Decision Support for Cargo Pickup and Delivery Under Uncertainty: A Combined Agent-Based Simulation and Optimization Approach

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

- (1)

- Optimization Model (MILP):

- (2)

- Stochastic Agent-Based Simulation (ABS):

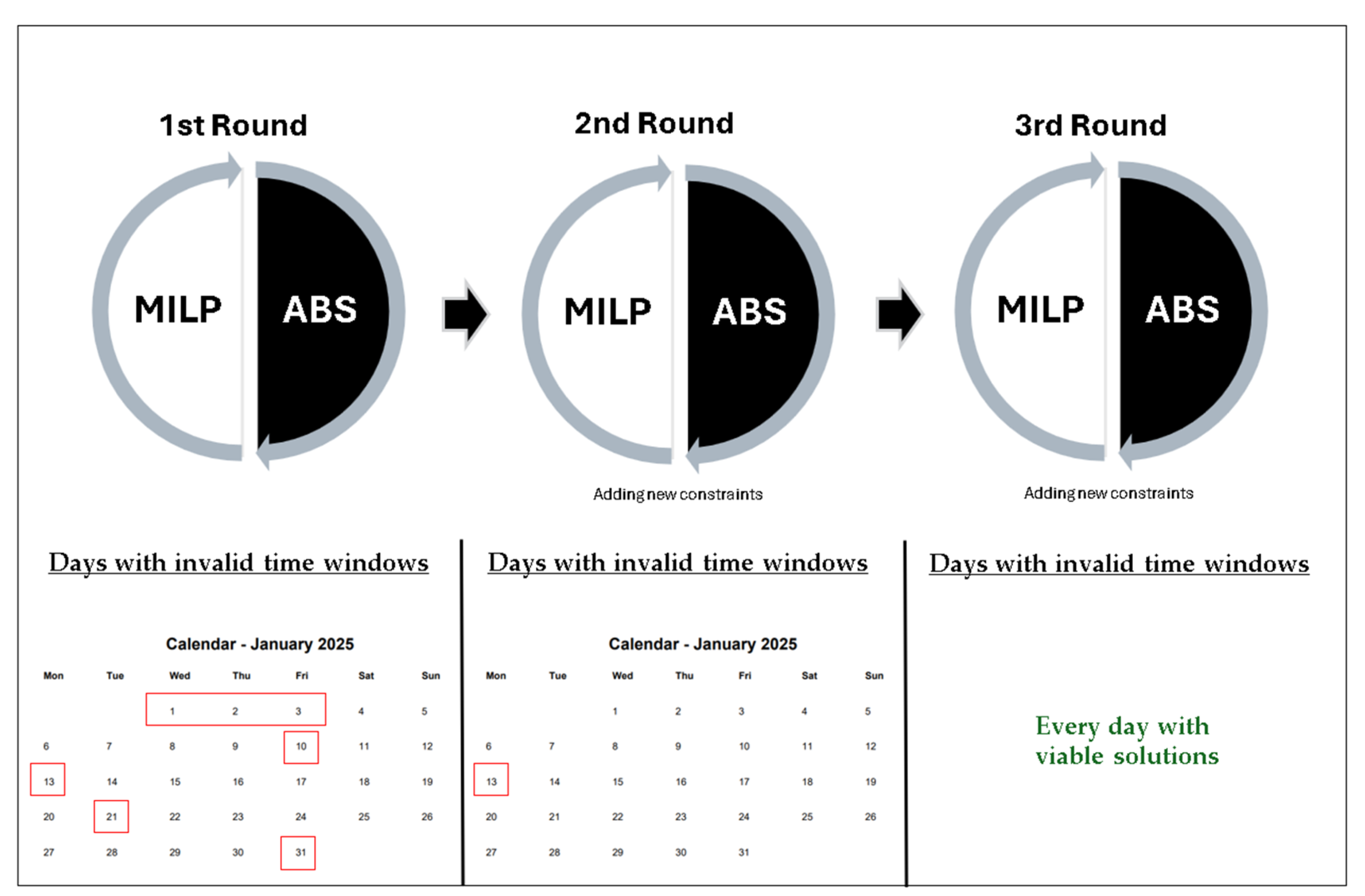

- Step 1: The MILP model generates optimal routing plans based on deterministic assumptions.

- Step 2: The plan is introduced into the ABS model, simulating solution under stochastic conditions to evaluate performance in realistic operational contexts. Any time window violations, capacity breaches, or delivery failures identified during this stage provide critical feedback for further optimization.

- Step 3: New routing constraints derived from ABS insights are modeled and integrated into the MILP model, generating new routing plan.

- Step 4: Revised plan is reassessed within the ABS model to confirm stability. If the solution remains stable, the process concludes; otherwise, it returns to Step 3, addressing identified issues through new routing constraints.

