Abstract

Prototyping and evaluation are imperative phases of the present product design and development process. Although digital modeling and analysis methods are widely employed at various product development stages, still, building a physical prototype makes the present typical process expensive and time consuming. Therefore, it is necessary to implement new technologies, such as virtual prototyping, which can enable industry to have a rapid and more controlled decision making process. Virtual prototyping has come a long way in recent years, where current environments enable stereoscopic visuals, surround sound and ample interaction with the generated models. It is also important to evaluate how representative the developed virtual prototype is when compared to the real-world counterpart and the sense of presence reported by users of the virtual prototype. This paper describes the systematic procedure to develop a virtual prototype of Gazal-1 (i.e., the first car prototype designed by Saudi engineers) in a semi-immersive virtual environment. The steps to develop a virtual prototype from CAD (computer-aided design) models are explained in detail. Various issues involved in the different phases for the development of the virtual prototype are also discussed comprehensively. The paper further describes the results of the subjective assessment of a developed virtual prototype of a Saudi Arabian-designed automobile. User’s feedback is recorded using a presence questionnaire. Based on the user-based study, it is revealed that the virtual prototype is representative of the real Saudi Arabian car and offers a flexible environment to analyze design features when compared against its physical prototype. The capabilities of the virtual environment are validated with the application of the car prototype. Finally, vital requirements and directions for future research are also presented.

1. Introduction

Increasing market competition and globalization have been directing the manufacturing industry to strive for a persistent decline in lead-time and product development cost, while promising high quality and ample varieties. Typical manufacturing processes are, however, no longer adequate to pace up the product development process to meet the ever-increasing range of customer demands, rigorous cost control and the complexity of new products. The flourishing launch of a product into the market can best happen if the product design and development cycle finish in a lesser time period and at the same time at the lowest cost while preserving very good product quality and reliability. In the last decade, the product market is becoming customer driven, resulting in shorter market life cycles. The customer-oriented market intensifies the stress on cost reduction in all products [1]. Nowadays, the preliminary stage of the product design process is to respond to customers’ needs and wishes [2]. Synergy between designers and customers is exigent, since their notions of products are diverse. The traditional way of designing and prototyping has to be reconsidered to integrate new technologies to alleviate product cycle time [3]. However during actual product development, many design and assembly decision issues need to be solved by engineers to accommodate customers’ needs [4]. Recently, numerous technologies have been established to solve these issues and result in swift product development. Prototypes can provide answers to such issues and hence influence the product development process. Computer-aided engineering (CAE) is a popular technique that may decrease products’ design cycle time and reduce the need of costly prototypes [3]. Among many developed technologies under CAE, virtual prototyping (VP) can be considered as a significant technological development. The accessibility and affordability of advanced computer technology has lined the way for increasing use of virtual instead of physical prototypes. VP integrates virtual reality (VR) simulation techniques with design and manufacturing methods to construct digital prototypes for consequent stereoscopic visualization, verification and optimization of product designs, along with the evaluation of product assemblability and manufacturability [5]. Based on the field of application, numerous definitions of VP can be given, but Tim Hodgson (Comptek Federal Systems Inc., Buffalo, NY, USA) proposed an appropriate one for product design:

“Virtual prototyping is a software-based engineering discipline that entails modelling a mechanical system, simulating and visualizing its 3D-motion behavior under real-world operating conditions, and refining/optimizing the design through iterative design studies prior to building the first physical prototype”.

It is intriguing to envisage a design process where there are no physical models or prototypes. It is alluring to envision product development without the delays and expense needed for building physical prototypes. VP has the capability to reduce the time for the product development process [6]. The decline in product cycle time is attained by reducing the design cycle time by real-time designing; and the time needed to make physical prototypes, which uses most of the time in the overall process. A designer, or a user, can touch, see, hear and use an upcoming product before its physical operation with lesser cost and effort than in the past. VP is the leading advantage of VR for manufacturing, as it saves much time and money that would be used for producing a physical prototype [7]. Based on virtual simulation, VP exemplifies not only the product’s unique design, but also the product’s risk-free test, particularly matching the high cost pilot fabrication of intricate mechanical systems. In addition to the cost savings of not building physical prototypes, VPs are effective as a tool for maintenance analysis [3].

Advancements in computing power and improved model representativeness of physical phenomena, along with the growing capability to transfer results between different types of modeling and analysis environments resulted in improving the range of the applications, robustness, accuracy, realism and cost effectiveness of VP [7]. A virtual prototype may be presented as a sequence of graphical imagery or computer-generated design mockups, in animated or stagnant format, generated in the form of mathematical models and put in storage digitally in computer working memory [5]. Generally, non-immersive VP offers various facilities, such as the development and presentation of three-dimensional (3D) solid models with a variety of colors and surface textures. It permits animation of the mechanisms, finite element analysis, ergonomics analysis and crash testing for automobile bodies, to name a few [8,9,10,11,12].

Immersive VP builds on top of VR technology, which immerses a user in the same virtual environment as that of the model. Some authors suggest that VP consists of three fields: virtual environment, simulation and manufacturing process design [13]. In contrast, Pratt states that practically any type of computer model will work for some purpose as a VP [6]. Currently, most commercially available VP tools regard VR as an integral part, due to the fact that VR offers a sense of being there in the virtual environment, which can augment the user’s abilities in terms of product evaluation, such as intuitive interaction, field of view changes, like in the real world, enhanced graphics and textures close to the real world.

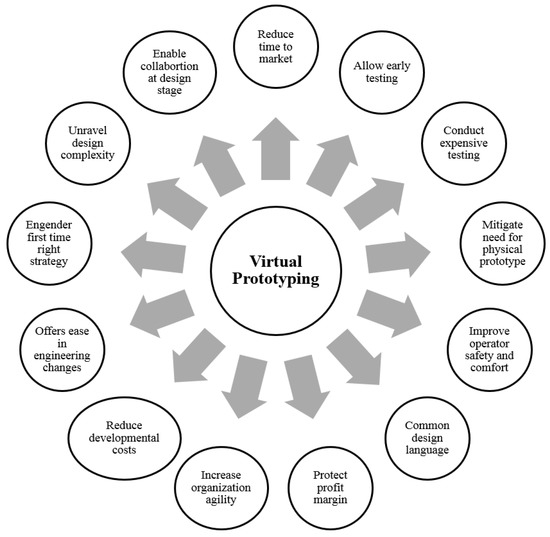

Prototypes are generally used for communication, design development and design verification [14]. Zorriassatine et al. identified five broad classes of VP based on their purposes and goals, which include prototypes for visualization, fit and interference of mechanical assembly, testing and validation of function and performance, assessment of manufacturing and assembly operations and human factor study [3]. An evaluation of VP tools, through understandings, published academic research and a number of leading industry case studies, acclaimed a clear number of benefits. These advantages are depicted in Figure 1 [15,16].

Figure 1.

Benefits of virtual prototyping.

As mentioned in Figure 1, VP is now capable of conducting expensive testing, such as crash testing of automobiles [1,17]. It is not astonishing that many small and mid-level organizations are confused over the implementation of VP. Many of them are oblivious about what VP technology has to offer. Some of them simply presume that the technology is very complicated and expensive. However, with advancements in hardware and software, the technology has become affordable even for small enterprises. Low-cost systems, such as the Oculus headset, are easily available on the market to give VR experience to the mobile phone user. VP has come a long way in recent years, away from amateurish graphics and incommodious headsets [18].

This paper discusses a step-by-step methodology for the development and evaluation of a semi-immersive VP of the first Saudi Arabian-designed car. The VP was built for visualizing and analyzing the aesthetic features of the car design in a realistic environment. Moreover, it will help in making decisions, such as interior and exterior color choices, evaluating the basic ergonomics [19] and the fitting and interference check of the mechanical assembly. The feature selection can be very useful in customized product development. The semi-immersive system provides a cost-effective solution, and it can be easily implemented by smaller enterprises [1].

To mitigate the gap between real and virtual, it is indispensable to prepare the digital mockup with prudence. On the one hand, the digital model has to reach a compromise between performance and fidelity to be used in the virtual world. On the other hand, it has to ensure functionalities and specificities imperative to its fabrication [20]. Therefore, this paper also presents a user-based study to assess the performance of the developed virtual environment with the help of a virtual prototype of a car as a case study. In the user-based study, certain tasks were assigned to the participants that need to be performed on the virtual prototype and the physical prototype of the car. Finally, participants were asked to fill out a questionnaire based on their experience with both the prototypes and, moreover, with the real model of the car. The results from this questionnaire are analyzed and presented in this paper.

