Combined Effect of Photocatalyst, Superplasticizer, and Glass Fiber on the Photocatalytic Activity and Technical Parameters of Gypsum

Abstract

1. Introduction

2. Results and Discussion

2.1. Consistency

2.2. Setting Time

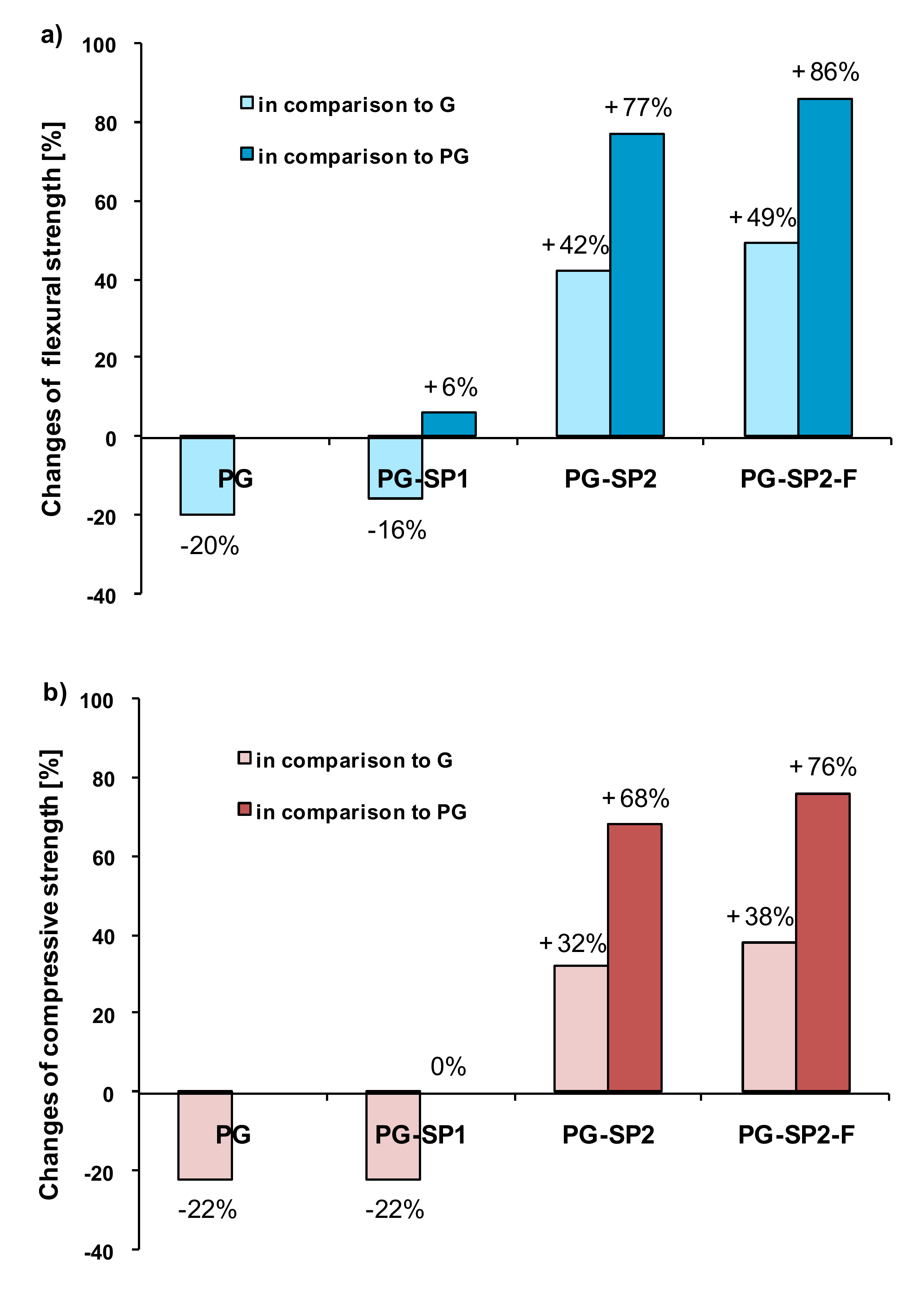

2.3. Mechanical Properties

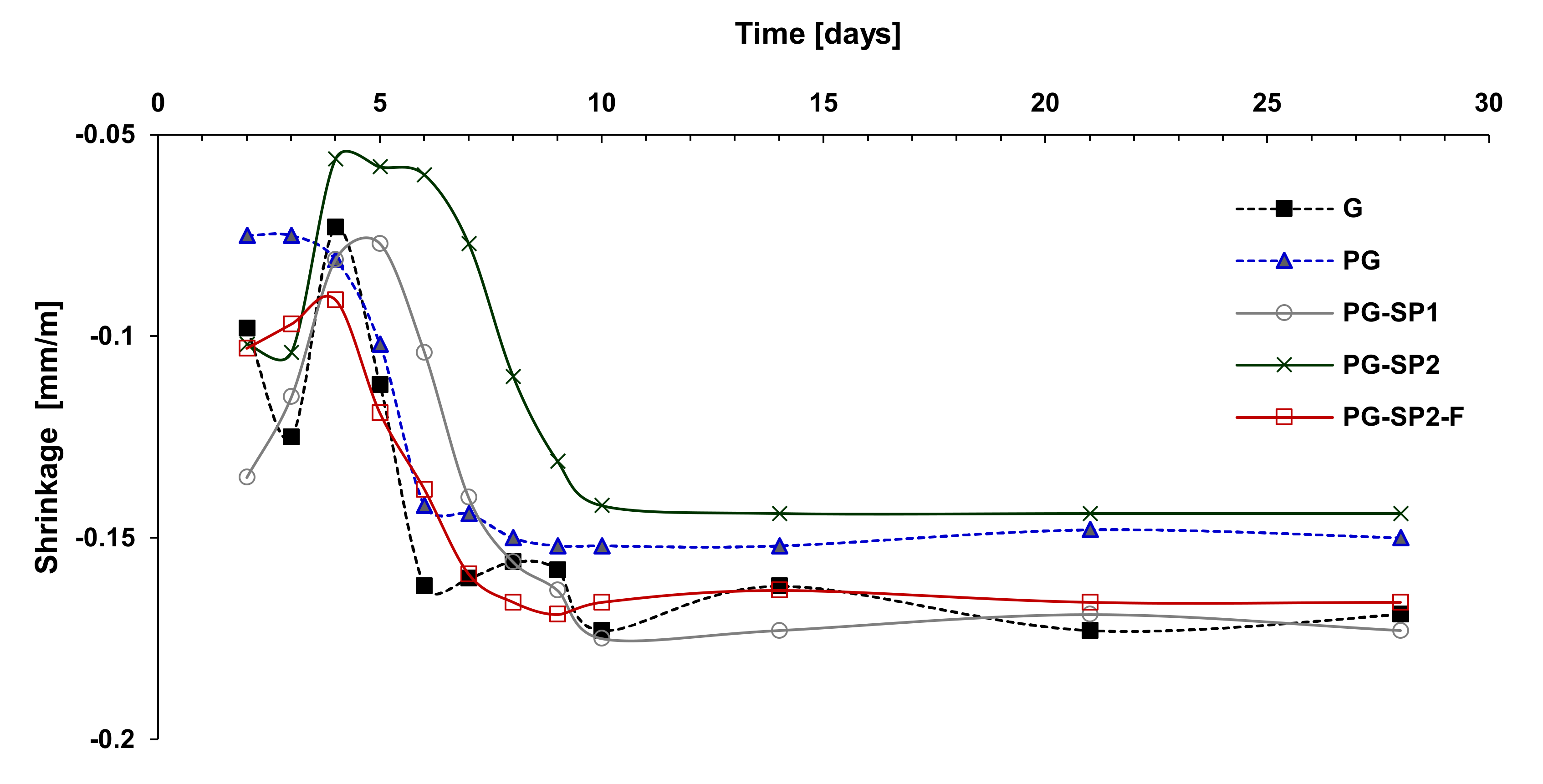

2.4. Shrinkage

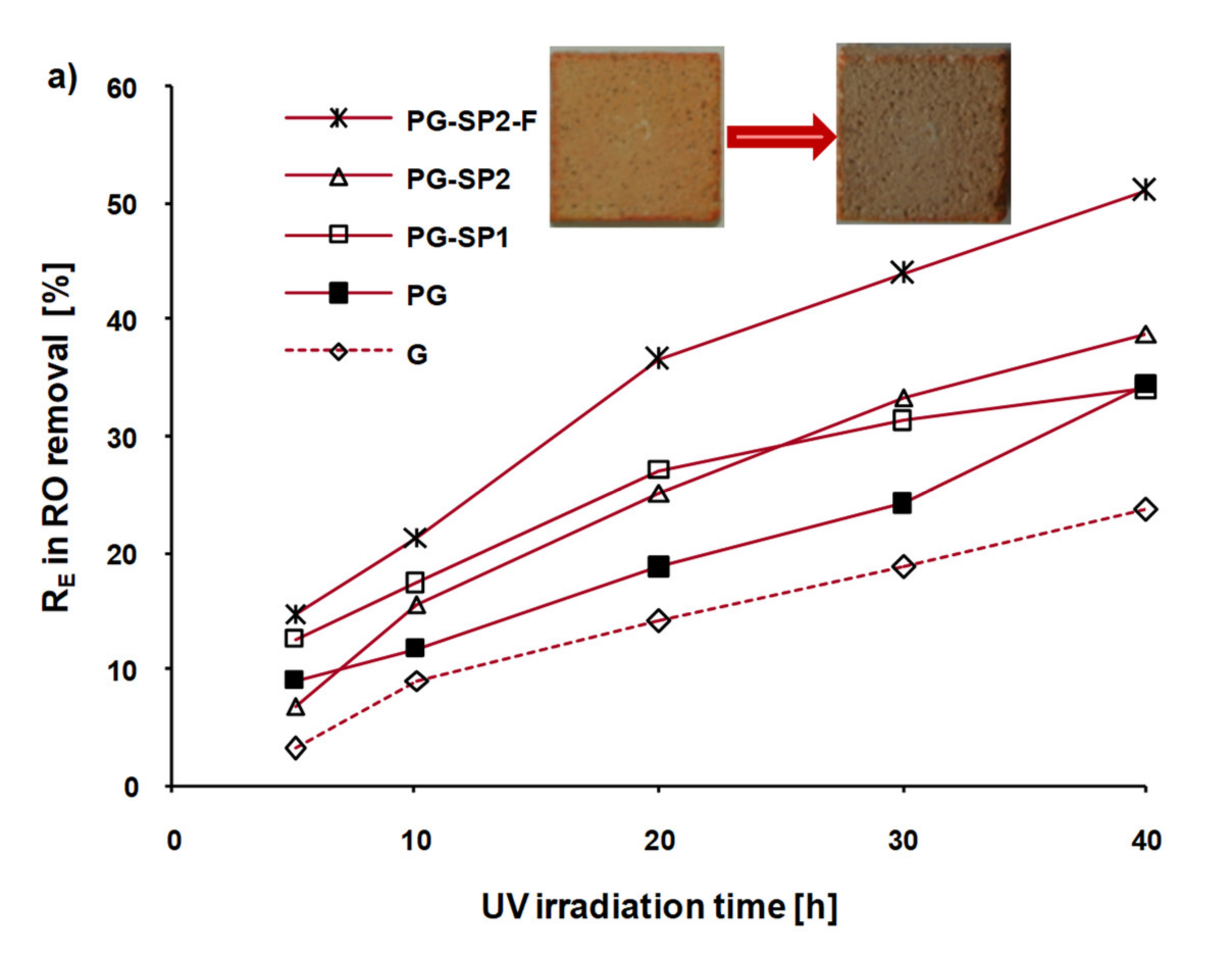

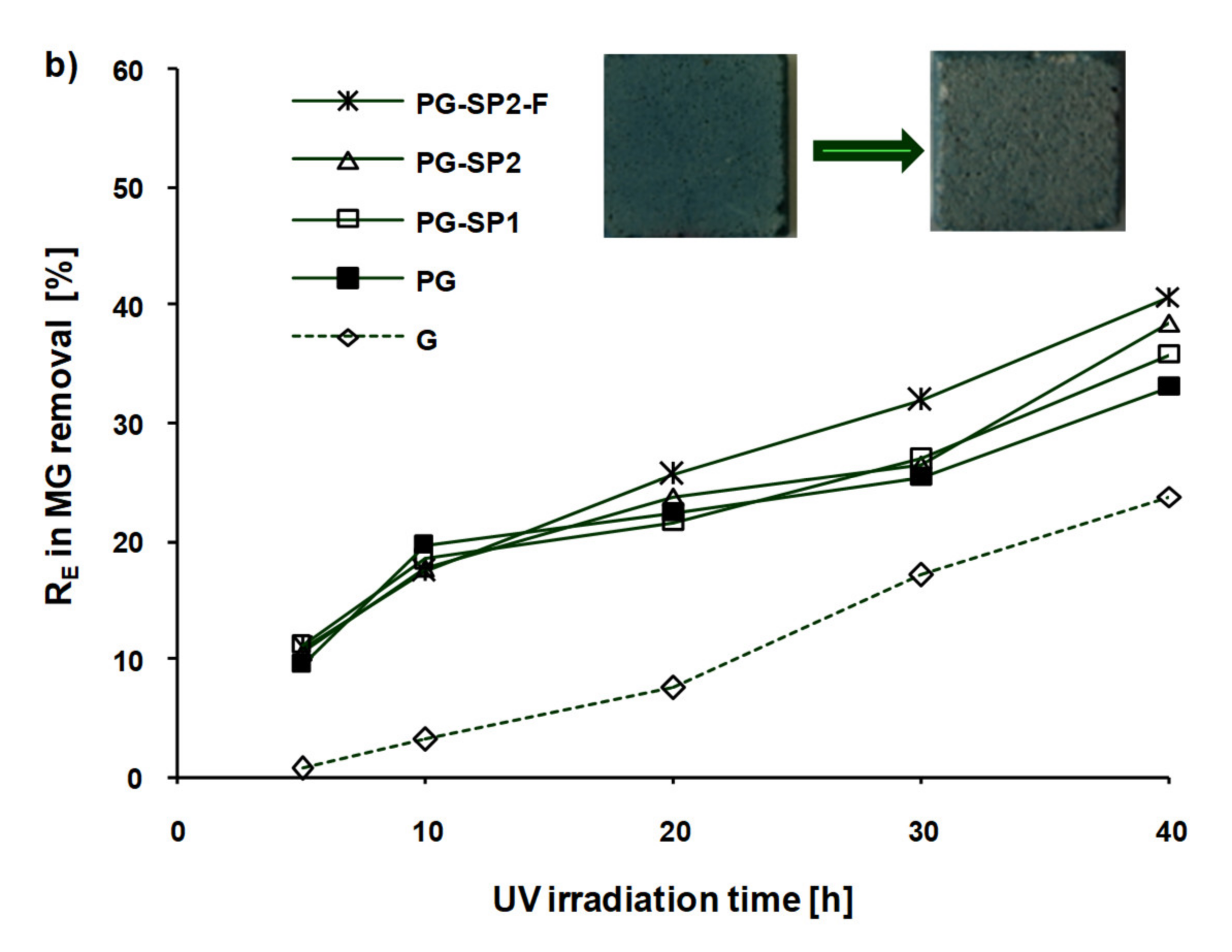

2.5. Photocatalytic Activity

3. Materials and Methods

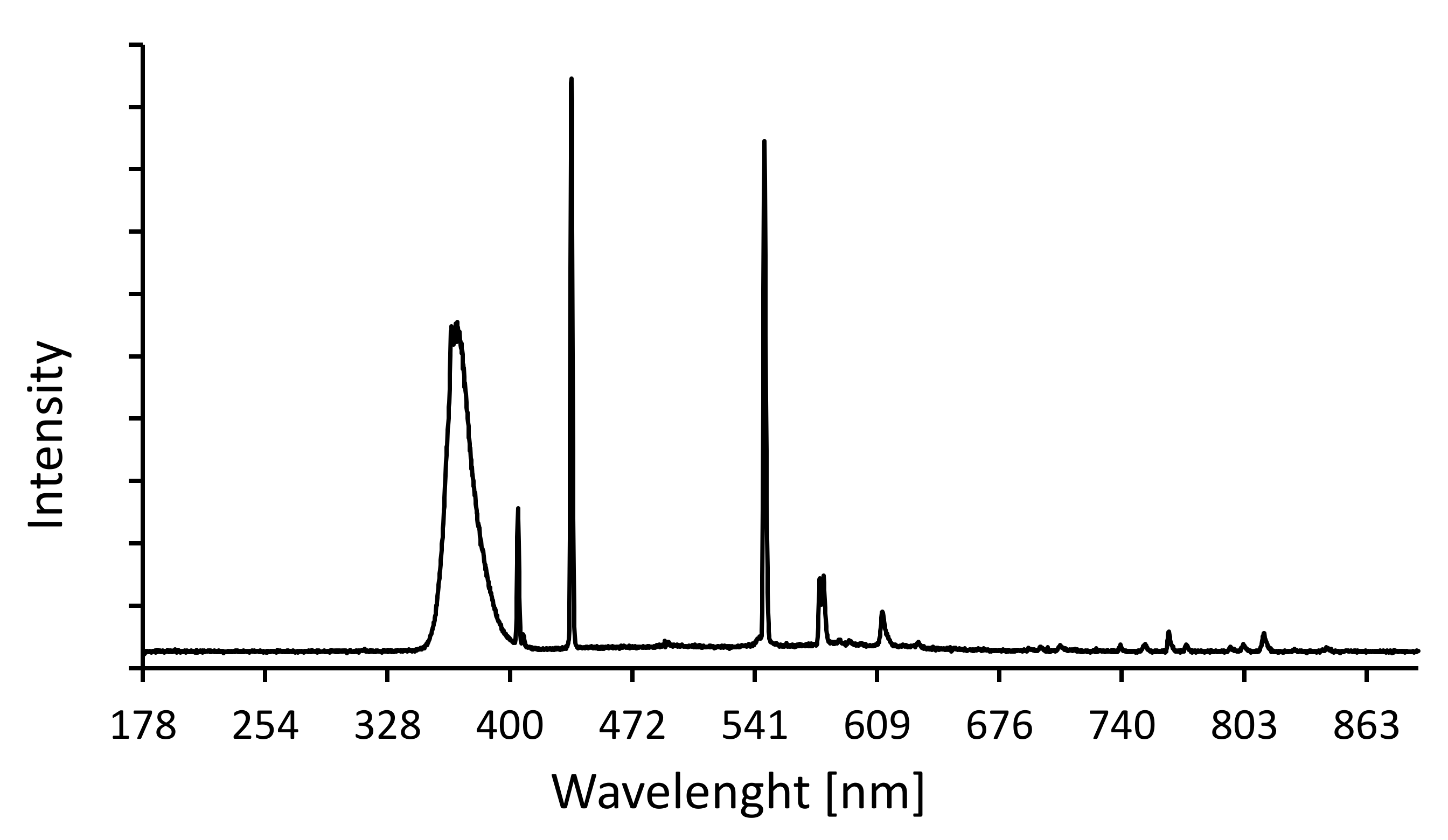

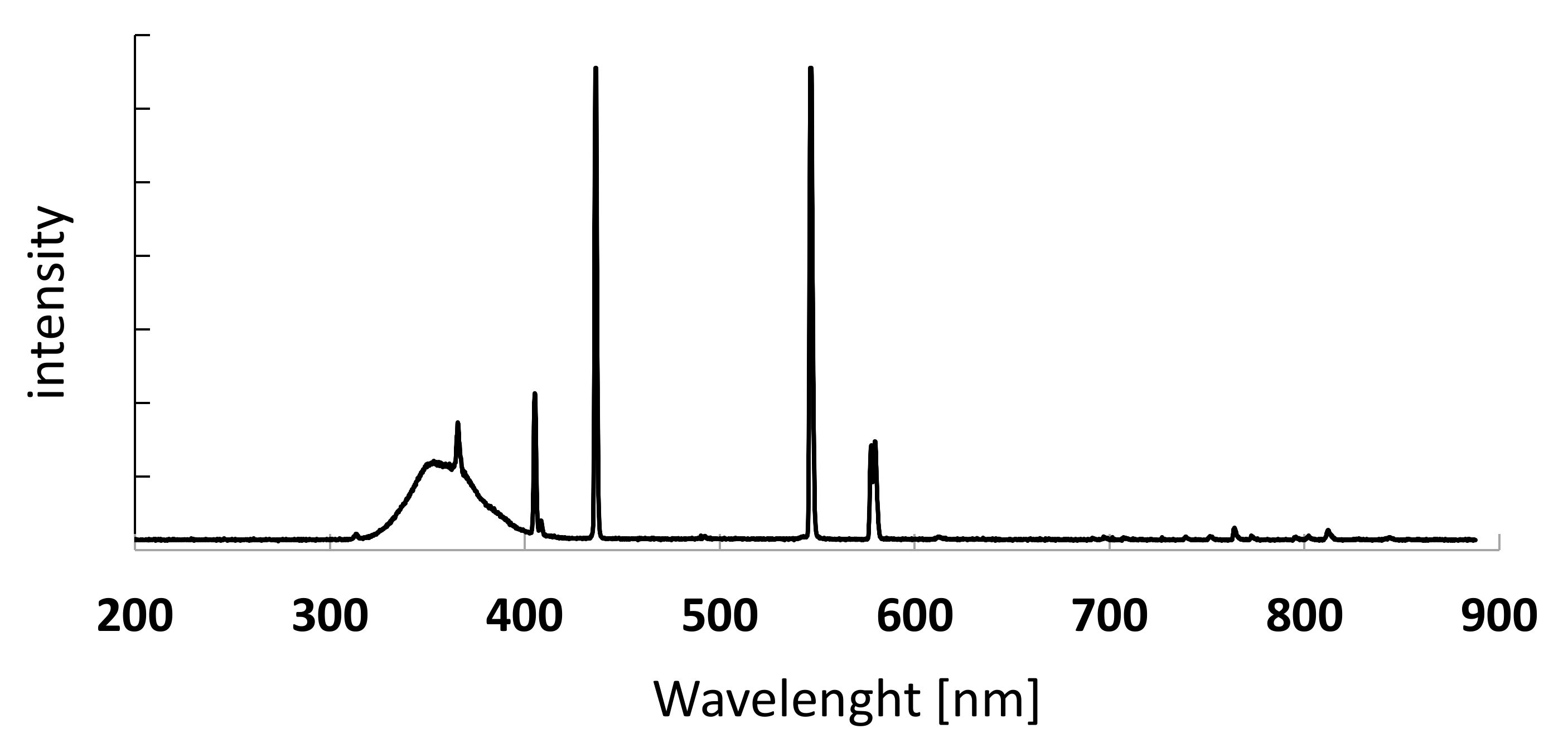

3.1. Materials

3.2. Preparation of Gypsum Samples

