Extraction and Assessment of Features Using Shannon Entropy and Rényi Entropy for Chatter Detection in Micro Milling

Abstract

1. Introduction

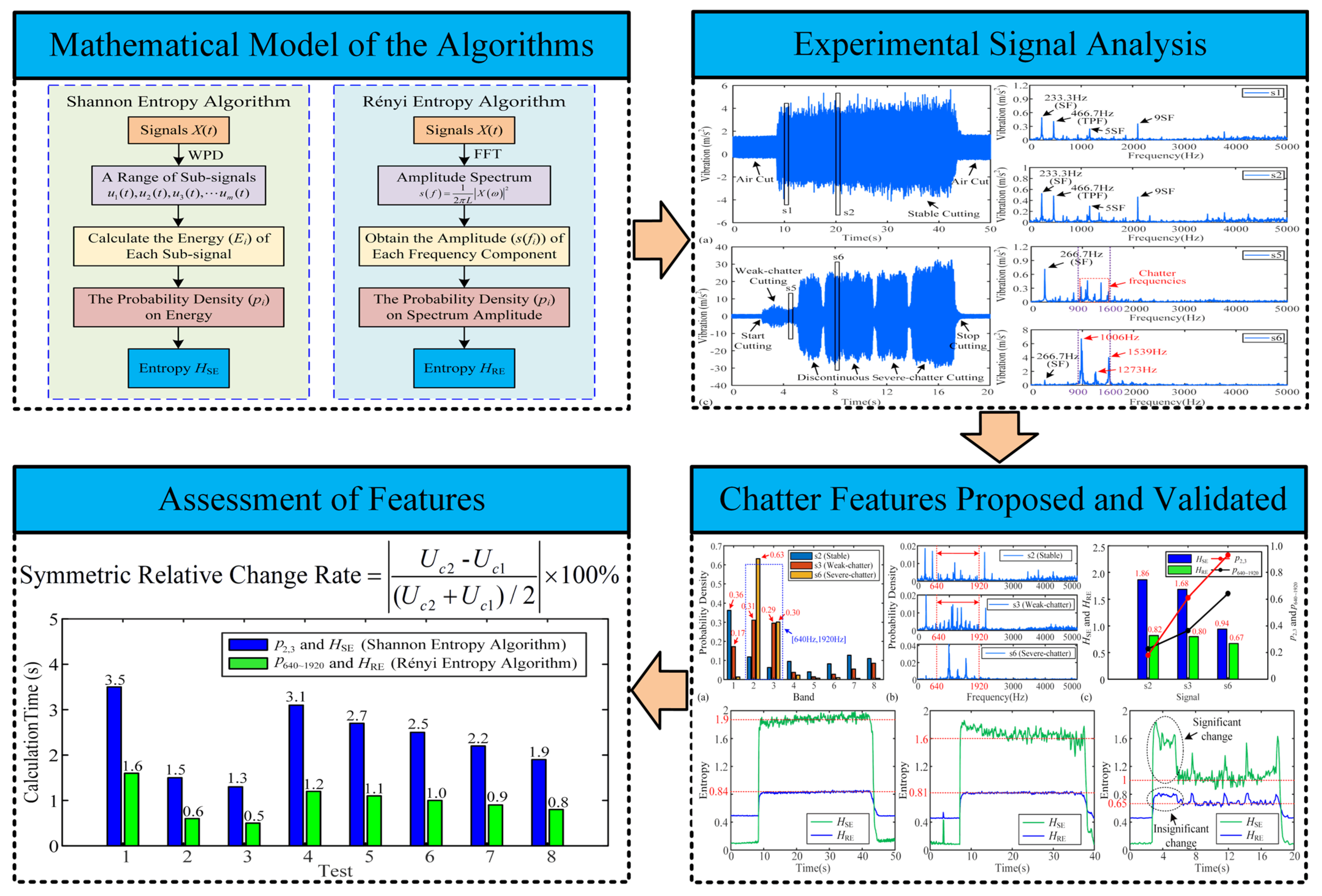

