Design of Metamaterial Sensor for Non Destructive Testing of Aircraft Composite Skin Damage

Abstract

1. Introduction

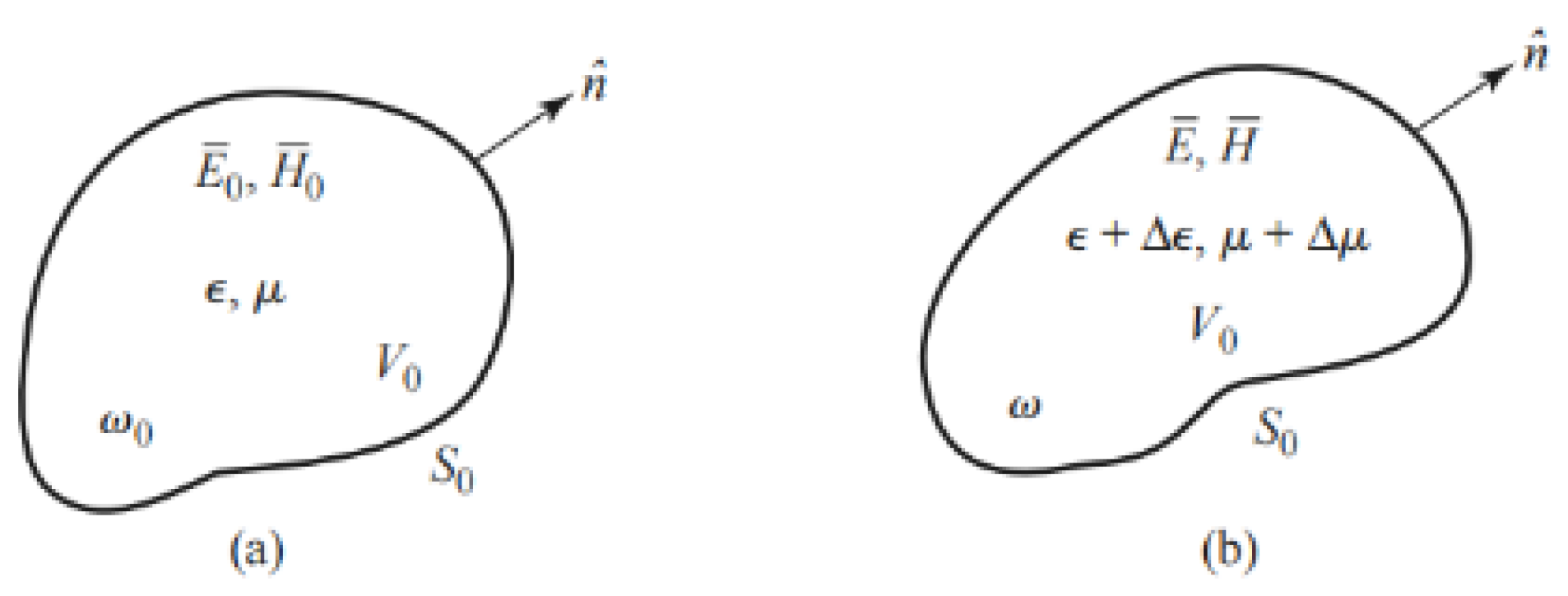

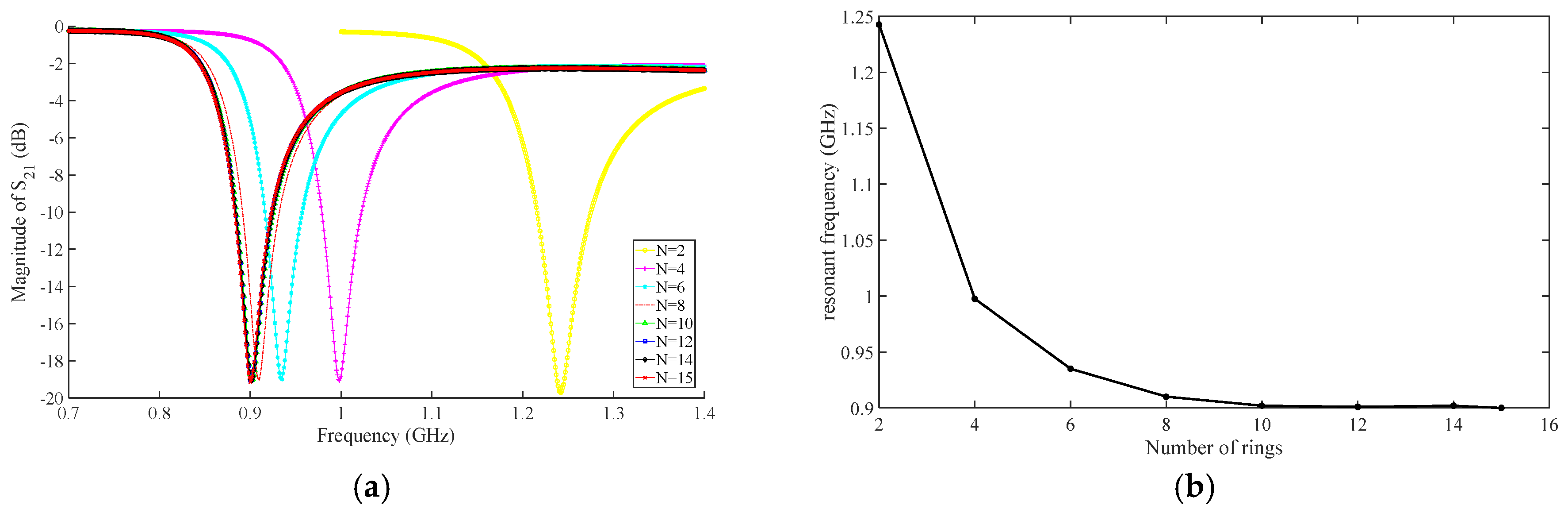

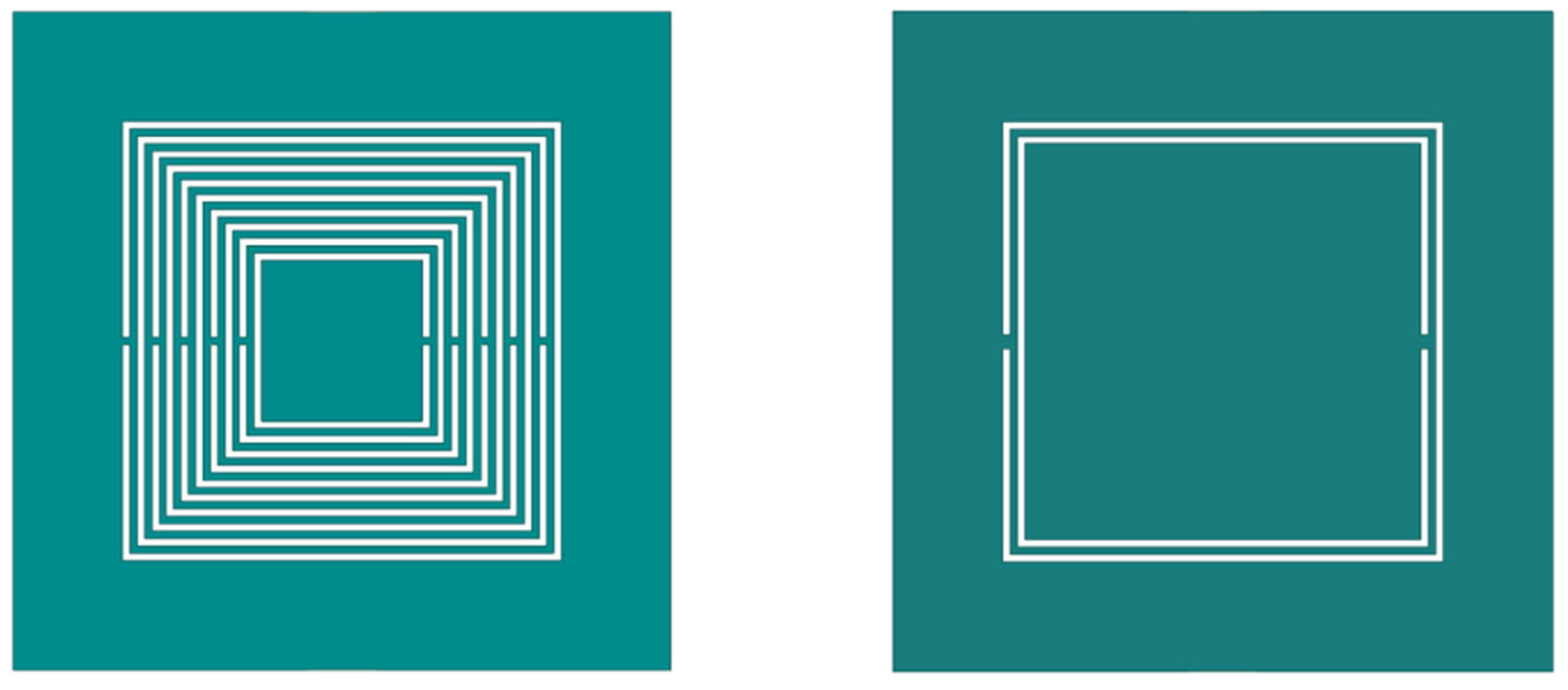