3.1. Mathematical Model Formulation

3.1.1. Pickup and Delivery Problem with Time Windows

3.1.2. Pickup and Delivery Problem with Time Windows and Transshipment

3.1.3. Simulation-Derived Constraints

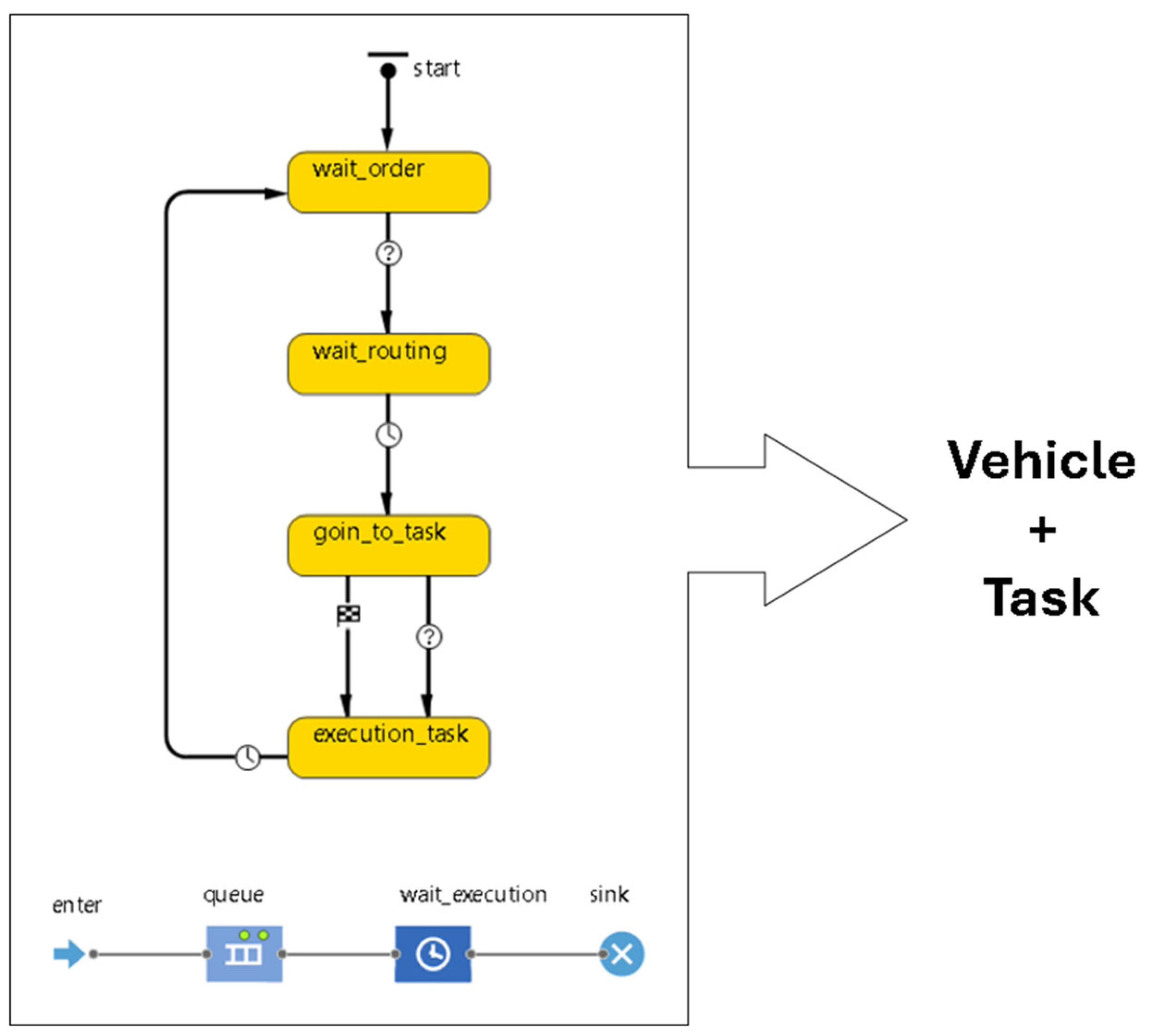

3.2. Agent-Based Simulation Using Anylogic

Implementation of ABS Model

3.3. Scenario Design and Experiments

- (a)

- Deterministic optimal scenario—representing the MILP output without incorporating uncertainty factors in travel or task execution times.

- (b)

- Optimal scenario with uncertainties—extending the deterministic case by introducing stochastic variations in travel times, incident occurrence, and task execution delays.

- (c)

- Optimal scenario with resilience strategies—complementing the uncertainty scenario with operational buffers such as extended time windows, vehicle contingency allocation, and transshipment policies.

