Artificial Intelligence Agent-Enabled Predictive Maintenance: Conceptual Proposal and Basic Framework

Abstract

1. Introduction

2. AI Agent Development

2.1. AI Agent Pyramid

2.2. AI Agent Development Platform

3. AI Agent Architecture for Predictive Maintenance

3.1. Data Acquisition and Preprocessing

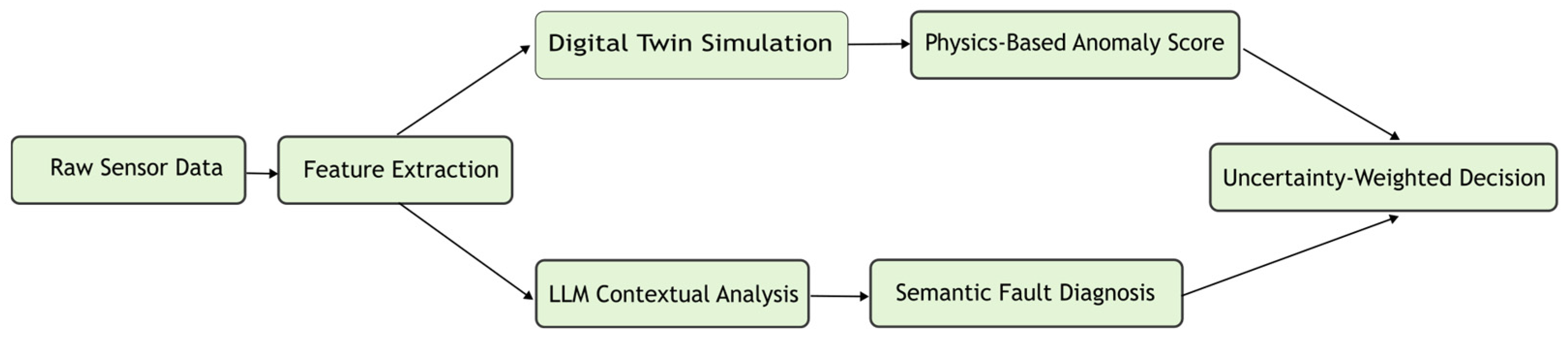

3.2. Digital Twin

3.3. AI Agent Core

3.4. Knowledge Integration

4. AI Agent Implementation Roadmap for Predictive Maintenance

4.1. Development Roadmap for AI Agent-Driven Predictive Maintenance System

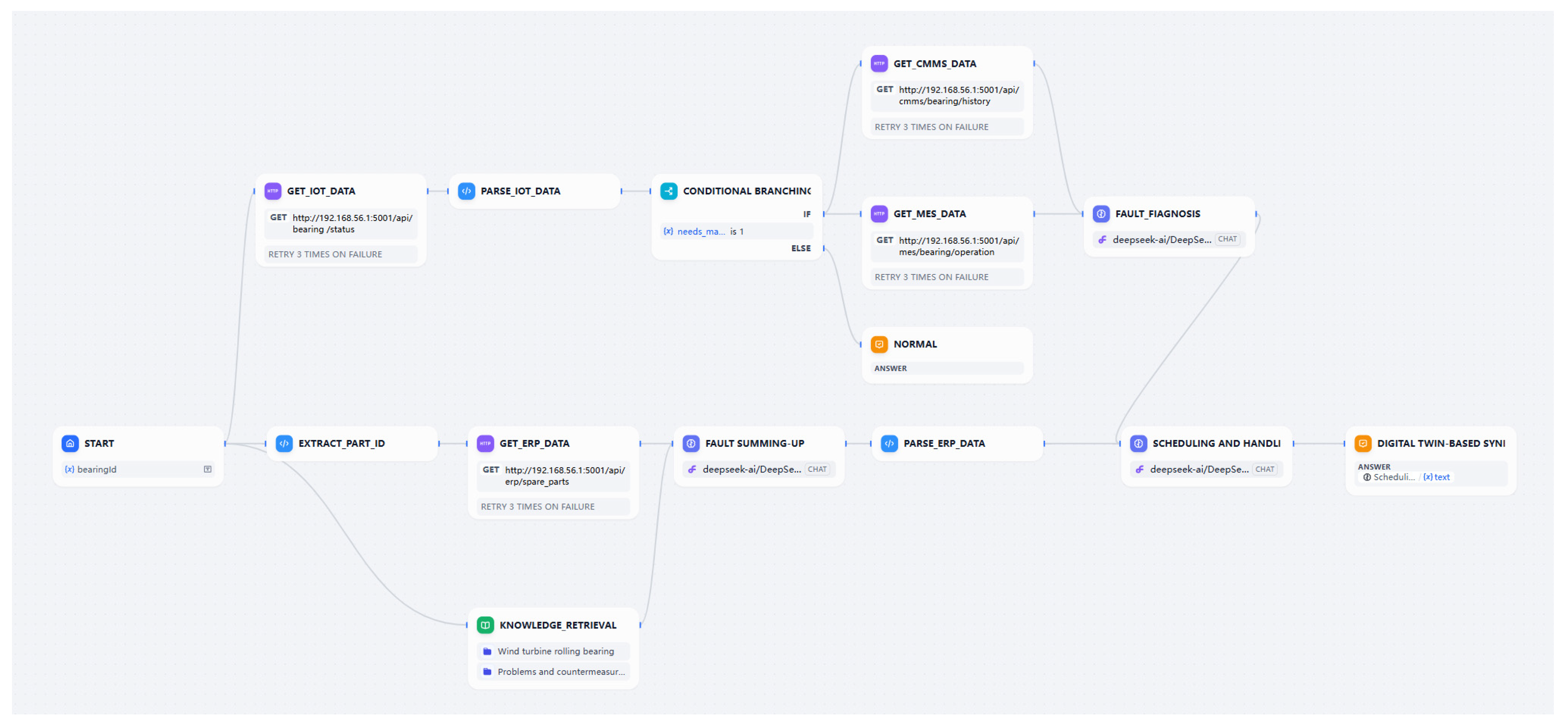

4.2. Prototype Demonstration

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| A2A | Agent-to-Agent |

| AI | Artificial Intelligence |

| API | Application Programming Interface |

| AR | Augmented Reality |

| BaaS | Backend as a Service |

| CBM | Condition-Based Maintenance |

| DevOps | Development and Operations |

| DT | Digital Twin |

| FFT | Fast Fourier Transform |

| GPT | Generative Pre-trained Transformer |

| IIoT | Industrial Internet of Things |

| LLM | Large Language Model |

| LLMOps | Large Language Model Operations |

| MCP | Model Context Provider |

| MLOps | Machine Learning Operations |

| NLP | Natural Language Processing |

| OPC | Open Platform Communications |

| PdM | Predictive Maintenance |

| PLC | Programmable Logic Controller |

| PM | Preventive Maintenance |

| RAG | Retrieval Augmented Generation |

| RCM | Reliability-Centered Maintenance |

| ROI | Return on Investment |

| RUL | Remaining Useful Life |

| SCADA | Supervisory Control And Data Acquisition |