2. Related Work

VP is an advanced and prevailing virtual simulation tool enabling rapid product development [16,21]. It was implemented primarily by large automotive, aerospace and shipbuilding industries [22,23]. Visualization of the Boeing 777, the first large aircraft built without the construction of a physical mockup, was done with a package named FlyThru. Boeing research has also created a series of experiments to investigate the advantages of VR, together with its use for maintainability analysis [24].

Presently, many automotive industries perform computer-based tests at the planning and design stages of vehicle development to explore challenges, such as design review, robustness, crashworthiness, handling, stability, noise, vibration and harshness. VP is a procedure that includes the use of virtual or digital prototypes and simulation techniques, often in a VR environment with advanced input and 3D stereoscopic output, to assess and improve a product design and to enable verification of planning and manufacturing processes [16,21,25,26,27,28,29].

With the help of life-like simulations, important aspects, such as the form and the manufacturability of a product, may be optimized without requiring much of prototypes and tooling. In fact, virtual simulation lessens the necessity for physical prototypes and, hence, mitigates tooling cost and material waste. Hence, it permits manufacturers to “get it right the first time” and give comfort to them to deliver quality products to customers on time and within budget [5].

Nevertheless, the present VP technique, which often implements either semi- or fully-immersive VR, is not without constraints, mostly with respect to the sense of immersion. Bochenek and Ragusa pointed out that it is essential to properly choose a VR system for expediting product design and development processes [25]. An investigation has been made with the use of four commercial VR display systems. It was revealed that the sense of immersion plays an imperative role in augmenting the design review process and that a higher sense of immersion will have better improvement.

Generally, semi-immersive VR systems (single-screen or desktop-based) are relatively easy to use, affordable and have good resolution. However, their users tend to be susceptible to environmental distractions. On the other hand, fully-immersive VR systems (Head mounted displays (HMDs), multi-screen or Cave Automatic Virtual Environment (CAVE)-based) can produce a comparatively higher sense of immersion that facilitates user interaction and collaboration. Nevertheless, they are generally more expensive, have less resolution and poor portability and need special space requirements [21]. Moreover, from time to time, the users of fully-immersive systems complained about cyber-sickness [1,30]. Hence, it is worthwhile to use semi-immersive VR to enhance the versatility and effectiveness of the virtual simulation at an affordable cost. In addition, PC-based or semi-immersive systems coupled with high computer processing power offer cost-effective solutions. Therefore, in this research, a semi-immersive VR system is used to assess the VP of Gazal-1 in a virtual environment.

Most of the literature in the VP field has dealt with its application in different fields; and how to develop the software tools. Based on a literature review, it is can be said that a step-by-step methodology to develop a VP is still not clearly defined in the research articles. Therefore, in this research work, a step-by-step methodology to develop a VP of a complete car in a semi-immersive environment is explained comprehensively.

2.1. Virtual Prototyping for Visualization

Visualization models are used for the evaluation of form, shape and appearance [4]. These mockups play an important role in the communication of product information among a variety of users, including marketing people, customers, managers, product development teams and engineering and even repair and maintenance people. Moreover, visual appearance works as a fascinating factor. Baxter explained three aspects of product attractiveness that are articulated through product appearance [31]:

- Attraction due to recognition of previously-used products

- Symbolic attraction (appeal to personal and social values of customers)

- Inherent attraction (intrinsic beauty of the product form)

At present, most commercial computer-aided design (CAD) packages provide 3D solid model photo pragmatic still and dynamic images that fulfill all appearance necessities. The 3D curves and surface models include added shape detail and intricacy in the computer-based prototypes, offering more realism and complexity. Visual acuity and allure can be examined for digital mockups with a range of types regarding product layout, explaining the overall product components and subassemblies, their associated colors and surface textures and finishes.

However, CAD tools only permit users to inspect 3D models from outside flat computer displays. That means the models and the users are in distinct realms. VR technology alleviates the barriers between the physical and digital world by immersing viewers in a virtual stereoscopic environment. Immersive VP visualization surpasses the conventional isometric representation by offering lively 3D viewing from all angles, in addition to graphical animations that can be exploited to represent several circumstances and scenarios for the target audience. The latest visualization software has the potential to simulate interactive navigation, such as variable-speed walking and flying through complicated assemblies of any size; thus facilitating efficient and realistic visual inspection, where magnified viewing allows close examination [32].

VP for visualization enables engineers, designers and product developers to work together concurrently within a digital world to elucidate design, manufacturing and maintainability concerns at the initial phase of product development [18]. Its visualization competences can be utilized to convey product aesthetics with greater clarity than still 3D CAD images, speeding up product conceptualization greatly. Visualization is also an appropriate tool for building factory layouts and planning production lines [3,5,33].

VP as a technology has gradually progressed in line with technical advances in computing to become an indispensable tool in a number of important engineering fields. From the viewpoint of industrial application, the technology has the capability to transfigure design and production planning. However, to comprehend this impressive ability, it must conquer acceptability hurdles, such as technological prejudice and affordability. Therefore, in this work, systematic steps are explained to develop an affordable system for design evaluation in a virtual environment. Table 1 provides a brief summary of the literature.

Table 1.

A brief summary of the research work in the field of virtual prototyping (VP).

2.2. Virtual Prototyping for Fits and Interference Check

It is essential to check how well subassemblies or individual components fit with the rest of the parts. Since it is cost ineffective and at times impossible to manufacture parts with accurate dimensions and features, dimensional tolerances are included in product design to accommodate variations due to manufacturing processes [4]. The clarity of design information represents a substantial benefit to checking product form, clearances and mating features. Fits and interference checks at an early period of product design may lessen down scrap, defects and rework; thus reducing the total cost of a product. Traditional fits and interference checks are time consuming, since the CAD model stores much information, and therefore, to process a large information pool, high computing power and time are required [1]. VP provides novel mechanisms for fits and interference checks by offering realistic 3D models and automated real-time collision detection; which results in the listing of all of the interferences, where clearances and interfering regions of the model can be highlighted using different colors [68]. It is more useful when a user wants to check if people are able to move/interact with the product without being hampering.

Figueiredo and Fernando developed a parallel collision detection algorithm for virtual prototype environments. A novel algorithm was proposed to determine intersecting surfaces at interactive speed in a virtual environment. The proposed algorithm was based on the overlapping axis-aligned bounding box (OAABB) [69].

Raabe et al. had presented a space-efficient, FPGA (field programmable gate array) optimized architecture to detect collisions among virtual objects. The design was based on a novel algorithm for testing discretely-oriented polytopes for overlap in 3D space [68]. In this research work, the oriented bounding boxes (OBB) collision detection technique is implemented.

Therefore, based on the literature, it can be said that developing a physical prototype is always a time-consuming and costly process. However, to analyze the design, one needs a certain platform to explore and examine the different features of the product. CAD provides a platform to analyze the design features digitally. Still, there are several problems associated with the CAD platform, such as: the file size of different CAD models is large, requiring high computing power to handle such a huge amount of data; the graphics are not realistic, and therefore, it cannot provide the true picture; the designer and model are in different realms, etc. VP provides an efficient solution to such types of problems. However, important information, such as kinematics, assembly structure and the kinematic relationship, that is already presented in the CAD model is lost in the data conversion process to VR [70]. CAD systems generate a continuous surface or volume descriptions of geometry, whereas rendering engines of VR systems process polygons or voxels. Therefore, for design reviews in VR, CAD models are converted to a polygonal model, and the process is known as tessellation. However, with the data conversion, some issues arise, such as loss of semantics (e.g., loss of product and model structure), inconsistent model quality (e.g., wrong surface orientation, cracks) and redundant model complexity (e.g., precision of tessellation, unnecessary or multiple geometries) [71]. Therefore, in this work, the complete car model was divided into several sub-assemblies to reduce time and effort. These sub-assemblies were converted to the VR format and then moved to their appropriate position in the virtual environment. That is why the collision detection feature was added to avoid interference between these sub-assemblies wherever it is required.

Hence, to analyze and review the design of the Gazal-1, a virtual prototype is developed through which various aesthetics features, like different colors, lightning conditioning, material, etc., can be explored. To explore the design and aesthetic features, an interactive semi-immersive environment has been created.

