A Large-Size MEMS Scanning Mirror for Speckle Reduction Application

Abstract

:1. Introduction

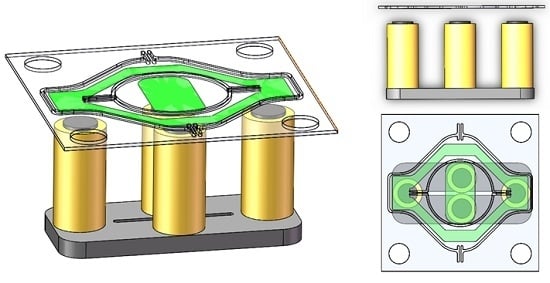

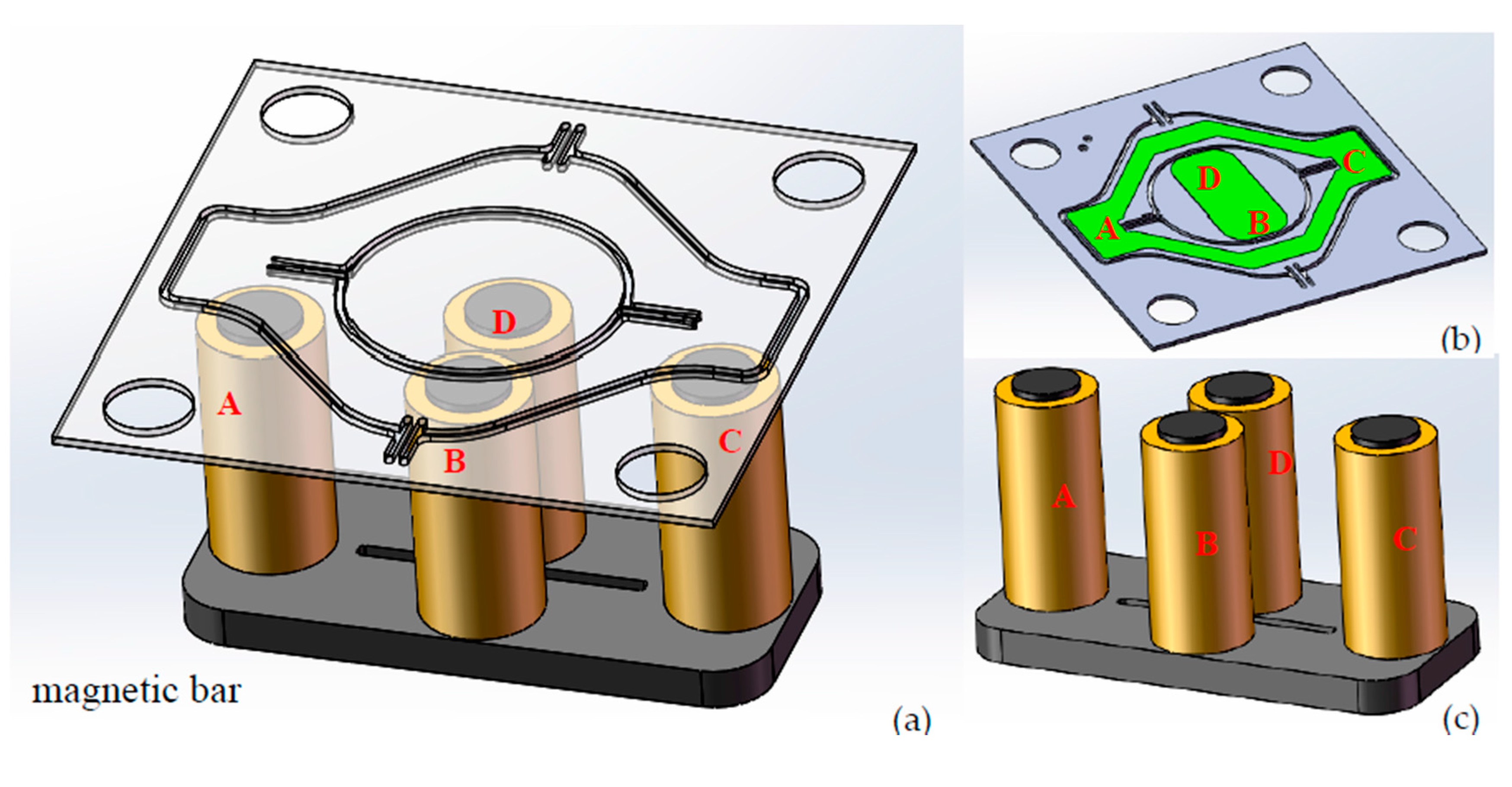

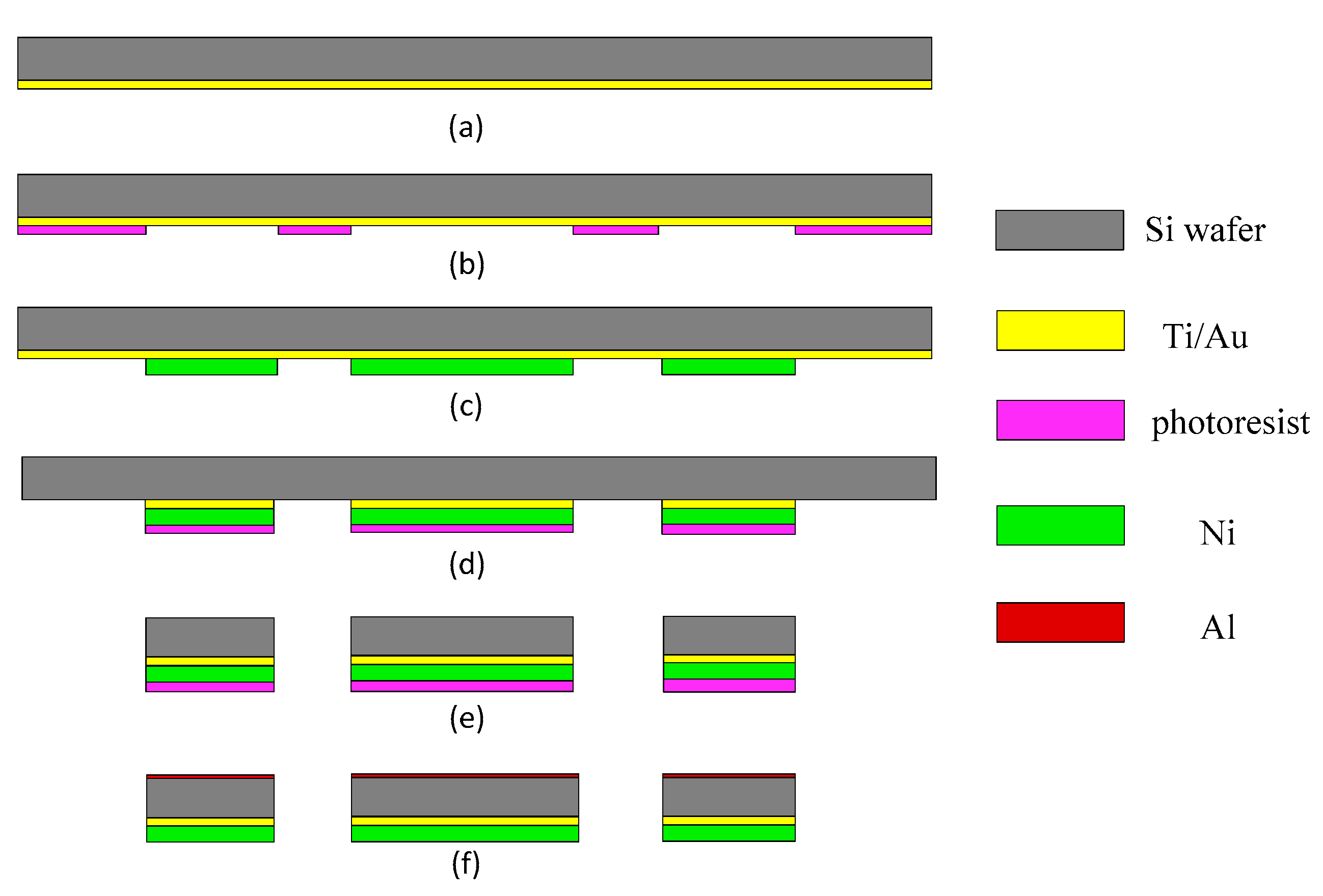

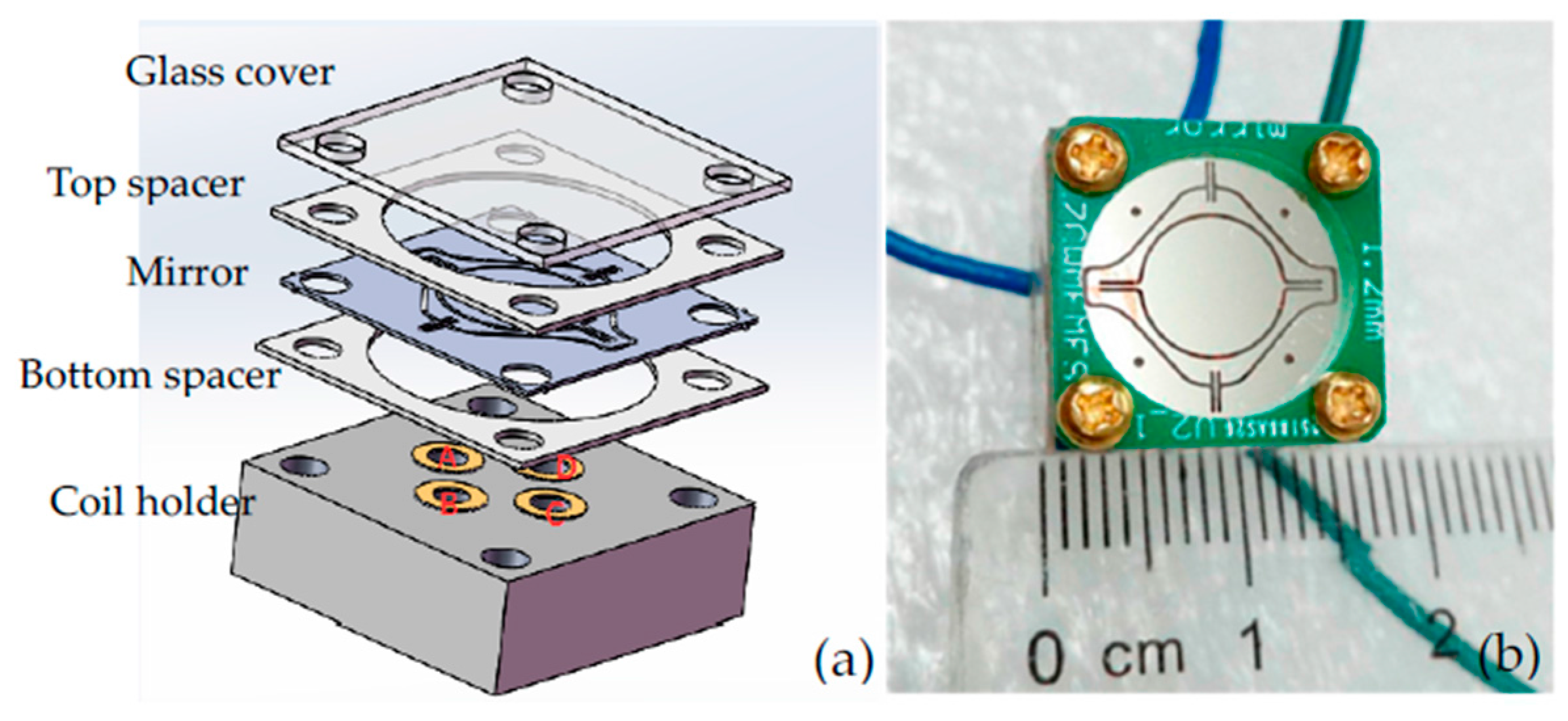

2. Design

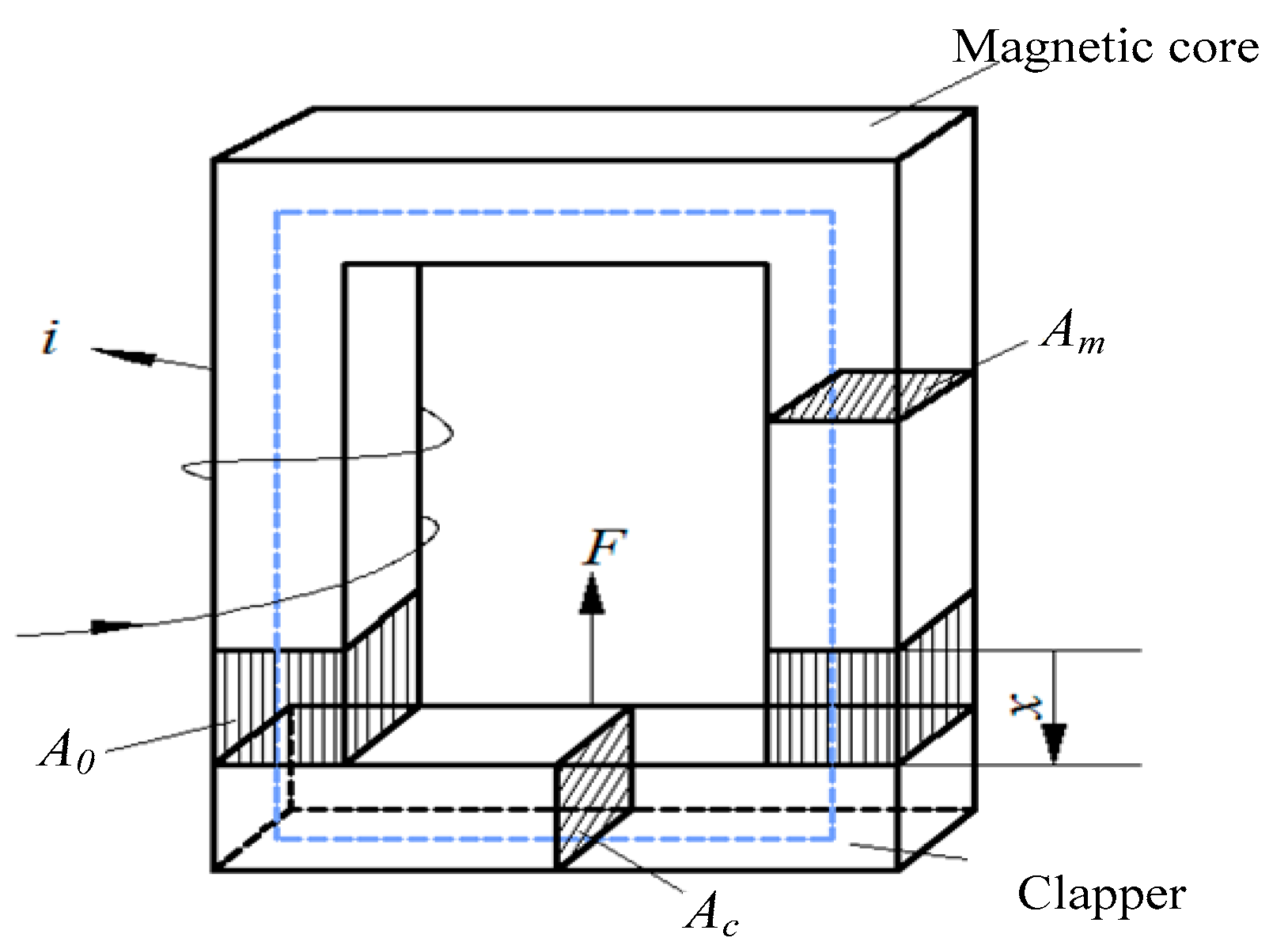

3. Fabrication

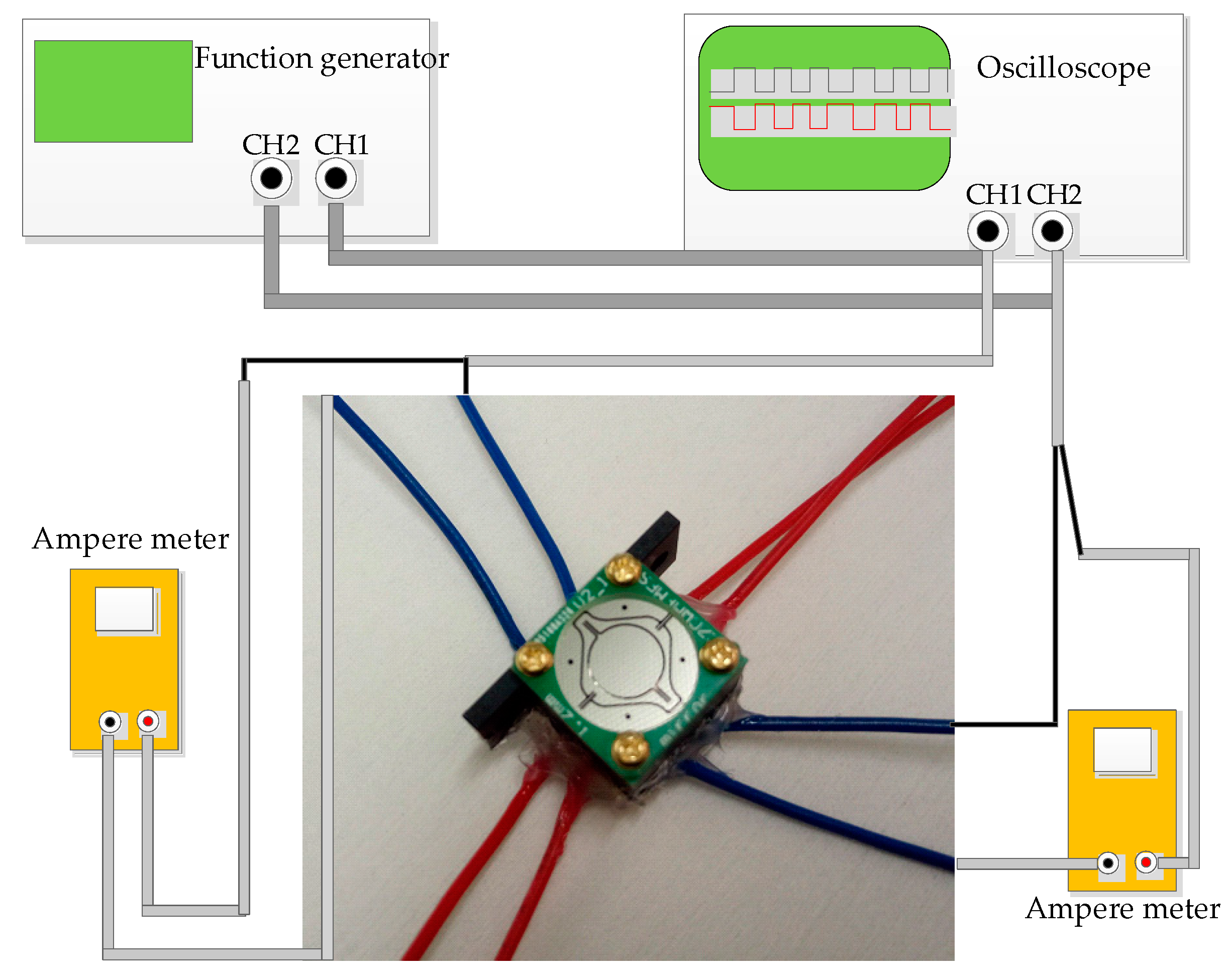

