Effect of Post-Processing Heat Treatment Temperature on Microstructural Evolution and Mechanical Properties of the Ti-6Al-2Sn-4Zr-2Mo Alloy Fabricated by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

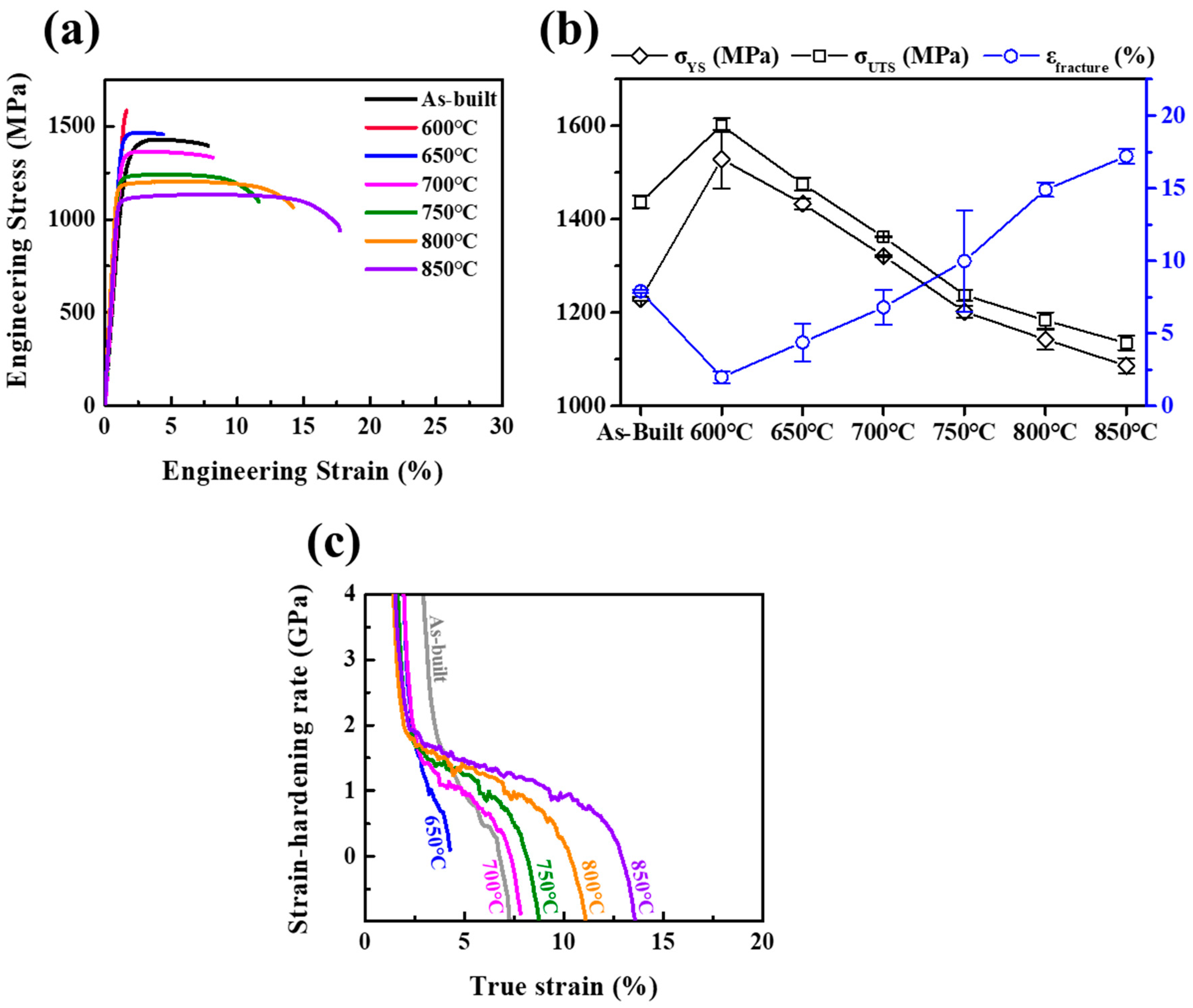

3.1. Mechanical Properties Evaluated by Tensile Tests

| Heat Treatment Condition | 0.2% Offset Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Fracture Elongation (%) |