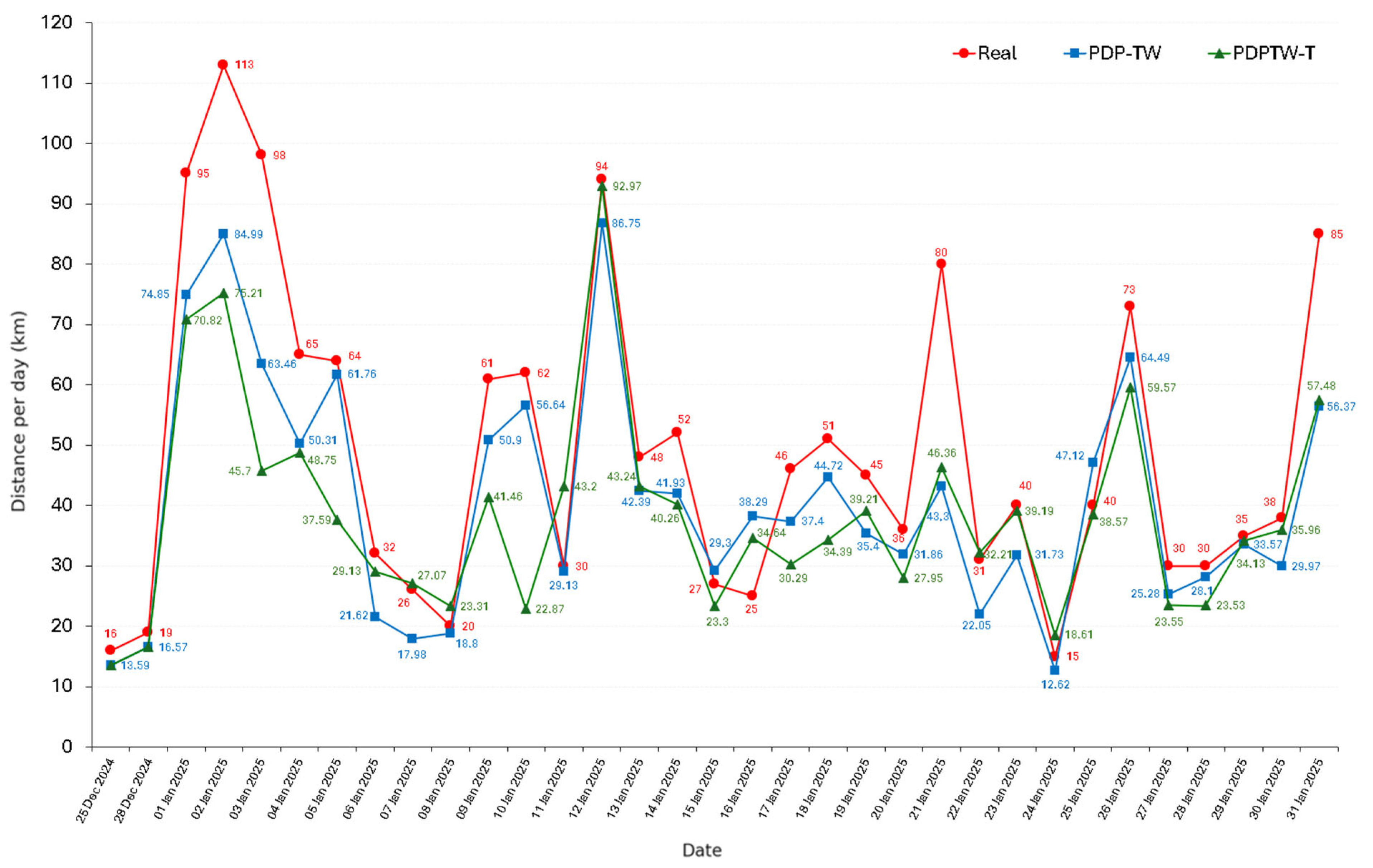

4. Results and Discussion

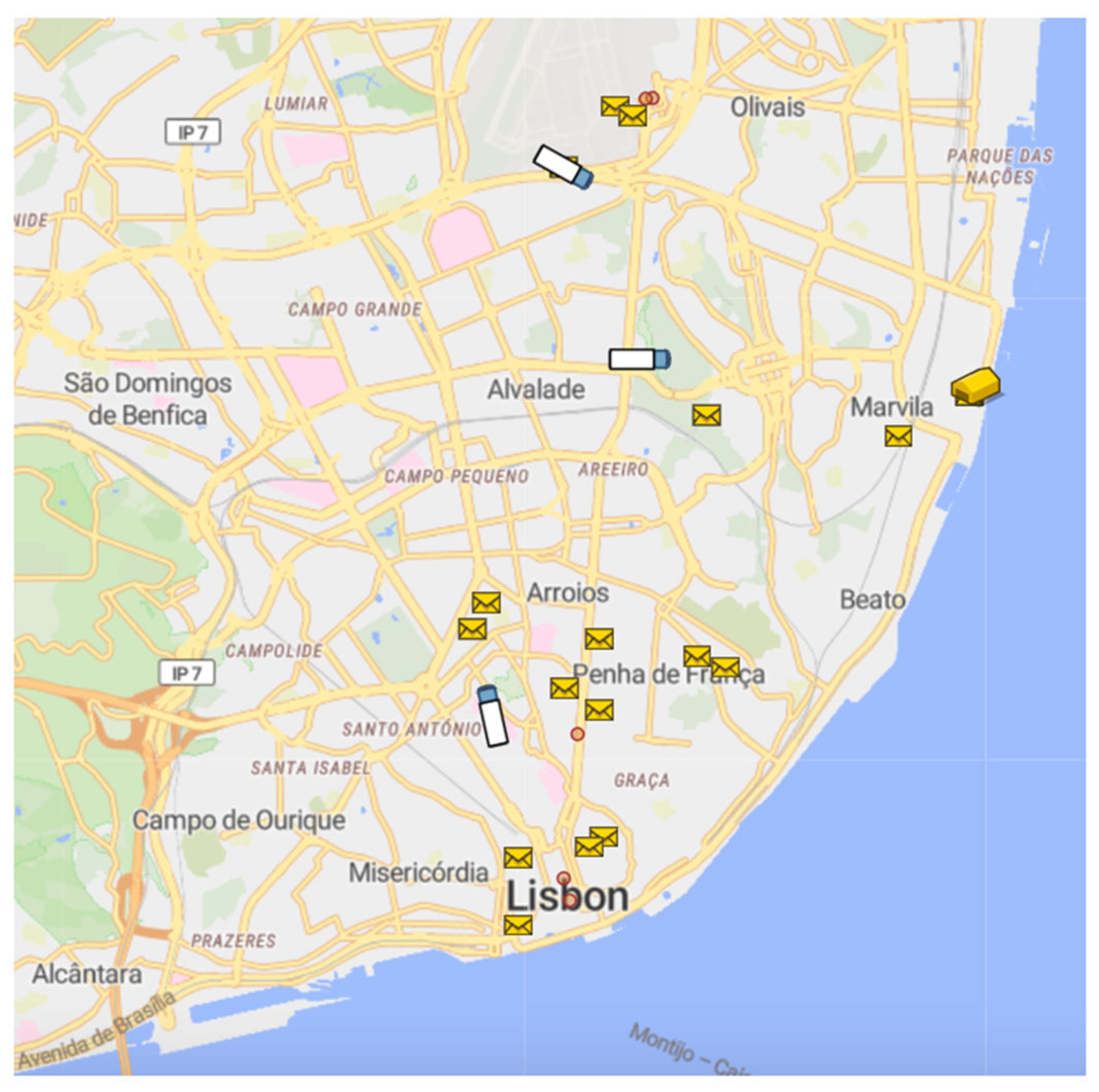

4.1. Case Study of Lisbon

4.2. Iterative MILP–ABS Analysis

4.3. Discussion and Comparison Between Approaches

4.4. Limitations

5. Conclusions and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alves, R.; Lima, R.d.S.; De Oliveira, L.K.; de Pinho, A.F. Conceptual Framework for Evaluating E-Commerce Deliveries Using Agent-Based Modelling and Sensitivity Analysis. Sustainability 2022, 14, 15505. [Google Scholar] [CrossRef]

- Moreno, R.P.; Lopes, R.B.; Ferreira, J.V.; Ramos, A.L.; Correia, D. A Study of the Main Mathematical Models Used in Mobility, Storage, Pickup and Delivery in Urban Logistics: A Systematic Review. Systems 2024, 12, 374. [Google Scholar] [CrossRef]

- Moreno, R.P.R.; Lopes, R.B.; Ramos, A.L.; Ferreira, J.V.; Correia, D.; Melo, I.E.S. de An Agent-Based Simulation and Optimization Approach for Sustainable Urban Logistics: A Case Study in Lisbon. Appl. Syst. Innov. 2025, 8, 66. [Google Scholar] [CrossRef]