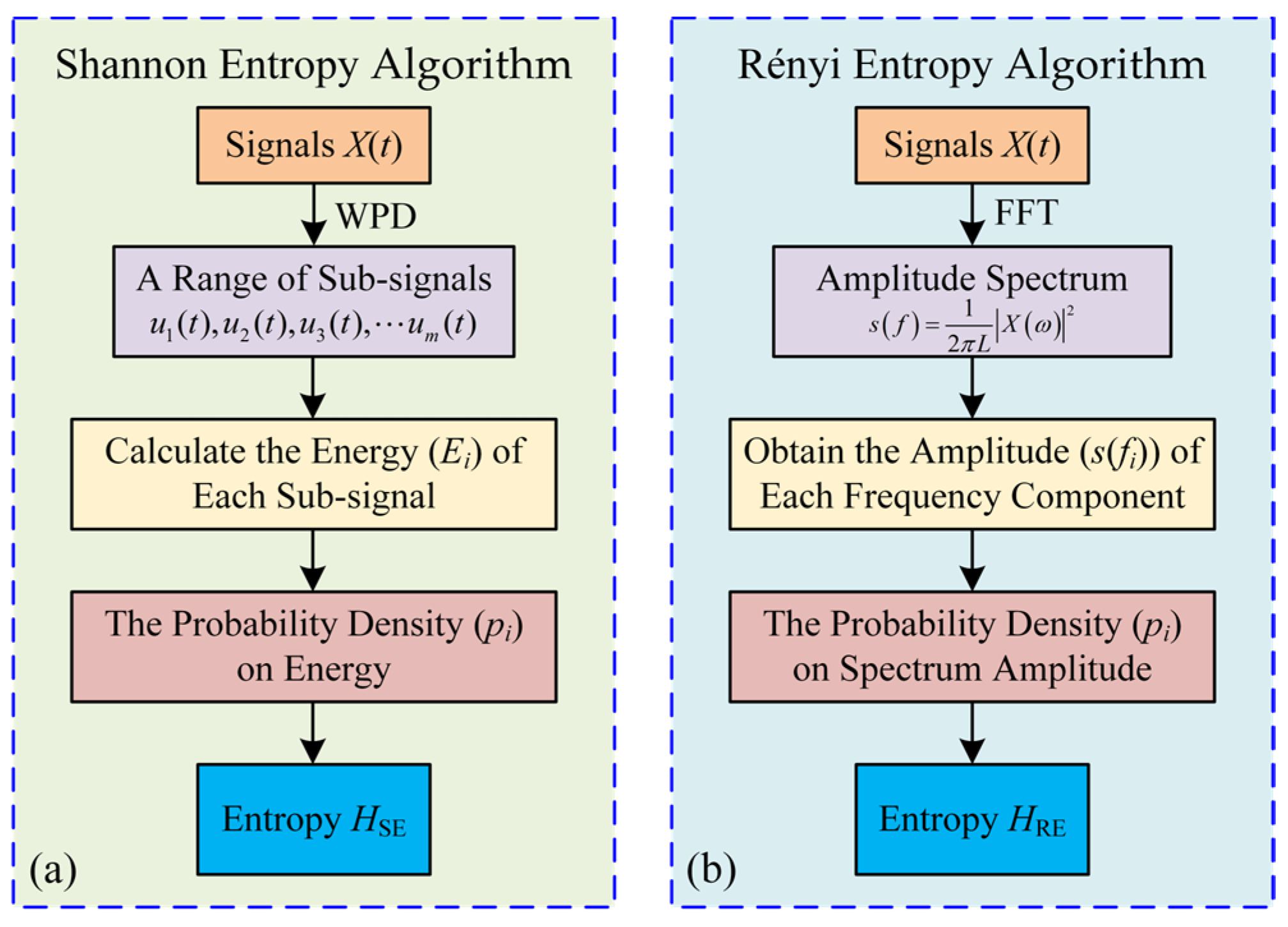

2. Feature Extraction Using Shannon Entropy and Rényi Entropy

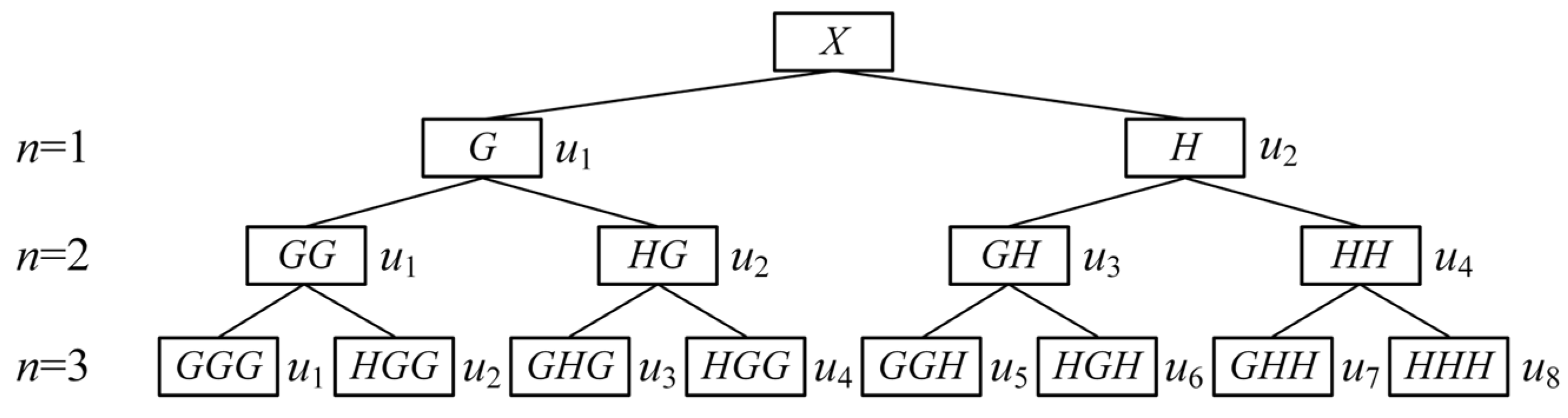

2.1. Mathematical Model of Shannon Entropy