2.3. Virtual Prototyping Assessment

Moreover, the assessment of the developed VP within the capabilities of the virtual environment is also important for finalizing the design of the product, and subjective evaluation is one of the effective techniques to do that. This fact is well supported by many researchers, such as Pontonnier et al., focused on the issue of properly designing a digital mockup to be used in simulation studies. A subjective evaluation of real (R), virtual (V) and virtual with force feedback (VF) environments was provided. Results indicated a real sensory and difficulty gap between R and VF, whereas a smaller difference was observed between R and V [72]. Bowman et al. reviewed the various methods available for the usability evaluation of the virtual environments. They mentioned that the issues in the evaluation of the common graphical user interface are different than the issues in the evaluation of virtual environments. A classification framework for the virtual environment evaluation method was also presented and tested by a case study [73]. Hu et al. validated a virtual environment developed for ergonomics measurements for a drilling task. Thirty participants performed the same tasks in the virtual environment, as well as in the real world. Five ergonomic evaluation indices were compared. The results showed that four indices were higher in the virtual environment than the real environment. Despite a significant difference in the indices, a fairly good correlation exists between real and virtual environments [74]. Pontonnier et al. also presented a study to evaluate the physical risk factor in a VR-based assembly task evaluation. Sixteen participants performed the assembly task in both real and virtual environments. The motion of the upper body and five muscle electromyographic activities were recorded to compute the normalized and averaged objective indicators of discomfort. The results revealed significant differences between measured indicators in real and virtual environments; however, fairly good correlations for objective indicators were found between real and virtual environments [75]. There are various benefits mentioned in the literature for the subjective evaluations [76,77]. Until now, research has been mainly focused on the evaluation of the product within the virtual world; however, less attention is paid about the fidelity and usability of the developed virtual world. Therefore, in this research work, the developed virtual prototype of the first Saudi Arabian-designed car (Gazal-1) was assessed in the semi-immersive virtual environment. The VP was built for visualizing the car design in a realistic semi-immersive virtual environment instead of the perceived three-dimensional CAD platform. The design was assessed to make decisions, such as interior and exterior color choices, to evaluate the basic ergonomics [19] and the fit and interference check of the mechanical assembly. The virtual environment presenting a 1:1 scale virtual prototype of the car was evaluated using a subjective questionnaire-based approach.

3. Methodology for VP Development

This section describes the step-by-step methodology for the development of the virtual prototype for the complete car.

3.1. Hardware Used

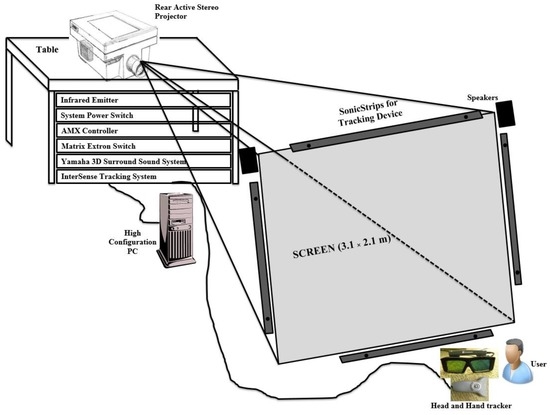

The different hardware peripherals are shown in Figure 2. They consist of:

- A 3.1 m × 2.1 m power-wall to provide a platform for 3D projection,

- A Christie Mirage rear-projected high-resolution (S + 6 K) projector to produce an immersive three-dimensional (3D) environment,

- Active shutter glasses for stereoscopic viewing,

- A Dell Precision T5400 workstation with a 2.33-GHz Intel Xeon processor and a 1.5-GB Nvidia FX5800 graphics card, which runs the software and enables the interaction between human and machine,

- An inertial tracking system (i.e., Intersense™ IS900) that provides dynamic, real-time measurement of the position and the orientation of the user’s head and hands,

- An AMX controller to control the lights, display and sound system.

Figure 2.

Hardware used: (a) screen; (b) rear projector; (c) hand wand; (d) shutter glasses with head tracker; (e) VR hardware controller with workstations; (f) AMX controller with space mouse and space ball.

The schematic diagram of the VR system is depicted by Figure 3. The rear projection-based system offers an advantage that all of the hardware and wires stay behind the screen. Thus, the user and the audience have a flawless view of the virtual environment.

Figure 3.

Schematic diagram of the semi-immersive VR system.

As shown in Figure 3, the system consists of an infrared emitter for active shutter glasses, a power switch to handle the power supply of different hardware (controlled by the AMX controller), a Matrix Extreme switch box, a Yamaha 3D surround sound system to provide the spatial auditory feedback and an Intersense tracking system to handle the hand wand and head tracker.

3.2. Software Used

The system runs with the help of several software tools, which built the virtual prototype environment:

- CATIA is used to construct the various components of the Gazal-1.

- PTC Division Mockup® is used to employ a number of aesthetic features and supplementary behavioral properties to the CAD models, so that the subsequent virtual environment is evenly matched with the real world.

- PTC Pro-engineer® is used as a link between the CATIA and PTC Division Mockup® software.

- Virtalis stereo-server is used to achieve interactive functionality, real-time visualization and integration of various VR devices.

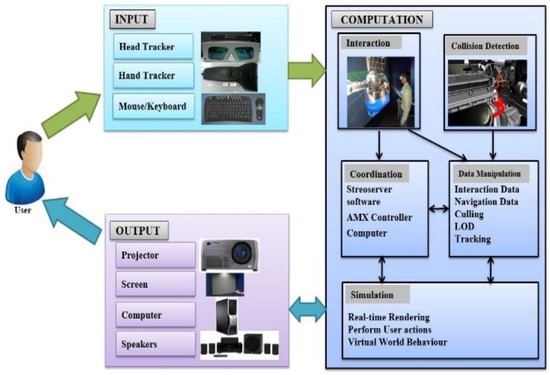

3.3. Information Processing

The information processing of the complete VP system is decomposed into three categories: input, output and computation. Figure 4 represents the information process diagram.

Figure 4.

Information processing diagram.

Input: The input to the system comes from the interaction devices, such as tracking devices (hand and head tracker), that are connected to the computer. The head tracker, hand tracker, keyboard and mouse are the input devices in the present study.

Computation: Computation converts the data collected by the devices into useful information. After input data are obtained, they have to be processed to a format that is readable by various applications. An interaction module converts the raw data (e.g., pressing the wand button) into semantic events (“picking the virtual object”). The data are then transferred to the central coordination component, which is responsible for calling the other modules to keep the system running. The coordinates of the trackers are constantly read by the system, and the position of the user’s virtual hand and view is changed accordingly. A special kind of simulation feature that is both important and complex is collision detection, which requires much computation. All of these modules constantly transfer the information to the CPU (central processing Unit) and GPU (graphical processing unit) of the computer.

Output: The output is the stereoscopic scene generated by various interactions of events, devices and applications. It is projected on the screen by the projector through which the user gets visual feedback. The major duty of this system is to generate an environment that can be perceived as a real one to the user. The sound system generates the spatial sound for auditory feedback.

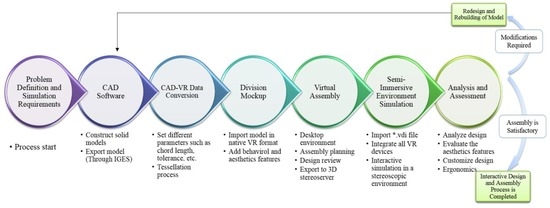

3.4. Developmental Procedure

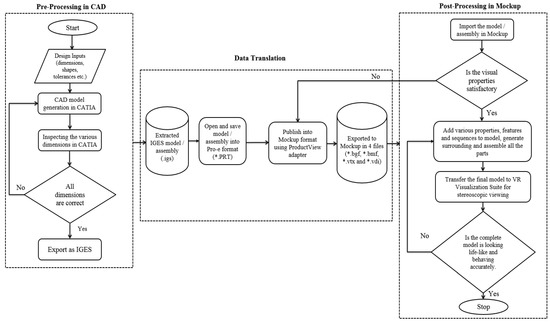

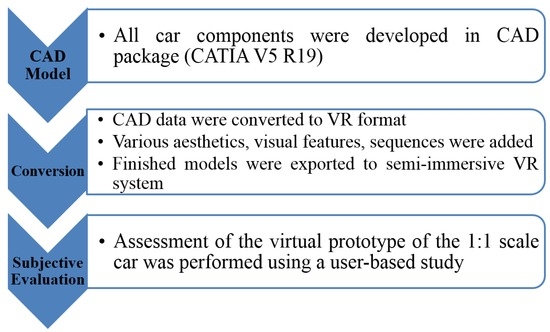

In this subsection, the steps involved in the development of the semi-immersive virtual prototype system are explained, as shown in Figure 5.