- Han, J.; Lee, C.; Park, S. A Robust Scenario Approach for the Vehicle Routing Problem with Uncertain Travel Times. Transp. Sci. 2014, 48, 373–390. [Google Scholar] [CrossRef]

- Srour, F.J.; Agatz, N.; Oppen, J. Strategies for Handling Temporal Uncertainty in Pickup and Delivery Problems with Time Windows. Transp. Sci. 2018, 52, 3–19. [Google Scholar] [CrossRef]

- Xue, G.; Wang, Z.; Wang, Y. The Restaurant Delivery Problem with Uncertain Cooking Time and Travel Time. Comput. Ind. Eng. 2024, 190, 110039. [Google Scholar] [CrossRef]

- Wang, Y.; Gou, M.; Luo, S.; Fan, J.; Wang, H. The Multi-Depot Pickup and Delivery Vehicle Routing Problem with Time Windows and Dynamic Demands. Eng. Appl. Artif. Intell. 2025, 139, 109700. [Google Scholar] [CrossRef]

- Dridi, I.H.; Kammarti, R.; Ksouri, M.; Borne, P. Genetic Algorithm for Mulicriteria Optimization of a Multi-Pickup and Delivery Problem with Time Windows. IFAC Proc. Vol. 2009, 42, 1538–1543. [Google Scholar] [CrossRef]

- Ma, Y.; Li, J.; Xue, J.; Li, Z. Online Crowdsourced Delivery Optimization Problem for Takeaway Orders with Balanced Rider Resources and Uncertain Travel Time. Transp. Lett. 2025, 1–20. [Google Scholar] [CrossRef]

- Giordano, A.; Christidis, P. Green Last-Mile Delivery: Adapting Beverage Distribution to Low Emission Urban Areas. Future Transp. 2025, 5, 65. [Google Scholar] [CrossRef]

- Murarețu, I.; Bădică, C. Optimal Agent-Based Pickup and Delivery with Time Windows and Electric Vehicles. Appl. Sci. 2024, 14, 7528. [Google Scholar] [CrossRef]

- Romano Alho, A.; Sakai, T.; Oh, S.; Cheng, C.; Seshadri, R.; Chong, W.H.; Hara, Y.; Caravias, J.; Cheah, L.; Ben-Akiva, M. A Simulation-Based Evaluation of a Cargo-Hitching Service for E-Commerce Using Mobility-on-Demand Vehicles. Future Transp. 2021, 1, 639–656. [Google Scholar] [CrossRef]

- Zhang, X.; Zeng, S. The Drone-Assisted Simultaneous Pickup and Delivery Problem with Time Windows. Comput. Oper. Res. 2025, 178, 106996. [Google Scholar] [CrossRef]

- Rao, C.; Goh, M.; Zhao, Y.; Zheng, J. Location Selection of City Logistics Centers under Sustainability. Transp. Res. Part Transp. Environ. 2015, 36, 29–44. [Google Scholar] [CrossRef]

- Lyu, Z.; Yu, A.J. The Pickup and Delivery Problem with Transshipments: Critical Review of Two Existing Models and a New Formulation. Eur. J. Oper. Res. 2023, 305, 260–270. [Google Scholar] [CrossRef]

- Berbeglia, G.; Cordeau, J.-F.; Laporte, G. Dynamic Pickup and Delivery Problems. Eur. J. Oper. Res. 2010, 202, 8–15. [Google Scholar] [CrossRef]

- Koç, Ç.; Laporte, G.; Tükenmez, İ. A Review of Vehicle Routing with Simultaneous Pickup and Delivery. Comput. Oper. Res. 2020, 122, 104987. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, P.; Guo, L.; Chen, P.; Ling, Y. Improving the ALNS Algorithm for PDPTW Problem Using a DDQN Agent. In Proceedings of the 2024 IEEE 13th Data Driven Control and Learning Systems Conference (DDCLS), Kaifeng, China, 17–19 May 2024; pp. 2114–2119. [Google Scholar]

- Hu, L. Logistics Vehicle Optimization Scheduling Based on Multi Constraint PDPTW Algorithm. 5th Int. Conf. Multi-Modal Inf. Anal. MMIA 2025, 262, 438–447. [Google Scholar] [CrossRef]

- Jun, S.; Lee, S. Evolutionary Neural Network for Learning of Scalable Heuristics for Pickup and Delivery Problems with Time Windows. Comput. Ind. Eng. 2022, 169, 108282. [Google Scholar] [CrossRef]

- Moreno, R.P.R.; Lopes, R.B.; Ramos, A.L.; Ferreira, J.V.; Correia, D. Vosviewer-Based Bibliometric Review of Transshipment Location Problem From 2000 to 2023. Rev. Gest. Soc. E Ambient. 2024, 18, e08753. [Google Scholar] [CrossRef]

- Rizk, Y.; Awad, M. A Quantum Genetic Algorithm for Pickup and Delivery Problems with Coalition Formation. Procedia Comput. Sci. 2019, 159, 261–270. [Google Scholar] [CrossRef]

- Marinelli, M.; Caggiani, L.; Alnajajreh, A.; Binetti, M. A Two-Stage Metaheuristic Approach for Solving the Vehicle Routing Problem with Simultaneous Pickup/Delivery and Door-to-Door Service. In Proceedings of the 2019 6th International Conference on Models and Technologies for Intelligent Transportation Systems (MT-ITS), Kraków, Poland, 5–7 June 2019; pp. 1–9. [Google Scholar]

- Konstantakopoulos, G.D.; Kechagias, E.P.; Gayialis, S.P.; Tatsiopoulos, I.P. Green Freight Distribution: A Case Study in Greece. In Operational Research in the Era of Digital Transformation and Business Analytics; Matsatsinis, N.F., Kitsios, F.C., Madas, M.A., Kamariotou, M.I., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 49–64. [Google Scholar]

