Explosion Suppression Mechanism Characteristics of MEMS S&A Device With In Situ Synthetic Primer

Abstract

1. Introduction

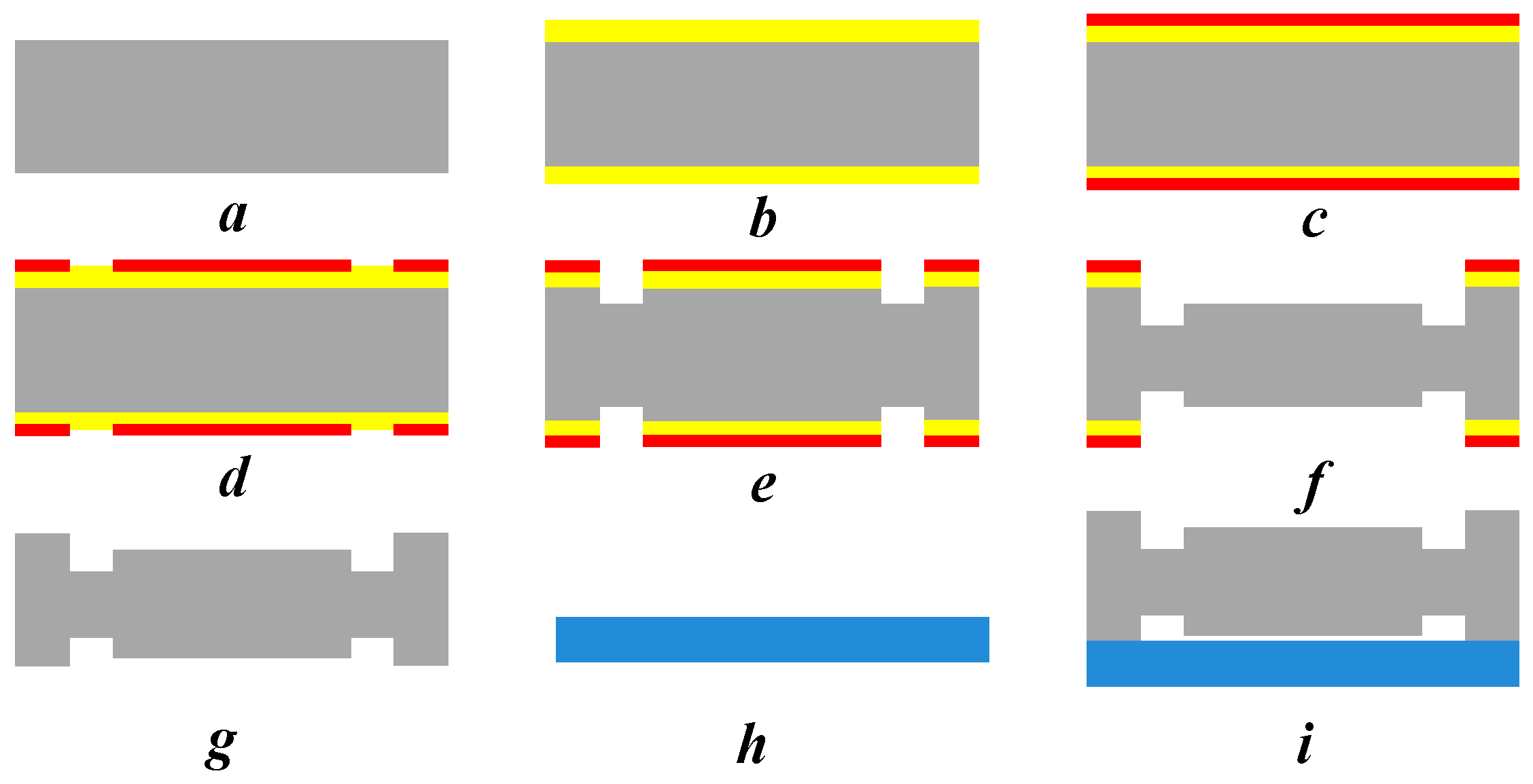

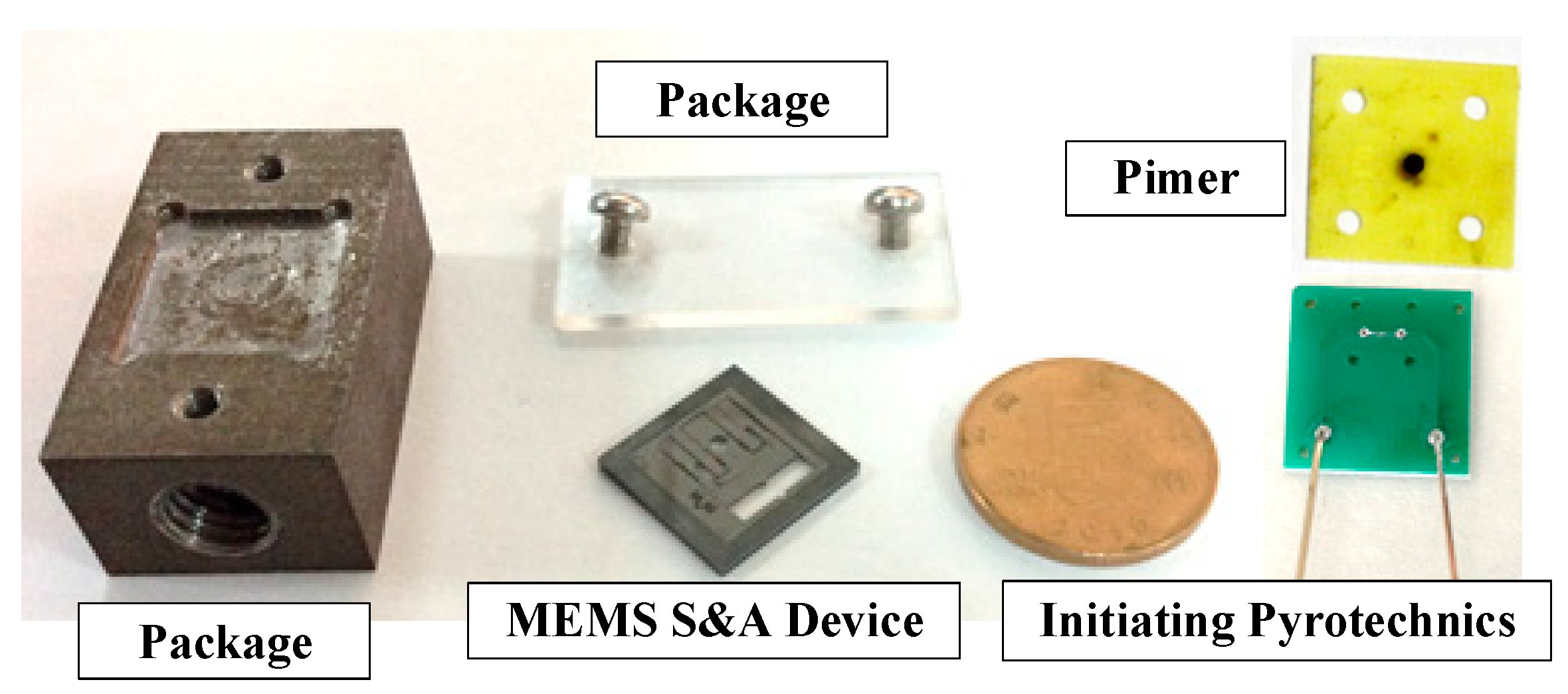

2. MEMS Safety and Arming (S&A) Device Design

3. Parametric Calculation Method of MEMS S&A Device Under Denotation Field

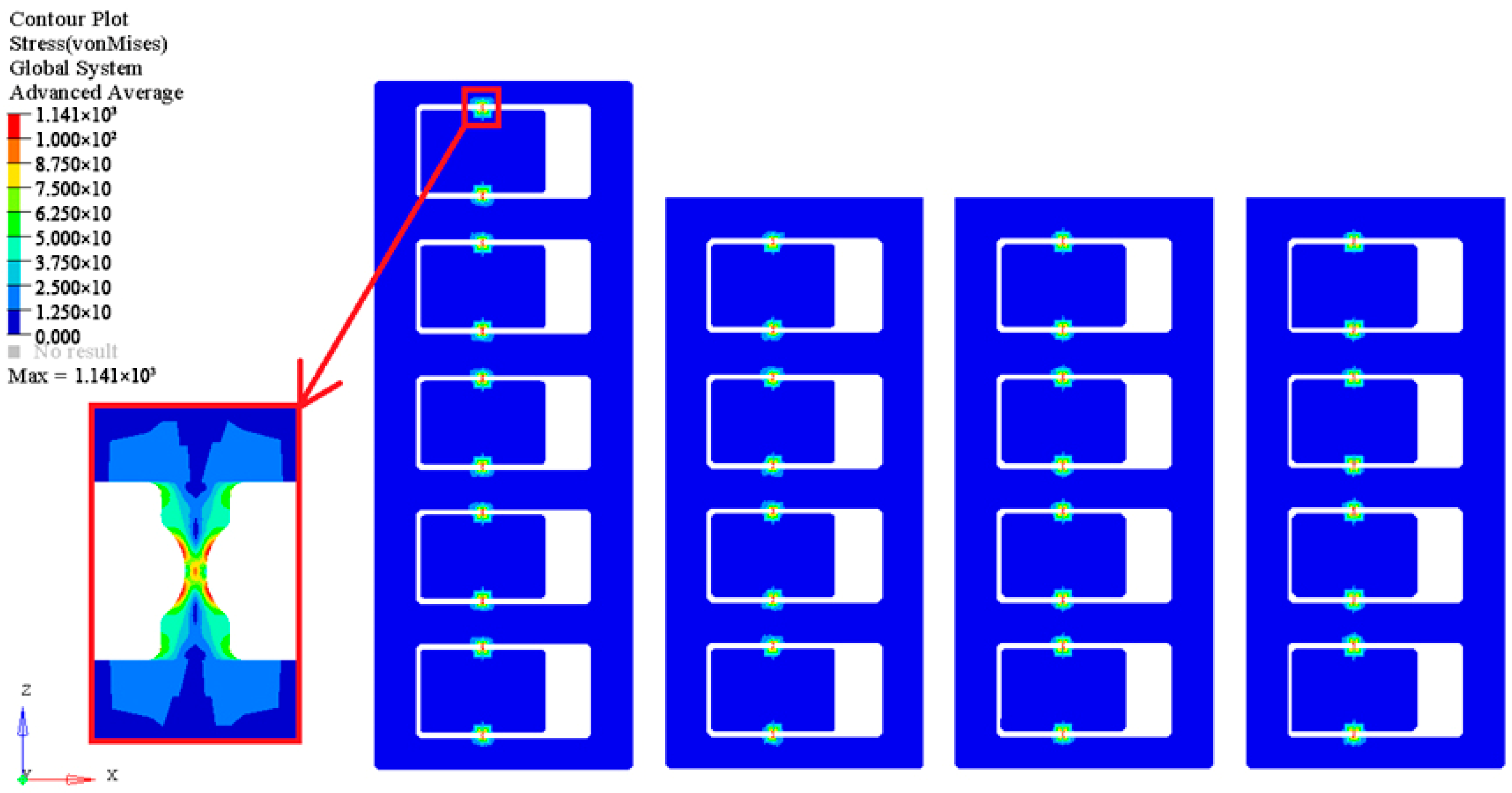

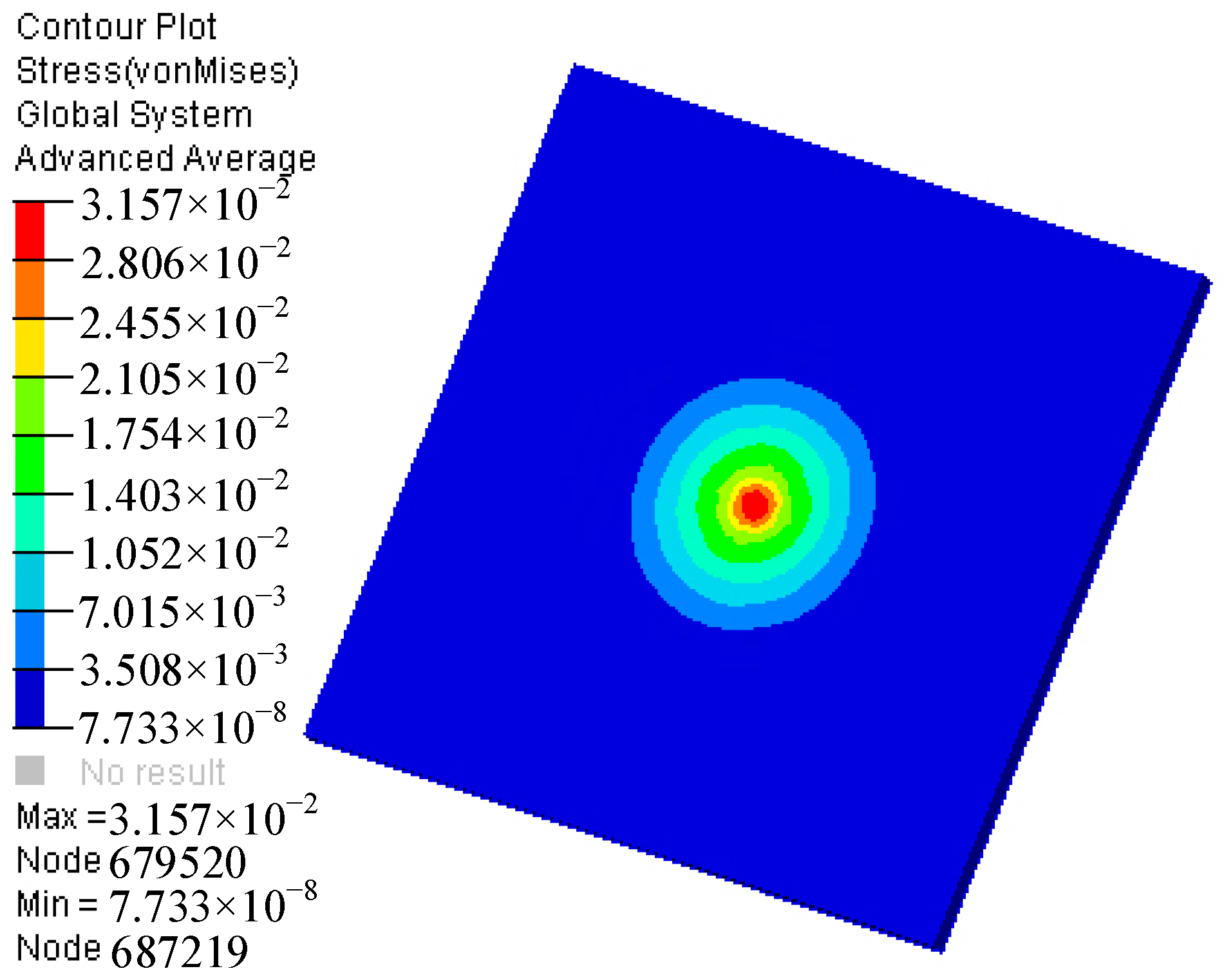

