Rounding of Negative Dry Film Resist by Diffusive Backside Exposure Creating Rounded Channels for Pneumatic Membrane Valves

Abstract

:1. Introduction

2. Experimental Section

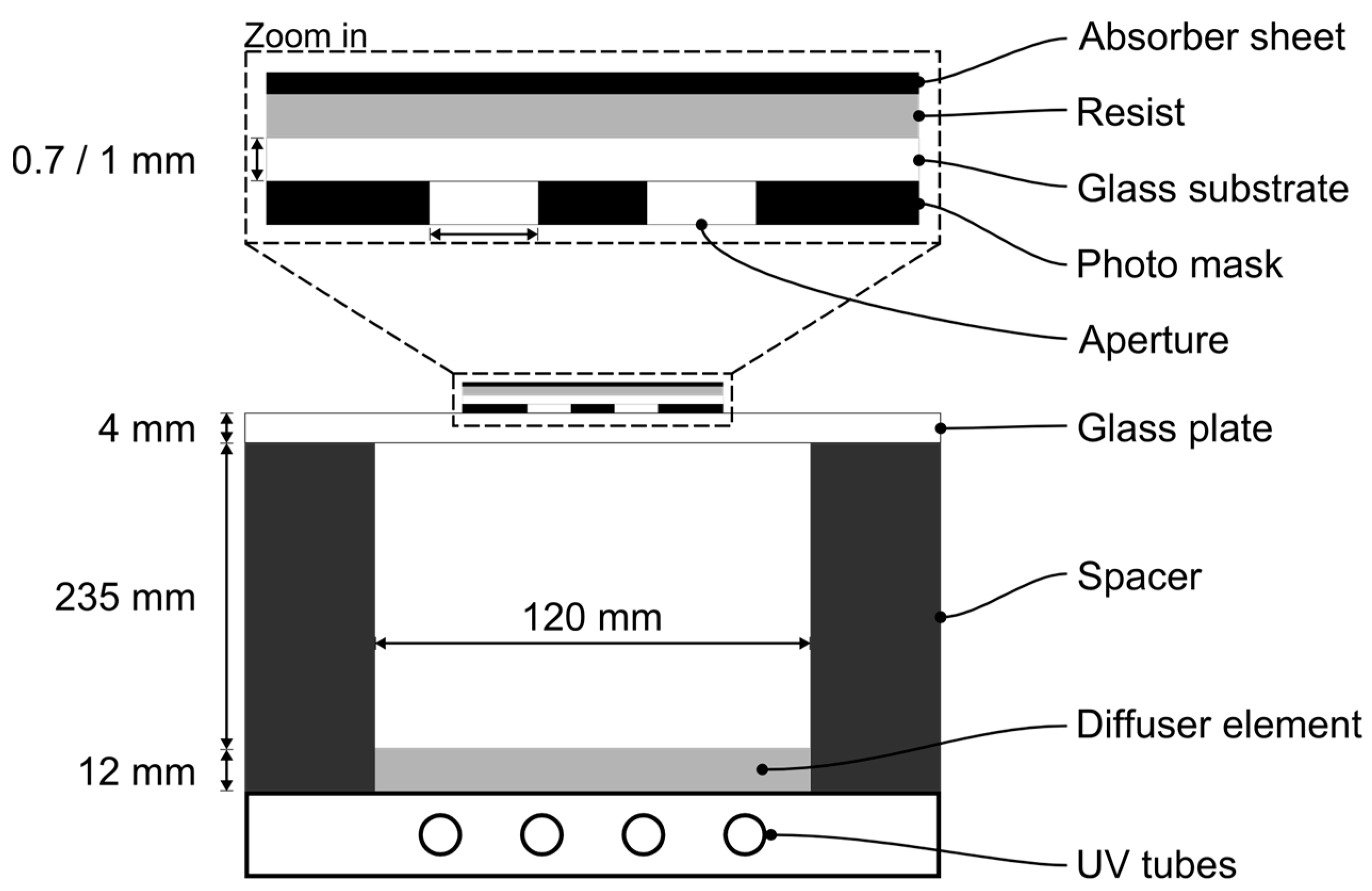

2.1. Diffuser Fabrication

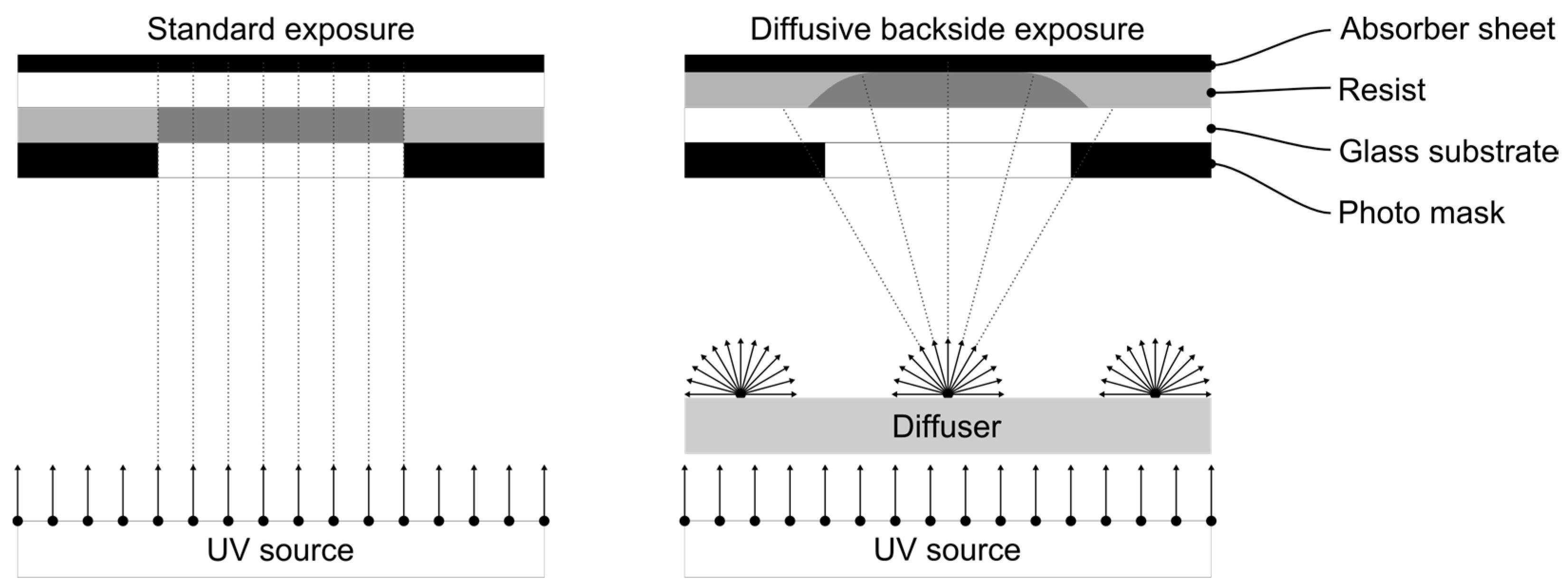

2.2. Diffusive Backside Exposure

2.3. Light Energy Measurements

| Exposure Time (s) | 240 | 360 | 480 |

|---|---|---|---|

| Energy Dose (mJ·cm−2) | 0.103 | 0.141 | 0.176 |

2.4. Master Fabrication

2.5. Profile Measurements

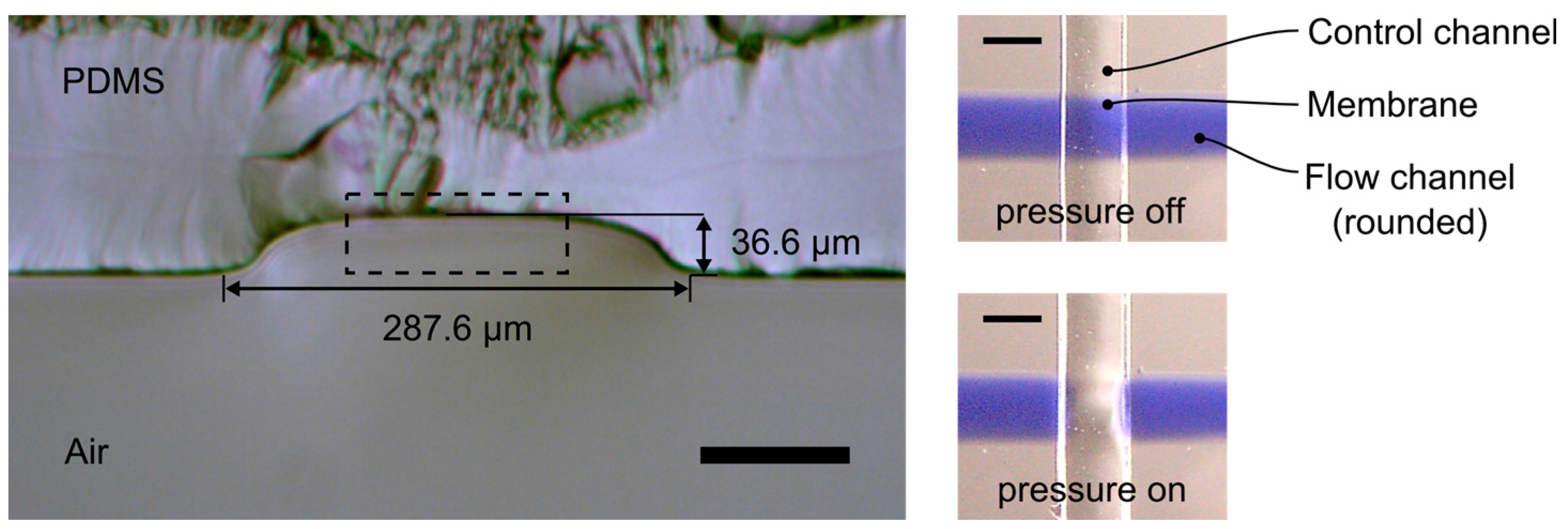

2.6. Pneumatic Valve

3. Results and Discussion

