Performance of Miniature Carbon Nanotube Field Emission Pressure Sensor for X-Ray Source Applications

Abstract

1. Introduction

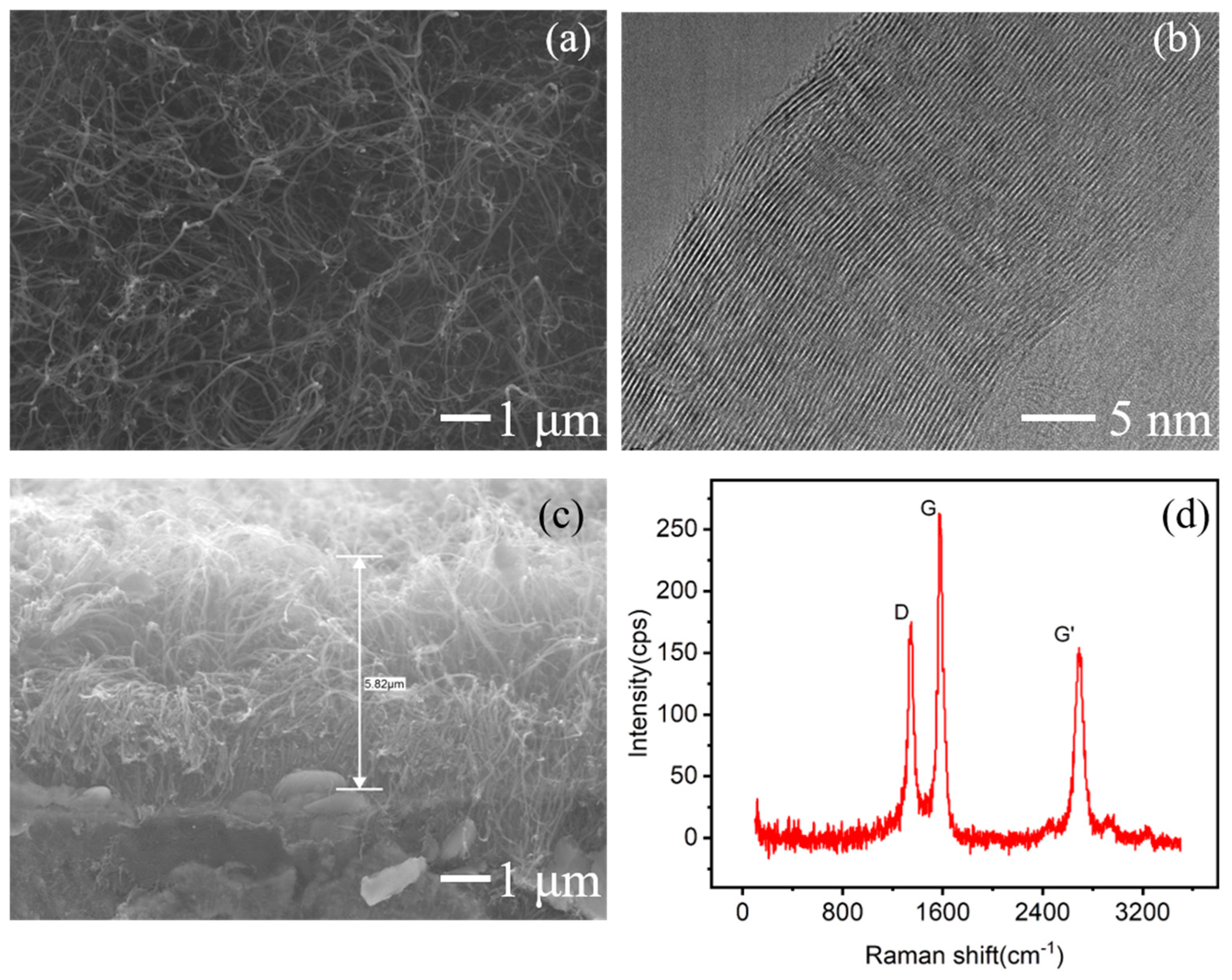

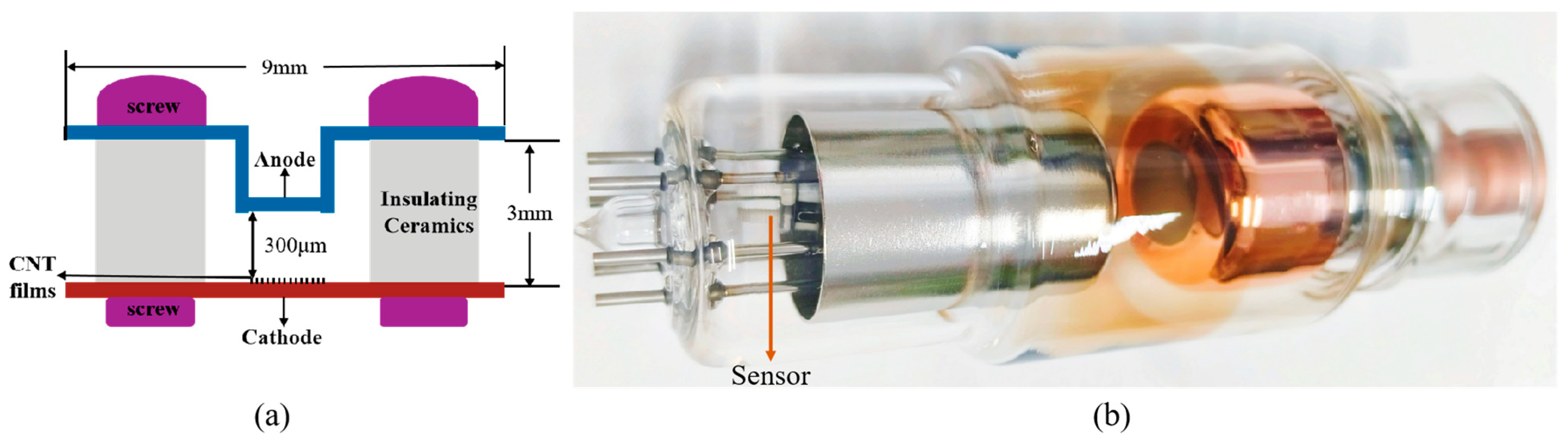

2. Materials and Methods

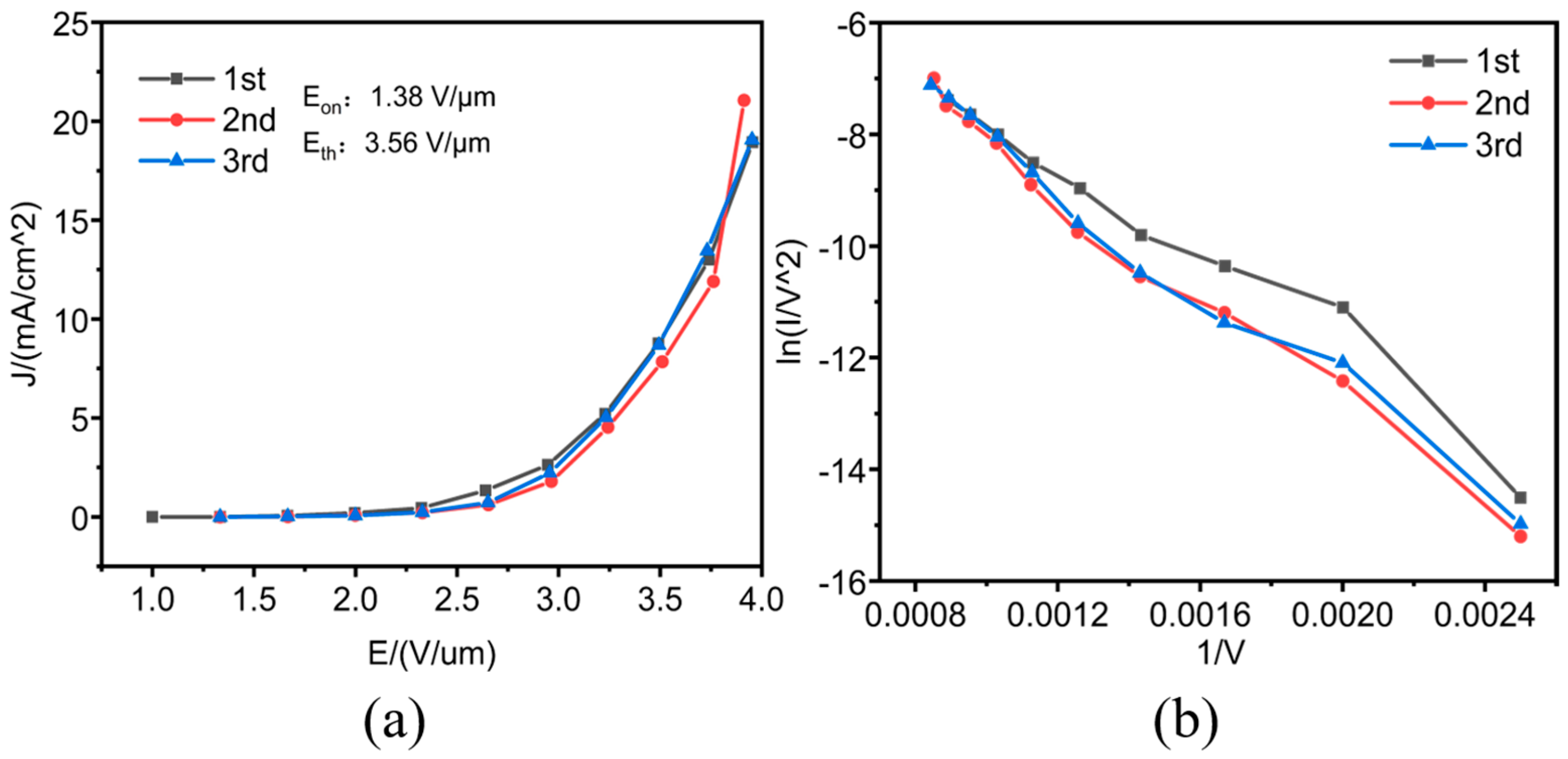

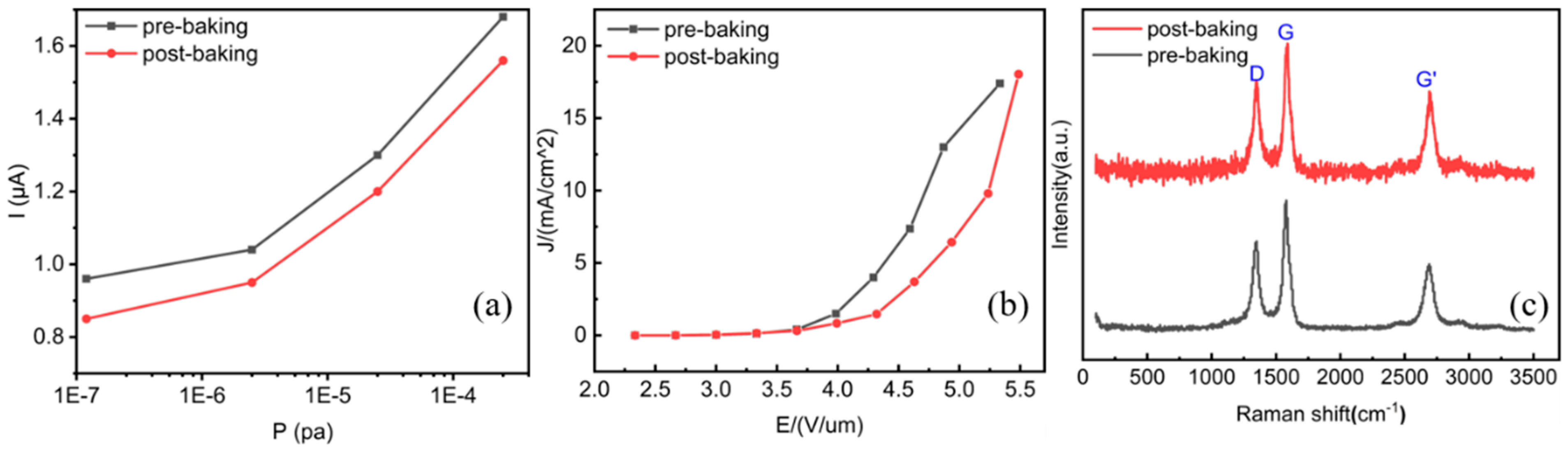

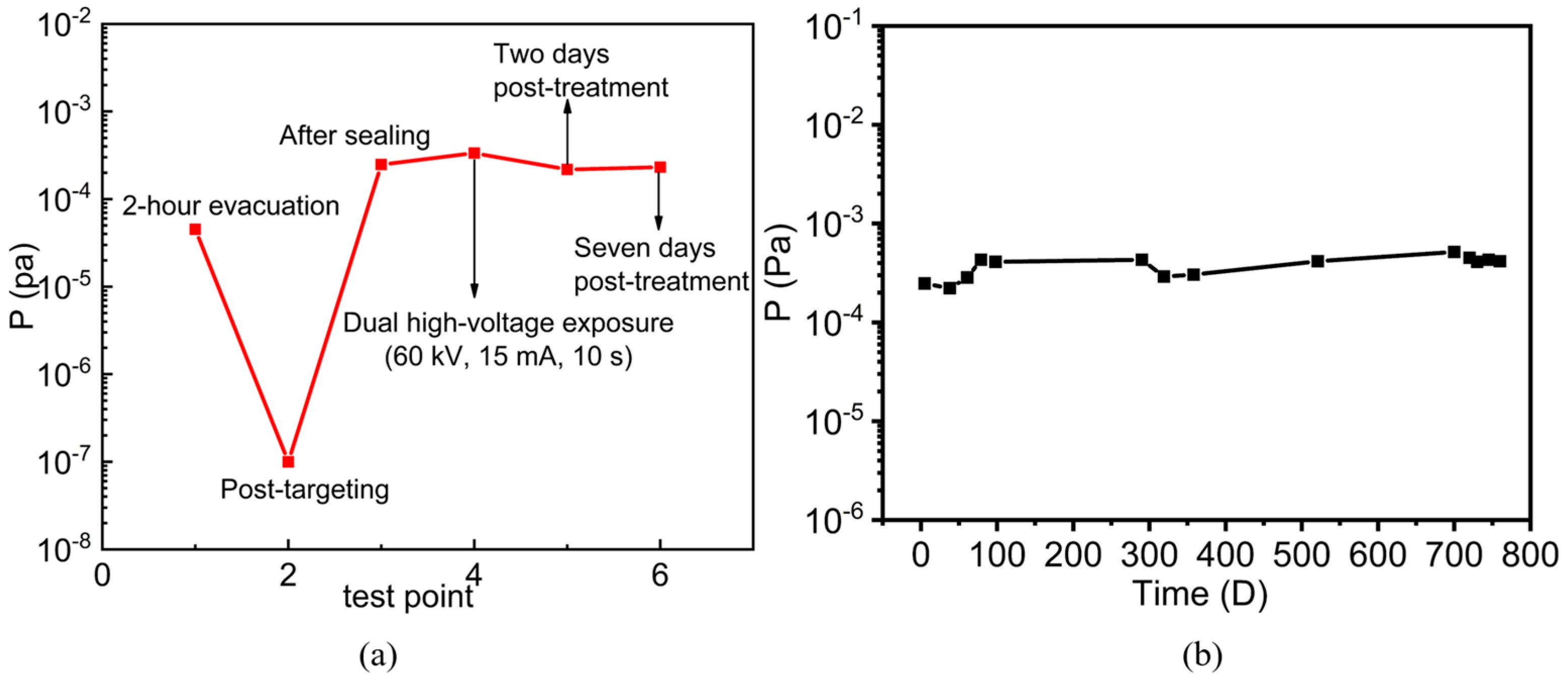

