1. Introduction

Modern industrial system design, particularly in highly regulated sectors like pharmaceuticals, is becoming more complex and requires increased flexibility. Combining mechanical, electrical, control, and software areas creates strong interdependencies that traditional, linear engineering methods often struggle to handle effectively [

1]. This can lead to late-stage conflicts, expensive redesigns, and delayed product launches [

2]. To address these issues, industry movements such as Industry 4.0 and Pharma 4.0 require connected, adaptable production systems driven by real-time data and decentralized decision-making. This approach necessitates smooth integration between high-level system models and operational data, enabling ongoing validation and flexible teamwork across disciplines [

3].

While Model-Based Systems Engineering (MBSE) provides formal models and a single source of truth for system requirements and architecture, its practical use often suffers from fragmented tools, inconsistent data, and limited integration with domain-specific simulations and real-world operations [

4]. Digital Twin (DT) technologies promise to link virtual models with physical assets for real-time monitoring and predictive insights, but often remain siloed and disconnected from upstream design models, limiting their value for early validation and cross-disciplinary coordination [

5].

At the same time, effective collaboration depends on more than tool interoperability. It requires capturing and reusing design knowledge systematically, managing organizational processes to support interdisciplinary work, and ensuring all stakeholders have access to consistent, up-to-date information [

6,

7]

This research introduces the implementation and assessment of an innovative web application, developed to facilitate model-driven design based on the CADA model as the theoretical backbone. It leverages knowledge graphs for semantic alignment, employs Axiomatic Design principles as its design workflow, and incorporates structured knowledge reuse through case-based reasoning. By tackling both technical and organisational challenges comprehensively, this approach seeks to promote agile, traceable, and sustainable system development aligned with Industry 4.0 and Pharma 4.0 principles.

2. Literature Review

Designing and developing modern industrial systems—particularly in mechatronics, process industries, and highly regulated sectors such as pharmaceutical manufacturing—faces growing complexity and demands for increased flexibility. This complexity arises from the need to integrate mechanical, electrical, control, and software domains simultaneously, while ensuring quality, safety, and compliance with relevant regulations. Traditional sequential engineering approaches often fail to address the strong interdependencies and evolving requirements across these domains, resulting in late-stage conflicts, costly redesigns, and increased time-to-market [

8,

9].

To address these challenges, MBSE has emerged as a key methodology, offering formal system representations (often in SysML) that provide a single source of truth for requirements, functional decomposition, and lifecycle traceability [

10,

11]. This is especially critical in the pharmaceutical sector, where Good Manufacturing Practice (GMP) guidelines require rigorous specification, validation, and traceability [

12,

13]. However, in practice, maintaining consistency between high-level system models and domain-specific simulations or implementation tools remains a persistent challenge. Heterogeneity in tools, manual model transformations, and disconnected workflows create barriers to effective integration and collaboration [

8,

14].

Model-Driven Engineering (MDE) frameworks, such as AutomationML, have mitigated some of these barriers by introducing standardised exchange formats that improve syntactic interoperability across disciplines. Nevertheless, semantic mismatches and the absence of dynamic consistency checking continue to cause integration problems, increasing risk and cost [

6]. Meanwhile, the Industry 4.0 and Pharma 4.0 visions require interconnected, adaptive production systems that rely on real-time information flows and decentralised decision-making [

11,

15]. Meeting these demands requires seamless links between virtual system models and operational data.

DT technology has advanced this vision by connecting virtual representations with physical assets, enabling real-time monitoring, simulation, and predictive maintenance. However, current DT implementations often remain siloed and poorly integrated with upstream MBSE models, limiting their value for early design verification and cross-disciplinary coordination [

11].

Recent research emphasizes enhancing DT systems with knowledge graphs to enable semantic integration, interoperability, and dynamic reasoning across heterogeneous data sources, helping bridge the gap between system models and live operational data [

16,

17].

Beyond tool and data integration, collaborative design also requires proactive management of knowledge and organisational processes. Knowledge-Based Engineering (KBE) methodologies emphasise the importance of capturing and reusing design knowledge to enhance quality and minimise redundant effort [

18]. Techniques such as Quality Function Deployment (QFD) help systematically translate customer requirements into technical specifications early in the design process, minimising downstream changes [

19]. Introducing advanced modelling and simulation tools in industrial settings requires more than technical deployment. It demands organisational adaptation, with redesigned structures and workflows that support integrated, cross-disciplinary collaboration and ensure all stakeholders have access to shared, up-to-date information [

20]. Finally, Design Research Methodology (DRM) offers a rigorous framework for structuring such research and development efforts through iterative clarification of goals, descriptive studies, prescriptive development of new methods, and context-sensitive evaluation, ensuring that proposed frameworks are both theoretically grounded and practically validated [

21].

The iSee platform is a Case-Based Reasoning (CBR) system designed to support the development of personalised and trustworthy explanations in Explainable Artificial Intelligence (XAI). It enables AI developers to select and adapt explanation strategies by reusing prior “explanation experiences”, i.e., documented cases that include the problem context, the chosen explanation method, and user evaluations. The platform comprises a case library, a retrieval engine for finding relevant past cases, and a revision engine for adapting them to new scenarios. iSee is particularly valuable in safety-critical domains such as healthcare, legal, and security applications, where clear and reliable AI explanations are essential. By focusing on the reuse of successful explanation designs and tailoring them to different users and contexts, iSee facilitates the development of human-centric and ethically transparent AI systems [

22].

The Virtual Design Assistant (VDA) exemplifies a next-generation collaborative design support system by embedding shared design principles, interactive communication, and collective learning into its architecture. Although not branded as a multi-user platform, its components are inherently collaborative and adaptable for team-based environments. It provides a strong foundation for future research and the development of collaborative AI-powered design ecosystems [

23].

To improve the accessibility and usability of MBSE models, especially for non-expert stakeholders, the SysML Document Traceability Framework (SDTF) and the Interactive Visualisation Engine for SysML Tools (InVEST) have been developed. InVEST serves as a visualisation layer that extracts and formats model data into stakeholder-relevant formats, including interactive dashboards, hierarchies, and wiki environments. These visualisations are generated using web technologies (e.g., JavaScript, D3, JSON) and present tailored, read-only model views that support collaborative review and documentation traceability. The study concludes with a forward-looking perspective, emphasising the need for deeper integration with collaborative environments, support for model editing from visualisations, and advanced filtering capabilities [

24].

