Recyclabl Metal (Ni, Fe) Cluster Designed Catalyst for Cellulose Pyrolysis to Upgrade Bio-Oil

Abstract

:1. Introduction

2. Results and Discussion

2.1. Catalyst Characteristics

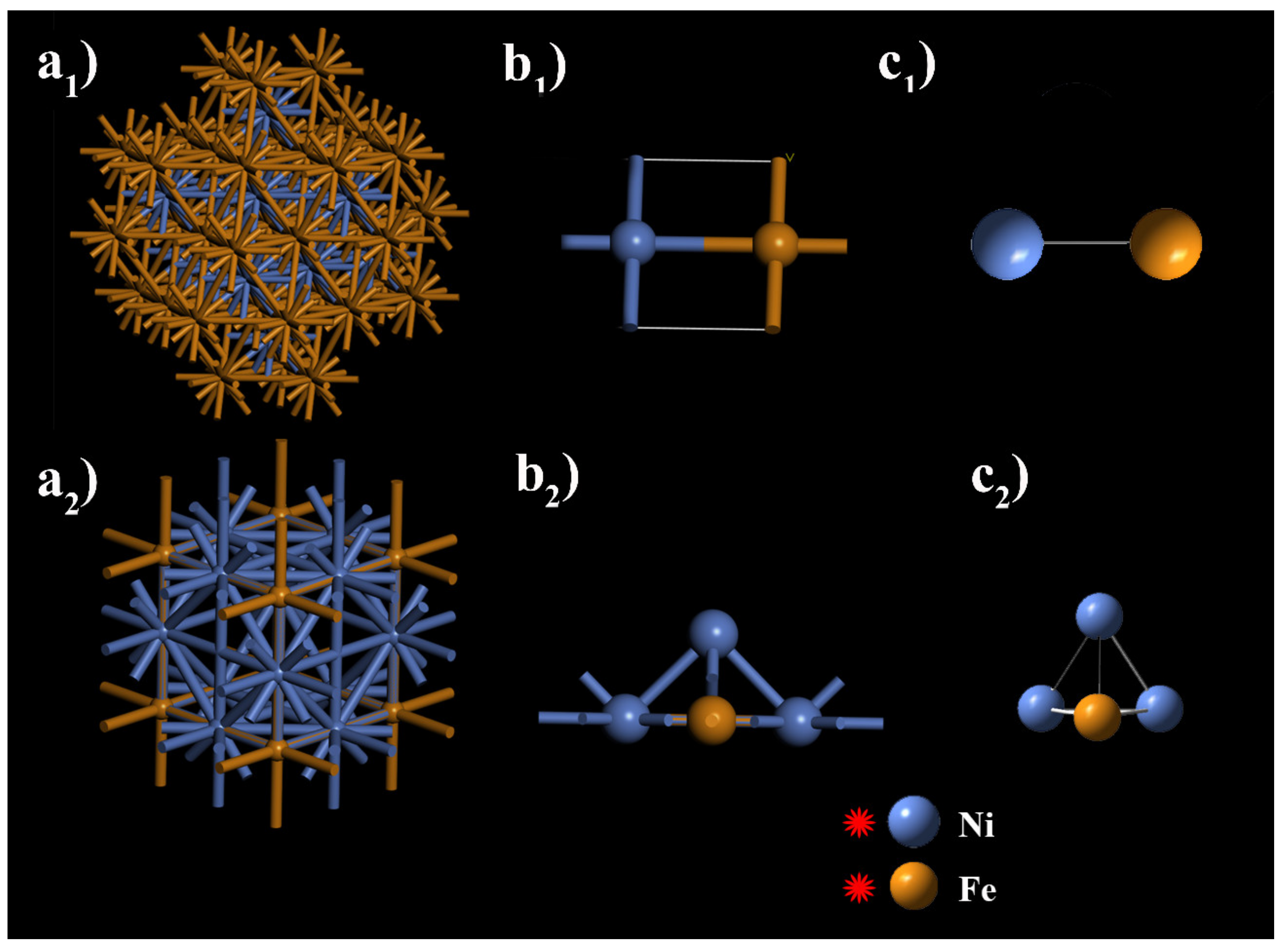

2.1.1. Structural Characteristics

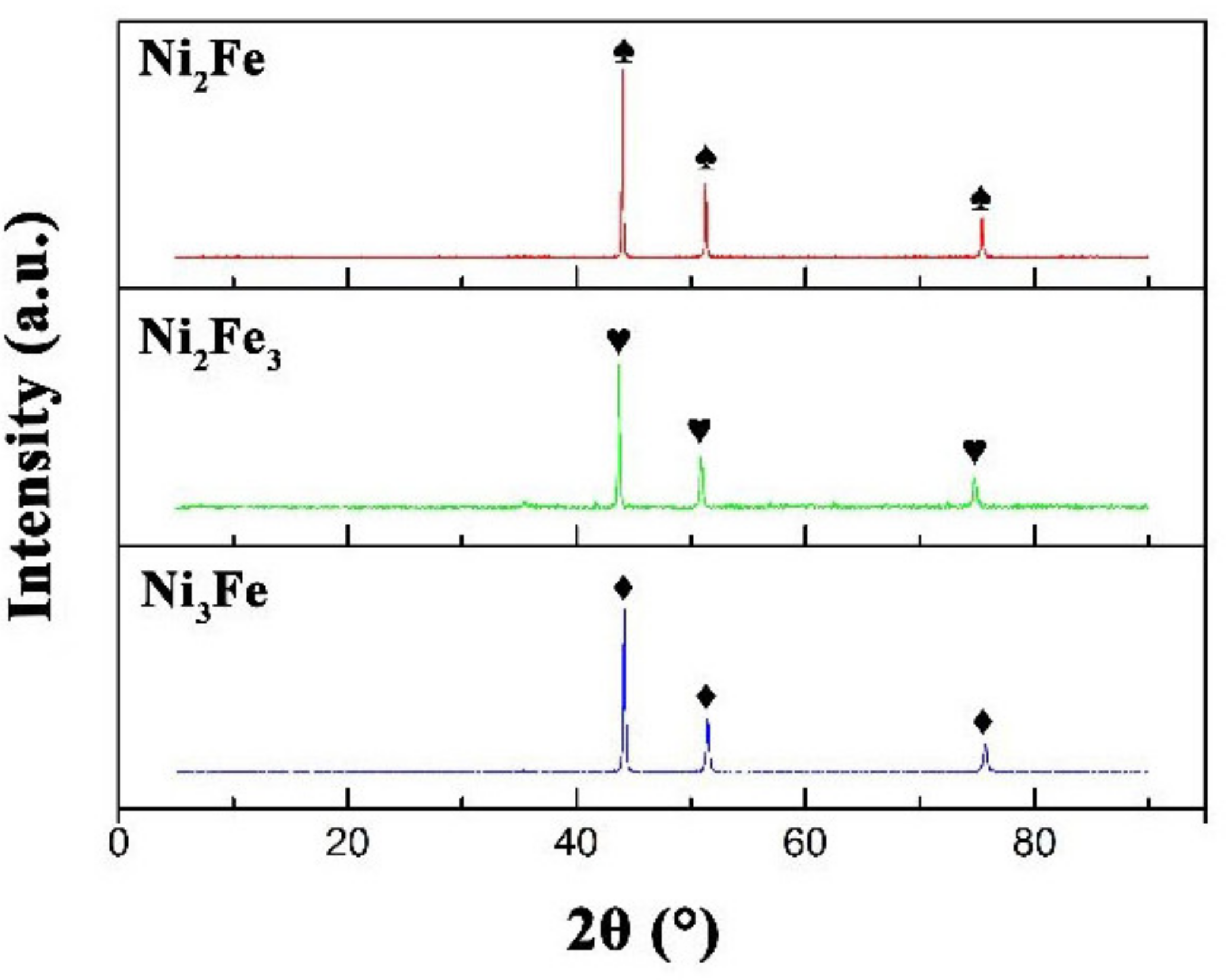

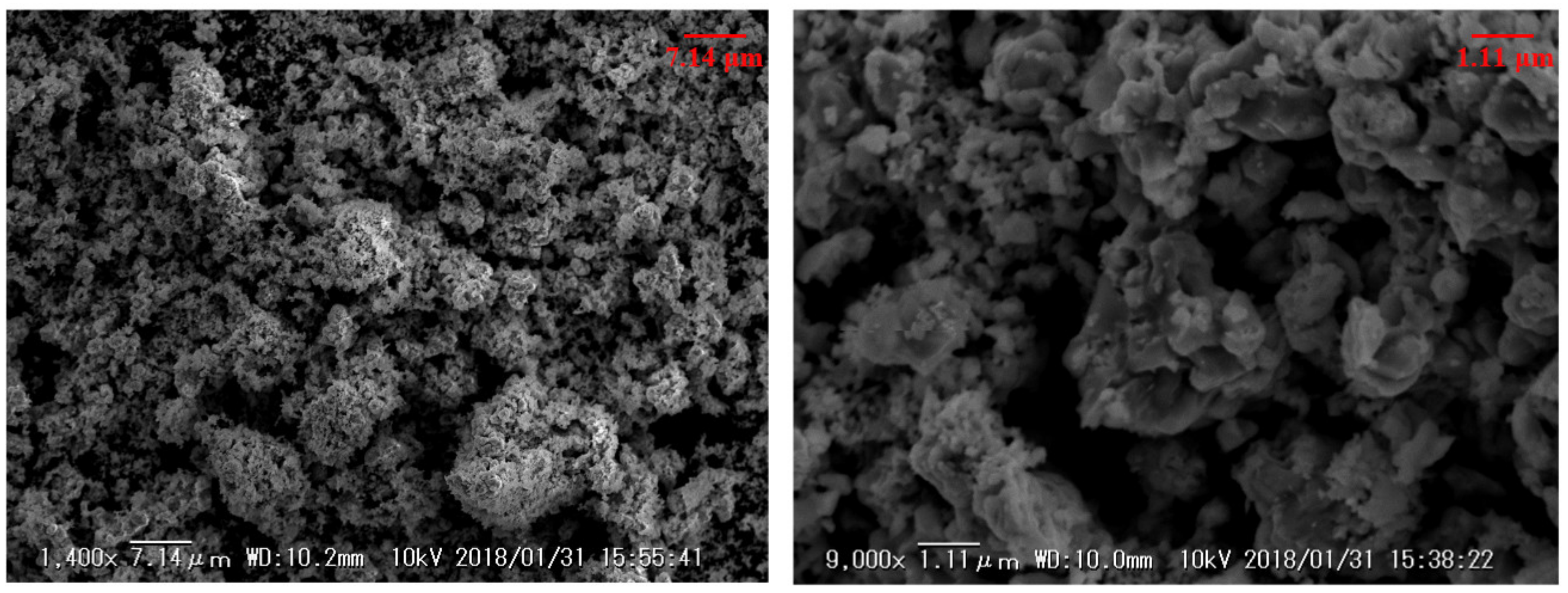

2.1.2. XRD, SEM-EDS and AES Analysis

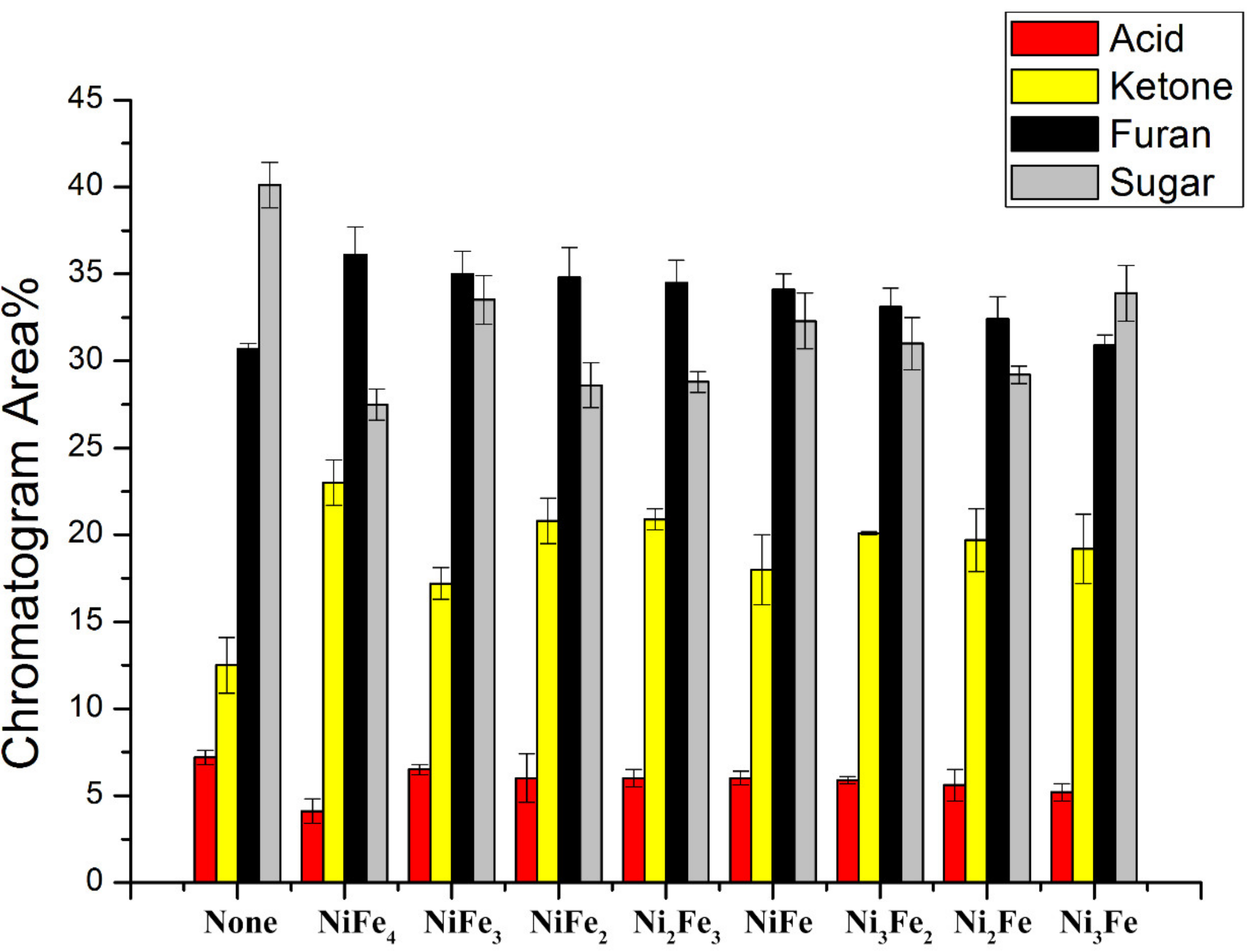

2.2. Pyrolysis Results

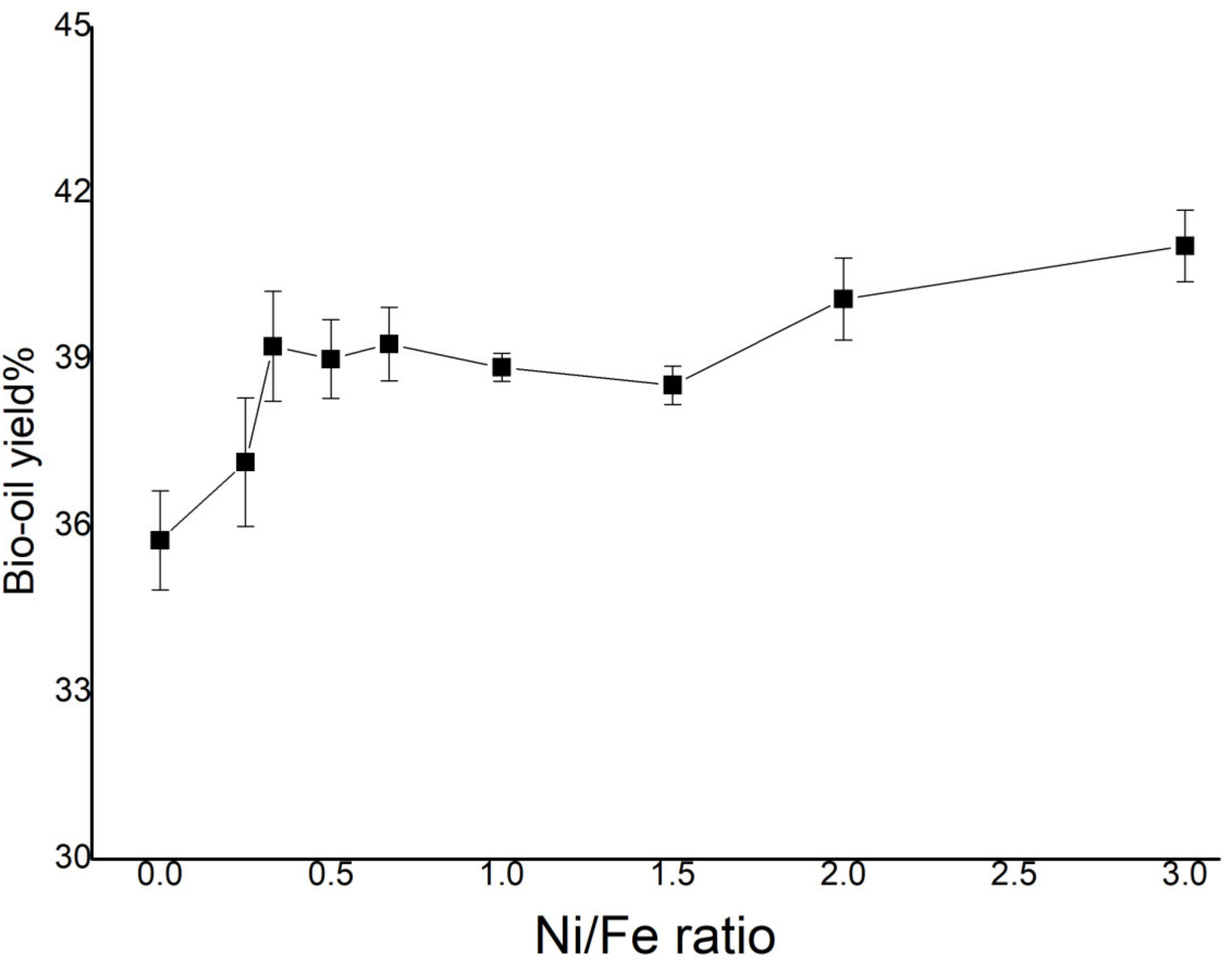

2.2.1. Pyrolysis Yields

