A Study of Mechanics in Brittle–Ductile Cutting Mode Transition

Abstract

:1. Introduction

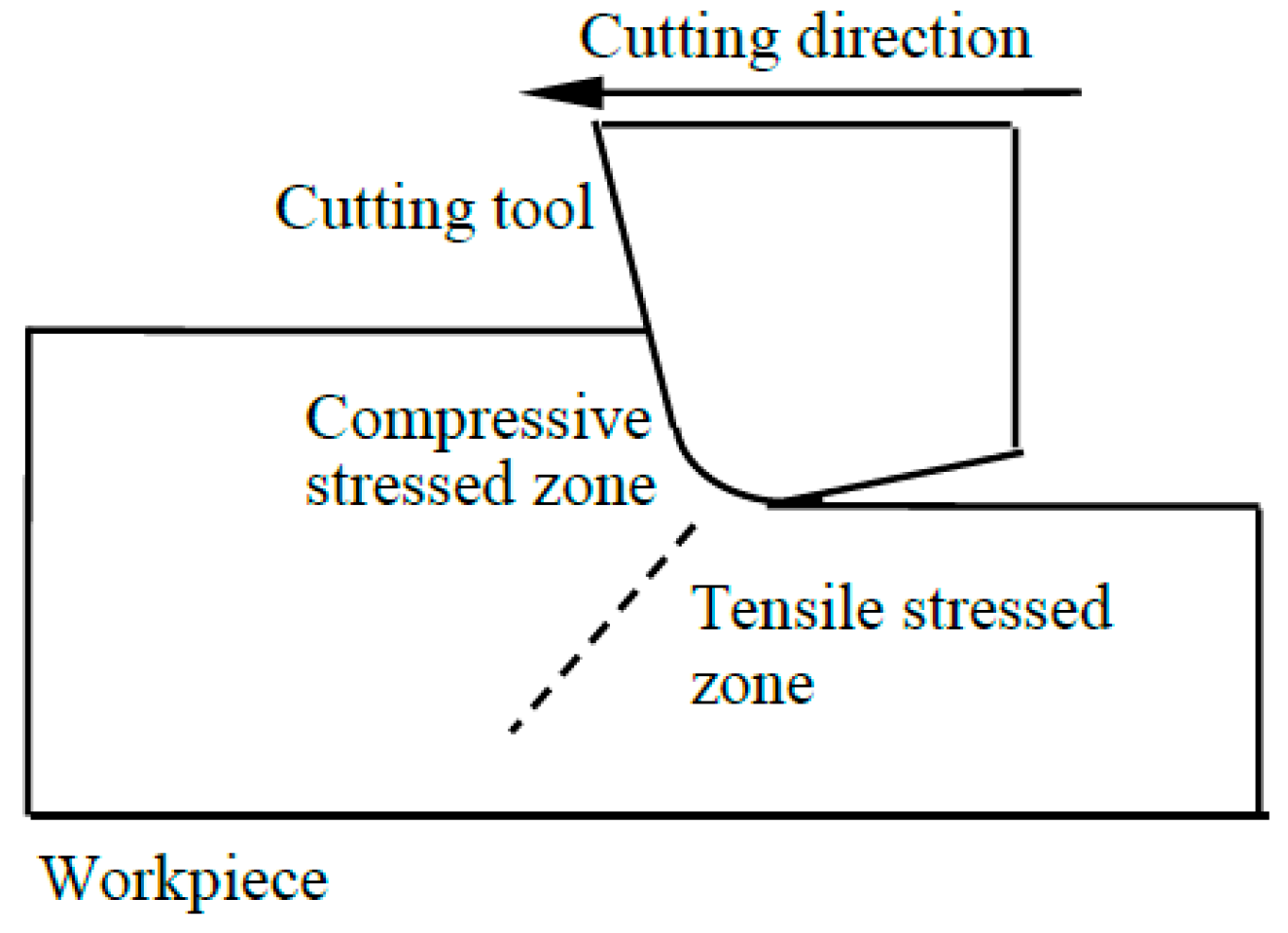

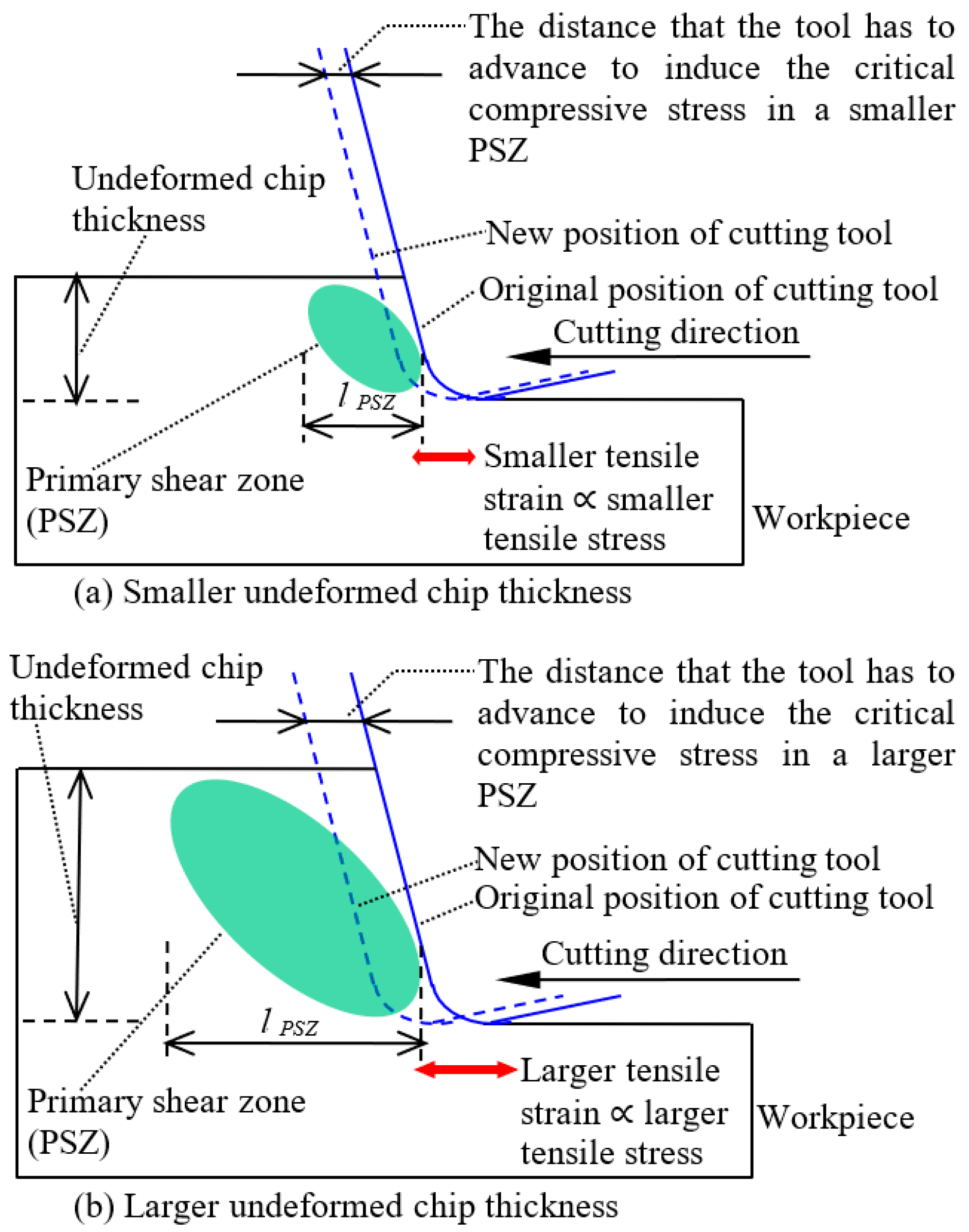