- Elbert, R.; Roeper, F. Simulation-Based Analysis of Improvements in Vehicle Routing with Time Windows Using A One-Sided VCG Mechanism for the Reallocation of Unfavorable Time Windows. In Proceedings of the 2023 Winter Simulation Conference (WSC), San Antonio, TX, USA, 10–13 December 2023; pp. 1795–1805. [Google Scholar]

- Liu, X.; Wang, D.; Yin, Y.; Cheng, T.C.E. Robust Optimization for the Electric Vehicle Pickup and Delivery Problem with Time Windows and Uncertain Demands. Comput. Oper. Res. 2023, 151, 106119. [Google Scholar] [CrossRef]

- Khalili-Fard, A.; Parsaee, S.; Bakhshi, A.; Yazdani, M.; Aghsami, A.; Rabbani, M. Multi-Objective Optimization of Closed-Loop Supply Chains to Achieve Sustainable Development Goals in Uncertain Environments. Eng. Appl. Artif. Intell. 2024, 133, 108052. [Google Scholar] [CrossRef]

- Layeb, S.B.; Jaoua, A.; Jbira, A.; Makhlouf, Y. A Simulation-Optimization Approach for Scheduling in Stochastic Freight Transportation. Comput. Ind. Eng. 2018, 126, 99–110. [Google Scholar] [CrossRef]

- Zong, Z.; Zheng, M.; Li, Y.; Jin, D. MAPDP: Cooperative Multi-Agent Reinforcement Learning to Solve Pickup and Delivery Problems. Proc. AAAI Conf. Artif. Intell. 2022, 36, 9980–9988. [Google Scholar] [CrossRef]

- Anderluh, A.; Nolz, P.C.; Hemmelmayr, V.C.; Crainic, T.G. Multi-Objective Optimization of a Two-Echelon Vehicle Routing Problem with Vehicle Synchronization and ‘Grey Zone’ Customers Arising in Urban Logistics. Eur. J. Oper. Res. 2021, 289, 940–958. [Google Scholar] [CrossRef]

- Malladi, S.S.; Erera, A.L.; White, C.C. Managing Mobile Production-Inventory Systems Influenced by a Modulation Process. Ann. Oper. Res. 2021, 304, 299–330. [Google Scholar] [CrossRef]

- Ulmer, M.W.; Thomas, B.W.; Campbell, A.M.; Woyak, N. The Restaurant Meal Delivery Problem: Dynamic Pickup and Delivery with Deadlines and Random Ready Times. Transp. Sci. 2021, 55, 75–100. [Google Scholar] [CrossRef]

- Chen, J.; Wang, L.; Wang, S.; Wang, X.; Ren, H. An Effective Matching Algorithm with Adaptive Tie-Breaking Strategy for Online Food Delivery Problem. Complex Intell. Syst. 2022, 8, 107–128. [Google Scholar] [CrossRef]

- AnyLogic: Simulation Modeling Software Tools & Solutions for Business. Available online: https://www.anylogic.com/ (accessed on 5 April 2025).

- Miller, C.E.; Tucker, A.W.; Zemlin, R.A. Integer Programming Formulation of Traveling Salesman Problems. J. ACM 1960, 7, 326–329. [Google Scholar] [CrossRef]

- Attajer, A.; Darmoul, S.; Chaabane, S.; Riane, F.; Sallez, Y. Benchmarking Simulation Software Capabilities Against Distributed Control Requirements: FlexSim vs. AnyLogic. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future; Borangiu, T., Trentesaux, D., Leitão, P., Cardin, O., Lamouri, S., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 520–531. [Google Scholar]

- Hussein, M.; Karam, A.; Eltoukhy, A.E.E.; Darko, A.; Zayed, T. Optimized Multimodal Logistics Planning of Modular Integrated Construction Using Hybrid Multi-Agent and Metamodeling. Autom. Constr. 2023, 145, 104637. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Abdelkhalek, S.; Hussien, M.; Zayed, T. A Hybrid Simulation Model for Modules Installation in Modular Integrated Construction Projects. Int. J. Constr. Manag. 2024, 24, 1407–1418. [Google Scholar] [CrossRef]

- Lubin, M.; Dowson, O.; Garcia, J.D.; Huchette, J.; Legat, B.; Vielma, J.P. JuMP 1.0: Recent Improvements to a Modeling Language for Mathematical Optimization. Math. Program. Comput. 2023, 15, 581–589. [Google Scholar] [CrossRef]

- The Leader in Decision Intelligence Technology—Gurobi Optimization. Available online: https://www.gurobi.com/ (accessed on 21 October 2025).

- Helo, P.; Rouzafzoon, J. An Agent-Based Simulation and Logistics Optimization Model for Managing Uncertain Demand in Forest Supply Chains. Supply Chain Anal. 2023, 4, 100042. [Google Scholar] [CrossRef]

- Saprykin, A.; Chokani, N.; Abhari, R.S. Uncertainties of Sub-Scaled Supply and Demand in Agent-Based Mobility Simulations with Queuing Traffic Model. Netw. Spat. Econ. 2021, 21, 261–290. [Google Scholar] [CrossRef]

- Armenta-Déu, C. Environmental Impact of Urban Surface Transportation: Influence of Driving Mode and Drivers’ Attitudes. Pollutants 2025, 5, 5. [Google Scholar] [CrossRef]

- Jorge, D.; Rocha, T.; Ramos, T.R.P. A Time-Driven Simulation–Optimization Framework for the Dynamic Heterogeneous Order-Courier Assignment Problem for Instant Deliveries. Transp. Res. Part E Logist. Transp. Rev. 2024, 192, 103783. [Google Scholar] [CrossRef]

- Wolfinger, D.; Salazar-González, J.-J. The Pickup and Delivery Problem with Split Loads and Transshipments: A Branch-and-Cut Solution Approach. Eur. J. Oper. Res. 2021, 289, 470–484. [Google Scholar] [CrossRef]

- Mitrović-Minić, S.; Laporte, G. The Pickup and Delivery Problem with Time Windows and Transshipment. INFOR 2006, 44, 217–227. [Google Scholar] [CrossRef]

