Fabrication and Microassembly of a mm-Sized Floating Probe for a Distributed Wireless Neural Interface

Abstract

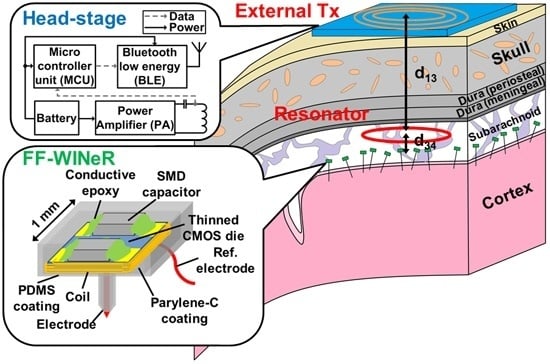

:1. Introduction

2. Power Delivery Considerations in Arbitrarily Distributed mm-Sized FF-WINeR Probes

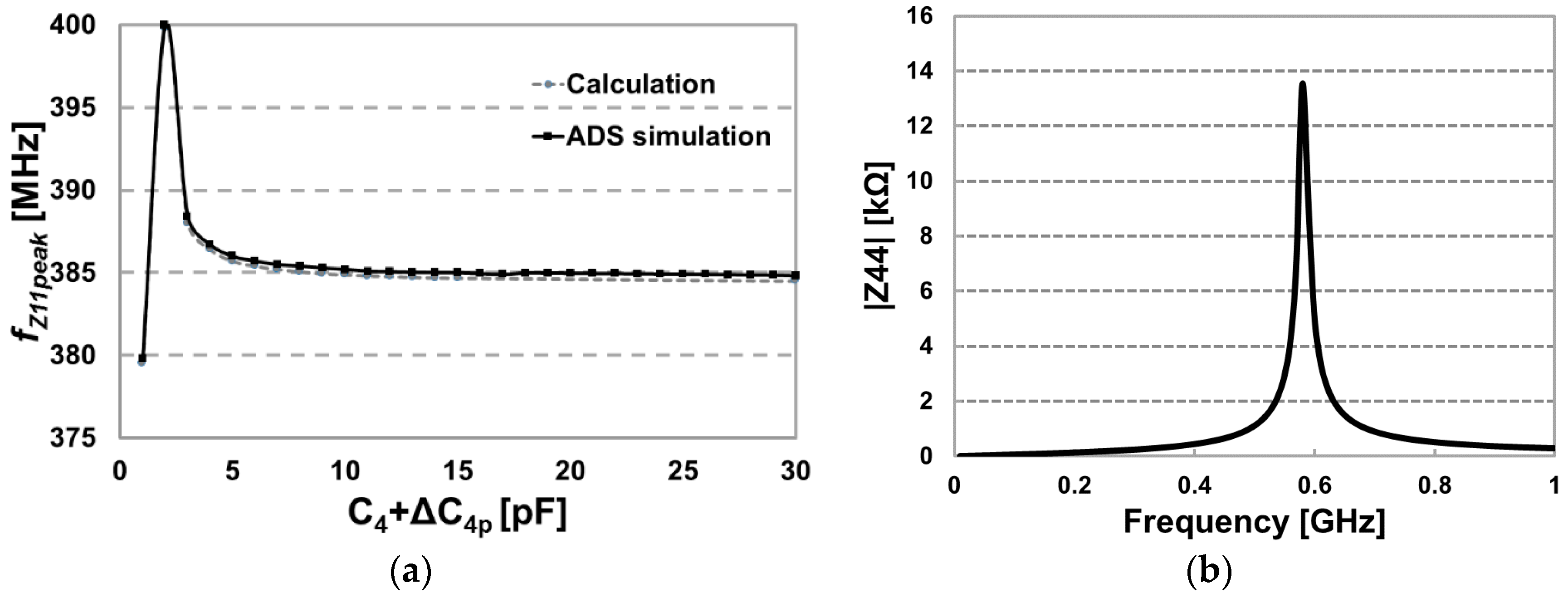

2.1. Design Parameters for 3-Coil Inductive Link Powering a Miniaturized Rx Coil

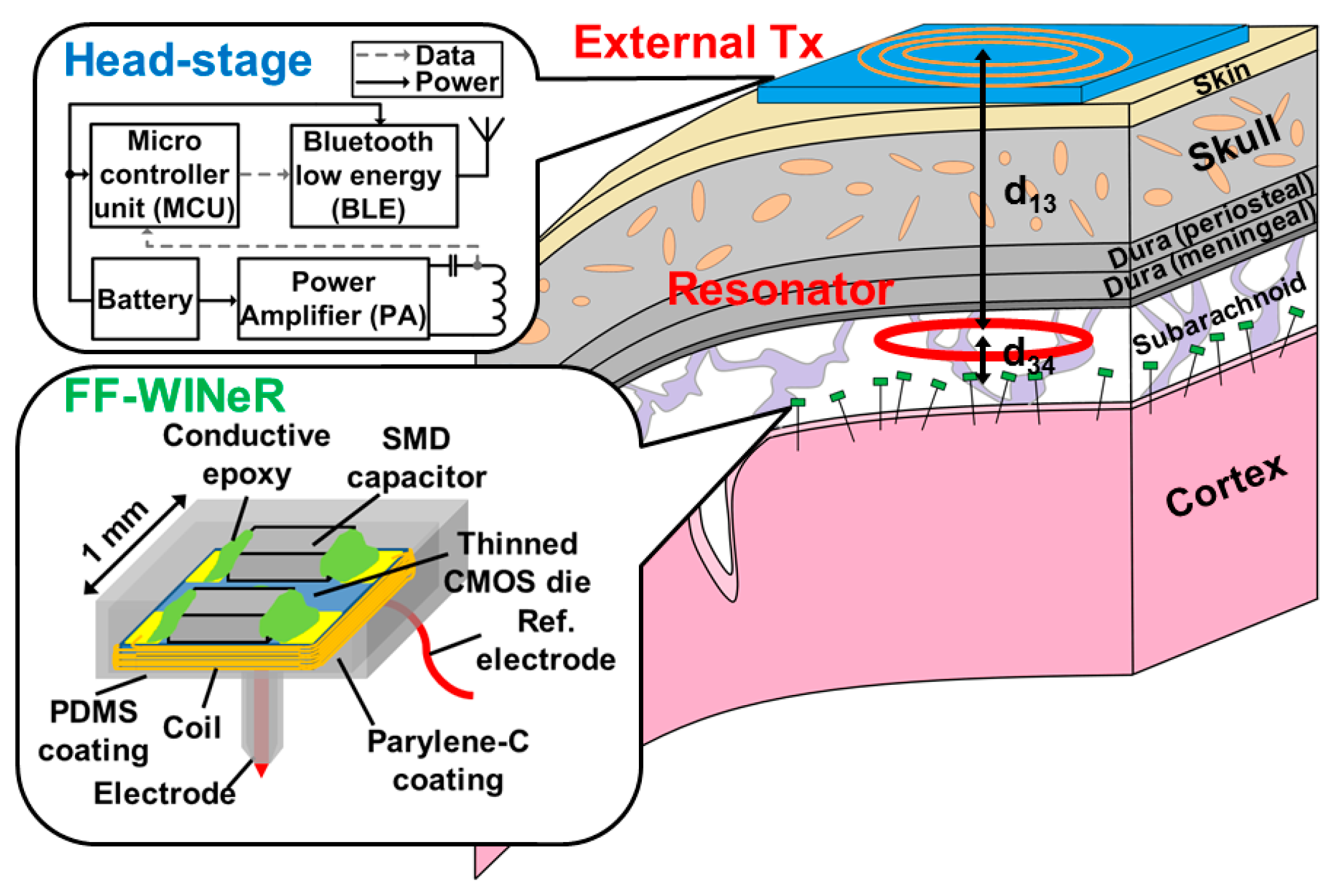

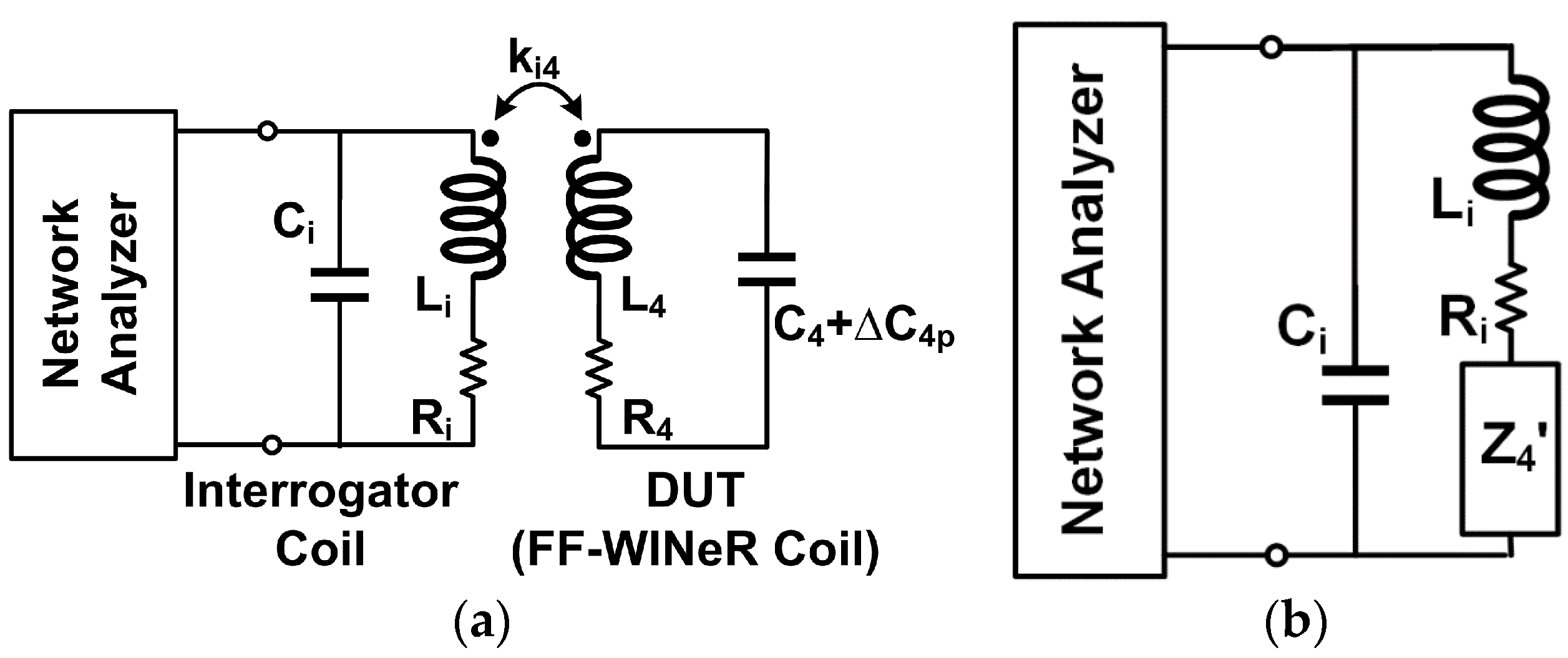

2.2. Bonding-Wire Wound Coil Design for FF-WINeR Probes and 3-Coil Inductive Link Design

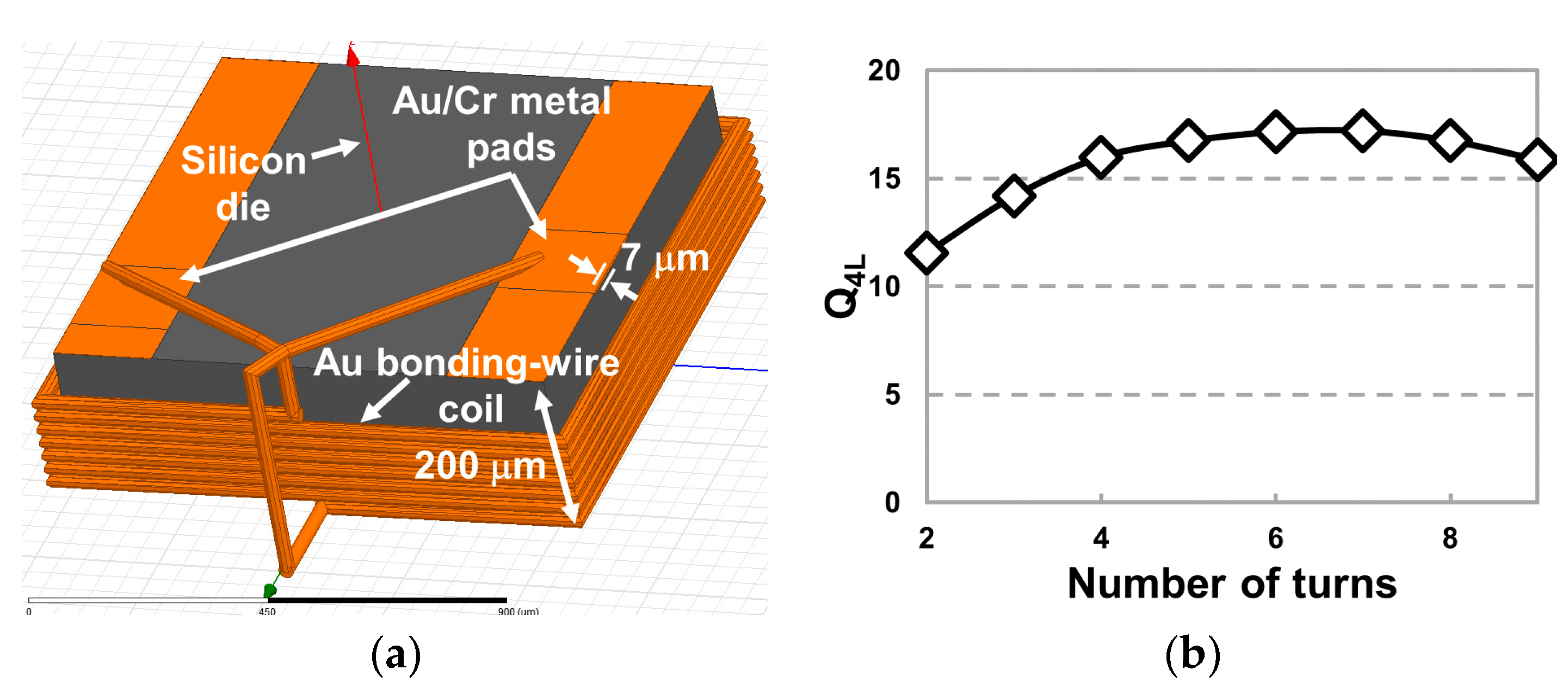

2.3. Wireless Power Transmission (WPT) to FF-WINeR Probes

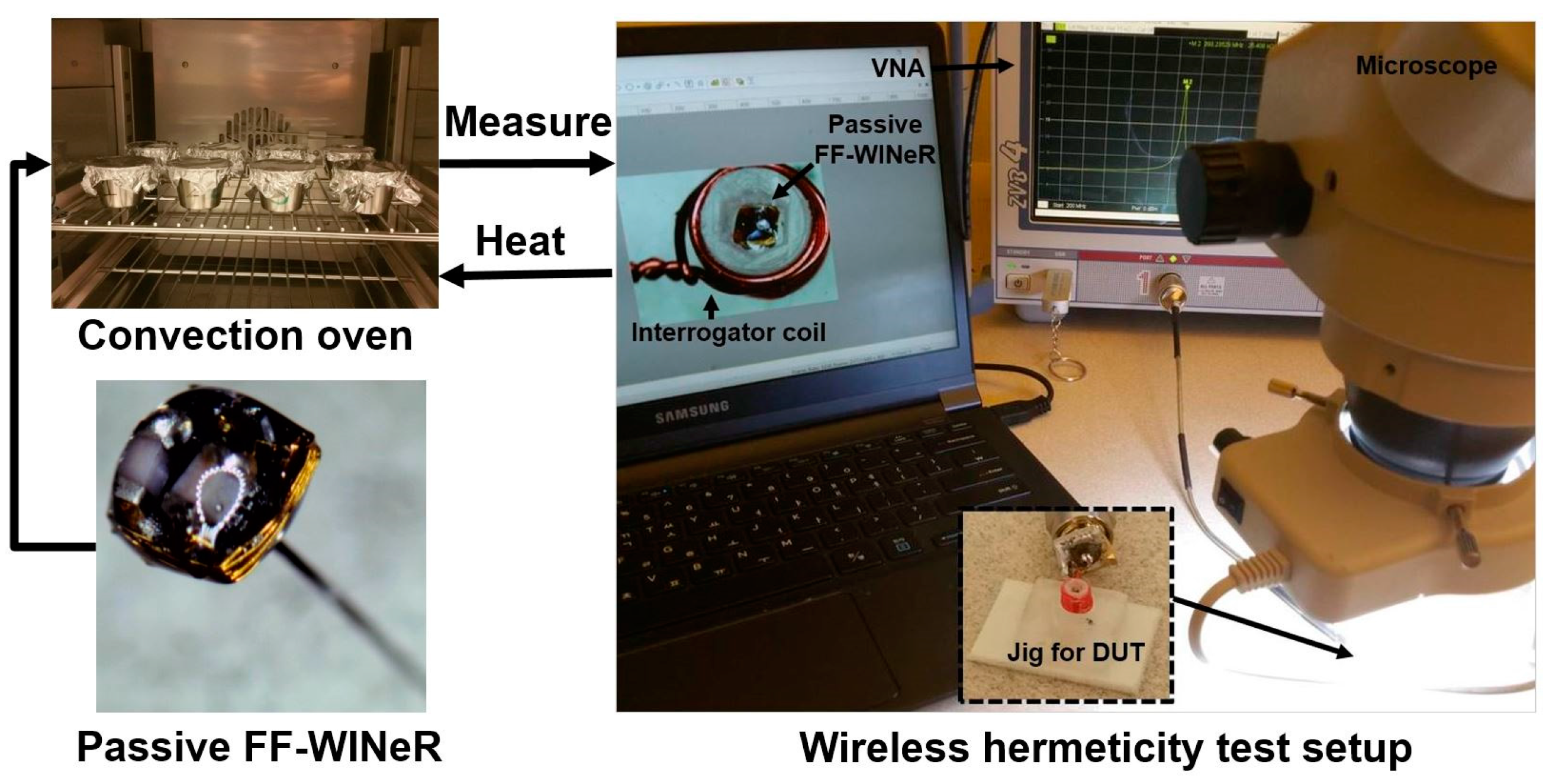

3. FF-WINeR Passive Probe Fabrication and Hermeticity Testing

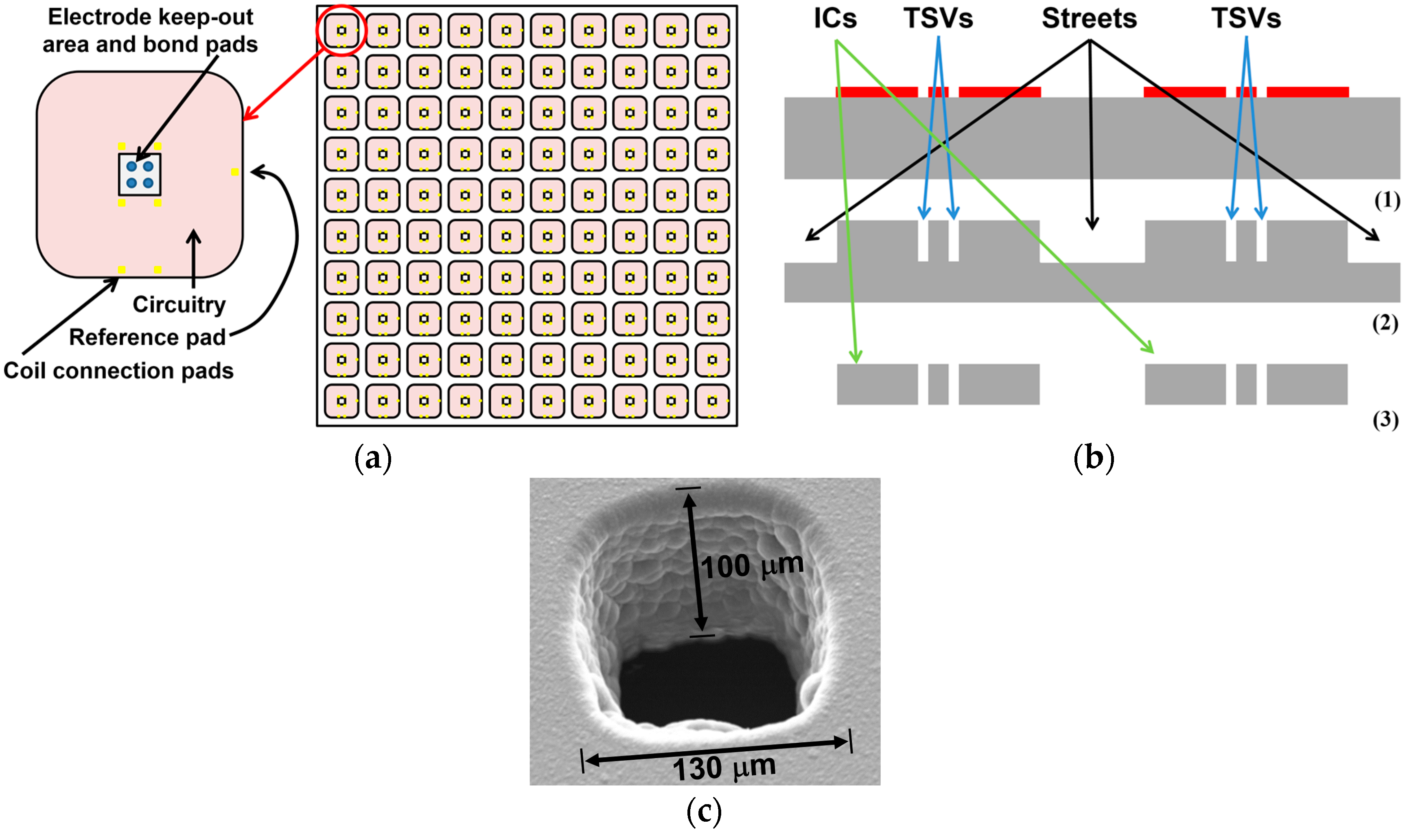

