3.1. Comparison of Surface Topography Measurements

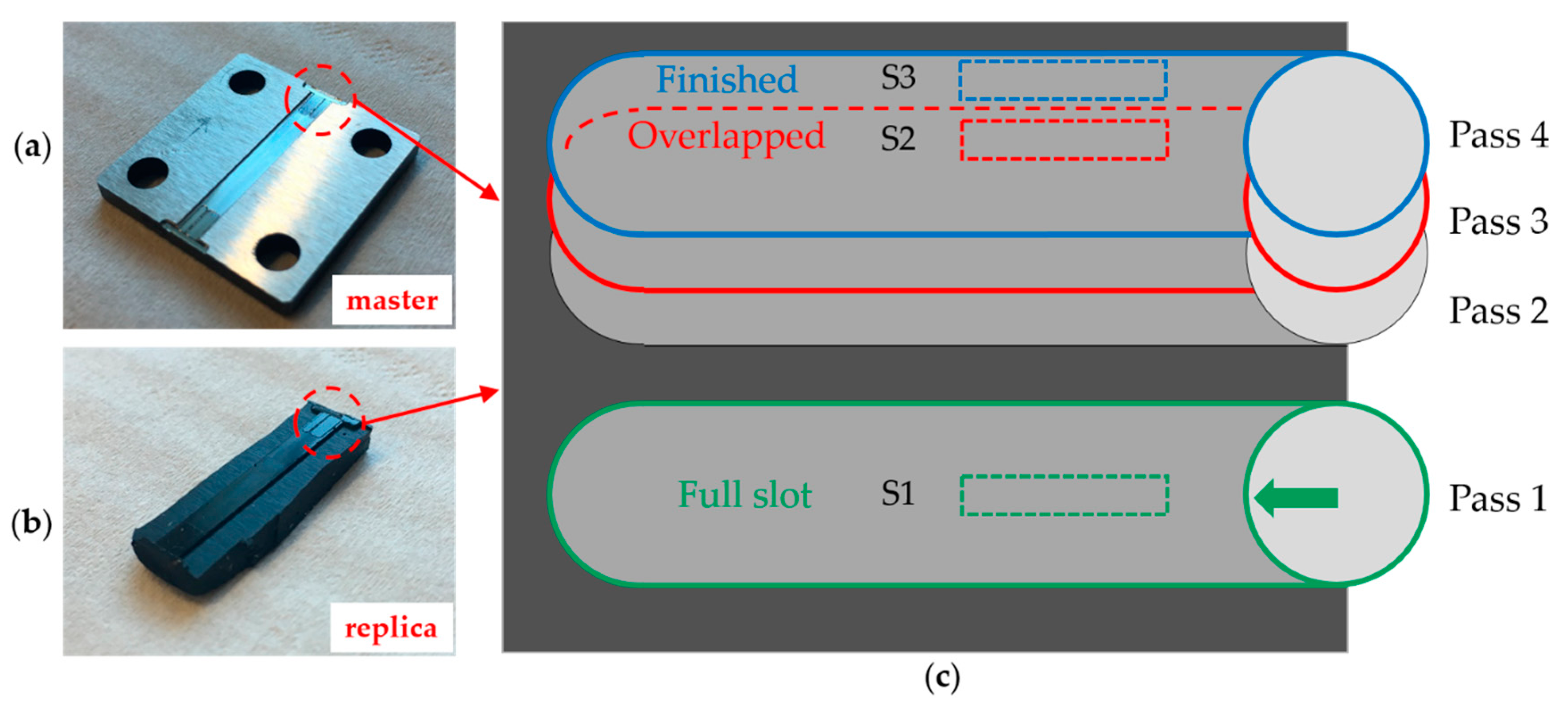

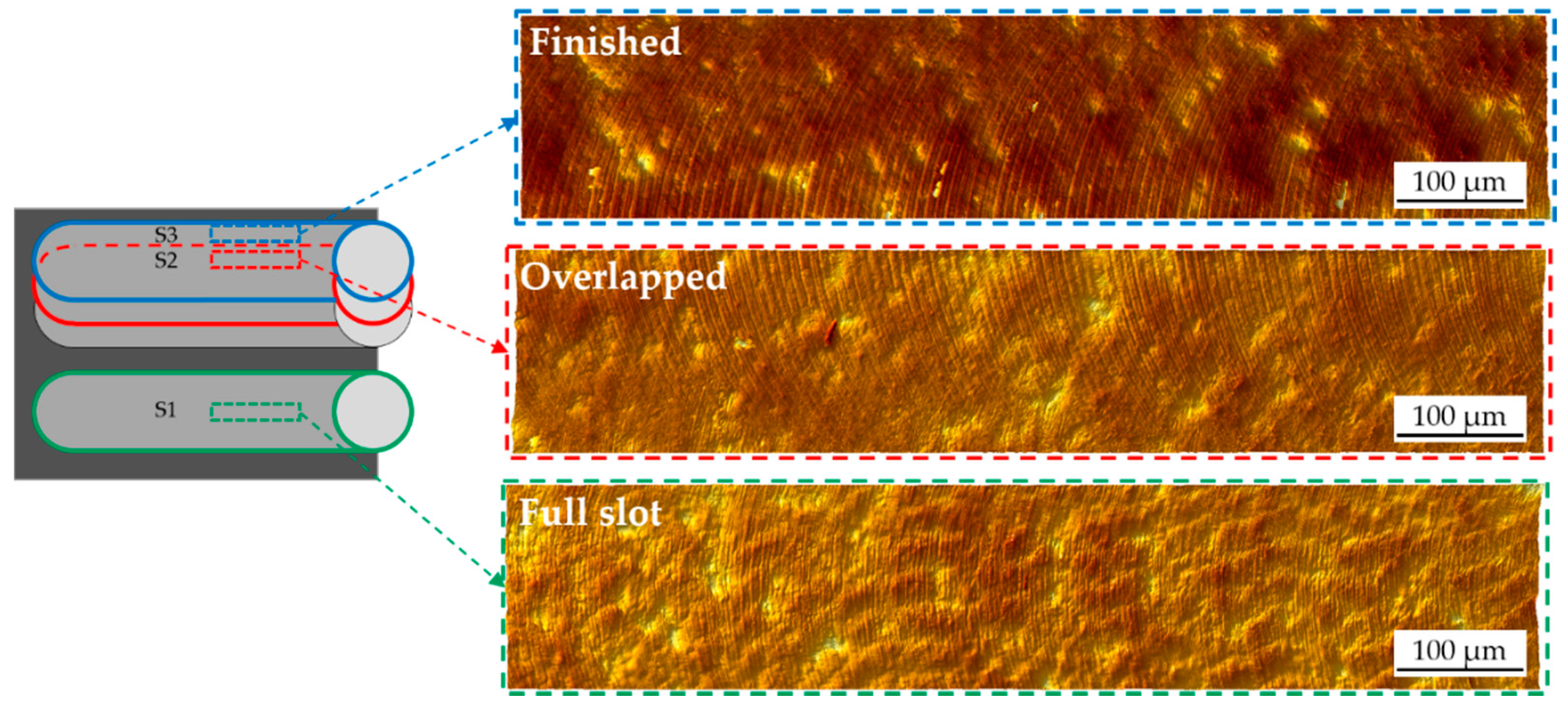

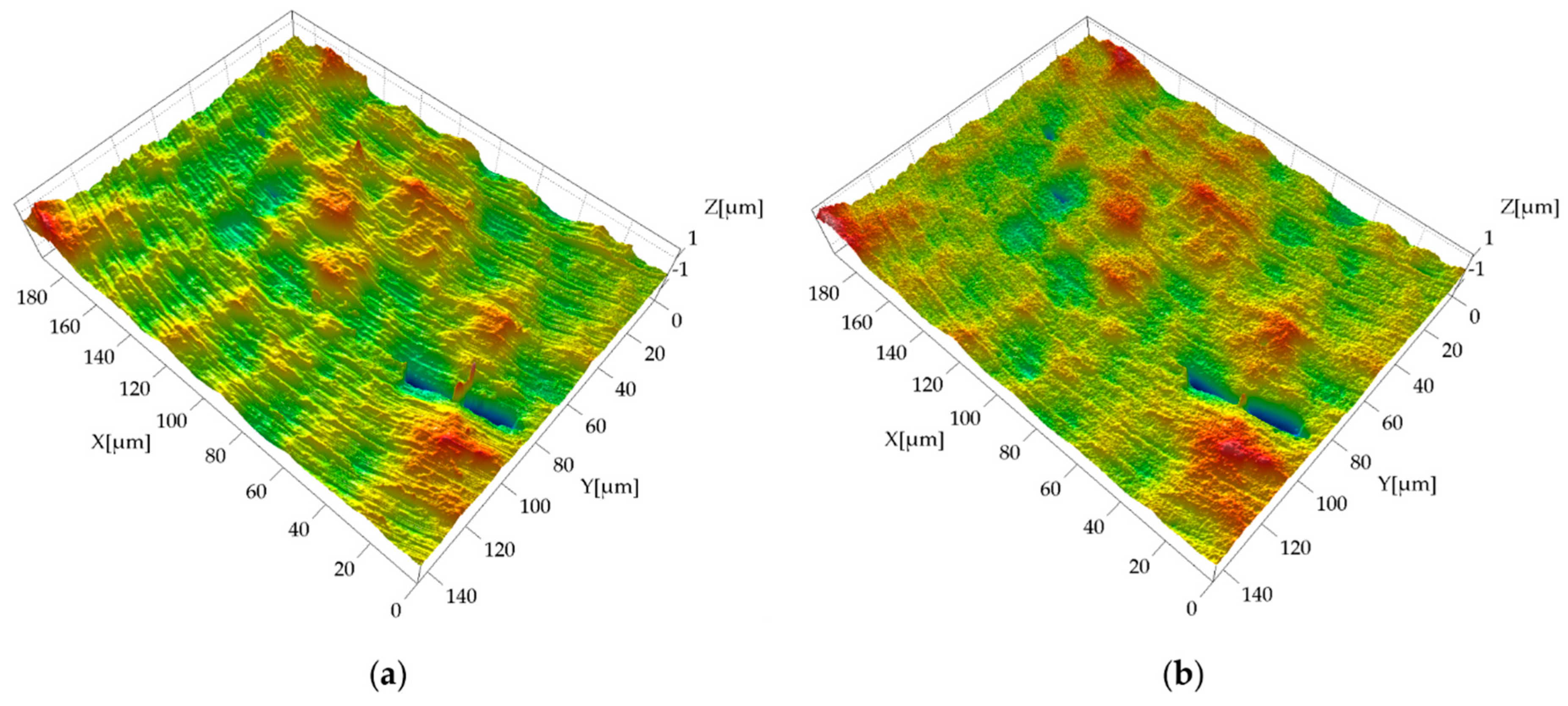

The replicated surfaces generally showed a good resemblance with the masters. The surface marks created by the micro tool were reproduced with fidelity, even in their finest details (see

Figure 5). Moreover, the silicone accurately reproduced local discontinuities in the surface texture.

