Nanoindentation Response of Monocrystalline Copper via Molecular Dynamics: Anisotropic Edge Effects

Abstract

1. Introduction

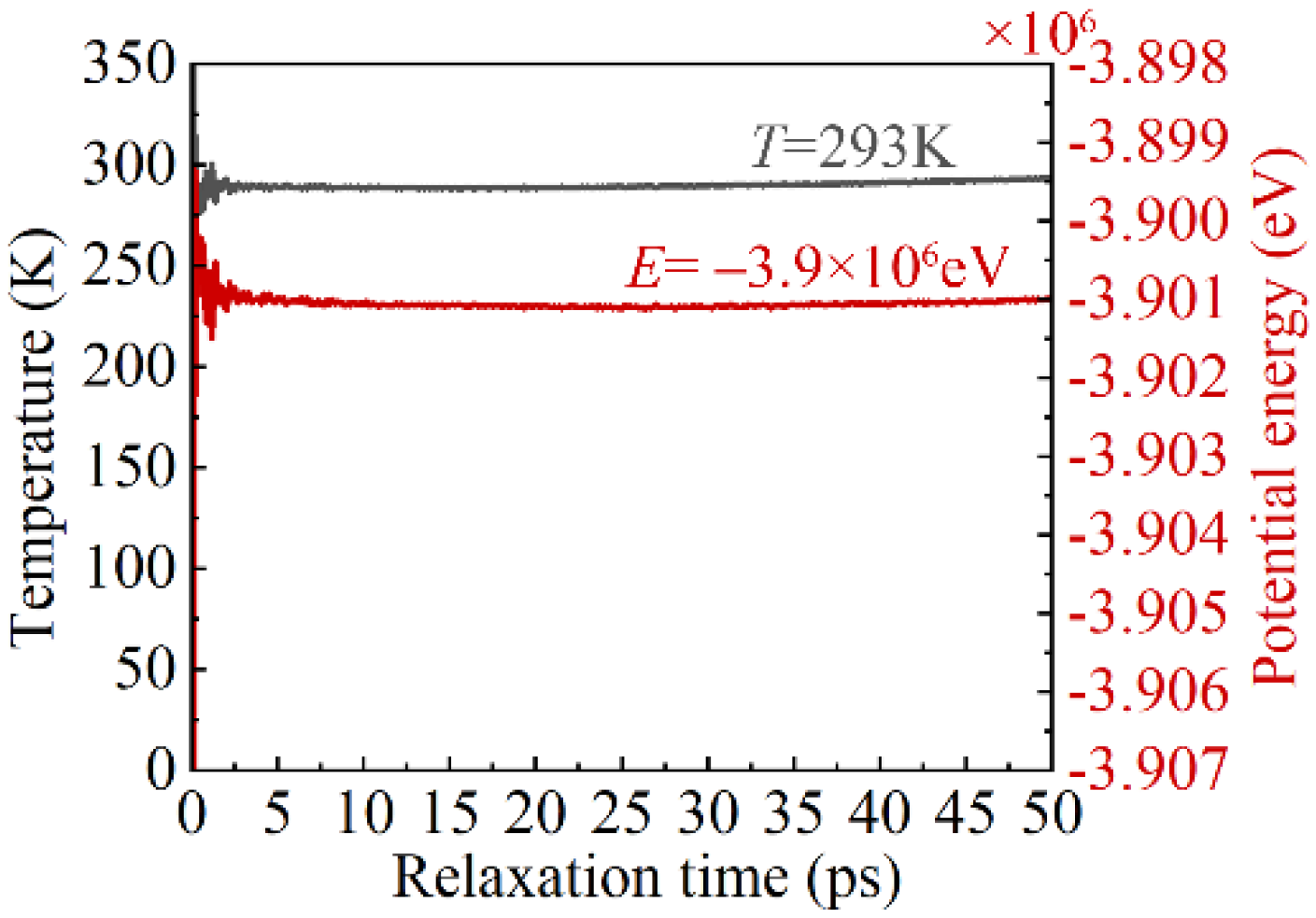

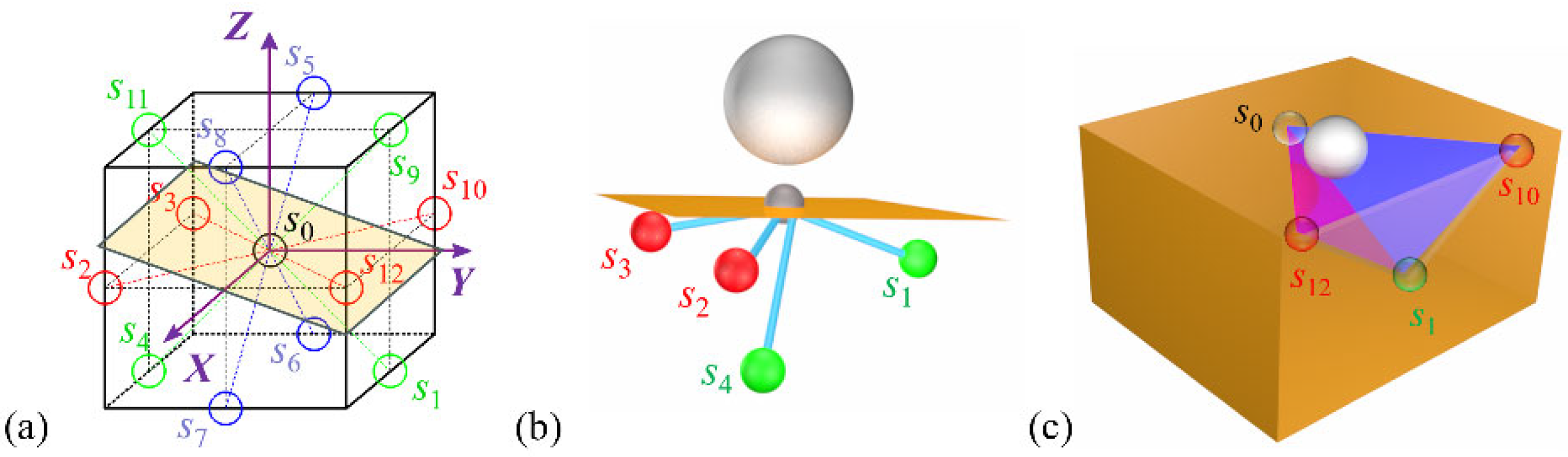

2. Materials and Methods

3. Results

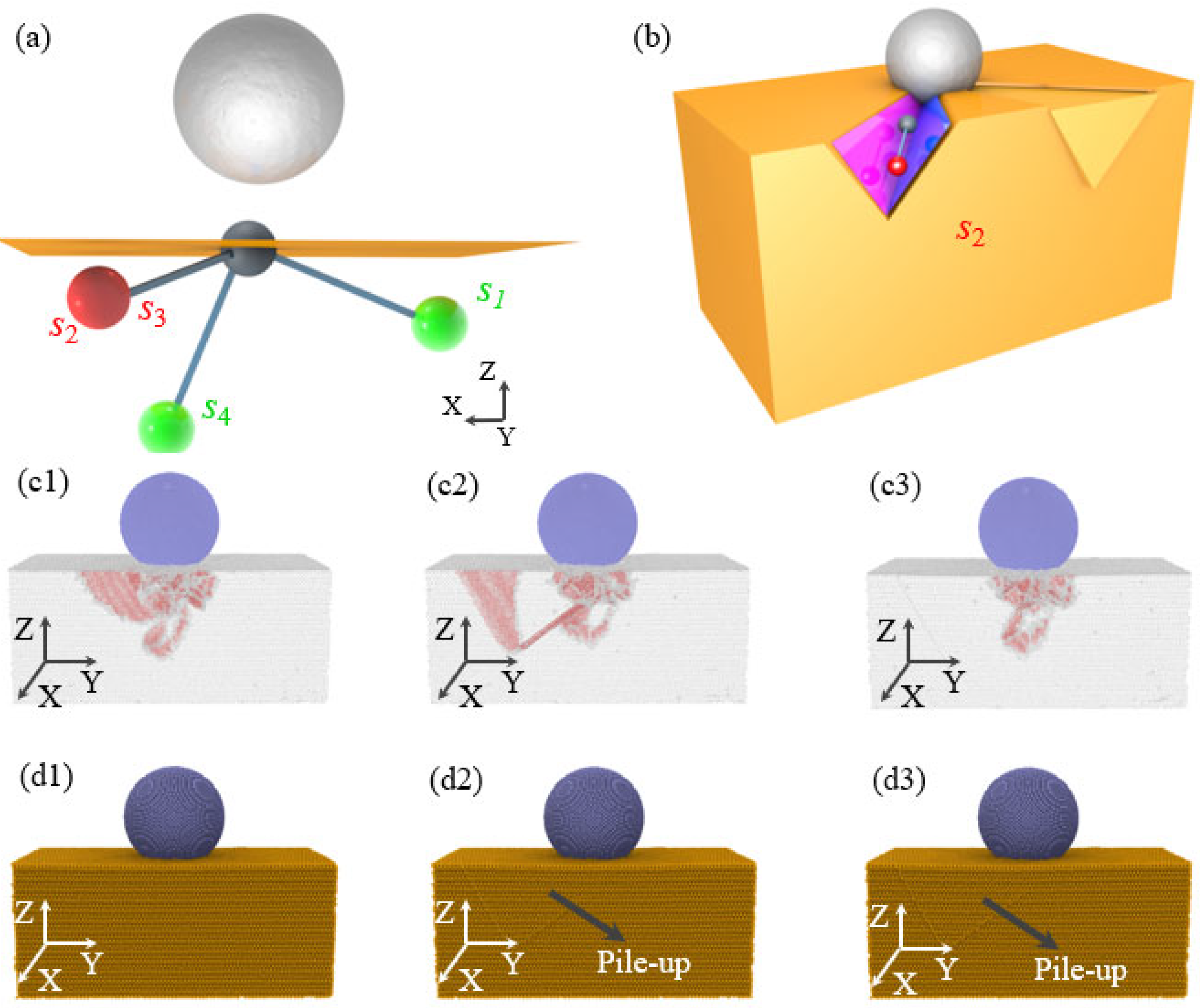

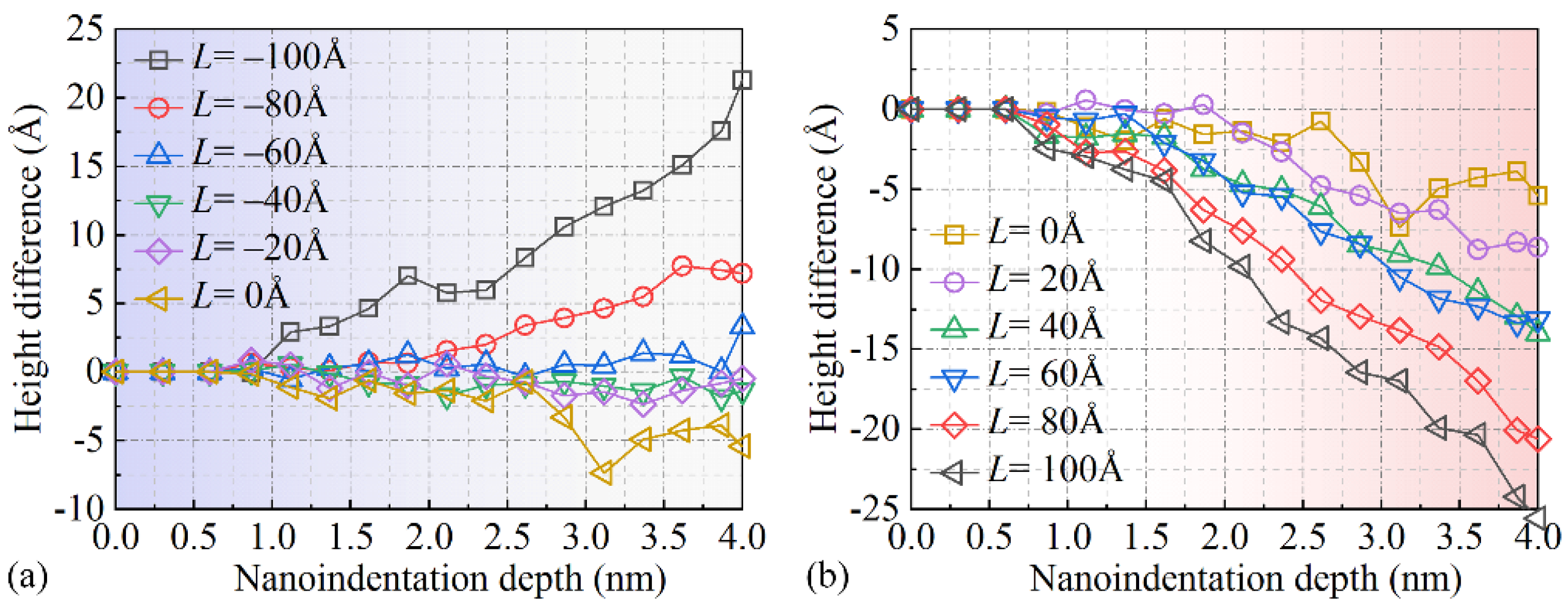

3.1. The Surface Sink-In and Side Squeeze-Out

3.2. The Distribution of Von Mises Stress

4. Conclusions

- (1)

- During the nanoindentation process of monocrystalline copper, significant surface sink-in and side squeeze-out phenomena were observed. The variation in indentation position led to differences in surface sink-in and side squeeze-out due to the activation of different [1 1 0] slip directions within the specimen. Specifically, surface sink-in in the specimen manifested as isosceles triangles with angles of 35° or 60°, while side squeeze-out exhibited differences in the distribution of isosceles triangles with a central region or right-angled triangles on both sides.