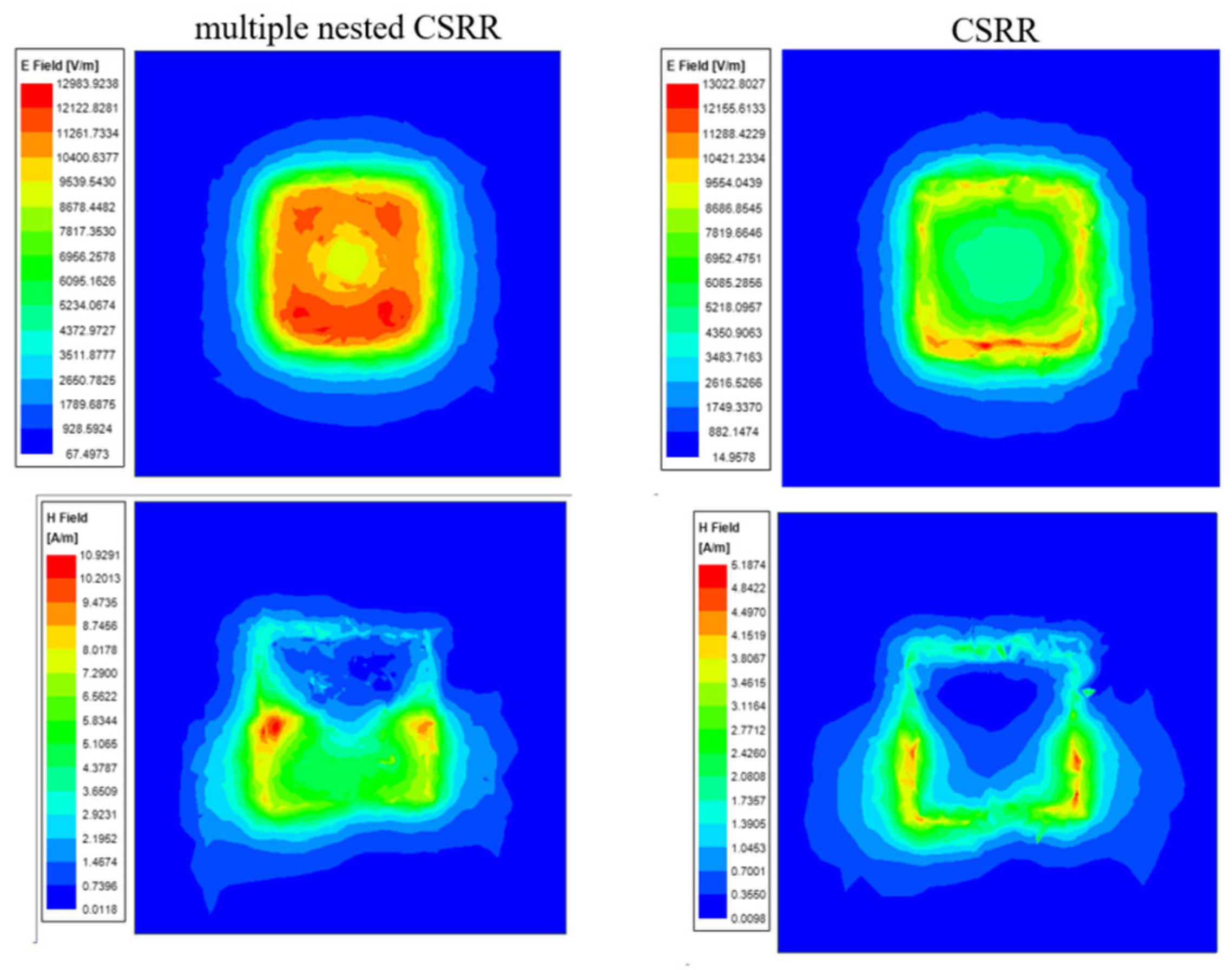

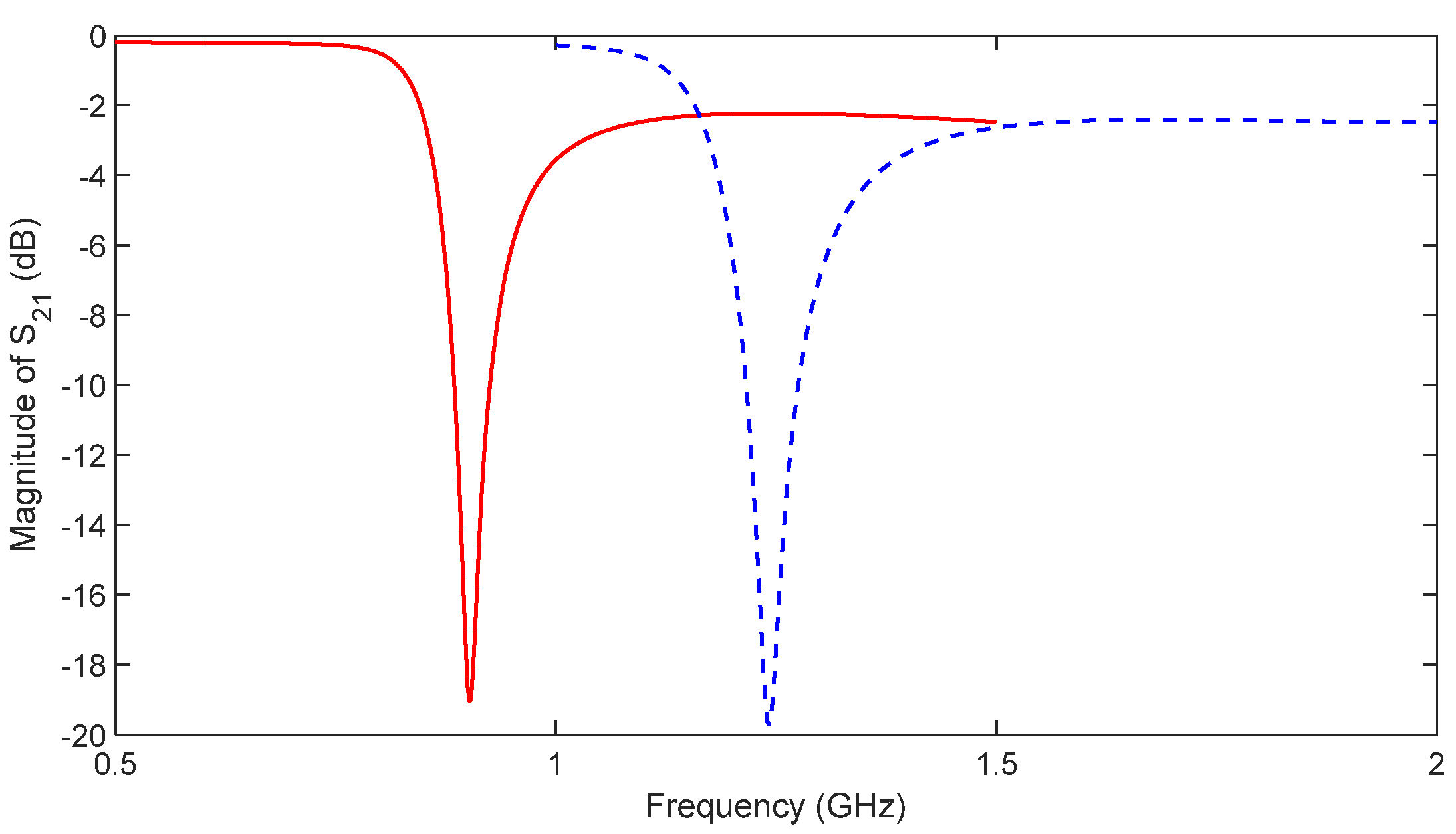

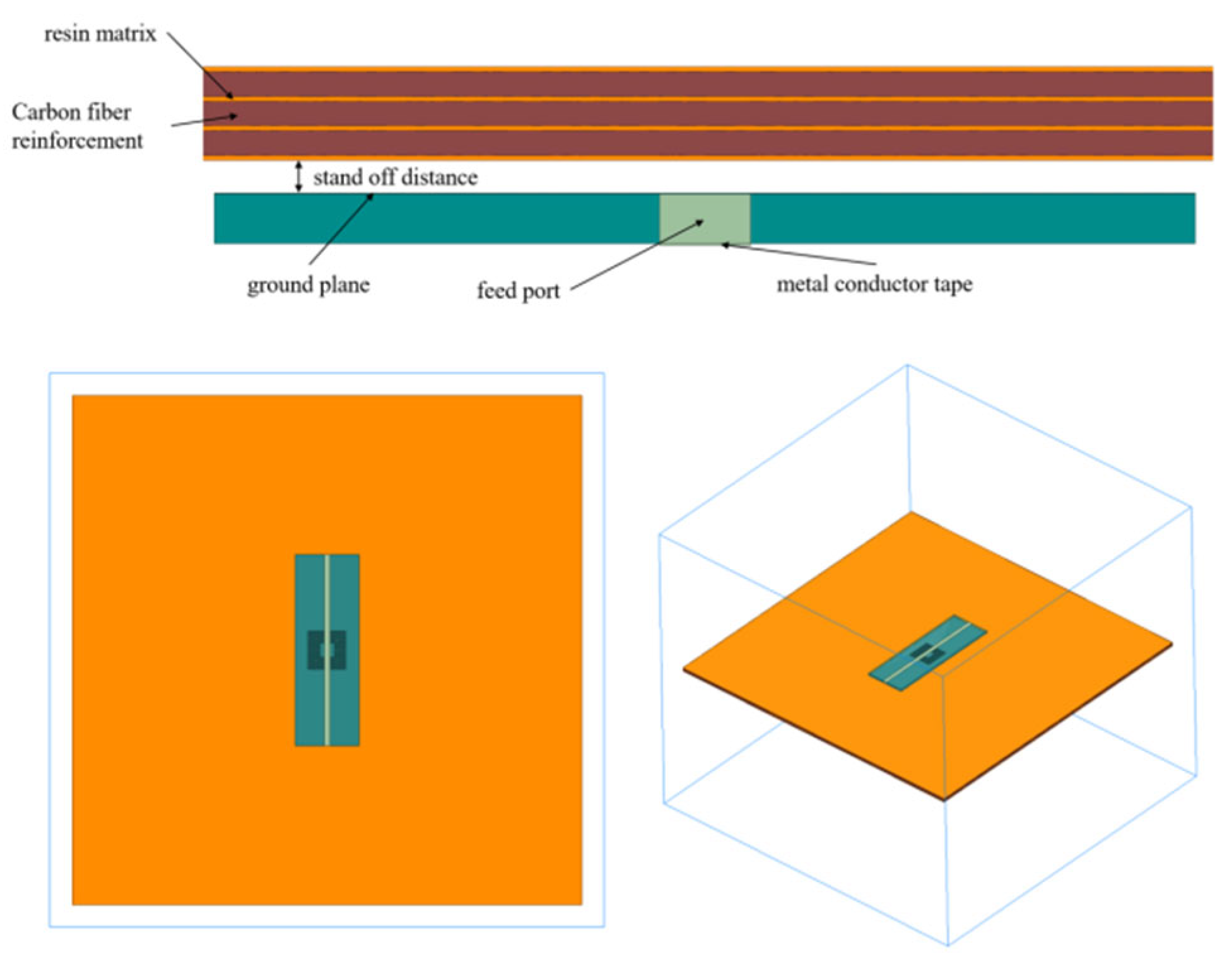

2. Model of Aircraft Composite Skin Defect

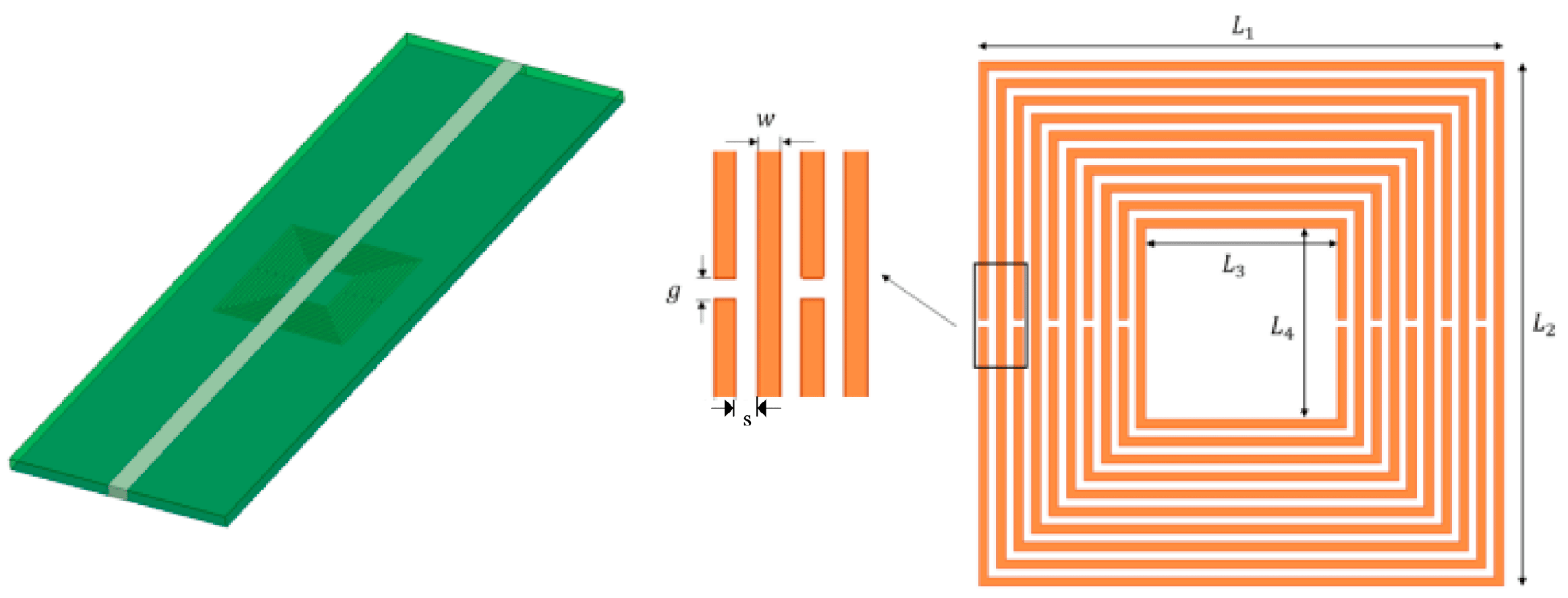

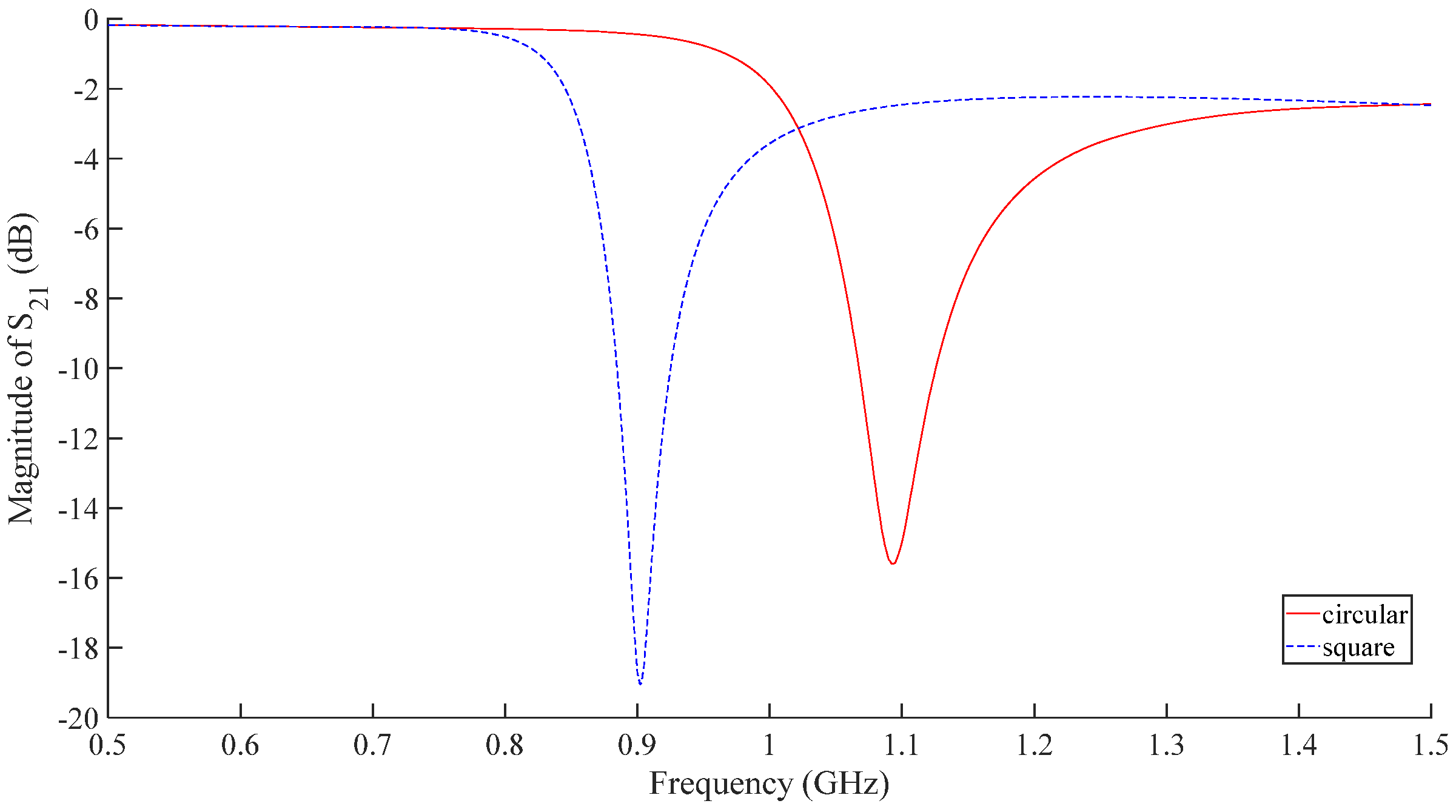

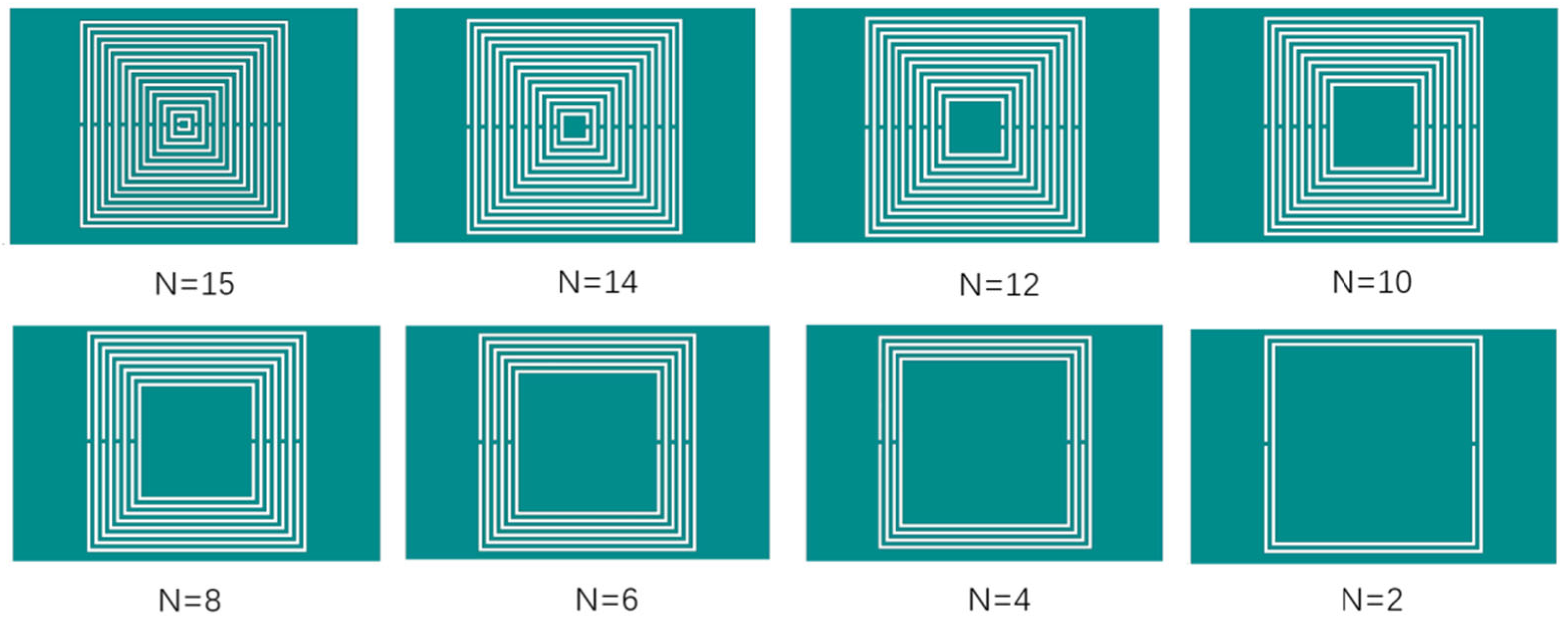