3.3. Measurements of Technical Parameters

3.4. Determination of Photocatalytic Activity

4. Conclusions

- A higher density of gypsum mortars as a result of 1 wt % of TiO2/N photocatalyst presence might be regulated to normal consistency by 0.01 wt % of polycarboxylic superplasticizer. Moreover, the water content in the photocatalytic mortar can be reduced about 12% by 0.2 wt % of the SP.

- The setting time was shortened through the catalytic action of TiO2/N in the hydration process and the facilitation of hydration by side chains of SP molecules as well as the lower water content to evaporation.

- The decrease of mechanical strength, which was observed after photocatalyst addition into gypsum plaster, was eliminated by SP. Precisely, a 12% reduction of water in the photocatalytic plaster, which was possible thanks to using the SP, involved prominent increases in the flexural and compressive strength of 77% and 68%, respectively, which correspond to 42% and 32% higher strengths in relation to the reference gypsum plaster. The additional glass fiber in the modified matrix enhanced the mechanical strength by several more percentages. The glass fiber should be accompanied by a superplasticizer to achieve the proper reinforcing action.

- The application of additional components such as SP and fiber reinforcement in a photocatalytic gypsum matrix might compensate for the mechanical changes induced by the connected photocatalyst particles, especially their high water demand and the changes of the pores’ distribution in gypsum material.

- Shrinkage reduction is mainly associated with photocatalyst presence and lower water content except for the obvious significance of curing conditions such as temperature and moisture level. The influence of superplasticizer molecules and glass fiber on shrinkage behavior was negligible.

- The modified materials can support the elimination of NOx from the air. The photocatalytic activity of photocatalytic gypsum plaster was maintained on the level of 30%, regardless of SP or glass fiber presence.

- The self-cleaning properties of gypsum material were gradually improved by (1) a modified photocatalyst (photocatalytic action), (2) to some extent by superplasticizer molecules due to limited agglomeration and the more accessible active photocatalyst surface, and (3) nearly two times by glass fiber due to the transportation of irradiation to deeper parts of the gypsum materials. The synergistic effect of the three components in a gypsum matrix during self-cleaning phenomenon was confirmed.

