3.1. Investigation of Microstructure and Hardness

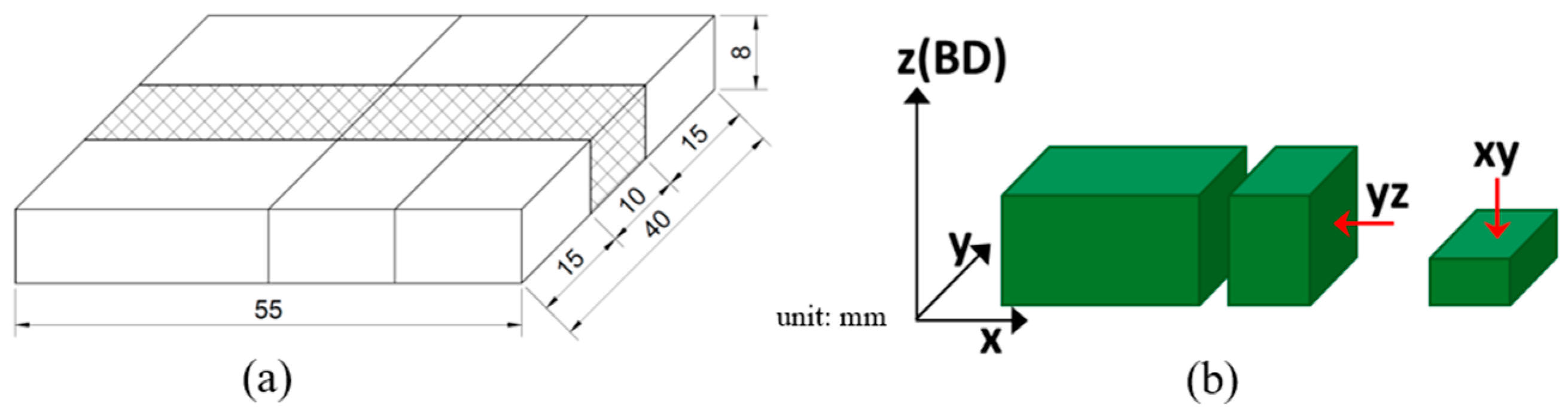

Figure 6 shows the microstructural evolutions of the LP-DED FSS 430 specimens fabricated under consistent laser process parameters, followed by various solution heat treatments. In the as-built sample (

Figure 6a,d,g,j), columnar grains were observed along the build direction, with minimal precipitation, reflecting rapid solidification and limited diffusion, as reported by Byun et al. [

8] and Lee et al. [

33]. The solution heat treatment at 815 °C (

Figure 6b,e,h,k) led to partial recrystallization, as indicated by the reduced aspect ratio of grains and the moderate precipitation of fine particles along grain boundaries and within grains. In contrast, the specimens treated at 980 °C (

Figure 6c,f,i,l) exhibited fully recrystallized [

12] and equiaxed grain structures, with a significant increase in both the size and density of precipitates, particularly along grain boundaries. These microstructural changes are attributed to enhanced diffusion, grain refinement, and carbide coarsening [

34] at elevated temperatures, which may improve wear resistance but could potentially reduce toughness due to carbide embrittlement [

35].

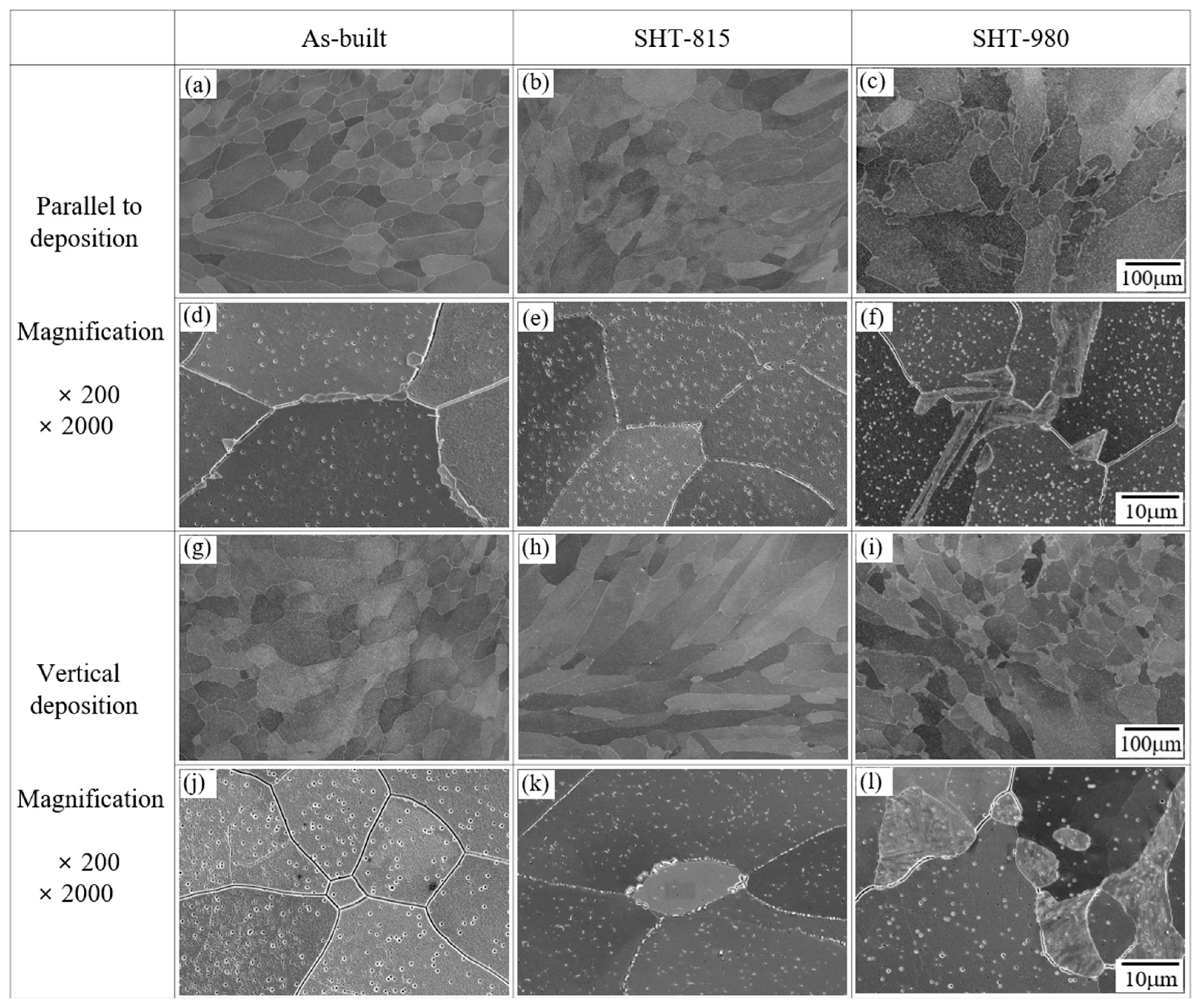

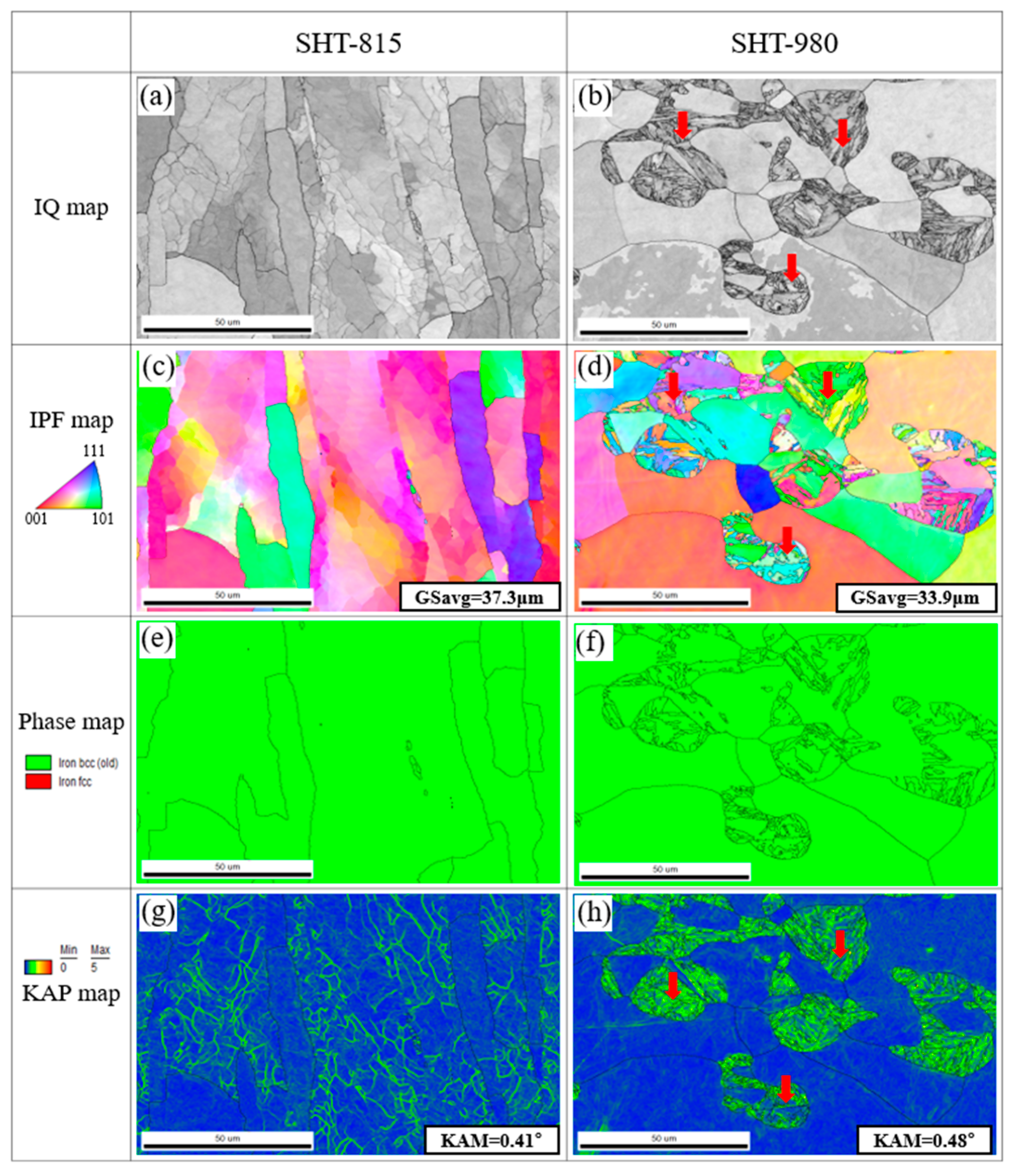

Figure 7 presents the SEM micrographs of the AISI 430 commercial plate specimens subjected to solution heat treatments at 815 °C (SHT-815) and 980 °C (SHT-980). In the low-magnification images parallel to the rolling direction (