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Withers, P.J.; Bouman, C.; Carmignato, S.; Cnudde, V.; Grimaldi, D.; Hagen, C.K.; Maire, E.; Manley, M.; Du Plessis, A.; Stock, S.R. X-ray computed tomography. Nat. Rev. Methods Primers 2021, 1, 18. [Google Scholar] [CrossRef]

- Liu, S.; Xie, Q.; Chen, Z.; Wu, Y.; Zi, Z.; Wu, X.; Cai, J.; Feng, J. High Linear Power E-Band Traveling-Wave Tube for Communication Applications. IEEE Trans. Electron Devices 2021, 68, 2984–2989. [Google Scholar] [CrossRef]

- Mohammadi, S.; Narang, R.; Ashani, M.M.; Sadabadi, H.; Sanati-Nezhad, A.; Zarifi, M.H. Real-time monitoring of Escherichia coli concentration with planar microwave resonator sensor. Microwave Opt. Technol. Lett. 2019, 61, 2534–2539. [Google Scholar] [CrossRef]

- Guo, N.; Qu, Z.; Xue, Q.; Liu, K.; Song, W.; Zhang, X.; Zhao, D.; Ding, H.; Feng, J. Overlap-mode extended interaction klystrons for broadband terahertz power amplifiers. IEEE Trans. Electron Devices 2022, 69, 1486–1491. [Google Scholar] [CrossRef]