|---|---|---|---|

| As-built | 1229.3 ± 4.7 | 1437.2 ± 13.0 | 7.9 ± 0.1 |

| 600 °C | 1528.8 ± 62.6 | 1601.4 ± 15.1 | 2.0 ± 0.4 |

| 650 °C | 1433.7 ± 11.9 | 1475.8 ± 13.9 | 4.4 ± 1.3 |

| 700 °C | 1321.4 ± 2.9 | 1362.5 ± 1.9 | 6.8 ± 1.2 |

| 750 °C | 1202.5 ± 13.1 | 1238.1 ± 11.7 | 10.0 ± 3.5 |

| 800 °C | 1142.5 ± 21.9 | 1183.6 ± 16.9 | 14.9 ± 0.5 |

| 850 °C | 1086.4 ± 16.5 | 1135.0 ± 15.0 | 17.2 ± 0.5 |

| Timet-6242 STA 970 °C/1 h + 595 °C/8 h [27] | 955 | 1045 | 18 |

3.2. Phase Identification Using X-Ray Diffraction

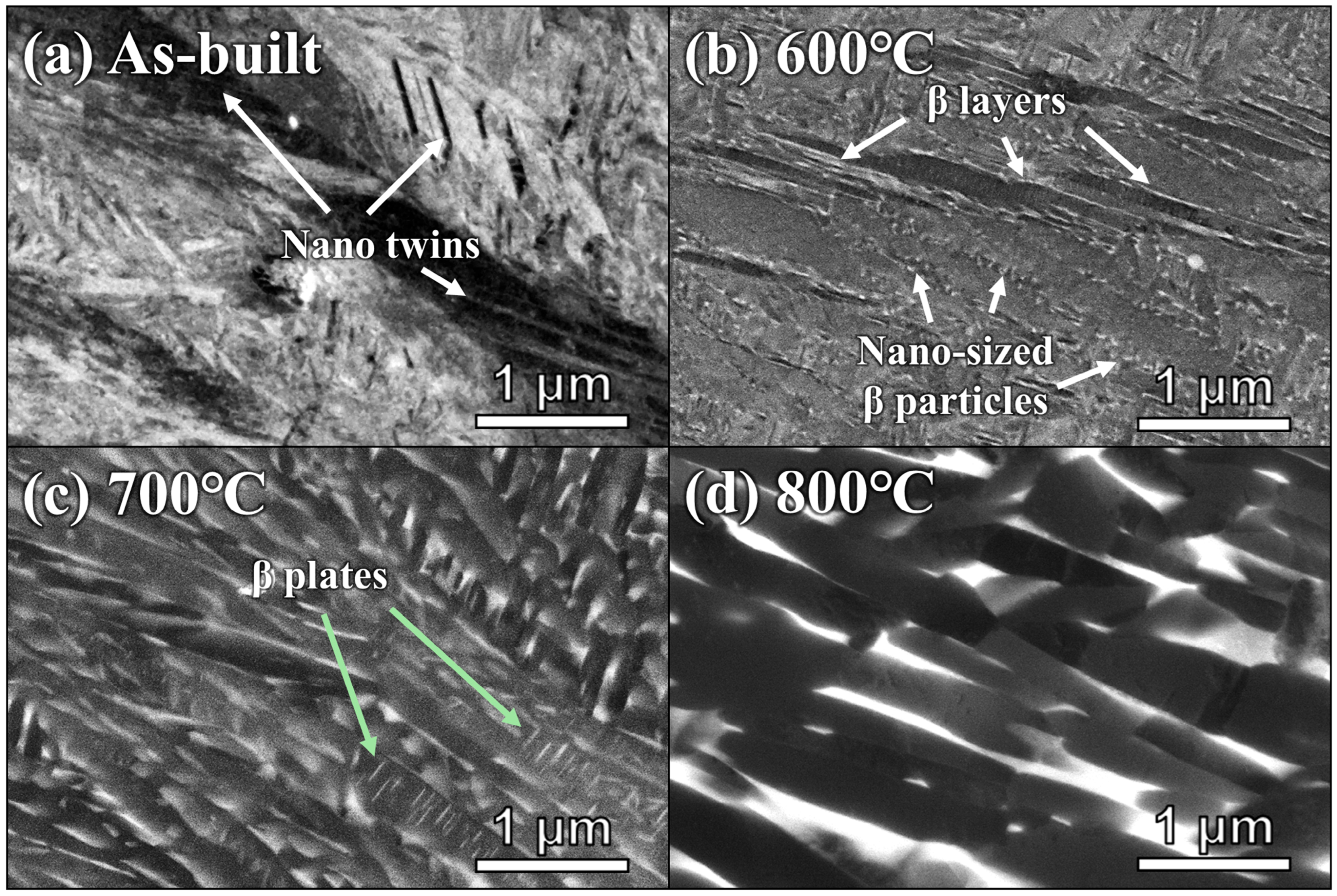

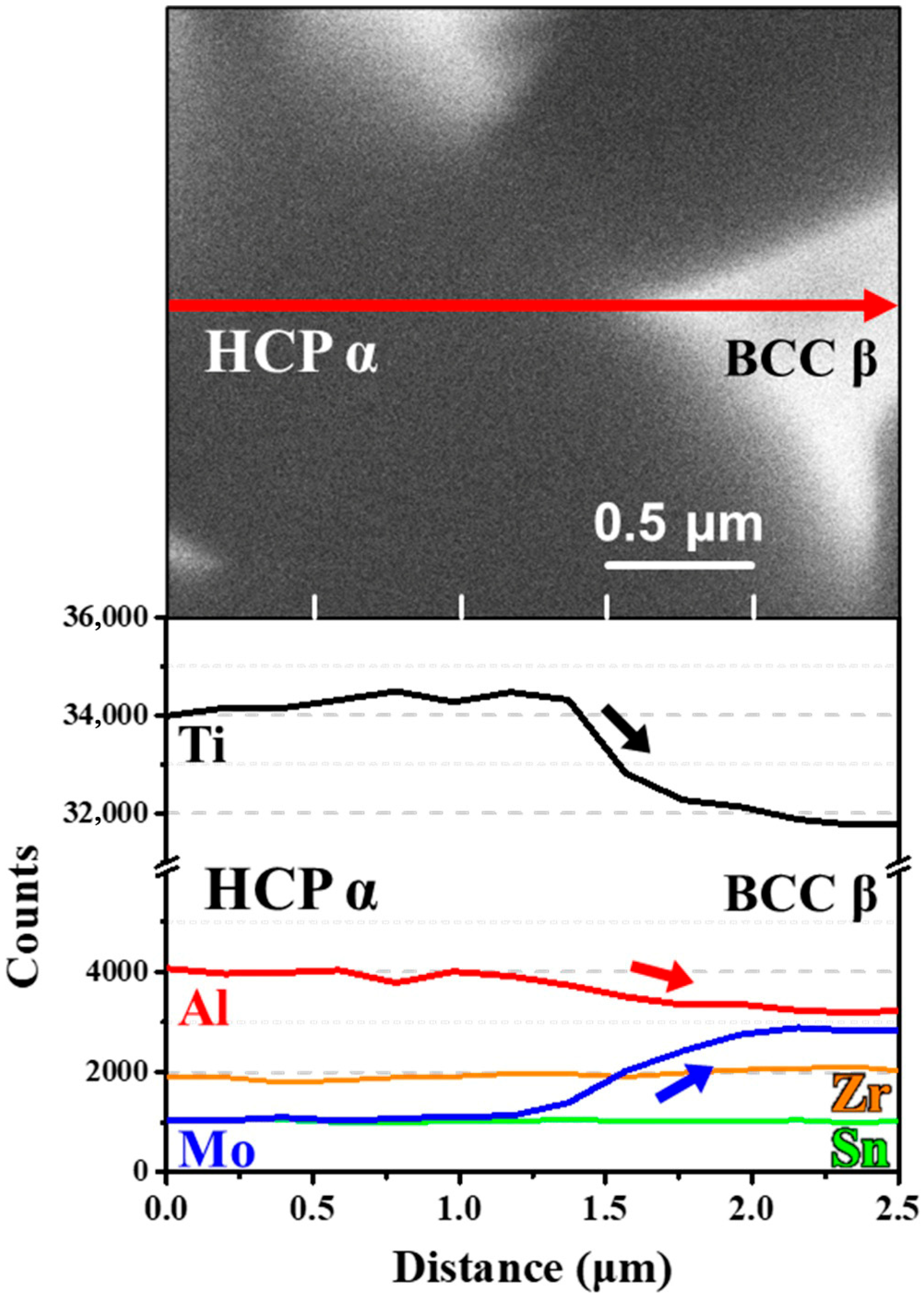

3.3. Microstructural Analysis

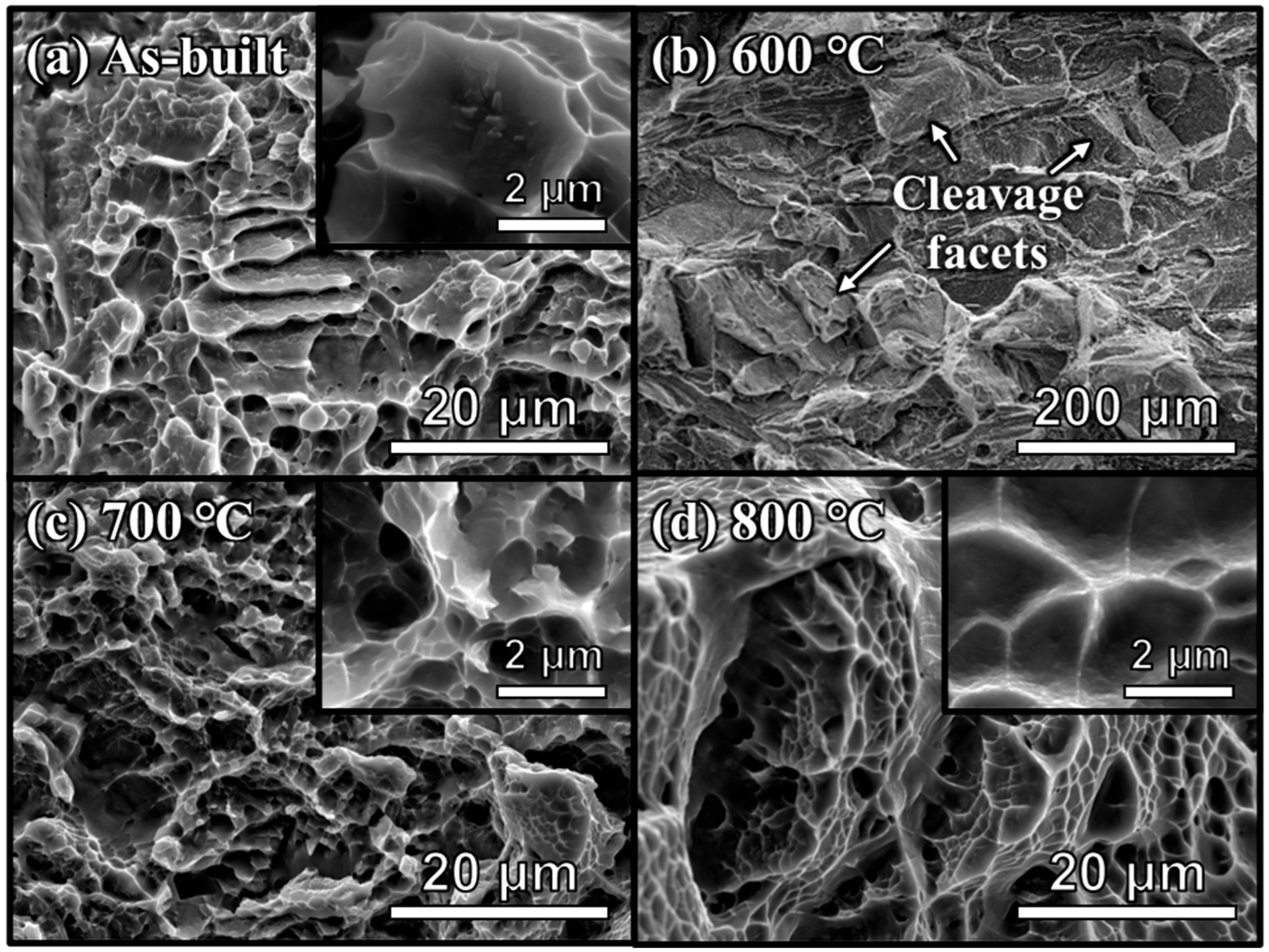

3.4. Fracture Surface Analysis

3.5. Comparison with Previously Reported Ti-6242 Alloys

4. Conclusions

- The as-built sample showed increased strength and relatively reduced elongation (1229.3 ± 4.7, 1437.2 ± 13.0 MPa, and 7.9 ± 0.1% for YS, UTS, and elongation, respectively), compared with the conventional Ti-6242 alloy, as shown in Table 2. This is due to the presence of the hard α′ martensite and twins within the α′ martensite.