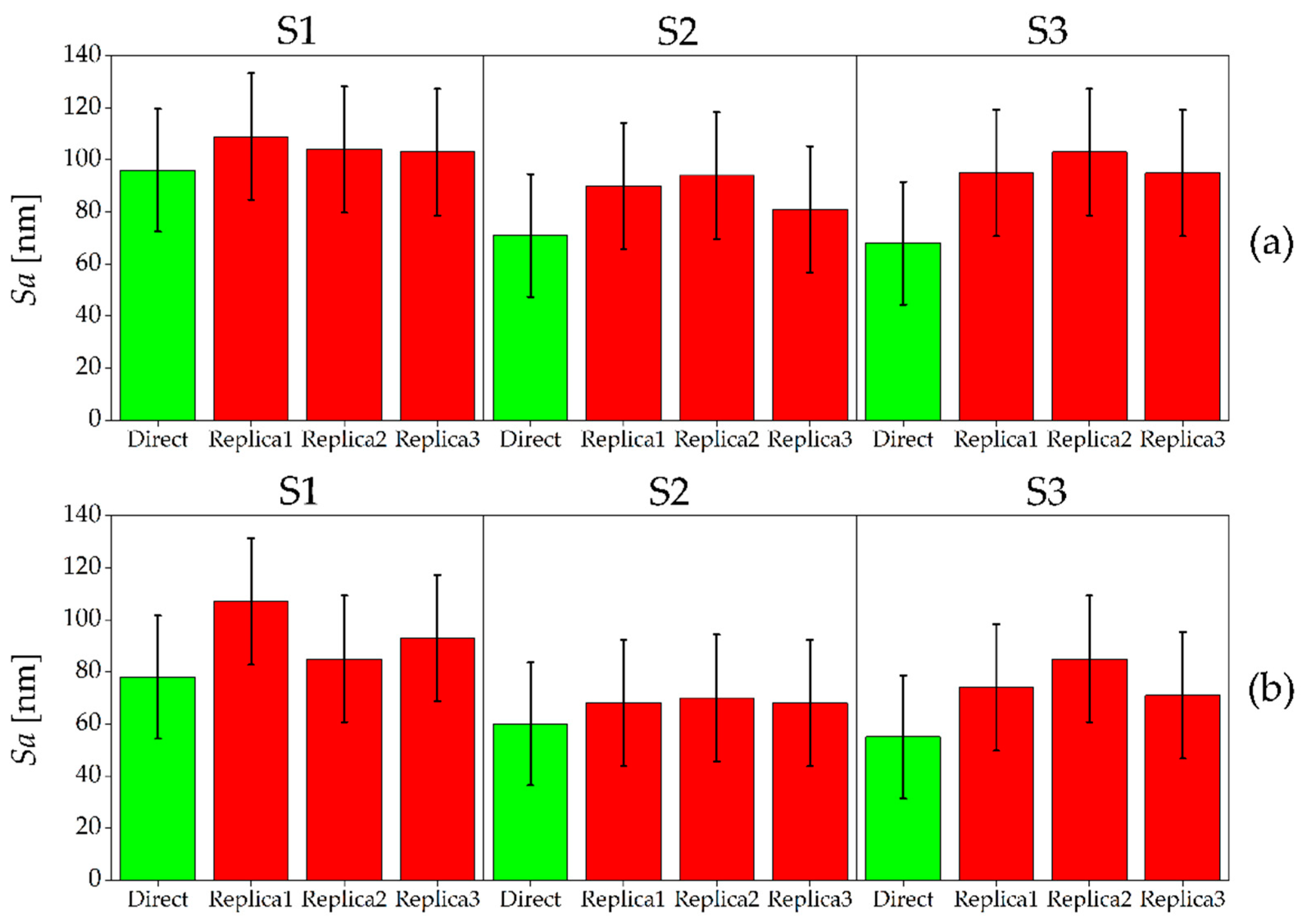

The results of the quantitative surface characterization for the hardened mold steel are presented in

Figure 6. For both Sample 1 and Sample 2, the direct measurement showed a decreasing average surface roughness when moving from the full slot surface (S1) to the other ones (S2 and S3). This is according to expectations, as S1 was machined in the cutting conditions that are typical of roughing operations. In general,

Sa measured on the master surfaces ranged between 55 nm and 96 nm. A certain roughness variability was observed between the direct measurements of the two samples. In particular, Sample 1 presented an 11 nm to 18 nm larger

Sa compared to Sample 2. This variability is due to the micromilling process itself, since the surfaces were machined in the same cutting conditions on the two samples. In comparison to the direct measurement, the three replicas always presented a larger

Sa. However, considering the measurement uncertainty, direct and indirect measurements provided, in all the cases, the same

Sa values. In fact, the uncertainty intervals overlap, making the measurement output equal from a metrological point of view. The standard deviations among the three silicone replicas range between 3 nm and 11 nm, demonstrating good repeatability of the replication procedure. Moreover, taking into account the measurement uncertainty, the replication procedure always provided consistent

Sa results.