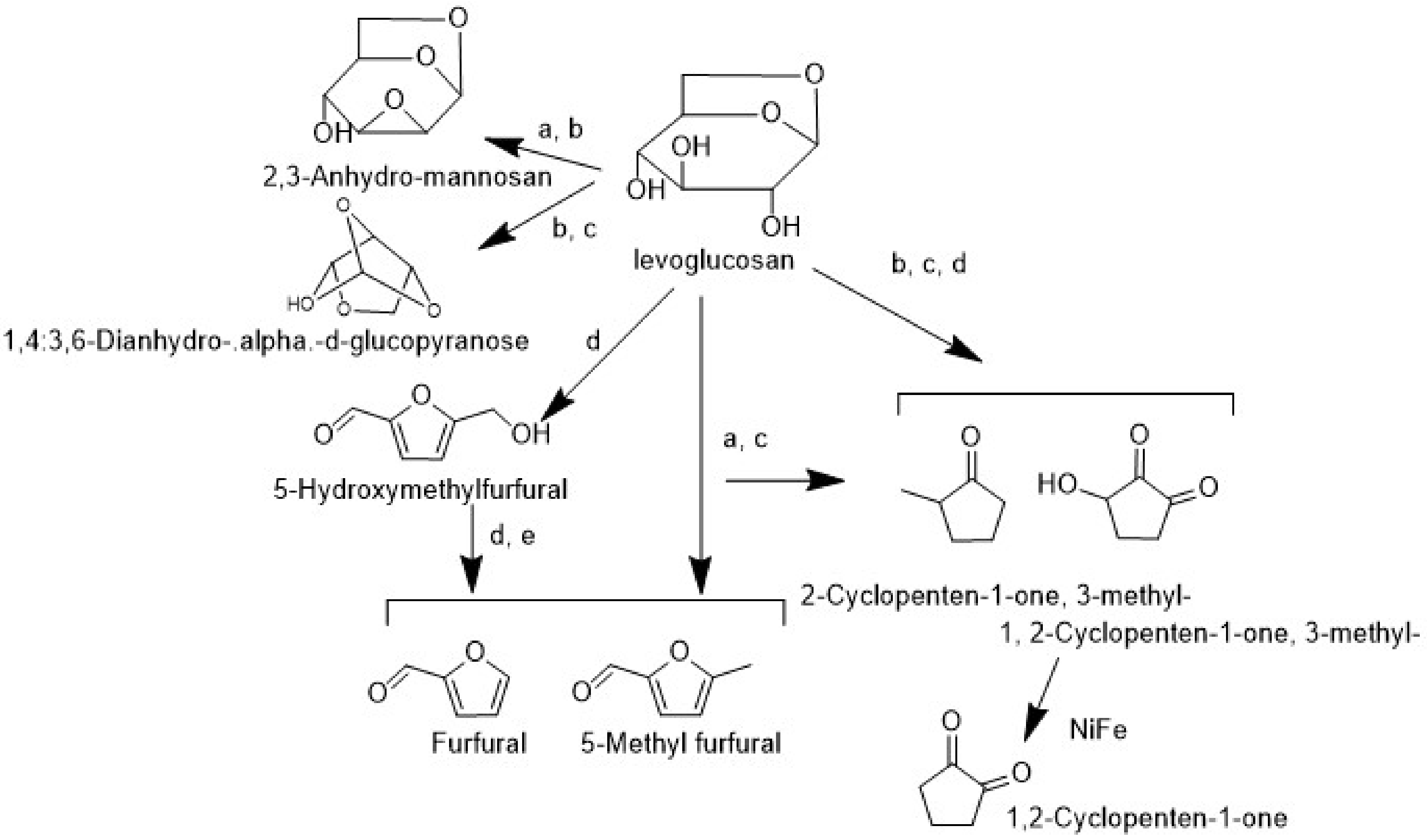

2.2.2. GC-MS Analysis

3. Materials and Methods

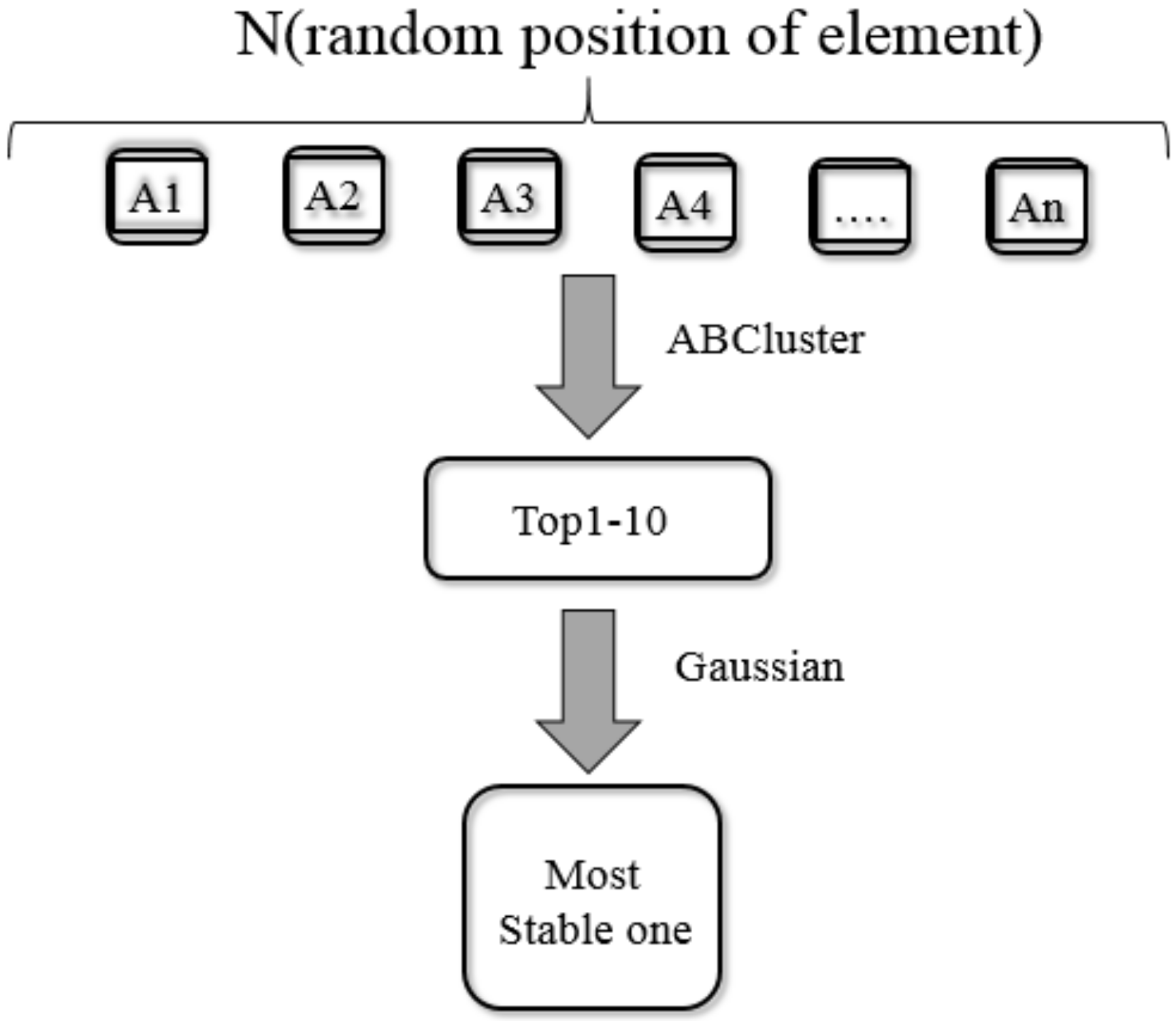

3.1. Computational Details

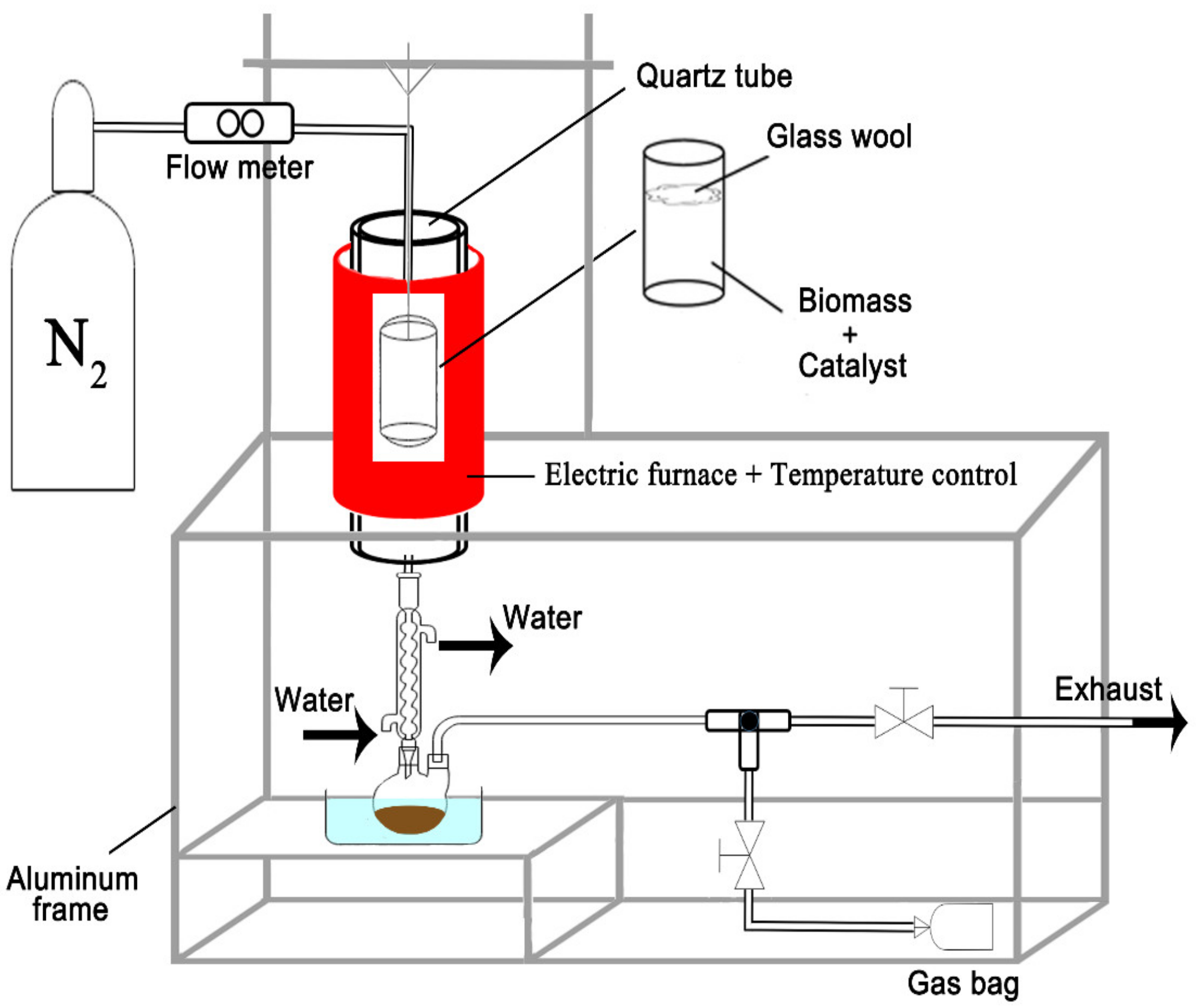

3.2. Experimental Details

3.2.1. Catalyst Preparation

3.2.2. Pyrolysis Method

3.2.3. XRD, SEM-EDS Characterization, AES analysis, Water Content and GC-MS Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Roser, M.; Ortiz-Ospina, E. World Population Growth. Available online: https://ourworldindata.org/world-population-growth (accessed on 7 October 2020).