- Heat treatment at 600 °C resulted in an insufficient elongation with a brittle surface, which was attributed to the formation of nano-sized β precipitates and layers caused by partial decomposition of α′ martensite.

- Heat treatment at higher temperatures (700 and 800 °C) exhibited a distinct decomposition of α′ martensite into the α + β lamellar structure and their growth, which led to a decrease in strength and an increase in elongation, showing a ductile surface with dimples.

- Compared with commercially processed Ti-6242 (casting and STA) and previously reported additively manufactured Ti-6242 alloys, the lowest yield strength and ultimate tensile strength are measured as 1086.4 ± 16.5 and 1135.0 ± 15.0 MPa, respectively, along with improved elongation in this study. These tensile properties are comparable to or higher than those of conventionally processed Ti-6242, indicating that appropriate post-processing heat treatments enable L-PBF Ti-6242 to reach performance levels suitable for practical applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Committee, A.H. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM International: Materials Park, OH, USA, 1990. [Google Scholar]

- Singh, P.; Pungotra, H.; Kalsi, N.S. On the characteristics of titanium alloys for the aircraft applications. Mater. Today Proc. 2017, 4, 8971–8982. [Google Scholar] [CrossRef]

- Boyer, R.R. Processing of Titanium and Titanium Alloys. In Metals Handbook Desk Edition; Davis, J.R., Ed.; ASM International: Materials Park, OH, USA, 1998; pp. 578–584. [Google Scholar]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Huang, Z.; Yang, T.; Kong, H.; Luan, J.; Wang, A.; Wang, D.; Kuo, W.; Wang, Y.; Liu, C.-T. In situ design of advanced titanium alloy with concentration modulations by additive manufacturing. Science 2021, 374, 478–482. [Google Scholar] [CrossRef] [PubMed]

- Dutta, B.; Froes, F.H. The Additive Manufacturing (AM) of titanium alloys. Met. Powder Rep. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Zhang, L.C.; Attar, H. Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: A review. Adv. Eng. Mater. 2016, 18, 463–475. [Google Scholar] [CrossRef]

- Park, K.; Cho, B.; Cho, J.; Oh, K.I.; Ha, S.Y.; Hong, S.H.; Lee, B.; Lee, C.; Song, G. Influence of Single Aging Treatment on the Mechanical Properties of Additively Manufactured Ultra-Thin 18Ni-300 Maraging Steel. Met. Mater. Int. 2025, 31, 701–712. [Google Scholar] [CrossRef]

- Su, C.; Yang, J.; Wei, T.; Zhang, Y.; Yang, P.; Zhou, J. Numerical simulation of the thermal behaviors for two typical damping alloys during selective laser melting. J. Manuf. Process. 2023, 101, 1419–1430. [Google Scholar] [CrossRef]

- Zhou, L.; Yuan, T.; Tang, J.; He, J.; Li, R. Mechanical and corrosion behavior of titanium alloys additively manufactured by selective laser melting–A comparison between nearly β titanium, α titanium and α+ β titanium. Opt. Laser Technol. 2019, 119, 105625. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the texture formation of selective laser melted Ti-6Al-4V. Metall. Mater. Trans. A 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Eshawish, N.; Malinov, S.; Sha, W.; Walls, P. Microstructure and Mechanical Properties of Ti-6Al-4V Manufactured by Selective Laser Melting after Stress Relieving, Hot Isostatic Pressing Treatment, and Post-Heat Treatment. J. Mater. Eng. Perform. 2021, 30, 5290–5296. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. On the machinability of directed energy deposited Ti6Al4V. Addit. Manuf. 2018, 19, 39–50. [Google Scholar] [CrossRef]