- (2)

- Regarding the von Mises stress distribution, it was found that the primary activated sliding directions, namely s1 and s4, induced the propagation of von Mises stress in the X-Z plane. For −60 Å ≤ L ≤ 80 Å, von Mises stress propagated inward along the s1 sliding direction. As the indenter approached the edges of the specimen, the area of von Mises stress distribution gradually decreased due to the influence of the s4 sliding direction inside the specimen, leading to a weakening of the edge effect. In the Y-Z plane, von Mises stress was primarily concentrated near the indenter and did not propagate into the specimen’s interior, as there were no corresponding [1 1 0] slip directions in the Y-Z plane.

- (3)

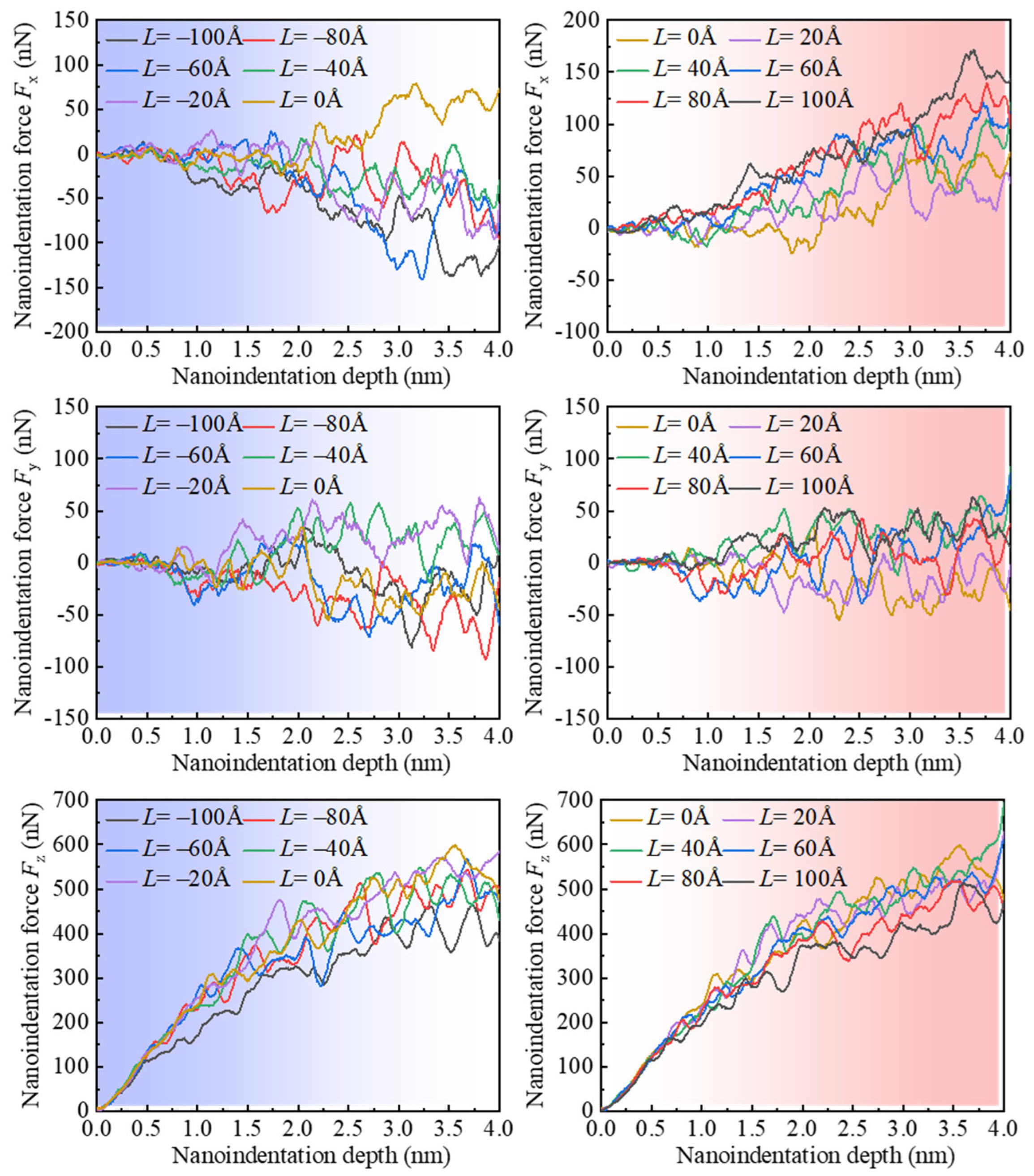

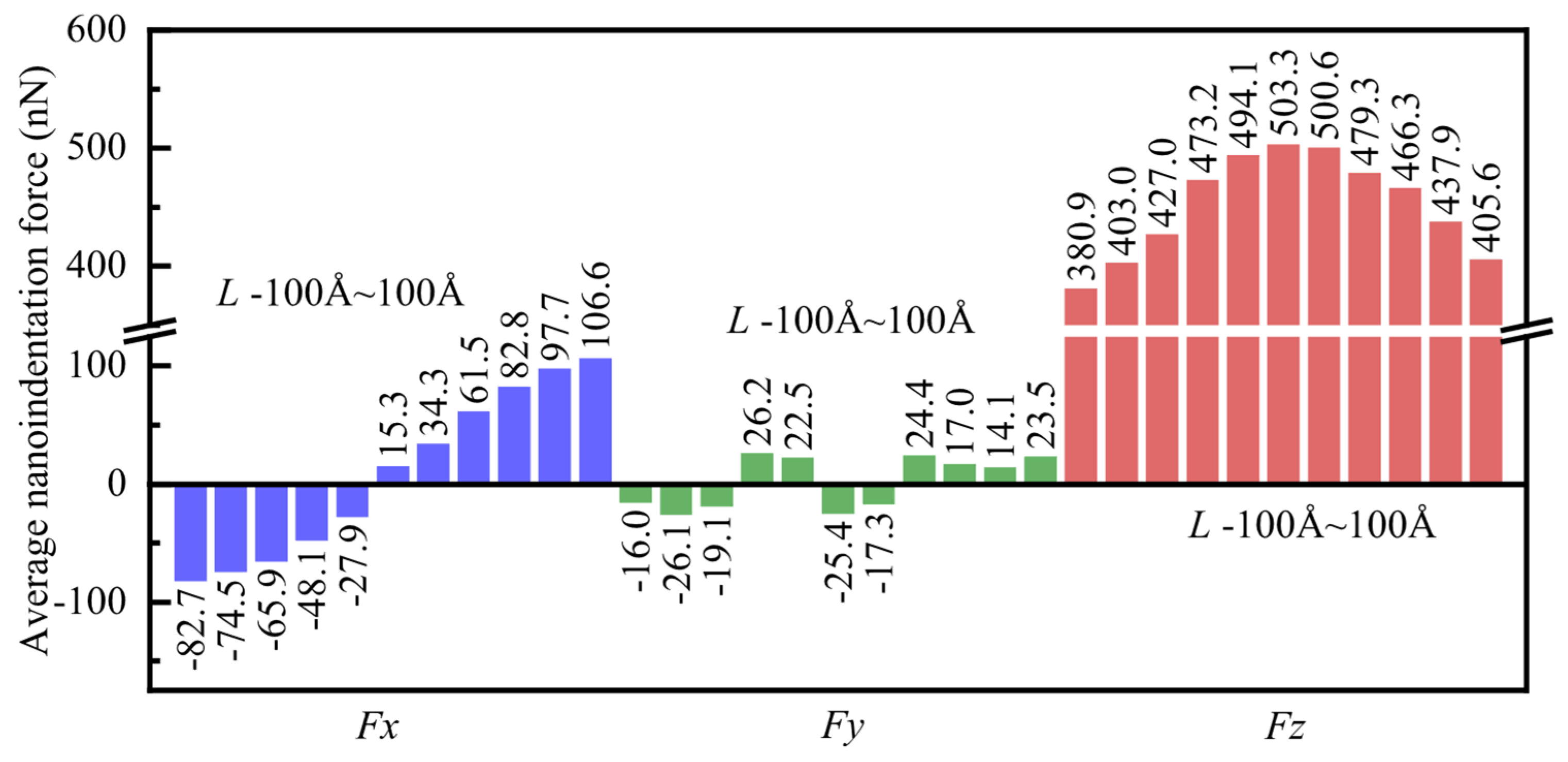

- Regarding the indentation force and hardness, it was observed that with increasing indentation depth, the fluctuation of the indentation force Fy became more pronounced. Simultaneously, when the indentation position approached the edges of the specimen, the unbalanced loading phenomenon of the indentation force Fx became more pronounced, while the indentation force Fz decreased. The nanoindentation hardness exhibited a significant edge effect on the (0 2 5) crystal plane of monocrystalline copper. The asymmetric (0 2 5) indentation plane of the monocrystalline copper specimen also resulted in pronounced anisotropic characteristics in the edge effect of the nanoindentation hardness. As the indentation position approached the edges of the specimen, the nanoindentation hardness gradually decreased.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Zhang, Z.; Li, Z.; Bai, Y.; Wang, G.; Li, S.; Zeng, T.; Li, C.; Lu, Y.; Han, B.; et al. A determination of the Planck constant by the generalized joule balance method with a permanent-magnet system at NIM. Metrologia 2016, 53, 86. