A Versatile Bonding Method for PDMS and SU-8 and Its Application towards a Multifunctional Microfluidic Device

Abstract

:1. Introduction

2. Materials and Methods

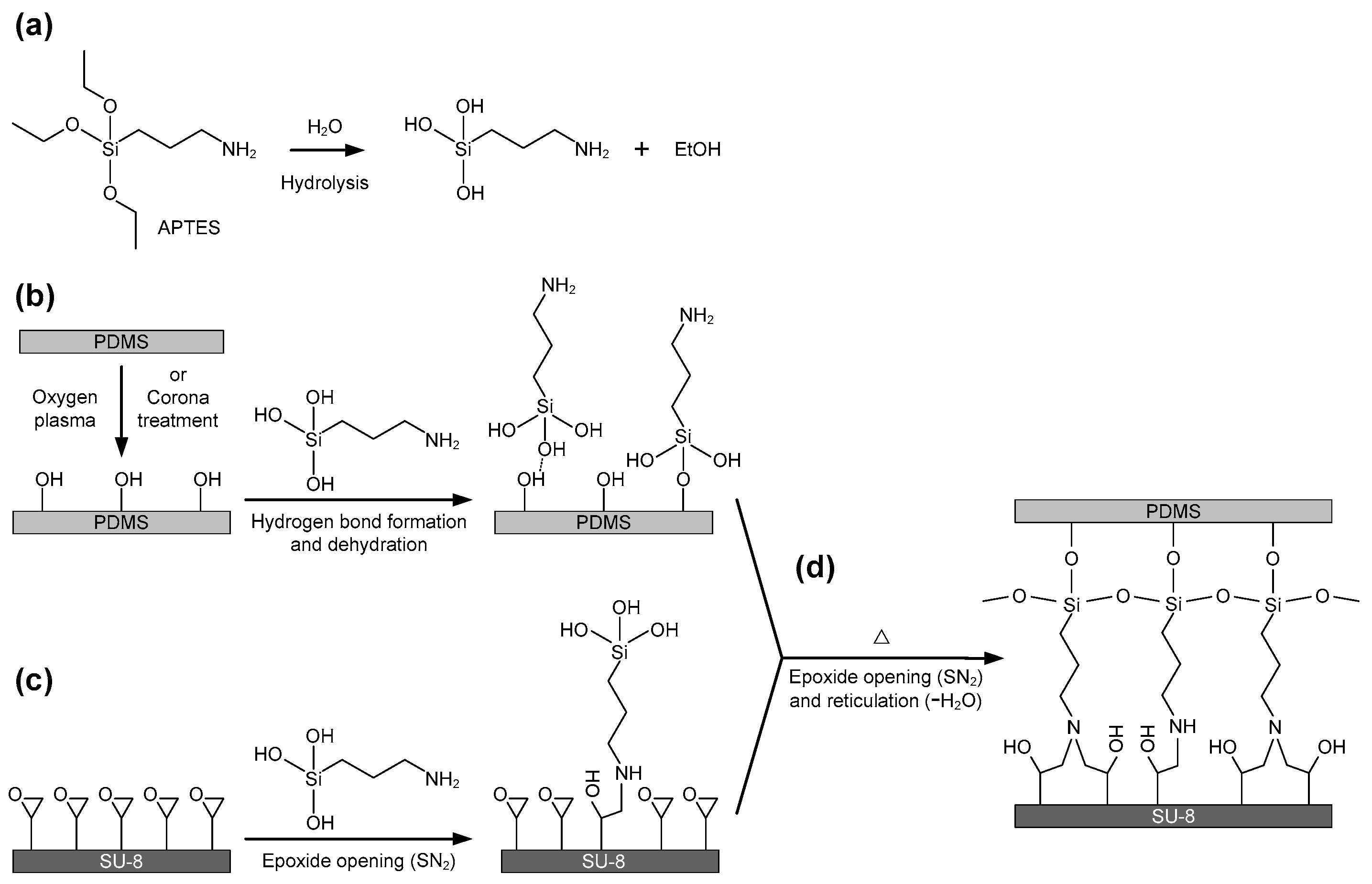

2.1. Surface Modification

2.2. Bonding Strategy

2.3. Surface Analysis

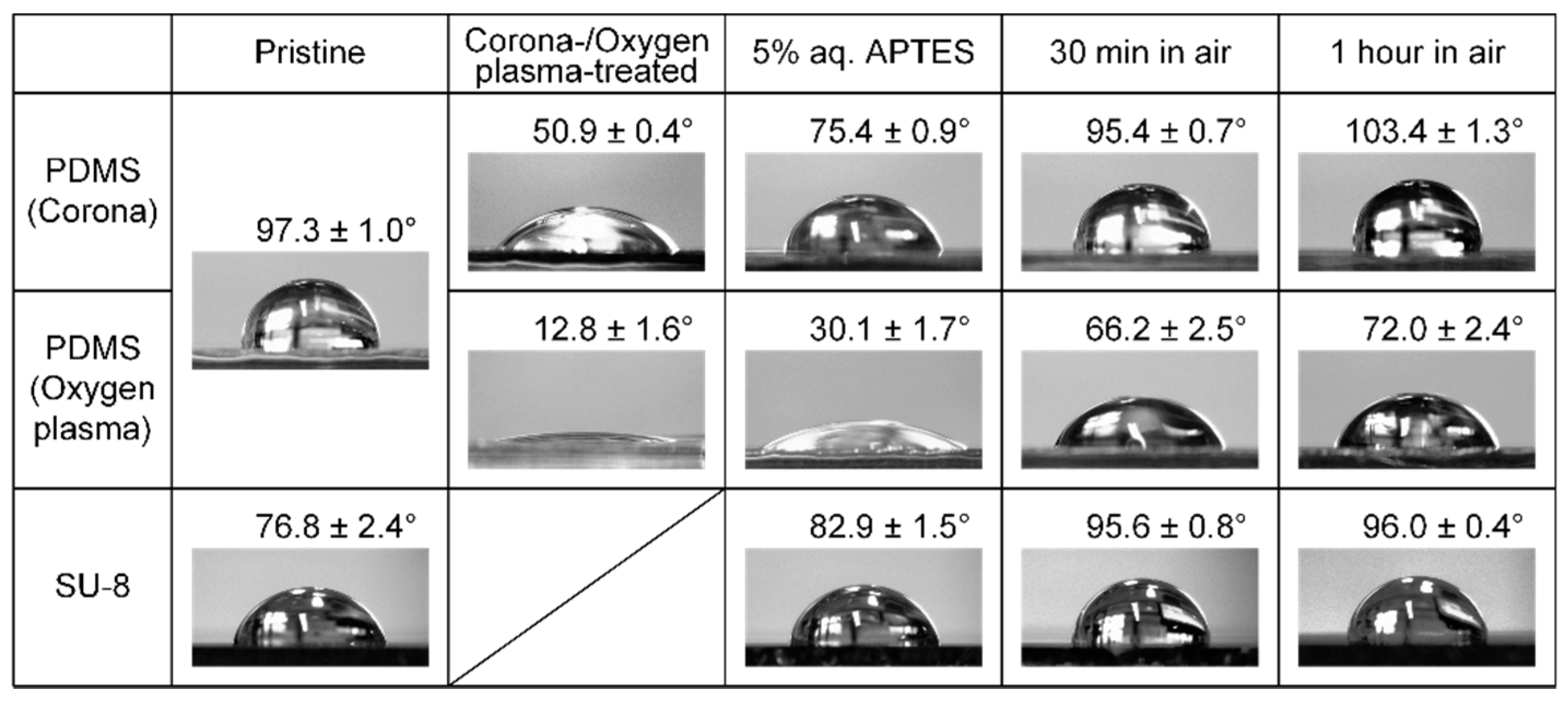

2.3.1. Contact Angle Measurement

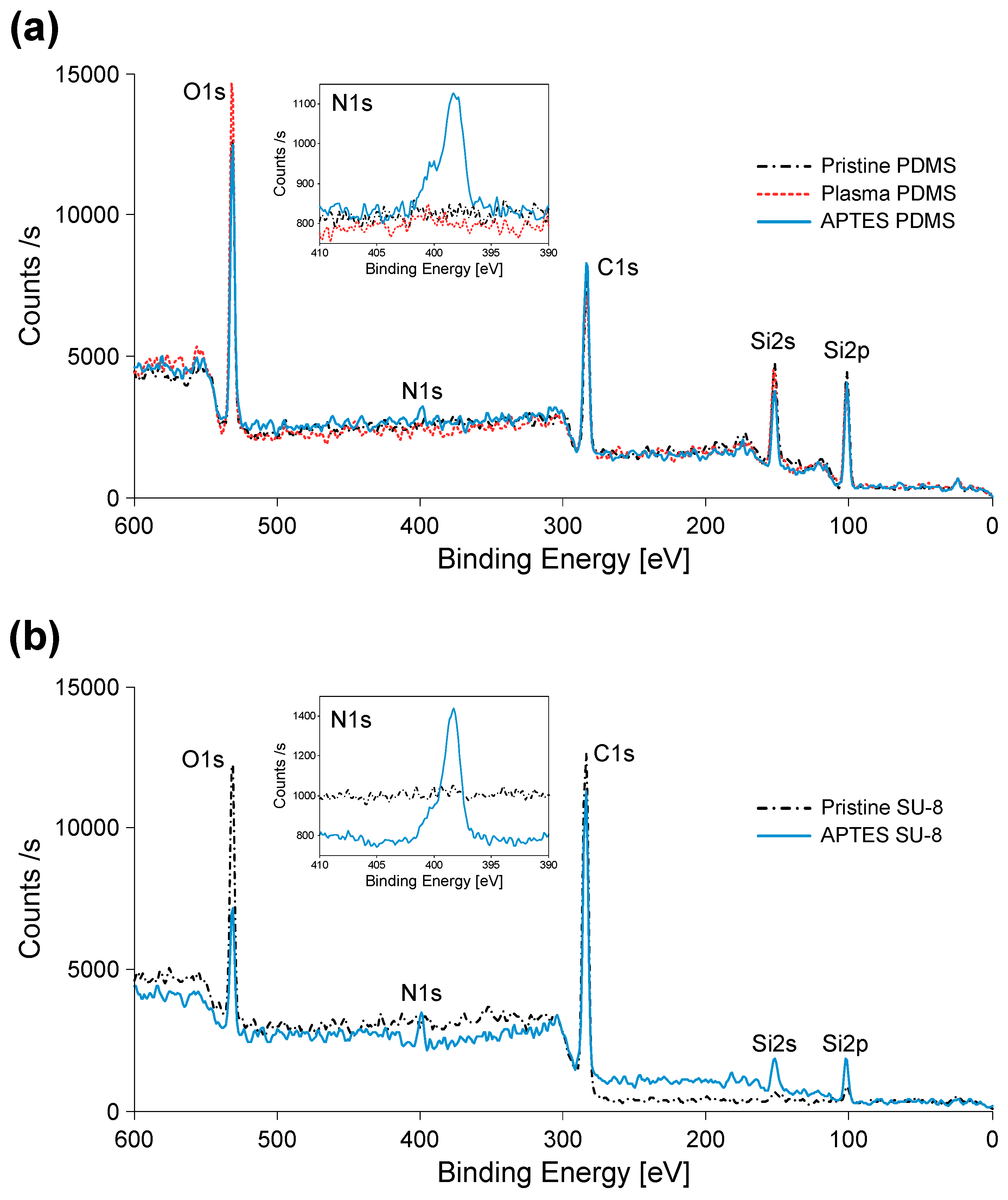