Research has shown that integrating model-based design into a graphical design assistant can be successfully applied to various use cases. By combining embedded theory with a user-centric application, users and organisations can gain significant benefits.

3. Materials and Methods

This research adopts a structured, iterative approach to develop and validate an integrated visual design assistant for collaborative design of complex industrial systems. The goal is to address persistent challenges in cross-disciplinary engineering, e.g., inconsistent models, poor knowledge reuse, or fragmented workflows, by integrating formal system modelling, semantic integration, and accessible visualisation within a single framework. The methodology is informed by DRM, which emphasises iterative stages of clarification, development, and evaluation to ensure solutions are both theoretically grounded and practically validated [

21].

3.1. Theory and Application

The following section illustrates how CADA functions as a central framework within the user-centred software. The main features of the method are outlined below, and the process of translating the theoretical components into the application design is clarified.

Building on the findings of the literature review, the CADA principles need to be expanded by incorporating collaboration mechanisms that combine MDE interoperability, structured knowledge graphs, and lightweight visualisation. To tackle technical, organisational, and knowledge management challenges effectively, the application must bridge the ongoing gaps between system-level design, domain-specific engineering, and operational validation.

CADA integrates axiomatic design principles with case-based reasoning and knowledge graphs to facilitate the structured reuse and traceability of design rationale, which is particularly important in regulated industries such as pharmaceuticals [

25].

3.1.1. Axiomatic Design

The axiomatic design theory serves as a strong guiding principle for this workflow-oriented design assistant. It is based on two central axioms:

- (1)

The Independence Axiom, which states that the functional requirements of a design should be maintained independently, meaning each function is satisfied without affecting others; and

- (2)

The Information Axiom, which emphasises minimising the information content of the design, leading to simpler and more reliable solutions.

The method encourages mapping customer needs to functional requirements and then to design parameters, systematically ensuring clear traceability and minimal coupling. Shifting back and forth between the domains while breaking down the design is known as Zig-Zagging. By following these axioms, designers create solutions that are both robust and adaptable. This approach helps prevent unintended interactions in complex systems and supports the development of high-quality and efficient designs [

26].

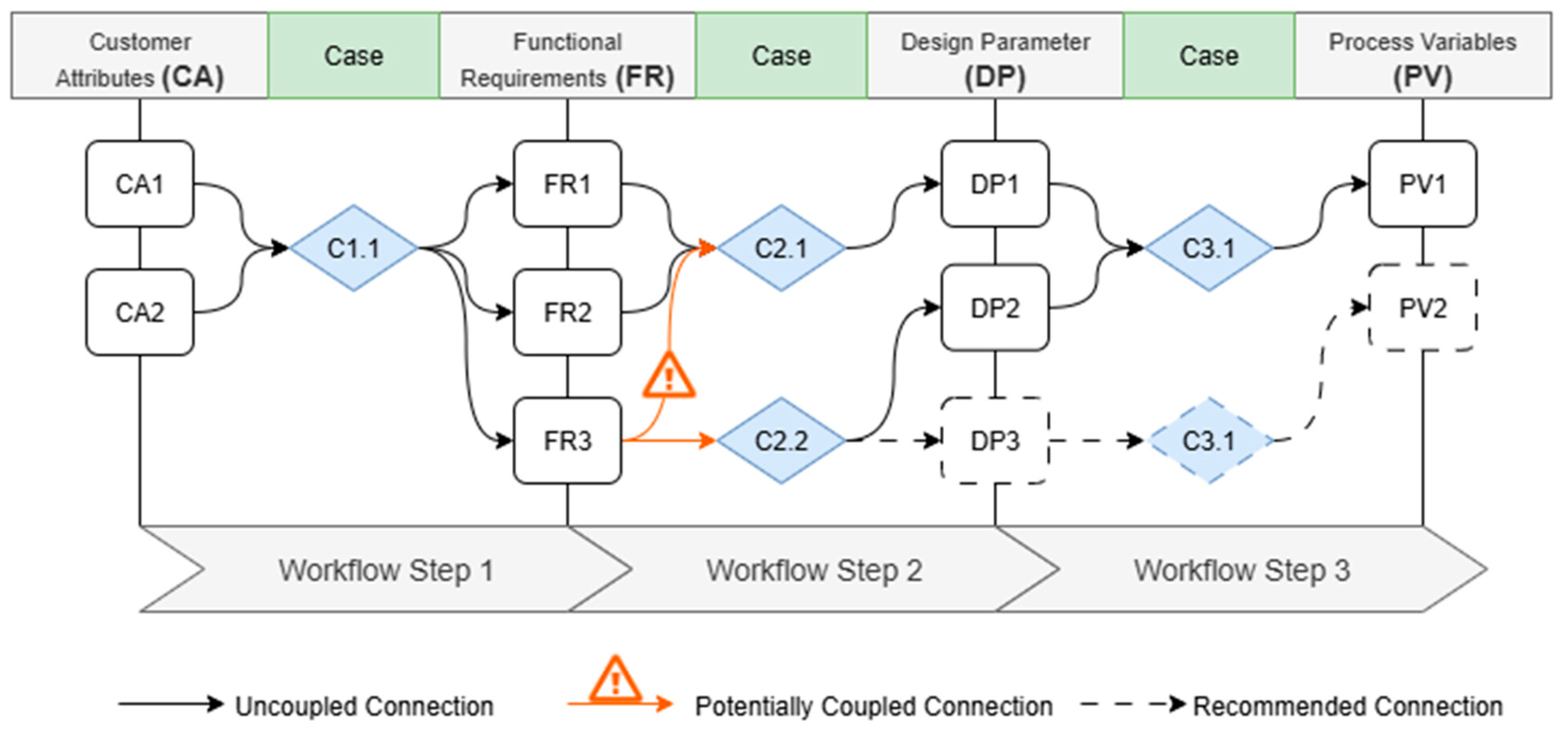

The four domains, the two axioms and Zig-Zagging are integrated into the CADA application as shown in

Figure 1.