2. Mechanics of Brittle–Ductile Cutting Mode Transition

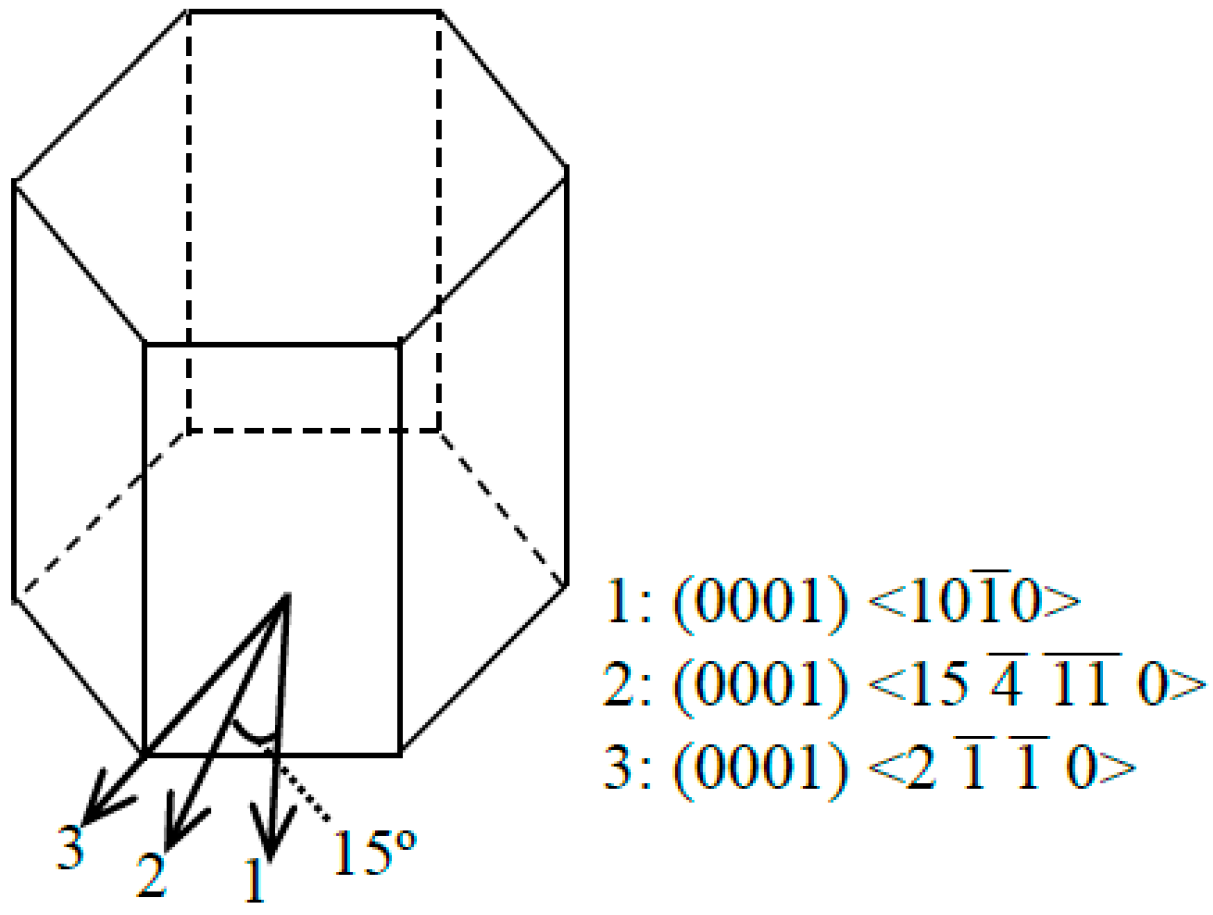

3. Examination of the Theory on 6H-SiC

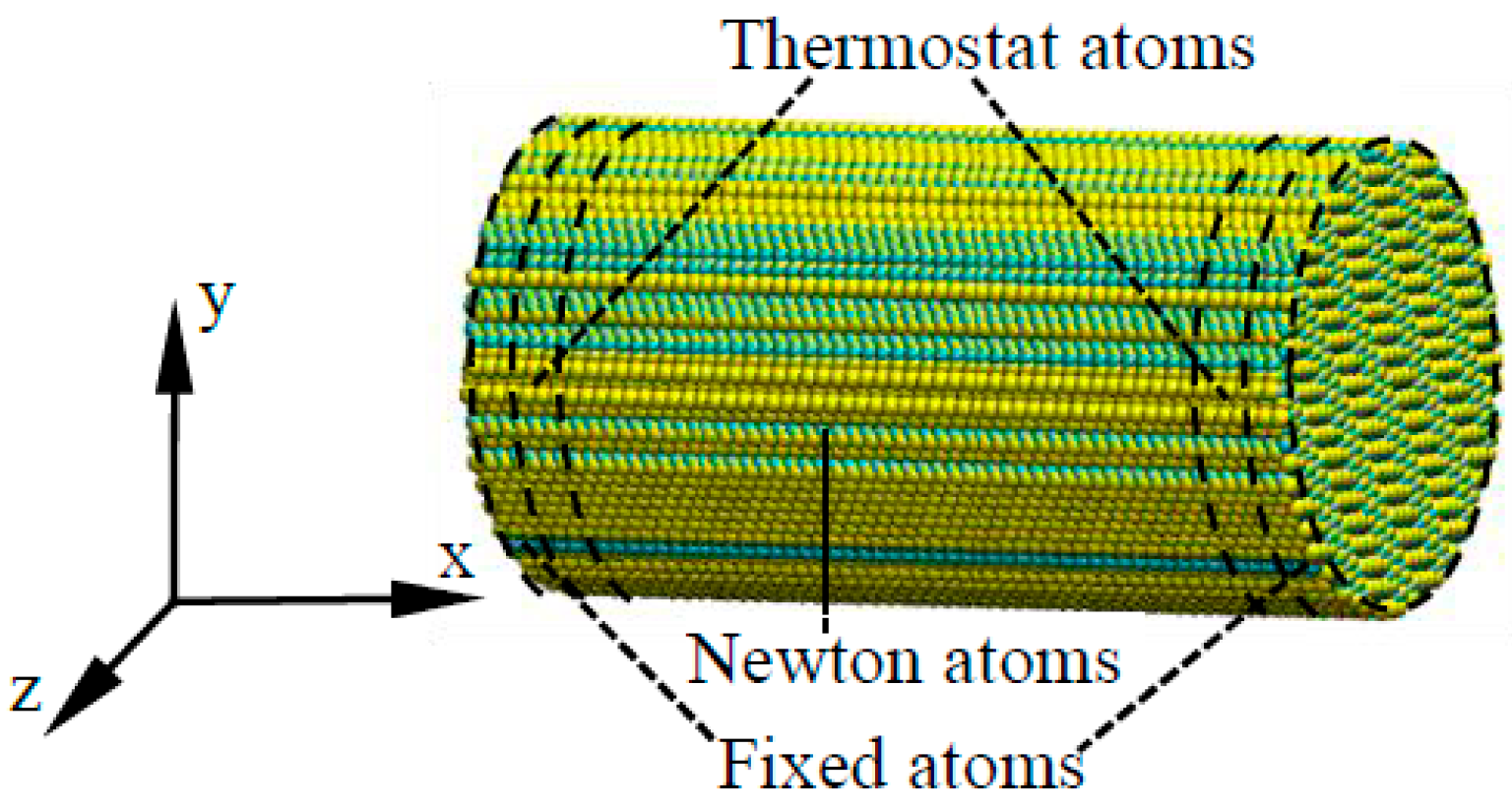

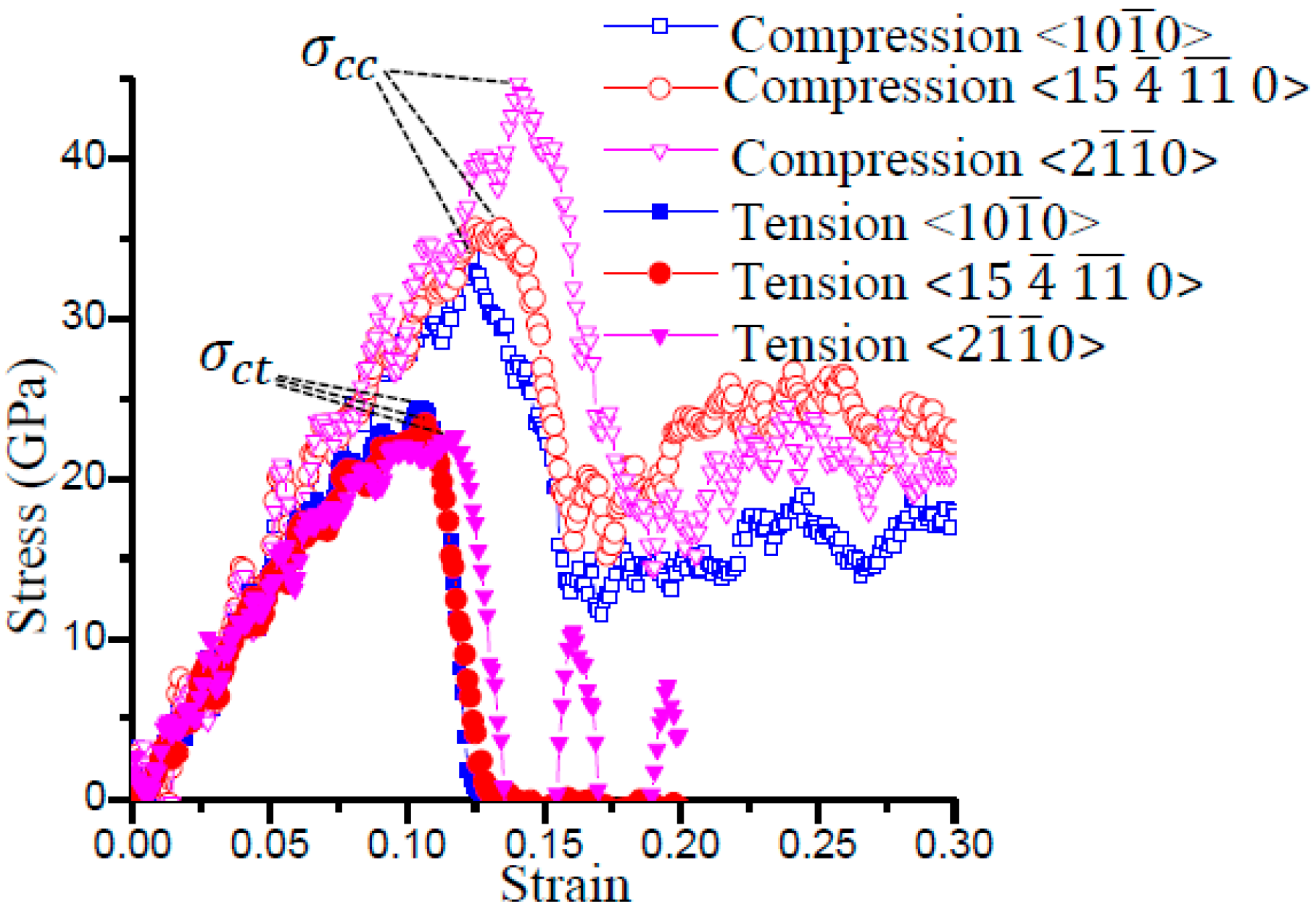