3.1. Silicon Die Fabrication Process

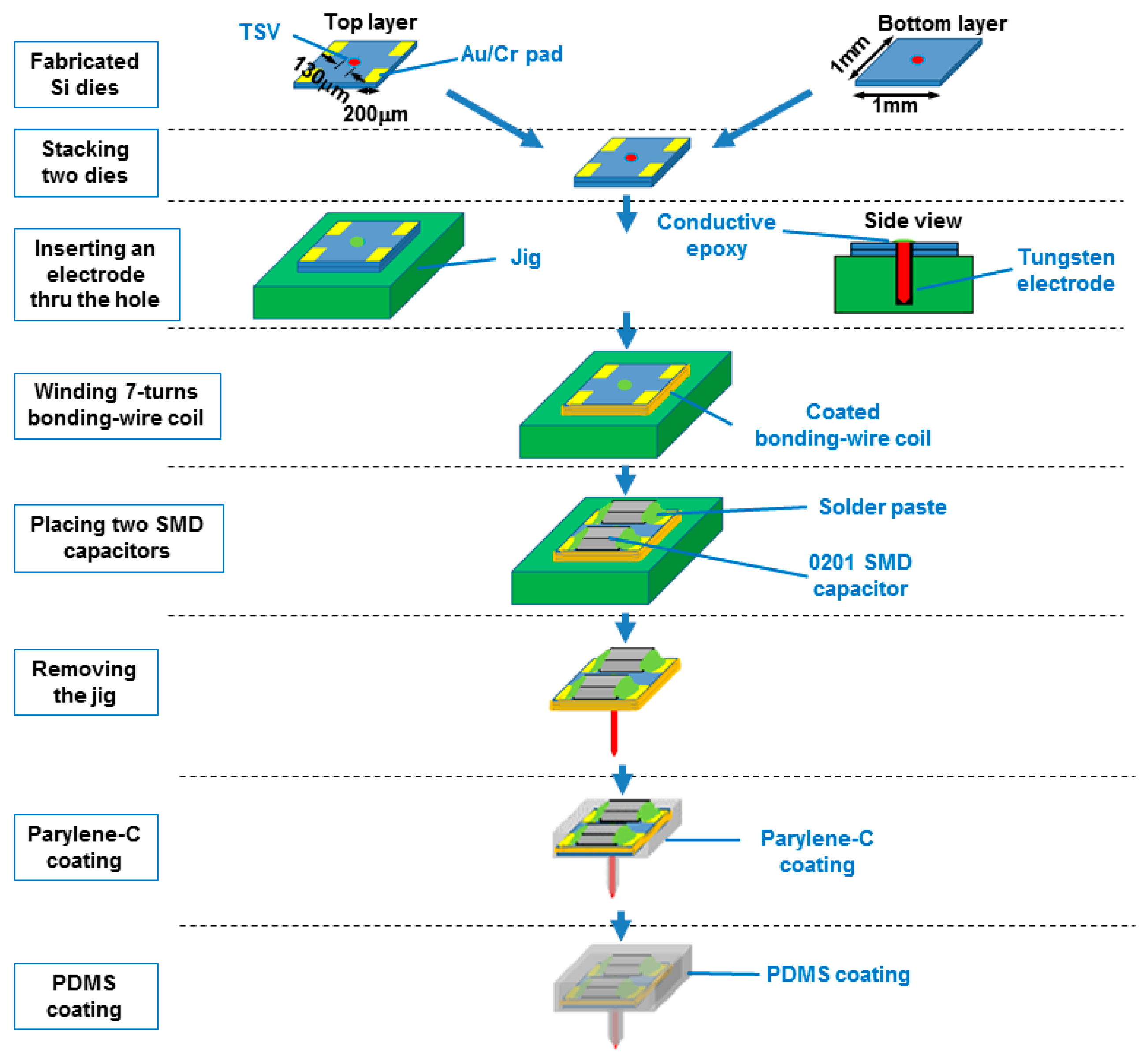

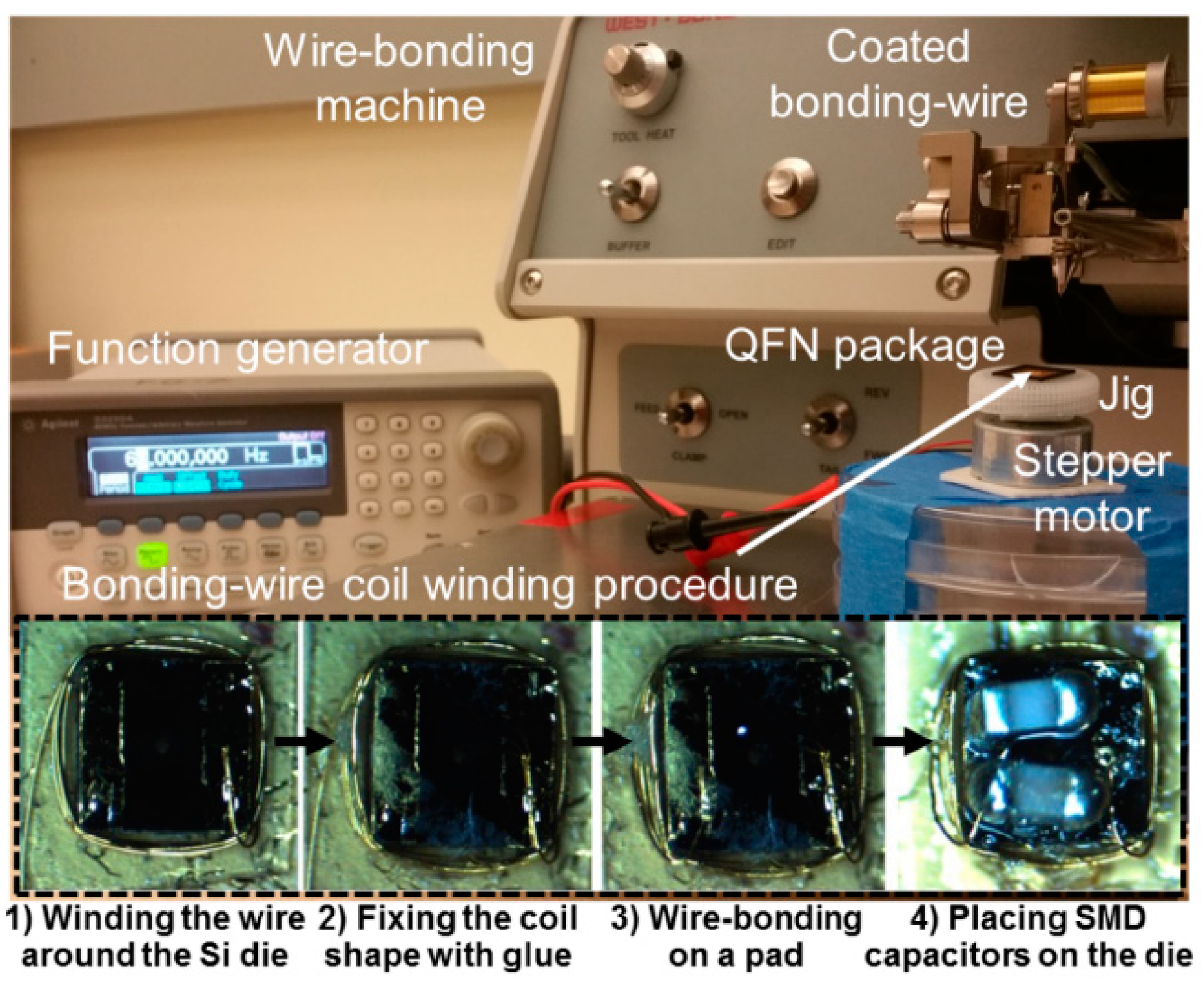

3.2. mm-Sized FF-WINeR Probes Microassembly

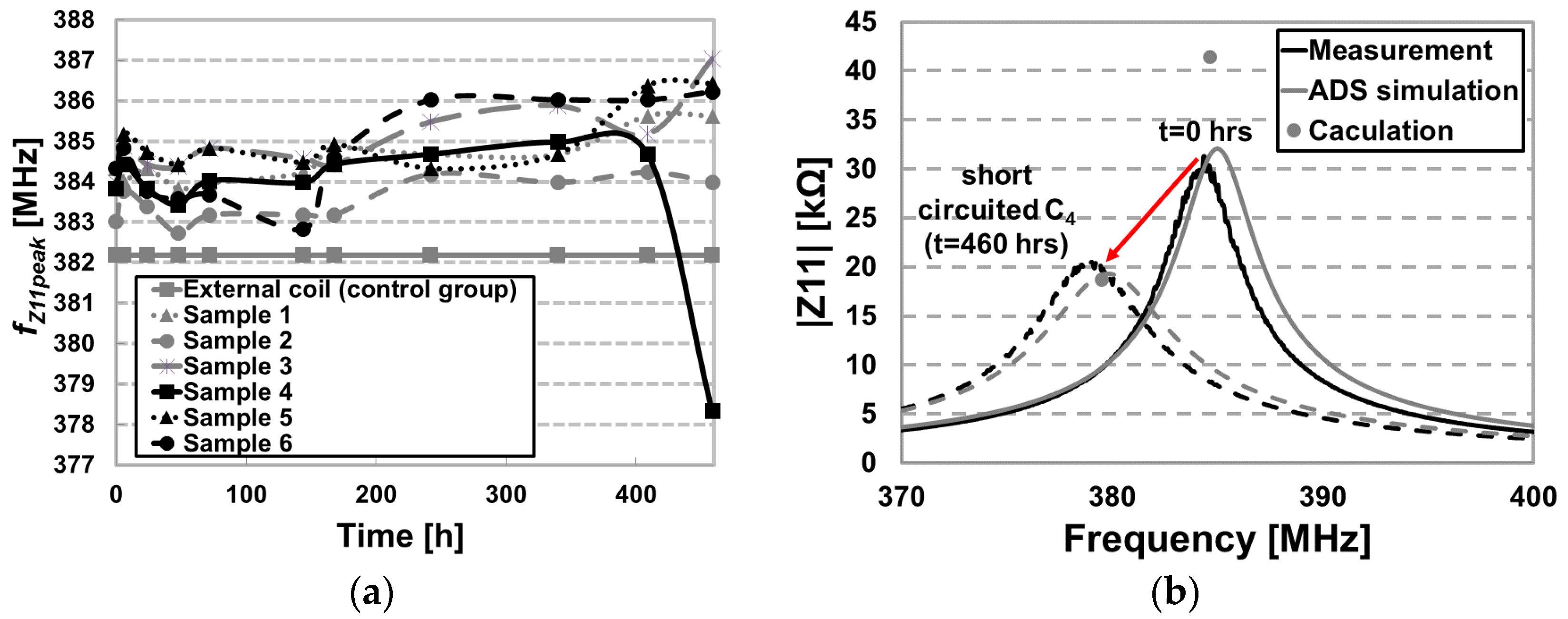

3.3. Hermeticity Testing for the Packaged FF-WINeR Probes

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| SUA | Single Unit Activity |

| MEMS | Microelectromechanical systems |

| Si | Silicon |

| PTE | Power Transfer Efficiency |

| PDL | Power Delivered to the Load |

| SNR | Signal to Noise Ratio |

| BMI | Brain Machine Interfaces |

| RF | Radio Frequency |

| CP | Conducting Polymer |

| FF-WINeR | Free-floating wireless implantable neural recording system |

| CMOS | Complimentary metal-oxide-semiconductor |

| PDMS | Polydimethylsiloxane |

| ASIC | Application Specific integrated circuit |