References

- Alves, F.; Badikyan, H.; Moreira, H.A.; Azevedo, J.; Moreira, P.M.; Romero, L.; Leitão, P. Deployment of a smart and predictive maintenance system in an industrial case study. In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; pp. 493–498. [Google Scholar] [CrossRef]

- Moleda, M.; Momot, A.; Mrozek, D. Predictive maintenance of boiler feed water pumps using SCADA data. Sensors 2020, 20, 571. [Google Scholar] [CrossRef]

- Salierno, G.; Morvillo, S.; Leonardi, L.; Cabri, G. An architecture for predictive maintenance of railway points based on big data analytics. In Proceedings of the International Conference on Advanced Information Systems Engineering, Grenoble, France, 8–12 June 2020; pp. 29–40. [Google Scholar]

- Zhu, T.; Ran, Y.; Zhou, X.; Wen, Y. A survey on intelligent predictive maintenance (IPdM) in the era of fully connected intelligence. IEEE Commun. Surv. Tutor. 2025. [Google Scholar] [CrossRef]

- Stanton, I.; Munir, K.; Ikram, A.; El-Bakry, M. Predictive maintenance analytics and implementation for aircraft: Challenges and opportunities. Syst. Eng. 2022, 26, 216–237. [Google Scholar] [CrossRef]

- Wang, J.; Liang, Y.; Zheng, Y.; Gao, R.X.; Zhang, F. An integrated fault diagnosis and prognosis approach for predictive maintenance of wind turbine bearing with limited samples. Renew. Energy 2020, 145, 642–650. [Google Scholar] [CrossRef]

- Xiong, M.; Wang, H.; Fu, Q.; Xu, Y. Digital twin–driven aero-engine intelligent predictive maintenance. Int. J. Adv. Manuf. Technol. 2021, 114, 3751–3761. [Google Scholar] [CrossRef]