One design cycle involves three workflow steps, each integrating two domains that represent the AD structure. A case layer links the attributes within the individual domains. Each workflow displays only information relevant to the respective domains and the cases connecting them, helping the designer focus on the current task and avoid information overload. Zig-Zagging is implemented in the knowledge graph representation by connecting attributes with wires. When a new attribute is inserted into a domain (e.g., DP3), the user must connect it in two workflow steps (Step 2 and 3 in this example) to ensure an error-free dataset. Adding new attributes may also require new cases (C3.1) or additional attributes in different domains (such as PV2) to describe the design. If axiom 1 is violated, the affected connections are shown in the visualisation using colour and symbols (FR3 to C2.1 and C2.2). The application uses the second axiom (Information Axiom) to recommend solutions based on the information necessary to describe a solution. The number of DP used to address all FR within a single design can distinguish between solutions. The fewer DP attributes (or a combination of DP and Cases) in a workflow, the better the solution, according to the 2nd axiom. Minimising information content can begin with the selection of FR and the subsequent mapping of DP in a zig-zagging approach to meet all CA through a simplified design. The graphical representation helps to identify FR that are not connected to CA, thus pointing out unnecessary overhead in the conceptual design.

3.1.2. Case-Based Reasoning

The backbone of the application was developed using a CBR framework, which enables problem-solving by leveraging solutions to previously encountered, similar cases. CBR mimics human problem-solving by retrieving, adapting, and reusing prior experiences, a process shown to be both intuitive and effective across various domains [

27,

28,

29,

30]. The standard CBR cycle, as described by Aamodt and Plaza [

27], comprises four main phases: Retrieve, Reuse (Adapt), Revise, and Retain (

Figure 2).

Retrieve: The system identifies and retrieves the most relevant historical design cases from a structured case database. Retrieval is performed using similarity measures, such as nearest neighbour search and classification algorithms, to compare new design problems with past cases.

Reuse: Retrieved solutions are adapted to meet the specific requirements of the current design problem. This adaptation process may involve direct solution transfer when cases are highly similar or more complex, semi-automatic modifications when significant differences exist. No general adaptation method exists; adaptation strategies are domain-specific and often require expert input.

Revise: The adapted solution is reviewed and, if necessary, further refined—either automatically or with expert intervention—to ensure its suitability for the new context.

Retain: The new problem–solution pair is stored in the case database, supporting continuous system learning. Mechanisms are in place to manage the growth of the case base and prevent performance degradation.

While significant progress has been made in retrieval methods, adaptation remains a substantial challenge due to the complexity and domain-specificity of the required modifications [

31]. To address this, the VDA employs a semi-automatic adaptation model that incorporates rule-based recommendations where appropriate. The system supports human oversight during the adaptation and revision phases, reflecting best practices in decision-support applications.

To process the CBR cycle at the front end of the application (

Figure 3), careful attention was paid to structuring the interface based on the phases mentioned above. First, the problem to be solved is generated as a network of input variables. The term ‘indices’ is used in the descriptions to refer to the tiniest fraction of the knowledge graph. A database query is generated from the input variables described, which checks for a match with existing definitions of a workflow in the case memory. The table in the ‘Retrieve’ section collects the filtered and sorted results. The entry with the best match is at the top of the table. A section declared as a toolbox on the right-hand side of the application contains the contents of the selected retrieved data record. From this selection, the user can easily transfer the elements to the ‘Revise’ and ‘Retain’ areas in the middle of the application. The toolbox also provides access to existing indices and cases via a search window. This option gives the user a uniform way to transfer and adapt the scenario displayed in the centre. Intuitive controls enable both adaptation and case saving.

The Knowledge Graph-oriented data visualisation helps maintain semantic consistency by linking indices, such as requirements or design parameters, to cases that form the problem-solution connection [

25]. The connection between indices and cases is established through relations, which will allow the complete representation of the datasets through a knowledge graph.

3.2. Collaborative Development and Stakeholder Alignment

Development followed the Process-Methods-Competencies (PMC) framework, ensuring alignment between design workflows, supporting tools, and the skills of all participants [

13]. A cross-functional peer group, including mechanical engineers and electronics and automation specialists, was actively involved in testing prototypes and refining the tool to ensure it met the needs of diverse stakeholders.

The mechanical design primarily outlines the basic concept, which is further refined by the accompanying disciplines. The experiment replicates this in two steps. First, mechanical designers work individually based on the tasks outlined in the customer requirements. Engineers from the domains of electronics and software then refine the existing design.

Before taking part, all individuals were fully informed about the purpose and procedures of the study, including the nature of data collection during interviews. Participants gave informed consent, recognising that their responses would be recorded, analysed, and used for scientific publication. It was explicitly stated that all collected data would be anonymised to ensure confidentiality and protect personal identities, in line with relevant ethical guidelines.

To validate the framework, case studies focused on pharmaceutical equipment design tasks were conducted. These scenarios involved mapping customer requirements to functional requirements and design parameters, ensuring traceability and supporting reuse of design knowledge.

To minimise the impact of the software’s capabilities and individual learning curves, the program is operated by the interviewer in all cases, based on the participant’s instructions.

The impact assessment strategy for CADA employed a mixed-methods approach, combining quantitative metrics with structured qualitative feedback to evaluate its effectiveness in enhancing conceptual design processes. Quantitatively, the evaluation included metrics such as the number of reused cases, the percentage of time saved when knowledge support was utilised, and reductions in cycle time across repeated workflows. It also assessed design independence by analysing the degree of functional requirement (FR) and design parameter (DP) decoupling using axiomatic design principles. Rework times were measured across different engineering disciplines to evaluate how the assistant functions influenced downstream design corrections. Additionally, the extent of collaboration was measured by tracking the number of comments and questions generated per workflow.

Qualitatively, structured expert feedback will be collected after the experiment through a series of interview questions. Participants evaluate the usability, support for knowledge reuse, and alignment with agile design principles.

These evaluations ensured the assistant met its goals of improving design quality, supporting knowledge reuse, and enabling agile, collaborative development consistent with Industry 4.0 principles.

