Modified Hammerstein-Like Hysteresis Modeling and Composite Control Methods for Fast Steering Mirrors

Abstract

1. Introduction

- A modified Hammerstein-like (MHL) hysteresis modeling approach is proposed; it integrates an input time delay, a rate-dependent hysteresis term, and a linear dynamic term in a cascaded structure. As we will see in the experiments, the presented model can effectively capture the dynamic characteristics of an FSM across a wide frequency range;

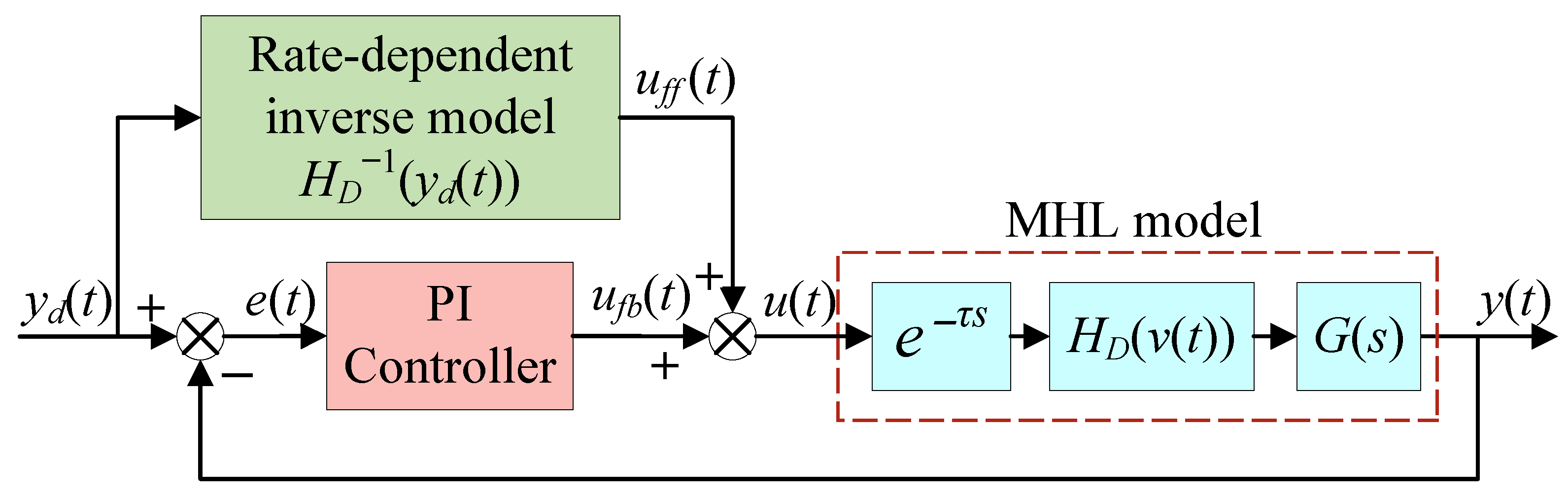

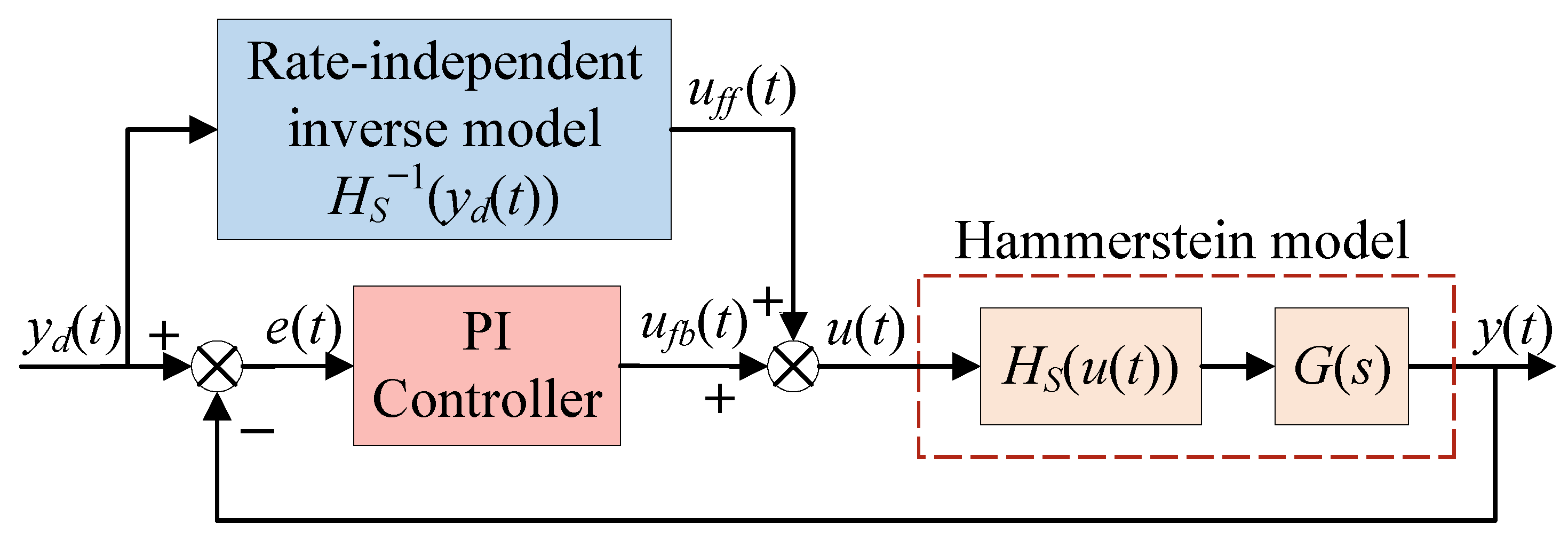

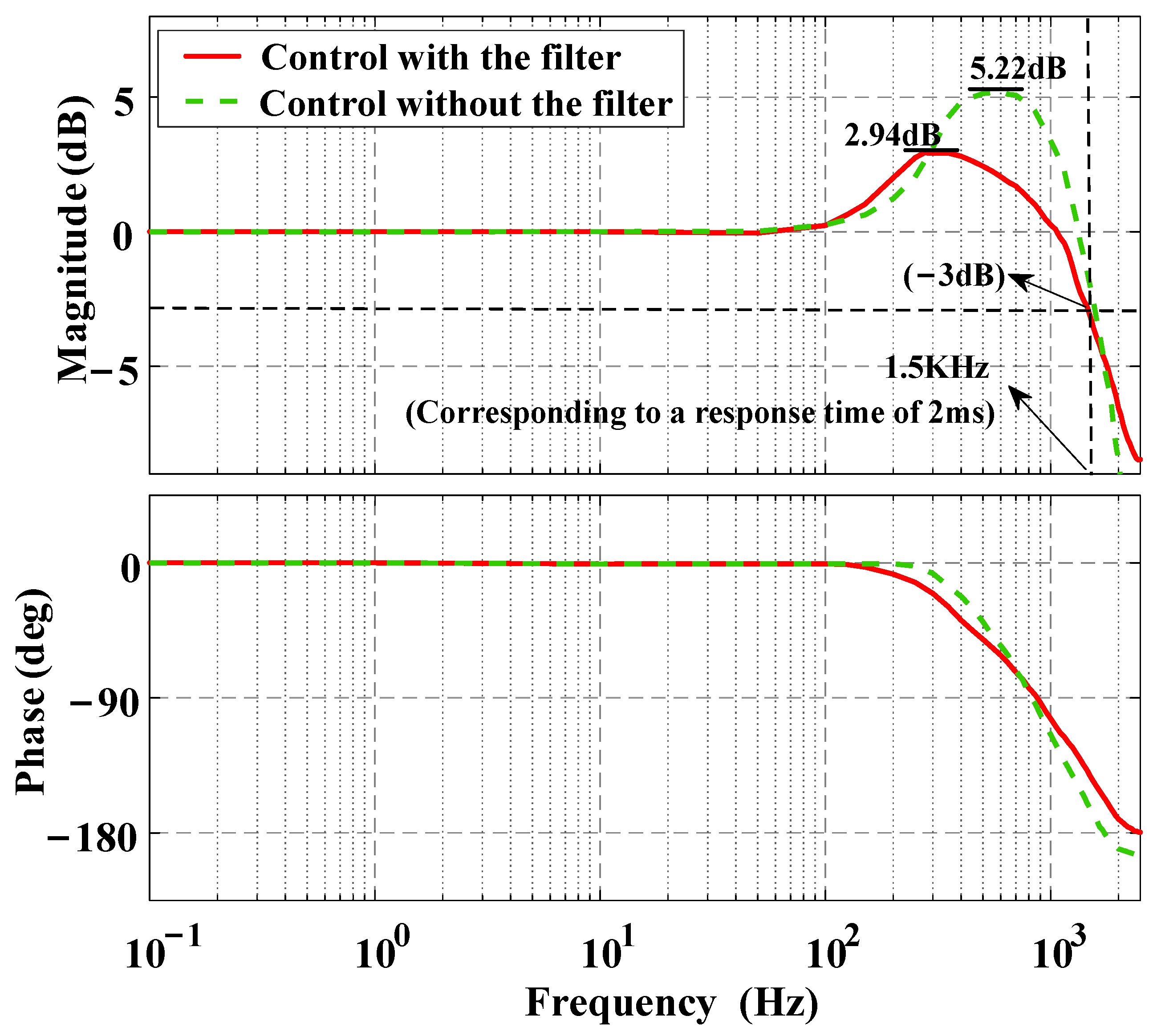

- A composite control method tailored for the MHL model is introduced. The presented controller consists of two parts: a feedforward compensator and a traditional proportional–integral (PI) controller. The feedforward compensator is the inverse of the rate-dependent term in the MHL model, while the PI controller is used for closed-loop regulation.