- Dixit, S.; Liu, S.; Murdoch, H.A.; Smith, P.M. Investigating build orientation-induced mechanical anisotropy in additive manufacturing 316L stainless steel. Mater. Sci. Eng. A 2023, 880, 145308. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Park, S.-H.; Yu, J.-H.; AlMangour, B.; Lee, K.-A. Improvement in the high-temperature creep properties via heat treatment of Ti-6Al-4V alloy manufactured by selective laser melting. Mater. Sci. Eng. A 2018, 715, 33–40. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Fang, G.; Leeflang, S.; Böttger, A.J.; Zadpoor, A.A.; Zhou, J. Effect of subtransus heat treatment on the microstructure and mechanical properties of additively manufactured Ti-6Al-4V alloy. J. Alloys Compd. 2018, 735, 1562–1575. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, X.; Yang, X.; Zhang, R.; Shen, Z.; Feng, Q. Specific heat treatment of selective laser melted Ti–6Al–4V for biomedical applications. Front. Mater. Sci. 2015, 9, 373–381. [Google Scholar] [CrossRef]

- Ter Haar, G.M.; Becker, T.H. Selective Laser Melting Produced Ti-6Al-4V: Post-Process Heat Treatments to Achieve Superior Tensile Properties. Materials 2018, 11, 146. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Ng, F.L.; Seet, H.L.; Nai, S.M.L. Tailoring the microstructure and mechanical property of laser powder bed fusion fabricated Ti–6Al–2Sn–4Zr–2Mo via heat treatment. J. Alloys Compd. 2022, 895, 162648. [Google Scholar] [CrossRef]

- Fan, H.; Yang, S. Effects of direct aging on near-alpha Ti–6Al–2Sn–4Zr–2Mo (Ti-6242) titanium alloy fabricated by selective laser melting (SLM). Mater. Sci. Eng. A 2020, 788, 139533. [Google Scholar] [CrossRef]

- Fan, H.; Wang, C.; Tian, Y.; Zhou, K.; Yang, S. Laser powder bed fusion (L-PBF) of Ti–6Al–4V/Ti–6Al–2Sn–4Zr–2Mo and Ti–6Al–4V/γ-TiAl bimetals: Processability, interface and mechanical properties. Mater. Sci. Eng. A 2023, 871, 144907. [Google Scholar] [CrossRef]

- Fleißner-Rieger, C.; Pfeifer, T.; Turk, C.; Clemens, H. Optimization of the post-process heat treatment strategy for a near-α titanium base alloy produced by laser powder bed fusion. Materials 2022, 15, 1032. [Google Scholar] [CrossRef] [PubMed]

- Sui, S.; Chew, Y.; Hao, Z.; Weng, F.; Tan, C.; Du, Z.; Bi, G. Effect of cyclic heat treatment on microstructure and mechanical properties of laser aided additive manufacturing Ti–6Al–2Sn–4Zr–2Mo alloy. Adv. Powder Mater. 2022, 1, 100002. [Google Scholar] [CrossRef]

- Dieter, G.E.; Bacon, D. Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1976; Volume 3. [Google Scholar]

- Titanium Metals Corporation. TIMETAL 6242 Datasheet. Available online: https://www.timet.com/documents/datasheets/near-alpha-alloys/timetal-6242.pdf (accessed on 24 November 2025).

- Prevey, P.S. X-Ray Diffraction Residual Stress Techniques. In Materials Characterization; Whan, R.E., Ed.; ASM International: Materials Park, OH, USA, 1986; Volume 10, pp. 380–392. [Google Scholar]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Cai, C.; Wu, X.; Liu, W.; Zhu, W.; Chen, H.; Qiu, J.C.D.; Sun, C.-N.; Liu, J.; Wei, Q.; Shi, Y. Selective laser melting of near-α titanium alloy Ti-6Al-2Zr-1Mo-1V: Parameter optimization, heat treatment and mechanical performance. J. Mater. Sci. Technol. 2020, 57, 51–64. [Google Scholar] [CrossRef]

- Tong, Z.; Ren, X.; Jiao, J.; Zhou, W.; Ren, Y.; Ye, Y.; Larson, E.A.; Gu, J. Laser additive manufacturing of FeCrCoMnNi high-entropy alloy: Effect of heat treatment on microstructure, residual stress and mechanical property. J. Alloys Compd. 2019, 785, 1144–1159. [Google Scholar] [CrossRef]

- Wang, X.; Chou, K. The effects of stress relieving heat treatment on the microstructure and residual stress of Inconel 718 fabricated by laser metal powder bed fusion additive manufacturing process. J. Manuf. Process. 2019, 48, 154–163. [Google Scholar] [CrossRef]

- Chao, Q.; Thomas, S.; Birbilis, N.; Cizek, P.; Hodgson, P.D.; Fabijanic, D. The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2021, 821, 141611. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley Online Library: Hoboken, NJ, USA, 2006. [Google Scholar]