2.3.2. X-ray Photoelectron Spectrometry (XPS) Analysis

2.4. Bonding Strength Analysis

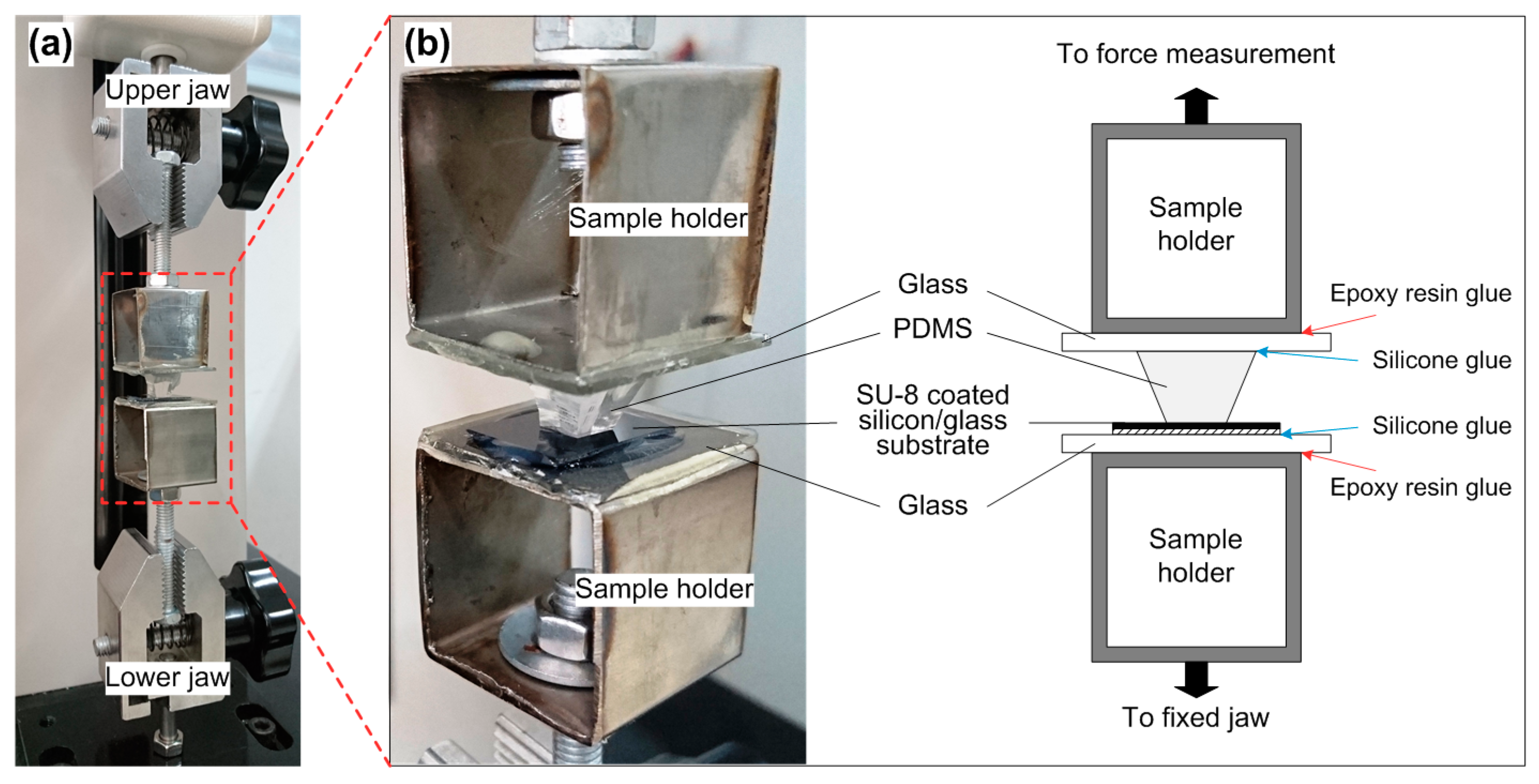

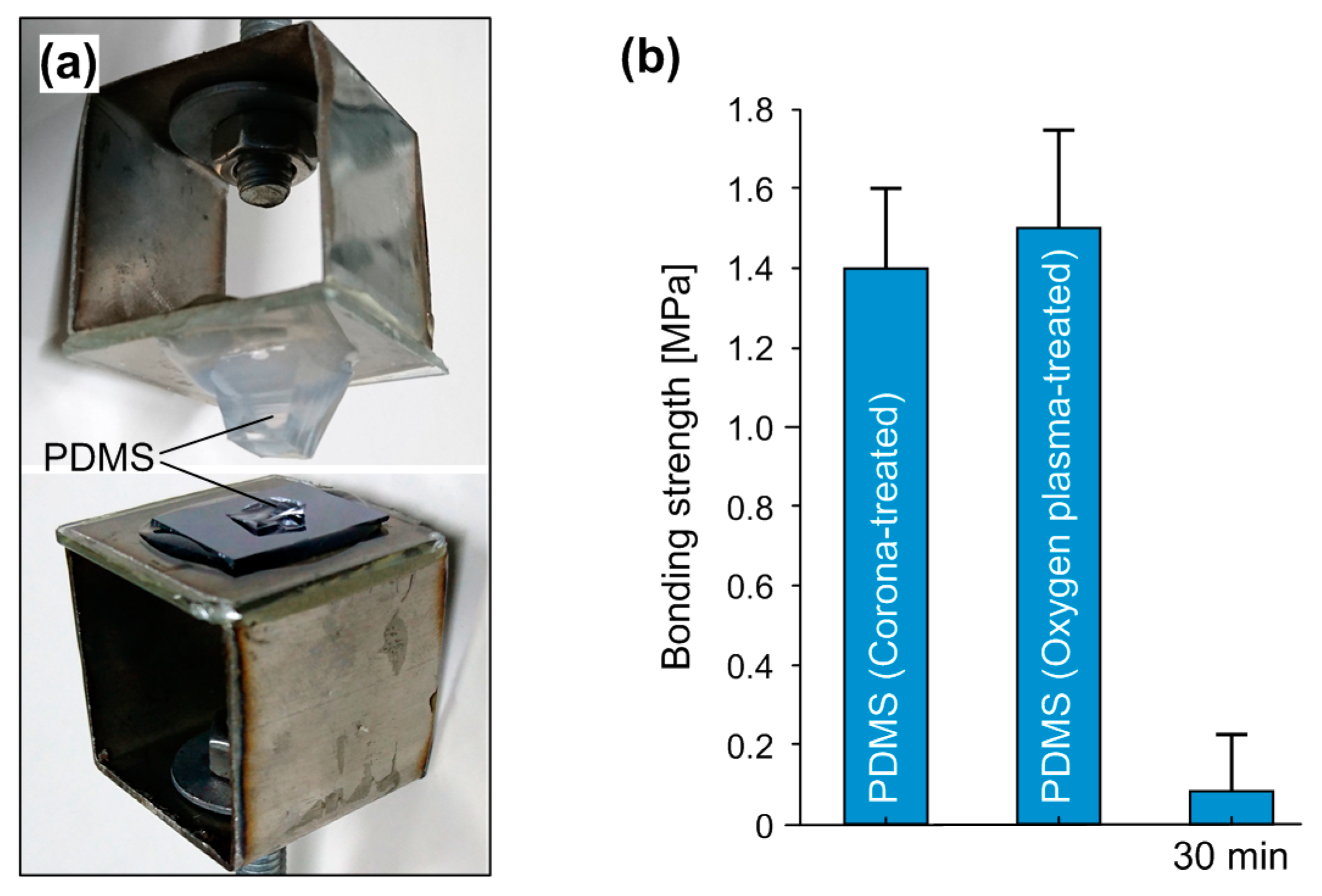

2.4.1. Tensile Strength Test

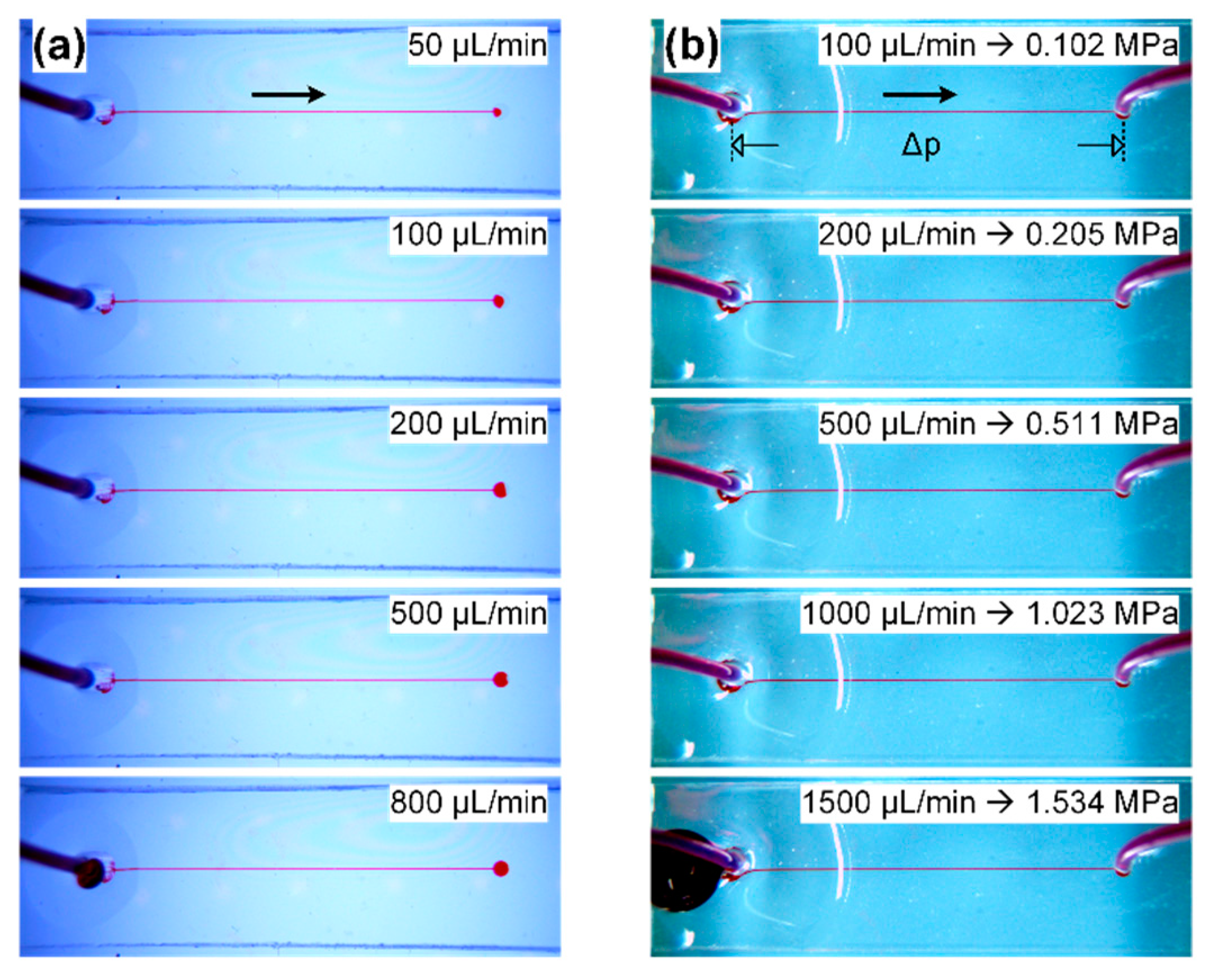

2.4.2. Leakage Test

2.5. Fabrication of the Metal-SU-8-PDMS Hybrid Device

3. Results and Discussion

3.1. Characterization of PDMS and SU-8 Surfaces

3.2. Bonding Strength