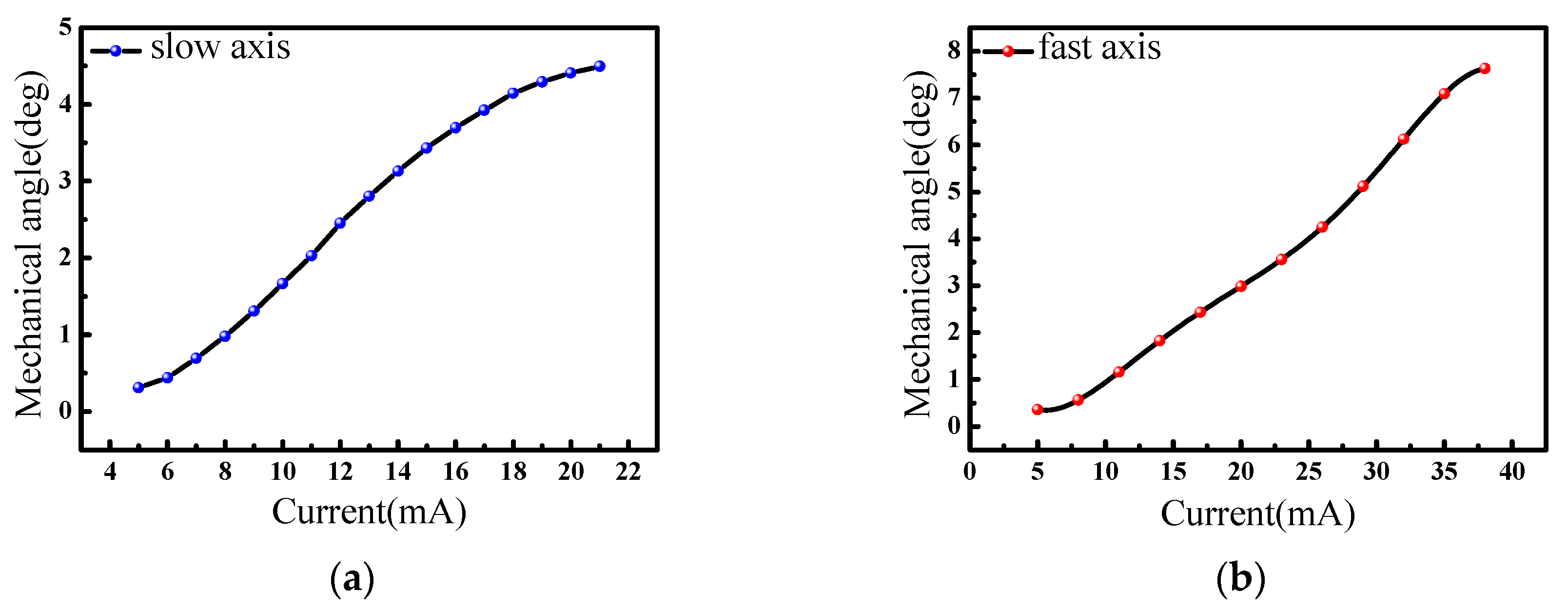

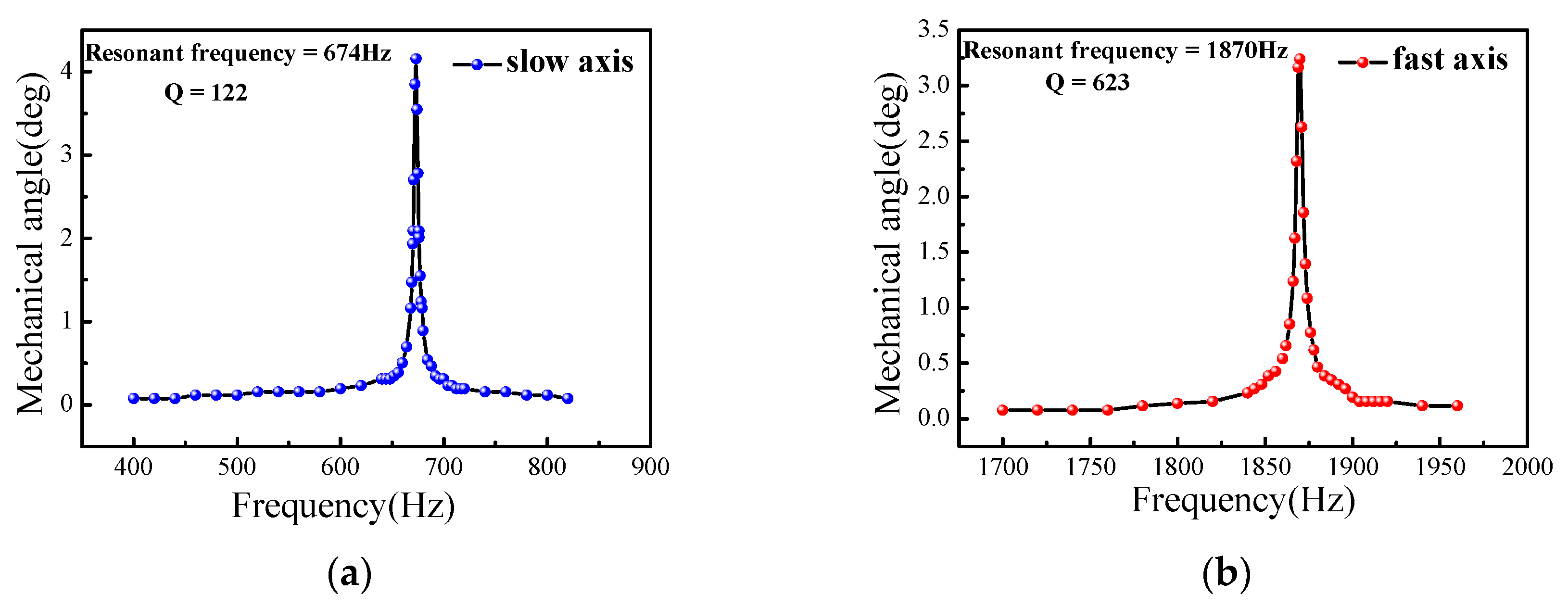

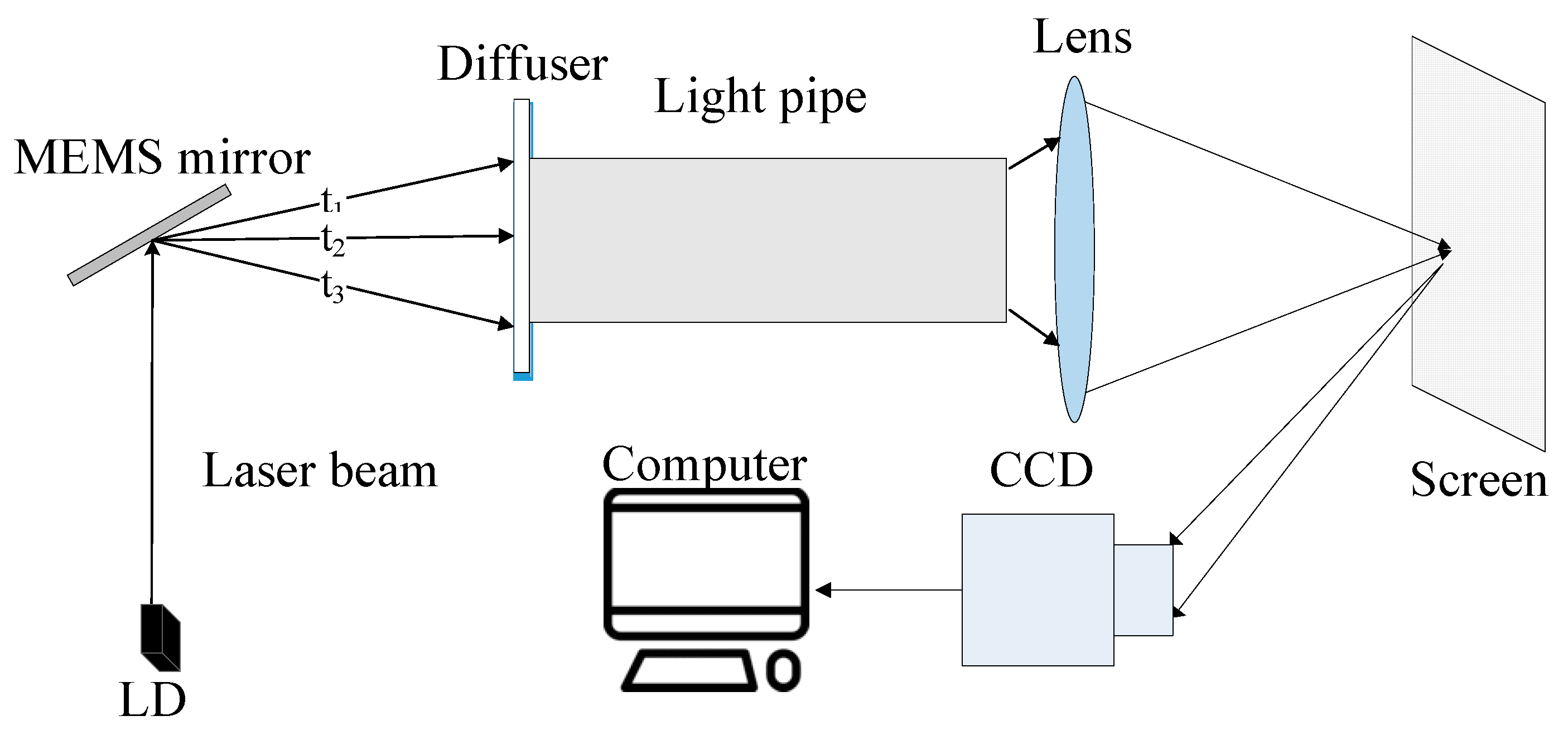

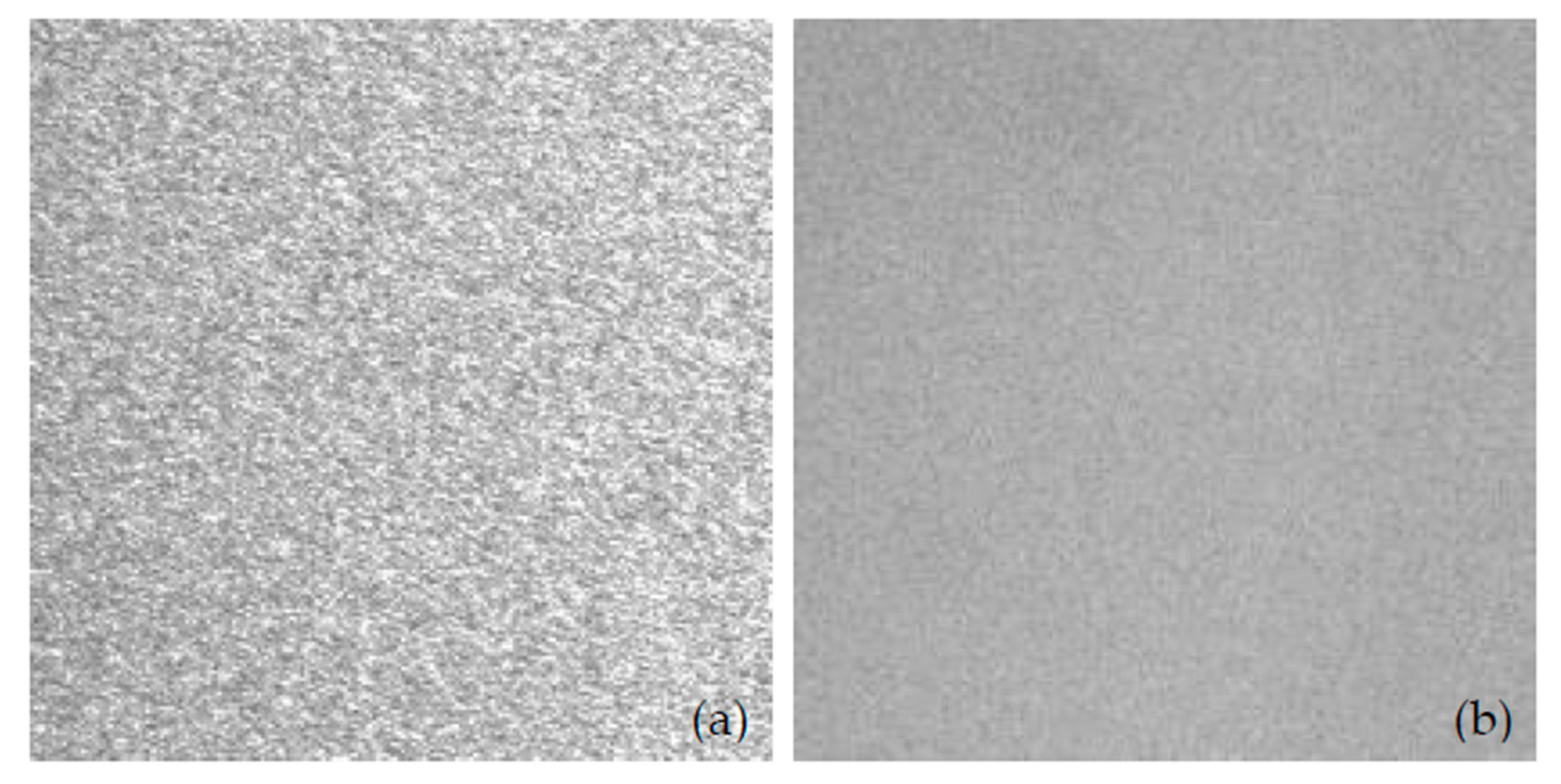

4. Characterization and Results

5. Application to Speckle Reduction

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tong, Z.; Shen, W.; Song, S.; Cheng, W.; Cai, Z.; Ma, Y.; Wei, L.; Ma, W.; Xiao, L.; Jia, S.; et