- Karim, M.; Munir, A.; Karim, M.; Muhammad-Sukki, F.; Abu-Bakar, S.; Sellami, N.; Bani, N.; Hassan, M. Energy Revolution for Our Common Future: An Evaluation of the Emerging International Renewable Energy Law. Energies 2018, 11, 1769. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z. China’s strategy for the development of renewable energies. Energy Source Part B 2017, 12, 971–975. [Google Scholar] [CrossRef] [Green Version]

- Lior, N. Energy resources and use: The present situation and possible paths to the future. Energy 2008, 33, 842–857. [Google Scholar] [CrossRef]

- Biofuels International Magazine. Market Study Global Biofuels Market to Grow to $246bn by 2024. Available online: http://biofuels-news.com/display_news/10395/market_study_global_biofuels_market_to_grow_to_246bn_by_2024/ (accessed on 6 October 2020).

- Lehto, J.; Oasmaa, A.; Solantausta, Y.; Kytö, M.; Chiaramonti, D. Review of fuel oil quality and combustion of fast pyrolysis bio-oils from lignocellulosic biomass. Appl. Energy 2014, 116, 178–190. [Google Scholar] [CrossRef]

- Wang, Y.X.; Fang, Y.M.; He, T.; Hu, H.Q.; Wu, J.H. Hydrodeoxygenation of dibenzofuran over noble metal supported on mesoporous zeolite. Catal. Commun. 2011, 12, 1201. [Google Scholar] [CrossRef]

- Lan, P.; Xu, Q.; Zhou, M.; Lan, L.; Zhang, S.; Yan, Y. Catalytic Steam Reforming of Fast Pyrolysis Bio-Oil in Fixed Bed and Fluidized Bed Reactors. Chem. Eng. Technol. 2010, 33, 2021. [Google Scholar] [CrossRef]