| MCU | Microcontroller unit |

| BLE | Bluetooth Low Energy |

| PA | Power amplifier |

| AFE | Analog Front-End |

| Tx | Transmitter |

| Rx | Receiver |

| SAR | specific absorption rate |

| HFSS | High frequency structural simulator |

| PCE | Power Conversion Efficiency |

| TSV | Through-silicon-vias |

| DRIE | Deep reactive ion etcher |

| IC | Integrated Circuits |

| DUT | Device under test |

| AF | Acceleration factor |

| RH | Relative humidity |

| MTTF | Mean time to failure |

References

- NIH Brain Initiative, Brain 2025, a Scientific Vision. Available online: http://www.braininitiative.nih.gov/2025/BRAIN2025.pdf (accessed on 22 August 2016).

- Desrochers, F.J.; Fujii, T.M.; Harlan, N.; Tierney, R.; Shimazu, P.L.; Amemori, K.; Graybiel, A.M. A system for recording neural activity chronically and simultaneously from multiple cortical and subcortical regions in nonhuman primates. J. Neurophysiol. 2012, 107, 1979–1995. [Google Scholar]

- Nicolelis, N. Actions from thoughts. Nature 2001, 409, 403–407. [Google Scholar] [CrossRef] [PubMed]

- Alivisatos, A.; Chun, M.; Church, G.; Deisseroth, K.; Donoghue, J.; Greenspan, R.; McEuen, P.; Roukes, M.; Sejnowski, T.; Weiss, P.; et al. The brain activity map. Science 2013, 339, 1284–1285. [Google Scholar] [CrossRef] [PubMed]

- Koch, C.; Reid, R.C. Neuroscience: Observatories of the mind. Nature 2012, 483, 397–398. [Google Scholar] [CrossRef] [PubMed]

- Yin, M.; Borton, D.A.; Komar, J.; Agha, N.; Lu, Y.; Li, H.; Laurens, J.; Lang, Y.; Li, Q.; Bull, C.; et al. Wireless neurosensor for full-spectrum electrophysiology recordings