al. Combination of micro-scanning mirrors and multi-mode fibers for speckle reduction in high lumen laser projector applications. Opt. Express 2017, 25, 3795–3804. [Google Scholar] [CrossRef] [PubMed]

- Subramaniam, S.; Le, C.P.; Kaur, S.; Kalicinski, S.; Ekwinska, M.; Halvorsen, E.; Akram, M.N. Design, modeling, and characterization of a microelectromechanical diffuser device for laser speckle reduction. J. Microelectromech. Syst. 2014, 23, 117–127. [Google Scholar]

- Young, E.J.; Kasdin, N.J.; Carlotti, A. Image Analysis with Speckles Altered by a Deformable Mirror. Available online: http://proceedings.spiedigitallibrary.org/proceeding.aspx?articleid=1744172 (accessed on 25 April 2017).

- Tong, Z.; Chen, X.; Akram, M.N.; Aksnes, A. Compound speckle characterization method and reduction by optical design. J. Disp. Technol. 2012, 8, 132–137. [Google Scholar] [CrossRef]

- Heger, A.; Schreiber, P.; Höfer, B. Development and Characterisation of a Miniaturized Laser Projection Display Based on MEMS-Scanning-Mirrors. Available online: http://proceedings.spiedigitallibrary.org/proceeding.aspx?articleid=1345482 (accessed on 25 April 2017).

- Kim, S.; Han, Y.G. Suppression of speckle patterns based on temporal angular decorrelation induced by multiple beamlets with diverse optical paths. J. Korean Phys. Soc. 2014, 64, 527–531. [Google Scholar] [CrossRef]

- Chen, X.; Svensen, Ø.; Akram, M.N. Speckle reduction in laser projection using a dynamic deformable mirror. Opt. Express 2014, 22, 11152–11166. [Google Scholar]

- Sprague, R.B.; Montague, T.; Brown, D. Bi-Axial Magnetic Drive for Scanned Beam Display Mirrors. Available online: http://proceedings.spiedigitallibrary.org/proceeding.aspx?articleid=859733 (accessed on 25 April 2017).