2. Modified Hammerstein-Like (MHL) Model and Its Identification Method

2.1. Rate-Independent Hysteresis Model Based on Madelung’s Rules

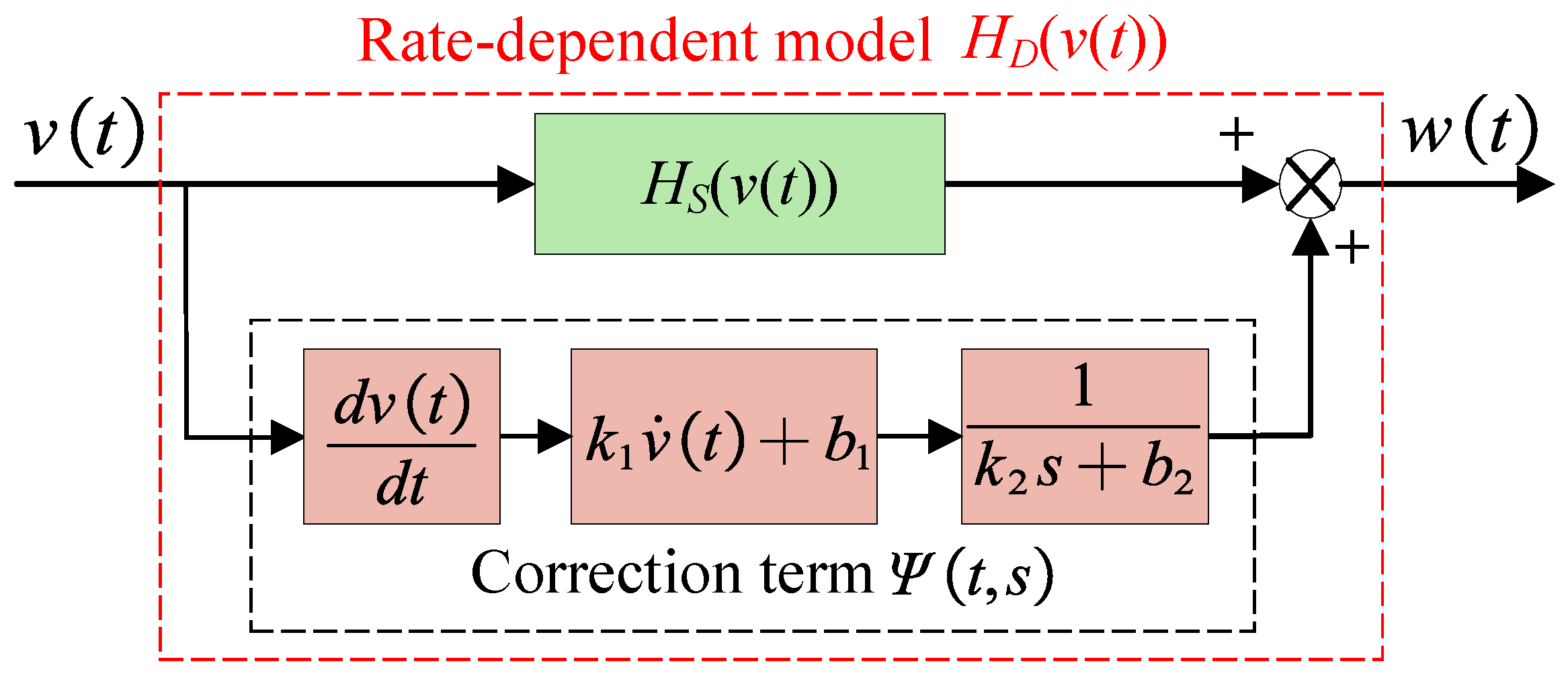