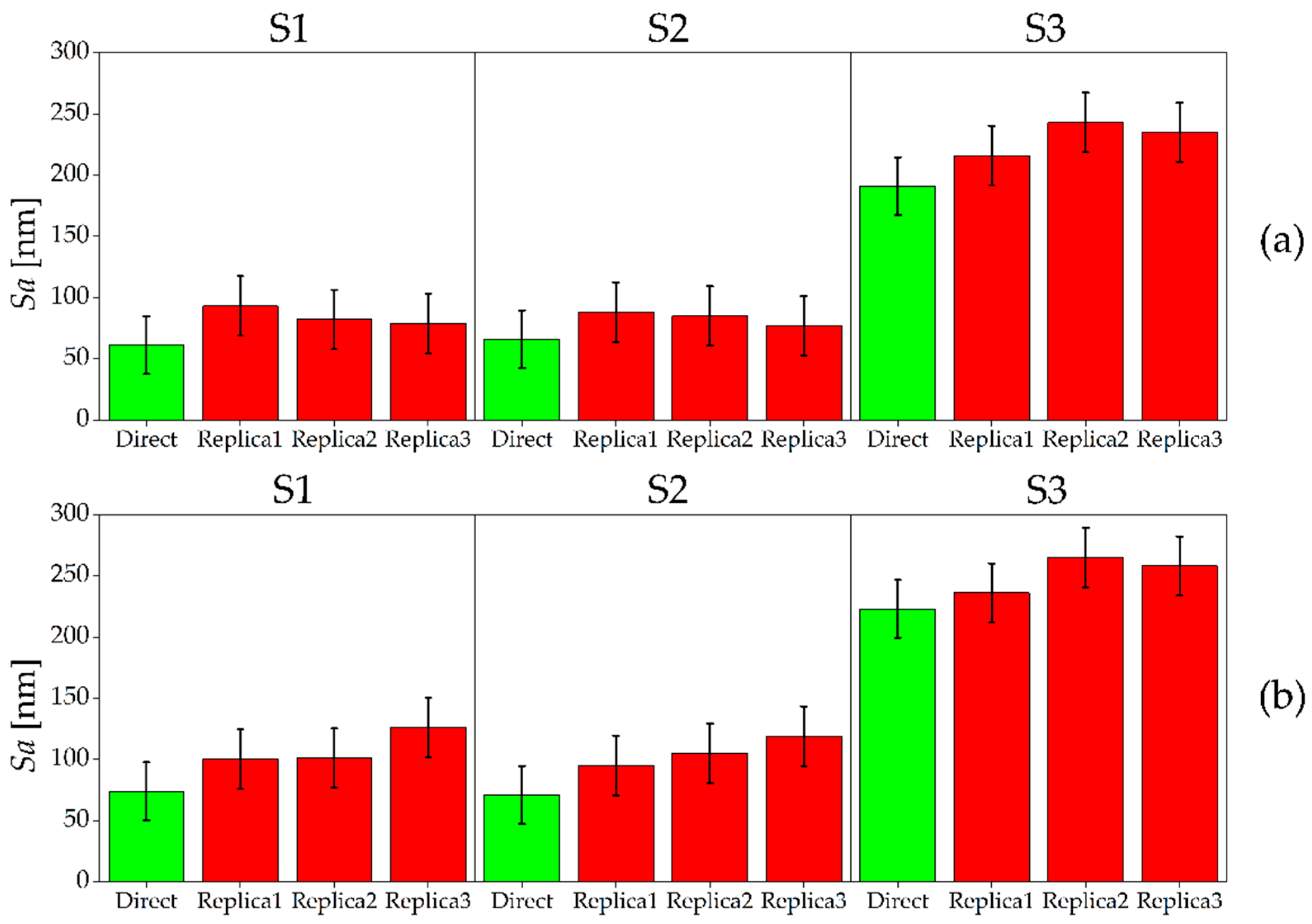

The results of the

Sa measurements for the AISI 440 A are shown in

Figure 7. In this case, S1 and S2 were produced with similar

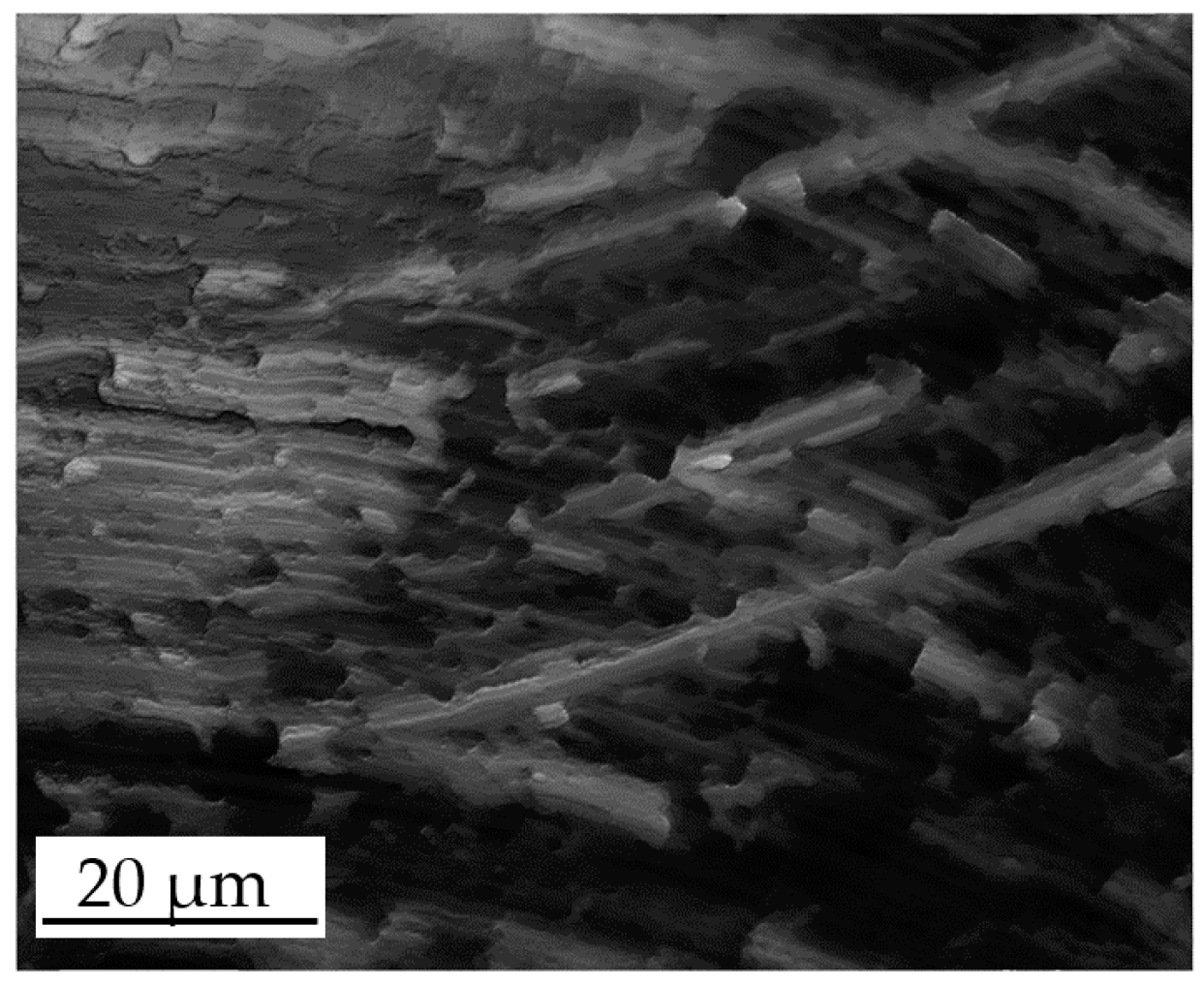

Sa roughness values (ranging between 61 nm and 74 nm for the two samples), while S3 had a significantly higher value of around 200 nm. This is contrary to expectations, as S3 was machined with the same radial depth of cut of S2. This unexpected increase of surface roughness was caused by the presence of plowing: for AISI 440 A, the last micromilling pass generated plowed marks on the surface, which diminished the surface quality (see

Figure 8). This event happened only for S3 because the material accumulated on the tool during the first three passes (see

Figure 1) leading to an increase of surface roughness [

7] during the last pass. The softness of the annealed material is the most probable reason for this phenomenon. As for the previous material, a certain variability between Sample 1 and Sample 2 was observed. When comparing direct and indirect measurements, the replication process again introduced an average overestimation of the surface roughness of the master. However, as for the hardened material, the uncertainty intervals of direct and indirect measurements overlap in almost all cases, except for Replica 3 of S1, Sample 2 and Replica 2 of S3, Sample 1. The replication process is once again very repeatable: the three different replicas always provided the same measurements output, being the standard deviations among the three indirect measurements included between 7 nm and 15 nm.

In both the hardened and annealed material, the replication procedure always introduced an overestimation of the roughness. The deviation ∆

Sa, calculated as the difference between average

Sa of the three replicas and

Sa of the master, did not show any dependence on the master roughness (see

Figure 9). In fact, while the roughness of metal surfaces increased, the deviation ∆

Sa remained mostly constant around the value of 24 nm. The fact that the parameter ∆

Sa assumed similar values for all the measured surfaces also demonstrates that there was not a dependence of the replication performance with respect to the two samples, the two materials and the three surface types, as also shown by the ANOVA results in

Table 7. The p-values were in fact always much larger than 5% for both single factors and two-ways interactions.

To further investigate this experimental observation, other areal parameters were taken into account in order to understand which roughness component caused the

Sa overestimation. In particular, the functional parameters

Svk,

Spk and

Sk were calculated for masters and replicas and then compared.

Svk is defined as the reduced dale height, and it provides an average indication of the valleys depth below the core roughness [

33].

Spk is the reduced peak height and represents the mean height of peaks above the core surface [

33]. Finally,

Sk is used to characterize the core surface roughness [

33]. In order to analyze how the silicone media replicated the valleys of the micromilled surfaces, it was chosen to compare the

Svk parameter calculated on the masters with the

Spk parameter of the corresponding replicas, since a valley on the master corresponds to a peak on the replica and vice versa. The core roughness was also utilized as parameter of comparison by means of

Sk to determine whether the overestimation of the indirect

Sa measurements is also related to an increase of this parameter.