- Oliveira, L.C.M.; Barbaroto, P.R.; Ferreira, L.O.S.; Doi, I. A novel Si micromachined moving-coil induction actuated mm-sized resonant scanner. J. Micromech. Microeng. 2005, 16, 165. [Google Scholar] [CrossRef]

- Akram, M.N.; Tong, Z.; Ouyang, G.; Chen, X.; Kartashov, V. Laser speckle reduction due to spatial and angular diversity introduced by fast scanning micromirror. Appl. Opt. 2010, 49, 3297–3304. [Google Scholar] [CrossRef] [PubMed]

- Bayat, D. Large Hybrid High Precision MEMS Mirrors. Ph.D. Dissertation, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2011. [Google Scholar]

- Bleuler, H.; Cole, M.; Keogh, P.; Larsonneur, R.; Larsonneur, R.; Maslen, E.; Okada, Y.; Traxler, A. Magnetic Bearings: Theory, Design, and Application to Rotating Machinery; Springer Science & Business Media: Berlin, Germany, 2009. [Google Scholar]

- Chen, M.; Yu, H.; Guo, S.; Xu, R.; Shen, W. An electromagnetically-driven MEMS micromirror for laser projection. In Proceedings of the 10th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xi’an, China, 7–11 April 2015; pp. 605–607. [Google Scholar]

- Chu, H.M.; Hane, K. Design, fabrication and vacuum operation characteristics of two-dimensional comb-drive micro-scanner. Sens. Actuators A Phys. 2011, 165, 422–430. [Google Scholar] [CrossRef]

- Tanner, D.M.; Walraven, J.A.; Helgesen, K.; Helgesen, K.; Irwin, L.W.; Brown, F.; Smith, N.F.; Masters, N. MEMS reliability in shock environments. In Proceedings of the 38th Annual 2000 IEEE International Reliability Physics Symposium, San Jose, CA, USA, 10–13 April 2000; pp. 129–138. [Google Scholar]

- Naumann, M.; Dietze, O.; McNeil, A.; Mehner, J.; Daniel, S. Reliability of anchors at surface micromachined devices in shock environments. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 570–573. [Google Scholar]

- GB4590-84, Mechanical and Climatic Test Methods for Semiconductor Integrated Circuits. Available online: http://down.bzwxw.com/12/GB%204590-1984.pdf (accessed on 25 April 2017). (In Chinese).

- Lee, J.Y.; Kim, T.H.; Yim, B.B.; Bu, J.U.; Kim, Y.J. Speckle reduction in laser picoprojector by combining optical phase matrix with twin green lasers and oscillating MEMS mirror for coherence suppression. Jpn. J. Appl. Phys. 2016, 55, 08RF03. [Google Scholar] [CrossRef]

- Pan, J.W.; Shih, C.H. Speckle reduction and maintaining contrast in a LASER pico-projector using a vibrating symmetric diffuser. Opt. Express 2014, 22, 6464–6477. [Google Scholar] [CrossRef] [PubMed]

- Pei, T.H.; Yeh, F.C.; Tsai, K.Y.; Li, J.H.; Liu, Z.R.; Hung, C.L. Simulation and experiment of speckle reduction by the beam splitting method on a pico-projection system. Adv. Mater. Res. 2014, 933, 572–577. [Google Scholar] [CrossRef]

- Goodman, J.W. Speckle Phenomena in Optics: Theory and Applications; Roberts and Company Publishers: Greenwood Village, CO, USA, 2007. [Google Scholar]

| Parameter | Value | Unites | |

|---|---|---|---|

| Diameter of the mirror | 6.5 | mm | |

| Thickness of the mirror | 200 | μm | |

| Width of the axis | Slow axis | 100 | μm |

| Fast axis | 160 | ||

| Length of the axis | Slow axis | 1500 | μm |

| Fast axis | 1750 | ||

| Thickness of the axes | 200 | μm | |

| Thickness of the nickel film | 20 | μm | |

| Outer diameter of the coil | 3 | mm | |

| Inner diameter of the coil | 2 | mm | |

| Height of the coil | 10 | mm | |

| Number of turns for the coil | 900 | - | |

| Resistence of the coil | 30 | Ω | |

| Measurement System | Integration Time/ms | Maxmium Intensity | Minimum Intensity | Mean Intensity | Contrast Value/% |

|---|---|---|---|---|---|

| With mirror | 50 | 157 | 108 | 126 | 4.58 |

| Without mirror | 50 | 255 | 94 | 179 | 18.19 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Zhou, P.; Wang, T.; He, J.; Yu, H.; Shen, W. A Large-Size MEMS Scanning Mirror for Speckle Reduction Application . Micromachines 2017, 8, 140. https://doi.org/10.3390/mi8050140

Li F, Zhou P, Wang T, He J, Yu H, Shen W. A Large-Size MEMS Scanning Mirror for Speckle Reduction Application . Micromachines. 2017; 8(5):140. https://doi.org/10.3390/mi8050140

Chicago/Turabian StyleLi, Fanya, Peng Zhou, Tingting Wang, Jiahui He, Huijun Yu, and Wenjiang Shen. 2017. "A Large-Size MEMS Scanning Mirror for Speckle Reduction Application " Micromachines 8, no. 5: 140. https://doi.org/10.3390/mi8050140

APA StyleLi, F., Zhou, P., Wang, T., He, J., Yu, H., & Shen, W. (2017). A Large-Size MEMS Scanning Mirror for Speckle Reduction Application . Micromachines, 8(5), 140. https://doi.org/10.3390/mi8050140