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Lu, Y.; Hu, P.; Liu, Y.; Xu, J.; Bai, Y.; Zeng, T.; Wang, G.; You, Q.; et al. The first determination of the Planck constant with the joule balance NIM-2. Metrologia 2017, 54, 763. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Lu, Y.; Hu, P.; Liu, Y.; Xu, J. The design and construction of the joule balance NIM-2. IEEE Trans. Instrum. Meas. 2017, 66, 1329–1336. [Google Scholar] [CrossRef]

- Hu, W.; Li, W.; Liu, Y.; Wang, Y.; Yang, X. Quasi-static analysis of a compliant tripod stage with plane compliant lever mechanism. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 1639–1650. [Google Scholar]

- Chen, J.; Wang, X.; Gao, H.; Yan, S.; Chen, S.; Liu, X.; Hu, X. Rolled electrodeposited copper foil with modified surface morphology as anode current collector for high performance lithium-ion batteries. Surf. Coat Technol. 2021, 410, 126881. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Gao, H.; Chen, S.; Li, W.; Liu, X.; Hu, X.; Yan, S. Rolled electrodeposited copper foil with modified surface morphology as anode current collector for high corrosion resistance in lithium-ion battery electrolyte. Surf. Coat Technol. 2021, 421, 127369. [Google Scholar] [CrossRef]

- Shen, X.; Shao, L.; Tian, Z.; Hu, Z.; Cao, G. Study on the application of carbon-coated copper foil as negative current collector for silicon-based lithium-ion batteries. Int. J. Electrochem. Sci. 2020, 15, 9013–9023. [Google Scholar] [CrossRef]