- Avgerinos, I.; Mourtos, I.; Tsompanidis, N.; Zois, G. Pickup & Delivery with Time Windows and Transfers: Combining Decomposition with Metaheuristics. arXiv 2025, arXiv:2505.02158. [Google Scholar] [CrossRef]

- Yernar, A.; Turan, C. Recent Developments in Vehicle Routing Problem under Time Uncertainty: A Comprehensive Review. Bull. Electr. Eng. Inform. 2025, 14, 1263–1275. [Google Scholar] [CrossRef]

| Notation | Description |

|---|---|

| Parameters | |

| quantity of baggage associated with request | |

| traveling distance between the arc using the vehicle | |

| traveling time between the arc | |

| earliest time that the request can be picked up at the location | |

| latest time that the request can be delivered at the location | |

| Variables | |

| 1 if vehicle travels through the arc , 0 otherwise. | |

| 1 if request is transported by vehicle through the arc , 0 otherwise. | |

| auxiliary variable used for sub-tour elimination, indicating the rank order in which node is visited (see Miller et al. [35]) | |

| arrival time for vehicle at location | |

| departure time for vehicle at location |

| Agent | Attribute | Description |

|---|---|---|

| Order/Task | Date | Scheduled date for pickup or delivery |

| Time | Scheduled time for pickup or delivery | |

| Address | Geographic coordinates for pickup/delivery (latitude and longitude) | |

| Dimension | Physical size of the item | |

| Vehicles/Driver | Capacity | Volume or weight of the merchandise |

| Load Capacity | Maximum cargo the vehicle can transport | |

| Address Time | Time required to reach the assigned address | |

| Warehouse | Storage Cost | Monetary cost for holding goods |

| Storage Capacity | Maximum volume supported for storage |

| Orders Date | Number of Tasks | Number of Drivers | Total Distance per Day (Km) | CO2 Emissions per Day | Warehouse Usage (Yes/No) |