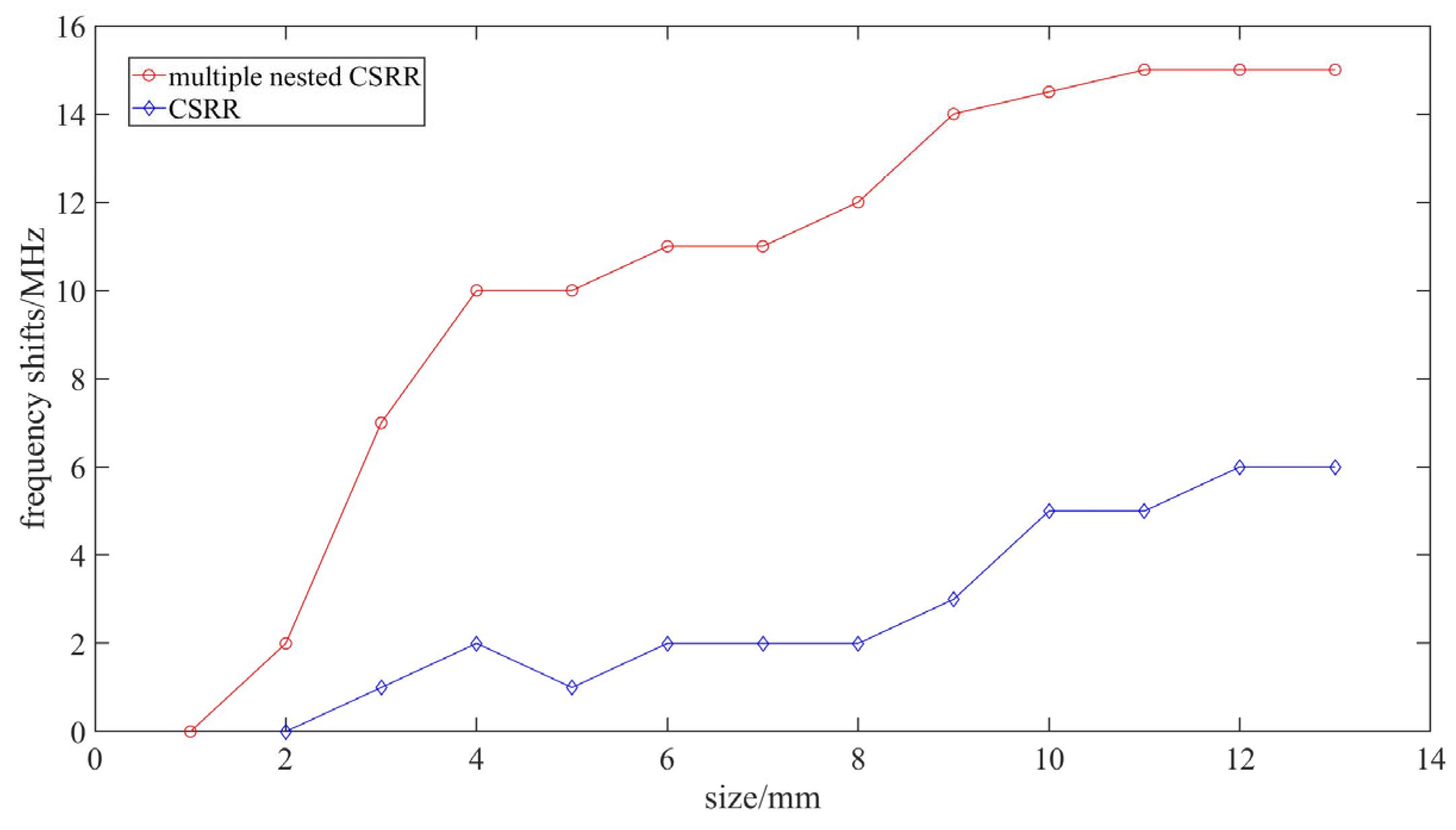

3. Design of Nested Multi-Layer CSRR Metamaterial Sensor

4. Simulation and Analysis of Aircraft Composite Skin Detection

4.1. Simulation Model

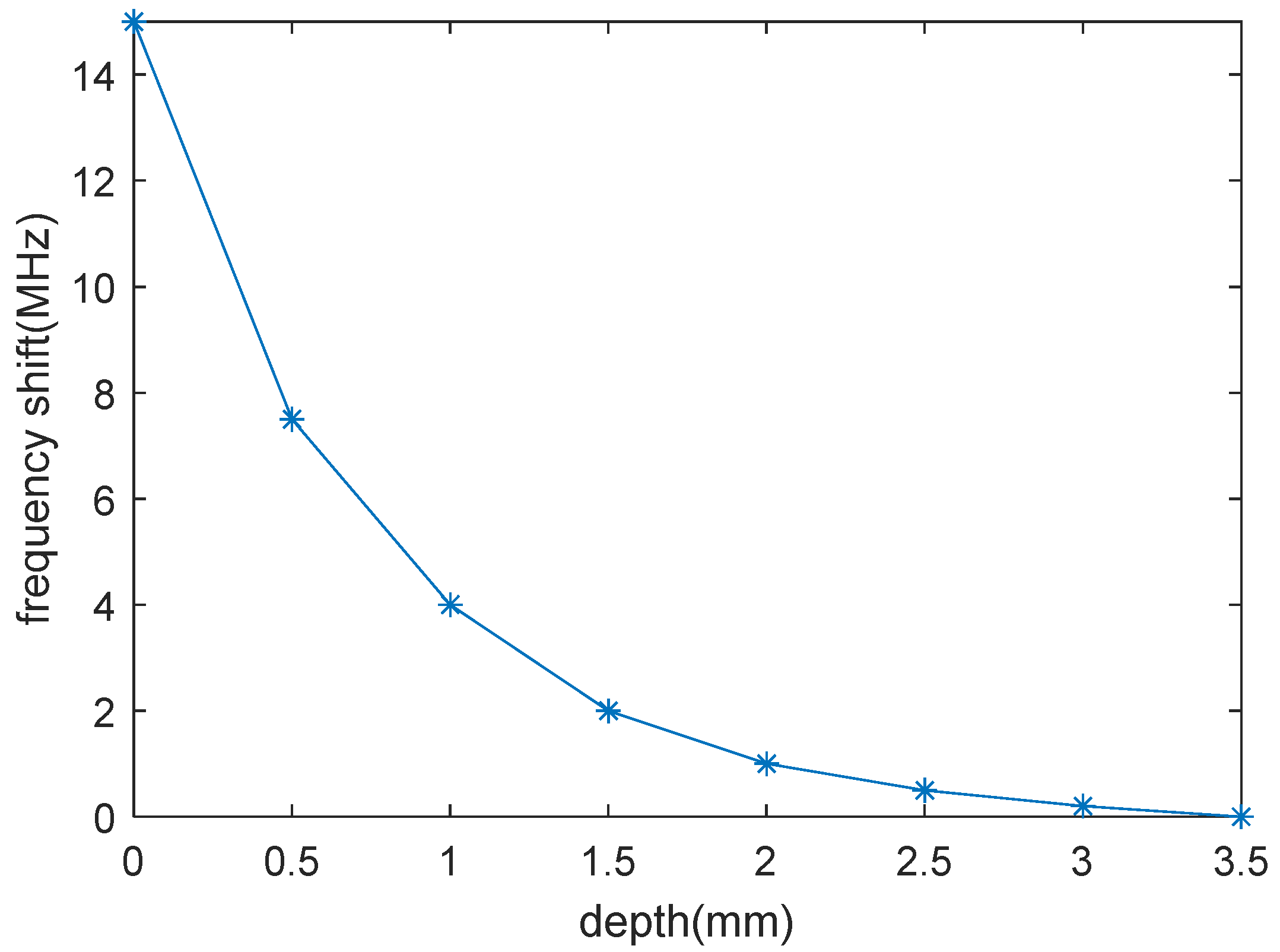