Figure 5.

Major steps involved in building the semi-immersive virtual prototyping system. IGES, Initial Graphics Exchange Specification.

3.4.1. Development of CAD Models

The CAD models are developed by the engineers of the Center of Manufacturing Technology Transfer (CMTT) using CATIA® V5 R19. The detailed CAD models of all of the exterior and interior parts of the car have been developed.

3.4.2. CAD to VR Data Conversion

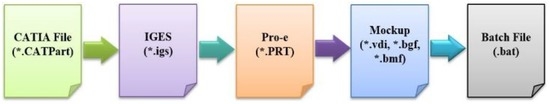

The CAD data need to be converted to the PTC Division Mockup® format (i.e., Native VR software). However, the conversion is done with the help of ProductView® object adapters, which are compatible with PTC Pro-e®; therefore, CATIA® models are exported to Pro-e® using the IGES (Initial Graphics Exchange Specification) files as a common format. IGES was selected as a common format in spite of STEP (Standard for the Exchange of Product model data) and other formats due to the fact that the IGES format retains the various properties of the model, like color, position etc., but the STEP files lose the color of the models during the data transfer from CATIA® to Pro-e®. During all of this conversion process, information regarding the assembly structure is retained; however, the location of the parts, texture, etc., are lost. The file size of the components also decreases drastically. From the Division Mockup, the models are exported to the Semi-Immersive VR Visualization Suite and run on that system using the batch files created there. The batch file triggers the various hardware, features and stereoscopic visualization. Figure 6 shows the file transfer hierarchy of the complete process.

Figure 6.

File transfer hierarchy for developing a virtual prototype.

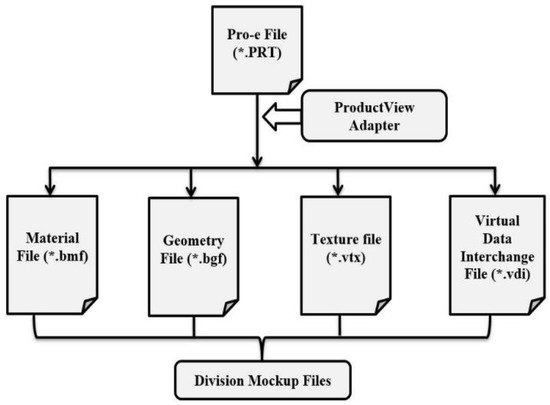

3.4.3. Modeling in Division Mockup

The ProductView® adapters splits the CAD models into four files, which store different information of the component. The four file types are explained below:

- ➢

- Material file (*.bmf): stores the information regarding the material of the CAD model.

- ➢

- Geometry file (*.bgf): stores the geometrical and shape information of the model.

- ➢

- Texture file (*.vtx): stores the information if there is some texture applied to the model.

- ➢

- Virtual data interchange file (*.vdi): contains parts hierarchies, interdependencies and properties.

Figure 7 shows the file structure used by Division Mockup®.

Figure 7.

File Structure of Division Mockup®.

Due to the large file size, small assemblies of various parts of Gazal-1 (such as engine assembly, door assembly, hood assembly, fender assembly, body-in-white, radiator, etc.) are imported into Division Mockup®. Then, a final assembly is built in the virtual environment to get a complete car model. For fast rendering, Mockup® provides features, such as LOD (level-of-detail) and culling (i.e., do not render the objects that are out of the viewer screen). Due to these features, the rendering quality is perceived to be very good by the user, resulting in a high frame rate. The surrounding of Gazal-1 in the virtual environment is developed using Autodesk 3ds Max®. The 3ds Max® model is also converted to the Mockup® format, and then, the surrounding and the complete Gazal-1 are merged in Mockup®. Various graphical properties are added to the Gazal-1, such as adding different material, colors, animations, lightning and camera views, to analyze the aesthetics and design of the car. In addition, different behaviors are also added, such as the change of car paint by key press, window glass animation, doors opening and closing animation, etc. These properties augment the virtual prototype and make it closer to the realistic model.

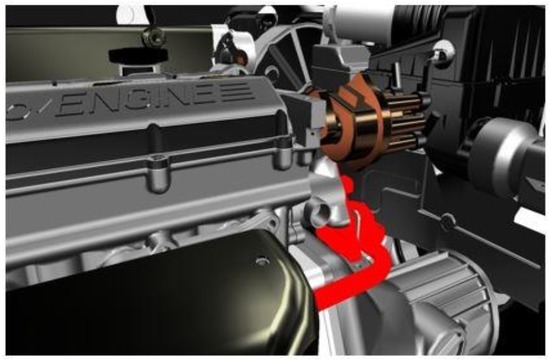

3.4.4. Collision Detection

Collison detection in the digital environment is important for the natural realization of the system. Inside the digital environment, when the virtual hand grabs the part, it is necessary to determine the collision status among the virtual hand and the virtual object [78]. Therefore, in this work, the oriented bounding box (OBB) algorithm for collision detection is employed. Therefore, if there is interference between different parts, then a user gets visual feedback by changing the part color to red. Figure 8 shows part interference in a virtual environment. In the developed virtual environment, no physical aspects were simulated; therefore, a user cannot feel the weight, friction and gravity. A user can pick and analyze the different parts of Gazal-1 using the virtual hand controlled by the hand tracker. Figure 8 shows a case of collision detection with visual feedback. The color of the components that are interfered with turns to red.

Figure 8.

Real-time collision detection with visual feedback.

The complete process flow chart is shown in Figure 9.

Figure 9.

Detailed flow chart for developing semi-immersive virtual prototyping environment.

As shown in Figure 9, there are three main stages in the complete process: (1) pre-processing in the CAD package; (2) data translation stage; and (3) post-processing in Mockup or the semi-immersive virtual environment.

4. Developed Virtual Prototype

The obtained result is the fully functional and interactive semi-immersive virtual prototype of the car with a 1:1 scale. The Gazal-1 is the first Saudi-designed passenger car, developed by professors, students, engineers and technicians at King Saud University. It is a sport utility vehicle (SUV). It is 4.8 m long and about 1.9 m wide and named after a desert deer. Figure 10 shows the physical prototype of Gazal-1.

Figure 10.

Physical prototype of Gazal-1 (courtesy of King Saud University).

The complete VR model of Gazal-1 was transferred to the semi-immersive visualization suite. A batch file was created here that integrates the model with the various devices and enables the stereoscopic view of the environment. Navigation of the user in the virtual environment is really important. The most natural way of navigation is the user walking in the virtual environment physically. Unfortunately, this was a constraint in this study, due to the fact that it requires full body tracking devices to depict the complete human body in the virtual world. Hence, a navigation method was applied by Mockup in which the user remains still, but he/she can fly-through the virtual world through the hand tracker joystick. In addition, the view of the virtual world changes according to the view of the user with the help of the head tracker. Interaction is another important aspect of the virtual environment. Interaction is provided using the hand tracker. A virtual hand depicts the hand tracker position through which a user can pick up and manipulate the object in the virtual world and interact in an intuitive way. In the virtual environment developed for Gazal-1, physics was not simulated; therefore, a user cannot feel the weight, friction and gravity.

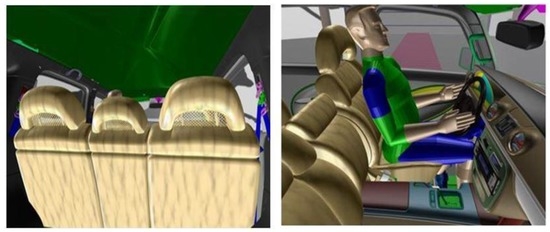

In the semi-immersive virtual environment, 3D models are visualized, in real time, using diverse light sources, colors, viewpoints and materials. The components and assemblies of the model can be altered, buckled and moved in 3D space and visualized in real time. With Mockup®, a realistic representation can be produced at any stage of development, so perceived quality reviews can be undertaken, and fit and finish problems can be solved immediately. Figure 11, Figure 12, Figure 13 and Figure 14 shows the virtual model of Gazal-1 with different viewpoints and features.

Figure 11.

Virtual prototype of Gazal-1 from different viewpoints.

Figure 12.

Interior view of Gazal-1 and virtual human for ergonomics analysis.