Figure 7a,b), the SHT-815 specimen (

Figure 7a) reveals elongated grains aligned along the rolling direction, suggesting incomplete recrystallization. In contrast, the SHT-980 specimen (

Figure 7b) shows more equiaxed and randomly oriented grains, indicating extensive recrystallization and grain structure homogenization at the higher temperature. The high-magnification SEM images (

Figure 7c,d) further illustrate the grain boundary characteristics. The SHT-815 specimen (

Figure 7c) exhibits relatively clean grain interiors with fine precipitates along the grain boundaries, indicative of limited diffusion during the lower-temperature treatment. The SHT-980 specimen (

Figure 7d) displays broader and more defined grain boundaries, along with signs of intragranular features, likely reflecting enhanced boundary mobility and precipitate coarsening due to increased thermal energy. The vertical-to-rolling orientation (

Figure 7e,f) shows a similar trend. The SHT-815 specimen (

Figure 7e) retains its deformed grain structure, while the SHT-980 specimen (

Figure 7f) demonstrates fully recrystallized, equiaxed grains, supporting the observations from the parallel orientation. At higher magnification (

Figure 7j,k), SHT-815 again shows partial boundary definition and finer grain structures (

Figure 7j), while SHT-980 (

Figure 7i) exhibits clearer grain boundaries with well-separated grains and visible second-phase particles or precipitates. These results confirm that solution heat treatment at 980 °C promotes complete recrystallization and improved grain boundary development in AISI 430, while the 815 °C treatment leads to only partial recrystallization, retaining deformation-induced features. The morphological transition, observed consistently in both orientations, validates the effectiveness of higher-temperature treatment for enhancing microstructural stability and uniformity in ferritic stainless steel.

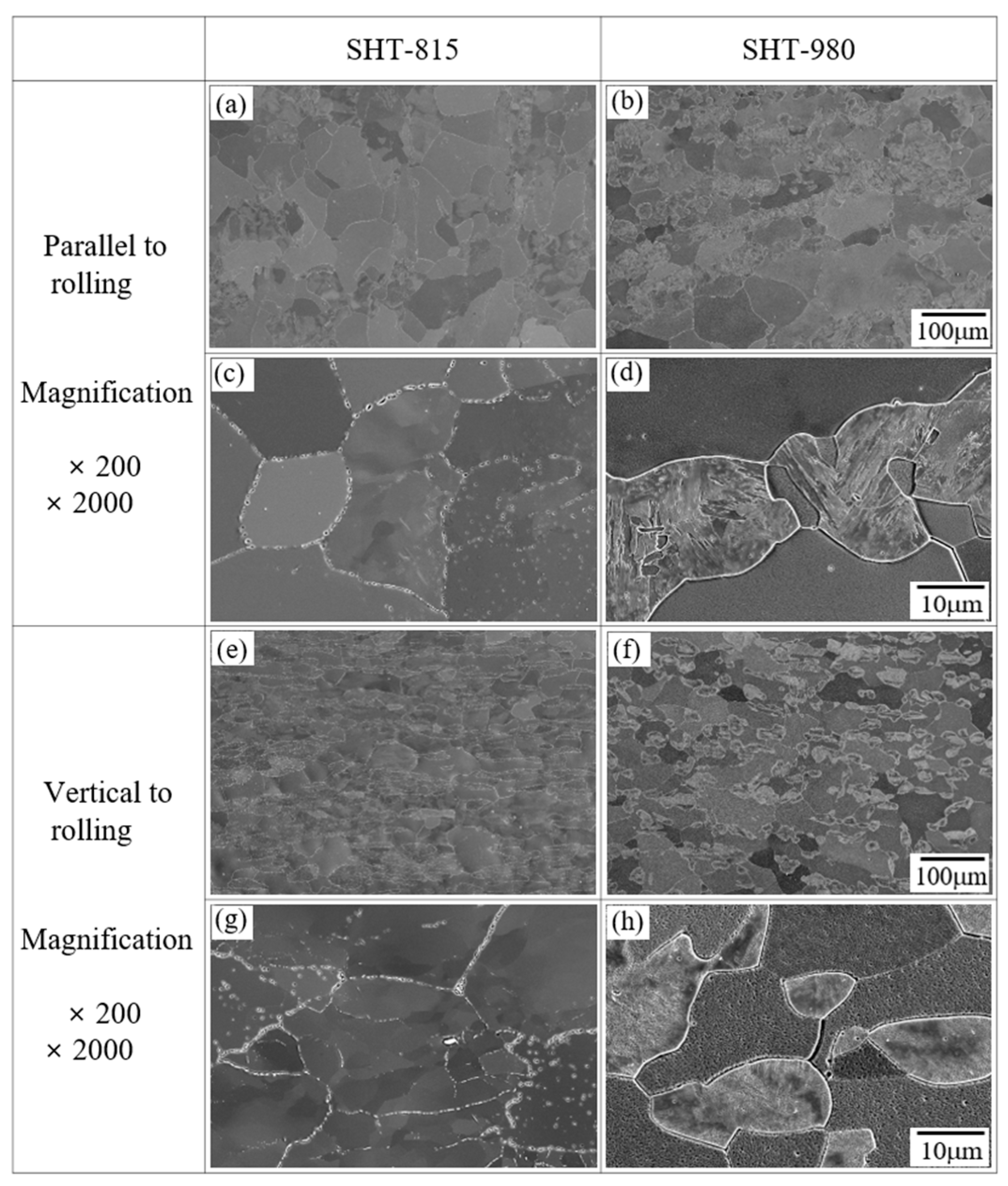

Figure 8 presents the EBSD analyses of the AISI 430 commercial plate specimens subjected to solution heat treatments at 815 °C (SHT-815) and 980 °C (SHT-980). The IQ maps (

Figure 8a,b) reveal distinct differences in grain morphology. The SHT-815 specimen exhibits elongated grains aligned predominantly with the rolling direction, indicating partial recrystallization. In contrast, the SHT-980 specimen shows fully recrystallized and equiaxed grains with well-defined boundaries, reflecting complete recrystallization at the elevated temperature. The corresponding IPF maps (

Figure 8c,d) support this observation. At 815 °C, the grains remain elongated and directionally textured, with an average grain size of 37.3 μm. After the heat treatment at 980 °C, the grains become more equiaxed and randomly oriented, with a slightly reduced average size of 33.9 μm, suggesting effective grain refinement and homogenization due to enhanced boundary mobility and recrystallization kinetics. The phase maps (

Figure 8e,f) confirm that both specimens retain a single-phase BCC ferritic structure, with no evidence of martensitic transformation, demonstrating the thermal phase stability of AISI 430 under the applied conditions. The KAM maps (

Figure 8g,h) provide insight into local strain distribution. The SHT-815 sample displays a higher density of local misorientations, particularly along grain boundaries, indicating the presence of residual strain and substructures from cold working. In contrast, the SHT-980 sample shows a more uniform and predominantly low KAM distribution, indicating reduced internal strain and enhanced microstructural recovery. Notably, the average KAM value for the SHT-980 sample (0.48°) was slightly higher than that of the SHT-815 sample (0.41°). This increase is attributed to the formation of new grain boundaries and the presence of martensitic grains interspersed with fine ferrite grains—highlighted by the red arrows—during the recrystallization process, as reported by Lu et al. [

36]. Collectively, these EBSD results confirm that the solution heat treatment at 980 °C is more effective in promoting complete recrystallization, reducing internal strain, and refining grain morphology, while maintaining phase stability in ferritic stainless steel AISI 430.