- Su, T.-T.; Ren, W.-F.; Yuan, J.-M.; Wang, K.; Chi, B.-Y.; Sun, R.-C. Fabrication of polyacrylic acid-based composite binders with strong binding forces on copper foils for silicon anodes in lithium-ion batteries. J. Ind. Eng. Chem. 2022, 109, 521–529. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Y.; Liu, Y.; Li, S.; Song, K.; Feng, C.; Wu, B.; Zhang, P.; Wu, H.; Gu, J.; et al. Texture evolution and its influence mechanism on properties of single crystal copper and polycrystalline copper during cumulative deformation. J. Mater. Res. Technol. 2023, 24, 6808–6819. [Google Scholar] [CrossRef]

- Tavazza, F.; Kuhr, B.; Farkas, D.; Levine, L. Ni Nanoindentation at the Nanoscale: Atomic Rearrangements at the Ni-C Interface. J. Phys. Chem. C 2017, 121, 2643–2651. [Google Scholar] [CrossRef]

- Barsoum, M.; Murugaiah, A.; Kalidindi, S.; Zhen, T.; Gogotsi, Y. Kink bands, nonlinear elasticity and nanoindentations in graphite. Carbon 2004, 42, 1435–1445. [Google Scholar] [CrossRef]

- Hua, L.; Hu, C.; Li, J.; Huang, B.; Du, J. Mechanical characterization of TiO2 nanowires flexible scaffold by nano-indentation/scratch. J. Mech. Behav. Biomed. Mater. 2022, 126, 105069. [Google Scholar] [CrossRef]

- Yang, P.; Zhang, X.; Yao, Z.; Shivpuri, R. Investigation on the crystal plasticity of α phase Ti-6Al-4V based on nano-indentation simulation and experiment. Mater. Charact. 2023, 203, 113074. [Google Scholar] [CrossRef]

- Gao, W.; Liu, C.; Liu, T.; Zhao, L.; Wang, C.; Shakoor, A.; Luo, T.; Jing, W.; Yang, P.; Lin, Q.; et al. An area-variant type MEMS capacitive sensor based on a novel bionic swallow structure for high sensitive nano-indentation measurement. Measurement 2022, 200, 111634. [Google Scholar] [CrossRef]

- Shi, J.; Chen, J.; Sun, K.; Sun, J.; Han, J.; Fang, L. Water film facilitating plastic deformation of Cu thin film under different nanoindentation modes: A molecular dynamics study. Mater. Chem. Phys. 2017, 198, 177–185. [Google Scholar] [CrossRef]