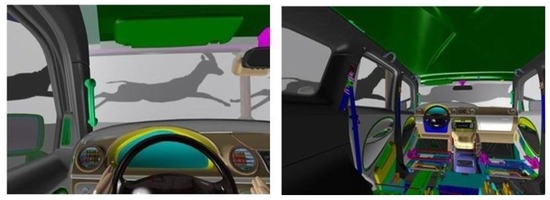

Figure 13.

Driver’s view and view without seats of Gazal-1.

Figure 14.

Gazal-1 virtual prototype with various exterior paint colors.

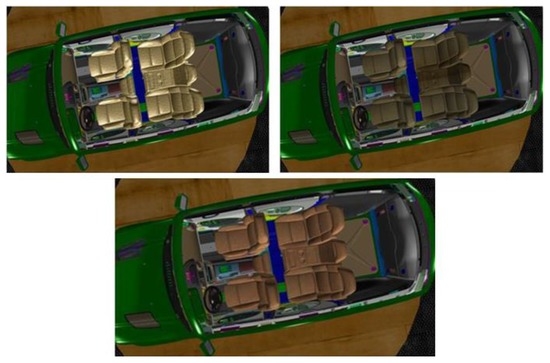

Figure 15 shows the virtual prototype with different leather seat schemes, so this kind of feature can be effectively used for designing a customized product with lesser cost and time.

Figure 15.

Virtual prototype of Gazal-1 with different leather seat schemes.

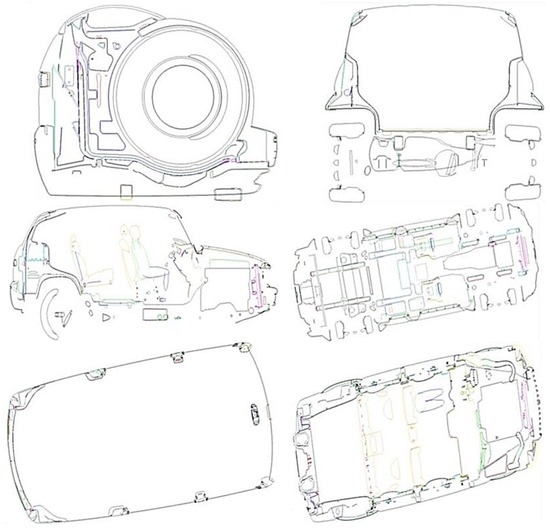

One of the important features available in the developed VP is the provision of viewing a sectional view of the developed prototype. Figure 16 represents the sectional views of various portions of Gazal-1. Sectional views are quite important for analyzing the design and assembly of various components. They provide us with an insightful view of the components. A sectional view not only reveals the actual internal shape of an object, but it also retains the significant outline of the external contour. Not many VR environments provide this feature. The developed environment provides a real-time dynamic sectional view feature.

Figure 16.

Dynamic sectional view of various portions of the VP of Gazal-1.

5. Evaluation of the Virtual Prototype of Gazal-1

The real Gazal-1 was a working car with all of the capabilities. The physical prototype has limited features, and it depicts the outer shape and body well; however, the interior of the car is not represented well in this prototype. It also misses functionalities, such as the radio, etc. The developed semi-immersive virtual prototype was equipped with the same aesthetics and design features as a real one. Furthermore, it offers more options to change the aesthetics as mentioned in previous sections.

As mentioned earlier, it is quite important to assess the quality of the developed virtual environment. Therefore, a user-based study is designed to evaluate the virtual environment with the help of the developed virtual prototype case study of Gazal-1. Figure 17 shows the major steps to perform the virtual prototype assessment of Gazal-1.

Figure 17.

Major steps of the evaluation methodology.

In order to assess the utility of the developed environment and identify opportunities for improvement, a user-based study was performed. Various steps involved in this study are explained in this section.

5.1. Questionnaires Used

A modified presence questionnaire was used to record the user’s feedback [79]. The questionnaire consists of 25 questions related to various aspects of virtual prototypes, such as quality of the virtual world, degree of immersiveness, responsiveness of the digital environment, etc. Each item was evaluated on a five-point scale, where one indicates very poor, two indicates poor, three indicates average, four indicates good and five indicates very good. For questions dealing with how much, one indicates very little, two indicates little, three indicates average, four indicates above average and five indicates a lot. Demographics information was also recorded for the participants using a separate questionnaire.

5.2. Apparatus

The experimental setup consists of a Dell Precision computer used to generate graphics and integrate various hardware systems. A Christie Mirage projector is used for rear side projection on the screen to create a semi-immersive virtual environment. Active stereo shutter glasses were used by the participants for stereoscopic viewing. Head and hand tracking was achieved using an Intersense IS-900™ Motion tracking system. Participants navigated and interacted with the virtual model through a hand wand, which was represented by a virtual hand in the digital environment. Figure 2 shows the apparatus used in the study.

5.3. Participants

Sixteen male students from the King Saud University (mean age 23.94 years; s.d. = 1.06) participated in this study. All participants reported normal or corrected to normal vision. All of the participants were right-handed except two of them. The demographics questionnaire also reveals that out of 16, three participants had experience of using VR, also in a gaming environment.

5.4. Procedure

The procedure followed for the user-based study of the VP of Gazal-1 is given below:

- Participants were asked to fill out a demographics questionnaire.

- A tour was made to show the participants the physical model of the Gazal-1 and the real model (as shown in Figure 18).

Figure 18. Physical prototype of Gazal-1 and the real car (courtesy of King Saud University).

Figure 18. Physical prototype of Gazal-1 and the real car (courtesy of King Saud University). - Before the start of a session, participants completed a small training. The training’s purpose was to make the participants familiar with the working of the various devices of the Advanced Manufacturing Institute’s (AMI) semi-immersive VR lab.

- Then, participants were required to complete several operations and tasks on the 1:1 scale virtual prototype of Gazal-1, such as open the car door with the virtual hand, start the engine, open the window, analyze different exterior colors, change the seat leather, operate the car radio, open the hood and analyze the components closely, to name a few. Same tasks were later performed by the participants on the physical prototype and then on the real model.

- Once these tasks were completed, participants completed a modified presence questionnaire.

5.5. Results

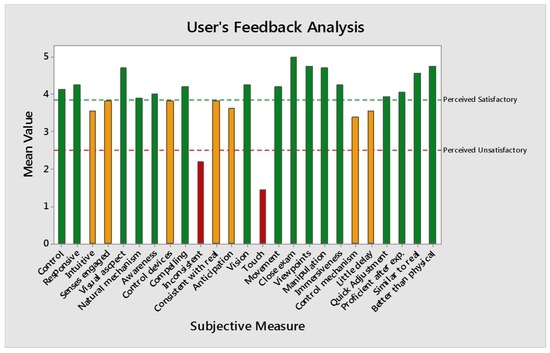

After completing all of the tasks, the participant’s subjective sense of presence was assessed using the modified presence questionnaire. The average score on the presence questionnaire was 4.02 (s.d. = 0.5821).

Figure 19 depicted the results of the user’s feedback analysis. A mean value below 2.5 is considered as unsatisfactory, and a mean value above 3.8 is considered as satisfactory (above 75%). Green color bars show the measures that are above the satisfactory level; orange bars show the measures in between satisfactory and unsatisfactory; while the red ones show the measures below unsatisfactory. Based on Figure 19, it can be seen that since the touch or force feedback is absent in the virtual environment, therefore the mean value for the measure is far below the satisfactory level. The other measures that are below the perceived satisfactory level are inconsistency, natural interaction, distraction due to the control mechanism and little delay. The virtual environment provides the feature to view the objects closely, from multiple viewpoints, and it also provides the in-depth or inside view of the component. Participants concluded that the virtual prototype of Gazal-1 is very similar to the real Gazal-1, and it is better representative of the real model than the physical prototype.

Figure 19.

Graphical representation of user’s feedback analysis.

Descriptive Statistics of User’s Feedback Data

The questionnaire consists of twenty-five questions on a scale of 1–5, which were assessing the various aspects of the virtual prototype of Gazal-1. The feedback of sixteen participants was recorded. This means that a “neutral” response would have a mean of 2.5. For most of the items on the questionnaire, the mean rating was above 2.5, indicating that, overall, the users feel positively about the virtual prototype. Only two questions resulted in a mean of less than 2.5, which were in relation to touch feedback and information from various senses. The absence of a haptic feedback system resulted in poor performance of the environment with respect to force feedback. Since it is not easy to integrate haptics as a natural interaction tool in the complex virtual environment, only visual and auditory feedbacks were available in the VR system, which is why the users did not perceive any information with other senses, such as olfactory and touch feedback. Therefore, the question related to multi-sensory feedback (Question 10) resulted in a low score. Otherwise, in most of the field, the virtual environment performs satisfactorily, according to the sample population. For the question concerned with the close examination of the object (Question 16), all of the users provide a rating of five, which means that the virtual environment is very much suitable for the close evaluation of virtual models. Similarly, a mean of 4.75 for the question regarding the comparison of the virtual prototype with the physical prototype suggests that the virtual prototype seems better representative of the real car than its physical counterpart, according to the sample population.