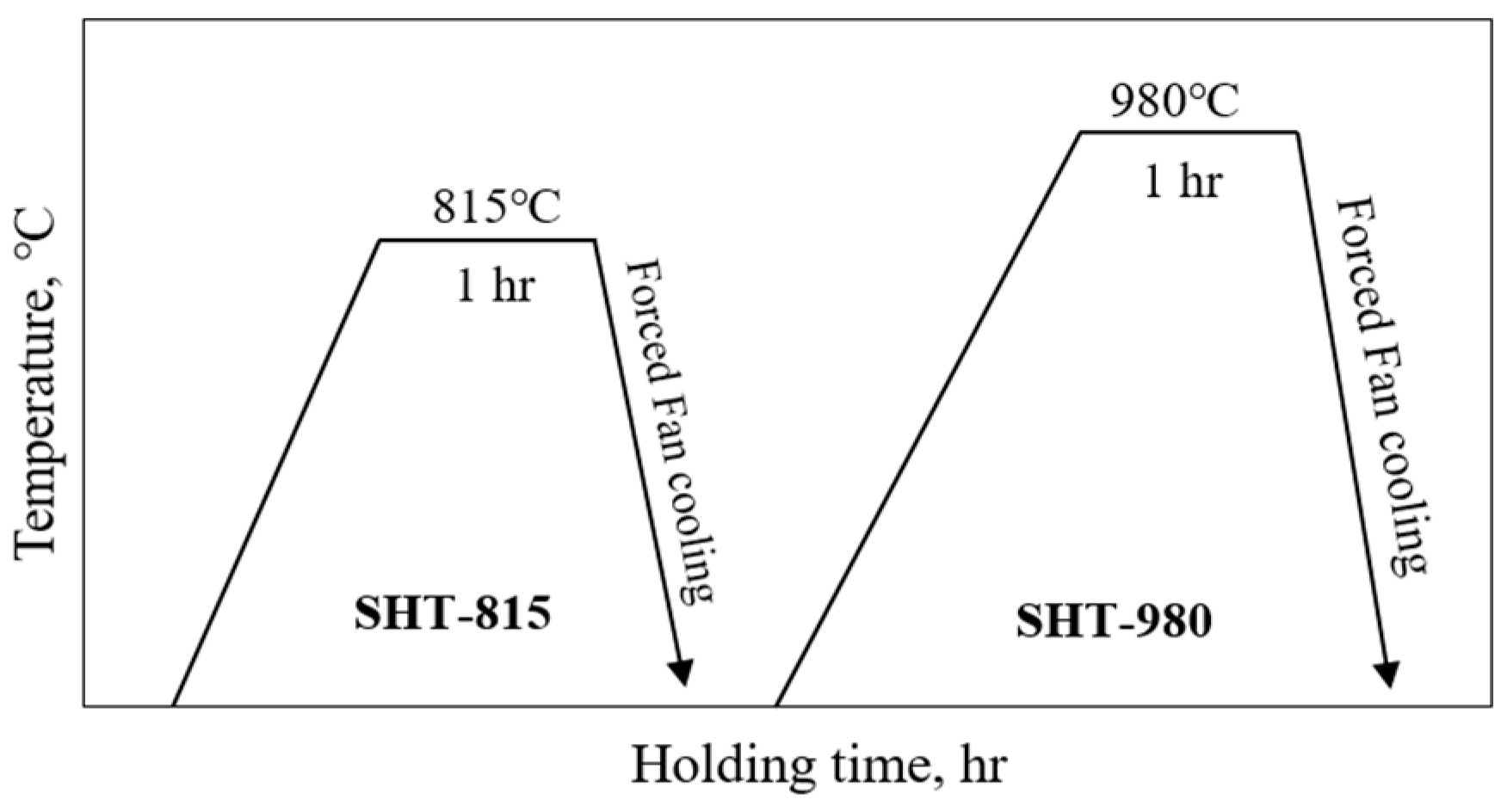

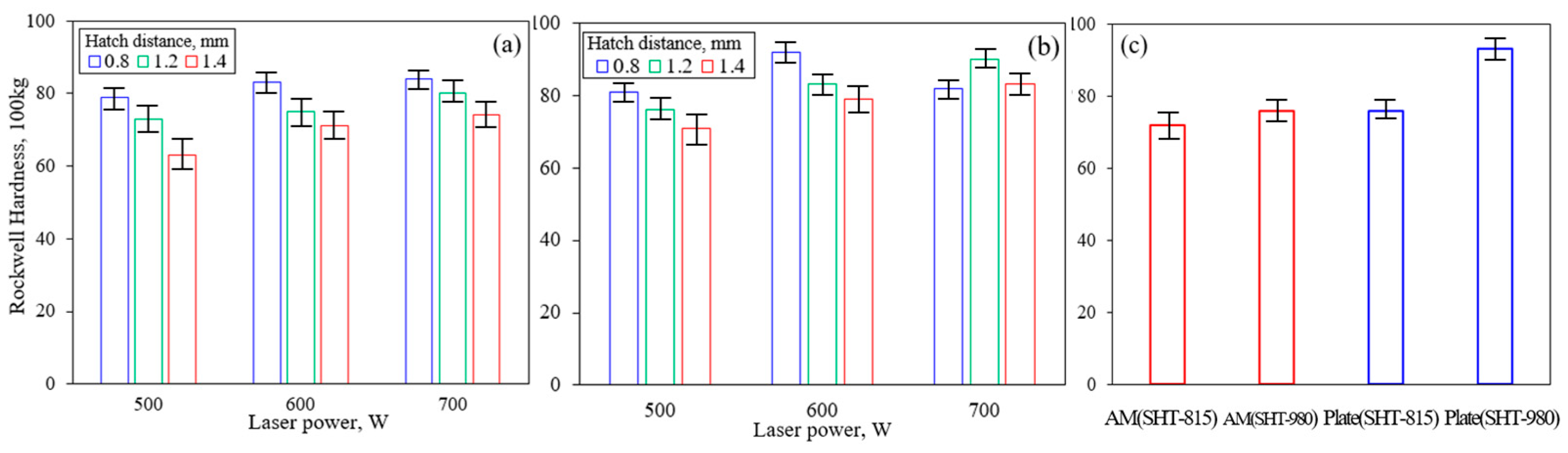

Figure 9 presents the Rockwell hardness (HRB, 100 kgf load) of the LP-DED fabricated FSS 430 specimens and commercial AISI 430 plates under different heat treatment conditions and laser processing parameters. In

Figure 9a,b, the solution heat-treated LP-DED specimens show clear trends in Rockwell hardness as a function of laser and hatch distance. In the solution heat treated at 815 °C, the hardness generally increases with increasing laser power, while wider hatch distances tend to reduce hardness due to insufficient overlap and weaker inter-track bonding. At 980 °C, the solution heat-treated specimens showed slightly higher hardness than those treated at 815 °C. This is because chromium carbide precipitation and coarsening occurred at the grain boundaries, as shown in

Figure 6. Notably, at the highest laser power of 700 W, the hardness values become more consistent across all hatch distances, indicating enhanced microstructural homogenization and possible stress relief.

Figure 9c compares AM specimens against commercial plate samples subjected to the same heat treatments. The SHT-980 commercial plate exhibits the highest hardness of 95 HRB, followed by the SHT-980 AM specimen treated at the same temperature. This enhancement is attributed to the cold-worked origin of the commercial plate, along with the fine-grained and uniform microstructure, low porosity, and efficient carbide precipitation during solution heat treatment. In contrast, the lower hardness of the specimen heat treated at 815 °C compared with those treated at 980 °C is attributed to the temperature being insufficient to fully promote the precipitation of strengthening phases such as chromium-rich carbides (e.g., Cr

23C

6).

