Design and Performance Testing of a Novel Three-Dimensional Elliptical Vibration Turning Device

Abstract

:1. Introduction

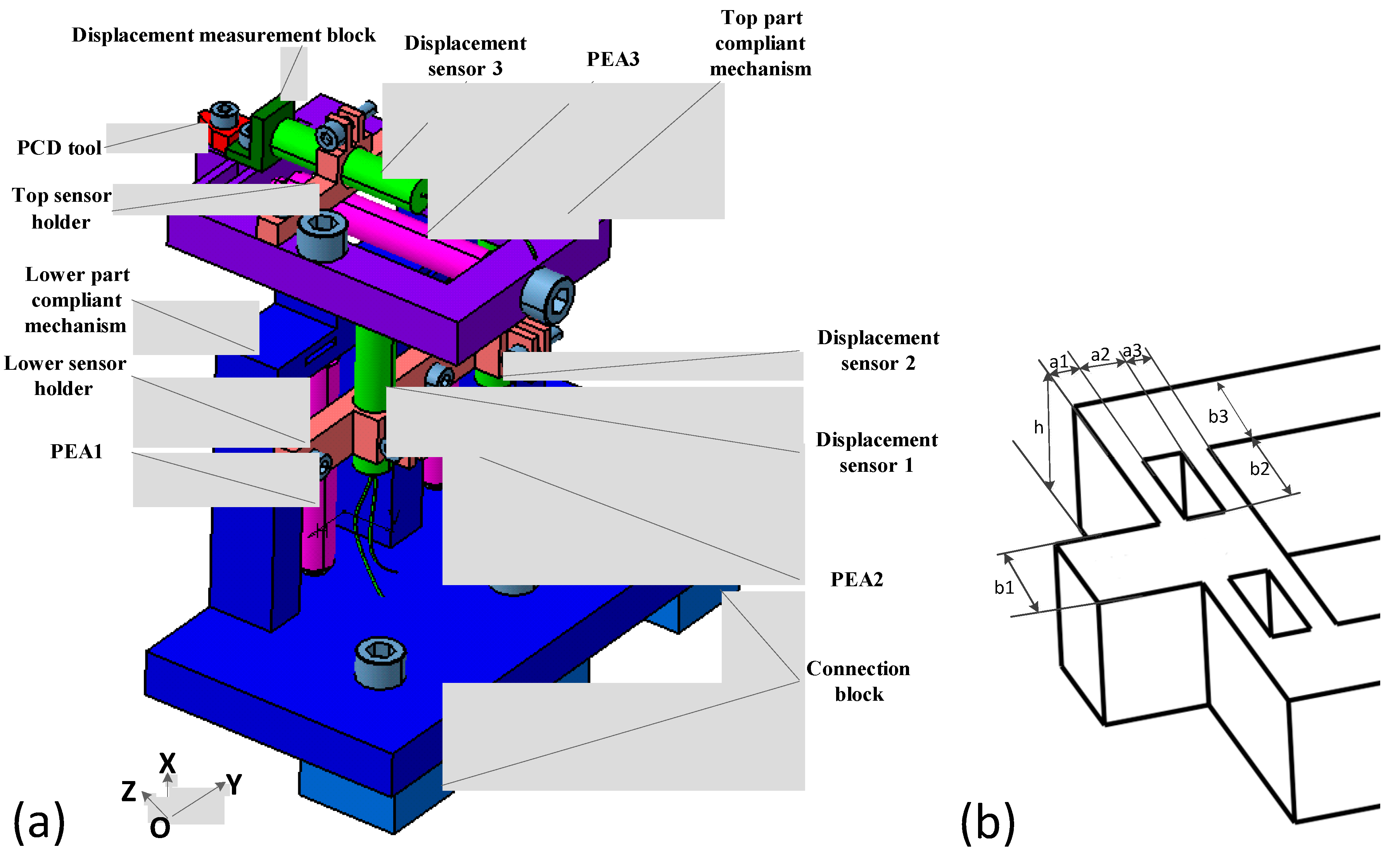

2. Mechanical Design

2.1. Design of 1-Degree-of-Freedom (DoF) Flexure-Based Compliant Mechanism

2.2. Structure Design

3. Performance Testing and Discussion

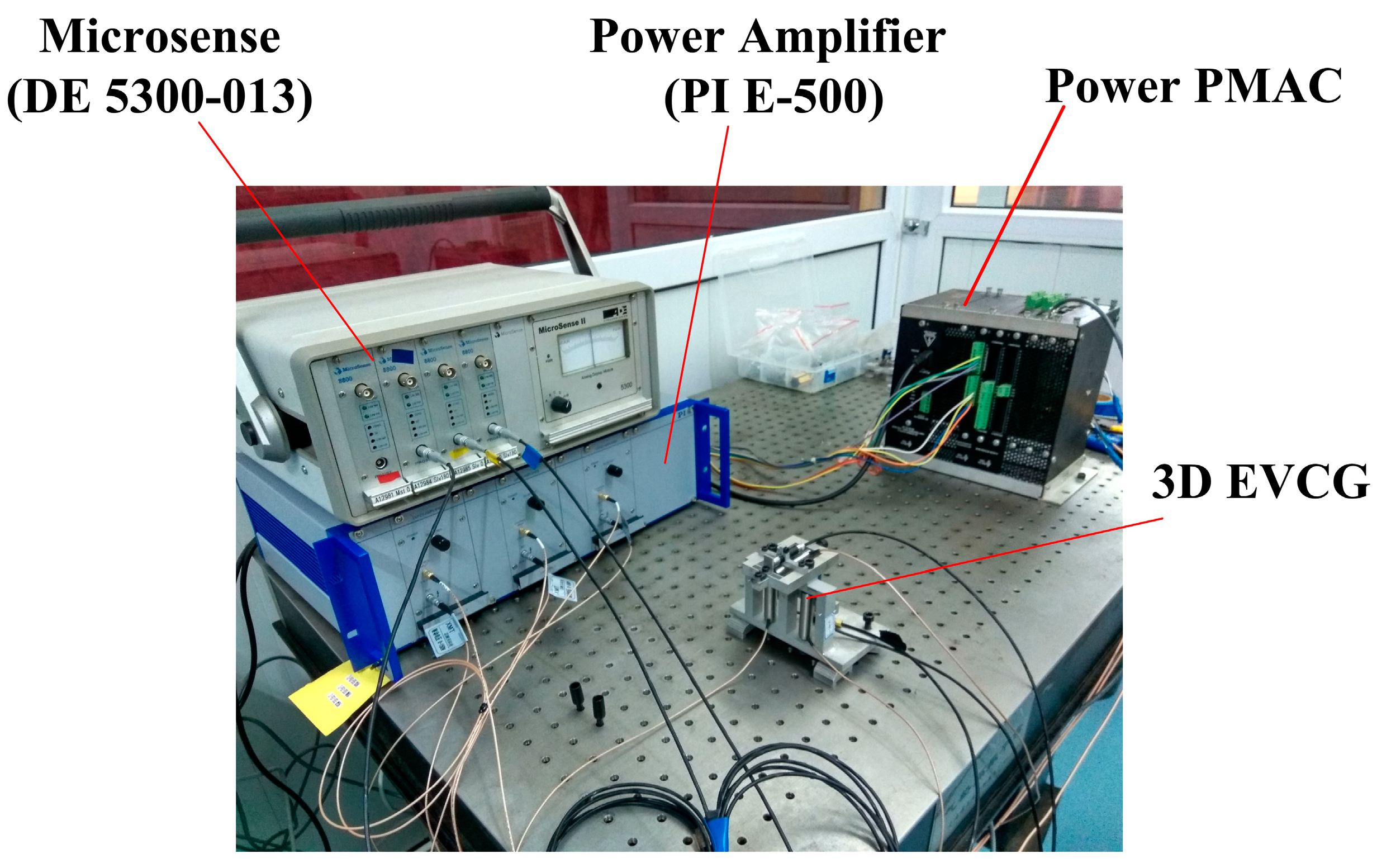

3.1. Experimental Setup

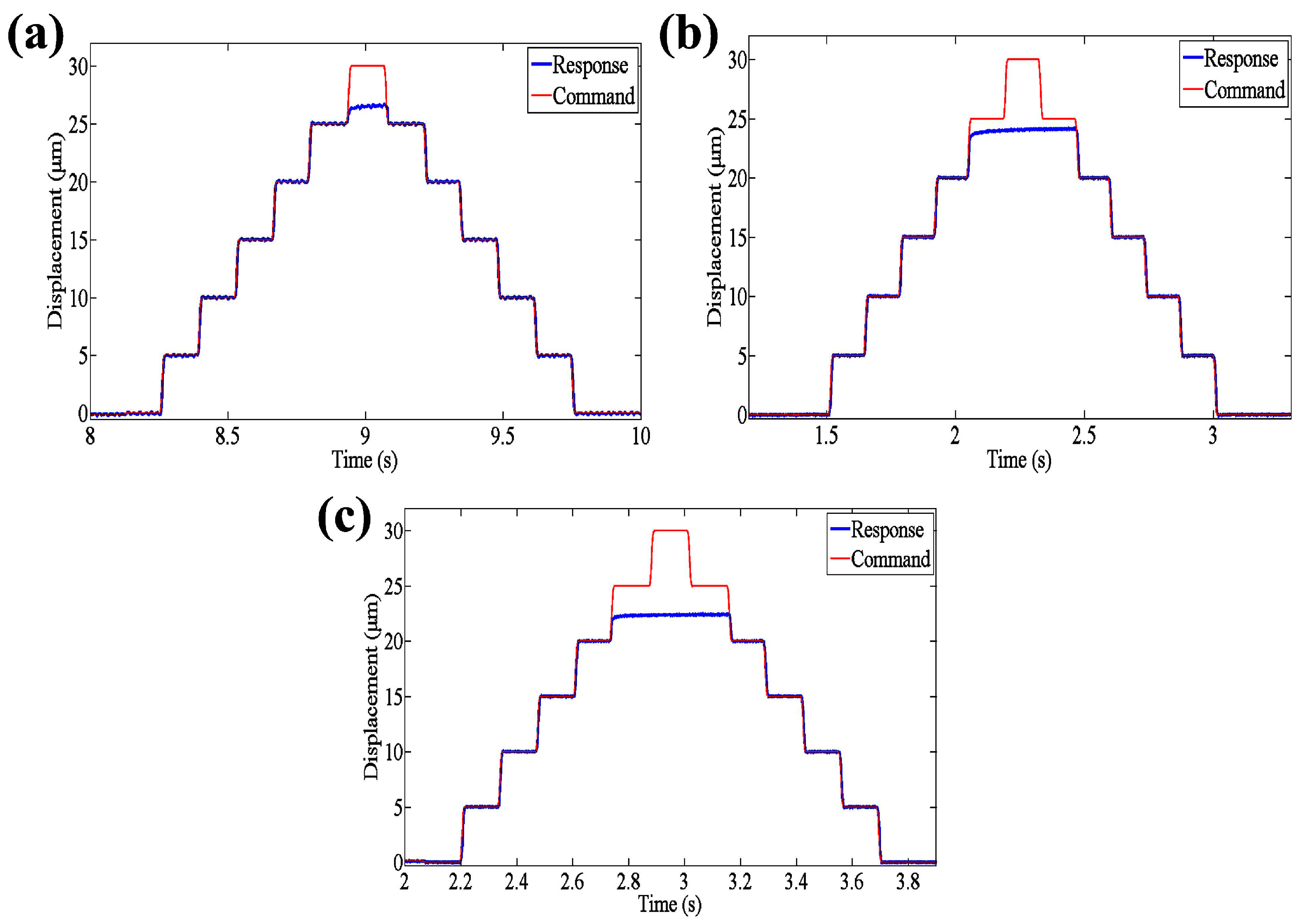

3.2. Stroke Test

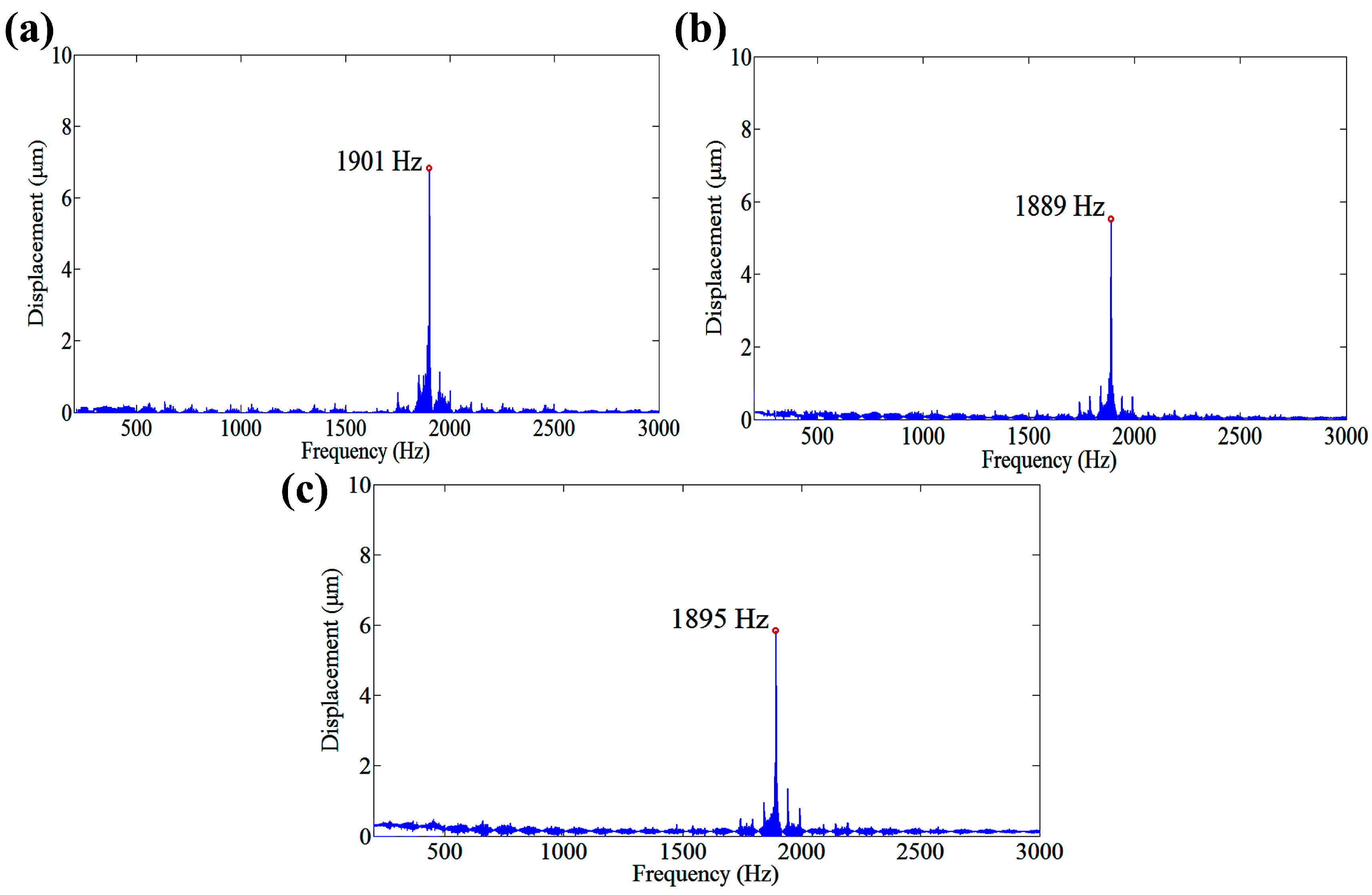

3.3. Dynamic Test

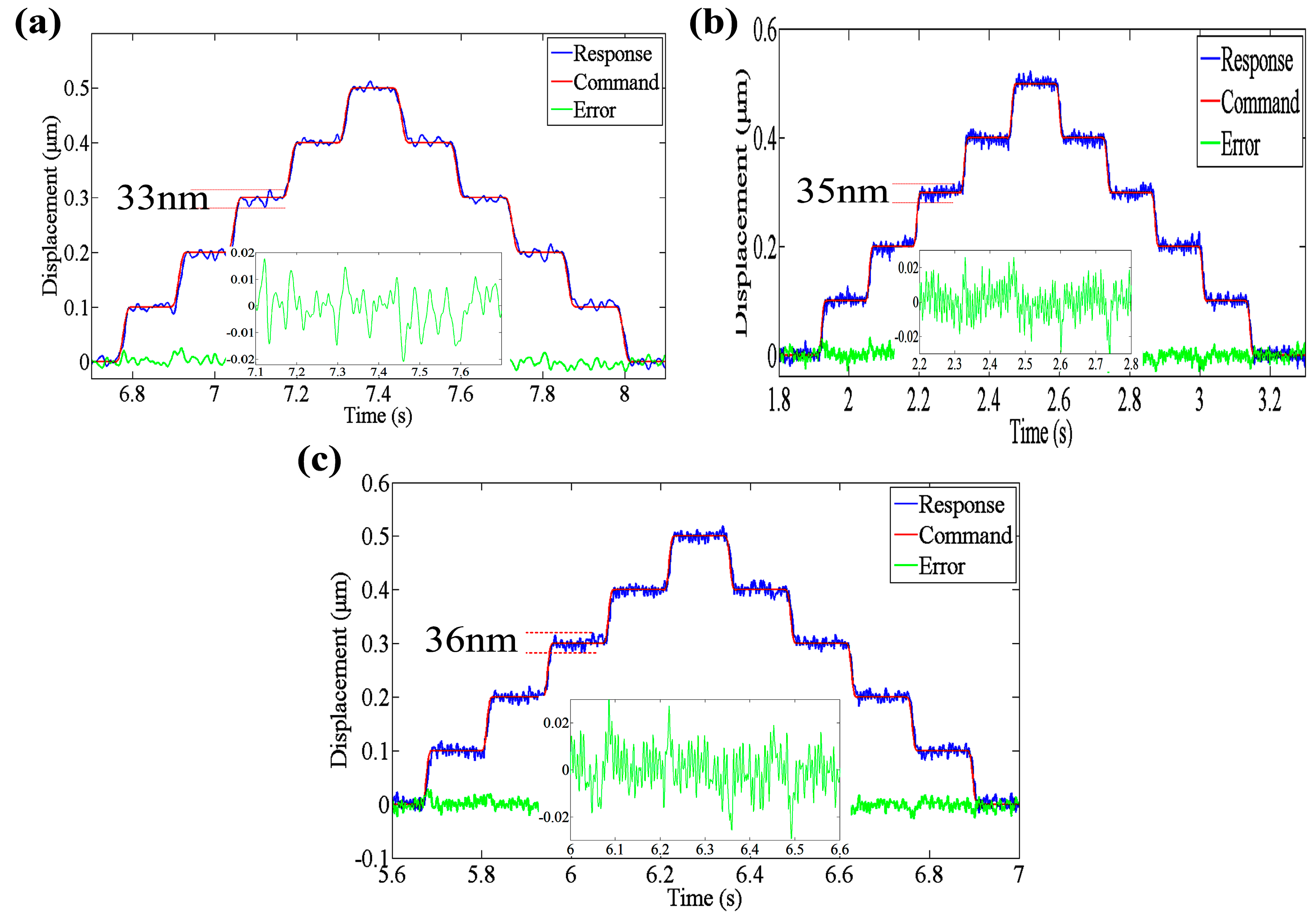

3.4. Resolution Tests and Tracking Accuracy Analysis