4. Results

This section presents the key findings of the study, organised into three main components: (i) the conceptual model of the application; (ii) the design proposals for the user interfaces; and (iii) the validation results derived from a user-centred experimental evaluation.

4.1. Data Model of the Application

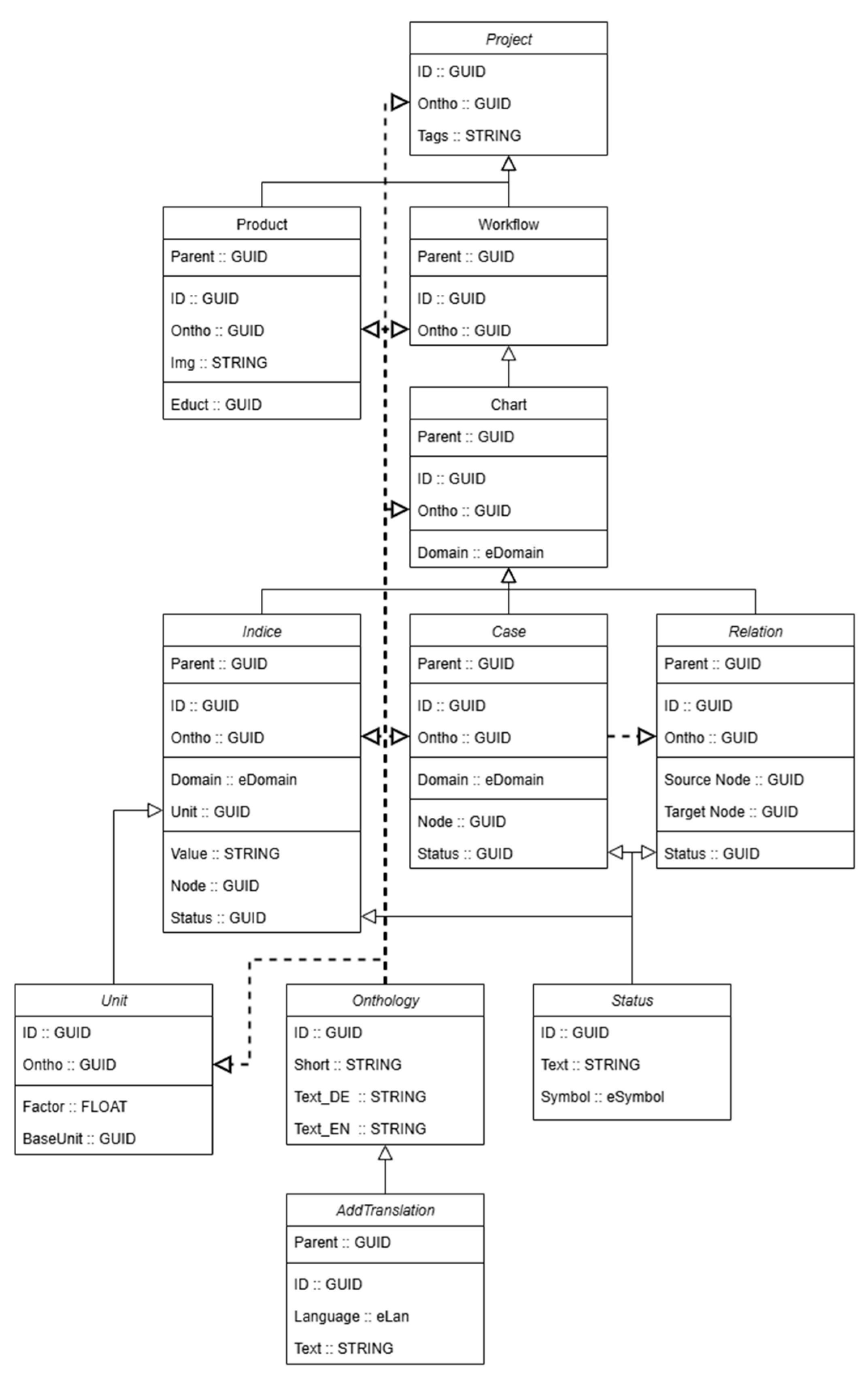

To enable this structured modelling, the following database architecture was developed (

Figure 4). The entry point for the user software is a project in which a designer works on the tasks at hand. Within a project, various workflows are employed as a structured approach to problem-solving. Ideally (but not necessarily), a customer requirement can be processed by an isolated workflow (see 1st axiom—independence of requirements). Within a workflow, there are three charts, each containing two domains of the AD framework, which support the zig-zagging mechanism (targeted work between two domains to focus on the abstraction required in this step) from the AD procedure (Customer Attributes, Functional Requirements, Design Parameters, and Process Variables). Within a chart, there is a finite number of indices per domain, as well as the case modules that map the indices to one another. The connections between the nodes are generated by relations. The backbone of the case database is located in the ontology table. Here, the language elements used are collected and mapped to the individual data records. This results in a deep integration of the language elements into the individual components of the application. In addition to the language element itself, an extended translation can be attached. An index can be completed by a variable element consisting of a numerical value, a conversion factor and a unit. A comment function and a status symbol can extend the graphical elements of a chart. This serves the planned collaboration functionalities, which can be used to strengthen interactive work between different stakeholders.