3.2. Wear Performance

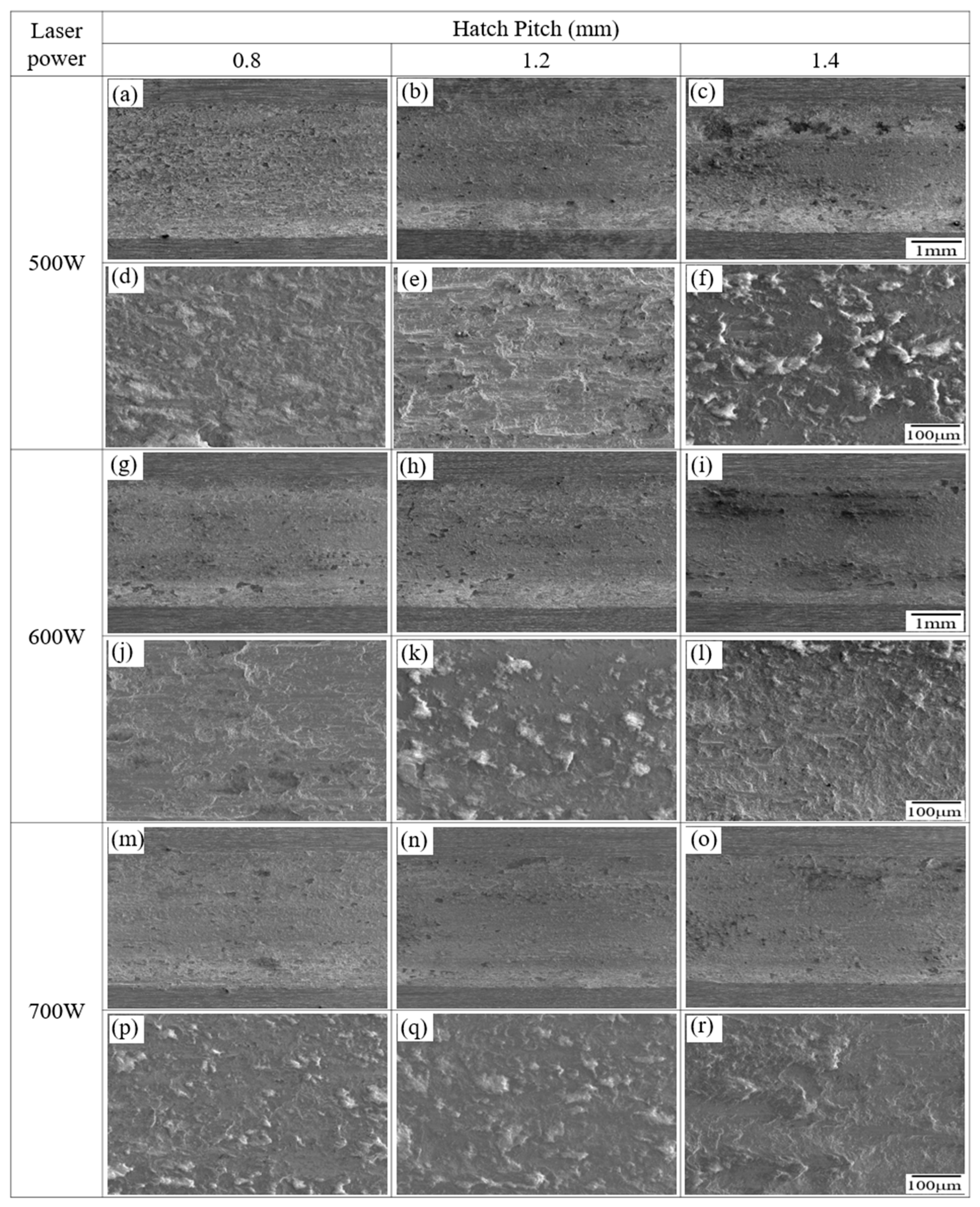

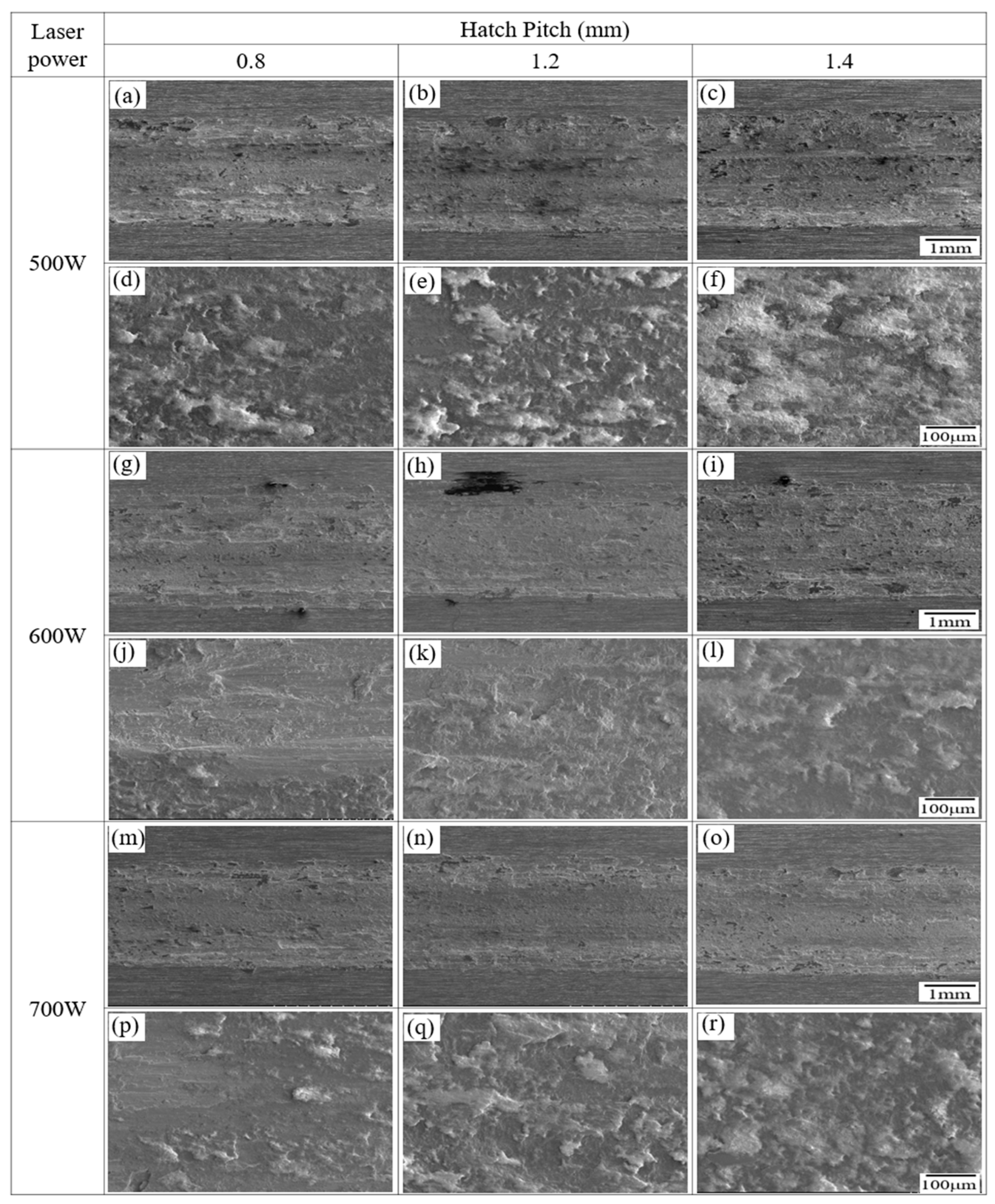

Figure 10 presents the SEM images of the worn surfaces of the LP-DED FSS 430 specimens fabricated under various combinations of laser power (500 W, 600 W, and 700 W) and hatch pitch (0.8 mm, 1.2 mm, and 1.4 mm). All samples were solution heat treated at 815 °C for 1 h prior to wear testing at ambient temperature (25 °C) under dry sliding conditions. It is generally recognized that oxidative wear dominates in ambient conditions, with adhesive wear also contributing. The wear track images suggest signs of oxidation and adhesion but lack clear grooves characteristic of abrasive wear. The mechanism involving oxidation film formation, growth to a critical thickness, and subsequent spallation aligns well with the observations in

Figure 10 [

37,

38,

39]. The wear surfaces are shown at both low and high magnifications to capture the general morphology and localized damage features. At 500 W, the worn surfaces show significant variation with hatch pitch. At 0.8 mm (

Figure 10a,d), the surface is relatively smooth with shallow grooves, indicating mild abrasive wear. As hatch pitch increases to 1.2 mm (

Figure 10b,e), more wear tracks and inter-track boundaries become apparent, suggesting a localized weakness in bonding. At 1.4 mm (

Figure 10c,f), severe abrasive wear with debris accumulation and micro-plowing is observed, reflecting poor inter-track fusion and increased porosity due to insufficient energy input and wider spacing. At 600 W, the wear surfaces demonstrate improved uniformity. The specimen with a 0.8 mm hatch pitch (

Figure 10g,j) shows minimal wear damage with fine, uniform grooves. At 1.2 mm (

Figure 10h,k), the localized abrasive wear features are slightly more pronounced but remain moderate. At 1.4 mm (

Figure 10i,l), the surface roughness increases.

At 700 W, all hatch distances (

Figure 10m–r) result in smooth and uniform worn surfaces with minimal debris or plowing. The wear tracks are finer and more continuous, indicating enhanced inter-track bonding and homogeneity resulting from sufficient laser energy input. Notably, even at the 1.4 mm hatch distance (

Figure 10o,r), the surface shows little evidence of severe wear, highlighting the robustness of the microstructure fabricated at this power level. These results indicate that both laser power and hatch distance significantly influence wear resistance in LP-DED FSS 430 specimens. A lower laser power combined with a wider hatch spacing leads to inferior inter-track bonding and a greater susceptibility to abrasive wear. In contrast, a higher laser power (≥600 W) ensures more consistent melting and bonding, which contributes to smoother wear surfaces and improved tribological performance. The findings confirm that optimized energy input is essential to enhance wear resistance in additive-manufactured ferritic stainless steel components.

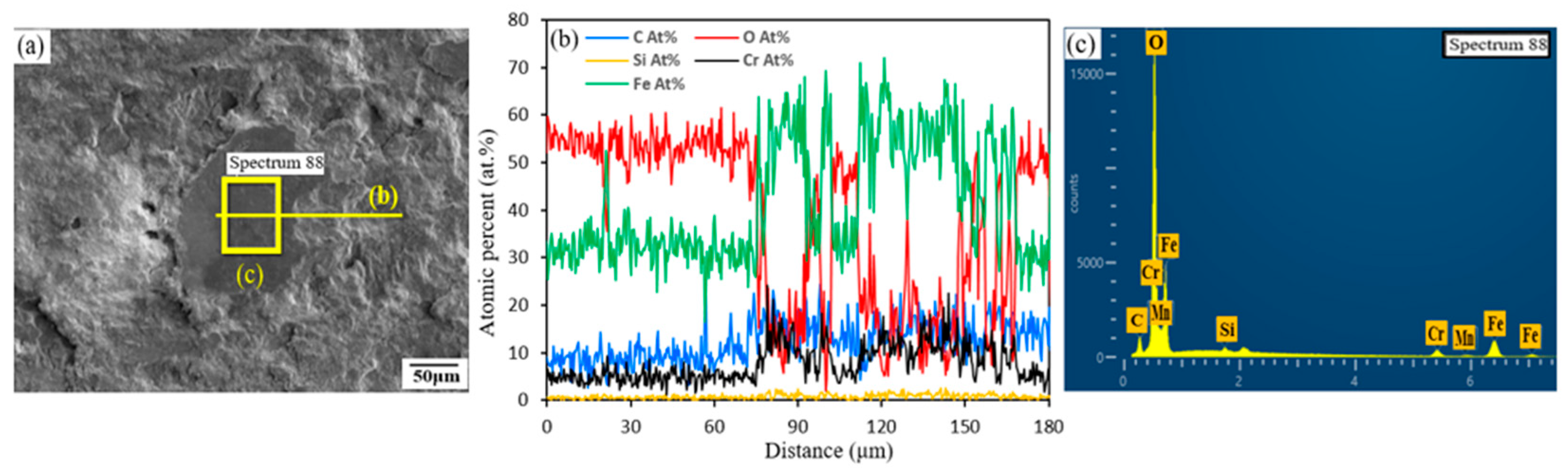

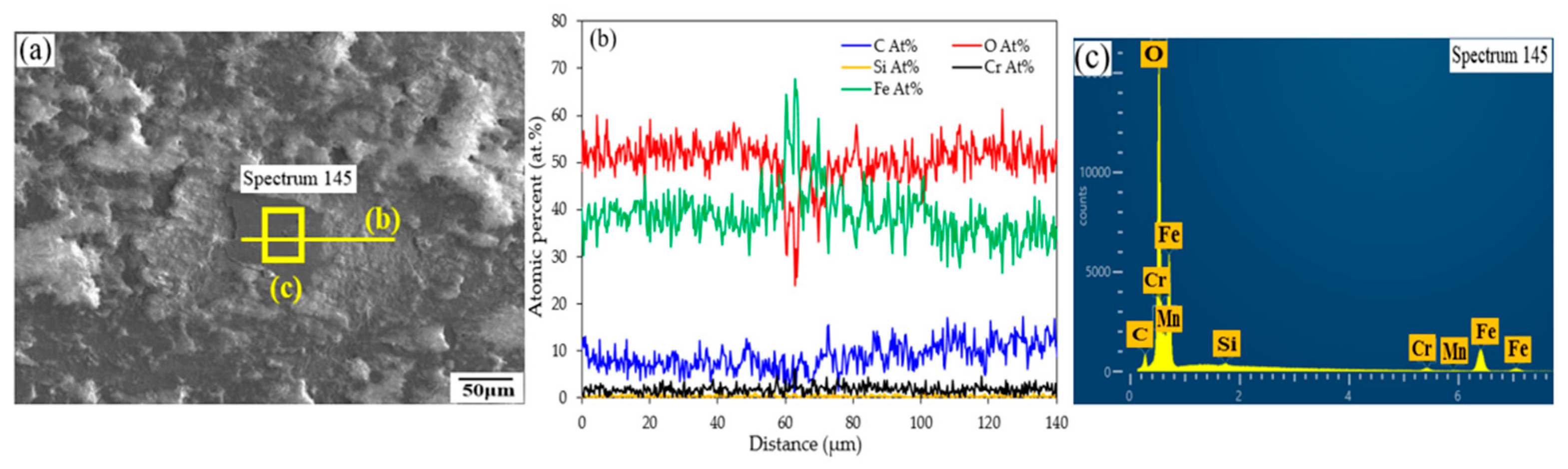

Figure 11 presents the SEM-EDS analyses of the worn surface of LP-DED FSS 430 fabricated at a laser power of 500 W and a hatch distance of 1.4 mm, following reciprocating wear testing at 25 °C. The SEM micrograph (

Figure 11a) highlights the analyzed region, which displays a rough, grooved surface morphology typical of abrasive wear. The presence of grooves and micro-plowing features suggests material removal due to hard asperity interaction under suboptimal processing conditions (low laser power and wide hatch distance). The EDS line scan across the selected area (

Figure 11b) reveals spatial variations in elemental composition. Notably, the Cr and O signals exhibit localized enrichment, suggesting the formation of chromium-rich oxides within the wear track. The Fe signal fluctuates along the scan path, potentially due to surface exposure and the removal of base metal in high-friction zones. The presence of Mn and Si in lower but detectable amounts further supports the idea of tribo-oxidation processes involving multiple alloying elements. The EDS point spectrum (

Figure 11c), acquired from a designated spot within the worn region, confirms the presence of Fe, Cr, O, Mn, and Si. The detection of oxygen in particular suggests oxidative wear, even at room temperature, likely induced by frictional heating at the contact interface during sliding. The spectrum supports the interpretation that the worn surface underwent tribochemical interactions, leading to oxide formation and the potential involvement of third-body wear mechanisms due to detached oxide particles or debris, as shown in

Figure 10c,f. These results indicate that LP-DED FSS 430 specimens fabricated at low laser power and wide hatch spacing are more susceptible to surface oxidation and wear damage.