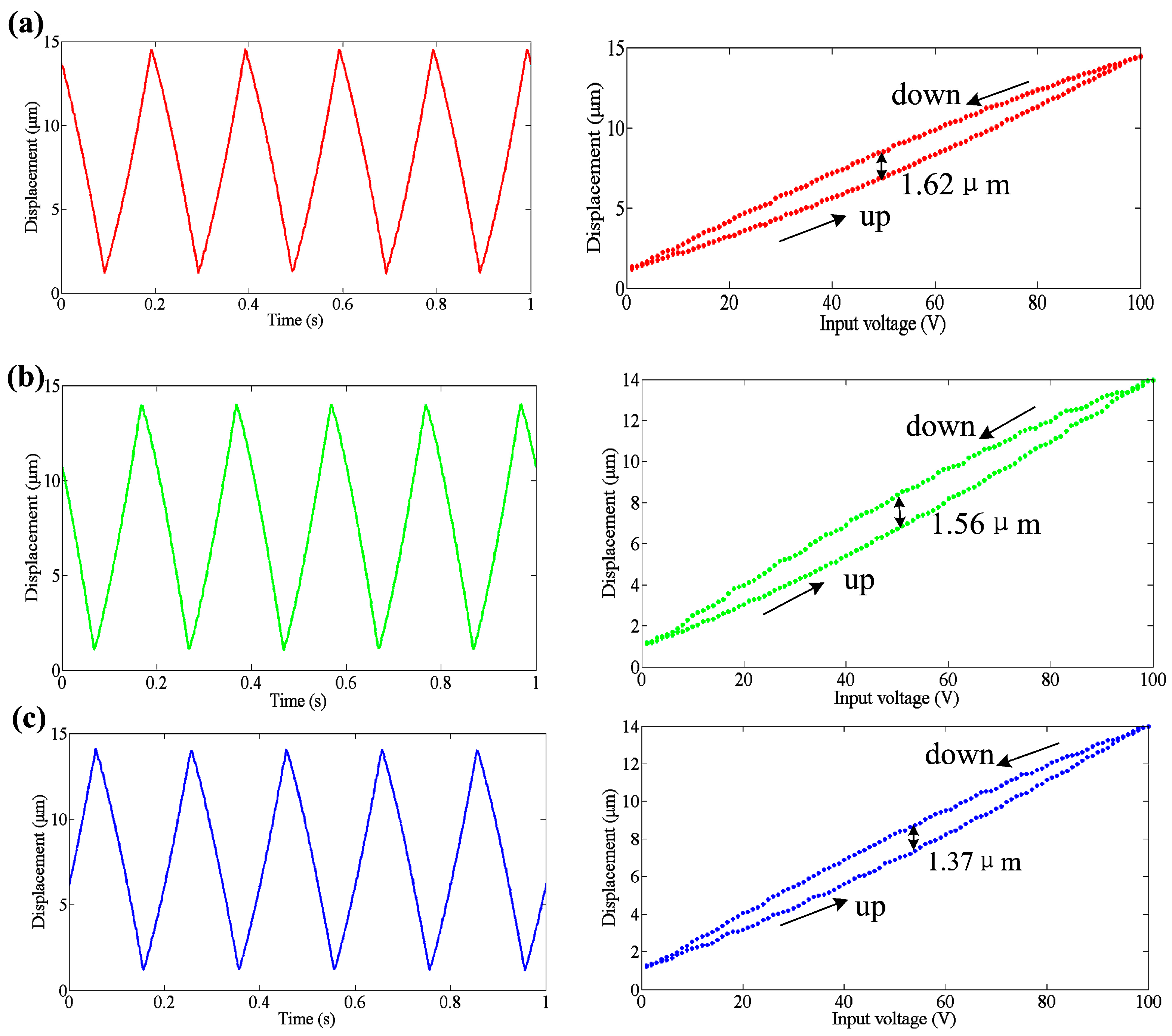

3.5. Hysteresis Analysis

4. Kinematical Modeling and Experimental Validation

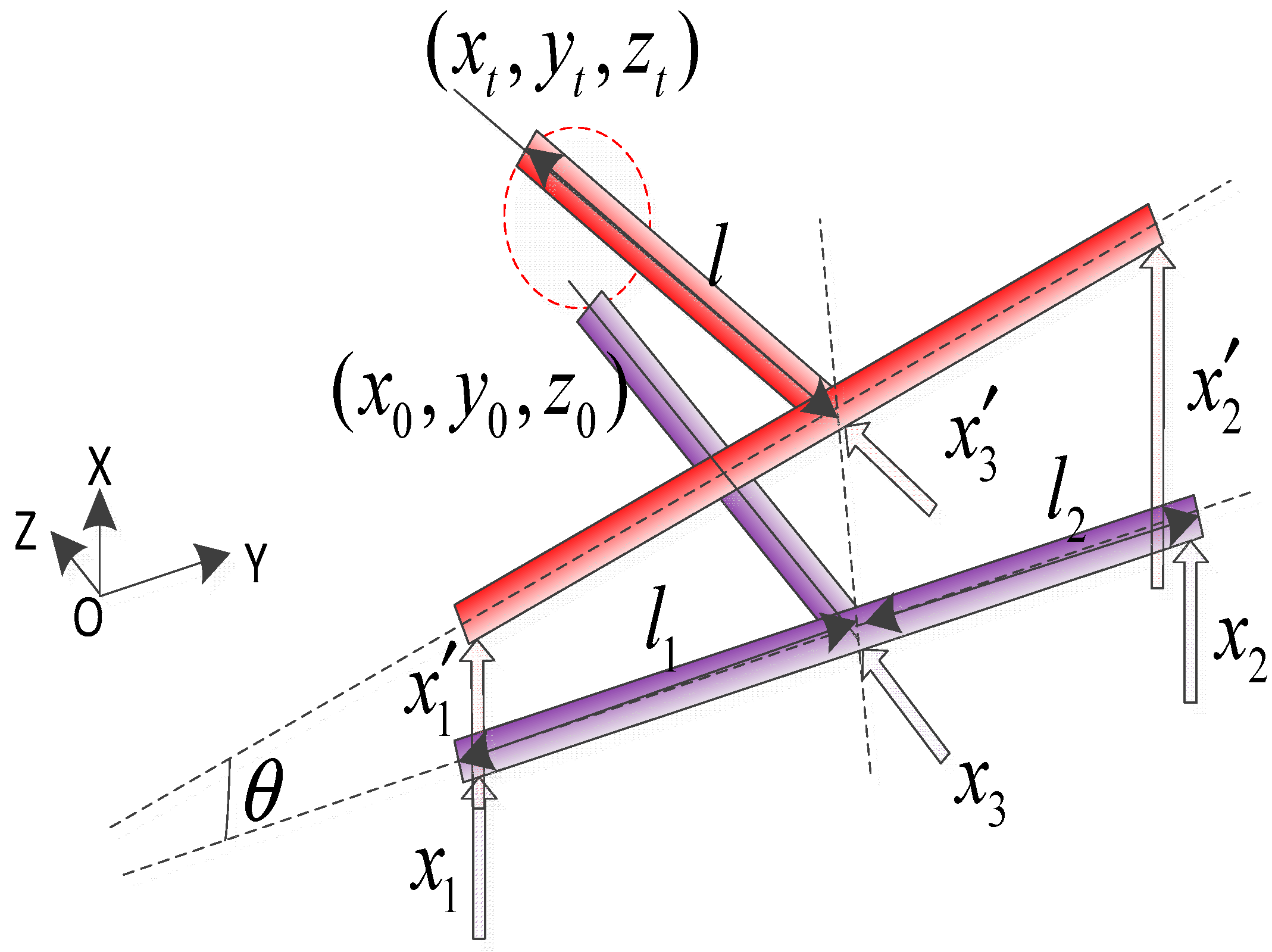

4.1. Kinematical Modeling

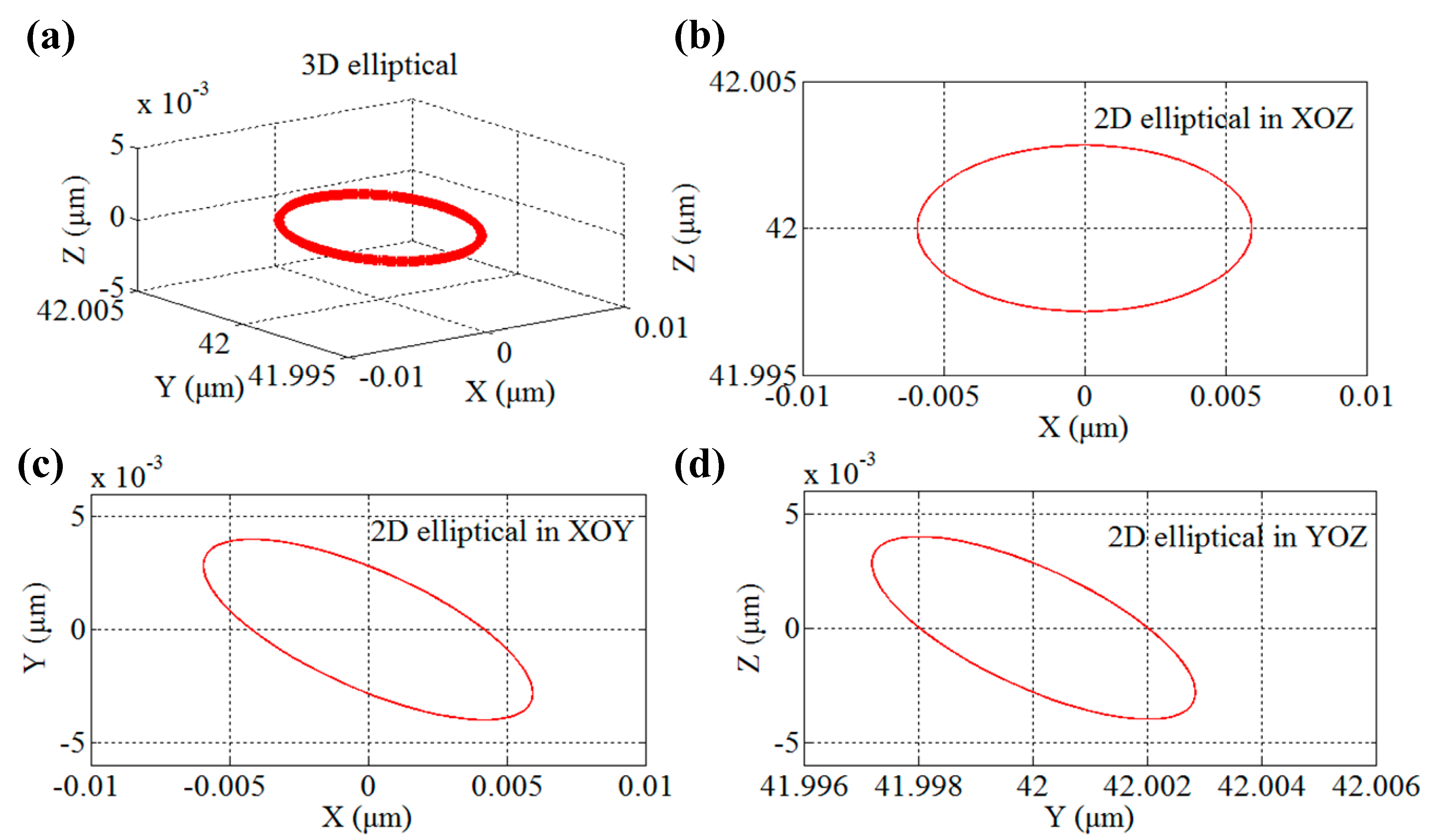

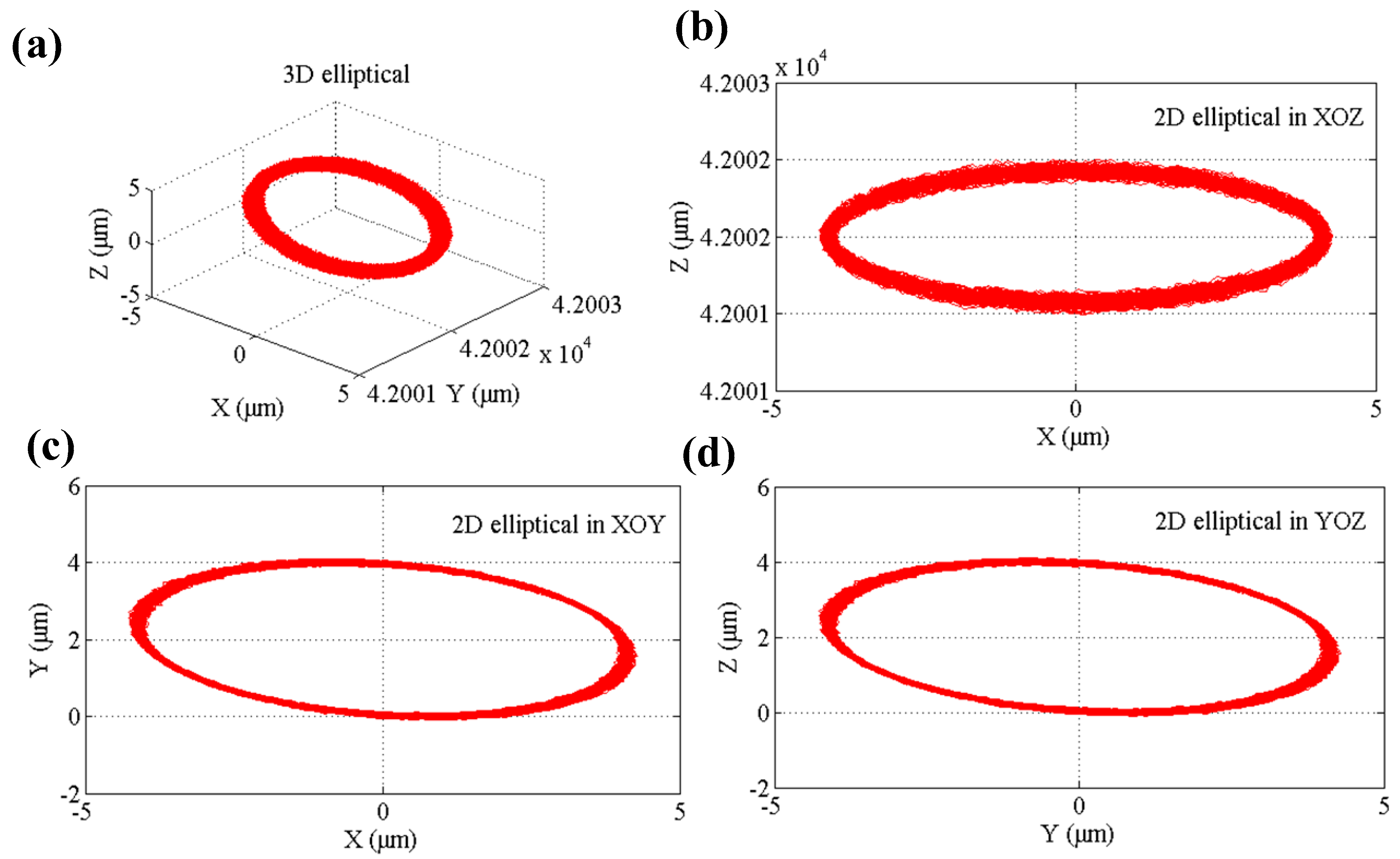

4.2. Experimental Validation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fang, F.Z.; Zhang, X.D.; Weckenmann, A.; Zhang, G.X.; Evans, C. Manufacturing and measurement of freeform optics. CIRP Ann.-Manuf. Technol. 2013, 62, 823–846. [Google Scholar] [CrossRef]