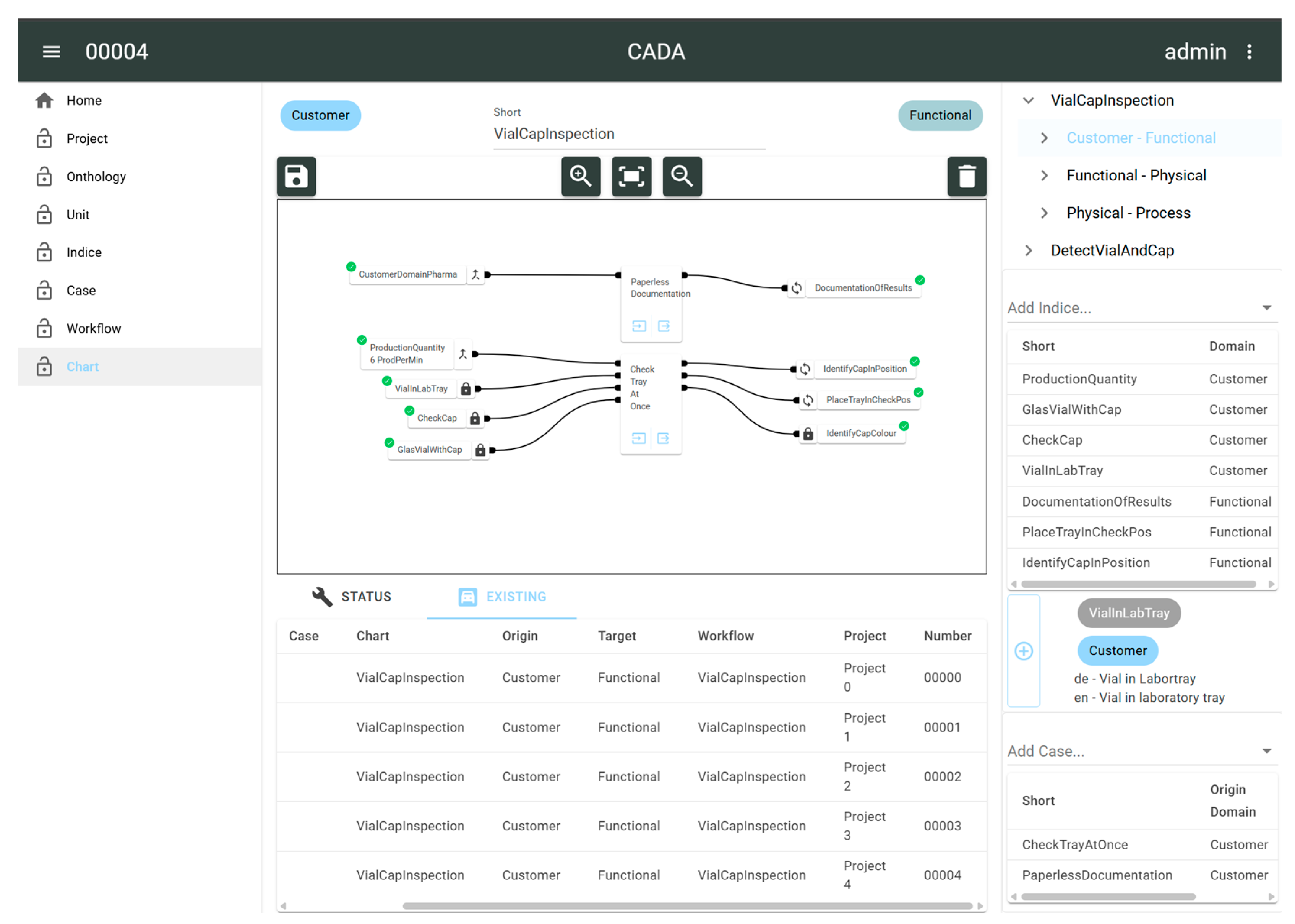

To implement the proposed VDA, we developed a web-based application (

Figure 5) built around a graph-based data representation. The lightweight visualisation offers an accessible, role-adaptable view for diverse stakeholders to inspect models, workflows, and case-based solutions along supportive algorithms for various actions.

The app was implemented using Microsoft Blazor [

32] as the technology stack for the frontend. It is complemented by MudBlazor [

33] as a controls library and Blazor. Diagrams [

34] for the node-based data visualisation. On the backend side, Microsoft.net Core 8 [

35] and ASP.net [

36] are used for the business logic and API calls. To support users in language-related tasks, the free version of the DeepL [

37] translator API is integrated. The backend is divided into two parts: one for user-related data and one for application-related data. Both parts share the same technology framework based on the Entity Framework [

38] to simplify database access. For development purposes, a file-based database like SQLite [

39] is a frequently used way due to its very low initial setup effort. One benefit of the Entity Framework is that the application code can remain largely unchanged when a later switch to an enterprise-grade database is needed. The communication between the frontend and backend is based on SignalR [

34], a real-time, easy-to-use connection and communication technology.

4.2. User Interface of the Application

The core of the application consists of a graphics area (

Figure 6) in which the user can create and connect individual information blocks (nodes). The indices are mapped to the separate domains and cases (central nodes) by dragging and dropping the connection points. Connections that lead to coupled functional requirements are indicated by warning messages on the drawn lines.

The lower half of the work area is divided into two halves. On the left is the comment and discussion function, where the various stakeholders interact. Each message is assigned a status that is displayed in the graphic area at the index. This provides a simple visual overview of the work status. The other half displays information corresponding to the selected dataset.

The main component of the graphical action area are the information nodes that make up the knowledge graph. The index nodes consist of three parts, the middle part containing the ontology term. To the right of the text is a symbol describing the type of information.

Figure 7 shows examples of methods (arrows), requirements (lock) and user actions (people). Each index can be extended by a status. In the example, confirmed requirements (green tick), warnings (orange warning sign) and error messages (red alarm clock) are listed. The case nodes are filled with a text module. In addition, input and output markers can be added. Buttons with input and output symbols are available for this purpose.

The lower half of the application can be switched to the existing references mode (

Figure 8). Here, a filtered and weighted list of existing references to indices or cases is displayed. The user can select a line, and the data records used in the reference are displayed in the toolbox (right-hand column). Here, individual elements can be selected and transferred to the graphic. The lower right-hand corner shows an example of such a transfer card.

4.3. Protocol and Results of the Experiment

To assess the validity of the developed theoretical model and graphical user interface, a series of five experiments was carried out with participants who have professional backgrounds in pharmaceutical engineering and at least seven years of industry experience.

The experiment is conducted as a case study where the participants are asked to design a specific task according to a formal description using the given tool.

To measure the tool’s impact on a conceptual design workflow, the following performance indicators (

Table 1) were evaluated. The individual categories used to analyse the captured data are presented in the headings of the following subchapters.

To ensure all participants started with the same information, the theory was explained and discussed consistently among all peers. C1–C3 required more details about the design workflow concept than C4 and C5, which only evaluated existing work. C4 understood the working principle the fastest, possibly because the Input-Action-Output structure resembles the logic of automation tasks.