|---|---|---|---|---|---|

| 25 December 2024 | 1 | 1 | 16 | 2.03 | Yes |

| 28 December 2024 | 1 | 1 | 19 | 2.42 | Yes |

| 1 January 2025 | 11 | 2 | 95 | 12.07 | Yes |

| 2 January 2025 | 14 | 2 | 113 | 14.36 | Yes |

| 3 January 2025 | 13 | 2 | 98 | 12.46 | No |

| 4 January 2025 | 9 | 2 | 65 | 8.26 | No |

| 5 January 2025 | 6 | 2 | 64 | 8.13 | No |

| 6 January 2025 | 3 | 2 | 32 | 4.07 | Yes |

| 7 January 2025 | 2 | 1 | 26 | 3.31 | No |

| 8 January 2025 | 2 | 1 | 20 | 2.54 | No |

| 9 January 2025 | 6 | 2 | 61 | 7.75 | No |

| 10 January 2025 | 6 | 3 | 62 | 7.88 | Yes |

| 11 January 2025 | 3 | 3 | 30 | 3.81 | No |

| 12 January 2025 | 6 | 2 | 94 | 11.95 | No |

| 13 January 2025 | 6 | 2 | 48 | 6.10 | Yes |

| 14 January 2025 | 5 | 2 | 52 | 6.61 | No |

| 15 January 2025 | 3 | 2 | 27 | 3.43 | No |

| 16 January 2025 | 1 | 1 | 25 | 3.18 | No |

| 17 January 2025 | 5 | 3 | 46 | 5.85 | Yes |

| 18 January 2025 | 5 | 2 | 51 | 6.48 | No |

| 19 January 2025 | 4 | 1 | 45 | 5.72 | No |

| 20 January 2025 | 4 | 2 | 36 | 4.58 | No |

| 21 January 2025 | 2 | 2 | 80 | 10.17 | No |

| 22 January 2025 | 3 | 1 | 31 | 3.94 | No |

| 23 January 2025 | 3 | 2 | 40 | 5.08 | No |

| 24 January 2025 | 1 | 1 | 15 | 1.91 | No |

| 25 January 2025 | 4 | 1 | 40 | 5.08 | No |

| 26 January 2025 | 8 | 2 | 73 | 9.28 | No |

| 27 January 2025 | 3 | 2 | 30 | 3.81 | No |

| 28 January 2025 | 3 | 1 | 30 | 3.81 | No |

| 29 January 2025 | 4 | 1 | 35 | 4.45 | No |

| 30 January 2025 | 3 | 1 | 38 | 4.83 | No |

| 31 January 2025 | 8 | 3 | 85 | 10.80 | No |

| Total | 158 | - | 1622 | 206.1562 | - |

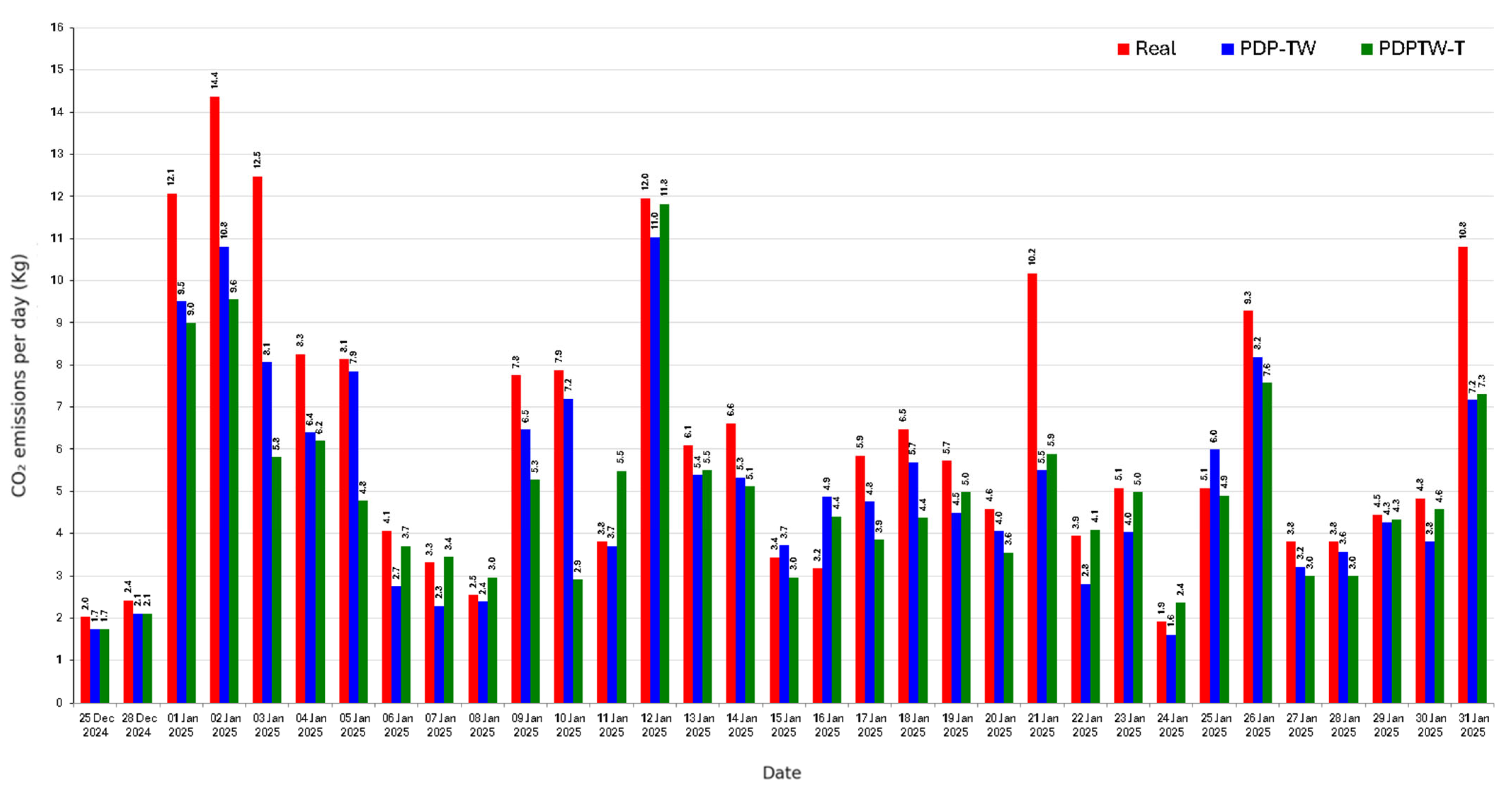

| Orders Date | Nb. Orders | Number of Drivers | Total Distance per Day (Km) | Computational Time (s) | CO2 Emissions per Day (Kg) | Cost (EUR Per Km) | Warehouse Cost (EUR) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Real | PDP-TW | PDPTW-T | Real | PDP-TW | PDPTW-T | PDP-TW | PDPTW-T | Real | PDP-TW | PDPTW-T | Real | PDP-TW | PDPTW-T | |||

| 25 December 2024 | 1 | 1 | 1 | 2 | 16 | 13.59 | 13.59 | 31.141 | 31.141 | 2.03 | 1.727 | 1.727 | 8.00 | 6.80 | 6.80 | 55 |

| 28 December 2024 | 1 | 1 | 1 | 2 | 19 | 16.57 | 16.57 | 27.198 | 27.198 | 2.42 | 2.106 | 2.106 | 9.50 | 8.29 | 8.29 | 35 |

| 1 January 2025 | 11 | 2 | 3 | 4 | 95 | 74.85 | 70.82 | 277.148 | 359.218 | 12.07 | 9.513 | 9.001 | 47.50 | 37.43 | 35.41 | 45 |

| 2 January 2025 | 14 | 2 | 3 | 4 | 113 | 84.99 | 75.21 | 297.038 | 2531.068 | 14.36 | 10.802 | 9.559 | 56.50 | 42.50 | 37.61 | 75 |

| 3 January 2025 | 13 | 3 | 2 | 4 | 98 | 63.46 | 45.70 | 468.741 | 613.258 | 12.46 | 8.066 | 5.808 | 49.00 | 31.73 | 22.85 | - |

| 4 January 2025 | 9 | 2 | 2 | 3 | 65 | 50.31 | 48.75 | 116.831 | 313.011 | 8.26 | 6.394 | 6.196 | 32.50 | 25.16 | 24.38 | - |

| 5 January 2025 | 6 | 3 | 3 | 3 | 64 | 61.76 | 37.59 | 88.624 | 68.614 | 8.13 | 7.850 | 4.778 | 32.00 | 30.88 | 18.80 | - |

| 6 January 2025 | 3 | 2 | 2 | 3 | 32 | 21.62 | 29.13 | 80.059 | 69.208 | 4.07 | 2.748 | 3.702 | 16.00 | 10.81 | 14.57 | 25 |

| 7 January 2025 | 2 | 1 | 1 | 2 | 26 | 17.98 | 27.07 | 75.140 | 68.092 | 3.31 | 2.285 | 3.441 | 13.00 | 8.99 | 13.54 | - |

| 8 January 2025 | 2 | 1 | 1 | 2 | 20 | 18.80 | 23.31 | 80.091 | 90.097 | 2.54 | 2.389 | 2.963 | 10.00 | 9.40 | 11.66 | - |

| 9 January 2025 | 6 | 2 | 2 | 3 | 61 | 50.90 | 41.46 | 92.733 | 97.777 | 7.75 | 6.469 | 5.270 | 30.50 | 25.45 | 20.73 | - |

| 10 January 2025 | 6 | 3 | 2 | 4 | 62 | 56.64 | 22.87 | 91.322 | 120.532 | 7.88 | 7.199 | 2.907 | 31.00 | 28.32 | 11.44 | 35 |

| 11 January 2025 | 3 | 3 | 1 | 3 | 30 | 29.13 | 43.20 | 98.110 | 123.127 | 3.81 | 3.702 | 5.491 | 15.00 | 14.57 | 21.60 | - |

| 12 January 2025 | 6 | 2 | 2 | 3 | 94 | 86.75 | 92.97 | 99.541 | 113.385 | 11.95 | 11.026 | 11.816 | 47.00 | 43.38 | 46.49 | - |