- Eschenbacher, A.; Saraeian, A.; Shanks, B.H.; Jensen, P.A.; Henriksen, U.B.; Ahrenfeldt, J.; Jensen, A.D. Insights into the scalability of catalytic upgrading of biomass pyrolysis vapors using micro and bench-scale reactors. Sustain. Energy Fuels 2020, 4, 3780–3796. [Google Scholar] [CrossRef]

- Huber, G.W.; Brown, R.C. Prospects and challenges of pyrolysis technologies for biomass conversion. Energy Technol. GER 2017, 5, 5–6. [Google Scholar] [CrossRef]

- Bridgwater, T. Challenges and opportunities in fast pyrolysis of biomass: Part I. Johns. Matthey Technol. Rev. 2018, 62, 118–130. [Google Scholar] [CrossRef]

- Funke, A.; Richter, D.; Niebel, A.; Dahmen, N.; Sauer, J. Fast pyrolysis of biomass residues in a twin-screw mixing reactor. JoVE 2016, e54395. [Google Scholar] [CrossRef]

- Zhou, G.; Li, J.; Yu, Y.; Li, X.; Wang, Y.; Wang, W.; Komarneni, S. Optimizing the distribution of aromatic products from catalytic fast pyrolysis of cellulose by ZSM-5 modification with boron and co-feeding of low-density polyethylene. Appl. Catal. A Gen. 2014, 487, 45–53. [Google Scholar] [CrossRef]

- Custodis, V.B.; Hemberger, P.; Ma, Z.; van Bokhoven, J.A. Mechanism of fast pyrolysis of lignin: Studying model compounds. J. Phys. Chem. B 2014, 118, 8524–8531. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Wei, L.; Julson, J.; Muthukumarappan, K.; Kharel, P.R. Upgrading pyrolysis bio-oil to hydrocarbon enriched biofuel over bifunctional Fe-Ni/HZSM-5 catalyst in supercritical methanol. Fuel Process. Technol. 2017, 167, 117–126. [Google Scholar] [CrossRef]

- Ji, X.; Liu, B.; Ma, W.; Chen, G.; Yan, B.; Cheng, Z. Effect of MgO promoter on Ni-Mg/ZSM-5 catalysts for catalytic pyrolysis of lipid-extracted residue of Tribonema minus. J. Anal. Appl. Pyrol. 2017, 123, 278–283. [Google Scholar] [CrossRef]

- Mutz, B.; Belimov, M.; Wang, W.; Sprenger, P.; Serrer, M.A.; Wang, D.; Grunwaldt, J.D. Potential of an alumina-supported Ni3Fe catalyst in the methanation of CO2: Impact of alloy formation on activity and stability. ACS Catal. 2017, 7, 6802–6814. [Google Scholar] [CrossRef]

- Gong, L.; Chen, J.J.; Mu, Y. Catalytic CO2 reduction to valuable chemicals using NiFe-based nanoclusters: A first-principles theoretical evaluation. Phys. Chem. Chem. Phys. 2017, 19, 28344–28353. [Google Scholar] [CrossRef]

- Liu, J.C.; Ma, X.L.; Li, Y.; Wang, Y.G.; Xiao, H.; Li, J. Heterogeneous Fe3 single-cluster catalyst for ammonia synthesis via an associative mechanism. Nat. Commun. 2018, 9, 1610. [Google Scholar] [CrossRef]

- Yu, J.; Hai, Y.; Cheng, B. Enhanced Photocatalytic H2-Production Activity of TiO2 by Ni(OH)2 Cluster Modification. J. Phys. Chem. C 2011, 115, 4953–4958. [Google Scholar] [CrossRef]

- Saito, N.; Cordier, S.; Lemoine, P.; Ohsawa, T.; Wada, Y.; Grasset, F.; Cross, J.S.; Ohashi, N. Lattice and Valence Electronic Structures of Crystalline Octahedral Molybdenum Halide Clusters-Based Compounds, Cs2[Mo6X14] (X = Cl, Br, I), Studied by Density Functional Theory Calculations. Inorg. Chem. 2017, 56, 6234–6243. [Google Scholar] [CrossRef]

- Bandyopadhyay, D. Chemisorptions effect of oxygen on the geometries, electronic and magnetic properties of small size Ni(n) (n = 1-6) clusters. J. Mol. Model. 2012, 18, 737–749. [Google Scholar] [CrossRef]

- Song, W.; Lu, W.C.; Wang, C.Z.; Ho, K.M. Magnetic and electronic properties of the nickel clusters Nin (n≤30). Comput. Theor. Chem. 2011, 978, 41–46. [Google Scholar] [CrossRef]

- Yao, Y.H.; Gu, X.; Ji, M.; Gong, X.G.; Wang, D.S. Structures and magnetic moments of Nin clusters. Phys. Lett. A 2007, 360, 629–631. [Google Scholar] [CrossRef]

- Liu, X.; Wang, C.Z.; Lin, H.Q.; Hupalo, M.; Thiel, P.A.; Ho, K.M.; Tringides, M.C. Structures and magnetic properties of Fe clusters on graphene. Phys. Rev. B 2014, 90, 155444. [Google Scholar] [CrossRef]

- Rao, B.K.; Ramos de Debiaggi, S.; Jena, P. Structure and magnetic properties of Fe-Ni clusters. Phys. Rev. B 2001, 64, 024418. [Google Scholar] [CrossRef]

- Nakazawa, T.; Igarashi, T.; Tsuru, T.; Kaji, Y. Ab initio calculations of Fe–Ni clusters. Comp. Mater. Sci. 2009, 46, 367–375. [Google Scholar] [CrossRef]

- Lavrentiev, M.Y.; Wrobel, J.S.; Nguyen-Manh, D.; Dudarev, S.L. Magnetic and thermodynamic properties of face-centered cubic Fe-Ni alloys. Phys. Chem. Chem. Phys. 2014, 16, 16049–16059. [Google Scholar] [CrossRef] [Green Version]

- Nie, L.; de Souza, P.M.; Noronha, F.B.; An, W.; Sooknoi, T.; Resasco, D.E. Selective conversion of m-cresol to toluene over bimetallic Ni–Fe catalysts. J. Mol. Catal. A Chem. 2014, 388–389, 47–55. [Google Scholar] [CrossRef]

- Li, S.Y.; Cross, J.S. Reusability of the Ni2Fe3 metal catalyst for upgrading pyrolyzed bio-oil. MATEC Web Conf. 2019, accepted. [Google Scholar]