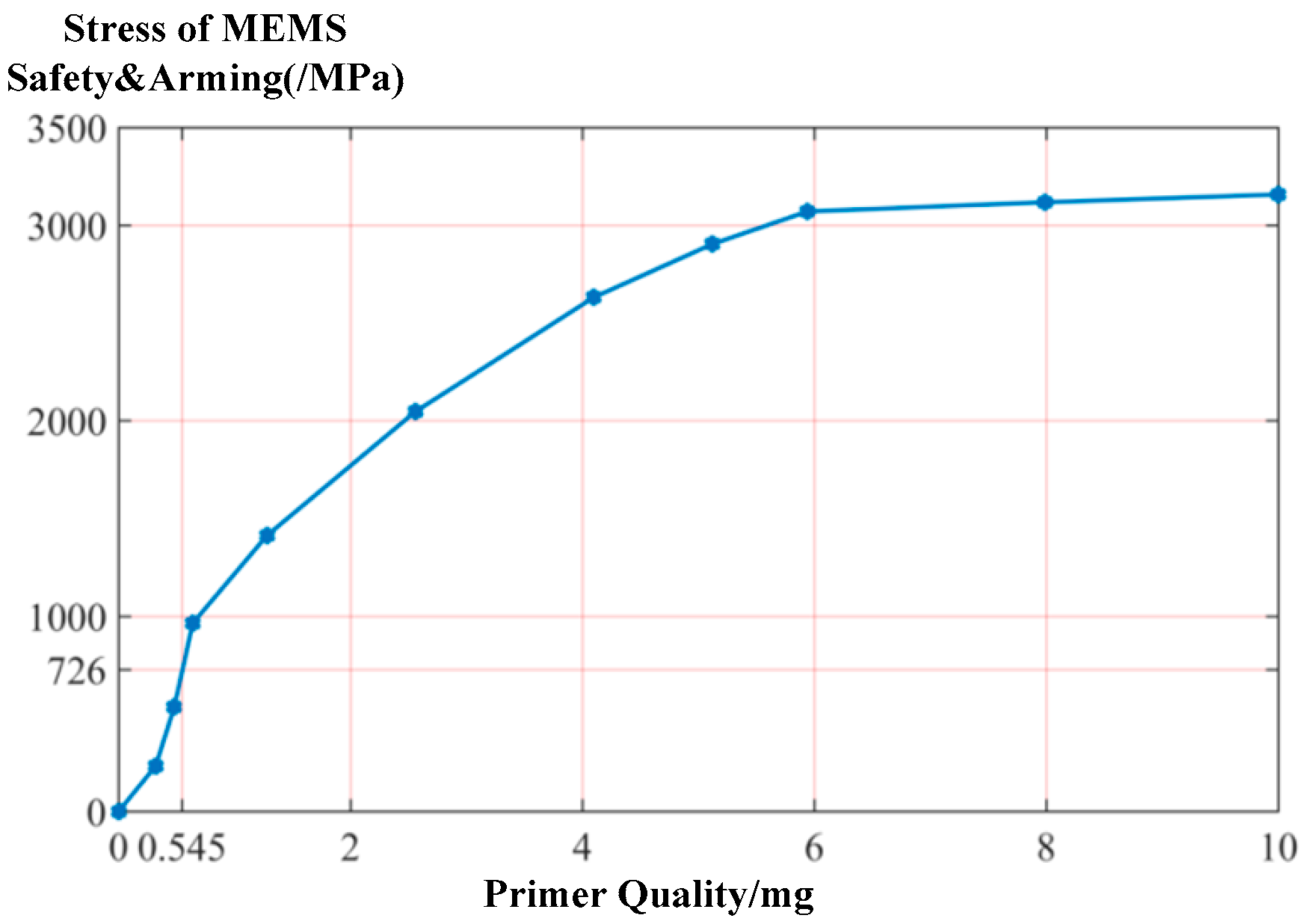

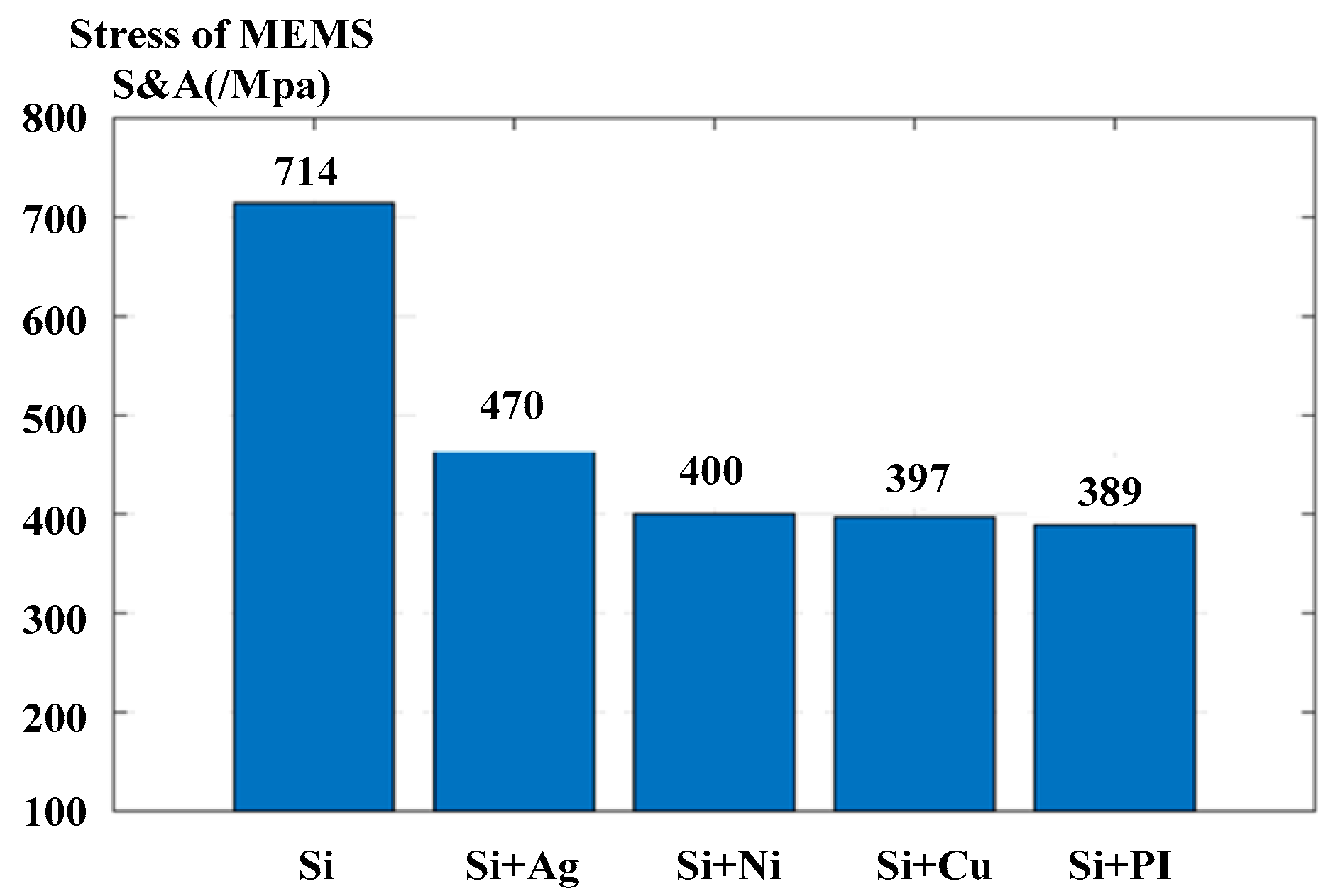

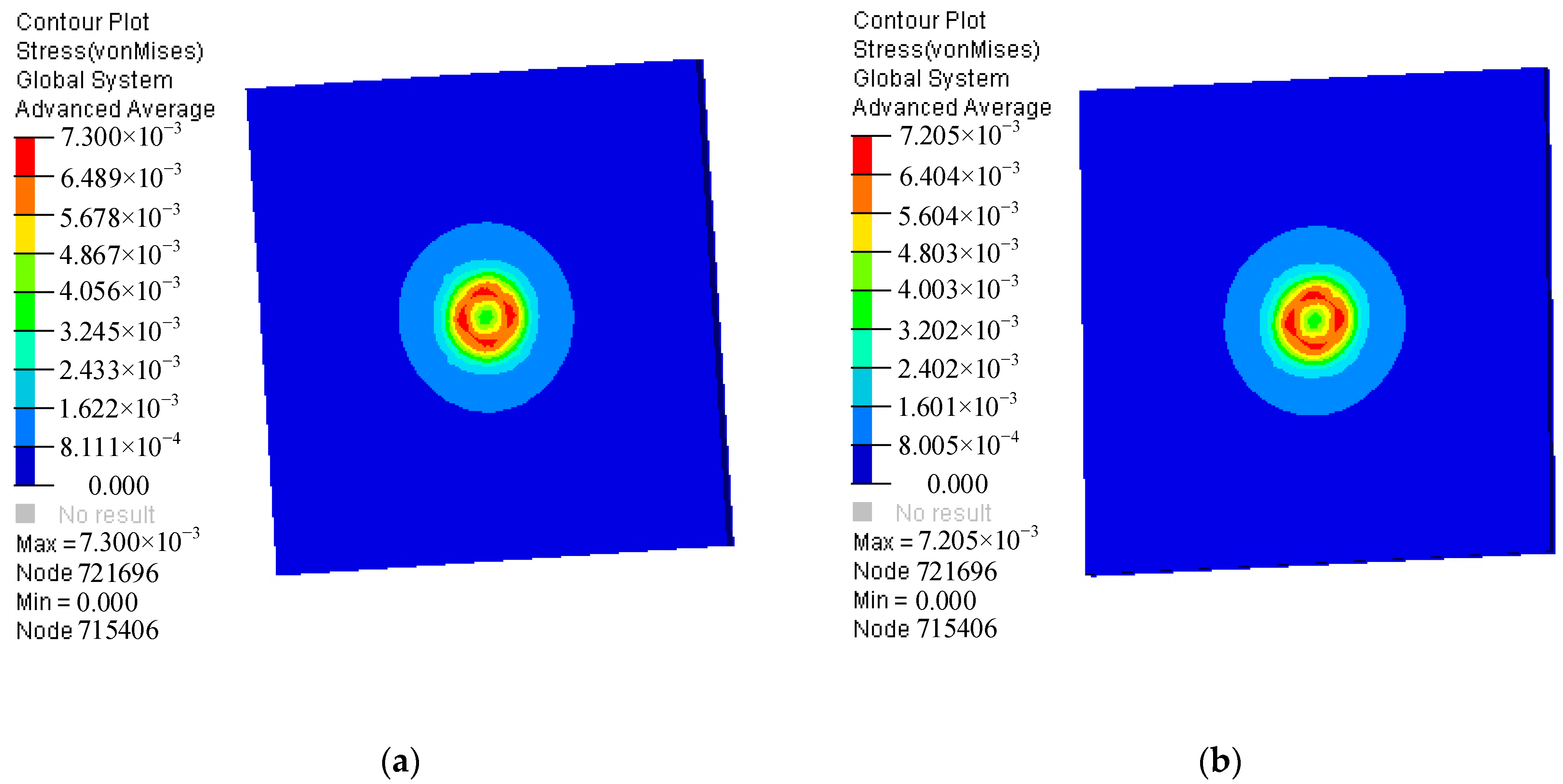

3.1. Calculation Method of Explosion-Suppression-Mechanism Performance of MEMS S&A Device

3.2. Parametric Optimization Design of MEMS S&A Device

4. Integrated Processing

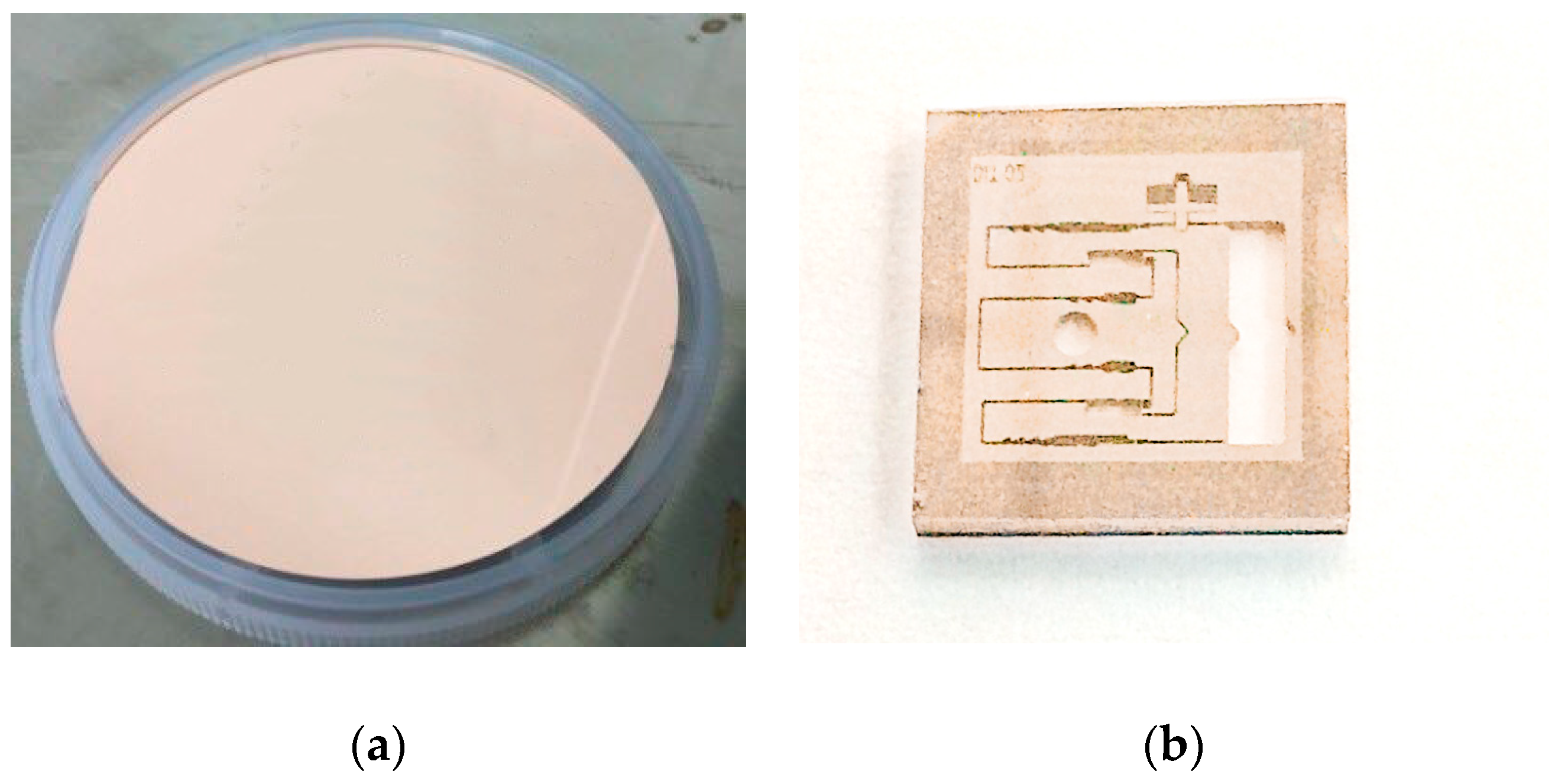

4.1. Silicon-Based MEMS Safety-System Processing Technology

4.2. Electroplated Metal as Explosion Suppression Mechanism Energy Absorbing Material