during free behavior. Neuron 2014, 84, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Yin, M.; Borton, D.A.; Aceros, J.; Patterson, W.R.; Nurmikko, A.V. A 100-channel hermetically sealed implantable device for chronic wireless neurosensing applications. IEEE Trans. Biomed. Circuits Syst. 2013, 7, 115–128. [Google Scholar] [PubMed]

- Sodagar, A.M.; Perlin, G.E.; Yao, Y.; Najafi, K.; Wise, K.D. An implantable 64-channel wireless microsystem for single-unit neural recording. IEEE J. Solid-State Circuits 2009, 44, 2591–2604. [Google Scholar] [CrossRef]

- Harrison, R.R.; Watkins, P.T.; Kier, R.J.; Lovejoy, R.O.; Black, D.J.; Greger, B.; Solzbacher, F. A low-power integrated circuit for a wireless 100-electrode neural recording system. IEEE J. Solid-State Circuits 2007, 42, 123–133. [Google Scholar] [CrossRef]

- Schwarz, D.A.; Lebedev, M.A.; Hanson, T.L.; Dimitrov, D.F.; Lehew, G.; Meloy, J.; Rajangam, S.; Subramanian, V.; Ifft, P.J.; Li, Z.; et al. Chronic, wireless recordings of large-scale brain activity in freely moving rhesus monkeys. Nat. Methods 2014, 11, 760–766. [Google Scholar] [CrossRef] [PubMed]

- Jorfi, M.; Skousen, J.L.; Weder, C.; Capadona, J.R. Progress towards biocompatible intracortical microelectrodes for neural interfacing applications. J. Neural Eng. 2014, 12, 011001. [Google Scholar] [CrossRef] [PubMed]

- Barrese, J.C.; Rao, N.; Paroo, K.; Triebwasser, C.; Vargas-Irwin, C.; Franquemont, L.; Donoghue, J.P. Failure mode analysis of silicon-based intracortical microelectrode arrays in non-human primates. J. Neural Eng. 2013, 10, 066014. [Google Scholar] [CrossRef] [PubMed]