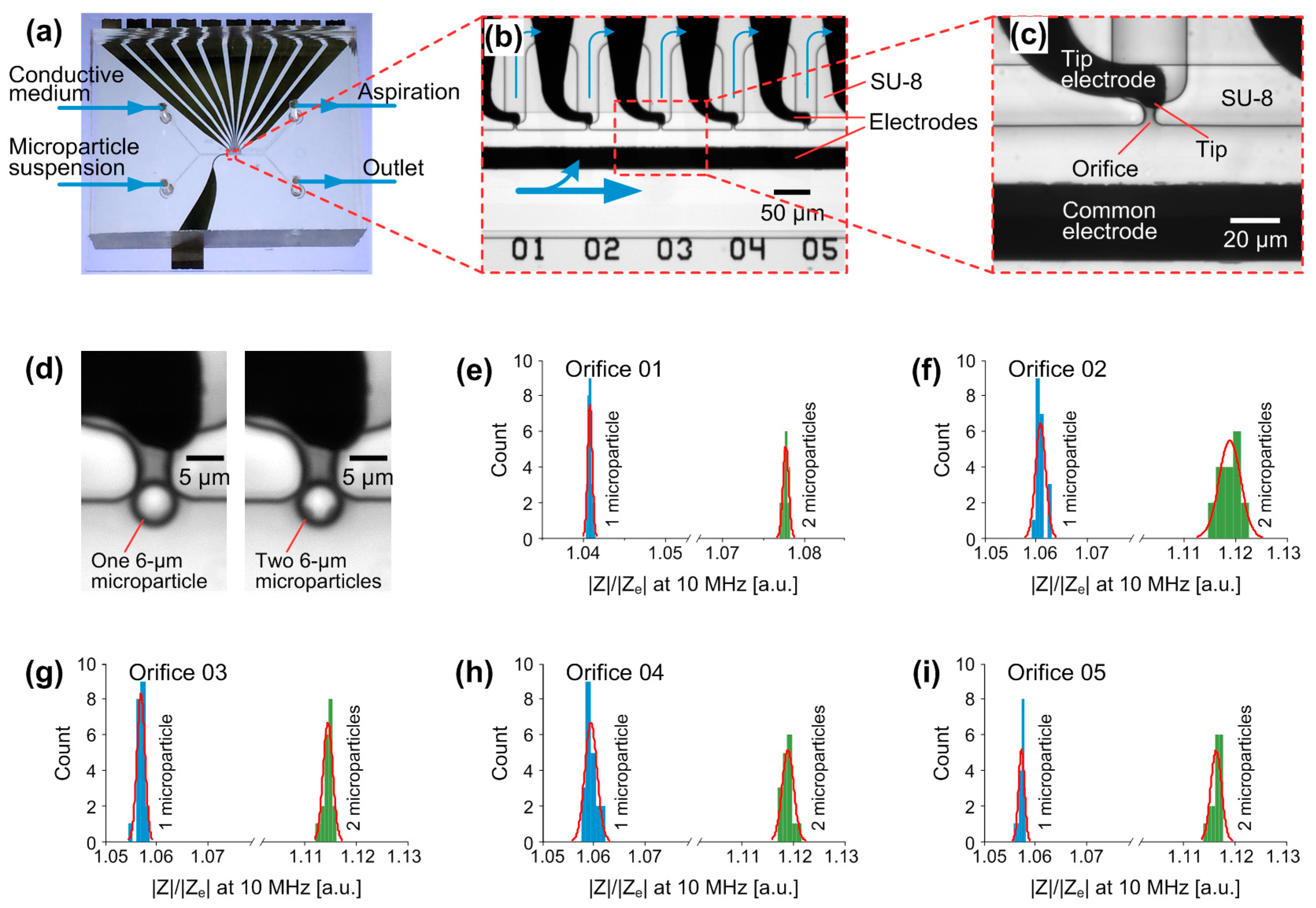

3.3. Towards Multifunctional Application of the Metal-SU-8-PDMS Hybrid Device

3.3.1. Trapping of Microparticles by Hydrodynamic Forces

3.3.2. Addressable Releasing of Trapped Microparticles by Negative Dielectrophoretic (nDEP) Forces

3.3.3. Identifying the Trapped Microparticles through Microfluidic Electrical Impedance Spectroscopy (EIS)