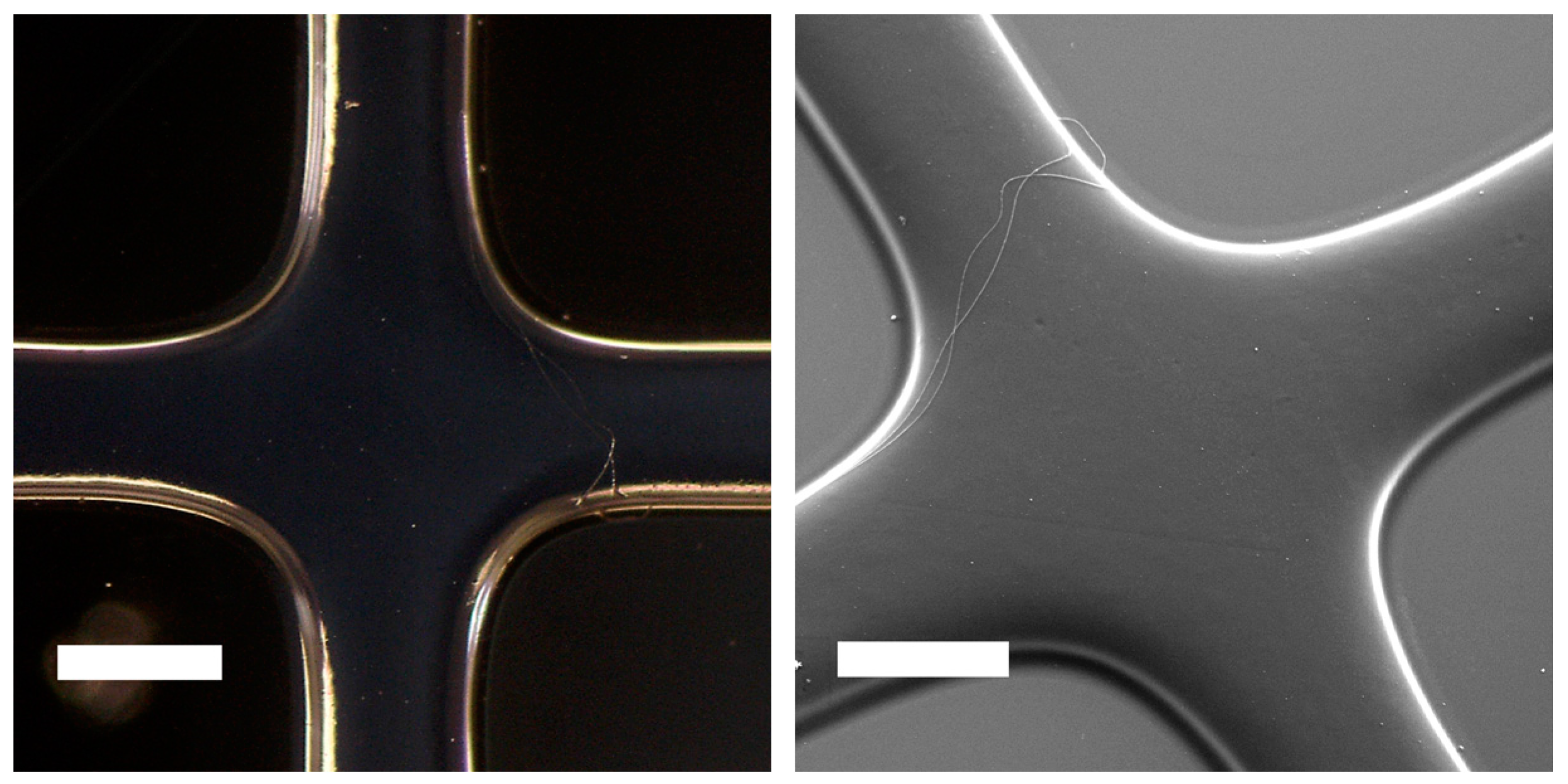

3.1. Diffuser Element and Backside Exposure

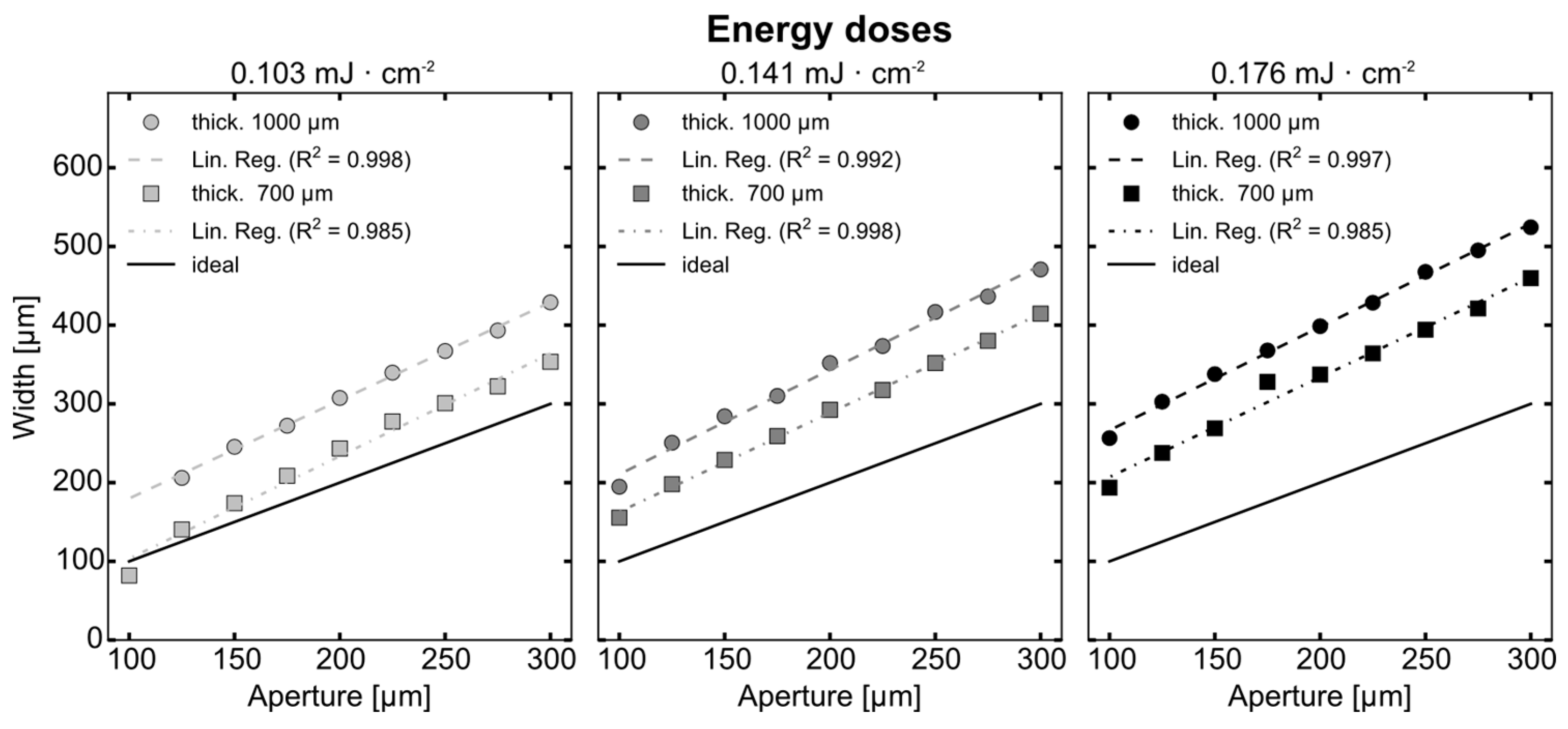

3.2. Structure Width

| Thickness (mm) | Energy Dose (mJ·cm−2) | m (-) | n (µm) | R2 (-) |

|---|---|---|---|---|

| 1.0 | 0.103 | 1.25 | 55.30 | 0.998 |

| 0.7 | 0.103 | 1.30 | −27.03 | 0.985 |

| 1.0 | 0.141 | 1.33 | 77.92 | 0.992 |

| 0.7 | 0.141 | 1.26 | 37.04 | 0.998 |

| 1.0 | 0.176 | 1.31 | 135.28 | 0.997 |

| 0.7 | 0.176 | 1.27 | 80.32 | 0.985 |

| - | Average | 1.29 | - | - |

| - | Deviation | 0.09 | - | - |

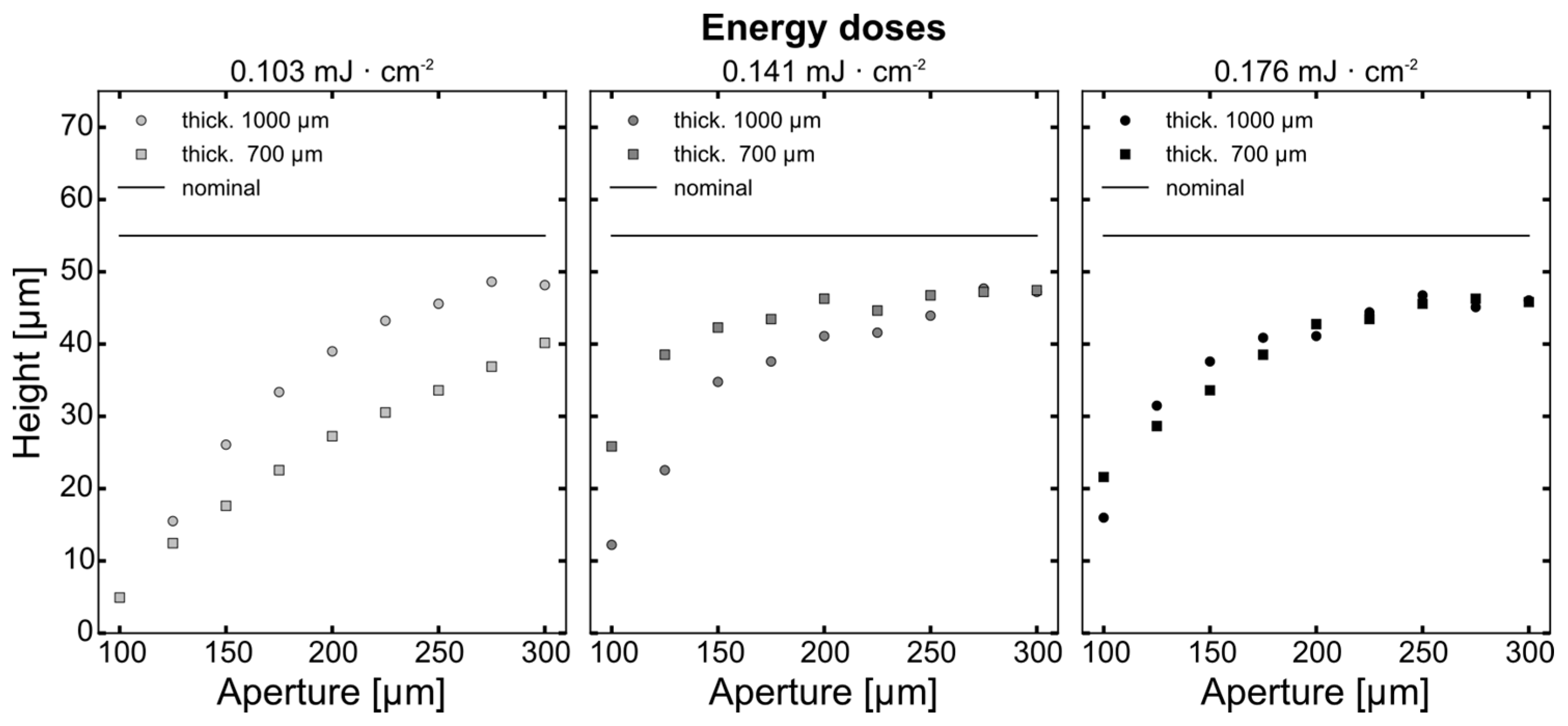

3.3. Structure Height