4.2. Detection of Internal Defects in Aircraft Composite Skin

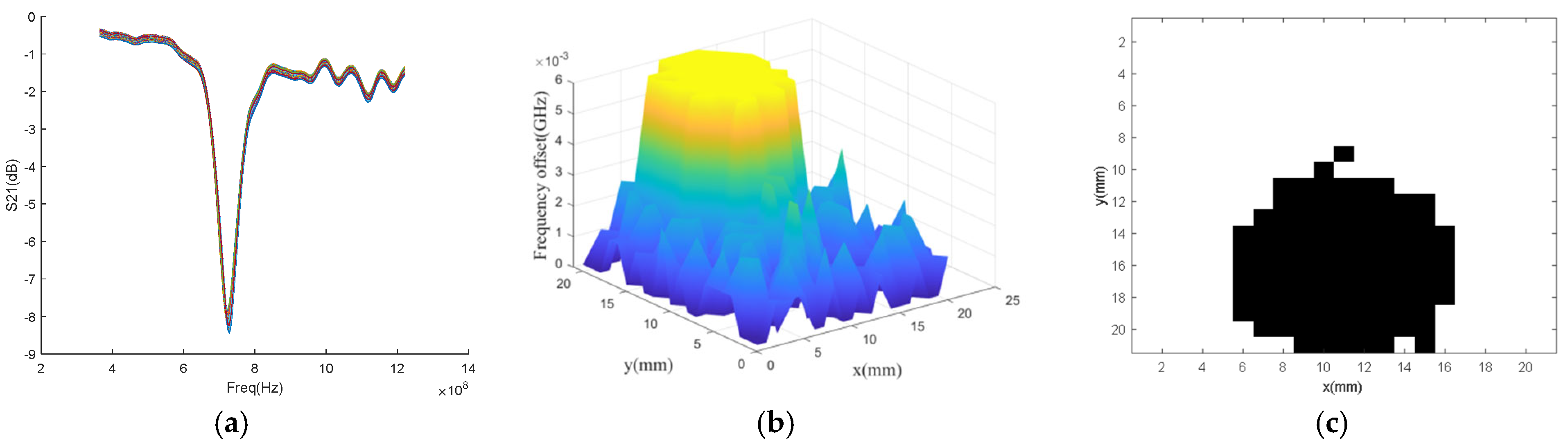

5. Experiment

5.1. Experimental Platform

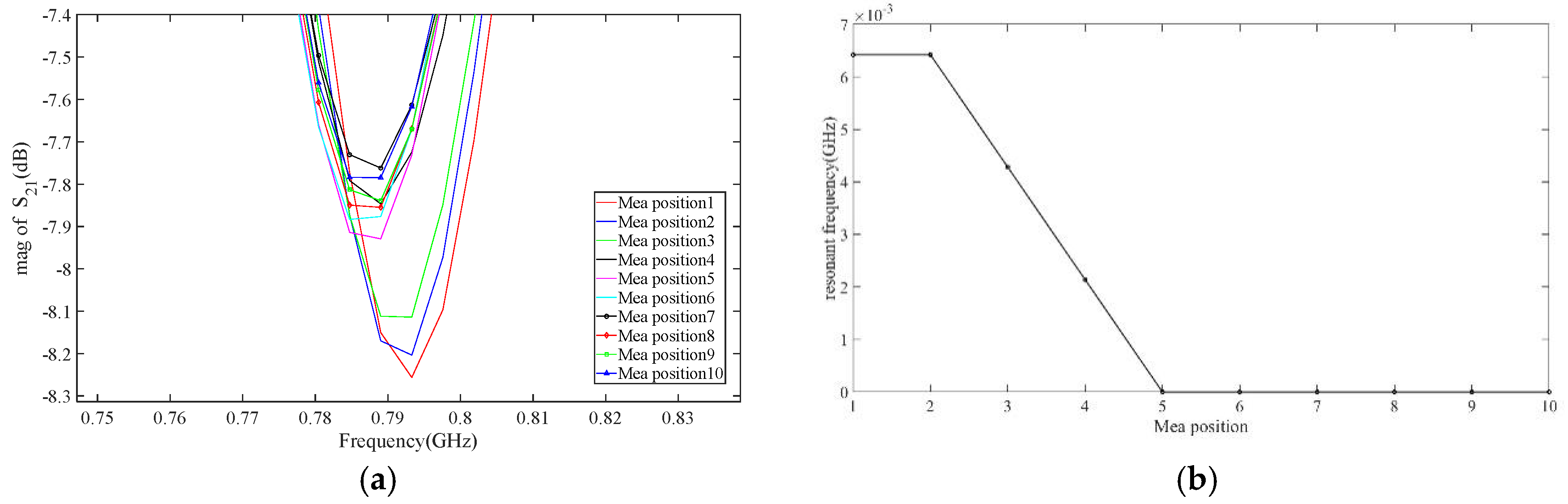

5.2. Experimental Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nassiraei, H.; Rezadoost, P. Local joint flexibility of tubular T/Y-joints retrofitted with GFRP under in-plane bending moment. Mar. Struct. 2021, 77, 102936. [Google Scholar] [CrossRef]

- Wu, R.; Zhang, H.; Yang, R.; Chen, W.; Chen, G. Nondestructive Testing for Corrosion Evaluation of Metal under Coating. Sensors 2021, 2021, 6640406. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. Static capacity of tubular X-joints reinforced with fiber reinforced polymer subjected to compressive load. Eng. Struct. 2021, 236, 112041. [Google Scholar] [CrossRef]

- Gupta, R.; Mitchell, D.; Blanche, J.; Harper, S.; Tang, W.; Pancholi, K.; Baines, L.; Bucknall, D.G.; Flynn, D. A Review of Sensing Technologies for Non-Destructive Evaluation of Structural Composite Materials. J. Compos. Sci. 2021, 5, 319. [Google Scholar] [CrossRef]