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- McDonald, J.C.; Duffy, D.C.; Anderson, J.R.; Chiu, D.T.; Wu, H.K.; Schueller, O.J.A.; Whitesides, G.M. Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 2000, 21, 27–40. [Google Scholar] [CrossRef]

- Unger, M.A.; Chou, H.P.; Thorsen, T.; Scherer, A.; Quake, S.R. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 2000, 288, 113–116. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Whitesides, G.M. Soft Lithography. Angew. Chem. Int. Ed. 1998, 37, 550–575. [Google Scholar] [CrossRef]

- Quake, S.R.; Scherer, A. From micro- to nanofabrication with soft materials. Science 2000, 290, 1536–1540. [Google Scholar] [CrossRef] [PubMed]

- Rogers, J.A.; Nuzzo, R.G. Recent progress in soft lithography. Mater. Today 2005, 8, 50–56. [Google Scholar] [CrossRef]

- Misun, P.M.; Rothe, J.; Schmid, Y.R.F.; Hierlemann, A.; Frey, O. Multi-analyte biosensor interface for real-time monitoring of 3D microtissue spheroids in hanging-drop networks. Microsyst. Nanoeng. 2016, 2, 16022. [Google Scholar] [CrossRef]

- Christopher, M.; Yu, S.; Craig, A.S. Solving the shrinkage-induced PDMS alignment registration issue in multilayer soft lithography. J. Micromech. Microeng. 2009, 19, 065015. [Google Scholar]