The results of the comparison are shown in

Figure 10. It is possible to observe that the

Svk values of the master are systematically lower than the

Spk values of the replicated surfaces. In particular, the

Spk of the replicas is on average 60% higher than the

Svk of the masters. This clearly demonstrates that the replication procedure generated surfaces having peaks that are higher than the valleys of the master. The same happens for

Sk: the indirect measurements provided an average 63% higher level of

Sk for all the produced surfaces, indicating that the core roughness is also increased after the replication procedure. Therefore, the

Sa overestimation introduced by the indirect measurements is caused by two distinct phenomena: the increase of the height of the peaks with respect to depths of the valleys and the increase of the core roughness.

This phenomenon is probably generated during the demolding phase of the replica. The two-component silicone during solidification penetrates in the master surface valleys, replicating the surface topography (see

Figure 5). When the solidified replica is manually removed, the silicone sticks to the deepest points of the surface valleys due to their very small width, making its removal more difficult than in other areas. Therefore, it appears that manual removal causes a nano-metric stretch perpendicular to the average plane of the surface, which results in the observed increase of both dale height and core roughness. This also explains why the overestimation is almost constant (see

Figure 9): the manual removal acts as external factor, and it does not depend on the experimental variables. Another evidence is given by the Kurtosis parameter

Sku [

33], which provides a quantitative evaluation of the sharpness of the roughness profile. The replicated surfaces had, on average, a 23% higher

Sku value, demonstrating that they have a sharper profile than the masters, as a consequence of the stretch induced by the manual removal.