2.2. Mathematical Model of Rényi Entropy

3. Experimental Assessment and Discussion

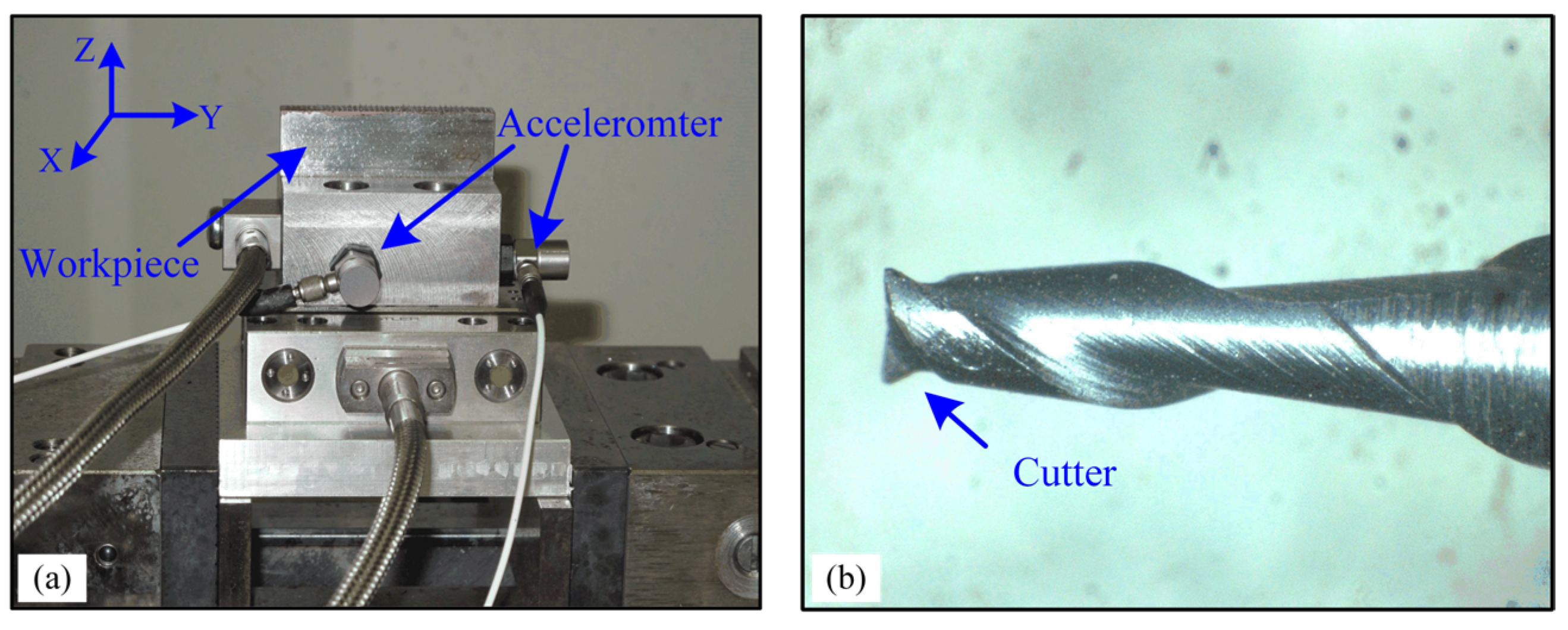

3.1. Experimental Setup