- Yao, D.; Wu, C.; Yang, H.; Hu, Q.; Nahil, M.A.; Chen, H.; Williams, P.T. Hydrogen production from catalytic reforming of the aqueous fraction of pyrolysis bio-oil with modified Ni–Al catalysts. Int. J. Hyrogen Energy 2014, 39, 14642–14652. [Google Scholar] [CrossRef] [Green Version]

- Sun, K.; Huang, Q.X.; Chi, Y.; Yan, J.H. Effect of ZnCl2-activated biochar on catalytic pyrolysis of mixed waste plastics for producing aromatic-enriched oil. Waste Manag. 2018, 81, 128–137. [Google Scholar] [CrossRef]

- Cho, D.W.; Yoon, K.; Ahn, Y.; Sun, Y.; Tsang, D.C.; Hou, D.; Song, H. Fabrication and environmental applications of multifunctional mixed metal-biochar composites (MMBC) from red mud and lignin wastes. J. Hazard. Mater. 2019, 374, 412–419. [Google Scholar] [CrossRef] [PubMed]

- Behrens, M.; Cross, J.S.; Akasaka, H.; Ohtake, N. A study of guaiacol, cellulose, and Hinoki wood pyrolysis with silica, ZrO2andTiO2 and ZSM-5 catalysts. J. Anal. Appl. Pyrol. 2017, 125, 178–184. [Google Scholar] [CrossRef]

- Xia, H.; Yan, X.; Xu, S.; Yang, L.; Ge, Y.; Wang, J.; Zuo, S. Effect of Zn/ZSM-5 and FePO4 Catalysts on Cellulose Pyrolysis. J. Chem. 2015, 2015, 1–11. [Google Scholar]

- Stefanidis, S.D.; Kalogiannis, K.G.; Iliopoulou, E.F.; Michailof, C.M.; Pilavachi, P.A.; Lappas, A.A. A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J. Anal. Appl. Pyrol. 2014, 105, 143–150. [Google Scholar] [CrossRef]

- Li, S.Y.; Cheng, S.; Cross, J.S. Homogeneous and Heterogeneous Catalysis Impact on Pyrolyzed Cellulose to Produce Bio-Oil. Catalysts 2020, 10, 178. [Google Scholar] [CrossRef] [Green Version]

- Yu, F.W.; Ji, D.X.; Nie, Y.; Luo, Y.; Huang, C.J.; Ji, J.B. Study on the pyrolysis of cellulose for bio-oil with mesoporous molecular sieve catalysts. Appl. Biochem. Biotechnol. 2012, 168, 174–182. [Google Scholar] [CrossRef] [PubMed]

- ToolBox, T.E. The Specific Heat of Metals and Metalloids (Semimetals). Available online: https://www.engineeringtoolbox.com/heat-capacity-d_338.html (accessed on 6 October 2020).

- Madelung, O.; White, G. Thermal Conductivity of Pure Metals and Alloys; Springer: Berlin/Heidelberg, Germany, 1991. [Google Scholar]

- Fabbri, D.; Torri, C.; Baravelli, V. Effect of zeolites and nanopowder metal oxides on the distribution of chiral anhydrosugars evolved from pyrolysis of cellulose: An analytical study. J. Anal. Appl. Pyrol. 2007, 80, 24–29. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, Z.; Dong, C.Q.; Zhang, Z.F.; Zhang, Y.; Yang, Y.P.; Zhu, X.F. Selective fast pyrolysis of biomass impregnated with ZnCl2: Furfural production together with acetic acid and activated carbon as by-products. J. Anal. Appl. Pyrol. 2011, 91, 273–279. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, R.; Lin, W.; Song, W. Pyrolysis of cellulose under catalysis of SAPO-34, ZSM-5, and Y zeolite via the Py-GC/MS method. Int. J. Green Energy 2016, 13, 853–858. [Google Scholar] [CrossRef]

- Ly, H.V.; Galiwango, E.; Kim, S.S.; Kim, J.; Choi, J.H.; Woo, H.C.; Othman, M.R. Hydrodeoxygenation of 2-furyl methyl ketone as a model compound of algal Saccharina Japonica bio-oil using iron phosphide catalyst. Chem. Eng. J. 2017, 317, 302–308. [Google Scholar] [CrossRef]

- Mehta, M.; Holthausen, M.H.; Mallov, I.; Perez, M.; Qu, Z.W.; Grimme, S.; Stephan, D.W. Catalytic Ketone Hydrodeoxygenation Mediated by Highly Electrophilic Phosphonium Cations. Angew. Chem. 2015, 54, 8250–8254. [Google Scholar] [CrossRef]

- King, A.E.; Brooks, T.J.; Tian, Y.H.; Batista, E.R.; Sutton, A.D. Understanding Ketone Hydrodeoxygenation for the Production of Fuels and Feedstocks From Biomass. ACS Catal. 2015, 5, 1223–1226. [Google Scholar] [CrossRef]

- Shafizadeh, F.R.E.D. Industrial pyrolysis of cellulosic materials. Appl. Polym. Symp. 1975, 28, 153–174. [Google Scholar]

- Thangalazhy-Gopakumar, S.; Adhikari, S.; Gupta, R.B.; Fernando, S.D. Influence of Pyrolysis Operating Conditions on Bio-Oil Components: A Microscale Study in a Pyroprobe. Energy Fuels 2011, 25, 1191–1199. [Google Scholar] [CrossRef]

- Lin, Y.C.; Cho, J.; Tompsett, G.A.; Westmoreland, P.R.; Huber, G.W. Kinetics and Mechanism of Cellulose Pyrolysis. J. Phys. Chem. C 2009, 113, 20097–20107. [Google Scholar] [CrossRef] [Green Version]

- Sanders, E.B.; Goldsmith, A.I.; Seeman, J.I. A model that distinguishes the pyrolysis of D-glucose, D-fructose, and sucrose from that of cellulose. Application to the understanding of cigarette smoke formation. J. Anal. Appl. Pyrol. 2003, 66, 29–50. [Google Scholar] [CrossRef]

- Nowakowski, D.J.; Jones, J.M. Uncatalysed and potassium-catalysed pyrolysis of the cell-wall constituents of biomass and their model compounds. J. Anal. Appl. Pyrol. 2008, 83, 12–25. [Google Scholar] [CrossRef]

- Lill, S.O.N.; Siegbahn, P.E. An autocatalytic mechanism for NiFe-hydrogenase: Reduction to Ni (I) followed by oxidative addition. Biochemistry 2009, 48, 1056–1066. [Google Scholar] [CrossRef]

- Kaya, A.A.; Erturk, K. Structural and optical properties of Fe/Ni: ZnO nanoparticles: Experimental and DFT studies. Appl. Phys. A 2018, 124, 346. [Google Scholar] [CrossRef]