- (1)

- Owing to the presence of impurities such as dust and particles, bubbles are highly likely to form during electroplating. To prevent bubble formation, the silicon substrate sheet was cleaned organically, mainly by acetone cleaning at 40 °C for 10 min and alcohol cleaning at 40 °C for 10 min. The copper seed layer was magnetron sputtered onto a substrate sheet on the silicon substrate. A bubble-prevention cleaning step was not required if the sputtering and plating times were short.

- (2)

- The MEMS S&A device was adhered to the cathode carrier plate with copper-conductive tape and the Si was washed with high-pressure deionized water for 15 min to eliminate any bubbles inside the deep hole.

- (3)

- The Si was soaked in 8% to 10% dilute sulfuric acid for 10 min to eliminate copper oxides on the copper seed-layer surface.

- (4)

- The cathode stage that carried the Si was immersed vertically in CuSO4 plating solution for electroplating, with the electroplating parameters given in Table 4.

- (5)

- The device was cleaned using deionized water to rinse the plated glass surface for 15 min.

- (6)

- To reduce the high metal surface roughness of the electroplated surface, the electroplated surface was polished by a polishing machine. This polishing step is vital for the subsequent metal-patterning process. Figure 11 shows the MEMS S&A device after the Cu electroplating process.

4.3. Preparation of PI Film as Denotation Energy Absorbing Material

5. Explosion Suppression Mechanism Test

- (1)

- The power supply was engaged to power the delay control module system.

- (2)

- The delay control module was set to delay the detonation command by 30 s.