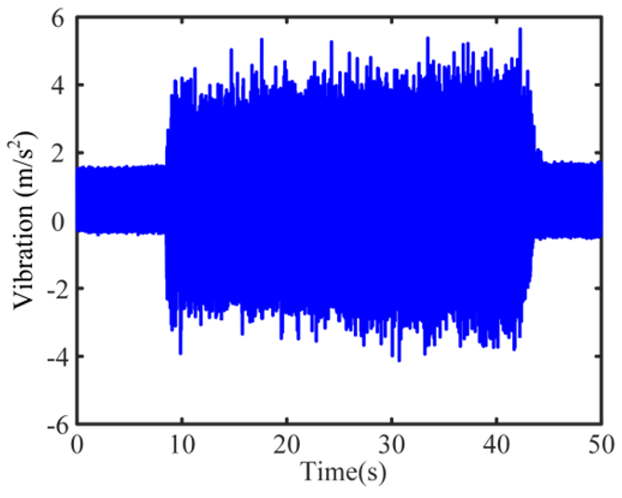

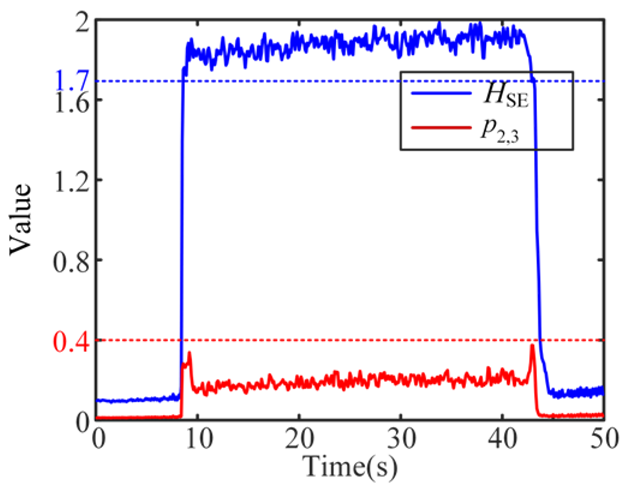

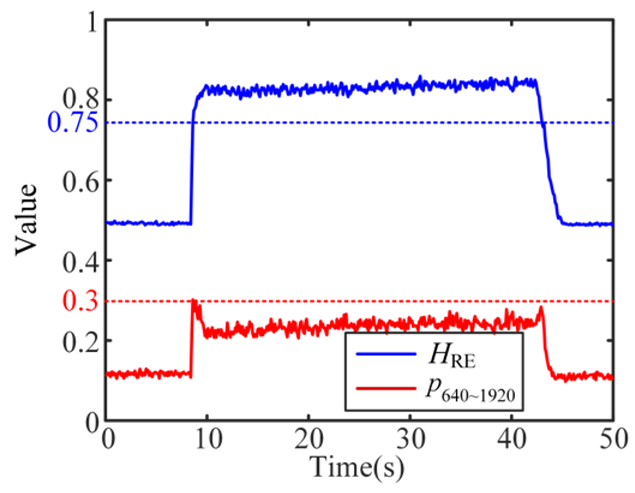

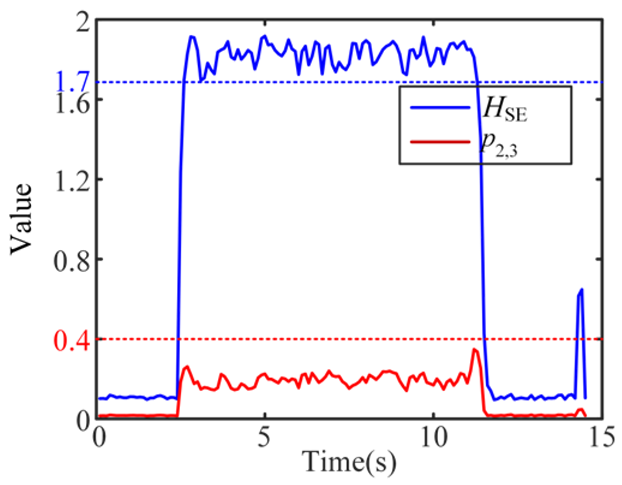

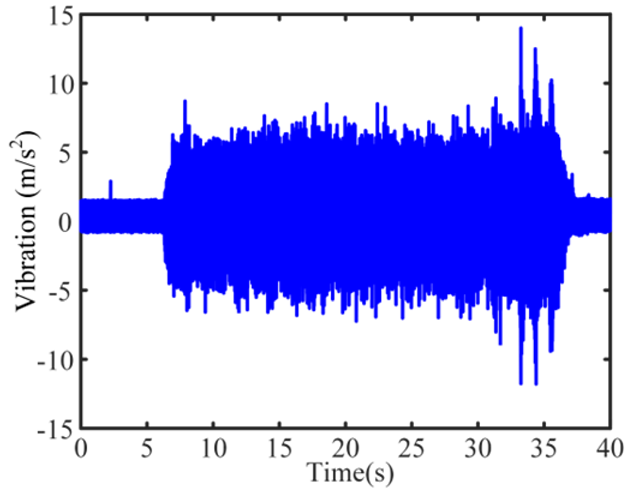