- Hong, S.; Kim, K.; Kim, Y.-M.; Hahn, J.-H.; Lee, C.-S.; Park, J.-H. Characterization of elastic moduli of Cu thin films using nanoindentation technique. Compos. Sci. Technol. 2005, 65, 1401–1408. [Google Scholar] [CrossRef]

- Lu, H.; Li, J.; Ni, Y. Position effect of cylindrical indenter on nanoindentation into Cu thin film by multiscale analysis. Comput. Mater. Sci. 2011, 50, 2987–2992. [Google Scholar] [CrossRef]

- Wang, F.; Xu, K. An investigation of nanoindentation creep in polycrystalline Cu thin film. Mater. Lett. 2004, 58, 2345–2349. [Google Scholar] [CrossRef]

- Peng, W.; Sun, K.; Abdullah, R.; Zhang, M.; Chen, J.; Shi, J. Strengthening mechanisms of graphene coatings on Cu film under nanoindentation: A molecular dynamics simulation. Appl. Surf. Sci. 2019, 487, 22–31. [Google Scholar] [CrossRef]

- Sun, W.; Jiang, Y.; Sun, G.; Hu, J.; Zhou, T.; Jiang, Z.; Lian, J. Nanoindentation creep behavior and its relation to activation volume and strain rate sensitivity of nanocrystalline Cu. Mater. Sci. Eng. A 2019, 751, 35–41. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, C.; Bei, H.; He, X.; Hu, W. Room temperature nanoindentation creep of nanocrystalline Cu and Cu alloys. Mater. Lett. 2012, 70, 26–29. [Google Scholar] [CrossRef]

- Tan, C.M.; Jeng, Y.R. Computer simulations of nanoindentation on Cu (1 1 1) with a void. Int. J. Solids Struct. 2009, 46, 1884–1889. [Google Scholar] [CrossRef][Green Version]

- Liu, B.; Hu, J.; Peng, G. Creep behaviors of nanocrystalline copper after stress reduction under nanoindentation at ambient temperature. Mater. Lett. 2023, 350, 134899. [Google Scholar] [CrossRef]

- Chen, J.; Wang, W.; Qian, L.H.; Lu, K. Critical shear stress for onset of plasticity in a nanocrystalline Cu determined by using nanoindentation. Scr. Mater. 2003, 49, 645–650. [Google Scholar] [CrossRef]

- Liu, Q.; Deng, L.; Wang, X.; Li, J. Formation of stacking fault tetrahedron in monocrystalline Cu during nanoindentation investigated by molecular dynamics. Comput. Mater. Sci. 2017, 131, 44–47. [Google Scholar] [CrossRef]

- Kim, B.-J.; Kim, S.-H.; Kayani, S.H.; Lee, Y.-H.; Kim, W.-K.; Cheon, H.-S.; Kim, J.; Cho, Y.-H. Melt thermal-rate treatment for uniform solute distribution and improved mechanical properties of an Al-Zn-Mg-Cu alloy prepared by direct-chill casting. J. Alloys. Compd. 2023, 967, 171745. [Google Scholar] [CrossRef]

- Guo, W.; Yi, Y.; Huang, S.; Ruan, J.; Guo, Y. Effect of warm-rolling temperature on the microstructural evolution and mechanical properties of large 2219 Al-Cu alloy rings. Mater. Today Commun. 2023, 36, 106702. [Google Scholar] [CrossRef]

- Tang, S.; Xiao, Z.; Ding, Y.; Li, Y.; Wang, R.; Jia, Y.; Gong, S.; Li, Z. Precipitation behavior and mechanical properties of a novel Cu–2Fe-0.5Ti alloy produced by thermos-mechanical treatment. Mater. Sci. Eng. A 2023, 882, 145453. [Google Scholar] [CrossRef]

- Shimada, Y.; Nakajima, Y.; Hishinuma, Y.; Ikeda, K.-I.; Noto, H.; Muroga, T.; Yoshida, K.; Konno, T.J.; Nagai, Y. Microstructure and mechanical property of Y2O3-based ODS-Cu alloy fabricated by MA-HIP with novel elemental addition process. Mater. Chem. Phys. 2023, 307, 128223. [Google Scholar] [CrossRef]

- Shi, C.; Ma, M.; Yang, B.; Liu, Y.; Huang, Y.; Du, Y. Effect of Ti additions on microstructure and mechanical properties of Cu–Cr–Zr alloy. J. Mater. Sci. Technol. 2023, 163, 69–80. [Google Scholar] [CrossRef]