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xia, Y.N.; Whitesides, G.M. Soft lithography. Annu. Rev. Mater. Sci. 1998, 37, 551–575. [Google Scholar]

- Duffy, D.C.; McDonald, J.C.; Schueller, O.J.A.; Whitesides, G.M. Rapid Prototyping of Microfluidic Systems in Poly(dimethylsiloxane). Anal. Chem. 1998, 70, 4974–4984. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Lu, Y.; Stump, A.; Reed, S.; Baer, T.; Schunk, R.; Perez-Luna, V.; Lopez, G.; Brinker, C. Rapid prototyping of patterned functional nanostructures. Nature 2000, 405, 56–60. [Google Scholar] [CrossRef] [PubMed]

- Qin, D.; Xia, Y.; Whitesides, G.M. Soft lithography for micro- and nanoscale patterning. Nat. Protoc. 2010, 5, 491–502. [Google Scholar] [PubMed]

- Forfang, W.B.D.; Conner, T.G.; You, B.H.; Park, T.; Song, I.H. Fabrication and characterization of polymer microprisms. Microsyst. Technol. 2014, 20, 2071–2077. [Google Scholar] [CrossRef]

- Abdelgawad, M.; Watson, M.W.L.; Young, E.W.K.; Mudrik, J.M.; Ungrin, M.D.; Wheeler, A.R. Soft lithography: Masters on demand. Lab Chip 2008, 8, 1379–1385. [Google Scholar] [PubMed]

- Li, C.W.; Cheung, C.N.; Yang, J.; Tzang, C.H.; Yang, M. PDMS-based microfluidic device with multi-height structures fabricated by single-step photolithography