2.2. Rate-Dependent Hysteresis Model

2.3. MHL Model

2.4. Parameter Identification

3. Composite Control Method

4. Experimental Verification

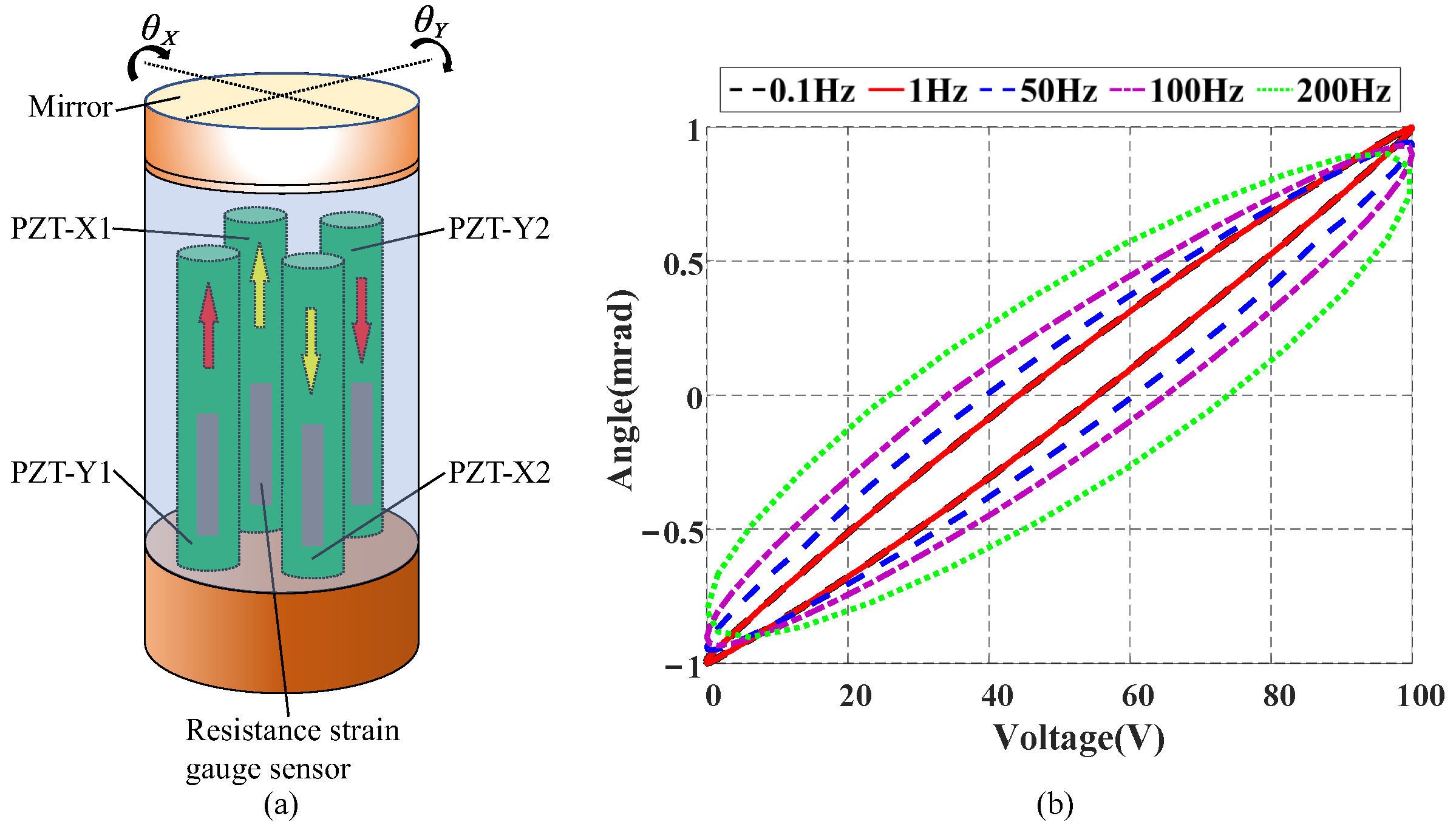