To measure the timely impact of the absence of system-side captured knowledge versus recommendation-based design tasks, the overall time needed for one design workflow is measured. C1 started with no information accessible in the system, thus needed the longest. C2 and C3 were supported by the existing knowledge, which reduced the design time by approximately two-thirds (C2/C1 = 0.37; C3/C1 = 0.34)

The candidates C4 and C5 needed more time for the review process of an existing workflow than C2 and C3 needed to create it from scratch, but were informed by the case knowledge data. Review, in this case, means understanding the presented knowledge graph, the information that comes with it, and updating and changing parts of it to revise the work and update the information content.

The Designer clustered the solution around seven cases within the workflow; they followed the same logic, which can be seen as an indicator that the implemented theory is a strong guidance along the design cycle. C4 simplified a part of the solution through the lens of an automation expert and thus created an uncoupled design. C5 again split the case into two individual subparts to better incorporate the knowledge from an electrical engineering perspective. This way of using the tools’ mechanisms points to a working collaboration platform.

According to the CADA framework, the number of indices is a measurable indicator that explains how much information is necessary to explain one problem to its solution path. In this experiment, the participants used around 20 indices to describe the solution. C4 changed parts of the solution of C3, and C5 added information on top of C4.

The design of C3 showed a partially coupled set of indices (

Figure 6) that was reviewed and subsequently uncoupled by C4. All other candidates worked with the principle of graphical feedback from the data relations in the visualisation of the knowledge graph to avoid coupled indices altogether.

The comments function simulated stakeholder interaction and was used by four of the five candidates to gather information about customer requirements or ask questions about the content of the indices. Through the review by C4 and C5, more comments were registered, which indicates that active review comes with the need to exchange information. The CADA application did support this need through the chat-like style on which the comment section is built in coexistence with the context-rich visualisation of the design workflow.

4.4. Main Results of the Experiment

The qualitative feedback on the theory, tool and workflow was organised into the following thematic categories:

General theoretical principles and their implementation into the design workflow

General recommendations for improvement

Applicability of the principles and the tool in complex projects

Table 2 summarises the main results identified in the category related to the general theoretical principles and their implementation. The participants describe the knowledge graph structure as intuitive and easy to understand. The collaboration mechanisms are suitable for the type of information exchanged among stakeholders, including customer requirements and feedback. The tool actively helps in developing a solution for a given problem.

The user feedback with general recommendations for improvement is presented in

Table 3. The user interface should be improved to make the incorporated principles easier to understand. The application should be enhanced to encourage user participation and foster creativity.

The assessments of the respondents regarding the transferability of the application to complex projects are listed in

Table 4. The application is likely capable of handling complex projects, as its workflow-oriented structure supports dividing tasks into smaller, manageable parts.

5. Discussion

Visual Design Assistants are increasingly vital for supporting conceptual design, especially in fields like engineering and pharmaceutical development, where systems are complex, multidisciplinary, and requirements evolve continuously. A significant advancement in this area is the integration of knowledge graphs, which enhance traceability, enable intelligent reasoning, and promote the reuse of design knowledge. An example system is the Case-Based Axiomatic Design Assistant (CADA), which exemplifies this progress by merging Axiomatic Design (AD) principles with Case-Based Reasoning (CBR) to facilitate structured, visual, and adaptive conceptual design.

Feedback from the participants has shown that the tool’s structure is intuitive and that using knowledge graphs in combination with AD as an active design support is particularly effective. The way how the AD principles are incorporated into the UI could benefit from some improvement in an extended version. CADA’s approach uniquely combines the rigorous theory of AD—linking functional requirements (FRs) with design parameters (DPs)—with CBR, which facilitates learning from and reusing old design cases. This hybrid approach is realised within a visual environment supported by a knowledge graph that organises design data and allows for dynamic case adjustments. Unlike earlier VDA systems like those by Ref. [

40], which relied on static domain ontologies and rule-based reasoning, CADA offers more flexible and iterative workflows that can adapt across different domains.

A recent notable development in this field is a system that leverages a knowledge graph for structural configuration in engineering equipment [

41]. It effectively retrieves structural information from patent databases through entity extraction and graph-based association models. Nonetheless, this approach mainly focuses on domain-specific knowledge and does not cover functional abstraction or reasoning about design rationale, which are core to the CADA method. Similarly, the context-aware cognitive design assistant (CACDA) introduced by Ref. [

42] offers real-time guidance via rule-based reasoning embedded in CAD software, enhancing rule application efficiency. However, CACDA emphasises rule compliance accuracy over conceptual exploration, a vital aspect in early-stage design that CADA aims to support.

One of the key takeaways from the experiment was the strong motivation to contribute to and understand the entire solution, rather than just the parts where their expertise could be applied. The app could enhance this by introducing more collaboration and creativity mechanisms. CADA’s collaborative aspect embodies Industrie 4.0 principles by encouraging decentralised and transparent decision-making. Its visual and collaborative functionalities differ from the isolated use of domain-specific engineering environments.

In particular, CADA offers mechanisms like shared annotations, inference visualisations and case discussions. This facilitates agile, cross-disciplinary development crucial in current engineering settings, where quick iteration and the reuse of validated knowledge are vital for maintaining a competitive edge.

In summary, CADA is a comprehensive and adaptable advancement in visual design assistants, grounded in theory and practical application. It combines structured knowledge, case reuse, visual reasoning, and collaborative support to offer a scalable solution that improves design quality and supports agile engineering workflows across diverse fields. Its alignment with Industry 4.0 principles and its strong performance in encouraging FR–DP decoupling and knowledge reapplication make it a key reference in the development of intelligent conceptual design tools.