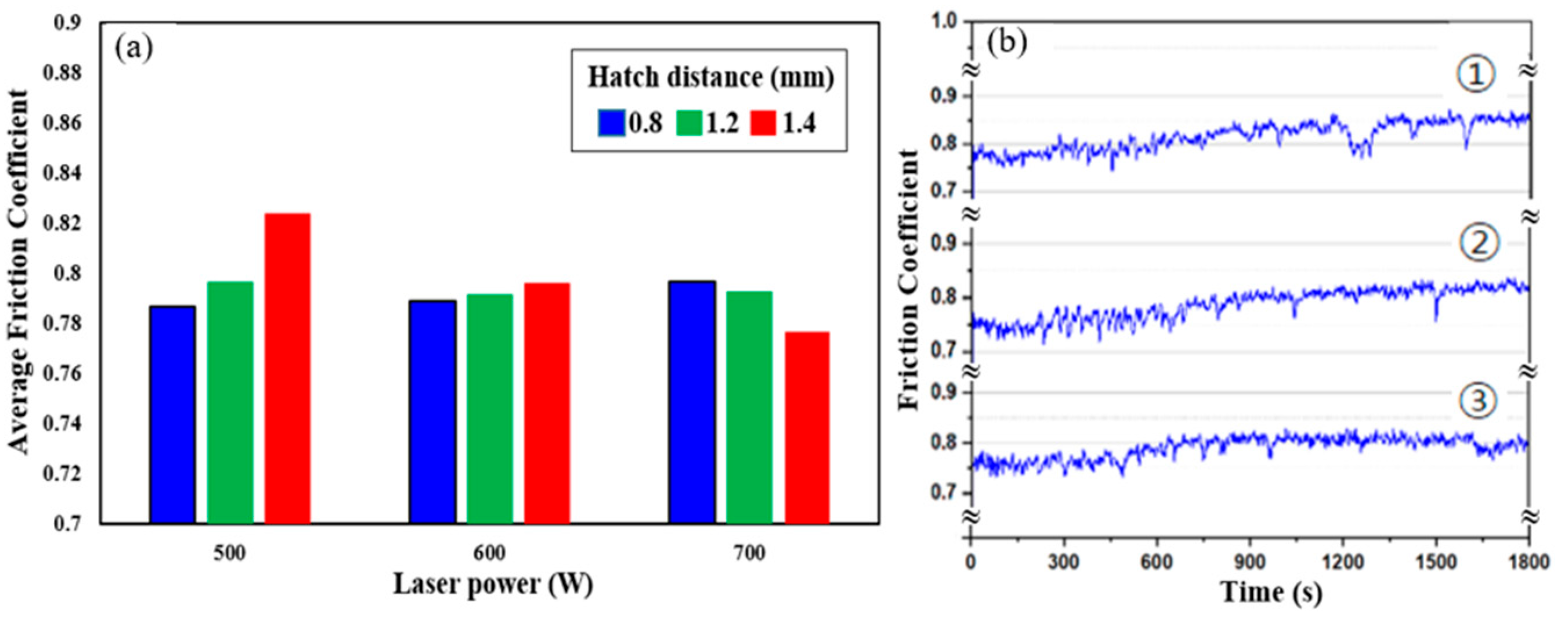

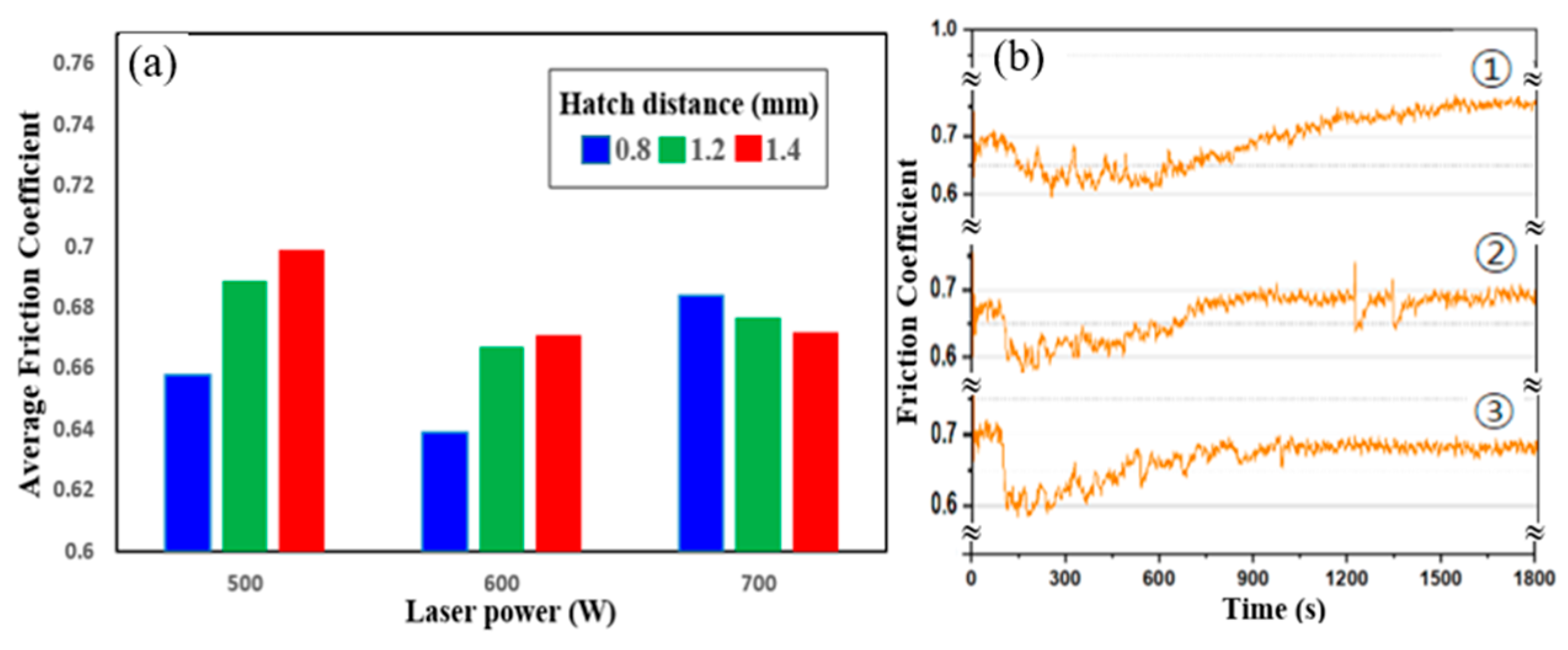

Figure 12 illustrates the frictional behavior of the LP-DED FSS 430 specimens fabricated under different laser powers and hatch distances, followed by solution heat treatment at 815 °C. The friction performance was evaluated under reciprocating sliding at 25 °C. In

Figure 12a, the average friction coefficient (AFC) varies with both laser power and hatch pitch. At 500 W, the AFC increases as hatch distance widens, reaching the highest value at 1.4 mm. This trend suggests that wider hatch spacing at lower energy input results in poor inter-track bonding and increased surface roughness, which in turn contributes to higher friction. At 600 W, the AFCs are relatively balanced across hatch distances, indicating improved melt pool overlap and microstructural homogeneity. At 700 W, the friction coefficients are consistently lower across all hatch distances, reflecting enhanced metallurgical bonding and smoother surface characteristics due to the higher energy input during fabrication.

Figure 12b shows the friction coefficient versus time curves for samples fabricated at 1.4 mm hatch distance and laser powers of ➀ 500 W, ➁ 600 W, and ➂ 700 W. The curve for 500 W exhibits greater fluctuation and a gradual upward trend, indicating that such fluctuations in friction curves during reciprocating wear tests are often associated with the spallation of tribofilms (e.g., oxide layers) [

40]. At 600 W, the curve becomes more stable, with moderate friction fluctuations. At 700 W, the friction coefficient remains steady throughout the test, confirming stable contact conditions and superior surface integrity. These results demonstrate that higher laser power and optimized hatch spacing significantly reduce friction and enhance sliding stability. The findings support that adequate energy input during LP-DED processing is critical for achieving smoother surface finish, better track fusion, and improved tribological performance.