using printed circuit board as masters. Analyst 2003, 128, 1137–1142. [Google Scholar] [CrossRef] [PubMed]

- Stroock, A.D.; Whitesides, G.M. Components for integrated poly (dimethylsiloxane) microfluidic systems. Electrophoresis 2002, 23, 3461–3473. [Google Scholar] [CrossRef] [PubMed]

- Vulto, P.; Glade, N.; Altomare, L.; Bablet, J.; Tin, L.D.; Medoro, G.; Chartier, I.; Manaresi, N.; Tartagni, M.; Guerrieri, R. Microfluidic channel fabrication in dry film resist for production and prototyping of hybrid chips. Lab Chip 2005, 5, 158–162. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Arias, F.; Brittain, S.; Zhao, X.; Grzybowski, B.; Torquato, S.; Whitesides, G.M. Making negative Poisson’s ratio microstructures by soft lithography. Adv. Mater. 1999, 11, 1186–1189. [Google Scholar] [CrossRef]

- Campo, A.D.; Greiner, C. SU-8: A photoresist for high-aspect-ratio and 3D submicron lithography. J. Micromech. Microeng. 2007, 17, R81. [Google Scholar] [CrossRef]

- Stephan, K.; Pittet, P.; Renaud, L.; Kleimann, P.; Morin, P.; Ouaini, N.; Ferrigno, R. Fast prototyping using a dry film photoresist: Microfabrication of soft-lithography masters for microfluidic structures. J. Micromech. Microeng. 2007, 17, N69. [Google Scholar] [CrossRef]