6. Discussion

Prototypes are important for the design thinking process, but they are reasonable only if they offer proper affordance that end users can perceive and evaluate. The survey of VP tools indicated that the technology has the potential to modernize both new product and new manufacturing process developments. The present study assessed the effectiveness of using immersive virtual reality for the prototyping tasks. Various design and aesthetics attributes of a virtual car were examined in the virtual environment. The results of the study indicated that the virtual prototype of the car is a close representative of its real model. This fact is in agreement with the previous literature [80]. This study provides the VP method for a complete car, which is not readily available in the literature. Most of the available studies regarding the VP of automobiles run on desktop environments that are non-immersive [62,63]; however, the Gazal-1 prototype is available in an interactive semi-immersive environment.

The lack of integration between VR and CAD software, employed in the design process, requires a great deal of effort to prepare the realistic virtual environment. In this paper, issues associated with the development of the VP environment, such as product representation, CAD-VR data transfer, prototype generation, human-computer interaction and manufacturing process simulation, are discussed. It can not only shorten the product development period, improve design quality, reduce test and development costs, but also can reduce development risk.

A VP of Gazal-1 is developed and presented in a semi-immersive virtual environment. Its different design features and aesthetics features are examined in the digital environment. The steps to create the virtual prototype using Division Mockup® are explained comprehensively in this paper. It has also been explained that CAD geometries have to be optimized for VR visualization, further described with attributes, such as material, color, etc. Moreover, it is summarized that information on kinematics constraints and functional simulation has to be added. In the virtual environment, a user can assess the virtual objects closely. It is possible to check kinematic constraints, analyze reachability, record sequences and, thereby, verify the whole concept of the product design.

The developed Gazal-1 VP extends visualization research by implementing a complete evaluation model that allows assessing different colors, textures and car operating mechanisms. It allows for interactive immersion and enables users to assess form, shape and appearance. Moreover, the Gazal-1 prototype implements collision detection algorithms to check interferences between different car components using a time efficient and effective process, as recommended by [1,69,78].

Moreover, the present study assessed the effectiveness of using immersive VR for the prototyping tasks. Various design and aesthetics attributes of a virtual car were examined in the semi-immersive virtual environment. The results of the study indicated that the virtual prototype of the car is a close representative of its real model. This fact is in agreement with the previous literature [80,81].

One of the interesting facts that was revealed through the user feedback study is that the developed virtual environment scores low on the natural interaction measure due to the absence of touch and auditory feedback. The overall performance of the virtual prototype of the car is rated better than its physical counterpart by the users.

The participants of our study had occasional or no VE experience. Therefore, the results of some features might deviate due to their first time use excitement. Still, further studies from various perspectives are needed. For these kinds of studies, our results offer building blocks on how users interpret the quality of VPs.

7. Conclusions and Future Work Directions

In this paper, the thought of coalescing VP with design is presented. By creating virtual prototypes, precise assessments of mass producibility and customer acceptance enable the better design of products. A VP of the first Saudi Arabian-designed car is developed and presented in a semi-immersive virtual environment.

Based on the development of the VP of the Gazal-1 case study, the following conclusions can be made:

- The unification of VP and VR techniques has potential to provide advanced visualization and manipulation capabilities for product development by facilitating visual assessment and obtaining the customer’s perception on the target product;

- The development of a VP environment shows great promise in providing intuitive strategies for people engaged in the design and prototyping process;

- VP provides an integrated structure for bridging different phases of the product development process, such as design, reviewing and marketing;

- Semi-immersive VR environments are cost effective and provide a good sense of immersion; these systems can be easily implemented in small enterprises;

- With the help of the collision detection technique, various interferences and clashes can also be diagnosed efficiently.

Based on the assessment of the developed VP of Gazal-1, the following conclusions are drawn:

- The results showed that the virtual prototype is representative of a real car. Therefore, one can judge various design and aesthetics features of the car quite effectively.

- The developed virtual environment gives enough immersiveness to the user that he/she can assume that the virtual world is close to the real one.

- The descriptive statistics suggest that the virtual prototype performs well for most of the aspects.

- On the basis of the results, it can be concluded that the VP possesses much potential, and it makes the product development process more efficient in terms of both cost and time.

Future research can include the addition of a physics engine in the virtual environment, which provides features, such as weight, gravity and friction that are a limitation of the developed system. It will augment the user’s interaction and experience with the digital model and make the digital world closer to the real world. A more advanced hardware system, such as haptic devices for providing force and tactile feedback, can be integrated with the system, so a user can act naturally with the virtual environment. Moreover, a more comprehensive user-based study can be performed, which includes objective measures, as well, with the subjective measures.

Acknowledgments

This project was financially supported by the King Saud University, Vice Deanship of Research Chairs. Moreover, this project was also funded by the National Plan for Science, Technology and Innovation (MAARIFAH), King Abdulaziz City for Science and Technology, Saudi Arabia (Award Number 12-INF2573-02).

Author Contributions

Mustufa H. Abidi designed and developed the virtual environment and conducted the experiments. Abdulrahman M. Al-Ahmari wrote the paper and analyzed the data. Abdulaziz M. El-Tamimi wrote the paper. Saied Darwish provided the CAD models and helped in the experimentation. Ali Ahmad wrote the paper and helped in the experimental design. All authors have read and approved the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Craig, A.; Sherman, W.R.; Will, J.D. Developing Virtual Reality Applications: Foundations of Effective Design; Morgan Kaufmann Publishers Inc.: Burlington, MA, USA, 2009; p. 448. [Google Scholar]

- Crilly, N.; Moultrie, J.; Clarkson, P.J. Shaping things: Intended consumer response and the other determinants of product form. Des. Stud. 2009, 30, 224–254. [Google Scholar] [CrossRef]

- Zorriassatine, F.; Wykes, C.; Parkin, R.; Gindy, N. A survey of virtual prototyping techniques for mechanical product development. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2003, 217, 513–530. [Google Scholar] [CrossRef]

- Ulrich, K.; Eppinger, S.D. Product Design and Development, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2011. [Google Scholar]

- Choi, S.H.; Cheung, H.H. Virtual prototyping for rapid product development. In Modeling and Simulation in Engineering; Alenxandru, P.C., Ed.; InTech: Rijeka, Croatia, 2012; pp. 203–224. [Google Scholar]

- Pratt, M.J. Virtual prototypes and product models in mechanical engineering. In Virtual Prototyping—Virtual Environments and the Product Design Process; Rix, J., Haas, S., Teixeira, J., Eds.; Chapman and Hall: London, UK, 1995; pp. 113–128. [Google Scholar]

- Chua, C.K.; Teh, S.H.; Gay, R.K.L. Rapid prototyping versus virtual prototyping in product design and manufacturing. Int. J. Adv. Manuf. Technol. 1999, 15, 597–603. [Google Scholar] [CrossRef]

- Kulkarni, A.; Kapoor, A.; Mahalinga-Iyer, R.-I.; Kosse, V. Virtual prototyping used as validation tool in automotive design. In Proceedings of the 19th International Congress on Modelling and Simulation (MODSIM2011), Perth, Australia, 12–16 December 2011; Chan, F., Marinova, D., Anderssen, R., Eds.; The Modelling and Simulation Society of Australia and New Zealand Inc.: Perth, Australia, 2011; pp. 419–425. [Google Scholar]

- Choi, S.H.; Cheung, H.H. A versatile virtual prototyping system for rapid product development. Comput. Ind. 2008, 59, 477–488. [Google Scholar] [CrossRef]

- Ha, S.; Kim, L.; Park, S.; Jun, C.; Rho, H. Virtual prototyping enhanced by a haptic interface. CIRP Ann. Manuf. Technol. 2009, 58, 135–138. [Google Scholar] [CrossRef]

- Sung, R.C.W.; Ritchie, J.M.; Robinson, G.; Day, P.N.; Corney, J.R.; Lim, T. Automated design process modelling and analysis using immersive virtual reality. Comput.-Aided Des. 2009, 41, 1082–1094. [Google Scholar] [CrossRef]