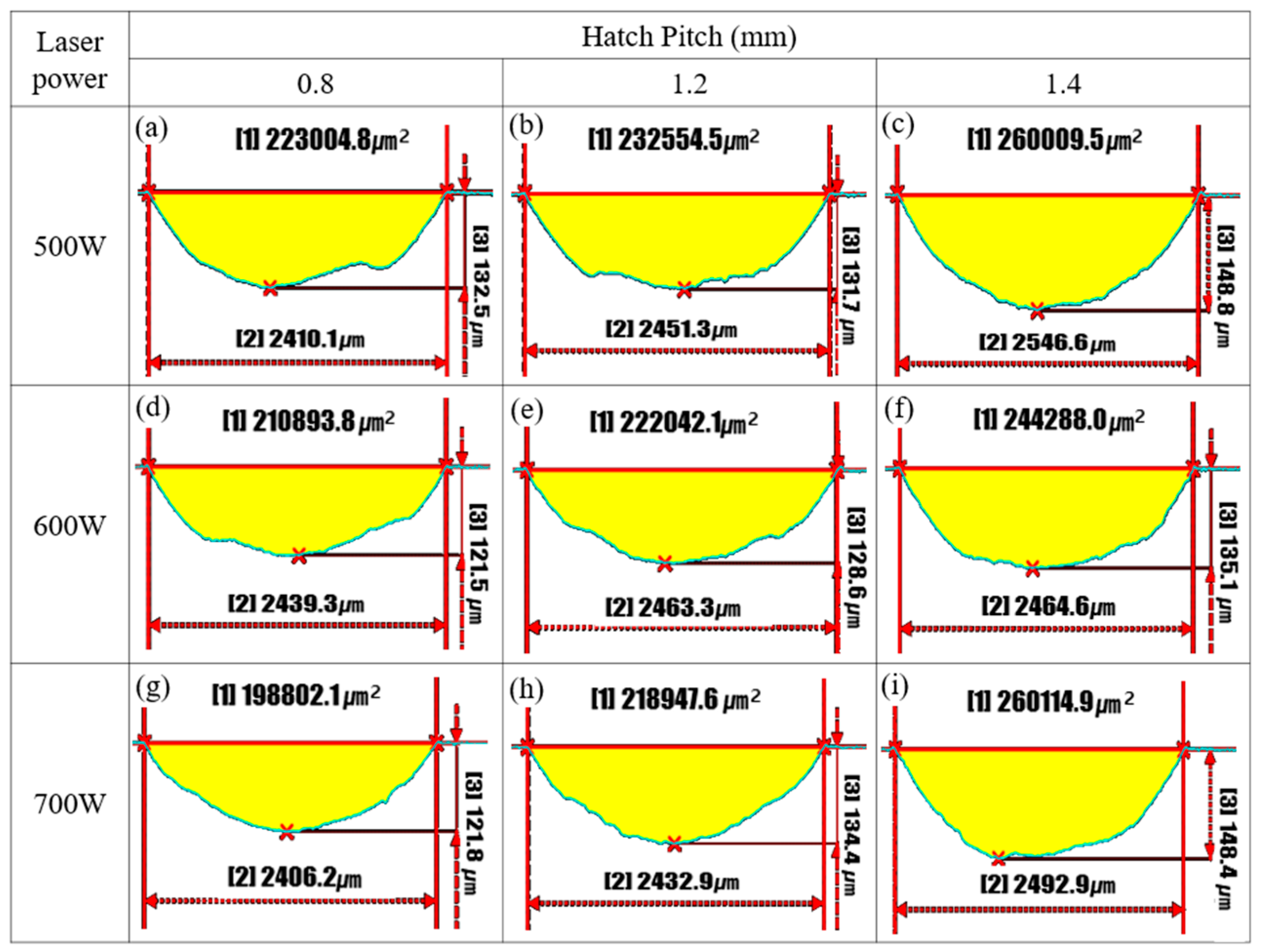

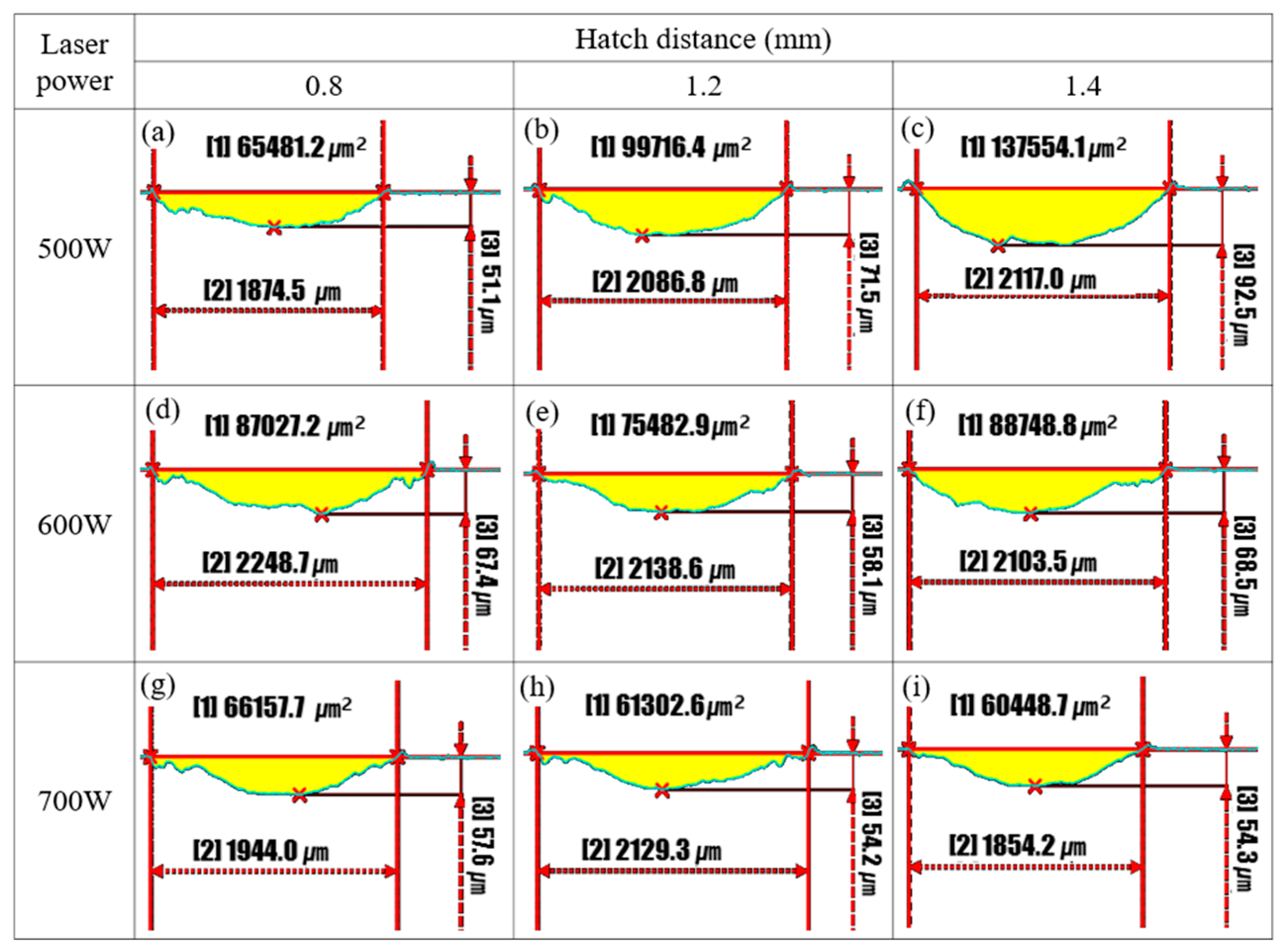

Figure 13 illustrates the cross-sectional profiles of wear tracks on the LP-DED FSS 430 specimens fabricated under varying laser powers (500 W, 600 W, and 700 W) and hatch distances (0.8 mm, 1.2 mm, and 1.4 mm). All specimens were subjected to solution heat treatment at 815 °C for 1 h prior to reciprocating wear testing at 25 °C. The wear area (yellow region), wear width, and maximum depth are quantitatively presented to evaluate the influence of the processing parameters on wear resistance. At 500 W, increasing hatch distance results in a noticeable increase in wear damage. The wear area rises from 223,004.8 μm

2 at 0.8 mm to 260,009.5 μm

2 at 1.4 mm, while the wear depth and width also increase. This indicates that a wider hatch distance under a low energy input causes weak inter-track bonding and a heterogeneous microstructure, making the surface more susceptible to material removal during sliding. At 600 W, a similar trend is observed, but with moderately improved wear performance. The wear area remains relatively stable across hatch distances (210,893.8–244,288.0 μm

2), and the maximum wear depth shows slightly lower values than the 500 W counterparts. This suggests that moderate laser power provides improved melt pool formation and bonding, reducing the susceptibility to severe wear. At 700 W, the wear behavior improves significantly, particularly at hatch distances of 0.8 mm and 1.2 mm, with wear areas of 198,802.1 μm

2 and 218,947.6 μm

2, respectively—the lowest among all conditions. Notably, even at 1.4 mm, the wear area (260,114.9 μm

2) remains comparable to the 500 W and 600 W cases, indicating that a higher laser energy compensates for the adverse effects of wider hatch spacing by enhancing inter-track fusion and surface integrity. These results confirm that higher laser power and optimized hatch spacing are critical to minimizing wear depth, width, and overall material loss. A low power and large hatch distance lead to poor bonding and high wear susceptibility, while a high power enhances wear resistance through improved microstructural homogeneity and densification.

Figure 14 shows the SEM images of the worn surfaces of LP-DED FSS 430 specimens fabricated under different laser powers (500 W, 600 W, and 700 W) and hatch distances (0.8, 1.2, and 1.4 mm), after solution heat treatment at 815 °C for 1 h and reciprocating wear testing at 300 °C. The figure includes both low- and high-magnification images to highlight the surface morphology and wear mechanisms. At 500 W, the worn surfaces exhibit significant degradation, especially as hatch distance increases. At 0.8 mm (

Figure 14a,d), the surface shows moderate abrasive wear with some plastic deformation. At 1.2 mm (

Figure 14b,e), the wear becomes more irregular, with increased surface roughness and oxide debris. At 1.4 mm (

Figure 14c,f), severe surface damage and delamination-like features are visible, indicating unstable inter-track bonding and increased thermal softening due to wider spacing and insufficient energy input. At 600 W, the wear damage is visibly reduced across all hatch distances. The worn surfaces (

Figure 14g–l) show smoother profiles with fewer signs of plowing or delamination. The surface at 0.8 mm (

Figure 14g,j) shows the least wear, while 1.4 mm (

Figure 14i,l) displays moderate roughness and particle detachment, indicating that 600 W provides a more stable microstructure with better thermal stability than 500 W. At 700 W, the worn surfaces are the smoothest among all conditions (

Figure 14m–r), regardless of the hatch distance. Minimal surface disruption is observed, with fine and uniform wear tracks and no significant oxide debris or delamination. Even at a 1.4 mm hatch distance (

Figure 14o,r), the wear morphology remains stable, demonstrating that a higher laser power ensures complete melting and strong inter-track bonding, which enhances high-temperature wear resistance. These observations confirm that a higher laser power, particularly 700 W, improves the thermal and mechanical stability of the LP-DED microstructure during elevated temperature wear. In contrast, a low power and wide hatch distances result in poor bonding, oxide layer formation, and surface degradation. Optimizing laser parameters is therefore critical to improving high-temperature tribological performance in ferritic stainless steel components produced by LP-DED.