Author Contributions

Funding

Conflicts of Interest

References

- Jimenez-Relinque, E.; Castellote, M. Qick assessment of the photocatalytic activity of TiO2 construction materials by nitroblue tetrazolium (NBT) ink. Constr. Build. Mater. 2019, 214, 1–8. [Google Scholar] [CrossRef]

- Binas, V.; Papadaki, D.; Maggos, T.; Katsanaki, A.; Kiriakidis, G. Study of innovative photocatalytic cement based coatings: The effect of supporting materials. Constr. Build. Mater. 2018, 168, 923–930. [Google Scholar] [CrossRef]

- Su, B.; Zhong, M.; Han, L.; Wei, M.; Liu, Y.; Yang, H.; Lei, Z. Eco-friendly preparation of hierarchically self-assembly porous ZnO nanosheets for enhanced photocatalytic performance. Mater. Res. Bull. 2020, 124, 110777–110781. [Google Scholar] [CrossRef]

- Shafaei, D.; Yang, S.; Berlouis, L.; Minto, J. Multiscale pore structure analysis of nano titanium dioxide cement mortar composite. Mater. Today Commun. 2020, 22, 100779–100788. [Google Scholar] [CrossRef]

- Makul, N. Modern sustainable cement and concrete composites: Review of current status, challenges and guidelines. Sustain. Mater. Technol. 2020, 25, e00155–e00169. [Google Scholar] [CrossRef]

- Demeestere, K.; Dewful, J.; De Witte, B.; Beeldens, A.; Van Langenhove, H. Heterogeneous photocatalytic removal of toluene from air on building materials enriched with TiO2. Build. Environ. 2008, 43, 406–414. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, F.; Xu, W.; Cao, S.; Zhu, H. Recent progress in enhancing photocatalytic efficiency of TiO2-based materials. Appl. Catal. A Gen. 2015, 495, 131–140. [Google Scholar] [CrossRef]

- Yang, Y.; Ji, T.; Su, W.; Yang, B.; Zhang, Y.; Yang, Z. Photocatalytic NOx abatement and self-cleaning performance of cementitious composites with g-C3N4 nanosheets under visible light. Constr. Build. Mater. 2019, 225, 120–131. [Google Scholar] [CrossRef]

- García Calvo, J.L.; Carballosa, P.; Castillo, A.; Revuelta, D.; Gutiérrez, J.P.; Castellote, M. Expansive concretes with photocatalytic activity for pavements: Enhanced performance and modifications of the expansive hydrates composition. Constr. Build. Mater. 2019, 218, 394–403. [Google Scholar] [CrossRef]

- Li, H.; Ding, S.; Zhang, L.; Ouyang, J.; Han, B. Effects of particle size, crystal phase and surface treatment of nano—TiO2 on the rheological parameters of cement paste. Constr. Build. Mater. 2020, 239, 117897–117906. [Google Scholar] [CrossRef]

- Zając, K.; Janus, M.; Morawski, A.W. Improved self-cleaning properties of photocatalytic gypsum plaster enriched with glass fiber. Materials 2019, 12, 357. [Google Scholar] [CrossRef] [PubMed]

- Pelaez, M.; Nolan, N.T.; Pillai, S.C.; Seery, M.K.; Falaras, P.; Kontos, A.G.; Dunlop, P.; Hamilton, J.; Byrne, J.; O’Shea, K.; et al. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B Environ. 2012, 125, 331–349. [Google Scholar] [CrossRef]

- Wang, W.; Tadé, M.O.; Shao, Z. Nitrogen – doped simple and complex oxides for photocatalysis: A review. Prog. Mater. Sci. 2018, 92, 33–63. [Google Scholar] [CrossRef]

- Noaman, A.T.; Abed, M.S.; Hamead, A.A.A. Production of polycarboxylate-ether superplasticizer (PCE) coated sand with modified hardened properties in cement mortar. Constr. Build. Mater. 2020, 245, 118442–118450. [Google Scholar] [CrossRef]

- Ma, B.; Qi, H.; Tan, H.; Su, Y.; Li, X.; Liu, X.; Li, C.; Zhang, T. Effect of aliphatic-based superplasticizer on rheological performance of cement paste plasticized by polycarboxylate superplasticizer. Constr. Build. Mater. 2020, 233, 117181–117189. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Time- and temperature- dependent rheological properties of cemented paste backfill that contains superplasticizer. Powder Technol. 2020, 360, 731–740. [Google Scholar] [CrossRef]

- Vo, M.L.; Plank, J. Dispersing effectiveness of a phosphated polycarboxylate in α- and β-calcium sulfate hemihydrate systems. Constr. Build. Mater. 2020, 237, 117731–117741. [Google Scholar] [CrossRef]

- Lin, X.; Liao, B.; Zhang, J.; Li, S.; Huang, J.; Pang, H. Synthesis and characterization of high –performance cross-linked polycarboxylate superplasticizers. Constr. Build. Mater. 2019, 210, 162–171. [Google Scholar] [CrossRef]

- Yang, L.; Yilmaz, E.; Li, J.; Liu, H.; Jiang, H. Effect of superplasticizer type and dosage on fluidity and strength behavior of cement tailings backfill with different solid contents. Constr. Build. Mater. 2018, 187, 290–298. [Google Scholar] [CrossRef]