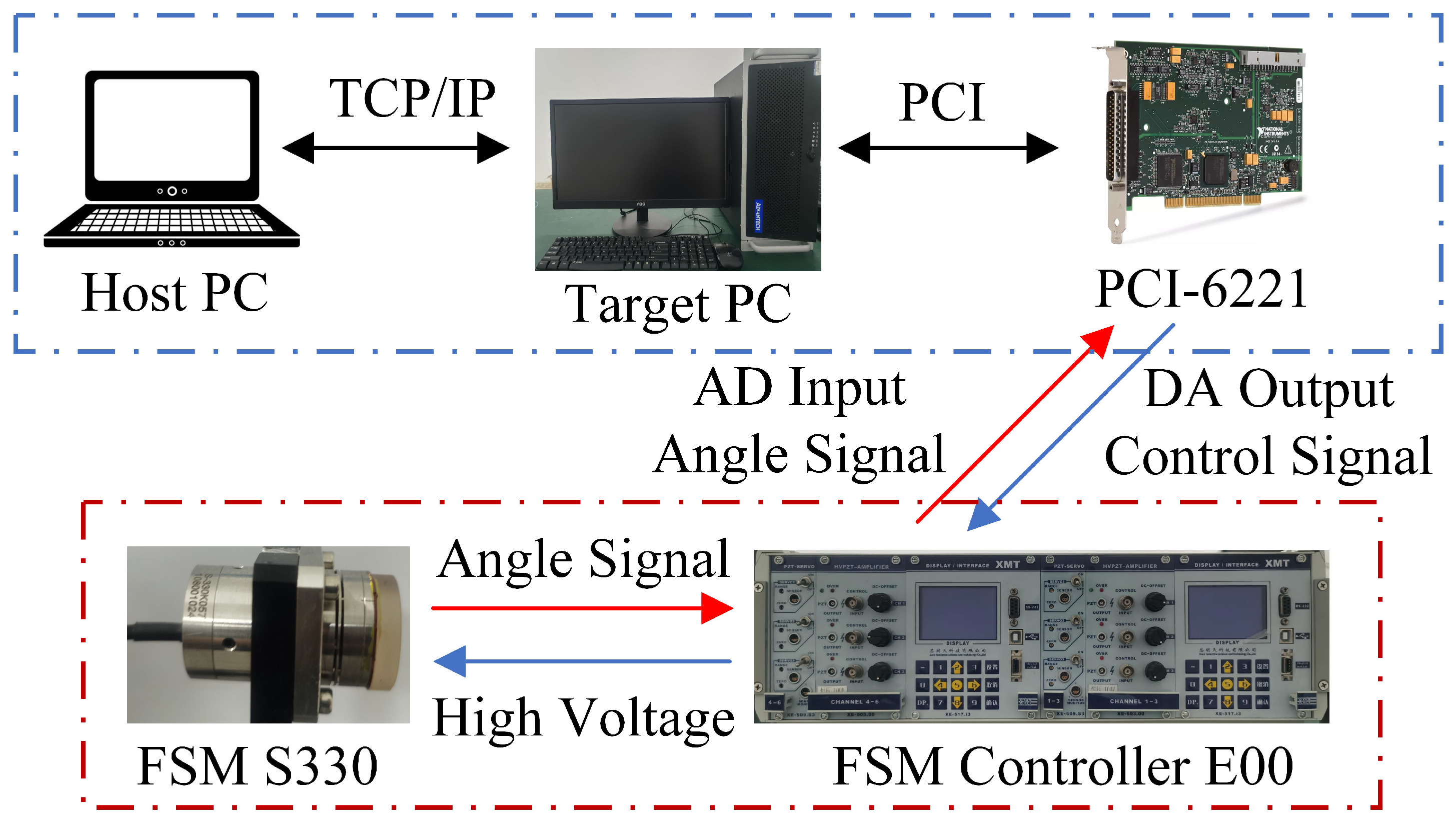

4.1. Experimental Setup

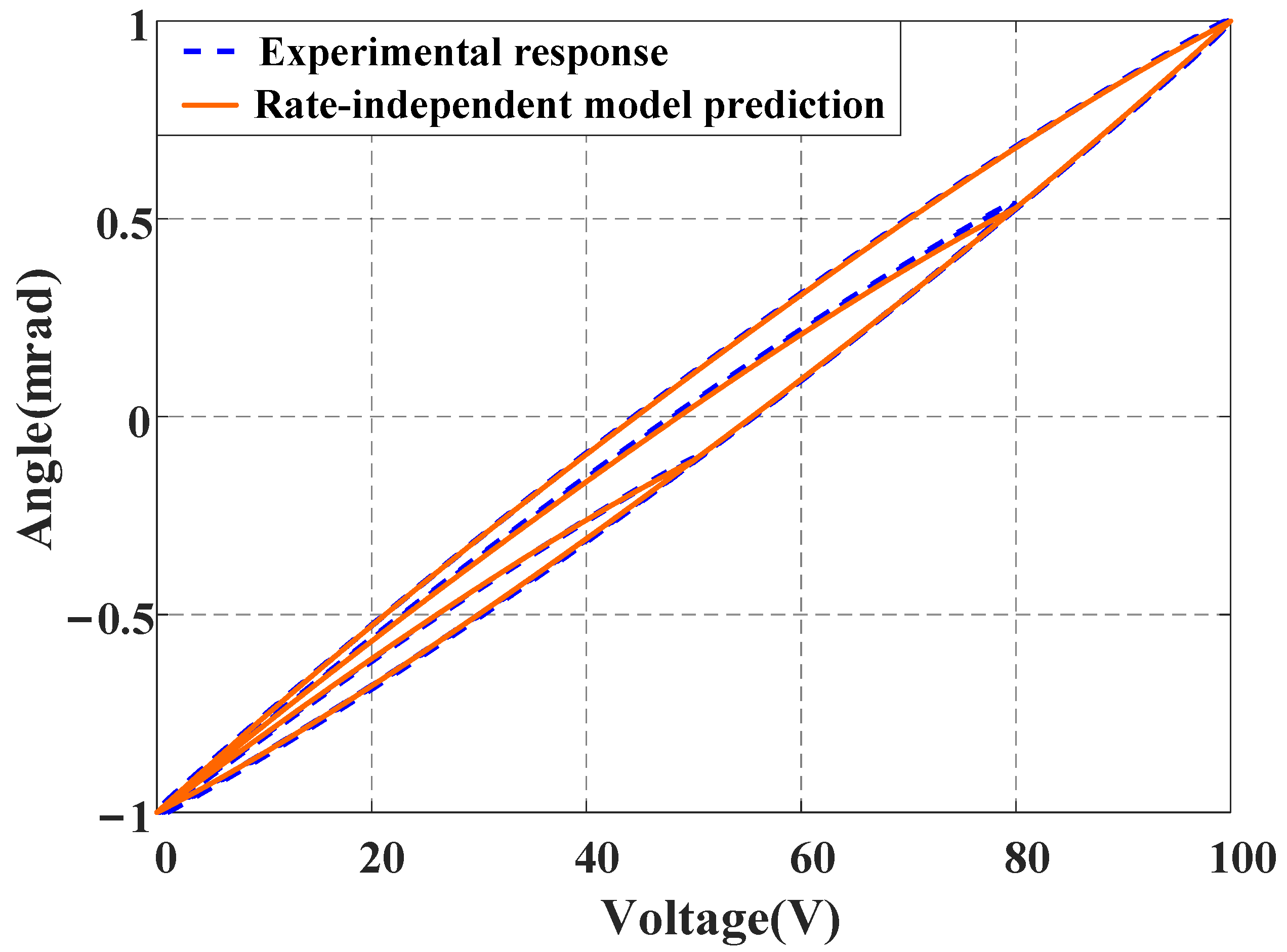

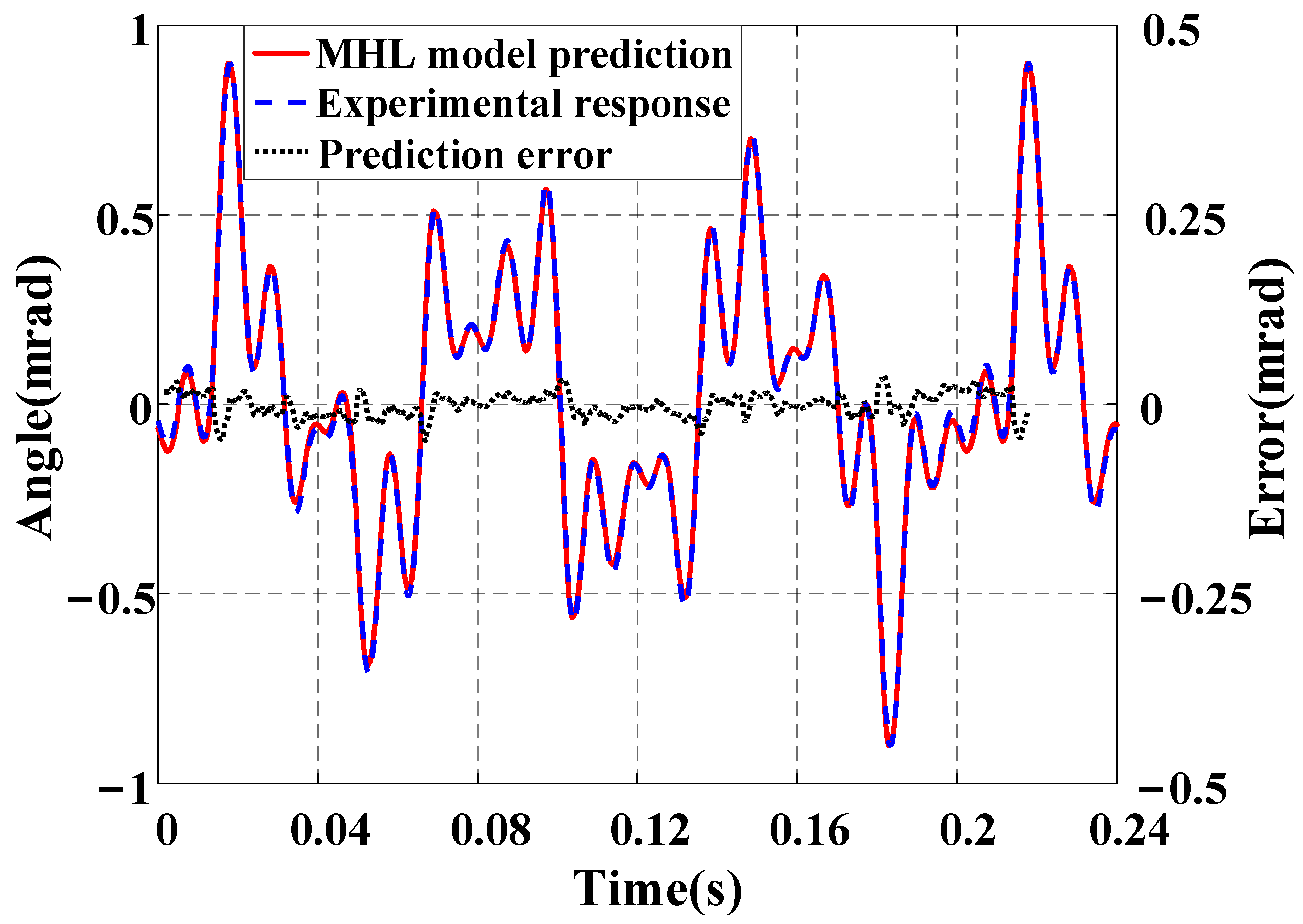