Figure 15 presents the SEM-EDS analysis of the worn surface of LP-DED FSS 430 fabricated at a laser power of 500 W and a hatch distance of 1.4 mm, after reciprocating wear testing at 300 °C. The SEM image (

Figure 15a) shows a worn surface characterized by irregular topography, micro-plowing, and evidence of surface oxidation or debris accumulation, indicating severe wear under elevated temperature conditions. The EDS line scan profile (

Figure 15b) reveals significant elemental fluctuations across the analyzed region. Notably, chromium (Cr) and oxygen (O) exhibit localized co-enrichment, suggesting the formation of chromium-rich oxides. This indicates that tribo-oxidation is an active wear mechanism at this temperature, where frictional heating promotes the growth of surface oxides. The relatively stable presence of iron (Fe) confirms the exposure of the base matrix, while the detection of manganese (Mn) and silicon (Si) in lower concentrations suggests their incorporation into the oxide phases. The EDS point spectrum (

Figure 15c) further confirms the presence of Fe, Cr, O, Mn, and Si in the worn region. The high oxygen content supports the interpretation of oxidative wear, and the detection of minor alloying elements reflects their migration or concentration in oxide layers or wear debris. The microstructural damage, combined with the oxidative features, indicates that the low laser power and wide hatch spacing used in fabrication result in reduced wear resistance and susceptibility to high-temperature degradation. These results demonstrate that inadequate energy input during LP-DED processing can lead to a heterogeneous microstructure prone to oxide formation and accelerated material removal during high-temperature sliding. It revealed that optimizing laser power and hatch distance is essential for suppressing tribo-oxidation and enhancing wear performance under thermal loading.

Figure 16 illustrates the frictional behavior of the LP-DED FSS 430 specimens fabricated under various laser powers and hatch distances after solution heat treatment at 815 °C, tested under reciprocating sliding at 300 °C. In

Figure 16a, the average friction coefficients (AFCs) decrease notably with increasing laser power. At 500 W, the specimens show relatively higher AFCs, especially at the largest hatch distance (1.4 mm), indicating poor surface integrity and increased plowing due to weak inter-track bonding. As the laser power increases to 600 W and 700 W, the AFCs become lower and more consistent across all hatch distances, reflecting an improved microstructural uniformity and a smoother surface finish resulting from better melting and densification.

Figure 16b presents the time-dependent friction coefficient profiles for specimens fabricated at a fixed hatch distance of 1.4 mm under three laser power conditions. The sample fabricated at ➀ 500 W exhibits a gradually increasing and fluctuating friction coefficient, indicating unstable contact and progressive surface damage. ➁ The 600 W sample shows a more stable friction profile with reduced variability. ➂ The 700 W sample maintains the lowest and most stable friction coefficient throughout the test duration, suggesting superior wear stability and reduced oxidation or third-body interaction. These results confirm that higher laser power significantly improves the high-temperature tribological performance of LP-DED FSS 430, particularly under wider hatch spacing, by enhancing surface bonding, reducing frictional fluctuations, and minimizing wear-induced instability.

Figure 17 presents the cross-sectional wear profiles of LP-DED FSS 430 specimens fabricated under varying laser powers (500 W, 600 W, and 700 W) and hatch distances (0.8, 1.2, and 1.4 mm), after solution heat treatment at 815 °C and reciprocating wear testing at 300 °C. The wear area (yellow region), track width, and maximum depth were quantified to evaluate the influence of the processing conditions on wear resistance. At 500 W, wear performance deteriorates with increasing hatch distance. The wear area increases markedly from 65,481.2 μm

2 at 0.8 mm to 137,554.1 μm

2 at 1.4 mm, accompanied by a greater depth and width.

This trend reflects incomplete melting and weak inter-track bonding under insufficient laser energy, especially at wider hatch spacing. The specimens fabricated at 600 W show improved wear resistance, with more moderate increases in wear area and depth across hatch distances. The lowest wear area (75,482.9 μm2) and depth (58.1 μm) occur at 0.8 mm, suggesting more effective melt pool overlap and bonding at this condition. At 700 W, wear resistance is significantly enhanced. The minimum wear area (60,448.7 μm2) and depth (54.3 μm) are observed at a 1.4 mm hatch distance, and even at 1.2 mm, the wear area (61,302.6 μm2) remains lower than those of the 500 W and 600 W counterparts. These results indicate that a higher laser power promotes improved metallurgical bonding and homogeneity, thereby enhancing thermal wear resistance. These data confirm that both laser power and hatch distance have a strong influence on the wear behavior of LP-DED FSS 430 at elevated temperatures. The optimal wear resistance was achieved at 700 W with a 1.4 mm hatch distance, while inadequate energy input and excessive spacing increased the wear severity. These findings emphasize the importance of parameter optimization to ensure mechanical integrity in high-temperature applications.

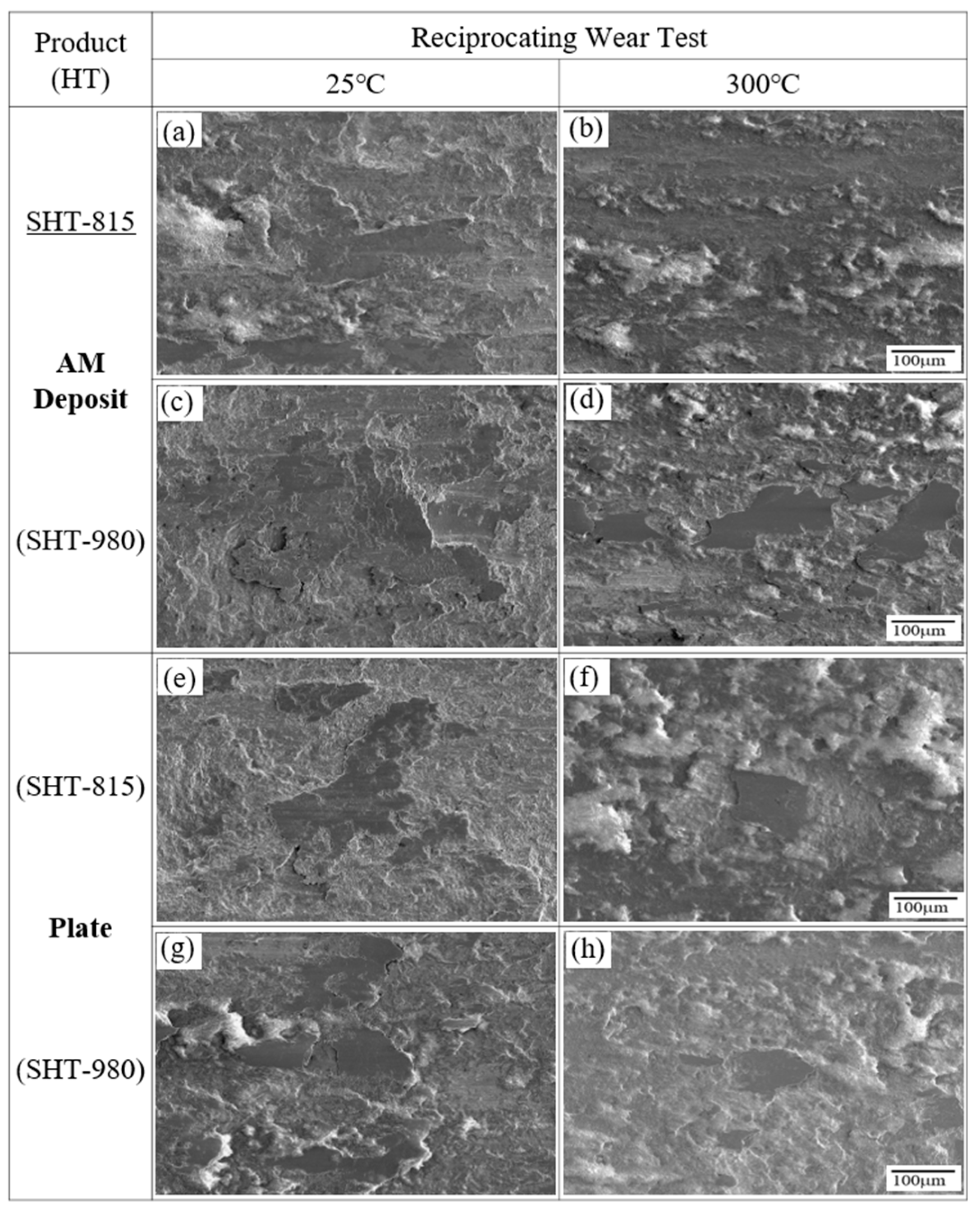

Figure 18 presents the SEM images of the worn surfaces of LP-DED FSS 430 (a–d) and AISI 430 commercial plate specimens (e–h) after solution heat treatments at 815 °C and 980 °C, followed by reciprocating wear tests conducted at 25 °C and 300 °C, respectively, under identical testing conditions. At 25 °C, the LP-DED samples (

Figure 18a,c) exhibit different wear behaviors depending on the heat treatment. The specimen treated at 815 °C (

Figure 18a) shows rougher wear tracks with plowing and debris, indicating partial recrystallization and a less uniform microstructure. In contrast, the 980 °C-treated specimen (

Figure 18c) presents smoother and more continuous wear tracks, suggesting improved surface stability due to full recrystallization and better inter-track bonding. Similarly, for the commercial plate at 25 °C (

Figure 18e,g), the 980 °C-treated specimen (

Figure 18g) displays fewer wear defects and a smoother morphology than the 815 °C counterpart (

Figure 18e), indicating enhanced wear resistance from grain refinement and microstructural homogenization. At the elevated temperature of 300 °C, all specimens show increased surface damage due to thermal softening and oxidation. However, the benefits of high-temperature heat treatment remain evident. The LP-DED specimen treated at 980 °C (

Figure 18d) shows less severe surface disruption compared with the one treated at 815 °C (

Figure 18b), implying improved thermal wear stability. Likewise, the 980 °C-treated commercial plate (

Figure 18h) shows more stable surface features and less adhesive wear compared with its 815 °C-treated counterpart (

Figure 18f). These results demonstrate that solution heat treatment at 980 °C enhances wear resistance at both room and elevated temperatures for both AM and wrought FSS 430, by promoting full recrystallization, improved grain structure, and stronger oxidation resistance.