- Savio, E.; de, C.L.; Schmitt, R. Metrology of freeform shaped parts. CIRP Ann.-Manuf. Technol. 2003, 56, 810–835. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, H.J.; Chen, S.J. Study on diamond cutting of nonrationally symmetric microstructured surfaces with fast tool servo. Mater. Manuf. Process. 2010, 25, 488–494. [Google Scholar] [CrossRef]

- Tang, X.R.; Nakamoto, K.; Obata, K.; Takeuchi, Y. Ultraprecision micromachining of hard material with tool wear suppression by using diamond tool with special chamfer. CIRP Ann.-Manuf. Technol. 2013, 62, 51–54. [Google Scholar] [CrossRef]

- Fang, F.Z.; Zhang, X.D.; Hu, X.T. Cylindrical coordinate machining of optical freeform surfaces. Opt. Express 2008, 16, 7323–7329. [Google Scholar] [CrossRef] [PubMed]

- Tian, F.; Yin, Z.; Li, S. Fast tool servo diamond turning of optical freeform surfaces for rear-view mirrors. Int. J. Adv. Manuf. Technol. 2015, 80, 1759–1765. [Google Scholar] [CrossRef]

- Yin, Z.Q.; Dai, Y.F.; Li, S.Y.; Guan, C.L.; Tie, G.P. Fabrication of off-axis aspheric surfaces using a slow tool servo. Int. J. Adv. Manuf. Technol. 2011, 51, 404–410. [Google Scholar] [CrossRef]

- Moriwaki, T.; Shamoto, E. Ultrasonic elliptical vibration cutting. CIRP Ann.-Manuf. Technol. 1995, 44, 31–34. [Google Scholar] [CrossRef]