- (3)

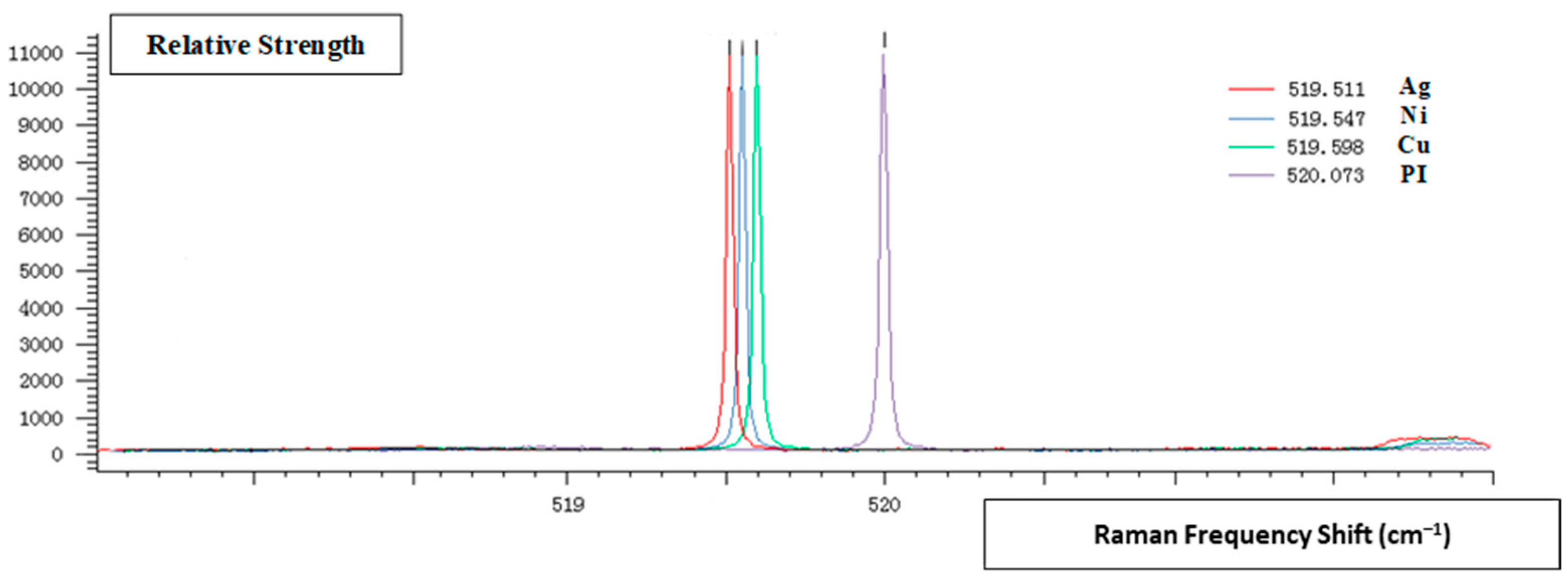

- When the delay time was complete, the delay control module output the detonation signal, which detonated the integrated microcharge system. The residual stress of the MEMS S&A device was tested by observing if the system in the explosion suppression mechanism state possessed breaks or chips. The explosion suppression mechanism sample was tested by Raman spectrometry to measure the residual stress between the MEMS S&A device and the energy-absorbing material. In summary, a reliable explosion suppression mechanism capability of the MEMS S&A device was achieved. The appearance of the MEMS S&A after the denotation wave output (Figure 15) shows that the MEMS S&A device integrated four types of energy-absorbing materials with a reliable explosion suppression mechanism capability.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, G.; Shi, G.; Sui, L.; Yi, F.; Wang, B. The application of multilayer elastic beam in MEMS safe and arming system. AIP Advances 2015, 5, 077151. [Google Scholar] [CrossRef]

- Onkar, K.; Sujay, G.; Ankush, H. Safety and arming mechanism (SAM) for mortar fuse. Int. J. Sci. Res. Dev. 2015, 3, 637–639. [Google Scholar]

- Wang, F.; Lou, W.; Fu, Y.; Wang, Y. Parametric research of MEMS safety and arming system. In Proceedings of the 8th Annual IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Suzhou, China, 7–10 April 2013. [Google Scholar]

- Robinson, C.H.; Wood, R.H.; Hoang, T.Q. Miniature MEMS-based electromechanical safety and arming device. U.S. Patent 6,964,231, 15 November 2005. [Google Scholar]

- Zunino, J.L.; Skelton, D.R.; Robinson, C. Reliability testing and analysis of safing and arming devices for army fuzes. In Proceedings of the MOEMS-MEMS 2008 MICRO AND NANOFABRICATION, San Jose, CA, USA, 19–24 January 2008. [Google Scholar]

- Robinson, C.H.; Wood, R. Ultra-Miniature, Monolithic, Mechanical Safety-and-Arming (S&A) Device for Projected Munitions. U.S. Patent 6,167,809B1, 2 January 2001. [Google Scholar]

- Pezous, H.; Rossi, C.; Sanchez, M.; Mathieu, F.; Dollat, X.; Charlot, S.; Salvagnac, L.; Conédéra, V. Integration of a MEMS based safe arm and fire device. Sens. Actuators, A 2010, 159, 157–167. [Google Scholar] [CrossRef]

- Hu, T.; Zhao, Y.; Zhao, Y.; Ren, W. Integration design of a MEMS based fuze. Sens. Actuators, A 2017, 268, 193–200. [Google Scholar] [CrossRef]

- Mink, S.S.; Starman, L.A.; Kladitis, P.E.; Bradley, K.C. Micromechanical cervix. In Proceedings of the 48th Midwest Symposium on Circuits and Systems, Covington, KY, USA, 7–10 August 2005. [Google Scholar]

- Perrin, M. New Generation Naval Artillery Multi-Function Fuse. In Proceedings of the NDIA’s 56th Annual Fuse Conference, Baltimore, MD, USA, 14–16 May 2012. [Google Scholar]

- Liu, F.; Lou, W.; Wang, F.; Wang, Y. Theoretical Method Research on a MEMS Safety and Arming Device. Adv. Mater. Res. 2014, 901, 93–97. [Google Scholar] [CrossRef]