- Turner, J.; Shain, W.; Szarowski, D.; Anderson, M.; Martins, S.; Isaacson, M.; Craighead, H. Cerebral astrocyte response to micromachined silicon implants. Exp. Neurol. 1999, 156, 33–49. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Bellamkonda, R.V.; Sun, W.; Levenston, M.E. Biomechanical analysis of silicon microelectrode-induced strain in the brain. J. Neural Eng. 2005, 2, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Green, R.A.; Lovell, N.H.; Wallace, G.G.; Poole-Warren, L.A. Conducting polymers for neural interfaces: Challenges in developing an effective long-term implant. Biomaterials 2008, 29, 3393–3399. [Google Scholar] [CrossRef] [PubMed]

- Abidian, M.R.; Martin, D.C. Multifunctional nanobiomaterials for neural interfaces. Adv. Funct. Mater. 2009, 29, 573–585. [Google Scholar] [CrossRef]

- Green, R.A.; Abidian, M.R. Conducting polymers for neural prosthetic and neural interface applications. Adv. Mater. 2015, 27, 7620–7637. [Google Scholar] [CrossRef] [PubMed]

- Castagnola, V.; Descamps, E.; Lecestre, A.; Dahan, L.; Remaud, J.; Nowak, L.G.; Bergaud, C. Parylene-based flexible neural probes with PEDOT coated surface for brain stimulation and recording. Biosens. Bioelectron. 2015, 67, 450–457. [Google Scholar] [CrossRef] [PubMed]

- McConnell, G.C.; Rees, H.D.; Levey, A.I.; Gutekunst, C.A.; Gross, R.E.; Bellamkonda, R.V. Implanted neural electrodes cause chronic, local inflammation that is correlated with local neurodegeneration. J. Neural Eng. 2009, 6, 056003. [Google Scholar] [CrossRef] [PubMed]

- Saxena, T.; Karumbaiah, L.; Gaupp, E.A.; Patkar, R.; Patil, K.; Patil, K.; Stanley, G.B.; Bellamkonda, R.V. The impact of chronic blood-brain barrier breach on intracortical electrode function. Biomaterials 2013, 34, 4703–4713. [Google Scholar] [CrossRef] [PubMed]

- Biederman, W.; Yeager, D.J.; Narevsky, N.; Koralek, A.C.; Carmena, J.M.; Alon, E.; Rabaey, J.M. A fully-integrated, miniaturized (0.125 mm2) 10.5 μW wireless neural sensor. IEEE J. Solid-State Circuits 2013, 48, 960–970. [Google Scholar] [CrossRef]

- Drake, K.L.; Wise, K.D.; Farraye, J.; Anderson, D.J.; BeMent, S.L. Performance of planar multisite microprobes in recording extracellular single-unit intracortical activity. IEEE Trans. Biomed. Eng. 1988, 35, 719–732. [Google Scholar] [CrossRef] [PubMed]

- Seo, D.; Carmena, J.M.; Rabaey, J.M.; Alon, E.; Maharbiz, M.M. Neural Dust: An Ultrasonic, Low Power Solution for Chronic Brain-Machine Interfaces. ArXiv E-Prints. 2013. Available online: http://arxiv.org/abs/1307.2196 (accessed on 22 August 2016).

- Yeon, P.; Tong, X.; Lee, B.; Mirbozorgi, A.; Ash, B.; Eckhardt, H.; Ghovanloo, M. Toward a distributed free-floating wireless implantable neural recording system. In Proceedings of the 38th IEEE Engineering in Medicine and Biology Society (EMBC), Lake Buena Vista, FL, USA, 17–20 August 2016; pp. 4495–4498.

- Szarowski, D.H.; Andersen, M.D.; Retterer, S.; Spence, A.J.; Isaacson, M.; Craighead, H.G.; Turner, J.N.; Shain, W. Brain responses to micromachined silicon devices. Brain Res. 2003, 983, 23–35. [Google Scholar] [CrossRef]

- Biran, R.; Martin, D.C.; Tresco, P.A. Neuronal cell loss accompanies the brain tissue response to chronically implanted silicon microelectrode arrays. Exp. Neurol. 2005, 195, 115–126. [Google Scholar] [CrossRef] [PubMed]

- He, W.; McConnell, G.C.; Bellamkonda, R.V. Nanoscale laminin coating modulates cortical scarring response around implanted silicon microelectrode arrays. J. Neural Eng. 2006, 3, 316–326. [Google Scholar] [CrossRef] [PubMed]

- Biran, R.; Martin, D.C.; Tresco, P.A. The brain tissue response to implanted silicon microelectrode arrays is increased when the device is tethered to the skull. J. Biomed. Mater. Res. A 2007, 82, 169–178. [Google Scholar] [CrossRef] [PubMed]

- Rabaey, J.; Mark, M.; Chen, D.; Sutardja, C.; Tang, C.; Gowda, S.; Wagner, M.; Werthimer, D. Powering and communicating with mm-size implants. In Proceedings of the Design, Automation, and Test in Europe Conference and Exhibition, Grenoble, France, 14–18 March 2011; pp. 1–6.

- Kiani, M.; Jow, U.; Ghovanloo, M. Design and optimization of a 3-coil inductive link for efficient wireless power transmission. IEEE Trans. Biomed. Circuits Syst. 2011, 5, 579–591. [Google Scholar] [CrossRef] [PubMed]

- Zargham, M.; Gulak, P.G. Maximum achievable efficiency in near-field coupled power-transfer systems. IEEE Trans. Biomed. Circuits Syst. 2012, 6, 228–245. [Google Scholar] [CrossRef] [PubMed]

- Ahn, D.; Ghovanloo, M. Optimal design of wireless power transmission links for millimeter-sized biomedical implants. IEEE Trans. Biomed. Circuits Syst. 2016, 10, 125–137. [Google Scholar] [CrossRef] [PubMed]

- Muller, R.; Le, H.P.; Li, W.; Ledochowitsch, P.; Gambini, S.; Bjorninen, T.; Koralek, A.; Carmena, J.M.; Maharbiz, M.M.; Alon, E.; et al. A minimally invasive 64-channel wireless μECoG implant. IEEE J. Solid-State Circuits 2015, 50, 344–359. [Google Scholar] [CrossRef]

- Finkenzeller, K.; Muller, D. RFID Handbook: Fundamentals and Applications in Contactless Smart Cards, Radio Frequency Identification and Near-Field Communication, 3rd ed.; Wiley: Hoboken, NJ, USA, 2010; pp. 66–70. [Google Scholar]

- Jow, U.; Ghovanloo, M. Design and optimization of printed spiral coils for efficient transcutaneous inductive power transmission. IEEE Trans. Biomed. Circuits Syst. 2007, 1, 193–202. [Google Scholar] [CrossRef] [PubMed]

- Jow, U.; Ghovanloo, M. Modeling and optimization of printed spiral coils in air, saline, and muscle tissue environments. IEEE Trans. Biomed. Circuits Syst. 2009, 3, 339–347. [Google Scholar]

- Harrison, R.R. Designing efficient inductive power links for implantable devices. In Proceedings of the 2007 IEEE International Symposium on Circuits and Systems, New Orleans, LA, USA, 27–30 May 2007; pp. 2080–2083.