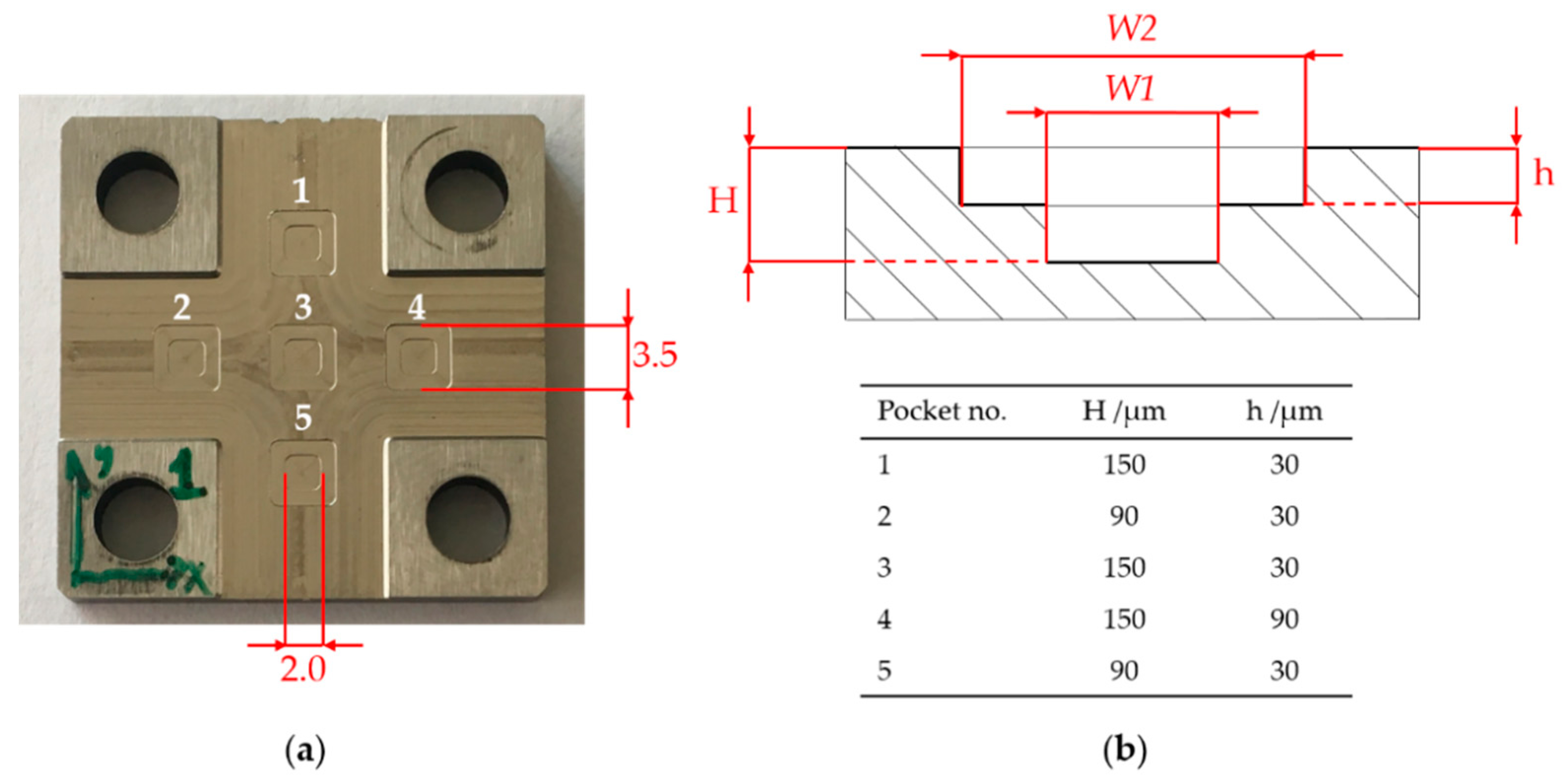

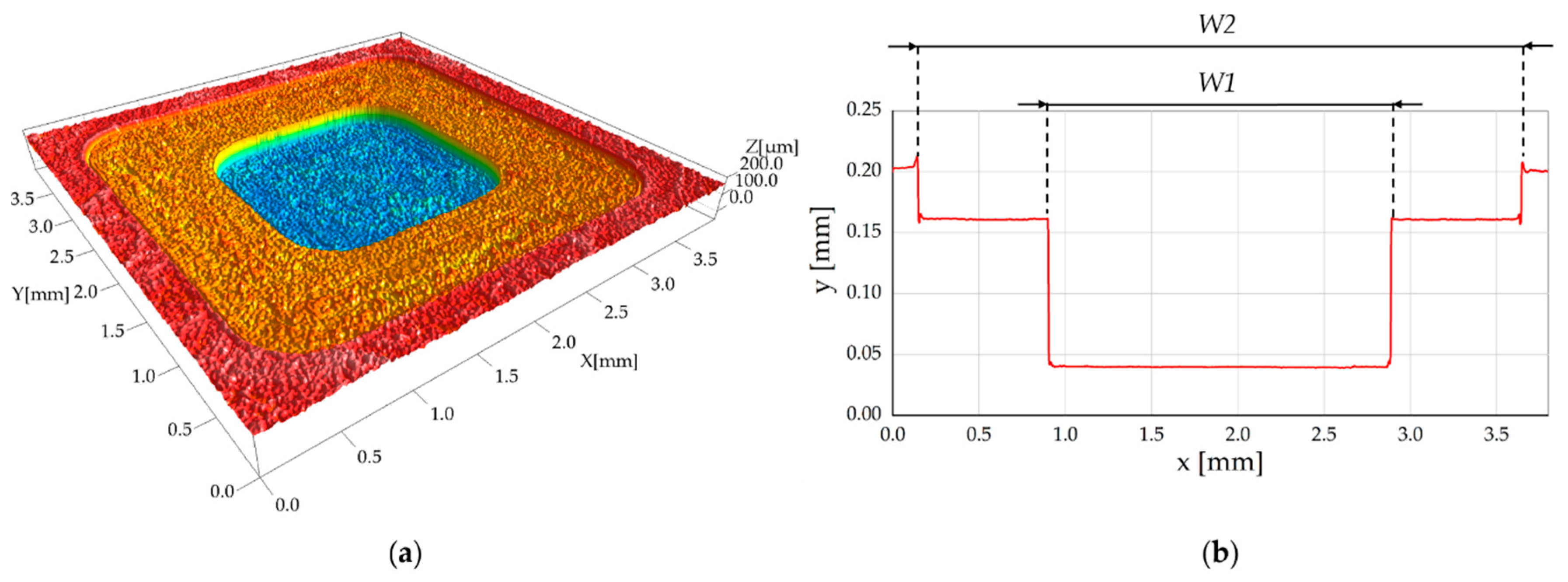

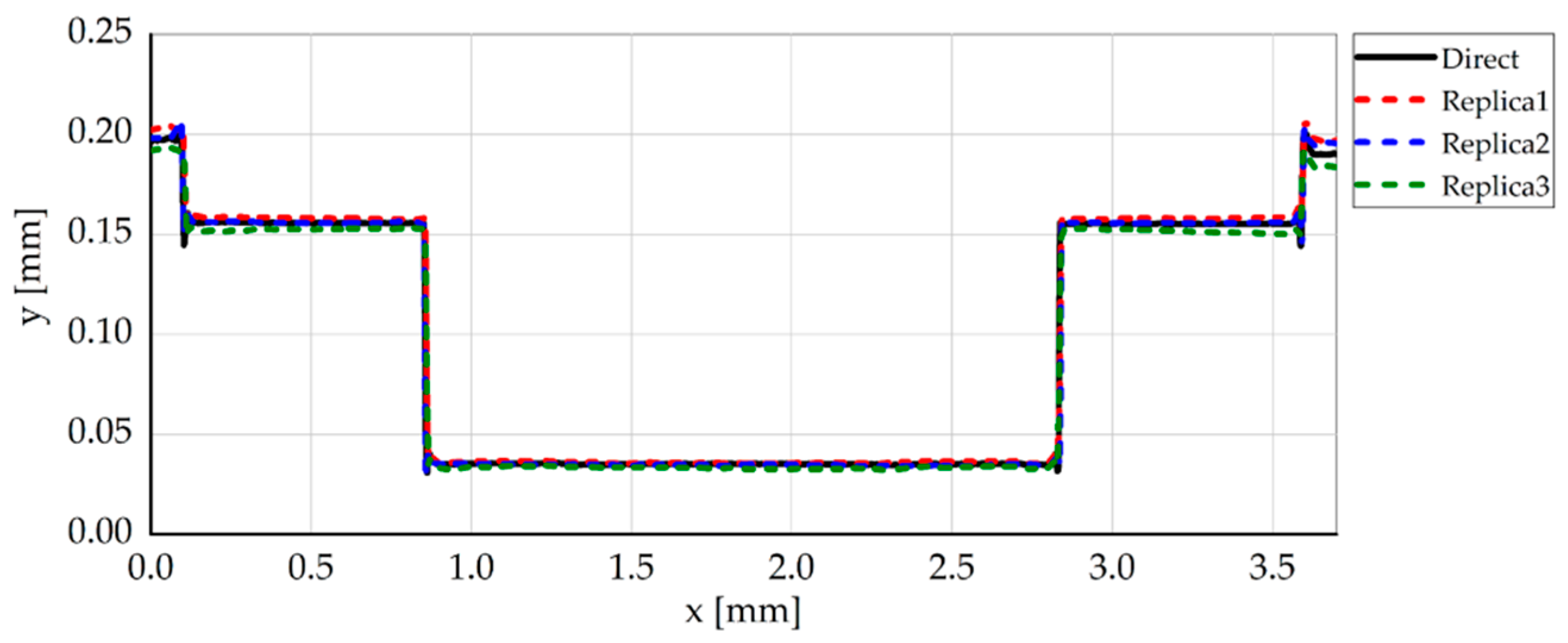

3.2. Comparison of Geometrical Measurements

The steel micromilled pockets and their silicone replicas had a very similar shape. In particular, the replicas were able to accurately reproduce the geometry of the vertical walls, since no trace of any tilt due to the shrinkage of the polymer was present. With regard to the steps of the pockets, a not-perfect perpendicularity of the silicone pockets with respect to the vertical axis was sometimes observed, as shown in

Figure 11 where Replica 3 presents a slightly tilted intermediate horizontal line. This micrometric deformation does not affect the width measurements.