- Bourdot, P.; Convard, T.; Picon, F.; Ammi, M.; Touraine, D.; Vézien, J.M. Vr–cad integration: Multimodal immersive interaction and advanced haptic paradigms for implicit edition of cad models. Comput.-Aided Des. 2010, 42, 445–461. [Google Scholar] [CrossRef]

- Jasnoch, U.; Kress, H.; Rix, J. Towards a virtual prototyping environment. In IFIP WG 5.10 on Virtual Environments and Their Applications and Virtual Prototyping; Springer: Coimbra, Portugal, 1994; pp. 173–183. [Google Scholar]

- Black, R. Design and Manufacture: An Integrated Approach; Palgrave Macmillan: London, UK, 1996. [Google Scholar]

- Kerttula, M.; Tokkonen, T. Virtual design of multiengineering electronics systems. Computer 2001, 34, 71–79. [Google Scholar] [CrossRef]

- Norton, A. Utilising Rapid Product Development and Late Customisation Methodologies within Manufacturing Smes; PRIME Faraday Partnership: Loughborough, UK, 2003. [Google Scholar]

- Barbani, D.; Baldanzini, N.; Pierini, M. Development and validation of an fe model for motorcycle–car crash test simulations. Int. J. Crashworthiness 2014, 19, 244–263. [Google Scholar] [CrossRef]

- Abidi, M.H.; Ahmad, A.; El-Tamimi, A.M.; Al-Ahmari, A.M. Development and evaluation of a virtual assembly trainer. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2012, 56, 2560–2564. [Google Scholar] [CrossRef]

- Abidi, M.H.; El-Tamimi, A.M.; Al-Ahmari, A.M.; Darwish, S.M.; Rasheed, M.S. Virtual ergonomic assessment of first saudi arabian designed car in a semi-immersive environment. Procedia Eng. 2013, 64, 622–631. [Google Scholar] [CrossRef]

- Stoffregen, T.; Bardy, B.; Smart, L.J.; Pagulayan, R. On the nature and evaluation of fidelity in virtual environments. In Virtual and Adaptive Environments: Applications, Implications, and Human Performance Issues; Hettinger, L.J., Haas, M.W., Eds.; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Mujber, T.S.; Szecsi, T.; Hashmi, M.S.J. Virtual reality applications in manufacturing process simulation. J. Mater. Process. Technol. 2004, 155–156, 1834–1838. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.K.; Park, J.H.; Park, B.J.; Jang, D.S. Applying digital manufacturing technology to ship production and the maritime environment. Integr. Manuf. Syst. 2002, 13, 295–305. [Google Scholar] [CrossRef]

- Wöhlke, G.; Schiller, E. Digital planning validation in automotive industry. Comput. Ind. 2005, 56, 393–405. [Google Scholar] [CrossRef]

- Abarbanel, B. The boeing 777—Concurrent engineering and digital pre-assembly. In Proceedings of the Thirteenth National Conference on Artificial Intelligence—Volume 2, 4–8 August 1996; AAAI Press: Portland, OR, USA, 1996; pp. 1589–1589. [Google Scholar]

- Bochenek, G.M.; Ragusa, J.M. In Study results: The use of virtual environments for product design. In Proceedings of the 1998 IEEE International Conference on Systems, Man, and Cybernetics, San Diego, CA, USA, 11–14 October 1998; Volume 1252, pp. 1250–1253.

- Gomes de Sá, A.; Zachmann, G. Virtual reality as a tool for verification of assembly and maintenance processes. Comput. Graph. 1999, 23, 389–403. [Google Scholar] [CrossRef]

- Patel, H.; Sharples, S.; Letourneur, S.; Johansson, E.; Hoffmann, H.; Lorisson, J.; Saluäär, D.; Stefani, O. Practical evaluations of real user company needs for visualization technologies. Int. J. Hum.-Comput. Stud. 2006, 64, 267–279. [Google Scholar] [CrossRef]

- Weyrich, M.; Drews, P. An interactive environment for virtual manufacturing: The virtual workbench. Comput. Ind. 1999, 38, 5–15. [Google Scholar] [CrossRef]

- Tseng, M.M.; Jiao, J.; Su, C.J. Virtual prototyping for customized product development. Integr. Manuf. Syst. 1998, 9, 334–343. [Google Scholar] [CrossRef]

- LaViola, J.J.J. A discussion of cybersickness in virtual environments. SIGCHI Bull. 2000, 32, 47–56. [Google Scholar] [CrossRef]

- Baxter, M. Product Design: Practical Methods for the Systematic Development of New Products; CRC Press: Boca Raton, FL, USA, 1995; p. 308. [Google Scholar]

- Li, L.; Li, J.S.; Du, F.; Si, D. Building virtual reality design system based on division mockup software. In Proceedings of the 2010 International Conference on Electrical and Control Engineering (ICECE), Wuhan, China, 25–27 June 2010; pp. 552–555.

- Sastry, L.; Boyd, D.R.S. Virtual environments for engineering applications. Virtual Real. 1998, 3, 235–244. [Google Scholar] [CrossRef]

- Manninen, T. Contextual virtual reality prototyping co-operative user-centred design using distributed simulations. In Proceedings of the NordiCHI2000 Conference, Stockholm, Sweden, 23–25 October 2000; pp. 1–2.

- Wang, G.G. Definition and review of virtual prototyping. J. Comput. Inf. Sci. Eng. 2002, 2, 232–236. [Google Scholar] [CrossRef]

- Fadel, G.; Crane, D.; Dooley, L.; Geist, R. A link between virtual and physical prototyping. In Proceedings of the SME Rapid Prototyping and Manufacturing Conference, Detroit, MI, USA, 8–10 February 2004.

- Cecil, J.; Kanchanapiboon, A. Virtual engineering approaches in product and process design. Int J. Adv. Manuf. Technol. 2007, 31, 846–856. [Google Scholar] [CrossRef]

- Kerttula, M.; Salmela, M.; Heikkinen, M. Virtual reality prototyping-a framework for the development of electronics and telecommunication products. In Proceedings of the 8th IEEE International Workshop on Rapid System Prototyping, Shortening the Path from Specification to Prototype, Chapel Hill, NC, USA, 24–26 June 1997; pp. 2–11.

- Trika, S.N.; Banerjee, P.; Kashyap, R.L. Virtual reality interfaces for feature-based computer-aided design systems. Comput.-Aided Des. 1997, 29, 565–574. [Google Scholar] [CrossRef]

- Song, P.; Krovi, V.; Kumar, V.; Mahoney, R. Design and virtual prototyping of human-worn manipulation devices. In Proceedings of the 1999 ASME Design Technical Conference and Computers in Engineering Conference, Las Vegas, NE, USA, 12–15 September 1999.

- Fok, S.C.; Xiang, W.; Yap, F.F. Feature-based component models for virtual prototyping of hydraulic systems. Int. J. Adv. Manuf. Technol. 2001, 18, 665–672. [Google Scholar] [CrossRef]

- Choi, S.H.; Chan, A.M.M. A virtual prototyping system for rapid product development. Comput.-Aided Des. 2004, 36, 401–412. [Google Scholar] [CrossRef]

- Repo, P.; Kerttula, M.; Salmela, M.; Huomo, H. Virtual product design case study: The nokia rfid tag reader. IEEE Pervasive Comput. 2005, 4, 95–99. [Google Scholar] [CrossRef]

- Choi, S.H.; Cheung, H.H. Multi-material virtual prototyping for product development and biomedical engineering. Comput. Ind. 2007, 58, 438–452. [Google Scholar] [CrossRef]

- Weber-Jahnke, J.H.; Stier, J. Virtual prototyping of automated manufacturing systems with geometry-driven petri nets. Comput.-Aided Des. 2009, 41, 942–951. [Google Scholar] [CrossRef]

- Ding, G.; Zou, Y.; Yan, K.; Jia, M. Oriented multi-body system virtual prototyping technology for railway vehicle. In Modeling and Simulation in Engineering; Alexandru, C., Ed.; InTech: Rijeka, Croatia, 2012; pp. 225–260. [Google Scholar]

- Németh, I.; Püspöki, J.; Haraszkó, C.; Mátyási, G.; Nagy, T.; Freeman, C.; Scott, R.W.; Baldwin, J.S. 3d design support for rapid virtual prototyping of manufacturing systems. Procedia CIRP 2013, 7, 431–436. [Google Scholar] [CrossRef]