- Morten Hannibal, M.; Nikolaj, A.F.L.; Poul-Erik, H.; Jørgen, G.; Kai, D. Accounting for PDMS shrinkage when replicating structures. J. Micromech. Microeng. 2014, 24, 127002. [Google Scholar]

- Gervais, T.; El-Ali, J.; Gunther, A.; Jensen, K.F. Flow-induced deformation of shallow microfluidic channels. Lab Chip 2006, 6, 500–507. [Google Scholar] [CrossRef] [PubMed]

- Hardy, B.S.; Uechi, K.; Zhen, J.; Pirouz Kavehpour, H. The deformation of flexible PDMS microchannels under a pressure driven flow. Lab Chip 2009, 9, 935–938. [Google Scholar] [CrossRef] [PubMed]

- Roh, C.; Lee, J.; Kang, C. The deformation of polydimethylsiloxane (PDMS) microfluidic channels filled with embedded circular obstacles under certain circumstances. Molecules 2016, 21, 798. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Baek, J.Y.; Lee, K.A.; Lee, S.H. Automatic aligning and bonding system of PDMS layer for the fabrication of 3D microfluidic channels. Sens. Actuators A Phys. 2005, 119, 593–598. [Google Scholar] [CrossRef]

- Sivakumarasamy, R.; Nishiguchi, K.; Fujiwara, A.; Vuillaume, D.; Clement, N. A simple and inexpensive technique for PDMS/silicon chip alignment with sub-µm precision. Anal. Methods 2014, 6, 97–101. [Google Scholar] [CrossRef]

- Li, X.; Yu, Z.T.F.; Geraldo, D.; Weng, S.; Alve, N.; Dun, W.; Kini, A.; Patel, K.; Shu, R.; Zhang, F.; et al. Desktop aligner for fabrication of multilayer microfluidic devices. Rev. Sci. Instrum. 2015, 86, 075008. [Google Scholar] [CrossRef] [PubMed]

- Friend, J.; Yeo, L. Fabrication of microfluidic devices using polydimethylsiloxane. Biomicrofluidics 2010, 4, 026502. [Google Scholar] [CrossRef] [PubMed]

- Lorenz, H.; Despont, M.; Fahrni, N.; LaBianca, N.; Renaud, P.; Vettiger, P. SU-8: A low-cost negative resist for MEMS. J. Micromech. Microeng. 1997, 7, 121. [Google Scholar] [CrossRef]

- Lorenz, H.; Laudon, M.; Renaud, P. Mechanical characterization of a new high-aspect-ratio near UV-photoresist. Microelectron. Eng. 1998, 41, 371–374. [Google Scholar] [CrossRef]

- Lorenz, H.; Despont, M.; Fahrni, N.; Brugger, J.; Vettiger, P.; Renaud, P. High-aspect-ratio, ultrathick, negative-tone near-UV photoresist and its applications for MEMS. Sens. Actuators A Phys. 1998, 64, 33–39. [Google Scholar] [CrossRef]

- Hui, Y.; Oluwaseyi, B.; Biao, L.; Todd, W.M.; Xin, Z. Building embedded microchannels using a single layered SU-8, and determining Young’s modulus using a laser acoustic technique. J. Micromech. Microeng. 2004, 14, 1576. [Google Scholar]

- Zhu, Z.; Frey, O.; Ottoz, D.S.; Rudolf, F.; Hierlemann, A. Microfluidic single-cell cultivation chip with controllable immobilization and selective release of yeast cells. Lab Chip 2012, 12, 906–915. [Google Scholar] [CrossRef] [PubMed]

- Haandbaek, N.; Burgel, S.C.; Heer, F.; Hierlemann, A. Characterization of subcellular morphology of single yeast cells using high frequency microfluidic impedance cytometer. Lab Chip 2014, 14, 369–377. [Google Scholar] [CrossRef] [PubMed]

- Bürgel, S.C.; Escobedo, C.; Haandbæk, N.; Hierlemann, A. On-chip electroporation and impedance spectroscopy of single-cells. Sens. Actuators B Chem. 2015, 210, 82–90. [Google Scholar] [CrossRef]

- Zhu, Z.; Frey, O.; Haandbaek, N.; Franke, F.; Rudolf, F.; Hierlemann, A. Time-lapse electrical impedance spectroscopy for monitoring the cell cycle of single immobilized S. pombe cells. Sci. Rep. 2015, 5, 17180. [Google Scholar] [CrossRef] [PubMed]

- Tsao, C.-W.; DeVoe, D.L. Bonding of thermoplastic polymer microfluidics. Microfluid. Nanofluid. 2009, 6, 1–16. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, P.; Xiao, G.; Watts, B.R.; Xu, C. Sealing SU-8 microfluidic channels using PDMS. Biomicrofluidics 2011, 5, 046503. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhao, P.; Xiao, G. The fabrication of polymer microfluidic devices using a solid-to-solid interfacial polyaddition. Polymer 2009, 50, 5358–5361. [Google Scholar] [CrossRef]