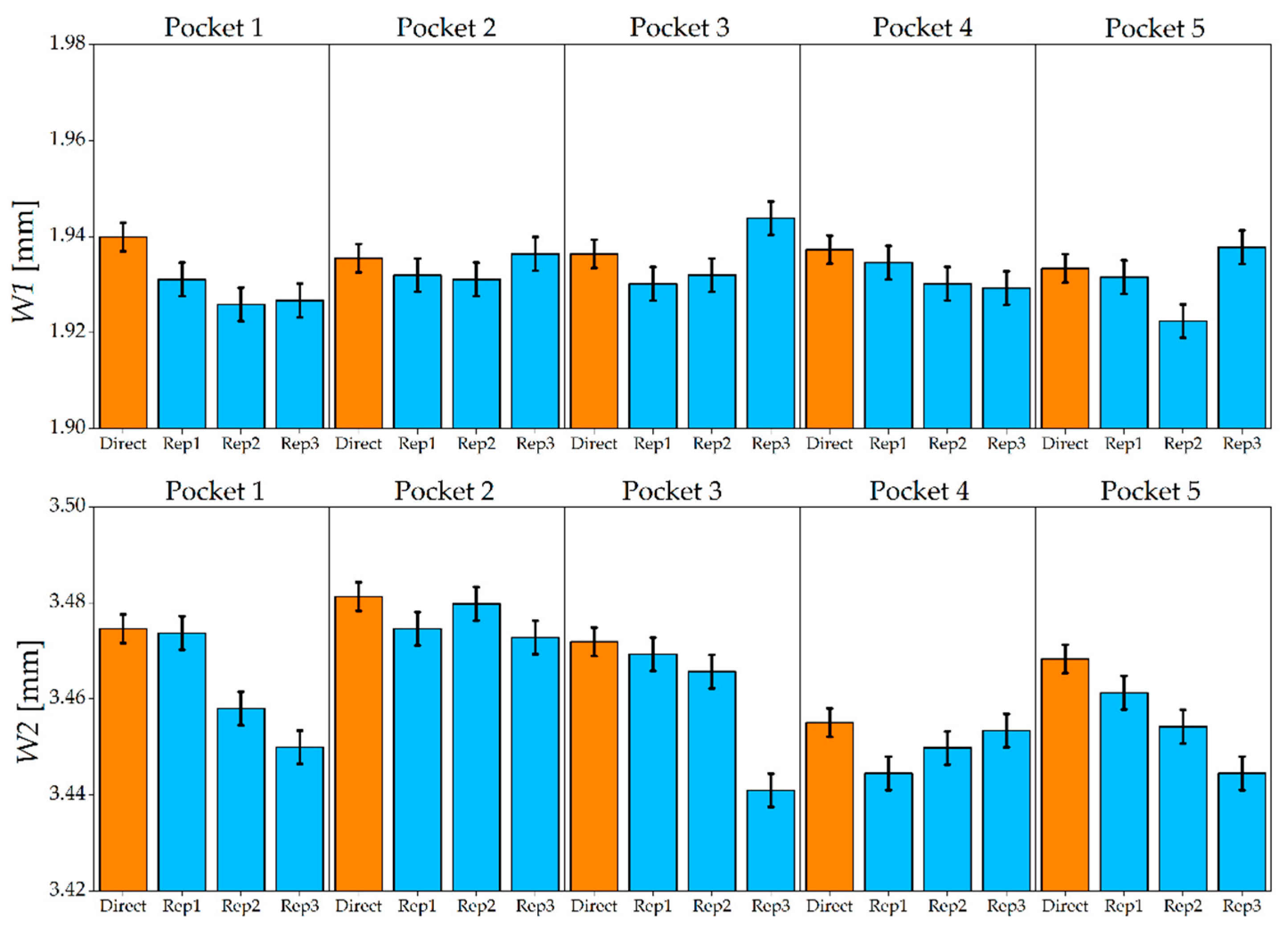

Figure 12 shows the results of the width measurements made on the AISI 440 H sample. The five steel micromilled pockets have an almost constant

W1, while a certain variability was observed for

W2. When comparing master and replicated widths, it is possible to observe that the indirect measurement generally provided a lower value for both the measurands. In fact, only in 10% of the cases the indirect evaluation generated an overestimation of

W1 and

W2. This finding in is accordance with the experiments carried out by Madsen et al. [

21], in which a shrinkage between master and PDMS replica was observed when measuring lateral geometrical features. Direct and indirect measurements provided the same output (i.e., the uncertainty intervals overlapped) in 53% of the comparisons for

W1 and in 40% for

W2, revealing that the replication fidelity was higher for the measurement of the inner geometry of the pockets (see

Figure 2). As regards the repeatability of the replication procedure, the average standard deviation, calculated among the three replicas and for the five pockets, equals 5 µm for

W1 measurements and 9 µm for

W2 measurements. It is therefore possible to conclude that the

W1 was replicated more accurately and precisely by the silicone media.