| 13 January 2025 | 6 | 2 | 3 | 3 | 48 | 42.39 | 43.24 | 101.250 | 140.424 | 6.10 | 5.388 | 5.496 | 24.00 | 21.20 | 21.62 | 15 |

| 14 January 2025 | 5 | 2 | 2 | 3 | 52 | 41.93 | 40.26 | 88.162 | 103.259 | 6.61 | 5.329 | 5.117 | 26.00 | 20.97 | 20.13 | - |

| 15 January 2025 | 3 | 2 | 2 | 3 | 27 | 29.26 | 23.30 | 69.146 | 99.141 | 3.43 | 3.719 | 2.965 | 13.50 | 14.63 | 11.67 | - |

| 16 January 2025 | 1 | 1 | 1 | 2 | 25 | 38.29 | 34.64 | 97.028 | 90.055 | 3.18 | 4.867 | 4.403 | 12.50 | 19.15 | 17.32 | - |

| 17 January 2025 | 5 | 3 | 2 | 2 | 46 | 37.40 | 30.29 | 88.291 | 99.399 | 5.85 | 4.754 | 3.850 | 23.00 | 18.70 | 15.15 | 20 |

| 18 January 2025 | 5 | 2 | 2 | 3 | 51 | 44.72 | 34.39 | 92.388 | 110.390 | 6.48 | 5.684 | 4.371 | 25.50 | 22.36 | 17.20 | - |

| 19 January 2025 | 4 | 1 | 1 | 3 | 45 | 35.40 | 39.21 | 99.925 | 140.930 | 5.72 | 4.499 | 4.984 | 22.50 | 17.70 | 19.61 | - |

| 20 January 2025 | 4 | 2 | 2 | 3 | 36 | 31.86 | 27.95 | 88.183 | 124.879 | 4.58 | 4.049 | 3.552 | 18.00 | 15.93 | 13.98 | - |

| 21 January 2025 | 2 | 2 | 2 | 3 | 80 | 43.27 | 46.36 | 98.286 | 111.185 | 10.17 | 5.500 | 5.892 | 40.00 | 21.64 | 23.18 | - |

| 22 January 2025 | 3 | 1 | 2 | 2 | 31 | 22.05 | 32.21 | 80.067 | 100.093 | 3.94 | 2.803 | 4.094 | 15.50 | 11.03 | 16.11 | - |

| 23 January 2025 | 3 | 2 | 2 | 3 | 40 | 31.73 | 39.19 | 108.095 | 140.184 | 5.08 | 4.033 | 4.981 | 20.00 | 15.87 | 19.60 | - |

| 24 January 2025 | 1 | 1 | 1 | 2 | 15 | 12.62 | 18.61 | 50.921 | 67.088 | 1.91 | 1.604 | 2.365 | 7.50 | 6.31 | 9.31 | - |

| 25 January 2025 | 4 | 2 | 2 | 3 | 40 | 47.12 | 38.57 | 66.153 | 87.132 | 5.08 | 5.989 | 4.902 | 20.00 | 23.56 | 19.29 | - |

| 26 January 2025 | 8 | 2 | 2 | 3 | 73 | 64.49 | 59.57 | 61.112 | 81.043 | 9.28 | 8.197 | 7.571 | 36.50 | 32.25 | 29.79 | - |

| 27 January 2025 | 3 | 2 | 1 | 3 | 30 | 25.28 | 23.55 | 51.087 | 70.072 | 3.81 | 3.213 | 2.993 | 15.00 | 12.64 | 11.78 | - |

| 28 January 2025 | 3 | 1 | 2 | 2 | 30 | 28.10 | 23.53 | 60.870 | 70.139 | 3.81 | 3.572 | 2.991 | 15.00 | 14.05 | 11.77 | - |

| 29 January 2025 | 4 | 1 | 2 | 3 | 35 | 33.57 | 34.13 | 40.178 | 61.287 | 4.45 | 4.267 | 4.338 | 17.50 | 16.79 | 17.07 | - |

| 30 January 2025 | 3 | 1 | 1 | 3 | 38 | 29.97 | 35.96 | 80.054 | 100.187 | 4.83 | 3.809 | 4.571 | 19.00 | 14.99 | 17.98 | - |

| 31 January 2025 | 8 | 3 | 2 | 3 | 85 | 56.37 | 57.48 | 82.036 | 91.578 | 10.80 | 7.165 | 7.306 | 42.50 | 28.19 | 28.74 | - |

| Total | 158 | - | - | - | 1622 | 1343.17 | 1270.68 | 3426.949 | 6514.191 | 206.16 | 170.72 | 161.50 | 811.00 | 671.59 | 635.34 | 305 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno, R.P.R.; Lopes, R.B.; Ramos, A.L.; Vasconcelos Ferreira, J.; Correia, D.; de Melo, I.E.S. Decision Support for Cargo Pickup and Delivery Under Uncertainty: A Combined Agent-Based Simulation and Optimization Approach. Computers 2025, 14, 462. https://doi.org/10.3390/computers14110462

Moreno RPR, Lopes RB, Ramos AL, Vasconcelos Ferreira J, Correia D, de Melo IES. Decision Support for Cargo Pickup and Delivery Under Uncertainty: A Combined Agent-Based Simulation and Optimization Approach. Computers. 2025; 14(11):462. https://doi.org/10.3390/computers14110462

Chicago/Turabian StyleMoreno, Renan Paula Ramos, Rui Borges Lopes, Ana Luísa Ramos, José Vasconcelos Ferreira, Diogo Correia, and Igor Eduardo Santos de Melo. 2025. "Decision Support for Cargo Pickup and Delivery Under Uncertainty: A Combined Agent-Based Simulation and Optimization Approach" Computers 14, no. 11: 462. https://doi.org/10.3390/computers14110462

APA StyleMoreno, R. P. R., Lopes, R. B., Ramos, A. L., Vasconcelos Ferreira, J., Correia, D., & de Melo, I. E. S. (2025). Decision Support for Cargo Pickup and Delivery Under Uncertainty: A Combined Agent-Based Simulation and Optimization Approach. Computers, 14(11), 462. https://doi.org/10.3390/computers14110462