- Wen, Y.; Rahman, M.F.; Xu, H.; Tseng, T.-L. Recent advances and trends of predictive maintenance from data-driven machine prognostics perspective. Measurement 2022, 187, 110276. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Medjaher, K. A new dynamic predictive maintenance framework using deep learning for failure prognostics. Reliab. Eng. Syst. Saf. 2019, 188, 251–262. [Google Scholar] [CrossRef]

- Hafeez, T.; Xu, L.; Mcardle, G. Edge intelligence for data handling and predictive maintenance in IIOT. IEEE Access 2021, 9, 49355–49371. [Google Scholar] [CrossRef]

- Killeen, P.; Ding, B.; Kiringa, I.; Yeap, T. IoT-based predictive maintenance for fleet management. Procedia Comput. Sci. 2019, 151, 607–613. [Google Scholar] [CrossRef]

- Nunes, P.; Santos, J.; Rocha, E. Challenges in predictive maintenance—A review. CIRP J. Manuf. Sci. Technol. 2023, 40, 53–67. [Google Scholar] [CrossRef]

- Dalzochio, J.; Kunst, R.; Pignaton, E.; Binotto, A.; Sanyal, S.; Favilla, J.; Barbosa, J. Machine learning and reasoning for predictive maintenance in Industry 4.0: Current status and challenges. Comput. Ind. 2020, 123, 103298. [Google Scholar] [CrossRef]

- Cachada, A.; Barbosa, J.; Leitño, P.; Gcraldcs, C.A.; Deusdado, L.; Costa, J.; Teixeira, C.; Teixeira, J.; Moreira, A.H.; Moreira, P.M.; et al. Maintenance 4.0: Intelligent and predictive maintenance system architecture. In Proceedings of the 2018 IEEE 23rd International Conference on Emerging Technologies and Factory Automation (ETFA), Turin, Italy, 4–7 September 2018; pp. 139–146. [Google Scholar] [CrossRef]

- Zonta, T.; Da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; Da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Andrianandrianina Johanesa, T.V.; Equeter, L.; Mahmoudi, S.A. Survey on AI applications for product quality control and predictive maintenance in industry 4.0. Electronics 2024, 13, 976. [Google Scholar] [CrossRef]

- Jin, Q.; Chen, H.; Hu, F. Proposal of Industry 5.0-Enabled Sustainability of Product–Service Systems and Its Quantitative Multi-Criteria Decision-Making Method. Processes 2024, 12, 473. [Google Scholar] [CrossRef]

- Abidi, M.H.; Mohammed, M.K.; Alkhalefah, H. Predictive maintenance planning for industry 4.0 using machine learning for sustainable manufacturing. Sustainability 2022, 14, 3387. [Google Scholar] [CrossRef]

- Pothukuchi, S.N. LLMOps: A Comprehensive Guide to Deploying Large Language Models in Production. IJSAT-Int. J. Sci. Technol. 2025, 16, 1–12. [Google Scholar] [CrossRef]

- Yang, L.; Luo, S.; Cheng, X.; Yu, L. Leveraging Large Language Models for Enhanced Digital Twin Modeling: Trends, Methods, and Challenges. arXiv 2025, arXiv:2503.02167. [Google Scholar] [CrossRef]

- Ferdousi, R.; Hossain, M.A.; Yang, C.; Saddik, A.E. Defecttwin: When llm meets digital twin for railway defect inspection. arXiv 2024, arXiv:2409.06725. [Google Scholar] [CrossRef]

- Russell-Gilbert, A. RAAD-LLM: Adaptive Anomaly Detection Using LLMs and RAG Integration. Ph.D. Thesis, Mississippi State University, Starkville, MS, USA, 2025. [Google Scholar]

- Palma, G.; Cecchi, G.; Rizzo, A. Large Language Models for Predictive Maintenance in the Leather Tanning Industry: Multimodal Anomaly Detection in Compressors. Electronics 2025, 14, 2061. [Google Scholar] [CrossRef]

- Timms, A.; Langbridge, A.; Antonopoulos, A.; Mygiakis, A.; Voulgari, E.; O’DOnncha, F. Agentic AI for Digital Twin. Proc. AAAI Conf. Artif. Intell. 2025, 39, 29703–29705. [Google Scholar] [CrossRef]

- Xia, Y.; Xiao, Z.; Jazdi, N.; Weyrich, M. Generation of asset administration shell with large language model agents: Toward semantic interoperability in digital twins in the context of industry 4.0. IEEE Access 2024, 12, 84863–84877. [Google Scholar] [CrossRef]