- Armstrong, C.M.; Snively, E.C.; Shumail, M.; Nantista, C.; Li, Z.; Tantawi, S.; Loo, B.W.; Temkin, R.J.; Griffin, R.G.; Feng, J.; et al. Frontiers in the application of RF vacuum electronics. IEEE Trans. Electron Devices 2023, 70, 2643–2655. [Google Scholar] [CrossRef] [PubMed]

- Ding, M.B.; Li, X.; Zhao, H. Study on the failure of electrovacuum devices. Electron. Devices 2004, 27, 763–766. [Google Scholar]

- Jiang, Z.C. Study on the Vacuum System of X-Ray Beamline. Master’s Thesis, National Tsing Hua University, Taiwan, China, 1994. [Google Scholar]

- Jin, C.; Zhang, Y.; Ling, W.; Chen, C.; Wang, H.; Hao, H.; Dong, Y.; Lu, Y.; Li, L. Vacuum system of the Space Plasma Environment Research Facilit. J. Vac. Sci. Technol. B 2023, 41, 034204. [Google Scholar] [CrossRef]

- Xu, W.; Wang, X.; Pan, X.; Bermak, A.; Lee, Y.K.; Yang, Y. A Wafer-Level Packaged CMOS MEMS Pirani Vacuum Gauge. IEEE Trans. Electron Devices 2021, 68, 5155–5161. [Google Scholar] [CrossRef]

- Dong, C.; Myneni G, R. Carbon nanotube electron source based ionization vacuum gauge. Appl. Phys. Lett. 2004, 84, 5443–5445. [Google Scholar] [CrossRef]

- Chen, X.; Hou, Z.; Liu, G.; Zeng, M.; Wu, X.; Xiao, D. A MEMS resonant vacuum gauge for high vacuum measurement. Vacuum 2024, 228, 113513. [Google Scholar] [CrossRef]

- Bundaleski, N.; Adame, C.; Bernien, M.; Illgen, C.; Jenninger, B.; Jousten, K.; Scuderi, F.; Silva, R.; Stöltzel, A.; Šetina, J.; et al. Novel ionisation vacuum gauge suitable as a reference standard: Influence of primary electron trajectories on the operation. Vacuum 2022, 201, 111041. [Google Scholar] [CrossRef]

- Mironov, A.E.; Yu, N.; Park, S.; Tuggle, M.; Gragg, J.; Kucera, C.; Hawkins, T.; Ballato, J.; Eden, J.G.; Dragic, P. All optical fiber thermal vacuum gauge. J. Phys. Photonics 2020, 2, 014006. [Google Scholar] [CrossRef]

- Han, X.; Li, G.; Xu, M.; Guo, C.; Wang, Y.; Feng, Y.; Li, D. Miniature capacitance diaphragm gauge for absolute vacuum measurement. Measurement 2022, 194, 110851. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, H.; Hou, Z.; Li, Q.; Wu, Y.; Wu, X.; Xiao, D. A MEMS Friction Gauge For High Vacuum Measurement. IEEE Trans. Electron Devices 2024, 71, 1231–1237. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, Z.; Tao, J.; Wen, L. A MEMS Pirani Vacuum Gauge Based on Porous Silicon. Micromachines 2025, 16, 296. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Huang, M.; Wu, Z.; Gao, Y.; Xia, Y.; Yang, P.; Fan, S.; Lu, X.; Yang, X.; Liang, L.; et al. Advances in high-performance MEMS pressure sensors: Design, fabrication, and packaging. Microsyst. Nanoeng. 2023, 9, 156. [Google Scholar] [CrossRef] [PubMed]

- Soni, S.K.; Thomas, B.; Kar, V.R. A comprehensive review on CNTs and CNT-reinforced composites: Syntheses, characteristics and applications. Mater. Today Commun. 2020, 25, 101546. [Google Scholar] [CrossRef]

- Kolahdouz, M.; Xu, B.; Nasiri, A.F.; Fathollahzadeh, M.; Manian, M.; Aghababa, H.; Wu, Y.; Radamson, H.H. Carbon-Related Materials: Graphene and Carbon Nanotubes in Semiconductor Applications and Design. Micromachines 2022, 13, 1257. [Google Scholar] [CrossRef] [PubMed]