6. Conclusions

The combined results show that CADA provides both theoretical and practical benefits to the field of conceptual design in complex engineering areas. Theoretically, CADA improves design methodology by combining Axiomatic Design with Case-Based Reasoning and Knowledge Graphs, creating a structured and flexible framework for handling functional requirements, solution principles, and reusable knowledge. This combination supports design theory by offering a model that enables traceability, modular reasoning, and formal assessment of design independence through FR–DP decoupling. Practically, the system enhances design quality, reduces development effort, and fosters agile, cross-disciplinary teamwork. Its alignment with Industry 4.0 like principles, such as interoperability, decentralised decision-making, real-time responsiveness, and user-centred development, demonstrates its relevance in real-world, high-complexity contexts like pharmaceutical manufacturing. Moreover, the collaborative features and knowledge reuse mechanisms lead to tangible improvements in design efficiency and cross-team collaboration.

The assessment of the application is limited to a conceptual validation of its working principle due to the small sample size of test users. To gain statistical significance, a larger-scale validation involving end users needs to be conducted to evaluate performance metrics. As the group of experts was chosen from a single company, there is a potential for selection bias among the test users. Future validation should include a more diverse user group across different companies. To further enhance the applicability metrics, the evaluation scope must be expanded to cover a broader range of applications and include long-term use of the tool.

Future work should aim to extend the system’s practical usability by enhancing its interface with creativity-support methods and gamification features, thereby increasing user engagement and supporting ongoing innovation in iterative design environments.

Author Contributions

Conceptualization, R.W.; methodology, R.W.; software, R.W.; validation, R.W., L.T. and I.S.-A.; formal analysis, R.W.; investigation, R.W.; resources, R.W.; data curation, R.W.; writing—original draft preparation, R.W.; writing—review and editing, R.W., L.T. and I.S.-A.; visualization, R.W.; supervision, L.T. and I.S.-A.; project administration, R.W. All authors have read and agreed to the published version of the manuscript.

Funding

The present study was developed in the scope of IDU at pester pac automation GmbH, NECE-UBI, Research Centre for Business Sciences (UIDB/04630/2020) and the Institute of Electronics and Informatics Engineering of Aveiro (IEETA) (UIDB/00127/2020) both funded by national funds through FCT–Fundação para a Ciência e a Tecnologia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data from this study can be obtained by contacting the corresponding author, as they are subject to individual intellectual property rights of the participants and the hosting company.

Conflicts of Interest

The author, Roland Wölfle, was employed by the company pester pac automation GmbH, Germany. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| MBSE | Model-Based Systems Engineering |

| DT | Digital Twin |

| GMP | Good Manufacturing Practice |

| MDE | Model-Driven Engineering |

| KBE | Knowledge-Based Engineering |

| QFD | Quality Function Deployment |

| CADA | Case-Based Axiomatic Design Assistant |

| DRM | Design Research Methodology |

| CBR | Case-Based Reasoning |

| XAI | Explainable Artificial Intelligence |

| VDA | Virtual Design Assistant |

| SDTF | SysML Document Traceability Framework |

| InVEST | Interactive Visualisation Engine for SysML Tools |

| PMC | Process-Methods-Competencies |

| AD | Axiomatic Design |

| FR | Functional Requirement |

| DP | Design Parameter |

| CACDA | Context-Aware Cognitive Design Assistant |

References

- Pedro, F.; Veiga, F.; Mascarenhas-Melo, F. Impact of GAMP 5, data integrity and QbD on quality assurance in the pharmaceutical industry: How obvious is it? Drug Discov. Today 2023, 28, 103759. [Google Scholar] [CrossRef]

- Assawarungsri, T.; Janthong, N. An Integration Matrix for Investigating the Impact of Design Changes in Mechatronic Products. Designs 2023, 7, 16. [Google Scholar] [CrossRef]

- Wiesner, S.; Marilungo, E. Cyber-Physical Product-Service Systems—Challenges for Requirements Engineering. Int. J. Autom. Technol. 2017, 11, 17–28. [Google Scholar] [CrossRef]

- Madni, A.M.; Sievers, M. Model-based systems engineering: Motivation, current status, and research opportunities. Syst. Eng. 2018, 21, 172–190. [Google Scholar] [CrossRef]

- Steinwandter, V.; Borchert, D.; Herwig, C. Data science tools and applications on the way to Pharma 4.0. Drug Discov. Today 2019, 24, 1795–1805. [Google Scholar] [CrossRef] [PubMed]

- Dworschak, F.; Kügler, P.; Schleich, B.; Wartzack, S. Model and Knowledge Representation for the Reuse of Design Process Knowledge Supporting Design Automation in Mass Customization. Appl. Sci. 2021, 11, 9825. [Google Scholar] [CrossRef]

- Chu, X.-Z.; Gao, L.; Qiu, H.-B.; Li, W.-D.; Shao, X.-Y. An expert system using rough sets theory and self-organizing maps to design space exploration of complex products. Expert Systems with Appl. 2010, 37, 7364–7372. [Google Scholar] [CrossRef]

- Estévez, E.; Marcos, M. An Approach to use Model Driven Design in Industrial Automation. In Proceedings of the 2008 IEEE International Conference on Emerging Technologies and Factory Automation, Proceedings, Hamburg, Germany, 15–18 September 2008; pp. 62–65. [Google Scholar]

- Hehenberger, P.; Zeman, K.; IEEE. Design activities in the development process of mechatronic systems. In Proceedings of the 2007 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Zurich, Switzerland, 4–7 September 2007; Volumes 1–3, pp. 817–822. [Google Scholar]

- Bavendiek, A.K.; Inkermann, D.; Vietor, T. Interrelations between processes, methods, and tools in collaborative design—A framework. In Proceedings of the 21st International Conference on Engineering Design (ICED 17), Vol. 8: Human Behaviour in Design, Vancouver, BC, Canada, 21–25 August 2017; pp. 349–358. [Google Scholar]

- Bouhali, I.; Idasiak, V.; Martinez, J.; Mhenni, F.; Choley, J.Y.; Palladino, L.; Kratz, F. A Collaboration Framework Using Digital Twin for Dynamic Simulation and Requirements Verification Based on MBSE and the MIC Concept. In Proceedings of the 2024 IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 15–18 April 2024; pp. 1–8. [Google Scholar]

- Wölfle, R.; Saur-Amaral, I.; Teixeira, L. Information Model for Pharmaceutical Smart Factory Equipment Design. Information 2025, 16, 412. [Google Scholar] [CrossRef]