- Patel, S.; Rao, V. Microstructure, mechanical properties and corrosion behaviour of Mg-Cu and Mg-Cu-Mn alloys. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Radhakrishnan, M.; Miller, C.; Mier, R.; Vogel, S.C.; Savage, D.J.; Carpenter, J.S.; Anderoglu, O.; Mara, N.A. The influence of thermomechanical treatment pathways on texture and mechanical properties in ARB Cu/Nb nanolaminates. Mater. Sci. Eng. A 2023, 886, 145610. [Google Scholar] [CrossRef]

- Lei, C.; Jin, F.; Wei, S.; Qiu, L.; Yin, Z. Influences of solution treatments on the microstructure and mechanical properties of TiCx-Cu (x = 0.5, 0.6, 0.7) cermets prepared by infiltration method. Ceram. Int. 2023, 50, 7211–7217. [Google Scholar] [CrossRef]

- Shi, X.; Huang, W.; Li, F.; Li, Z.; Xu, Z.; Jiang, X.; Wei, X. Analysis on the anisotropic electromechanical properties of lead magnoniobate titanate single crystal for ring type ultrasonic motors. AIP Adv. 2016, 6, 115017. [Google Scholar] [CrossRef]

- Wang, Q.; Bai, Q.; Chen, J.; Guo, Y.; Xie, W. Stress-induced formation mechanism of stacking fault tetrahedra in nano-cutting of single crystal copper. Appl. Surf. Sci. 2015, 355, 1153–1160. [Google Scholar] [CrossRef]

- Zhao, P.; Wu, J.; Chen, H.; Liu, H.; Li, D.; Tan, J. Molecular dynamics simulation study of interaction mechanism between grain boundaries and subgrain boundaries in nano-cutting. J. Manuf. Process. 2021, 67, 418–426. [Google Scholar] [CrossRef]

- Ma, Y.; Dong, X.; Li, L.; Cao, Q.; Gong, Z.; Lu, Y.; Hu, X. A molecular dynamics study on microscopic mechanism of nano-polished single crystal copper. Mater. Today Commun. 2024, 41, 110942. [Google Scholar] [CrossRef]

- Faken, D.; Jónsson, H. Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 1994, 2, 279–286. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Model Simul. Mat. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Gao, Y.F.; Larson, B.C.; Lee, J.H.; Nicola, L.; Tischler, J.Z.; Pharr, G.M. Lattice rotation patterns and strain gradient effects in face-centered-cubic single crystals under spherical indentation. J. Appl. Mech. 2015, 82, 061007. [Google Scholar] [CrossRef]

- Iracheta, O.; Bennett, C.J.; Sun, W. The influence of the indentation size in relation to the size of the microstructure of three polycrystalline materials indented with a Berkovich indenter. Mater. Sci. Eng. A 2017, 706, 330–341. [Google Scholar] [CrossRef]

- Kucharski, S.; Maj, M.; Ryś, M.; Petryk, H. Size effects in spherical indentation of single crystal copper. Int. J. Mech. Sci. 2024, 272, 109138. [Google Scholar] [CrossRef]

| Nanoindentation Parameters | Value |

|---|---|

| Specimen material | Monocrystalline copper |

| Specimen dimensions (nm3) | 30 × 30 × 15 |

| Loading velocity (m/s) | 50 |

| Nanoindentation depth (nm) | 3.5 |

| Potential function | EAM, Morse |

| Initial temperature (K) | 293 |

| Timestep (fs) | 1 |

| D (eV) | αA − B (Å − 1) | rA-B (Å) | |

|---|---|---|---|

| C-Cu | 0.087 | 5.140 | 2.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, D.; Wu, P.; Liu, H.; Li, Z.; Tan, J. Nanoindentation Response of Monocrystalline Copper via Molecular Dynamics: Anisotropic Edge Effects. Micromachines 2025, 16, 570. https://doi.org/10.3390/mi16050570

Du D, Wu P, Liu H, Li Z, Tan J. Nanoindentation Response of Monocrystalline Copper via Molecular Dynamics: Anisotropic Edge Effects. Micromachines. 2025; 16(5):570. https://doi.org/10.3390/mi16050570

Chicago/Turabian StyleDu, Desong, Peng Wu, Huan Liu, Zhengkun Li, and Jiubin Tan. 2025. "Nanoindentation Response of Monocrystalline Copper via Molecular Dynamics: Anisotropic Edge Effects" Micromachines 16, no. 5: 570. https://doi.org/10.3390/mi16050570

APA StyleDu, D., Wu, P., Liu, H., Li, Z., & Tan, J. (2025). Nanoindentation Response of Monocrystalline Copper via Molecular Dynamics: Anisotropic Edge Effects. Micromachines, 16(5), 570. https://doi.org/10.3390/mi16050570