- Tan, H.; Deng, X.; Gu, B.; Ma, B.; Luo, S.; Zhi, Z.; Guo, Y.; Zou, F. Effect of borax and sodium tripolyphosphate on fluidity of gypsum paste plasticized by polycarboxylate superplasticizer. Constr. Build. Mater. 2018, 176, 394–402. [Google Scholar] [CrossRef]

- Peng, J.; Qu, J.; Zhang, J.; Chen, M.; Wan, T. Adsorption charecteristics of water—Reducing agents on gypsum surface and its effect on the rheology of gypsum plaster. Cement Concrete Res. 2005, 35, 527–531. [Google Scholar] [CrossRef]

- Guan, B.; Ye, Q.; Zhang, J.; Lou, W.; Wu, Z. Interaction between α—calcium sulfate hemihydrate and superplasticizer from the point of adsorption characteristics, hydration and hardening process. Cement Concrete Res. 2010, 40, 253–259. [Google Scholar] [CrossRef]

- Pundir, A.; Garg, M.; Singh, R. Evaluation of properties of gypsum plaster—Superplasticizer blends of improved performance. J. Build. Eng. 2015, 4, 223–230. [Google Scholar] [CrossRef]

- Sakthieswaran, N.; Sophia, M. Effect of superplasticizers on the properties of latex modified gypsum plaster. Constr. Build. Mater. 2018, 179, 675–691. [Google Scholar] [CrossRef]

- Zając, K.; Rucińska, T.; Morawski, A.; Janus, M. Photocatalytic gypsum plasters – studies of air cleaning properties and selected technical parameters. Cem. WapnoBeton 2019, 1, 10–20. [Google Scholar]

- Kondratieva, N.; Barre, M.; Goutenoire, F.; Sanytsky, M.; Rousseau, A. Effect of additives SiC on the hydration and the crystallization processes of gypsum. Constr. Build. Mater. 2020, 235, 117479–117488. [Google Scholar] [CrossRef]

- Moghadam, H.A.; Mirzaei, A. Comparing the effects of a retarder and accelerator on properties of gypsum building plaster. J. Build. Eng. 2020, 28, 101075–101082. [Google Scholar] [CrossRef]

- Chen, J.; Kou, S.C.; Poon, C.S. Hydration and properties of nano-TiO2 blended cement composites. Cement Concrete Comp. 2012, 34, 642–649. [Google Scholar] [CrossRef]

- Lucas, S.S.; Ferreira, V.M.; Barroso de Aguiar, J.L. Incorporation of titanium dioxide nanoparticles in mortars—Influence of microstructure in the hardened state properties and photocatalytic activity. Cement Concrete Res. 2013, 43, 112–120. [Google Scholar] [CrossRef]

- Wu, H.-C.; Xia, Y.-M.; Hu, X.-Y.; Liu, X. Improvement on mechanical strength and water absorption of gypsum modeling material with synthetic polymers. Ceram. Int. 2014, 40, 14899–14906. [Google Scholar] [CrossRef]

- Zhang, G.; Li, G.; Li, Y. Effects of superplasticizers and retarders on the fluidity and strength of sulphoaluminate cement. Constr. Build. Mater. 2016, 126, 44–54. [Google Scholar] [CrossRef]

- Huang, W.-H. Improving the properties of cement-fly ash grout using fiber and superplasticizer. Cement Concrete Res. 2001, 31, 1033–1041. [Google Scholar] [CrossRef]

- Farzadnia, N.; Noorvand, H.; Yasin, A.M.; Aziz, F.N.A. The effect of nano silica on short term drying shrinkage of POFA cement mortars. Constr. Build. Mater. 2015, 95, 636–646. [Google Scholar] [CrossRef]

- Sonebi, M.; García-Taengua, E.; Hossain, K.M.A.; Khatib, J.; Lachemi, M. Effect of nanosilica addition on the fresh properties and shrinkage of mortars with fly ash and superplasticizer. Constr. Build. Mater. 2015, 84, 269–276. [Google Scholar] [CrossRef]

- Alsayed, S.H. Influence of superplasticizer, plasticizer, and silica fume on the drying shrinkage of high-strength concrete subjected to hot-drying field conditions. Cement Concrete Res. 1998, 28, 1405–1415. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hsien, Y.-C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Khed, V.C.; Liew, M.S. Optimization of hybrid fibres in engineering cementitious composites. Constr. Build. Mater. 2018, 190, 24–37. [Google Scholar] [CrossRef]

- Nguyen, C.H.; Fu, C.C.; Juang, R.S. Degradation of methylene blue and methyl orange by palladium-doped TiO2 photocatalysis for water reuse: Efficiency and degradation pathways. J. Clean. Prod. 2018, 202, 413–427. [Google Scholar] [CrossRef]

- Bubacz, K.; Choina, J.; Dolat, D.; Borowiak-Paleń, E.; Moszyński, D.; Morawski, A.W. Studies on nitrogen modified TiO2 photocatalyst prepared in different conditions. Mater. Res. Bull. 2010, 45, 1085–1091. [Google Scholar] [CrossRef]