4.2. Parameter Identification Results

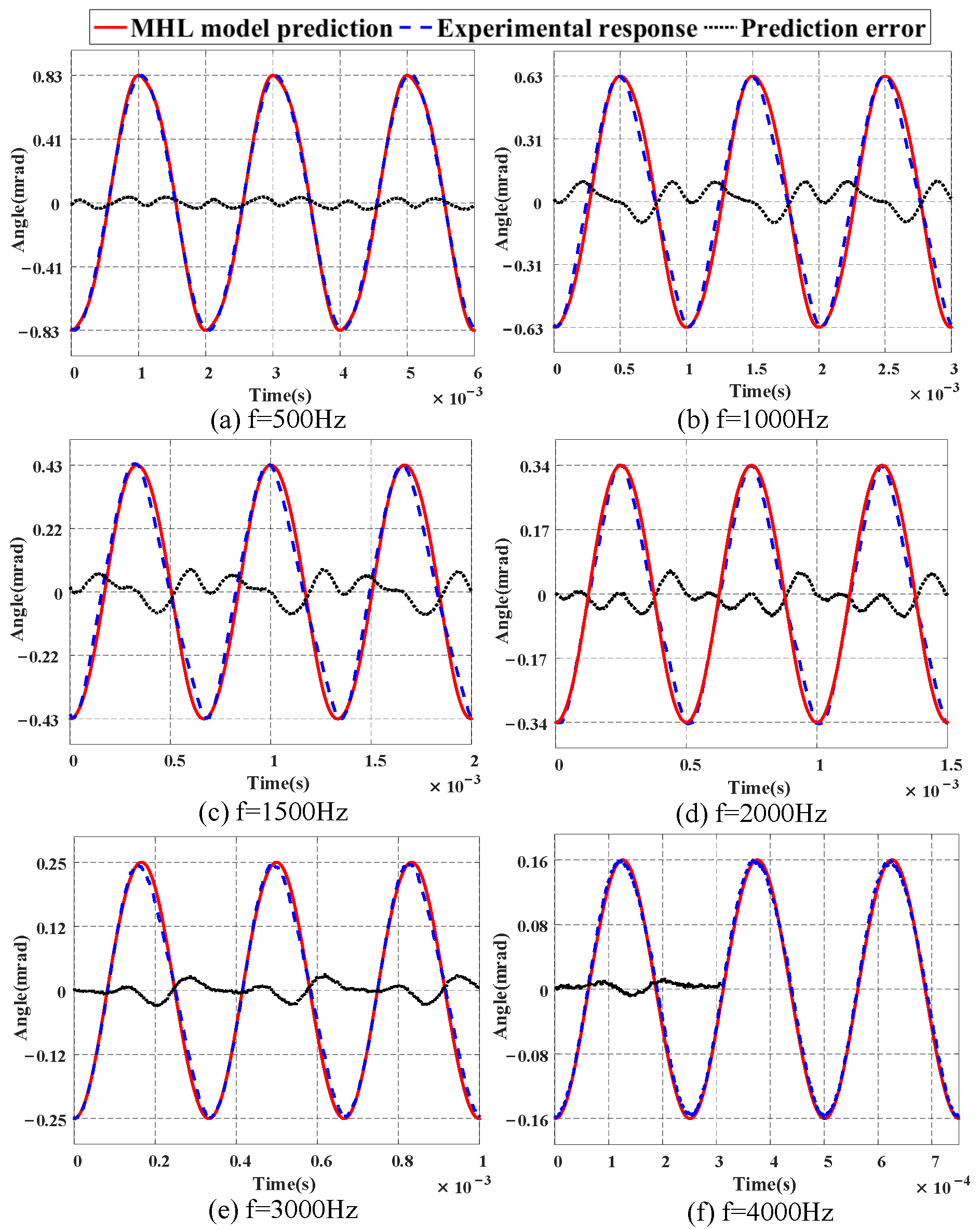

4.3. Model Verification Results

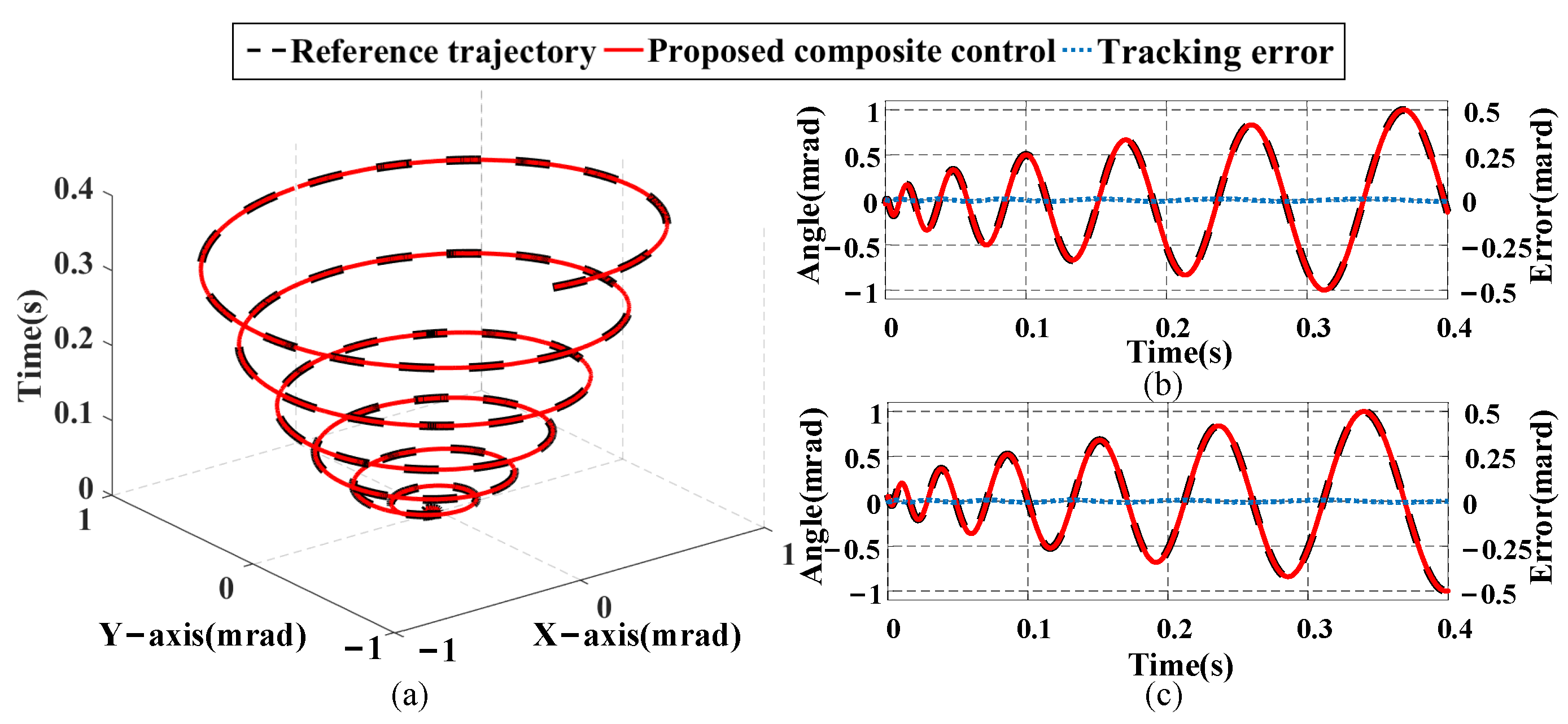

4.4. Tracking Performance

- (1)