3.1. Molecular Dynamics (MD) Simulation of Mechanical Properties

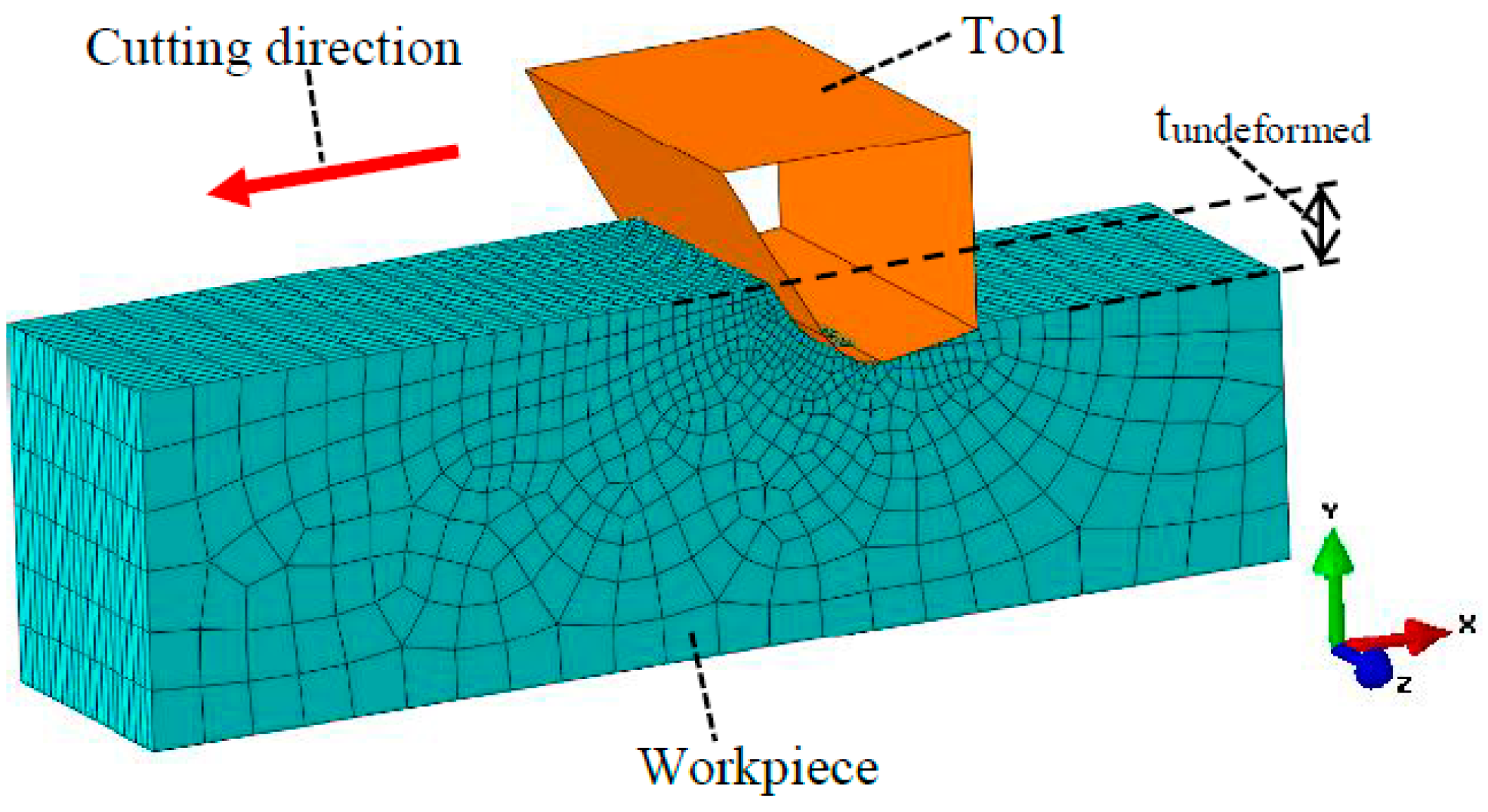

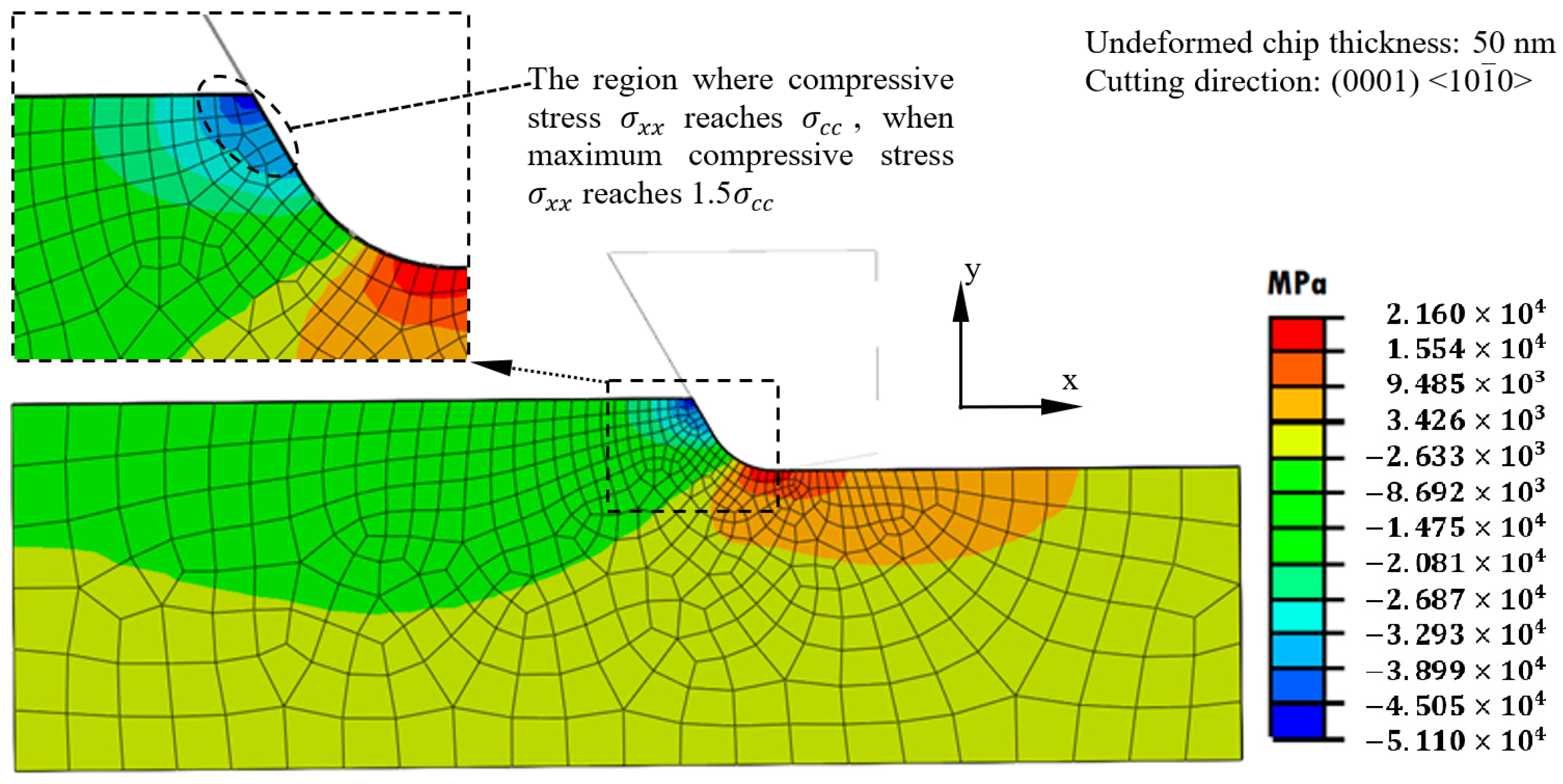

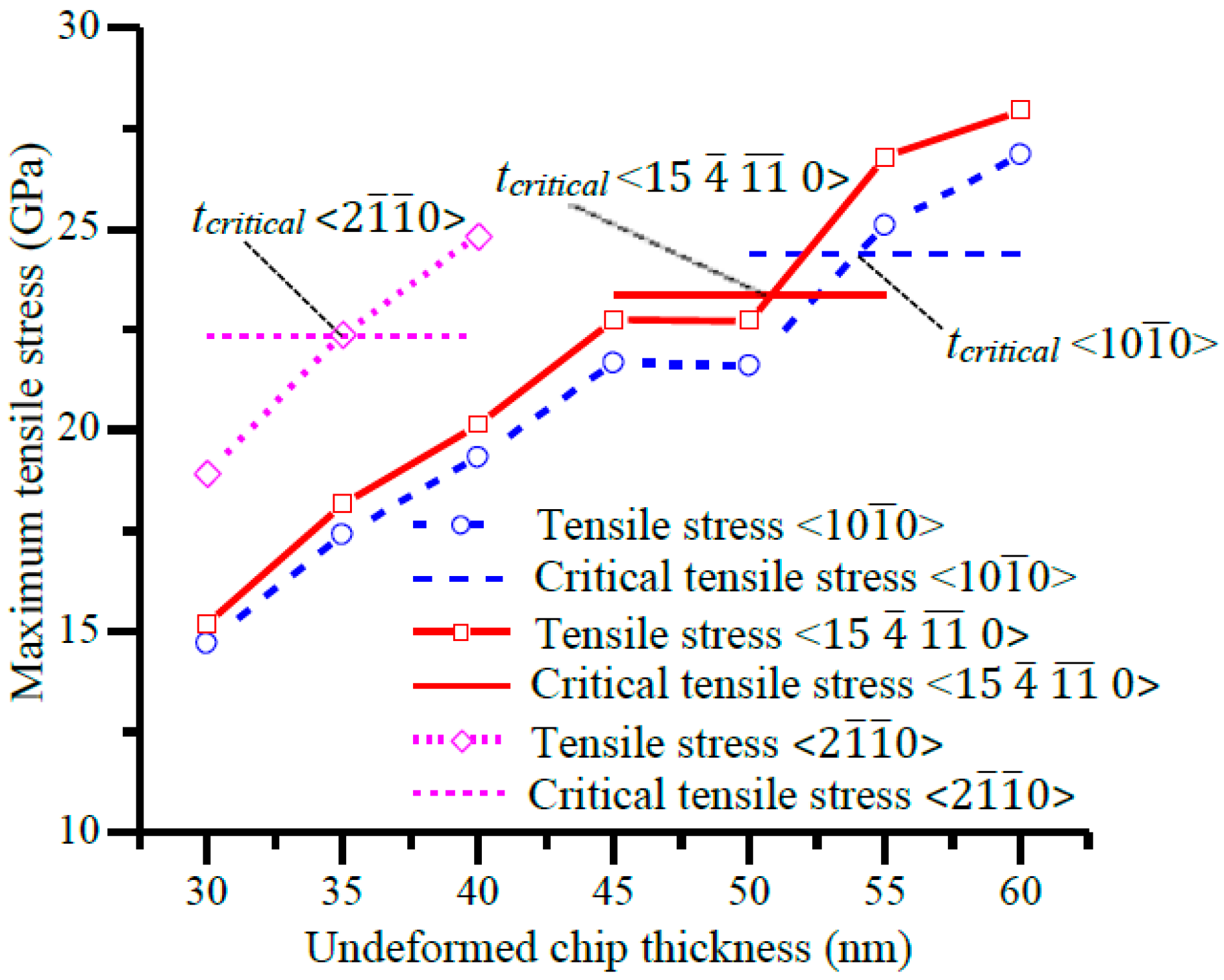