- Yeh, P.Y.; Zhang, Z.; Lin, M.; Cao, X. Nonfouling hydrophilic poly(ethylene glycol) engraftment strategy for PDMS/SU-8 heterogeneous microfluidic devices. Langmuir 2012, 28, 16227–16236. [Google Scholar] [CrossRef] [PubMed]

- Toepke, M.W.; Beebe, D.J. PDMS absorption of small molecules and consequences in microfluidic applications. Lab Chip 2006, 6, 1484–1486. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Huang, S.-H.; Mosser, S.; Heuschkel, M.; Bertsch, A.; Fraering, P.; Chen, J.-J.; Renaud, P. A simple and reliable PDMS and SU-8 irreversible bonding method and its application on a microfluidic-MEA device for neuroscience research. Micromachines 2015, 6, 1465. [Google Scholar] [CrossRef]

- Talaei, S.; Frey, O.; van der Wal, P.D.; de Rooij, N.F.; Koudelka-Hep, M. Hybrid microfluidic cartridge formed by irreversible bonding of SU-8 and PDMS for multi-layer flow applications. Procedia Chem. 2009, 1, 381–384. [Google Scholar] [CrossRef]

- Vlachopoulou, M.E.; Tserepi, A.; Pavli, P.; Argitis, P.; Sanopoulou, M.; Misiakos, K. A low temperature surface modification assisted method for bonding plastic substrates. J. Micromech. Microeng. 2009, 19, 015007. [Google Scholar] [CrossRef]

- Howarter, J.A.; Youngblood, J.P. Optimization of silica silanization by 3-aminopropyltriethoxysilane. Langmuir 2006, 22, 11142–11147. [Google Scholar] [CrossRef] [PubMed]

- Sunkara, V.; Cho, Y.-K. Investigation on the mechanism of aminosilane-mediated bonding of thermoplastics and poly(dimethylsiloxane). ACS Appl. Mater. Interfaces 2012, 4, 6537–6544. [Google Scholar] [CrossRef] [PubMed]

- Meador, M.A.B.; Weber, A.S.; Hindi, A.; Naumenko, M.; McCorkle, L.; Quade, D.; Vivod, S.L.; Gould, G.L.; White, S.; Deshpande, K. Structure−property relationships in porous 3D nanostructures: Epoxy-cross-linked silica aerogels produced using ethanol as the solvent. ACS Appl. Mater. Interfaces 2009, 1, 894–906. [Google Scholar] [CrossRef] [PubMed]

- Yamada, M.; Seki, M. Hydrodynamic filtration for on-chip particle concentration and classification utilizing microfluidics. Lab Chip 2005, 5, 1233–1239. [Google Scholar] [CrossRef] [PubMed]

- Pohl, H.A.; Hawk, I. Separation of living and dead cells by dielectrophoresis. Science 1966, 152, 647–649. [Google Scholar] [CrossRef] [PubMed]

- Pethig, R.; Huang, Y.; Wang, X.B.; Burt, J.P.H. Positive and negative dielectrophoretic collection of colloidal particles using interdigitated castellated microelectrodes. J. Phys. D Appl. Phys. 1992, 25, 881–888. [Google Scholar] [CrossRef]

- Pethig, R. Dielectrophoresis: Status of the theory, technology, and applications. Biomicrofluidics 2010, 4, 022811. [Google Scholar] [CrossRef] [PubMed]

- Taff, B.M.; Voldman, J. A scalable addressable positive-dielectrophoretic cell-sorting array. Anal. Chem. 2005, 77, 7976–7983. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Frey, O.; Franke, F.; Haandbæk, N.; Hierlemann, A. Real-time monitoring of immobilized single yeast cells through multifrequency electrical impedance spectroscopy. Anal. Bioanal. Chem. 2014, 406, 7015–7025. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Chen, P.; Liu, K.; Escobedo, C. A Versatile Bonding Method for PDMS and SU-8 and Its Application towards a Multifunctional Microfluidic Device. Micromachines 2016, 7, 230. https://doi.org/10.3390/mi7120230

Zhu Z, Chen P, Liu K, Escobedo C. A Versatile Bonding Method for PDMS and SU-8 and Its Application towards a Multifunctional Microfluidic Device. Micromachines. 2016; 7(12):230. https://doi.org/10.3390/mi7120230

Chicago/Turabian StyleZhu, Zhen, Pan Chen, Kegang Liu, and Carlos Escobedo. 2016. "A Versatile Bonding Method for PDMS and SU-8 and Its Application towards a Multifunctional Microfluidic Device" Micromachines 7, no. 12: 230. https://doi.org/10.3390/mi7120230

APA StyleZhu, Z., Chen, P., Liu, K., & Escobedo, C. (2016). A Versatile Bonding Method for PDMS and SU-8 and Its Application towards a Multifunctional Microfluidic Device. Micromachines, 7(12), 230. https://doi.org/10.3390/mi7120230