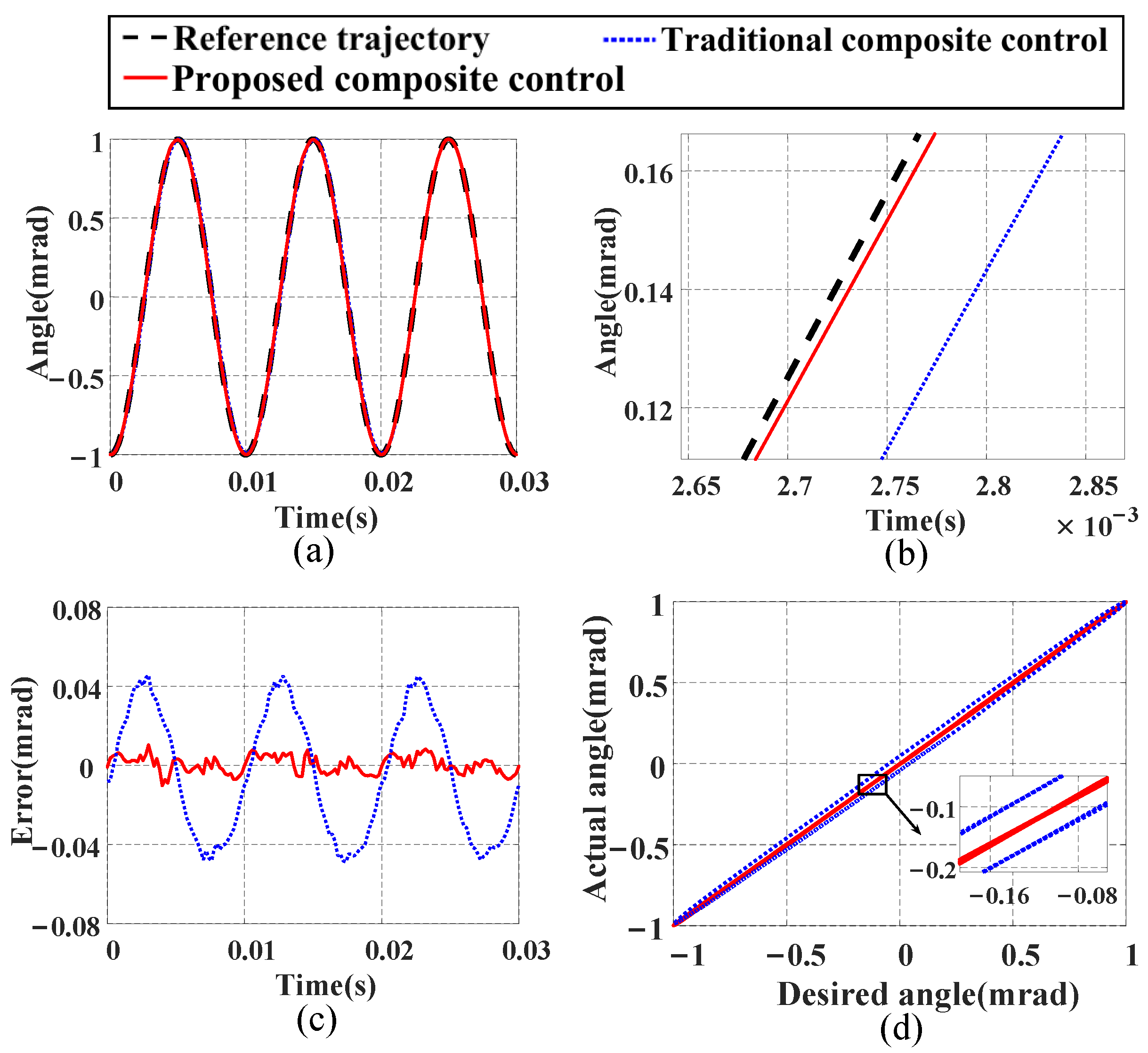

- Tracking performance under a single-frequency signal: We input a 100 Hz sinusoidal signal as the reference trajectory for the FSM, and Figure 14 shows the tracking results. From Figure 14a–c, it can be seen that the proposed composite control method exhibits higher tracking accuracy and smaller tracking errors. Compared with the traditional composite control method, the NME is reduced by 78.6%, and the NRMSE is decreased by 86.16%. Additionally, Figure 14d shows that the proposed composite control method maintains high linearity, indicating its superiority over the traditional composite control method in tracking a single-frequency signal and proving its good tracking performance.

- (2)

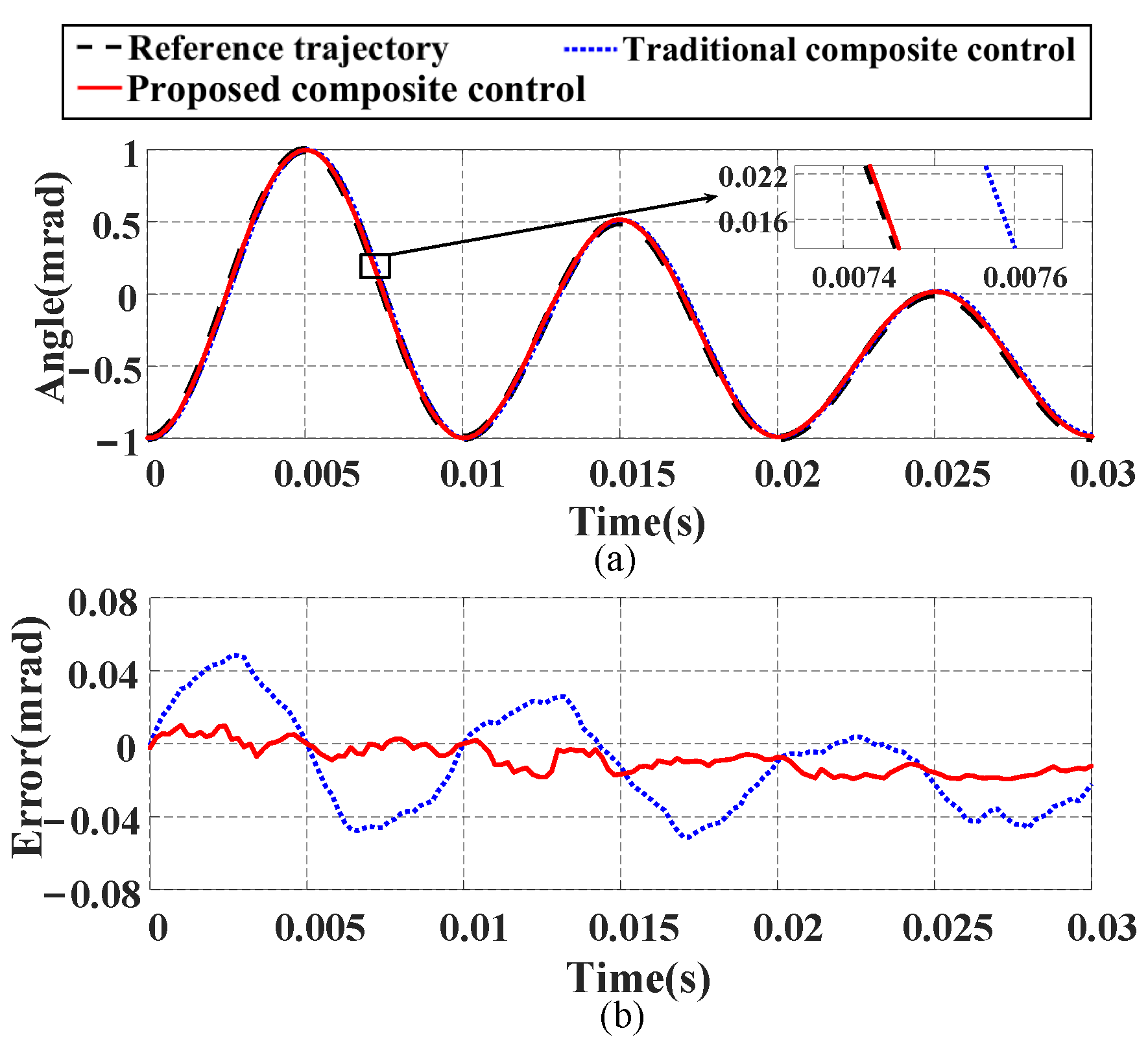

- Tracking performance under a decreasing signal: A signal with a frequency of 100 Hz and decreasing amplitude is generated to verify the performance of the proposed composite control method, with the tracking results shown in Figure 15. The experimental results demonstrate that the proposed composite control method achieves better tracking performance compared with the traditional composite control method. Specifically, the NME and NRMSE values are reduced by 62.11% and 60.54%, respectively.