- Puccetti, G.; Stevens, C.J.; Reggiani, U.; Sandrolini, L. Experimental and numerical investigation of termination impedance effects in wireless power transfer via metamaterial. Energies 2015, 8, 1882–1895. [Google Scholar] [CrossRef]

- Kim, S.; Tathireddy, P.; Normann, R.A.; Solzbacher, F. Thermal impact of an active 3-D microelectrode array implanted in the brain. IEEE Trans. Neural Syst. Rehabil. Eng. 2007, 15, 493–501. [Google Scholar] [PubMed]

- Eckhardt, H.; Ufer, S. Flexible Electronic Devices and Related Methods. U.S. Patent 8,836,125, 16 September 2014. [Google Scholar]

- Eckhardt, H.; Ufer, S. Flexible Electronic Devices and Related Methods. U.S. Patent 8,525,340, 3 September 2013. [Google Scholar]

- Eckhardt, H.; Ufer, S. Fabrication of Electronic Devices Including Flexible Electrical Circuits. U.S. Patent 8,173,490, 8 May 2012. [Google Scholar]

- Eckhardt, H.; Ufer, S. Electronic Devices Including Flexible Electrical Circuits and Related Methods. U.S. Patent 7,898,074, 1 March 2011. [Google Scholar]

- Raimann, M.; Peter, A.; Mager, D.; Wallrabe, U.; Korvink, J. Microtransformer-based isolated signal and power transmission. IEEE Trans. Power Electron. 2012, 27, 3996–4004. [Google Scholar] [CrossRef]

- Harpster, T.J.; Nikles, S.A.; Dokmeci, M.R.; Najafi, K. Long-term hermeticity and biological performance of anodically bonded glass-silicon implantable packages. IEEE Trans. Device Mater. Reliab. 2005, 5, 458–466. [Google Scholar] [CrossRef]

- Takahata, K.; Gianchandani, Y.B.; Wise, K.D. Micromachined antenna stents and cuffs for monitoring intraluminal pressure and flow. J. Microelectromech. Syst. 2006, 15, 1289–1298. [Google Scholar] [CrossRef]

- Kiani, M.; Ghovanloo, M. The circuit theory behind coupled-mode magnetic resonance-based wireless power transmission. IEEE Trans. Circuits Syst. I 2012, 59, 2065–2074. [Google Scholar] [CrossRef] [PubMed]

- Dow Corning Corporation. Sylgard® 184 Silicone Elastomer; Dow Corning Corporation: Midland, MI, USA, 2014. [Google Scholar]

- Fitzsimmons, J.R.; Beck, B.L.; Brooker, H.R. Double resonant quadrature birdcage. Magn. Reson. Med. 1993, 30, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Chiao, M.; Lin, L. Accelerated hermeticity testing of a glass-silicon package formed by rapid thermal processing aluminum-to-silicon nitride bonding. Sens. Actuators A 2002, 97, 405–409. [Google Scholar] [CrossRef]

- Ellerman, P. Calculating Reliability Using FIT & MTTF: Arrhenius HTOL Model. Available online: http://www.microsemi.com/document-portal/doc_view/124041-calculating-reliability-using-fit-mttf-arrhenius-htol-model (accessed on 24 August 2016).

- Lee, B.; Yeon, P.; Ghovanloo, M. A multi-cycle Q-modulation for dynamic optimization for inductive links. IEEE Trans. Ind. Electron. 2016, 63, 5091–5100. [Google Scholar] [CrossRef] [PubMed]

| Parameters (i = 1, 3, 4) | Tx Coil (L1) | Resonator Coil (L3) | Rx Coil (L4) |

|---|---|---|---|

| Inductance, Li | 85 nH | 38 nH | 94 nH |

| Quality factor, Qi | 400 | 325 | 22 |

| Outer diameter, Doi | 51 mm | 36 mm | 1 mm×1 mm |

| Line width, wx/thickness, ti | 5 mm/0.2 mm | 4 mm/0.2 mm | 25 μm (diameter) |

| Number of turns, Ni | 1 | 1 | 7 |

| Parameters | Interrogator Coil (Li) | FF-WINeR Rx Coil (L4) |

|---|---|---|

| Inductance | 122.9 nH | 92 nH |

| Resistance | 0.674 Ω | 1.88 Ω |

| Capacitance | 1.41 pF | 15 pF |

| Outer diameter | 3 mm | 1 mm × 1 mm |

| Wire diameter | 63.5 μm | 25 μm |

| Number of turns | 7 | 7 |

| Coupling coefficient (ki4) | 0.11 | |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeon, P.; Mirbozorgi, S.A.; Ash, B.; Eckhardt, H.; Ghovanloo, M. Fabrication and Microassembly of a mm-Sized Floating Probe for a Distributed Wireless Neural Interface. Micromachines 2016, 7, 154. https://doi.org/10.3390/mi7090154

Yeon P, Mirbozorgi SA, Ash B, Eckhardt H, Ghovanloo M. Fabrication and Microassembly of a mm-Sized Floating Probe for a Distributed Wireless Neural Interface. Micromachines. 2016; 7(9):154. https://doi.org/10.3390/mi7090154

Chicago/Turabian StyleYeon, Pyungwoo, S. Abdollah Mirbozorgi, Bruce Ash, Helmut Eckhardt, and Maysam Ghovanloo. 2016. "Fabrication and Microassembly of a mm-Sized Floating Probe for a Distributed Wireless Neural Interface" Micromachines 7, no. 9: 154. https://doi.org/10.3390/mi7090154

APA StyleYeon, P., Mirbozorgi, S. A., Ash, B., Eckhardt, H., & Ghovanloo, M. (2016). Fabrication and Microassembly of a mm-Sized Floating Probe for a Distributed Wireless Neural Interface. Micromachines, 7(9), 154. https://doi.org/10.3390/mi7090154