3.2. Finite Element Method (FEM) Modelling of the Stress States

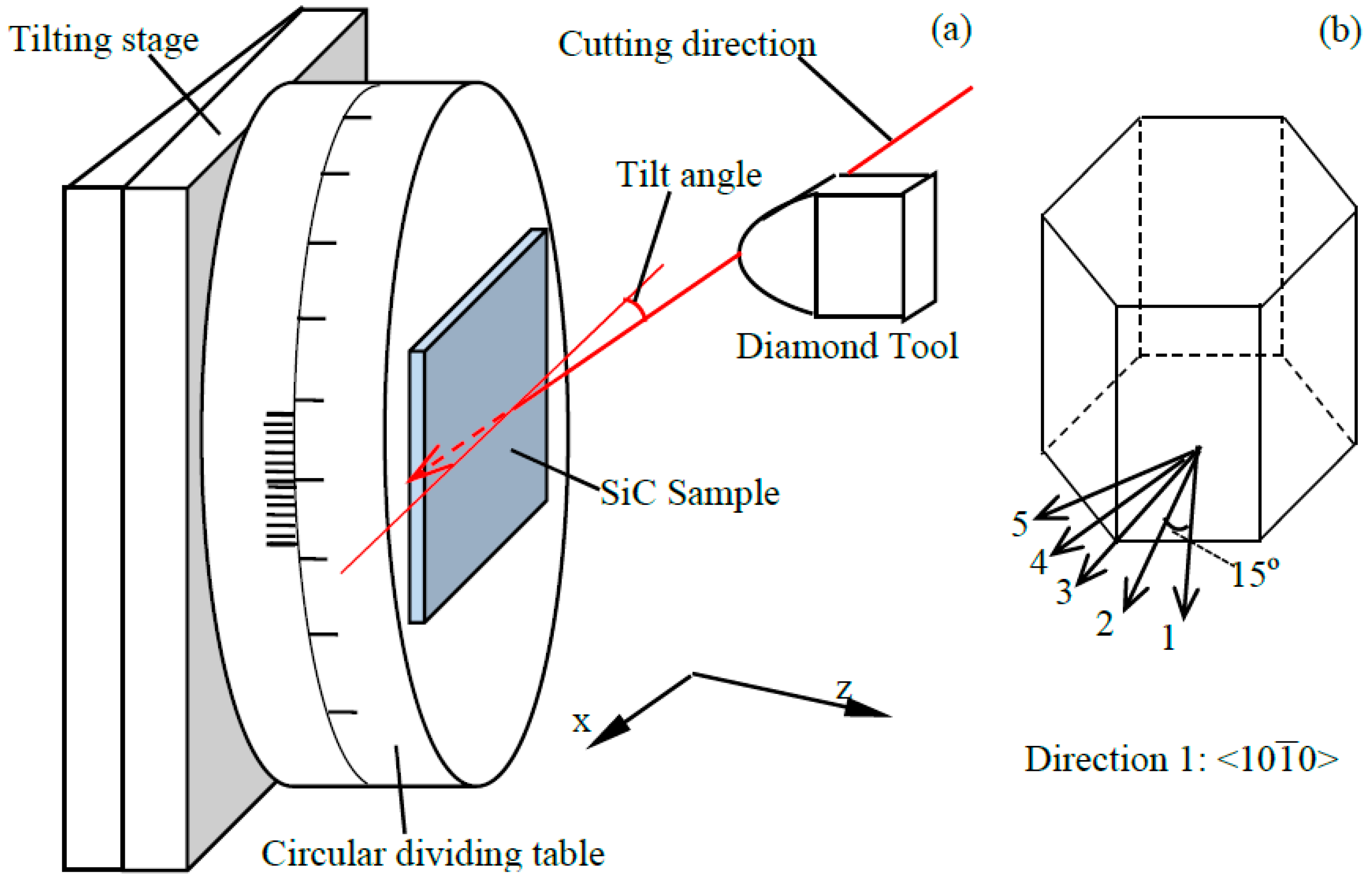

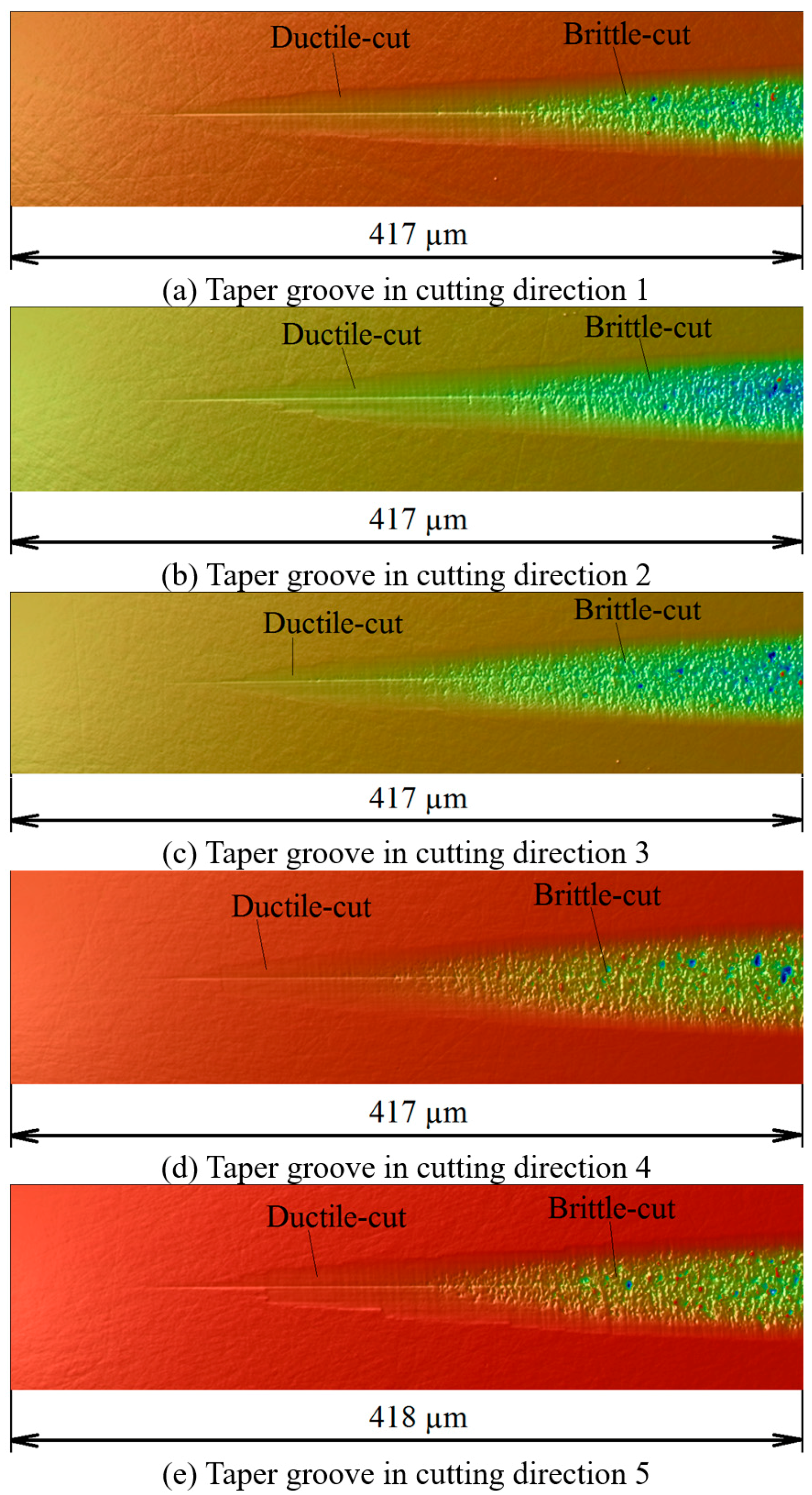

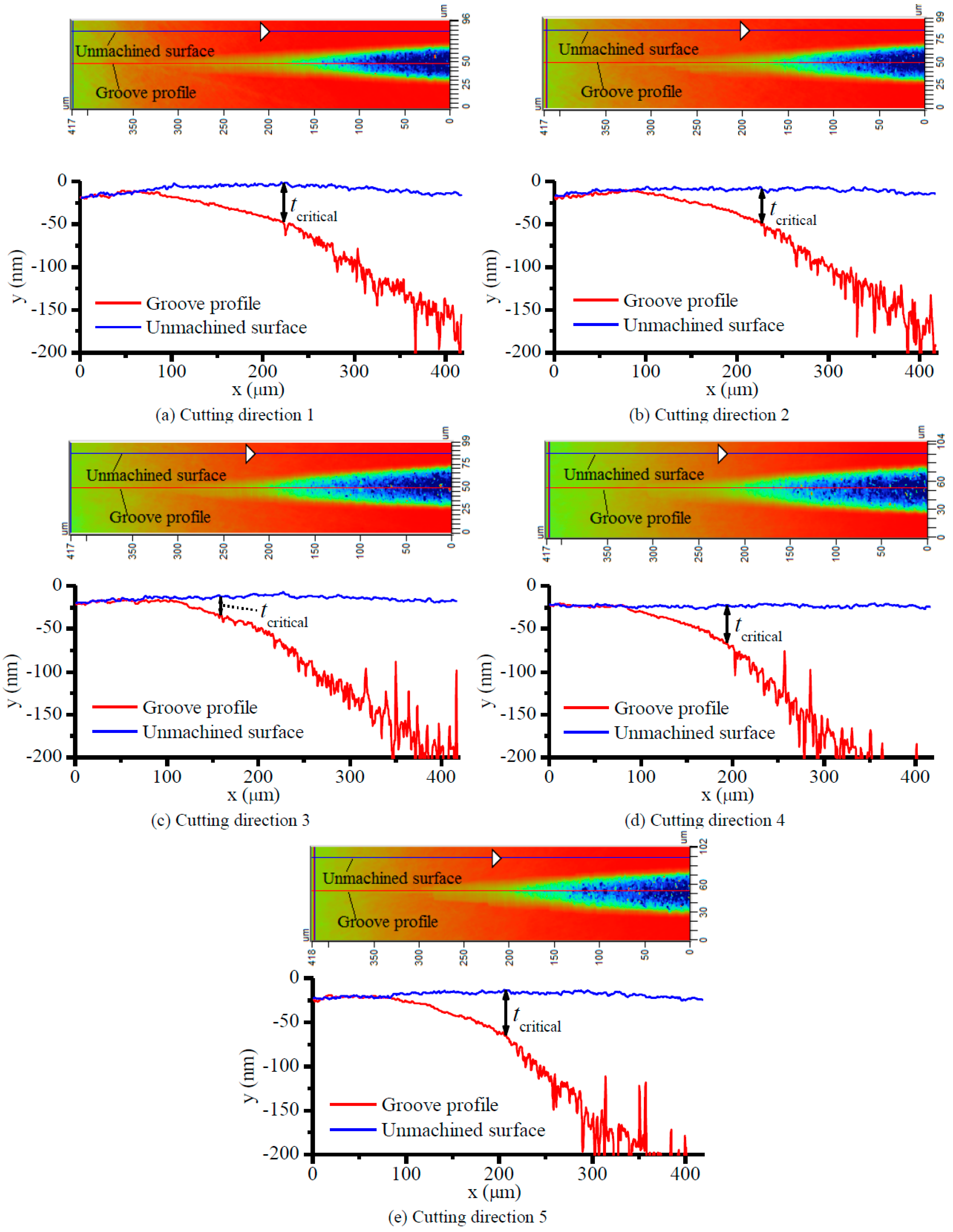