- Shamoto, E.; Moriwaki, T. Ultaprecision diamond cutting of hardened steel by applying elliptical vibration cutting. CIRP Ann.-Manuf. Technol. 1999, 48, 441–444. [Google Scholar] [CrossRef]

- Shamoto, E.; Suzuki, N.; Moriwaki, T.; Naoi, Y. Development of ultrasonic elliptical vibration controller for elliptical vibration cutting. CIRP Ann.-Manuf. Technol. 2002, 51, 327–330. [Google Scholar] [CrossRef]

- Shamoto, E.; Suzuki, N.; Tsuchiya, E.; Hori, Y.; Inagaki, H.; Yoshino, K. Development of 3 DOF ultrasonic vibration tool for elliptical vibration cutting of sculptured surfaces. CIRP Ann.-Manuf. Technol. 2005, 54, 321–324. [Google Scholar] [CrossRef]

- Li, X.; Zhang, D.Y. Ultrasonic elliptical vibration transducer driven by single actuator and its application in precision cutting. J. Mater. Process. Technol. 2006, 180, 91–95. [Google Scholar] [CrossRef]

- Kim, G.D.; Loh, B.G. An ultrasonic elliptical vibration cutting device for micro V-groove machining: Kinematical analysis and micro V-groove machining characteristics. J. Mater. Process. Technol. 2007, 190, 181–188. [Google Scholar] [CrossRef]

- Guo, P.; Ehmann, K.F. Development of a tertiary motion generator for elliptical vibration texturing. Precis. Eng. 2013, 37, 364–371. [Google Scholar] [CrossRef]

- Ahn, J.H.; Lim, H.S.; Son, S.M. Improvement of micro-machining accuracy by 2-dimensional vibration cutting. Proc. ASPE 1999, 20, 150–153. [Google Scholar]

- Cerniway, M.A. Elliptical Diamond Milling: Kinematics, Force and Tool Wear. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2002. [Google Scholar]

- Negishi, N. Elliptical Vibration Assisted Machining with Single Crystal Diamond Tools. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2003. [Google Scholar]