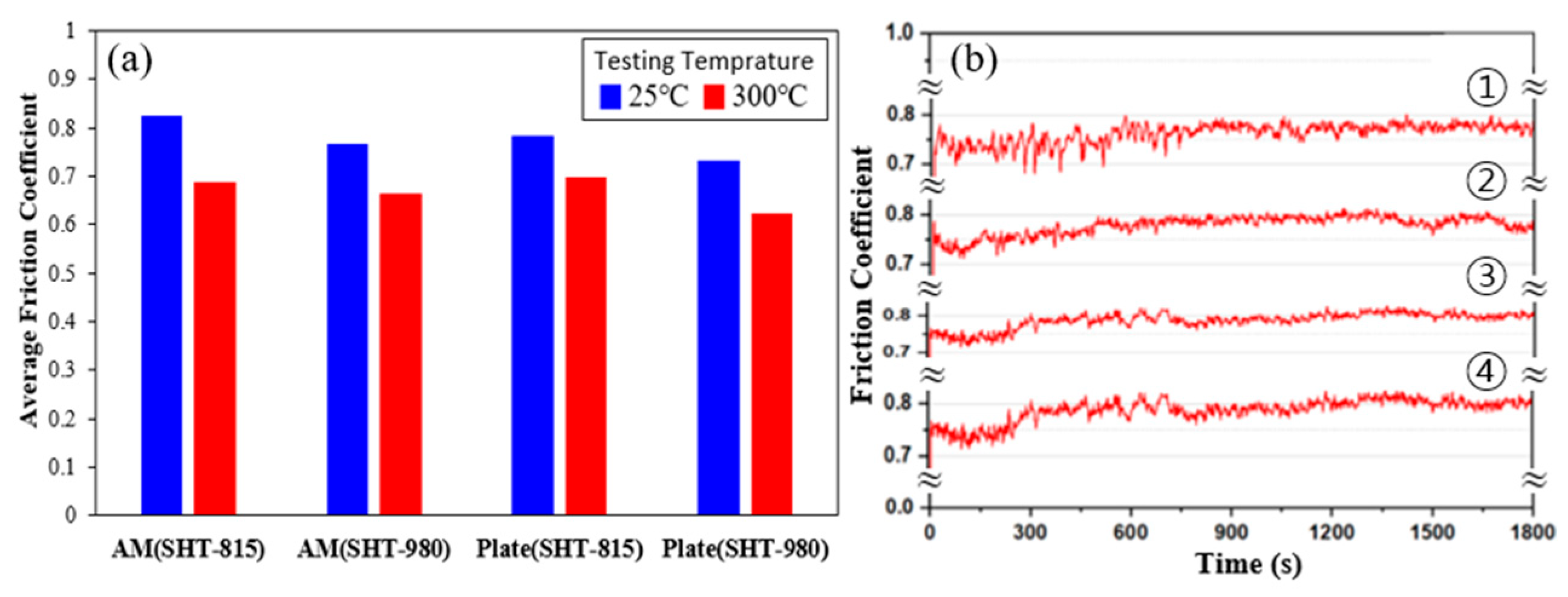

Figure 19 illustrates the frictional behavior of the LP-DED FSS 430 and AISI 430 commercial plate specimens after reciprocating wear tests performed at 25 °C and 300 °C, respectively.

Figure 19a shows the average friction coefficients (AFCs), while

Figure 19b presents the time-dependent friction profiles at 300 °C. In

Figure 19a, the AFCs for all specimens tend to decrease slightly at 300 °C compared with 25 °C, likely due to the formation of lubricious oxide layers or thermal softening that reduces contact stress. Among the LP-DED samples, those treated at 980 °C exhibit lower AFCs than those treated at 815 °C, suggesting improved surface stability and microstructural uniformity after higher-temperature heat treatment. A similar trend is observed in the commercial plate specimens, where SHT-980 results in reduced friction relative to SHT-815. The friction coefficient versus time curves at 300 °C (

Figure 19b) provide further insight. The LP-DED specimens (➀ and ➁) display higher initial coefficients and more fluctuation than the commercial plates (➂ and ➃), indicating greater surface instability and potential microstructural inhomogeneity from additive processing. Nevertheless, the LP-DED sample treated at 980 °C (➁) exhibits a more stable curve compared with the one treated at 815 °C (➀), again highlighting the benefits of high-temperature heat treatment. The commercial plates show smoother, more consistent friction profiles, with the SHT-980 specimen (➃) maintaining the lowest and most stable coefficient throughout the test. These results demonstrate that both elevated heat treatment temperature and base material type significantly influence friction behavior, with higher-temperature treatments improving sliding stability and reducing friction, especially under elevated temperature conditions.

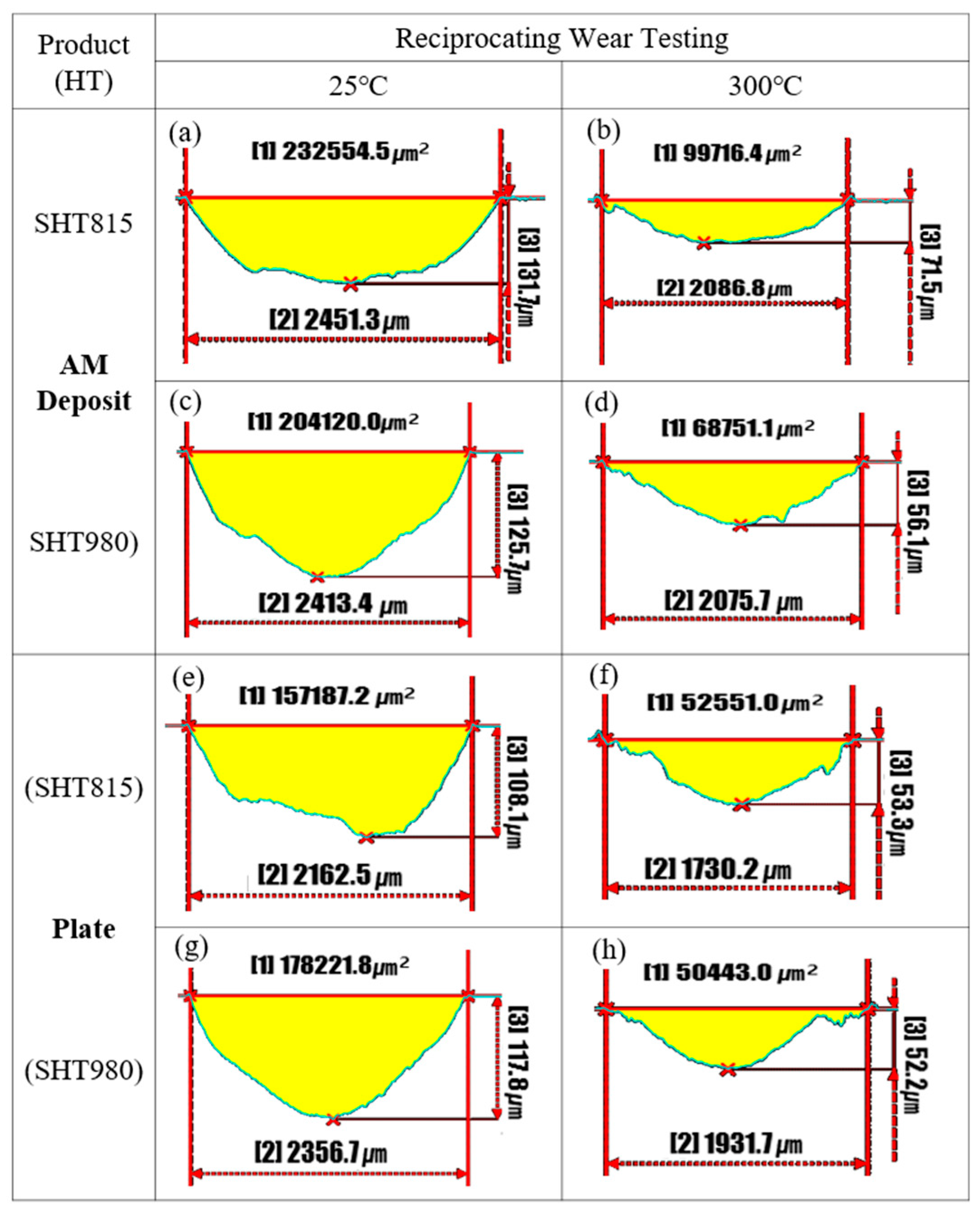

Figure 20 presents the cross-sectional profiles of wear tracks on the LP-DED FSS 430 specimens and AISI 430 commercial plate specimens after reciprocating wear testing at 25 °C and 300 °C, respectively. For both the LP-DED and commercial materials, the wear areas of the specimens heat treated at both 815 °C and 980 °C were greater during wear testing at 25 °C than at 300 °C. This trend suggests that higher testing temperatures facilitate the formation of protective oxide layers, which likely contributed to reduced material loss through oxidative wear mechanisms. Notably, the AISI 430 commercial plate specimens exhibited significantly lower wear areas than the LP-DED specimens under the same heat treatment and testing conditions. This superior wear resistance was attributed to the homogeneous and refined microstructure of the rolled plate, as shown in

Figure 7 and

Figure 8, which retained finer grain sizes than those of the LP-DED FSS 430 specimen, as presented in

Figure 6. In terms of wear depth, similar trends were observed. The maximum wear depths at 300 °C were consistently lower than those measured at 25 °C for all specimens, with the most pronounced reduction seen in the LP-DED samples heat treated at 980 °C. This indicates that solution heat treatment at 980 °C not only promoted recrystallization and carbide precipitation, but also enhanced the thermal stability of the wear surface. Overall, these results confirm the beneficial effects of higher solution heat treatment temperatures and elevated operating temperatures on high-temperature wear resistance, particularly in applications such as turbine seal components.