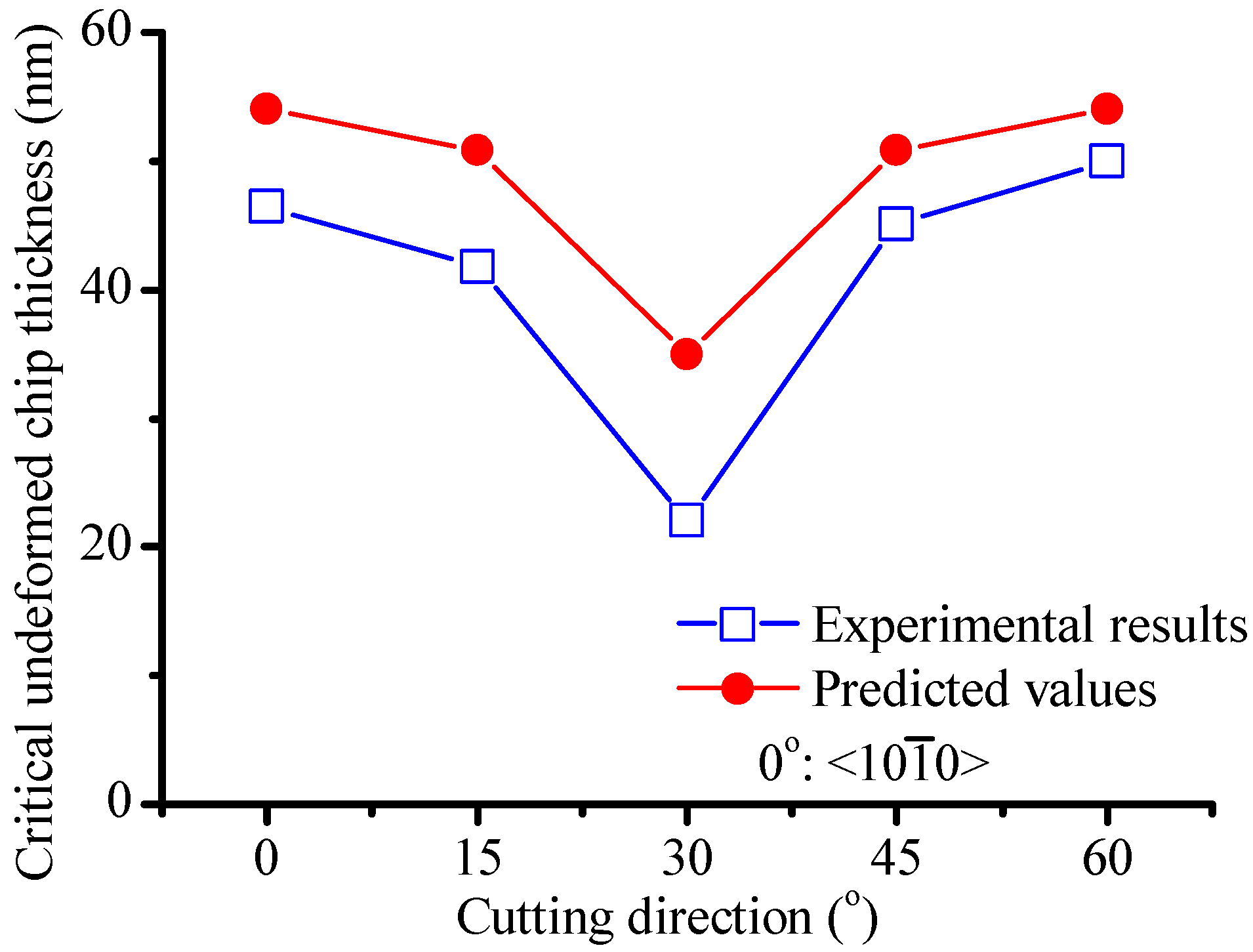

3.3. Experimental Verification

4. Discussion

5. Conclusions

- I.

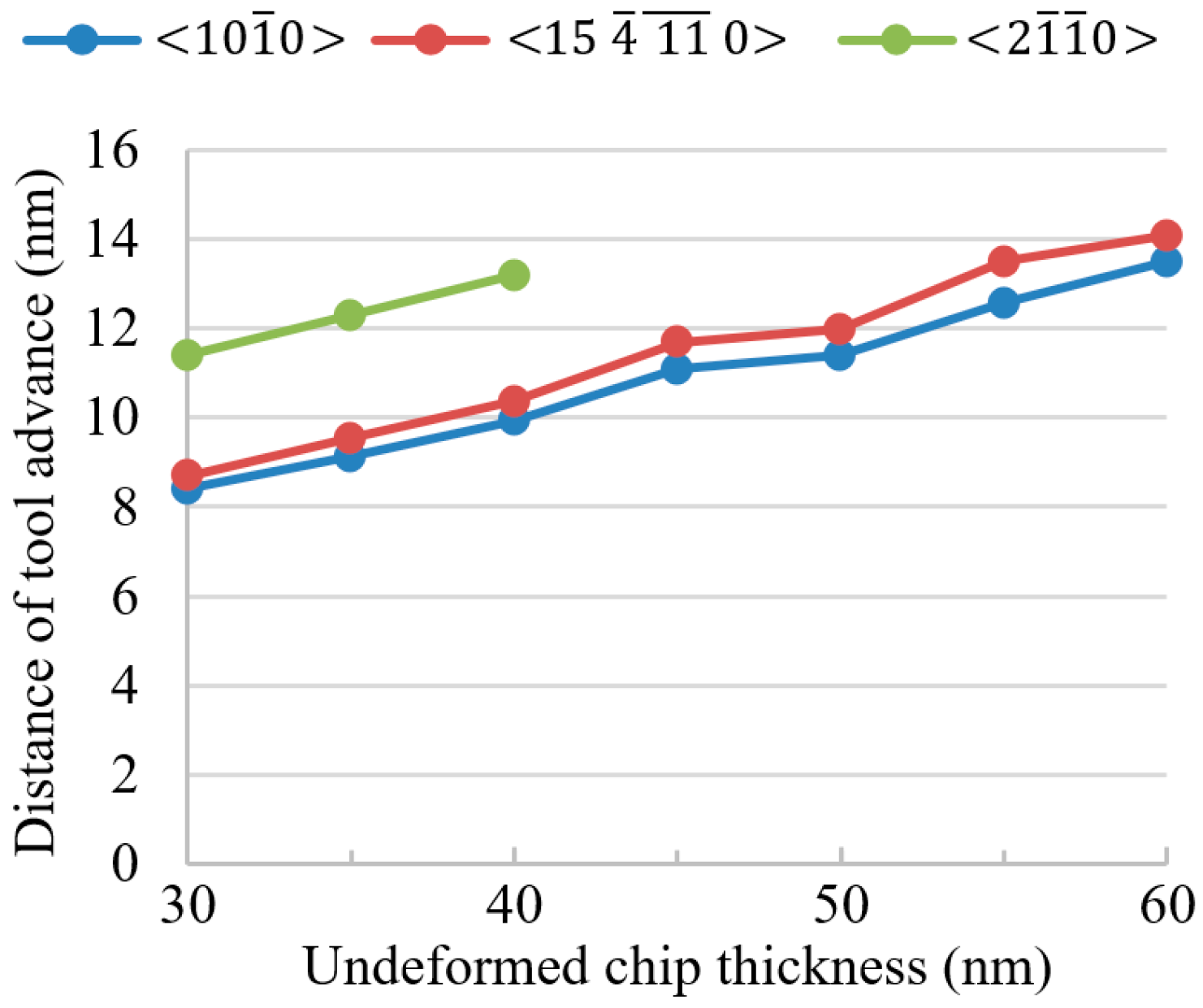

- The distance of tool advancement required to induce the same magnitude of critical compressive stress decreases with undeformed chip thickness, and consequently the tensile stress induced below and behind the tool also decreases with undeformed chip thickness.

