [98] |

| Lecitase ultra (phospholipase) | 45 | 7 | 28 | - | Glycerolysis of soybean oil -catalyzing glycerolysis of soybean oil to produce DAG | [99] |

| Candida sp. | 40 | 7.4 | 19 | - | Production of biodiesel | [102] |

| Yarrowia lipolytica | 40 | 8 | 5 | - | Enrichment of polyunsaturated fatty acids | [103] |

| CALB | 30 | 7.4 | 10 | 35 days (94.41%) | Methyl esterification of oleic acid | [104] |

| CALB, Rhizomucor miehei lipase | 25 | 7 | - | - | Hydrolysis of rac-methyl mandelate Regioselective hydrolysis of triacetin | [105] |

| Thermomyces lanuginosus | 50 | 7 | - | - | Synthesis of butyl butyrate | [106] |

| Aspergillus niger | 50 | 8 cycles (<50%) | - | Preparation of biodiesel | [107] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mokhtar, N.F.; Abd. Rahman, R.N.Z.R.; Muhd Noor, N.D.; Mohd Shariff, F.; Mohamad Ali, M.S. The Immobilization of Lipases on Porous Support by Adsorption and Hydrophobic Interaction Method. Catalysts 2020, 10, 744. https://doi.org/10.3390/catal10070744

Mokhtar NF, Abd. Rahman RNZR, Muhd Noor ND, Mohd Shariff F, Mohamad Ali MS. The Immobilization of Lipases on Porous Support by Adsorption and Hydrophobic Interaction Method. Catalysts. 2020; 10(7):744. https://doi.org/10.3390/catal10070744

Chicago/Turabian StyleMokhtar, Nur Fathiah, Raja Noor Zaliha Raja Abd. Rahman, Noor Dina Muhd Noor, Fairolniza Mohd Shariff, and Mohd Shukuri Mohamad Ali. 2020. "The Immobilization of Lipases on Porous Support by Adsorption and Hydrophobic Interaction Method" Catalysts 10, no. 7: 744. https://doi.org/10.3390/catal10070744

APA StyleMokhtar, N. F., Abd. Rahman, R. N. Z. R., Muhd Noor, N. D., Mohd Shariff, F., & Mohamad Ali, M. S. (2020). The Immobilization of Lipases on Porous Support by Adsorption and Hydrophobic Interaction Method. Catalysts, 10(7), 744. https://doi.org/10.3390/catal10070744