- Thiruvengadam, M.; Rajakumar, G.; Swetha, V.; Ansari, M.A.; Alghamdi, S.; Almehmadi, M.; Halawi, M.; Kungumadevi, L.; Raja, V.; Sabura Sarbudeen, S.; et al. Recent Insights and Multifactorial Applications of Carbon Nanotubes. Micromachines 2021, 12, 1502. [Google Scholar] [CrossRef] [PubMed]

- Mittal, M.; Kumar, A. Carbon nanotube (CNT) gas sensors for emissions from fossil fuel burning. Sensor Actuat. B-Chem. 2014, 203, 349–362. [Google Scholar] [CrossRef]

- Nguyen, L.H.; Phi, T.V.; Phan, P.Q.; Vu, H.N.; Nguyen-Duc, C.; Fossard, F. Synthesis of multi-walled carbon nanotubes for NH3 gas detectio. Phys. E 2007, 37, 54–57. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Burghard, M. Chemically functionalized carbon nanotubes. Small 2005, 1, 180–192. [Google Scholar] [CrossRef] [PubMed]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Cao, H.; Yu, Y.; Chen, S.G. Corrosion protection of silane coatings modified by carbon nanotubes on stainless steel. Int. J. Electrochem. Sci. 2015, 10, 3497–3509. [Google Scholar] [CrossRef]

- Hatipoglu, G.; Kartal, M.; Uysal, M.; Cetinkaya, T.; Akbulut, H. The effect of sliding speed on the wear behavior of pulse electro co-deposited Ni/MWCNT nanocomposite coatings. Tribol. Int. 2016, 98, 59–73. [Google Scholar] [CrossRef]

- Luo, K.; Peng, H.; Zhang, B.; Chen, L.; Zhang, P.; Peng, Z.; Fu, X. Advances in carbon nanotube-based gas sensors: Exploring the path to the future. Coord. Chem. Rev. 2024, 518, 216049. [Google Scholar] [CrossRef]

- Meyyappan, M. Carbon nanotube-based chemical sensors. Small 2016, 12, 2118–2129. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhang, N.; Zhang, Z. High-Performance Carbon Nanotube Electronic Devices: Progress and Challenges. Micromachines 2025, 16, 554. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Gao, W.; Emaminejad, S.; Kiriya, D.; Ota, H.; Nyein, H.Y.Y.; Takei, K.; Javey, A. Printed carbon nanotube electronics and sensor systems. Adv. Mater. 2016, 28, 4397–4414. [Google Scholar] [CrossRef] [PubMed]

- Chumak, M.A.; Shchegolkov, A.V.; Popov, E.O.; Filippov, S.V.; Kolosko, A.G.; Shchegolkov, A.V.; Babaev, A.A. Investigation of Field Emission Properties of Carbon Nanotube Arrays of Different Morphologies. Nanomaterials 2024, 14, 763. [Google Scholar] [CrossRef] [PubMed]

- Qian, K.; Chen, T.; Yan, B.; Lin, Y.; Xu, D.; Sun, Z.; Cai, B. Research on carbon nanotube array field emission pressure sensors. Electron. Lett. 2005, 41, 824–825. [Google Scholar] [CrossRef]

- Naje, A.N.; Ibraheem, R.R.; Ibrahim, F.T. Parametric Analysis of NO2 Gas Sensor Based on Carbon Nanotubes. Photonic Sens. 2016, 6, 153–157. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Z.; He, Y.; Mao, S.; Guo, D.; Wei, X. A MEMS-Type Ionization Vacuum Sensor With a Wide Measurement Range. IEEE Electron Device Lett. 2024, 45, 909–912. [Google Scholar] [CrossRef]

- Dong, C.; Luo, H.; Cai, J.; Wang, F.; Zhao, Y.; Li, D. Hydrogen sensing characteristics from carbon nanotube field emissions. Nanoscale 2016, 8, 5599–5604. [Google Scholar] [CrossRef] [PubMed]

- Dong, C.; Liu, R.; Wang, J.; Yu, H.; Kang, S.; Huang, W.; Jia, W.; Qian, W. Mini-type low pressure helium detection from adsorption enhanced carbon nanotube field emission. Sensor Actuat. B-Chem. 2023, 380, 133327. [Google Scholar] [CrossRef]