- (3)

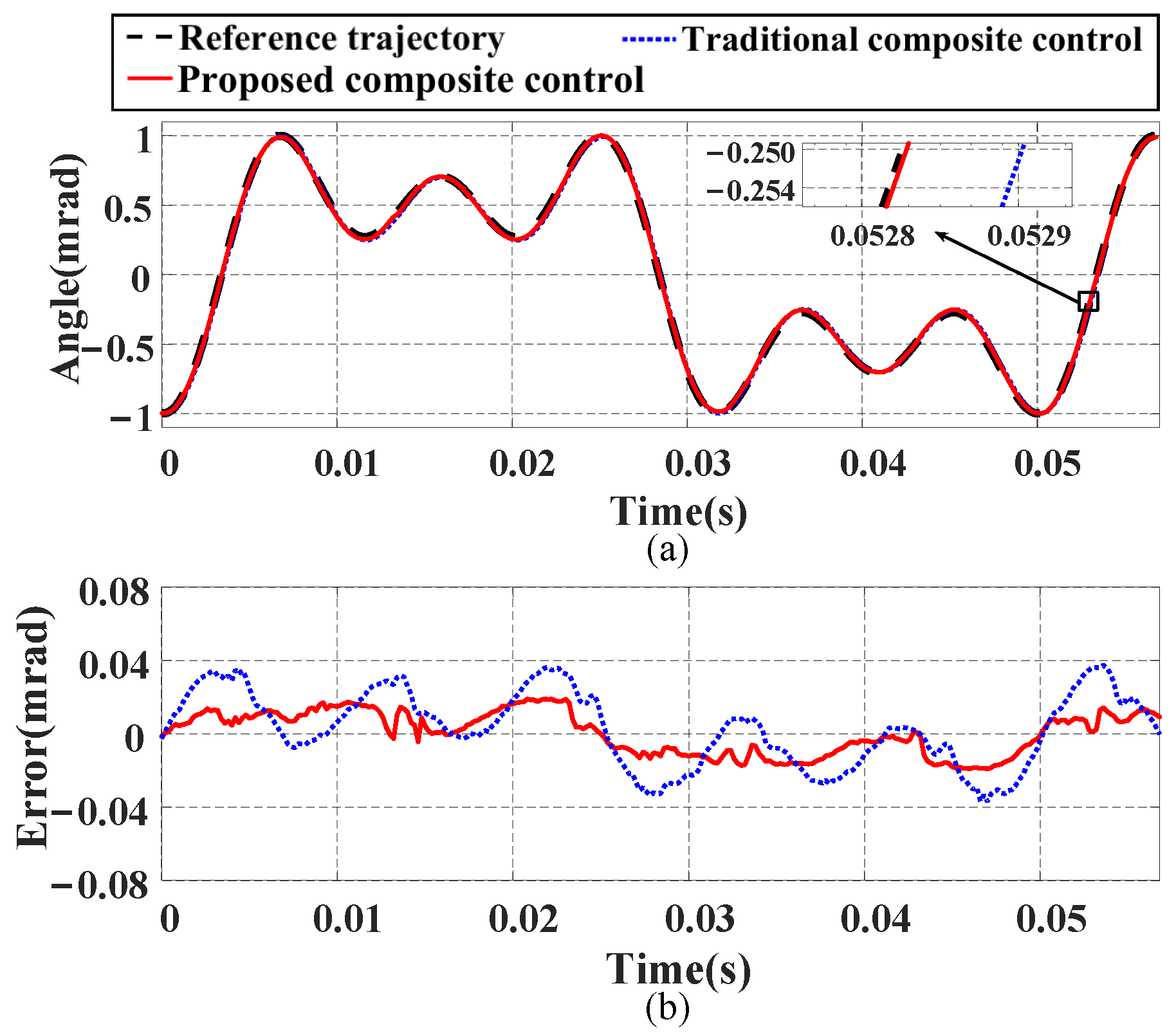

- Tracking performance under a multi-frequency signal: We construct a multi-frequency signal containing frequency components of 20 Hz, 60 Hz, and 100 Hz to verify the tracking ability of both methods for complex signals. The results shown in Figure 16 indicate that the proposed composite control method has better tracking ability. Numerically, compared with the traditional composite control method, the NME and NRMSE values are reduced by 48.66% and 43.14%, respectively. The tracking errors of both methods under the three test signals are detailed in Table 4.

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Wang, Y.; Zhou, H.; Bai, F.; Chen, G.; Ma, J. Comprehensive approach to modeling and identification of a two-axis piezoelectric fast steering mirror system based on multi-component analysis and synthesis. Mech. Syst. Signal Proc. 2019, 127, 50–67. [Google Scholar] [CrossRef]

- Cao, K.; Du, H.; Zhang, J.; Hao, G.; Ran, Q.; Ma, J. Calculation of average acquisition probability for spiral–circular composite scanning in free space optical communication. Opt. Commun. 2023, 532, 129267. [Google Scholar] [CrossRef]

- Jiles, D.C.; Atherton, D.L. Theory of ferromagnetic hysteresis. J. Magn. Magn. Mater. 1986, 61, 48–60. [Google Scholar] [CrossRef]

- Rosenbaum, S.; Ruderman, M.; Strohla, T.; Bertram, T. Use of JilesAtherton and Preisach hysteresis models for inverse feed-forward control. IEEE Trans. Magn. 2010, 46, 3984–3989. [Google Scholar] [CrossRef]

- Gu, G.; Zhu, L.; Su, C.; Ding, H.; Fatikow, S. Modeling and Control of Piezo-Actuated Nanopositioning Stages: A Survey. IEEE Trans. Autom. Sci. Eng. 2016, 13, 313–332. [Google Scholar] [CrossRef]

- Zou, J.; Gu, G. High-Precision Tracking Control of a Soft Dielectric Elastomer Actuator With Inverse Viscoelastic Hysteresis Compensation. IEEE-ASME Trans. Mechatron. 2019, 24, 36–44. [Google Scholar] [CrossRef]

- Ang, W.; Khosla, P.; Riviere, C. Feedforward Controller With Inverse Rate-Dependent Model for Piezoelectric Actuators in Trajectory-Tracking Applications. IEEE-ASME Trans. Mechatron. 2007, 12, 134–142. [Google Scholar] [CrossRef]

- Li, Z.; Fan, X.; Long, D.; Yang, Z.; Shi, C. A Modular Direct Description Method With Low Memory Usage and Execution Time for Hysteresis Modeling and Compensation of Piezoelectric Actuators. IEEE Trans. Autom. Sci. Eng. 2025, 22, 2819–2830. [Google Scholar] [CrossRef]

- Zhu, W.; Wang, D. Non-symmetrical Bouc–Wen model for piezoelectric ceramic actuators. Sens. Actuator A-Phys. 2012, 181, 51–60. [Google Scholar] [CrossRef]

- Wang, G.; Chen, G.; Bai, F. Modeling and identification of asymmetric Bouc–Wen hysteresis for piezoelectric actuator via a novel differential evolution algorithm. Sens. Actuator A-Phys. 2015, 235, 105–118. [Google Scholar] [CrossRef]