- Wang, F.; Lou, W.; Wang, Y.; Liu, F.; Lu, J.; Wu, J. Design and Analysis of a Novel Locking Mechanism of MEMS Safety and Arming Device. Key Eng. Mater. 2014, 609, 856–859. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.; Hu, T.; Xu, W.; Zhao, Y.; Bai, Y.; Ren, W. Design of a large displacement thermal actuator with a cascaded V-beam amplification for MEMS safety and arming devices. Microsyst. Technol. 2015, 21, 2367–2374. [Google Scholar] [CrossRef]

- Spearing, S.M. Materials Issues in Microelectromechanical Systems. Acta Mater. 2000, 48, 179–196. [Google Scholar] [CrossRef]

- Xie, R.; Ren, X.; Liu, L.; Xue, Y.; Fu, D.; Zhang, R. Research on design and firing performance of Si-based detonator. Defence Technol. 2014, 10, 34–39. [Google Scholar] [CrossRef]

- Zhang, K.L.; Chou, S.K.; Ang, S.S.; Tang, X.S. A MEMS-based soild propellant microthruster with Au/Ti igniter. Sens. Actuators A 2005, 122, 113–123. [Google Scholar] [CrossRef]

- Maurer, W.H.; Soto, G.H.; Hollingsworth, D.R. Method for utilizing a MEMS safe arm device for microdetonation. U.S. Patent 7,007,606, 7 March 2006. [Google Scholar]

| Material | ρ/(kg/m3) | Modulus of Elasticity E/GPa | Poisson’s Ratio ν | Breaking Strength/MPa |

|---|---|---|---|---|

| Si | 2330 | 182 | 0.27 | 726 |

| Glass | 2550 | 88 | 0.16 | 480 |

| Ag | 10,500 | 732 | 0.2 | 605 |

| PI | 1420 | 200 | 0.37 | 1.1 |

| Cu | 8960 | 1230 | 0.34 | 315 |

| Ni | 8900 | 2010 | 0.31 | 515 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Density ρ/(g/cm3) | 2.29 | A/100 Gpa | 4.1 |

| Explosion Suppression Mechanism speed D/(cm/μs) | 0.47 | B/100 Gpa | 0.045 |

| Explosive pressure PCJ/100 GPa | 0.126 | R1 | 4.9 |

| Initial relative volume V0 | 1.0 | ω* | 0.3 |

| Initial ratio E0/100 GPa | 0.085 | R2 | 1.3 |

| Parameter | Value | ||||

|---|---|---|---|---|---|

| Size (mm) | Φ2.5 × 1.47 | Φ2.5 × 1.17 | Φ2.5 × 0.87 | Φ2.5 × 0.75 | Φ2.5 × 0.6 |

| Quality (mg) | 10 | 7.989 | 5.94 | 5.121 | 4.097 |

| Size (mm) | Φ2.5 × 0.375 | Φ2.5 × 0.1875 | Φ2.5 × 0.09375 | Φ2.5 × 0.07032 | Φ2.5 × 0.04688 |

| Quality (mg) | 2.56 | 1.28 | 0.64 | 0.4802 | 0.3201 |

| Electroplated Solution | CuSO4 | Coating Thickness | 100 μm |

|---|---|---|---|

| Electroplated solution concentration | 190 g/L | Stirring frequency | 40 times/min |

| Current density | 2.9 A/dm2 | Electroplated cycle rate | 8 L/min |

| Voltage | 2.8 V | Time | 20 min |

| Corrosion | Proportion Ratio (Volume) | Corrosion Rate | Horizontal Drill Rate |

|---|---|---|---|

| CH3COOH:H2O2:H2O | 1:1:20 | 35 nm/min | 19.8 nm/min |

| Rotating Speed (r/s) | Accelerometer (r/s2) | Time (s) | |

|---|---|---|---|

| Process1 | 500 | 500 | 10 |

| process2 | 1000 | 500 | 10 |

| process3 | 1500 | 500 | 10 |

| process4 | 2000 | 500 | 10 |

| process5 | 2500 | 500 | 10 |

| process6 | 3000 | 500 | 30 |

| Adhesive Material | Frequency Shift Peak (cm−1) | Peak Width (cm−1) | Residual Stress (MPa) |

|---|---|---|---|

| Ni | 519.547 | 4.79463 | 197.055 |

| PI | 520.073 | 5.36339 | 31.755 |

| Cu | 519.598 | 4.94299 | 174.87 |

| Ag | 519.511 | 4.79051 | 212.715 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, H.; Lou, W.; Wang, D.; Zheng, F. Explosion Suppression Mechanism Characteristics of MEMS S&A Device With In Situ Synthetic Primer. Micromachines 2018, 9, 652. https://doi.org/10.3390/mi9120652

Feng H, Lou W, Wang D, Zheng F. Explosion Suppression Mechanism Characteristics of MEMS S&A Device With In Situ Synthetic Primer. Micromachines. 2018; 9(12):652. https://doi.org/10.3390/mi9120652

Chicago/Turabian StyleFeng, Hengzhen, Wenzhong Lou, Dakui Wang, and Fuquan Zheng. 2018. "Explosion Suppression Mechanism Characteristics of MEMS S&A Device With In Situ Synthetic Primer" Micromachines 9, no. 12: 652. https://doi.org/10.3390/mi9120652

APA StyleFeng, H., Lou, W., Wang, D., & Zheng, F. (2018). Explosion Suppression Mechanism Characteristics of MEMS S&A Device With In Situ Synthetic Primer. Micromachines, 9(12), 652. https://doi.org/10.3390/mi9120652