- Frisch, M.J.; Trucks, G.W.; Schlegel, H.B.; Scuseria, G.E.; Robb, M.A.; Cheeseman, J.R.; Scalmani, G.; Barone, V.; Petersson, G.A.; Nakatsuji, H.; et al. Gaussian 16. Revision A 3; Gaussian, Inc.: Wallingford, CT, USA, 2016. [Google Scholar]

- Accelrys Software Inc. Material Studio Modeling Environment, Release 6; Accelrys Software Inc.: San Diego, CA, USA, 2011. [Google Scholar]

- De, G.; Tapfer, L. Formation of copper and silver nanometer dimension clusters in silica by the sol-gel process. Appl. Phys. Lett. 1996, 68, 3820. [Google Scholar] [CrossRef]

- Jayaprakash, J.; Srinivasan, N.; Chandrasekaran, P.; Girija, E.K. Synthesis and characterization of cluster of grapes like pure and Zinc-doped CuO nanoparticles by sol-gel method. Spetrochim. Acta A 2015, 136, 1803–1806. [Google Scholar] [CrossRef]

| Cluster | Symmetry | ΔG (kJ/mol) | Eb (kJ/mol) |

|---|---|---|---|

| NiFe | C∞ | 277.1 | 149.6 |

| Ni2Fe | C2V | 254.2 | 194.5 |

| NiFe2 | C2V | 186.8 | 172.5 |

| Ni3Fe | C3V | 252.3 | 219.7 |

| Ni2Fe2 | C2V | 243.4 | 216.0 |

| NiFe3 | CS | 229.6 | 194.5 |

| Ni4Fe | C1 | 230.3 | 228.8 |

| Ni3Fe2 | C1 | 240.8 | 231.2 |

| Ni2Fe3 | C2V | 279.0 | 235.8 |

| NiFe4 | C1 | 355.1 | 235.0 |

| Ni5Fe | C2V | 270.1 | 241.0 |

| Ni4Fe2 | C2V | 306.9 | 249.8 |

| Ni3Fe3 | C1 | 266.5 | 249.9 |

| Ni2Fe4 | D2H | 309.1 | 254.3 |

| NiFe5 | C1 | 276.9 | 247.4 |

| Cellulose | Acid | Alcohol | Aldehydes | Esters | Furans | Ketone | Phenol | Sugar | HC | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| None | 7.2 ± 0.4 | 4.1 ± 0.2 | 0.36 ± 0.1 | 0.60 ± 0.44 | 30.7 ± 0.3 | 12.5 ± 1.6 | 2.7 ± 0.2 | 40.1 ± 1.3 | 0.0 | 1.8 ± 0.8 |

| NiFe | 6.0 ± 1.4 | 4.0 ± 0.6 | 0 | 0.55 ± 0.4 | 34.1 ± 0.9 | 18.0 ± 2.0 | 3.1 ± 0.8 | 32.3 ± 1.6 | 0.58 ± 0.2 | 1.4 ± 0.9 |

| Ni2Fe | 5.6 ± 0.9 | 4.5 ± 0.5 | 0 | 0.30 ± 0.2 | 32.4 ± 1.3 | 19.7 ± 1.8 | 4.1 ± 0.8 | 29.2 ± 0.5 | 0.37 ± 0.3 | 3.8 ± 0.9 |

| Ni3Fe | 5.2 ± 0.5 | 4.5 ± 0.3 | 0 | 0.31 ± 0.2 | 30.9 ± 0.6 | 19.2 ± 2.0 | 2.7 ± 0.4 | 33.9 ± 1.6 | 0.29 ± 0.2 | 3.0 ± 1.5 |

| NiFe2 | 6.0 ± 1.4 | 3.9 ± 0.8 | 0 | 0.49 ± 0.4 | 34.8 ± 1.7 | 20.8 ± 1.3 | 3.5 ± 1.2 | 28.6 ± 1.3 | 0.60 ± 0.2 | 1.3 ± 0.8 |

| NiFe3 | 6.5 ± 0.3 | 3.8 ± 0.6 | 0 | 0.36 ± 0.1 | 35.0 ± 1.3 | 17.2 ± 0.9 | 3.0 ± 0.5 | 33.5 ± 1.4 | 0.40 ± 0.3 | 0.24 ± 0.1 |

| NiFe4 | 4.1 ± 0.7 | 3.4 ± 0.3 | 0 | 0.30 ± 0.2 | 36.1 ± 1.6 | 23.0 ± 1.3 | 4.4 ± 1.0 | 27.5 ± 0.9 | 0.80 ± 0.1 | 0.43 ± 0.3 |

| Ni2Fe3 | 6.0 ± 0.5 | 4.0 ± 0.7 | 0 | 0.34 ± 0.1 | 34.5 ± 1.3 | 20.9 ± 0.6 | 4.3 ± 0.4 | 28.8 ± 0.6 | 0.51 ± 0.0 | 0.68 ± 0.5 |

| Ni3Fe2 | 5.9 ± 0.2 | 4.7 ± 0.1 | 0 | 0.38 ± 0.1 | 33.1 ± 1.1 | 20.1 ± 0.1 | 2.7 ± 0.1 | 31.0 ± 1.5 | 0.49 ± 0.2 | 1.6 ± 0.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Yu, D.; Cheng, S.; Cross, J.S. Recyclabl Metal (Ni, Fe) Cluster Designed Catalyst for Cellulose Pyrolysis to Upgrade Bio-Oil. Catalysts 2020, 10, 1160. https://doi.org/10.3390/catal10101160

Li S, Yu D, Cheng S, Cross JS. Recyclabl Metal (Ni, Fe) Cluster Designed Catalyst for Cellulose Pyrolysis to Upgrade Bio-Oil. Catalysts. 2020; 10(10):1160. https://doi.org/10.3390/catal10101160

Chicago/Turabian StyleLi, Siyi, Dan Yu, Shuo Cheng, and Jeffrey S. Cross. 2020. "Recyclabl Metal (Ni, Fe) Cluster Designed Catalyst for Cellulose Pyrolysis to Upgrade Bio-Oil" Catalysts 10, no. 10: 1160. https://doi.org/10.3390/catal10101160

APA StyleLi, S., Yu, D., Cheng, S., & Cross, J. S. (2020). Recyclabl Metal (Ni, Fe) Cluster Designed Catalyst for Cellulose Pyrolysis to Upgrade Bio-Oil. Catalysts, 10(10), 1160. https://doi.org/10.3390/catal10101160