- Choi, S.H.; Cai, Y. A virtual prototyping system with reconfigurable actuators for multi-material layered manufacturing. Comput. Ind. 2014, 65, 37–49. [Google Scholar] [CrossRef]

- Moldovan, C.C.; Staretu, I. A virtual prototyping system research and implementation in a collaborative plm environment. Procedia Technol. 2016, 22, 1006–1013. [Google Scholar] [CrossRef]

- Falk, J.; Schwarzer, T.; Zhang, L.; Glaß, M.; Teich, J. Automatic communication-driven virtual prototyping and design for networked embedded systems. Microprocessors Microsyst. 2015, 39, 1012–1028. [Google Scholar] [CrossRef]

- Dumont, G.; Pontonnier, C.; Wang, Z. Ves:Virtual reality based on interactive mechanical simulation for design improvement. In Asme-Acier (Advances in Computers and Information in Engineering Research); ASME: New York, NY, USA, 2014; Volume 1, p. 24. [Google Scholar]

- Krovi, V.; Kumar, V.; Ananthasuresh, G.K.; Vezien, J.-M. Design and virtual prototyping of rehabilitation aids. Trans. ASME: J. Mech. Des. 1999, 121, 456–458. [Google Scholar] [CrossRef]

- Rai, S.; Ramesh, P.S.; Tan, C. Virtual prototyping of xerographic components. In Proceedings of the 1998 ASME Design Technical Conference and Design Automation Conference, GA, USA, 13–16 September 1998.

- Mase, T.; Wang, J.T.; Mayer, R.; Bonello, K.; Pachon, L. A virtual bumper test laboratory for fmvr 581. In Proceedings of the 1999 ASME Design Technical Conference and Computers in Engineering Conference, Las Vegas, NE, USA, 12–15 September 1999; pp. 1037–1044.

- Yin, Z.; Ding, H.; Xiong, Y. Virtual prototyping of mold design: Geometric mouldability analysis for near-net-shape manufactured parts by feature recognition and geometric reasoning. Comput.-Aided Des. 2001, 33, 137–154. [Google Scholar] [CrossRef]

- Shen, Q.; Gausemeier, J.; Bauch, J.; Radkowski, R. A cooperative virtual prototyping system for mechatronic solution elements based assembly. Adv. Eng. Inform. 2005, 19, 169–177. [Google Scholar] [CrossRef]

- Wang, Z. Interactive virtual prototyping of a mechanical system considering the environment effect. Part 2: Simulation quality. Comptes Rendus Mécanique 2011, 339, 605–615. [Google Scholar] [CrossRef]

- Zhang, G.; Zhou, N. Study on integrated design method for series traction mechanism of heavy machinery based on virtual prototyping. Phys. Procedia 2012, 25, 2–7. [Google Scholar] [CrossRef]

- Berti, G.; Monti, M. A virtual prototyping environment for a robust design of an injection moulding process. Comput. Chem. Eng. 2013, 54, 159–169. [Google Scholar] [CrossRef]

- Aromaa, S.; Väänänen, K. Suitability of virtual prototypes to support human factors/ergonomics evaluation during the design. Appl. Ergon. 2016, 56, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Mahoney, D.P. Driving VR. Comput. Graph. World 1995, 18, 22–33. [Google Scholar]

- Haug, E.; Chen, L.D.; Papelis, Y.; Solis, D. Virtual proving ground simulation for highway safety research and vehicle design. In Virtual Nonlinear Multibody Systems; Schiehlen, W., Valášek, M., Eds.; Springer: Prague, Czech Republic, 2003; Volume 103, pp. 213–232. [Google Scholar]

- Luo, Y.B.; Chen, D.F.; Xiao, T.Y. A distributed image-based virtual prototyping system with novel rendering tactics. Int. J. Adv. Manuf. Technol. 2005, 26, 236–242. [Google Scholar] [CrossRef]

- Lawson, G.; Herriotts, P.; Malcolm, L.; Gabrecht, K.; Hermawati, S. The use of virtual reality and physical tools in the development and validation of ease of entry and exit in passenger vehicles. Appl. Ergon. 2015, 48, 240–251. [Google Scholar] [CrossRef] [PubMed]

- Drivet, A.; Ramírez-Mendoza, R.A.; Flores, L.; Sename, O.; Vassal, C.P.; Dugard, L. Virtual prototyping for vehicle dynamic modelling. IFAC Proc. Vol. 2006, 39, 986–991. [Google Scholar] [CrossRef]

- Khaldi, F.E.; Ahouangonou, C.; Niess, M.; David, O. Cloud based hpc for innovative virtual prototyping methodology: Automotive applications. Transp. Res. Procedia 2016, 14, 993–1002. [Google Scholar] [CrossRef]

- Lawson, G.; Salanitri, D.; Waterfield, B. Future directions for the development of virtual reality within an automotive manufacturer. Appl. Ergon. 2016, 53, 323–330. [Google Scholar] [CrossRef] [PubMed]

- Raabe, A.; Hochgurtel, S.; Anlauf, J.; Zachmann, G. Space-efficient fpga-accelerated collision detection for virtual prototyping. In Proceedings of the Design, Automation and Test in Europe (DATE '06), Munich, Germany, 6–10 March 2006.

- Figueiredo, M.; Fernando, T. An efficient parallel collision detection algorithm for virtual prototype environments. In Proceedings of the Tenth International Conference on Parallel and Distributed Systems, 7–9 July 2004; pp. 249–256.

- Lorenz, M.; Spranger, M.; Riedel, T.; Pürzel, F.; Wittstock, V.; Klimant, P. Cad to VR—A methodology for the automated conversion of kinematic cad models to virtual reality. Procedia CIRP 2016, 41, 358–363. [Google Scholar] [CrossRef]

- Graf, H.; Brunetti, G.; Stork, A. A methodology supporting the preparation of 3d-cad data for design reviews in VR. In Proceedings of the 7th International Design Conference on DESIGN, Dubrovnik, Croatia, 14–17 May 2002; pp. 489–496.

- Pontonnier, C.; Dumont, G.; Samani, A.; Madeleine, P.; Badawi, M. Designing and evaluating a workstation in real and virtual environment: Toward virtual reality based ergonomic design sessions. J. Multimodal User Interfaces 2014, 8, 199–208. [Google Scholar] [CrossRef]

- Bowman, D.A.; Gabbard, J.L.; Hix, D. A survey of usability evaluation in virtual environments: Classification and comparison of methods. Presence Teleoper. Virtual Environ. 2002, 11, 404–424. [Google Scholar] [CrossRef]

- Hu, B.; Ma, L.; Zhang, W.; Salvendy, G.; Chablat, D.; Bennis, F. Predicting real-world ergonomic measurements by simulation in a virtual environment. Int. J. Ind. Ergon. 2011, 41, 64–71. [Google Scholar] [CrossRef]

- Pontonnier, C.; Samani, A.; Badawi, M.; Madeleine, P.; Dumont, G. Assessing the ability of a VR-based assembly task simulation to evaluate physical risk factors. IEEE Trans. Vis. Comput. Graph. 2014, 20, 664–674. [Google Scholar] [CrossRef] [PubMed]

- Gibbs, M.J.; Merchant, K.A.; Stede, W.A.V.D.; Vargus, M.E. The benefits of evaluating performance subjectively. Perform. Improv. 2005, 44, 26–32. [Google Scholar] [CrossRef]

- Frederiksen, A.; Lange, F.; Kriechel, B. Subjective Performance Evaluations and Employee Careers; Zukunft der Arbeit Institute for the Study of Labor; IZA: Bonn, Germany, 2012. [Google Scholar]

- Ding, G.; Wang, J.; Zhang, X. Collision detection between the virtual hand and virtual parts in VA. Appl. Res. Comput. 2003, 20, 29–31. [Google Scholar]

- Witmer, B.G.; Singer, M.J. Measuring presence in virtual environments: A presence questionnaire. Presence Teleoperators Virtual Environ. 1998, 7, 225–240. [Google Scholar] [CrossRef]

- Kim, C.; Lee, C.; Lehto, M.R.; Yun, M.H. Affective evaluation of user impressions using virtual product prototyping. Hum. Factors Ergon. Manuf. Serv. Ind. 2011, 21, 1–13. [Google Scholar] [CrossRef]

- Kaapu, T.; Tiainen, T. User experience: Consumer understandings of virtual product prototypes. In Scandinavian Information Systems Research; Kautz, K., Nielsen, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 60, pp. 18–33. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).