- Ronneberg, T.; Davies, C.M.; Hooper, P.A. Revealing relationships between porosity, microstructure and mechanical properties of laser powder bed fusion 316L stainless steel through heat treatment. Mater. Des. 2020, 189, 108481. [Google Scholar] [CrossRef]

- Iftikhar, H.; Park, K.; Jung, Y.; Lee, K.; Hong, S.H.; Kim, K.B.; Lee, C.; Song, G. Overcoming strength-ductility trade-off via L21 precipitate-strengthening in Al0.3CoCrNiTi0.1 high entropy alloy at room and cryogenic temperatures. J. Mater. Res. Technol. 2025, 39, 933–944. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Zhang, H.; Yang, Y.; Zhu, Y.; Huang, A.; Zhang, K. Martensite decomposition and its effect on mechanical performance in laser powder bed fusion Ti–6.5Al–2Zr–1Mo–1V alloy. Mater. Sci. Eng. A 2025, 937, 148449. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, B.; Zhang, Y.; Niu, H.; Zhang, D. Manipulating the strength and tensile ductility of a PM near α titanium alloy by adjusting the morphologies and volume fractions of α and βt domains. Mater. Sci. Eng. A 2022, 859, 144184. [Google Scholar] [CrossRef]

- Qin, W.; Li, J.; Liu, Y.; Kang, J.; Zhu, L.; Shu, D.; Peng, P.; She, D.; Meng, D.; Li, Y. Effects of grain size on tensile property and fracture morphology of 316L stainless steel. Mater. Lett. 2019, 254, 116–119. [Google Scholar] [CrossRef]

- Broek, D. The role of inclusions in ductile fracture and fracture toughness. Eng. Fract. Mech. 1973, 5, 55–66. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, J.; Tan, H.; Zhang, G.; Lin, X.; Huang, W. Achieving superior ductility for laser solid formed extra low interstitial Ti-6Al-4V titanium alloy through equiaxial alpha microstructure. Scr. Mater. 2018, 146, 187–191. [Google Scholar] [CrossRef]

| Elements (Wt. %) | |||||

|---|---|---|---|---|---|

| Powder | Ti | Al | Sn | Zr | Mo |

| Ti-6242 | Bal. | 5.1 ± 0.08 | 1.64 ± 0.13 | 3.52 ± 0.23 | 2.16 ± 1.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Park, K.; Jung, Y.; Im, S.; Lee, K.; Kwon, M.; Hong, S.; Moon, J.; Seong, J.; Park, J.; Song, G. Effect of Post-Processing Heat Treatment Temperature on Microstructural Evolution and Mechanical Properties of the Ti-6Al-2Sn-4Zr-2Mo Alloy Fabricated by Laser Powder Bed Fusion. Micromachines 2026, 17, 16. https://doi.org/10.3390/mi17010016

Park K, Jung Y, Im S, Lee K, Kwon M, Hong S, Moon J, Seong J, Park J, Song G. Effect of Post-Processing Heat Treatment Temperature on Microstructural Evolution and Mechanical Properties of the Ti-6Al-2Sn-4Zr-2Mo Alloy Fabricated by Laser Powder Bed Fusion. Micromachines. 2026; 17(1):16. https://doi.org/10.3390/mi17010016

Chicago/Turabian StylePark, Kanghyun, Yunjong Jung, Seongjin Im, Kangjin Lee, Mincheol Kwon, Soonjik Hong, Jongun Moon, Junmo Seong, Jinman Park, and Gian Song. 2026. "Effect of Post-Processing Heat Treatment Temperature on Microstructural Evolution and Mechanical Properties of the Ti-6Al-2Sn-4Zr-2Mo Alloy Fabricated by Laser Powder Bed Fusion" Micromachines 17, no. 1: 16. https://doi.org/10.3390/mi17010016

APA StylePark, K., Jung, Y., Im, S., Lee, K., Kwon, M., Hong, S., Moon, J., Seong, J., Park, J., & Song, G. (2026). Effect of Post-Processing Heat Treatment Temperature on Microstructural Evolution and Mechanical Properties of the Ti-6Al-2Sn-4Zr-2Mo Alloy Fabricated by Laser Powder Bed Fusion. Micromachines, 17(1), 16. https://doi.org/10.3390/mi17010016