- Yoon, S.; Song, J.; Li, J. AI agent-based intelligent digital twins for building operations and maintenance. J. Build. Eng. 2025, 108, 130476. [Google Scholar] [CrossRef]

- Lima Romero, M.; Suyama, R. Agentic AI for Intent-Based Industrial Automation. arXiv 2025, arXiv:2506.04980. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, H.W.; Huang, J.; Wang, S.; Yu, F.; Yang, H.; Wang, Y. AgentBuilder: Automating agent creation via large language model-driven systems. Neurocomputing 2025, 646, 130476. [Google Scholar] [CrossRef]

- Dong, L.; Lu, Q.; Zhu, L. AgentOps: Enabling Observability of LLM Agents. arXiv 2024, arXiv:2411.05285. [Google Scholar] [CrossRef]

- Hausi, A.M.; Litoiu, M.; Rivera, L.F.; Rasolroveicy, M.; Villegas, N.M.; Tamura, G.; Watts, I.; Erpenbach, E.; Shwartz, L. Proactive Continuous Operations using Large Language Models (LLMs) and AIOps. In Proceedings of the 33rd Annual International Conference on Computer Science and Software Engineering, Las Vegas, NV, USA, 11–14 September 2023; pp. 198–199. [Google Scholar]

- Arai, K. Design of On-Premises Version of RAG with AI Agent for Framework Selection Together with Dify and DSL as Well as Ollama for LLM. Int. J. Adv. Comput. Sci. Appl. 2024, 15, 117–123. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive maintenance and intelligent sensors in smart factory. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef] [PubMed]

- Samatas, G.G.; Moumgiakmas, S.S.; Papakostas, G.A. Predictive maintenance-bridging artificial intelligence and iot. In Proceedings of the 2021 IEEE World AI IoT Congress (AIIoT), Seattle, WA, USA, 10–13 May 2021; pp. 413–419. [Google Scholar] [CrossRef]

- Chen, S.; Bekar, E.T.; Bokrantz, J.; Skoogh, A. AI-enhanced digital twins in maintenance: Systematic review, industrial challenges, and bridging research–practice gaps. J. Manuf. Syst. 2025, 82, 678–699. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Georgoulias, K.; Chryssolouris, G. The use of Digital Twin for predictive maintenance in manufacturing. Int. J. Comput. Integr. Manuf. 2019, 32, 1067–1080. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Svennevig, P.R.; Svidt, K.; Han, D.; Nielsen, H.K. A Digital Twin predictive maintenance framework of air handling units based on automatic fault detection and diagnostics. Energy Build. 2022, 261, 111988. [Google Scholar] [CrossRef]

- Yang, H.; Siew, M.; Joe-Wong, C. An llm-based digital twin for optimizing human-in-the loop systems. In Proceedings of the 2024 IEEE International Workshop on Foundation Models for Cyber-Physical Systems & Internet of Things (FMSys), Hong Kong, China, 13–15 May 2024; pp. 26–31. [Google Scholar] [CrossRef]

- Cao, Q.; Zanni-Merk, C.; Samet, A.; Reich, C.; De Beuvron, F.D.; Beckmann, A.; Giannetti, C. KSPMI: A knowledge-based system for predictive maintenance in industry 4.0. Robot. Comput. Integr. Manuf. 2022, 74, 102281. [Google Scholar] [CrossRef]

- Russell-Gilbert, A.; Sommers, A.; Thompson, A.; Cummins, L.; Mittal, S.; Rahimi, S.; Seale, M.; Jaboure, J.; Arnold, T.; Church, J. Aad-llm: Adaptive anomaly detection using large language models. In Proceedings of the 2024 IEEE International Conference on Big Data (BigData), Washington, DC, USA, 15–18 December 2024; pp. 4194–4203. [Google Scholar] [CrossRef]

- Ayvaz, S.; Alpay, K. Predictive maintenance system for production lines in manufacturing: A machine learning approach using IoT data in real-time. Expert Syst. Appl. 2021, 173, 114598. [Google Scholar] [CrossRef]

- Zhang, N.; Vergara-Marcillo, C.; Diamantopoulos, G.; Shen, J.; Tziritas, N.; Bahsoon, R.; Theodoropoulos, G. Large language models for explainable decisions in dynamic digital twins. arXiv 2024, arXiv:2405.14411. [Google Scholar] [CrossRef]