- Kim, H.S.; Kim, S.I.; Lee, K.I.; Lee, D.H.; Bang, Y.B.; Lee, K.I. Development of a programmable vibration cutting tool for diamond turning of hardened mold steels. Int. J. Adv. Manuf. Technol. 2009, 40, 26–40. [Google Scholar] [CrossRef]

- Kurniawan, R.; Ko, T.J. A new tool holder design with two-dimensional motion for fabricating micro-dimple and groove patterns. Int. J. Adv. Manuf. Technol. 2014, 15, 1165–1171. [Google Scholar] [CrossRef]

- Zhou, X.Q.; Zuo, C.M.; Liu, Q.; Wang, R.Q.; Lin, J.Q. Development of a double-frequency elliptical vibration cutting apparatus for freeform surface diamond machining. Int. J. Adv. Manuf. Technol. 2016, 87, 2099–2111. [Google Scholar] [CrossRef]

- Lin, J.; Han, J.; Lu, M.; Yu, B.; Gu, Y. Design, analysis and testing of a new piezoelectric tool actuator for elliptical vibration turning. Smart Mater. Struct. 2017, 26, 8. [Google Scholar] [CrossRef]

- Lin, J.; Lu, M.; Zhou, X. Development of a Non-Resonant 3D Elliptical Vibration Cutting Apparatus for Diamond Turning. Exp. Tech. 2016, 40, 173–183. [Google Scholar] [CrossRef]

- Zhu, Z.; To, S.; Zhang, S.; Zhou, X.Q. High-Throughput Generation of Hierarchical Micro/Nanostructures by Spatial Vibration-Assisted Diamond Cutting. Adv. Mater. Interfaces 2016, 3. [Google Scholar] [CrossRef]

- Zhu, Z.; To, S.; Ehmann, K.F.; Zhou, X.Q. Design, analysis, and realization of a novel piezoelectrically actuated rotary spatial vibration system for micro-/nano-machining. IEEE/ASME Trans. Mechatron. 2017, 22, 1227–1237. [Google Scholar] [CrossRef]

- Hao, G.B.; Li, H.Y. Nonlinear analytical modeling and characteristic analysis of a class of compound multibeam parallelogram mechanisms. J. Mech. Robot. 2015, 7, 041016. [Google Scholar] [CrossRef]

- Hao, G.B.; Li, H.Y. Extended static modeling and analysis of compliant compound parallelogram mechanisms considering the initial internal axial force. J. Mech. Robot. 2016, 8, 041008. [Google Scholar] [CrossRef]

- Borboni, A.; Santis, D.D. Large defection of a non-linear, elastic, asymmetric Ludwick cantilever beam subjected to horizontal force, vertical force and bending torque at the free end. Meccanica 2014, 49, 1327–1336. [Google Scholar]

- Polit, S.; Dong, J. Design of high-bandwidth high-precision flexure-based nanopositioning modules. J. Manuf. Syst. 2009, 28, 71–77. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, X.; Liu, Q.; Zhao, S. Multi-objective optimum design of fast tool servo based on improved differential evolution algorithm. J. Mech. Sci. Technol. 2011, 25, 3141–3149. [Google Scholar] [CrossRef]

- Tian, Y.; Shirinzadeh, B.; Zhang, D. A flexure-based mechanism and control methodology for ultra-precision turning operation. Precis. Eng. 2009, 33, 160–166. [Google Scholar] [CrossRef]

- Pham, H.H.; Chen, I.M. Stiffness modeling of flexure parallel mechanism. Precis. Eng. 2005, 29, 467–478. [Google Scholar] [CrossRef]

- Lobontiu, N.; Garcia, E. Analytical model of displacement amplification and stiffness optimization for a class of flexure-based compliant mechanisms. Comput. Struct. 2003, 81, 2797–2810. [Google Scholar] [CrossRef]

- Lobontiu, N.; Paine, J.S.N.; Garcia, E.; Goldfarb, M. Design of symmetric conic-section flexure hinges based on closed-form compliance equations. Mech. Mach. Theory 2002, 37, 477–498. [Google Scholar] [CrossRef]

- Pei, X.; Yu, J.J.; Zong, G.H.; Bi, S.S. An effective pseudo-rigid-body method for beam-based compliant mechanisms. Precis. Eng. 2010, 34, 634–639. [Google Scholar] [CrossRef]

| Parameters | H (mm) | a1 = a3 (mm) | a2 (mm) | b1 = b2 = b3 (mm) |

|---|---|---|---|---|

| Value | 10 | 3 | 2 | 10 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Han, J.; Lu, M.; Zhou, J.; Gu, Y.; Jing, X.; Feng, D. Design and Performance Testing of a Novel Three-Dimensional Elliptical Vibration Turning Device. Micromachines 2017, 8, 305. https://doi.org/10.3390/mi8100305

Lin J, Han J, Lu M, Zhou J, Gu Y, Jing X, Feng D. Design and Performance Testing of a Novel Three-Dimensional Elliptical Vibration Turning Device. Micromachines. 2017; 8(10):305. https://doi.org/10.3390/mi8100305

Chicago/Turabian StyleLin, Jieqiong, Jinguo Han, Mingming Lu, Jiakang Zhou, Yan Gu, Xian Jing, and Da Feng. 2017. "Design and Performance Testing of a Novel Three-Dimensional Elliptical Vibration Turning Device" Micromachines 8, no. 10: 305. https://doi.org/10.3390/mi8100305

APA StyleLin, J., Han, J., Lu, M., Zhou, J., Gu, Y., Jing, X., & Feng, D. (2017). Design and Performance Testing of a Novel Three-Dimensional Elliptical Vibration Turning Device. Micromachines, 8(10), 305. https://doi.org/10.3390/mi8100305