- Kang, S.; Qian, W.; Liu, R.; Yu, H.; Zhu, W.; Liao, X.; Wang, F.; Huang, W.; Dong, C. Miniature vacuum sensor based on gas adsorptions from carbon nanotube field emitters. Vacuum 2023, 207, 111663. [Google Scholar] [CrossRef]

- Shen, P.C.; Lin, Y.; Wang, H.; Park, J.H.; Leong, W.S.; Lu, A.Y.; Palacios, T.; Kong, J. CVD technology for 2-D materials. IEEE Trans. Electron Devices 2018, 65, 4040–4052. [Google Scholar] [CrossRef]

- Zhu, W.; Qian, W.; Liu, R.; Huang, W.; Luo, H.; Dong, C. Field emission energy distribution studies of single multi-walled carbon nanotube emitter with gas adsorptions. Vacuum 2022, 199, 110933. [Google Scholar] [CrossRef]

- Sett, D.; Basak, D. Highly enhanced H2 gas sensing characteristics of Co: ZnO nanorods and its mechanism. Sensor Actuat. B-Chem. 2017, 243, 475–483. [Google Scholar] [CrossRef]

- Rahman, E.; Nojeh, A. Adsorbate-enhanced field-emission from single-walled carbon nanotubes: A comparative first-principles study. Nanotechnology 2019, 30, 175202. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Cai, J.; Luo, H.; Kang, S.; Qian, W.; Dong, C. Low-pressure hydrogen sensing based on carbon nanotube field emission: Mechanism of atomic adsorption induced work function effects. Carbon 2017, 124, 669–674. [Google Scholar] [CrossRef]

- Chen, T.; Sun, Z.; Wang, L.L.; Chen, Y.W.; Guo, P.S.; Que, W.X. Annealing temperature effect on the field emission properties of carbon nanotube films. Surf. Rev. Lett. 2007, 14, 969–972. [Google Scholar] [CrossRef]

- Han, J.H.; Lee, S.H.; Berdinsky, A.S.; Kim, Y.W.; Yoo, J.B.; Park, C.Y.; Choi, J.J.; Jung, T.; Han, I.T.; Kim, J.M. Effects of various post-treatments on carbon nanotube films for reliable field emission. Diam. Relat. Mater. 2005, 14, 1891–1896. [Google Scholar] [CrossRef]

- Niven, J.F.; Johnson, M.B.; Juckes, S.M.; White, M.A.; Alvarez, N.T.; Shanov, V. Influence of annealing on thermal and electrical properties of carbon nanotube yarns. Carbon 2016, 99, 485–490. [Google Scholar] [CrossRef]

| Parameter | This Work | CNT Arrays | MWNT | SWCNT | MEMS Sensor (Yttrium Oxide) |

|---|---|---|---|---|---|

| Threshold field (V/μm) | 3.56 | 2.3 | / | / | / |

| Sensitivity | 10−7–10−3 Pa | / | 101–550 kPa | 3%NO2–79.81% | 1 × 10−4–100 Pa |

| Dimension parameter | 4 × 9 mm2 | 1 cm2 | 6 × 6 mm2 | 2 × 2 cm2 | 12 × 12 × 3.3 mm3 |

| References | [31] | [32] | [33] | [34] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Peng, W.; Huang, W.; Ye, N.; Dong, C. Performance of Miniature Carbon Nanotube Field Emission Pressure Sensor for X-Ray Source Applications. Micromachines 2025, 16, 817. https://doi.org/10.3390/mi16070817

Zhou H, Peng W, Huang W, Ye N, Dong C. Performance of Miniature Carbon Nanotube Field Emission Pressure Sensor for X-Ray Source Applications. Micromachines. 2025; 16(7):817. https://doi.org/10.3390/mi16070817

Chicago/Turabian StyleZhou, Huizi, Wenguang Peng, Weijun Huang, Nini Ye, and Changkun Dong. 2025. "Performance of Miniature Carbon Nanotube Field Emission Pressure Sensor for X-Ray Source Applications" Micromachines 16, no. 7: 817. https://doi.org/10.3390/mi16070817

APA StyleZhou, H., Peng, W., Huang, W., Ye, N., & Dong, C. (2025). Performance of Miniature Carbon Nanotube Field Emission Pressure Sensor for X-Ray Source Applications. Micromachines, 16(7), 817. https://doi.org/10.3390/mi16070817