- II.

- The tensile stress would become lower than the critical tensile stress for brittle fracture when the undeformed chip thickness becomes sufficiently small, and thereby becomes insufficient to induce brittle fractures. Hence the decrease of tensile stress with the decrease of undeformed chip thickness is considered to be the key factor for enabling brittle–ductile cutting mode transition.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Blackley, W.S.; Scattergood, R.O. Ductile-regime machining model for diamond turning of brittle materials. Precis. Eng. 1991, 13, 95–103. [Google Scholar] [CrossRef]

- Bifano, T.G.; Dow, T.A.; Scattergood, R.O. Ductile-regime grinding: A new technology for machining brittle materials. J. Eng. Ind. 1991, 113, 184–189. [Google Scholar] [CrossRef]

- Arif, M.; Xinquan, Z.; Rahman, M.; Kumar, S. A predictive model of the critical undeformed chip thickness for ductile-brittle transition in nano-machining of brittle materials. Int. J. Mach. Tools Manuf. 2013, 64, 114–122. [Google Scholar] [CrossRef]

- Cheng, J.; Wu, J.; Gong, Y.D.; Wen, X.L.; Wen, Q. Experimental study on the single grit interaction behaviour and brittle–ductile transition of grinding with a diamond micro-grinding tool. Int. J. Adv. Manuf. Technol. 2016, 91, 1029–1226. [Google Scholar] [CrossRef]

- Mizumoto, Y.; Maas, P.; Kakinuma, Y.; Min, S. Investigation of the cutting mechanisms and the anisotropic ductility of monocrystalline sapphire. CIRP Ann.-Manuf. Technol. 2017, 66, 89–92. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Zhang, Y.; Jia, D.; Zhang, X.; Hou, Y.; Li, R.; Wang, J. Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions. Int. J. Mach. Tools Manuf. 2017, 122, 56–65. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Fang, H.; Tian, R. Influence of cutting parameters on the ductile-brittle transition of single-crystal calcium fluoride during ultra-precision cutting. Int. J. Adv. Manuf. Technol. 2017, 89, 219–225. [Google Scholar] [CrossRef]

- Chen, J.B.; Fang, Q.H.; Wang, C.C.; Du, J.K.; Liu, F. Theoretical study on brittle–ductile transition behavior in elliptical ultrasonic assisted grinding of hard brittle materials. Precis. Eng. 2016, 46, 104–117. [Google Scholar] [CrossRef]

- Zhou, M.; Zhao, P. Prediction of critical cutting depth for ductile-brittle transition in ultrasonic vibration assisted grinding of optical glasses. Int. J. Adv. Manuf. Technol. 2016, 86, 1775–1784. [Google Scholar] [CrossRef]

- Nakasuji, T.; Kodera, S.; Hara, S.; Matsunaga, H.; Ikawa, N.; Shimada, S. Diamond turning of brittle materials for optical components. CIRP Ann.-Manuf. Technol. 1990, 39, 89–92. [Google Scholar] [CrossRef]

- Shimada, S.; Ikawa, N.; Inamura, T.; Takezawa, N.; Ohmori, H.; Sata, T. Brittle–ductile transition phenomena in microindentation and micromachining. CIRP Ann.-Manuf. Technol. 1995, 44, 523–526. [Google Scholar] [CrossRef]

- Ueda, K.; Sugita, T.; Tsuwa, H. Application of fracture mechanics in micro-cutting of engineering ceramics. CIRP Ann.-Manuf. Technol. 1983, 32, 83–86. [Google Scholar] [CrossRef]

- Ueda, K.; Sugita, T.; Hiraga, H.; Iwata, K. A j-integral approach to material removal mechanisms in microcutting of ceramics. CIRP Ann.-Manuf. Technol. 1991, 40, 61–64. [Google Scholar] [CrossRef]

- Hiatt, G.D. A Fracture Mechanics Technique for Predicting the Ductile Regime in Single Point Diamond Turning of Brittle Materials. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 1992. [Google Scholar]

- Venkatachalam, S.; Li, X.; Liang, S.Y. Predictive modeling of transition undeformed chip thickness in ductile-regime micro-machining of single crystal brittle materials. J. Mater. Process. Technol. 2009, 209, 3306–3319. [Google Scholar] [CrossRef]

- Fang, F.; Venkatesh, V. Diamond cutting of silicon with nanometric finish. CIRP Ann.-Manuf. Technol. 1998, 47, 45–49. [Google Scholar] [CrossRef]

- Liu, K.; Li, X. Ductile cutting of tungsten carbide. J. Mater. Process. Technol. 2001, 113, 348–354. [Google Scholar] [CrossRef]

- Yan, J.; Yoshino, M.; Kuriagawa, T.; Shirakashi, T.; Syoji, K.; Komanduri, R. On the ductile machining of silicon for micro electro-mechanical systems (MEMS), opto-electronic and optical applications. Mater. Sci. Eng. A 2001, 297, 230–234. [Google Scholar] [CrossRef]

- Yan, J.; Syoji, K.; Tamaki, J.I. Crystallographic effects in micro/nanomachining of single-crystal calcium fluoride. J. Vac. Sci. Technol. B 2004, 22, 46–51. [Google Scholar] [CrossRef]

- Liu, K.; Li, X.; Rahman, M.; Neo, K.; Liu, X. A study of the effect of tool cutting edge radius on ductile cutting of silicon wafers. Int. J. Adv. Manuf. Technol. 2007, 32, 631–637. [Google Scholar] [CrossRef]

- Liu, K.; Li, X.; Liang, S. The mechanism of ductile chip formation in cutting of brittle materials. Int. J. Adv. Manuf. Technol. 2007, 33, 875–884. [Google Scholar] [CrossRef]

- Yan, J.; Syoji, K.; Kuriyagawa, T.; Suzuki, H. Ductile regime turning at large tool feed. J. Mater. Process. Technol. 2002, 121, 363–372. [Google Scholar] [CrossRef]

- Fang, F.; Wu, H.; Zhou, W.; Hu, X. A study on mechanism of nano-cutting single crystal silicon. J. Mater. Process. Technol. 2007, 184, 407–410. [Google Scholar] [CrossRef]

- Morris, J.; Callahan, D. Origins of microplasticity in low-load scratching of silicon. J. Mater. Res. 1994, 9, 2907–2913. [Google Scholar] [CrossRef]

- Tanikella, B.; Somasekhar, A.; Sowers, A.; Nemanich, R.; Scattergood, R. Phase transformations during microcutting tests on silicon. Appl. Phys. Lett. 1996, 69, 2870–2872. [Google Scholar] [CrossRef]

- Patten, J.A.; Gao, W.; Yasuto, K. Ductile regime nanomachining of single-crystal silicon carbide. J. Manuf. Sci. Eng. 2005, 127, 522–532. [Google Scholar] [CrossRef]

- Tanaka, H.; Shimada, S.; Anthony, L. Requirements for ductile-mode machining based on deformation analysis of mono-crystalline silicon by molecular dynamics simulation. CIRP Ann.-Manuf. Technol. 2007, 56, 53–56. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J. Effect of high-pressure coolant supply when machining nickel-base, inconel 718, alloy with coated carbide tools. J. Mater. Process. Technol. 2004, 153, 1045–1050. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Wojciechowski, S.; Michalski, M.; Legutko, S. The influence of the cooling conditions on the cutting tool wear and the chip formation mechanism. J. Manuf. Process. 2016, 24, 107–115. [Google Scholar] [CrossRef]