- Han, X.; Wang, Z.; Xie, M.; He, Y.; Li, Y.; Wang, W. Remaining useful life prediction and predictive maintenance strategies for multi-state manufacturing systems considering functional dependence. Reliab. Eng. Syst. Saf. 2021, 210, 107560. [Google Scholar] [CrossRef]

- Calabrese, M.; Cimmino, M.; Fiume, F.; Manfrin, M.; Romeo, L.; Ceccacci, S.; Paolanti, M.; Toscano, G.; Ciandrini, G.; Carrotta, A.; et al. SOPHIA: An event-based IoT and machine learning architecture for predictive maintenance in industry 4.0. Information 2020, 11, 202. [Google Scholar] [CrossRef]

- Yang, H.; LaBella, A.; Desell, T. Predictive maintenance for general aviation using convolutional transformers. Proc. AAAI Conf. Artif. Intell. 2022, 36, 12636–12642. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Georgoulias, K.; Arkouli, Z.; Makris, S. Methodology for enabling digital twin using advanced physics-based modelling in predictive maintenance. Procedia CIRP 2019, 81, 417–422. [Google Scholar] [CrossRef]

| Technical Tier | Tools | Key Platforms | Core Architecture | Technical Differentiation |

|---|---|---|---|---|

| L1: Low-Code Platforms | • Dify | Visual orchestration engine | • Built-in LLMOps (monitoring/eval) • Enterprise RBAC/SSO integration | Rapid deployment of secure enterprise assistants |

| • Coze | Plugin-based interaction design | • Multimodal extensions (image/voice) • Cross-platform bot deployment (WeChat/Discord) | Consumer-facing social agents | |

| • Bubble | Web application generator | • No-code API connectors • Dynamic data binding | Business workflow automation (CRM/ERP integration) | |

| L2: API-Driven Layer | • OpenAI Assistant API | Function calling engine | • Code interpreter + file retrieval | Lightweight knowledge assistants |

| • Anthropic Claude Kit | Constitutional AI constraints | • Self-correction mechanisms • Structured output control | High-risk compliance agents | |

| • LangSmith | LLM observability layer | • Chain call cost/latency tracing • Prompt version comparison | LLM application debugging | |

| L3: Full-Code Frameworks | • LangChain | Modular chaining (LCEL) | • 200+ tool integration • Async chain scheduling | Complex RAG pipelines |

| • AutoGen | Conversational programming | • Interruptible agent sessions • Human-in-the-loop tuning | Multi-expert collaboration | |

| • Haystack | Neural search framework | • Hybrid retrieval (keyword + vector) • Domain fine-tuning | High-precision domain knowledge base | |

| • CrewAI | Organizational modeling | • Task dependency graphs • Resource contention handling | Enterprise task decomposition | |

| • LangGraph | State machine engine | • Cyclic workflow checkpoints • Distributed agent coordination | Real-time supply chain tracking |

| Dimension | Traditional PdM Method | Proposed Method |

|---|---|---|

| Technical Architecture | Reliance on single models, static rules | Multi-agent collaboration + RAG + large models + digital twin closed-loop |

| Development Paradigm | Dependency on specialized development teams | Tiered agent platforms (L1/L2/L3) lowering entry barriers |

| Knowledge Utilization | Siloed historical data, delayed updates | RAG enables real-time retrieval of the latest knowledge bases and dynamic updates |

| Decision Reliability | Lack of risk simulation | Digital twins pre-test maintenance actions to avoid unexpected and hidden dangers |

| Operational Mechanism | Model degradation, no iterative optimization | LLMOps-driven continuous learning and feedback loops |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, W.; Hu, F. Artificial Intelligence Agent-Enabled Predictive Maintenance: Conceptual Proposal and Basic Framework. Computers 2025, 14, 329. https://doi.org/10.3390/computers14080329

Jiang W, Hu F. Artificial Intelligence Agent-Enabled Predictive Maintenance: Conceptual Proposal and Basic Framework. Computers. 2025; 14(8):329. https://doi.org/10.3390/computers14080329

Chicago/Turabian StyleJiang, Wenyu, and Fuwen Hu. 2025. "Artificial Intelligence Agent-Enabled Predictive Maintenance: Conceptual Proposal and Basic Framework" Computers 14, no. 8: 329. https://doi.org/10.3390/computers14080329

APA StyleJiang, W., & Hu, F. (2025). Artificial Intelligence Agent-Enabled Predictive Maintenance: Conceptual Proposal and Basic Framework. Computers, 14(8), 329. https://doi.org/10.3390/computers14080329