- Wangler, N.; Gutzweiler, L.; Kalkandjiev, K.; Müller, C.; Mayenfels, F.; Reinecke, H.; Zengerle, R.; Paust, N. High-resolution permanent photoresist laminate TMMF for sealed microfluidic structures in biological applications. J. Micromech. Microeng. 2011, 21, 095009. [Google Scholar] [CrossRef]

- Vulto, P.; Huesgen, T.; Albrecht, B.; Urban, G.A. A full-wafer fabrication process for glass microfluidic chips with integrated electroplated electrodes by direct bonding of dry film resist. J. Micromech. Microeng. 2009, 19, 077001. [Google Scholar] [CrossRef]

- Jiang, L.T.; Huang, T.C.; Chang, C.Y.; Ciou, J.R.; Yang, S.Y.; Huang, P.H. Direct fabrication of rigid microstructures on a metallic roller using a dry film resist. J. Micromech. Microeng. 2008, 18, 015004. [Google Scholar] [CrossRef]

- Futai, N.; Gu, W.; Takayama, S. Rapid prototyping of microstructures with bell-shaped cross-sections and its application to deformation-based microfluidic valves. Adv. Mater. 2004, 16, 1320–1323. [Google Scholar] [CrossRef]

- Fordyce, P.M.; Diaz-Botia, C.A.; DeRisi, J.L.; Gomez-Sjoberg, R. Systematic characterization of feature dimensions and closing pressures for microfluidic valves produced via photoresist reflow. Lab Chip 2012, 12, 4287–4295. [Google Scholar] [CrossRef] [PubMed]

- Elga Europe. Ordyl SY300: Product Data Sheet. Available online: http://www.elgaeurope.it/user/download_ctg.aspx?TIPO=F&FILE=OBJ00078.PDF&NOME=Product+Data+Sheet_SY300.pdf (accessed on 1 September 2014).

- Vulto, P.; Glade, N.; Altomare, L.; Bablet, J.; Medoro, G.; Leonardi, A.; Romani, A.; Chartier, I.; Manaresi, N.; Tartagni, M.; et al. Dry film resist for fast fluidic prototyping. In Proceedings of the 8th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Malmö, Sweden, 26–30 September 2004; Royal Society of Chemistry: London, UK; Volume 2, pp. 43–45.

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Meth. 2012, 9, 676–682. [Google Scholar] [CrossRef] [PubMed]

- O’Neill, F.T.; Sheridan, J.T. Photoresist reflow method of microlens production Part I: Background and experiments. Opt. Int. J. Light Electron. Opt. 2002, 113, 391–404. [Google Scholar] [CrossRef]

- Lai, D.; Frampton, J.P.; Sriram, H.; Takayama, S. Rounded multi-level microchannels with orifices made in one exposure enable aqueous two-phase system droplet microfluidics. Lab Chip 2011, 11, 3551–3354. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frank, P.; Haefner, S.; Paschew, G.; Richter, A. Rounding of Negative Dry Film Resist by Diffusive Backside Exposure Creating Rounded Channels for Pneumatic Membrane Valves. Micromachines 2015, 6, 1588-1596. https://doi.org/10.3390/mi6111442

Frank P, Haefner S, Paschew G, Richter A. Rounding of Negative Dry Film Resist by Diffusive Backside Exposure Creating Rounded Channels for Pneumatic Membrane Valves. Micromachines. 2015; 6(11):1588-1596. https://doi.org/10.3390/mi6111442

Chicago/Turabian StyleFrank, Philipp, Sebastian Haefner, Georgi Paschew, and Andreas Richter. 2015. "Rounding of Negative Dry Film Resist by Diffusive Backside Exposure Creating Rounded Channels for Pneumatic Membrane Valves" Micromachines 6, no. 11: 1588-1596. https://doi.org/10.3390/mi6111442

APA StyleFrank, P., Haefner, S., Paschew, G., & Richter, A. (2015). Rounding of Negative Dry Film Resist by Diffusive Backside Exposure Creating Rounded Channels for Pneumatic Membrane Valves. Micromachines, 6(11), 1588-1596. https://doi.org/10.3390/mi6111442