- Chrysafi, A.P.; Athanasopoulos, N.; Siakavellas, N.J. Damage detection on composite materials with active thermography and digital image processing. Int. J. Therm. Sci. 2017, 116, 242–253. [Google Scholar] [CrossRef]

- Wang, B.; He, P.; Kang, Y.; Jia, J.; Liu, X.; Li, N. Ultrasonic Testing of Carbon FiberReinforced Polymer Composites. J. Sens. 2022, 2022, 5462237. [Google Scholar]

- Shoukroun, D.; Massimi, L.; Endrizzi, M.; Bate, D.; Olivo, A.; Fromme, P. Composites impact damage detection and characterization using ultrasound and x-ray NDE techniques. In Health Monitoring of Structural and Biological Systems XIV; SPIE: Bellingham, WA, USA, 2020; Volume 11381, pp. 27–33. [Google Scholar]

- Du, Y.; Li, X.; Xie, S.; Yang, S.; Chen, Z. Reconstruction of cracks in a carbon fiberreinforced polymer laminate plate from signals of eddy current testing. J. Compos. Mater. 2020, 54, 3527–3536. [Google Scholar] [CrossRef]

- Yang, X.; Yin, Y.; Zhang, D.; Wu, S.; Huang, K.; Yuan, J.; Zhu, Z. Array Waveguide Probe Loaded with Split-Ring Resonators for Sizing the Cracks in Metal Surface. IEEE Microw. Wirel. Compon. Lett. 2018, 28, 171–173. [Google Scholar] [CrossRef]

- Hu, B.; Ren, Z.; Boybay, M.S.; Ramahi, O.M. Waveguide Probe Loaded with Split-Ring Resonators for Crack Detection in Metallic Surfaces. IEEE Trans. Microw. Theory Tech. 2014, 62, 871–878. [Google Scholar] [CrossRef]

- Albishi, A.M. Complementary Split-Ring Resonator for Crack Detection in Metallic Surfaces. IEEE Microw. Wirel. Compon. Lett. 2012, 22, 330–332. [Google Scholar] [CrossRef]

- Li, Z.; Wang, T.; Haigh, A.; Meng, Z.; Wang, P. Non-contact detection of impact damage in carbon fibre composites using a complementary split-ring resonator sensor. J. Electr. Eng. 2019, 70, 489–493. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering; Publishing House of Elec.: Beijing, China, 2004. [Google Scholar]

- Zhao, K.; Jia, Y. Study on Equivalent Modeling Technology of Helicopter Complex Skin Structure. In Proceedings of the IEEE 4th Information Technology and Mechatronics Engineering Conference, Chongqing, China, 14–16 December 2018; Volume 264, p. 268. [Google Scholar]

- Holloway, C.L.; Sarto, M.S.; Johansson, M. Analyzing carbonffber composite materials with equivalent-layer models. IEEE Trans. Electromagn. Compat. 2005, 47, 833–844. [Google Scholar] [CrossRef]

- Gao, R.X.; Lee, H.M.; Ewe, W.B.; Tay, S.W.; Thitsartarn, W.; Yang, Z.; Mahmoudi, M.; Juanda, E.; Kohler, J.; Wang, W. Electromagnetic characterization and measurement of conductive aircraft CFRP composite for lightning protection and EMI shielding. IEEE Trans. Instrum. Meas. 2023, 72, 1–11. [Google Scholar] [CrossRef]

- Jing, Z.; Cai, G.; Yu, X.; Wang, B. Ultrasonic detection and evaluation of delamination defects in carbon ffber composites based on ffnite element simulation. Compos. Struct. 2024, 3535, 118749. [Google Scholar]

- Cheng, J.; Zhu, Y.; Wang, B.; Liu, M.; Xu, D.; Qiu, J.; Takagi, T. Noncontact visualization of multiscale defects in CFRP composites using eddy current testing with T-R probe. NDT E Int. 2024, 145, 103138. [Google Scholar] [CrossRef]

- Huang, J.; Wei, Q.; Zhuo, L.; Zhu, J.; Li, C.; Wang, Z. Detection and quantiffcation of artiffcial delaminations in CFRP composites using ultrasonic thermography. Infrared Phys. Technol. 2023, 130, 104579. [Google Scholar] [CrossRef]

| Parameter | Unit (mm) |

|---|---|

| shape | square |

| 12 | |

| 12 | |

| N | 10 |

| 4.4 | |

| 4.4 | |

| 0.2 | |

| 0.2 | |

| 0.2 |

| Material | Conductivity (S/m) | Relative Permittivity | Relative Permeability |

|---|---|---|---|

| longitude carbon fiber | 1 | ||

| transverse carbon fiber | 1 | ||

| resin matrix | 0 | 4.4 | 1 |

| air | 0 | 1 | 1 |

| References | Type | Defect Detection Resolution |

|---|---|---|

| [17] | Ultrasonic | 3 mm |

| [18,19] | eddy current | 6 mm |

| The work | Metamaterial sensor | 2 mm |

| Scan Points | Resonant Frequency (GHz) |

|---|---|

| 1 (A) | 0.793292 |

| 2 | 0.793292 |

| 3 | 0.791152 |

| 4 | 0.789011 |

| 5 | 0.786871 |

| 6 | 0.786871 |

| 7 | 0.786871 |

| 8 | 0.786871 |

| 9 | 0.786871 |

| 10 (B) | 0.786871 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Kang, R.; Qin, K. Design of Metamaterial Sensor for Non Destructive Testing of Aircraft Composite Skin Damage. Micromachines 2025, 16, 284. https://doi.org/10.3390/mi16030284

Zhu Z, Kang R, Qin K. Design of Metamaterial Sensor for Non Destructive Testing of Aircraft Composite Skin Damage. Micromachines. 2025; 16(3):284. https://doi.org/10.3390/mi16030284

Chicago/Turabian StyleZhu, Zhaoxuan, Rongqing Kang, and Kaiyu Qin. 2025. "Design of Metamaterial Sensor for Non Destructive Testing of Aircraft Composite Skin Damage" Micromachines 16, no. 3: 284. https://doi.org/10.3390/mi16030284

APA StyleZhu, Z., Kang, R., & Qin, K. (2025). Design of Metamaterial Sensor for Non Destructive Testing of Aircraft Composite Skin Damage. Micromachines, 16(3), 284. https://doi.org/10.3390/mi16030284