- Ahmed, K.; Yan, P.; Li, S. Duhem Model-Based Hysteresis Identification in Piezo-Actuated Nano-Stage Using Modified Particle Swarm Optimization. Micromachines 2021, 12, 315. [Google Scholar] [CrossRef] [PubMed]

- Gan, J.; Mei, Z.; Chen, X.; Zhou, Y.; Ge, M. A Modified Duhem Model for Rate-Dependent Hysteresis Behaviors. Micromachines 2019, 10, 680. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Hu, H.; Wang, H. Identification and experimental assessment of two-input Preisach model for coupling hysteresis in piezoelectric stack actuators. Sens. Actuator A-Phys. 2014, 220, 92–100. [Google Scholar] [CrossRef]

- Gu, G.; Zhu, L.; Su, C. Modeling and Compensation of Asymmetric Hysteresis Nonlinearity for Piezoceramic Actuators With a Modified Prandtl–Ishlinskii Model. IEEE Trans. Ind. Electron. 2014, 61, 1583–1595. [Google Scholar] [CrossRef]

- Zhou, C.; Feng, C.; Aye, Y.; Ang, W. A Digitized Representation of the Modified Prandtl–Ishlinskii Hysteresis Model for Modeling and Compensating Piezoelectric Actuator Hysteresis. Micromachines 2021, 12, 942. [Google Scholar] [CrossRef]

- Liu, Y.; Du, D.; Qi, N.; Zhao, J. A Distributed Parameter Maxwell-Slip Model for the Hysteresis in Piezoelectric Actuators. IEEE Trans. Ind. Electron. 2019, 66, 7150–7158. [Google Scholar] [CrossRef]

- Delibas, B.; Arockiarajan, A.; Seemann, W. Rate dependent properties of perovskite type tetragonal piezoelectric materials using micromechanical model. Int. J. Solids Struct. 2006, 43, 697–712. [Google Scholar] [CrossRef]

- Vaiana, N.; Sessa, S.; Marmo, F.; Rosati, L. A class of uniaxial phenomenological models for simulating hysteretic phenomena in rate-independent mechanical systems and materials. Nonlinear Dyn. 2018, 93, 1647–1669. [Google Scholar] [CrossRef]

- Cao, K.; Li, R. Modeling of Rate-Independent and Symmetric Hysteresis Based on Madelung’s Rules. Sensors 2019, 19, 352. [Google Scholar] [CrossRef]

- Li, R.; Cao, K.; Yu, X.; Zeng, M. Modeling and Compensation Algorithms of Asymmetric Nonlinearity for Piezoelectric Actuators Based on Madelung’s Rules. IEEE Trans. Ind. Electron. 2021, 68, 11359–11368. [Google Scholar] [CrossRef]

- Al Janaideh, M.; Rakheja, S.; Su, C. Experimental characterization and modeling of rate-dependent hysteresis of a piezoceramic actuator. Mechatronics 2009, 19, 656–670. [Google Scholar] [CrossRef]

- Al Janaideh, M.; Krejčí, P. Inverse Rate-Dependent Prandtl–Ishlinskii Model for Feedforward Compensation of Hysteresis in a Piezomicropositioning Actuator. IEEE-ASME Trans. Mechatron. 2013, 18, 1498–1507. [Google Scholar] [CrossRef]

- Hao, G.; Cao, K.; Li, R.; Li, Z.; Du, H.; Tan, L. Rate-dependent hysteresis modeling and compensation for fast steering mirrors. Sens. Actuator A-Phys. 2024, 376, 115568. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, Y.; Shao, M.; Zhu, X. Theoretical and experimental investigation study of discrete time rate-dependent hysteresis modeling and adaptive vibration control for smart flexible beam with MFC actuators. Sens. Actuator A-Phys. 2022, 344, 113738. [Google Scholar]

- Li, W.; Liu, K.; Yang, Z.; Wang, W. Dynamic modeling and disturbance rejection compensation for hysteresis nonlinearity of high voltage piezoelectric stack actuators. Smart Mater. Struct. 2022, 32, 025007. [Google Scholar] [CrossRef]

- Wadikhaye, S.; Yong, Y.; Bhikkaji, B.; Moheimani, S. Control of a piezoelectrically actuated high-speed serial-kinematic AFM nanopositioner. Smart Mater. Struct. 2014, 23, 025030. [Google Scholar] [CrossRef]

- Gu, G.; Li, C.; Zhu, L.; Su, C. Modeling and Identification of Piezoelectric-Actuated Stages Cascading Hysteresis Nonlinearity With Linear Dynamics. IEEE-ASME Trans. Mechatron. 2016, 21, 1792–1797. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, P. Enhanced robust nanopositioning control for an X-Y piezoelectric stage with sensor delays: An infinite dimensional H∞ optimization approach. Mechatronics 2021, 75, 102511. [Google Scholar] [CrossRef]

- Chai, G.; Tan, Y.; Tan, Q.; Dong, R.; Long, X. Predictive Gradient Based Control Using Hammerstein Model for MEMS Micromirrors. IEEE-ASME Trans. Mechatron. 2024, 29, 2125–2137. [Google Scholar] [CrossRef]

- Zirka, S.; Moroz, Y. Hysteresis modeling based on transplantation. IEEE Trans. Magn. 1995, 31, 3509–3511. [Google Scholar] [CrossRef]

- Zirka, S.; Moroz, Y. Hysteresis modeling based on similarity. IEEE Trans. Magn. 1999, 35, 2090–2096. [Google Scholar] [CrossRef]

| Model | Inverse Model | |

|---|---|---|

| Model | Inverse Model | |

|---|---|---|

| 1 | 1 |

| Frequency | 500 Hz | 1000 Hz | 1500 Hz | 2000 Hz | 3000 Hz | 4000 Hz |

|---|---|---|---|---|---|---|

| NME | 2.65% | 8.47% | 8.96% | 8.99% | 6.28% | 4.29% |

| NRMSE | 1.46% | 4.84% | 4.88% | 4.44% | 2.85% | 1.87% |

| Types of | Traditional Composite Control | Proposed Composite Control |

|---|---|---|

| Reference Trajectories | (NME/NRMSE) | (NME/NRMSE) |

| Single-frequency signal | ||

| Decreasing signal | ||

| Multi-frequency signal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, K.; Li, Z.; Hao, G.; Li, R.; Zhang, J.; Ma, J. Modified Hammerstein-Like Hysteresis Modeling and Composite Control Methods for Fast Steering Mirrors. Micromachines 2025, 16, 626. https://doi.org/10.3390/mi16060626

Cao K, Li Z, Hao G, Li R, Zhang J, Ma J. Modified Hammerstein-Like Hysteresis Modeling and Composite Control Methods for Fast Steering Mirrors. Micromachines. 2025; 16(6):626. https://doi.org/10.3390/mi16060626

Chicago/Turabian StyleCao, Kairui, Zekun Li, Guanglu Hao, Rui Li, Jie Zhang, and Jing Ma. 2025. "Modified Hammerstein-Like Hysteresis Modeling and Composite Control Methods for Fast Steering Mirrors" Micromachines 16, no. 6: 626. https://doi.org/10.3390/mi16060626

APA StyleCao, K., Li, Z., Hao, G., Li, R., Zhang, J., & Ma, J. (2025). Modified Hammerstein-Like Hysteresis Modeling and Composite Control Methods for Fast Steering Mirrors. Micromachines, 16(6), 626. https://doi.org/10.3390/mi16060626