- Ding, B.Y. Pharma Industry 4.0: Literature review and research opportunities in sustainable pharmaceutical supply chains. Process Saf. Environ. Prot. 2018, 119, 115–130. [Google Scholar] [CrossRef]

- Barenji, R.V.; Akdag, Y.; Yet, B.; Oner, L. Cyber-physical-based PAT (CPbPAT) framework for Pharma 4.0. Int. J. Pharm. 2019, 567, 18445. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Meister, F.; Khanal, P.; Daub, R. Digital-supported problem solving for shopfloor steering using case-based reasoning and Bayesian networks. Procedia CIRP 2023, 119, 140–145. [Google Scholar] [CrossRef]

- Bhatt, S.; Sheth, A.; Shalin, V.; Zhao, J.J. Knowledge Graph Semantic Enhancement of Input Data for Improving AI. IEEE Internet Comput. 2020, 24, 66–72. [Google Scholar] [CrossRef]

- Li, B.M.; Xie, S.Q.; Xu, X. Recent development of knowledge-based systems, methods and tools for One-of-a-Kind Production. Knowl.-Based Syst. 2011, 24, 1108–1119. [Google Scholar] [CrossRef]

- Chan, L.K.; Wu, M.L. Quality function deployment: A literature review. Eur. J. Oper. Res. 2002, 143, 463–497. [Google Scholar] [CrossRef]

- Kellner, A.; Ringhofer, S.; Hehenberger, P.; Weingartner, L.; Friedl, M. The impact on organizational structures of model-based mechatronic system design. In Proceedings of the 3rd International Conference on System-Integrated Intelligence: New Challenges for Product and Production Engineering, Paderborn, Germany, 13–15 June 2016; pp. 333–340. [Google Scholar]

- Blessing, L.T.M.; Chakrabarti, A. DRM, a Design Research Methodology; Springer: London, UK, 2009. [Google Scholar]

- Caro-Martínez, M.; Recio-García, J.A.; Díaz-Agudo, B.; Darias, J.M.; Wiratunga, N.; Martin, K.; Wijekoon, A.; Nkisi-Orji, I.; Corsar, D.; Pradeep, P.; et al. iSee: A case-based reasoning platform for the design of explanation experiences. Knowl. Based Syst. 2024, 302, 112305. [Google Scholar] [CrossRef]

- Kim, S.G.; Yoon, S.M.; Yang, M.; Choi, J.; Akay, H.; Burnell, E. AI for design: Virtual design assistant. Cirp Ann. Manuf. Technol. 2019, 68, 141–144. [Google Scholar] [CrossRef]

- Trase, K.; Fink, E. A Model-Driven Visualization Tool for Use with Model-Based Systems Engineering Projects. In Proceedings of the 2014 IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2014. [Google Scholar]

- Wölfle, R.; Saur-Amaral, I.; Teixeira, L. Case-Based Axiomatic Design Assistant (CADA): Combining Axiomatic Design and Case-Based Reasoning to Create a Design Knowledge Graph for Pharmaceutical Engineering. Appl. Sci. 2025, 15, 1467. [Google Scholar] [CrossRef]

- Suh, N.P.; Cochran, D.S.; Lima, P.C. Manufacturing System Design. CIRP Ann. 1998, 47, 627–639. [Google Scholar] [CrossRef]

- Aamodt, A.; Plaza, E. Case-based reasoning—Foundational issues, methodological variations, and system approaches. AI Commun. 1994, 7, 39–59. [Google Scholar] [CrossRef]

- Cunningham, P.; Bonzano, A. Knowledge engineering issues in developing a case-based reasoning application. Knowl. Based Syst. 1999, 12, 371–379. [Google Scholar] [CrossRef]

- deMantaras, R.L.; Plaza, E. Case-based reasoning: An overview. AI Commun. 1997, 10, 21–29. [Google Scholar]

- Schultheis, A.; Zeyen, C.; Bergmann, R. An Overview and Comparison of Case-Based Reasoning Frameworks. In Proceedings of the Case-Based Reasoning Research and Development, ICCBR 2023, Aberdeen, UK, 17–20 July 2023; pp. 327–343. [Google Scholar]

- Yan, A.J.; Cheng, Z.J. A Review of the Development and Future Challenges of Case-Based Reasoning. Appl. Sci. 2024, 14, 7130. [Google Scholar] [CrossRef]

- Blazor, Version 8.0.18; NET Foundation; Microsoft: Redmond, WA, USA, 2024.

- Larsson, J. MudBlazor; Version 8.6.0; MudBlazor: Gardnet AB, Sweden, 2024. [Google Scholar]

- Zanid, H. Blazor.Diagrams, Version 3.0.3; Blazor.Diagrams Contributors: 2024; Available online: https://github.com/Blazor-Diagrams/Blazor.Diagrams (accessed on 15 August 2025).

- NET 8, Version 8.0.18; NET Foundation; Microsoft: Redmond, WA, USA, 2024.

- ASP.NET, Version 8.0.18; NET Foundation; Microsoft: Redmond, WA, USA, 2024.

- Kutyłowski, J. DeepL API; Version 3.0.3; DeepL SE: Cologne, Germany, 2024. [Google Scholar]

- Entity Framework Core; Version 8.0.11; NET Foundation; Microsoft: Redmond, WA, USA, 2024.

- Hipp, D.R. SQLite, Version 3.50.4; SQLite Consortium: Charlotte, NC, USA, 2024. [Google Scholar]

- Kraft, B.; Nagl, M. Visual knowledge specification for conceptual design: Definition and tool support. Adv. Eng. Inform. 2007, 21, 67–83. [Google Scholar] [CrossRef]

- Huang, Z.C.; Guo, X.; Li, J.; Zhao, W.; Wang, J.; Li, Q.P. A field-based knowledge graph assisted conceptual design for structure configuration of engineering equipment. J. Eng. Des. 2024, 36, 1279–1301. [Google Scholar] [CrossRef]

- Huet, A.; Pinquié, R.; Véron, P.; Mallet, A.; Segonds, F. CACDA: A knowledge graph for a context-aware cognitive design assistant. Comput. Ind. 2021, 125, 103377. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).