- Maruda, R.W.; Legutko, S.; Krolczyk, G.M.; Raos, P. Influence of cooling conditions on the machining process under MQCL and MQL conditions. Teh. Vjesn.-Tech. Gaz. 2015, 22, 965–970. [Google Scholar] [CrossRef]

- Vagnorius, Z.; Sorby, K. Effect of high-pressure cooling on life of SiAlON tools in machining of Inconel 718. Int. J. Adv. Manuf. Technol. 2011, 54, 83–92. [Google Scholar] [CrossRef]

- Cai, M.; Li, X.; Rahman, M. Study of the mechanism of nanoscale ductile mode cutting of silicon using molecular dynamics simulation. Int. J. Mach. Tools Manuf. 2007, 47, 75–80. [Google Scholar] [CrossRef]

- Xiao, G.; To, S.; Zhang, G. Molecular dynamics modelling of brittle–ductile cutting mode transition: Case study on silicon carbide. Int. J. Mach. Tools Manuf. 2015, 88, 214–222. [Google Scholar] [CrossRef]

- Patten, J.A. Cutting tool edge radius and depth of cut influence on the generation of the high pressure phase transformation during ductile machining. In Proceedings of the ASPE Spring Topical Meeting on Silicon Machining, Carmel-By-The-Sea, CA, USA, 13–16 April 1998; pp. 88–91. [Google Scholar]

- Blackley, W.; Scattergood, R.O. Chip topography for ductile-regime machining of germanium. J. Manuf. Sci. Eng. 1994, 116, 263–266. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Osman, M.O.M.; Hayajneh, M.T. Re-evaluation of the basic mechanics of orthogonal metal cutting: Velocity diagram, virtual work equation and upper-bound theorem. Int. J. Mach. Tools Manuf. 2001, 41, 393–418. [Google Scholar] [CrossRef]

- Inamura, T.; Takezawa, N.; Kumaki, Y.; Sata, T. On a possible mechanism of shear deformation in nanoscale cutting. CIRP Ann.-Manuf. Technol. 1994, 43, 47–50. [Google Scholar] [CrossRef]

- Wang, H.; Riemer, O.; Rickens, K.; Brinksmeier, E. On the mechanism of asymmetric ductile-brittle transition in microcutting of (111) CaF2 single crystals. Scr. Mater. 2016, 114, 21–26. [Google Scholar] [CrossRef]

- Yan, J.; Zhao, H.; Kuriyagawa, T. Effects of tool edge radius on ductile machining of silicon: An investigation by fem. Semicond. Sci. Technol. 2009, 24, 075018. [Google Scholar] [CrossRef]

- Wang, S.; An, C.; Zhang, F.; Wang, J.; Lei, X.; Zhang, J. An experimental and theoretical investigation on the brittle ductile transition and cutting force anisotropy in cutting KDP crystal. Int. J. Mach. Tools Manuf. 2016, 106, 98–108. [Google Scholar] [CrossRef]

- Shibata, T.; Fujii, S.; Makino, E.; Ikeda, M. Ductile-regime turning mechanism of single-crystal silicon. Precis. Eng. 1996, 18, 129–137. [Google Scholar] [CrossRef]

- Leung, T.P.; Lee, W.B.; Lu, X.M. Diamond turning of silicon substrates in ductile-regime. J. Mater. Process. Technol. 1998, 73, 42–48. [Google Scholar] [CrossRef]

- O’Connor, B.P.; Marsh, E.R.; Couey, J.A. On the effect of crystallographic orientation on ductile material removal in silicon. Precis. Eng. 2005, 29, 124–132. [Google Scholar] [CrossRef]

- Chen, H.; Dai, Y.; Zheng, Z.; Gao, H.; Li, X. Effect of crystallographic orientation on cutting forces and surface finish in ductile cutting of KDP crystals. Mach. Sci. Technol. 2011, 15, 231–242. [Google Scholar] [CrossRef]

- Dornfeld, D.A.; Lee, D.E. Precision Manufacturing; Springer: New York, NY, USA, 2008. [Google Scholar]

- Adachi, S. Handbook on Physical Properties of Semiconductors; Springer: New York, NY, USA, 2004; Volume 1. [Google Scholar]

- Vashishta, P.; Kalia, R.K.; Nakano, A.; Rino, J.P. Interaction potential for silicon carbide: A molecular dynamics study of elastic constants and vibrational density of states for crystalline and amorphous silicon carbide. J. Appl. Phys. 2007, 101, 103515. [Google Scholar] [CrossRef]

- Kikuchi, H.; Kalia, R.K.; Nakano, A.; Vashishta, P.; Branicio, P.S.; Shimojo, F. Brittle dynamic fracture of crystalline cubic silicon carbide (3c-sic) via molecular dynamics simulation. J. Appl. Phys. 2005, 98, 103524. [Google Scholar] [CrossRef]

- Coati, A.; Sauvage-Simkin, M.; Garreau, Y.; Pinchaux, R.; Argunova, T.; Aid, K. () R30° reconstruction of the 6H-SiC (0001) surface: A simple T4 Si adatom structure solved by grazing-incidence X-ray diffraction. Phys. Rev. B 1999, 59, 12224. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with ovito—The open visualization tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Gao, W. Precision Nanometrology: Sensors and Measuring Systems for Nanomanufacturing; Springer: London, UK, 2010. [Google Scholar]

- Yang, W.; Liu, X.; Lu, W.; Yu, N.; Chen, L.; Zhou, L.; Chang, S. A novel white light interference based AFM head. J. Lightw. Technol. 2017, 35, 3604–3610. [Google Scholar] [CrossRef]

- Meng, B.; Zhang, F.; Li, Z. Deformation and removal characteristics in nanoscratching of 6H-SiC with berkovich indenter. Mater. Sci. Semicond. Process. 2015, 31, 160–165. [Google Scholar] [CrossRef]

- Jacob, J.; Patten, J.A.; Bhattacharya, B.; Couey, J.A.; Marsh, E.R. Determination of the ductile to brittle transition and critical depth of cut in 6H-silicon carbide through fly cutting. In Proceedings of the ASPE Annual Meeting, Norfolk, VA, USA, 9–14 October 2005. [Google Scholar]

- Chiu, W.C.; Endres, W.J.; Thouless, M. An experimental study of orthogonal machining of glass. Mach. Sci. Technol. 2000, 4, 253–275. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Workpiece dimension | Φ8.7 nm × 17.4 nm |

| Total atoms | Around 101,600 |

| Loading rate | 1.74 m/s |

| Orientation | ||

|---|---|---|

| (0001) <100> | 24, 380 MPa | 33, 744 MPa |

| (0001) <15 0> | 23, 364 MPa | 35, 574 MPa |

| (0001) <20> | 22, 338 MPa | 44, 718 MPa |

| Parameter | Value |

|---|---|

| Tool rake angle | −30° |

| Clearance angle | 10° |

| Edge radius (nm) | 50 |

| (nm) | 30, 35, 40, 45, 50, 55, 60 |

| Cutting speed (mm/s) | 3 |

| Cutting plane | (0001) |

| Cutting direction | <100>, <15 0>, <20> |

| Parameter | Value |

|---|---|

| Tilt angle | ~0.03° |

| Rake angle | −30° |

| Clearance angle | 10° |

| Cutting speed | 3 mm/s |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, G.; Ren, M.; To, S. A Study of Mechanics in Brittle–Ductile Cutting Mode Transition. Micromachines 2018, 9, 49. https://doi.org/10.3390/mi9020049

Xiao G, Ren M, To S. A Study of Mechanics in Brittle–Ductile Cutting Mode Transition. Micromachines. 2018; 9(2):49. https://doi.org/10.3390/mi9020049

Chicago/Turabian StyleXiao, Gaobo, Mingjun Ren, and Suet To. 2018. "A Study of Mechanics in Brittle–Ductile Cutting Mode Transition" Micromachines 9, no. 2: 49. https://doi.org/10.3390/mi9020049

APA StyleXiao, G., Ren, M., & To, S. (2018). A Study of Mechanics in Brittle–Ductile Cutting Mode Transition. Micromachines, 9(2), 49. https://doi.org/10.3390/mi9020049