- Janus, M.; Mądraszewski, S.; Zając, K.; Kusiak-Nejman, E.; Morawski, A.W.; Stephan, D. Photocatalytic activity and mechanical properties of cements modified with TiO2/N. Materials 2019, 12, 3756. [Google Scholar] [CrossRef]

- Zając, K.; Janus, M.; Kuźmiński, K.; Morawski, A.W. Preparation of gypsum building materials with photocatalytic properties. A strong emphasis on waste gypsum from flue gas desulfurization. Przem. Chem. 2016, 95, 2222–2226. [Google Scholar]

- Janus, M.; Zając, K.; Ehm, C.; Stephan, D. Fast method for testing the photocatalytic performance of modified gypsum. Catalysts 2019, 9, 693. [Google Scholar] [CrossRef]

- Munafò, P.; Goffredo, G.B.; Quagliarini, E. TiO2-based nanocoatings for preserving architectural stone surfaces: An overview. Constr. Build. Mater. 2015, 84, 201–218. [Google Scholar] [CrossRef]

- Graziani, L.; Quagliarini, E.; D’Orazio, M. The role of roughness and porosity on the self-cleaning and anti-biofouling efficiency of TiO2-Cu and TiO2-Ag nanocoatings applied on fired bricks. Constr. Build. Mater. 2016, 129, 116–124. [Google Scholar] [CrossRef]

| Sample | SP Dose (wt. %) | W/P Ratio | Average Spread Diameter with Standard Deviations (cm) |

|---|---|---|---|

| G | - | 0.67 | 10.0 |

| 0.80 | 13.0 | ||

| 0.85 | 14.5 ± 0.1 | ||

| PG | - | 0.85 | 13.8 ± 0.2 |

| 0.88 | 15.1 ± 0.1 | ||

| 0.87 | 14.6 ± 0.1 | ||

| PG-SP1 | 0.50 | 0.85 | 16.6 ± 0.1 |

| 0.20 | 0.85 | 16.0 | |

| 0.10 | 0.85 | 16.0 | |

| 0.05 | 0.85 | 15.9 ± 0.1 | |

| 0.01 | 0.85 | 14.7 ± 0.2 |

| Sample | SP Dose (wt.%) | W/P Ratio | Average Spread Diameter with Standard Deviations (cm) |

|---|---|---|---|

| G | - | 0.75 | 12.0 |

| PG | - | 0.75 | 11.3 |

| PG-SP2 | 0.10 | 0.75 | 14.1 ± 0.1 |

| 0.15 | 0.75 | 14.2 ± 0.1 | |

| 0.20 | 0.75 | 14.4 ± 0.1 |

| Sample | TiO2/N Dose (wt.%) | SP Dose (wt.%) | F Dose (wt.%) | W/P Ratio |

|---|---|---|---|---|

| G | 0.00 | 0.00 | 0.00 | 0.85 |

| PG | 1.00 | 0.00 | 0.00 | 0.85 |

| PG-SP1 | 1.00 | 0.01 | 0.00 | 0.85 |

| PG-SP2 | 1.00 | 0.20 | 0.00 | 0.75 |

| PG-SP2-F | 1.00 | 0.20 | 0.30 | 0.75 |

| Sample | NO Removal (µg/cm2/h) | NO2 Formation (µg/cm2/h) | NOx Total Removal (µg/cm2/h) | Rate of NOx Degradation with Standard Deviations (%) |

|---|---|---|---|---|

| G | 1.18 | 0.00 | 1.18 | 2.4 ± 0.5 |

| PG | 11.67 | 1.47 | 10.20 | 31.0 ± 2.0 |

| PG-SP1 | 12.48 | 1.39 | 11.09 | 33.4 ± 1.0 |

| PG-SP2 | 10.95 | 1.20 | 9.75 | 29.4 ± 2.0 |

| PG-SP2-F | 12.31 | 1.15 | 11.16 | 33.3 ± 2.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zając, K.; Czyżewski, A.; Kaszyńska, M.; Janus, M. Combined Effect of Photocatalyst, Superplasticizer, and Glass Fiber on the Photocatalytic Activity and Technical Parameters of Gypsum. Catalysts 2020, 10, 385. https://doi.org/10.3390/catal10040385

Zając K, Czyżewski A, Kaszyńska M, Janus M. Combined Effect of Photocatalyst, Superplasticizer, and Glass Fiber on the Photocatalytic Activity and Technical Parameters of Gypsum. Catalysts. 2020; 10(4):385. https://doi.org/10.3390/catal10040385

Chicago/Turabian StyleZając, Kamila, Adam Czyżewski, Maria Kaszyńska, and Magdalena Janus. 2020. "Combined Effect of Photocatalyst, Superplasticizer, and Glass Fiber on the Photocatalytic Activity and Technical Parameters of Gypsum" Catalysts 10, no. 4: 385. https://doi.org/10.3390/catal10040385

APA StyleZając, K., Czyżewski, A., Kaszyńska, M., & Janus, M. (2020). Combined Effect of Photocatalyst, Superplasticizer, and Glass Fiber on the Photocatalytic Activity and Technical Parameters of Gypsum. Catalysts, 10(4), 385. https://doi.org/10.3390/catal10040385