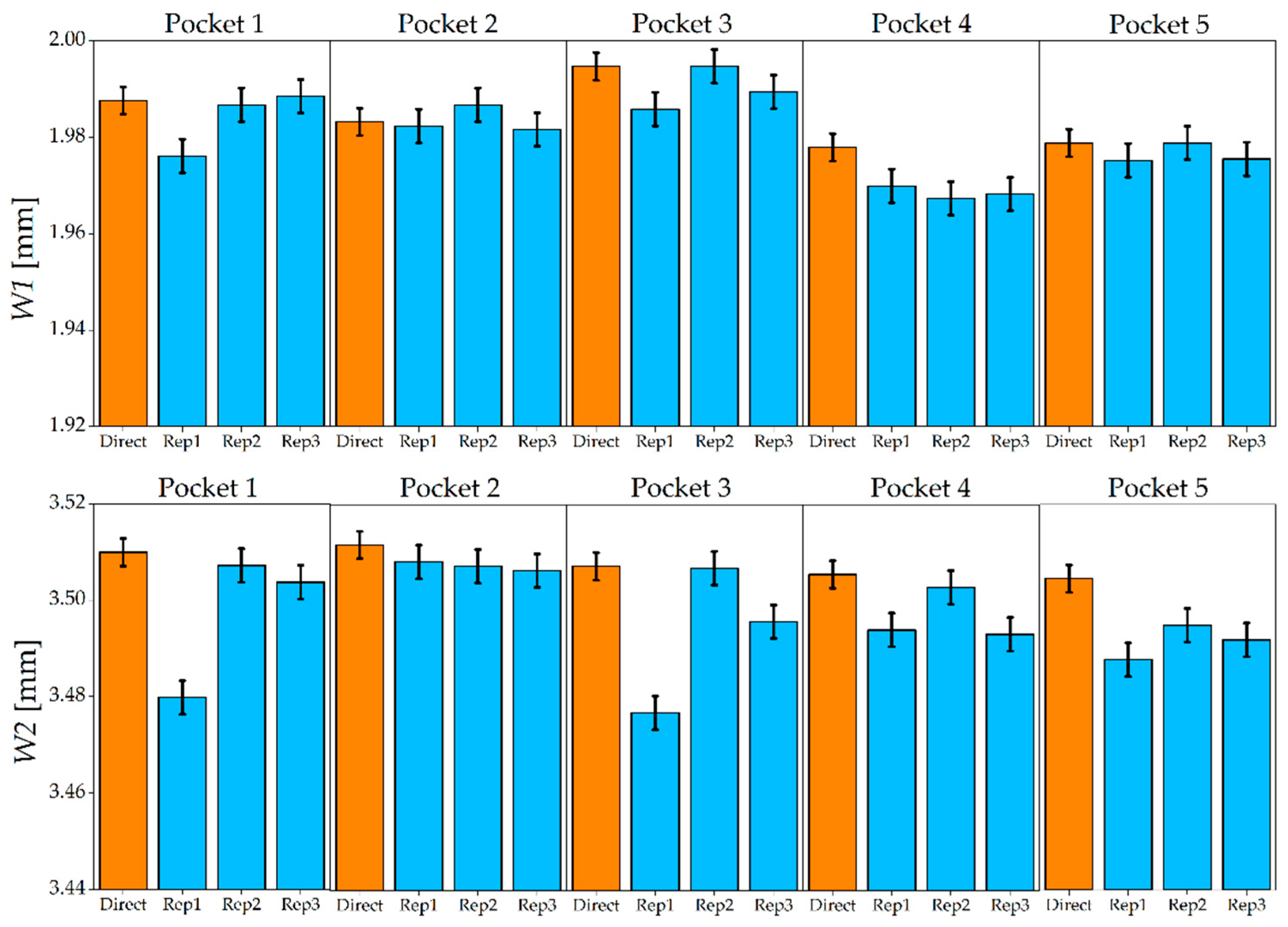

Figure 13 shows the results for the AISI 440 A sample. As in the harder material, the replication generally introduced an underestimation: only in one case out of 30 the width of the replicated specimen was larger than that of the master. The uncertainty intervals of direct and indirect measurements overlap in 67% of the cases for

W1 and in 47% of the cases for

W2. Concerning the repeatability of the three replicas, average standard deviations of 3 µm and 8 µm were observed for

W1 and

W2, respectively. Therefore, as for the hardened steel, a better replication was achieved for the internal width of the micromilled pockets.

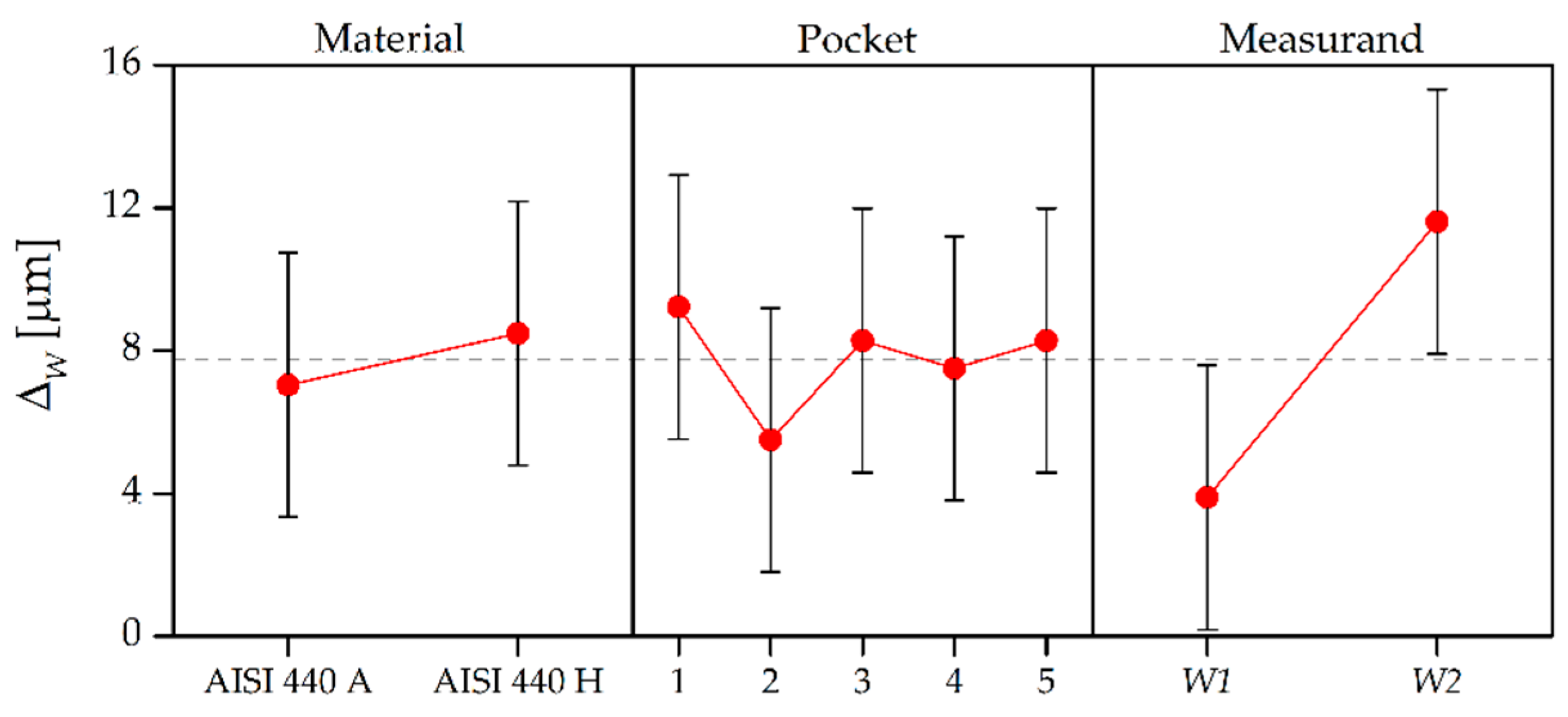

The results in terms of deviation ∆

W, calculated as the difference between direct and indirect measurement outputs, are summarized in

Figure 14 and

Table 8 in which the ANOVA results for ∆

W are shown. It may be seen that average deviation was approximately 8 µm, demonstrating that the silicone media was able to achieve replication fidelity down to a single micrometer digit. The replication performance did not depend on the material of the master, as the p-value was larger than 5% for this experimental factor. The same conclusion can be drawn for the five pockets: the replication performance was unaffected by the different depth of the geometry under indirect measurement. On the contrary, the fidelity of the replicas was greatly affected by the type of measurand. When measuring

W2, the deviation was on average 8 µm higher than when measuring

W1. This suggests that the silicone media better replicates geometries that are more internal with respect to the outer surface on which it is applied (see

Figure 2).

In order to further characterize the behavior of the silicone when replicating geometrical features, the shrinkage

sW was calculated as:

where

Wmaster and

Wreplica are the width measurements carried out on the master and on the replica, respectively. By considering both

W1 and

W2, the average shrinkage equaled 0.27% ± 0.03%, where the last value represents the expanded uncertainty calculated by means of the law of propagation of error [

34] applied to Equation (5). This parameter is particularly useful, since it gives precise indications on what is the percentage underestimation introduced by the replication procedure when measuring micromilled geometries. Therefore, it can be used to determine the dimension of the master when only an indirect measurement is available, provided that the uncertainty value of the shrinkage is taken into account.