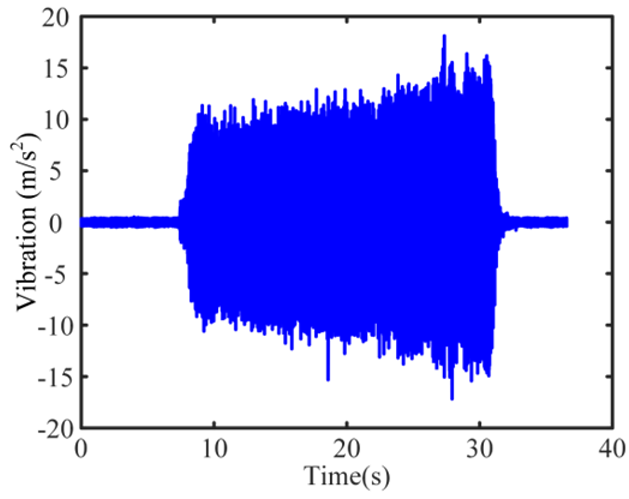

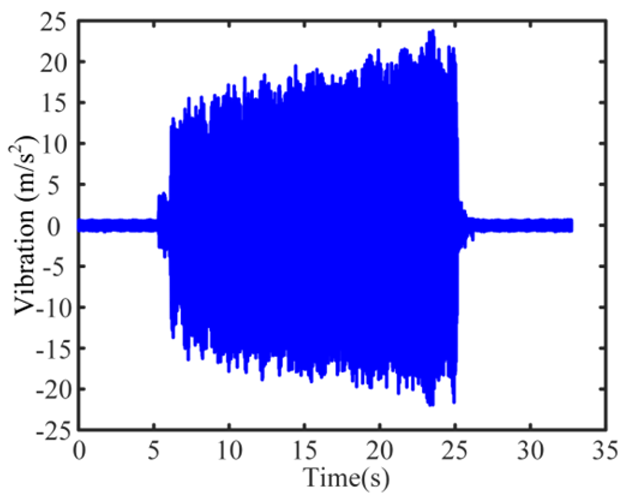

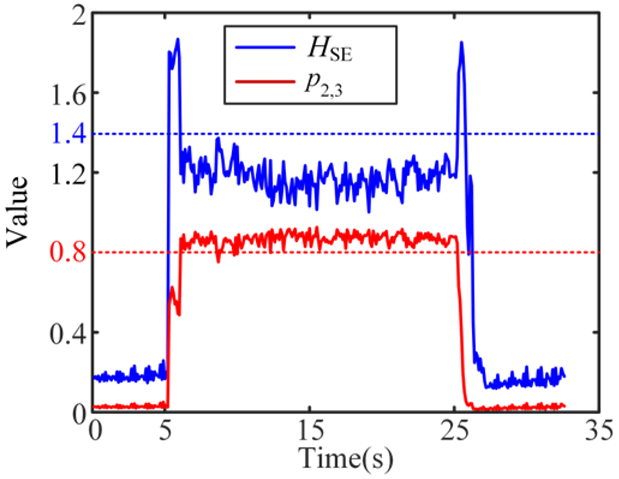

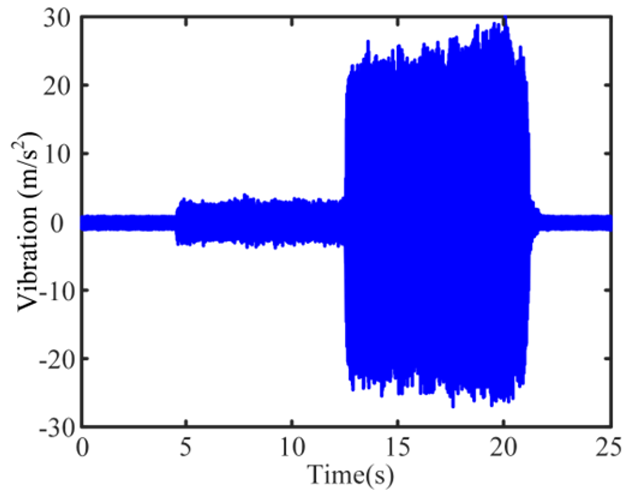

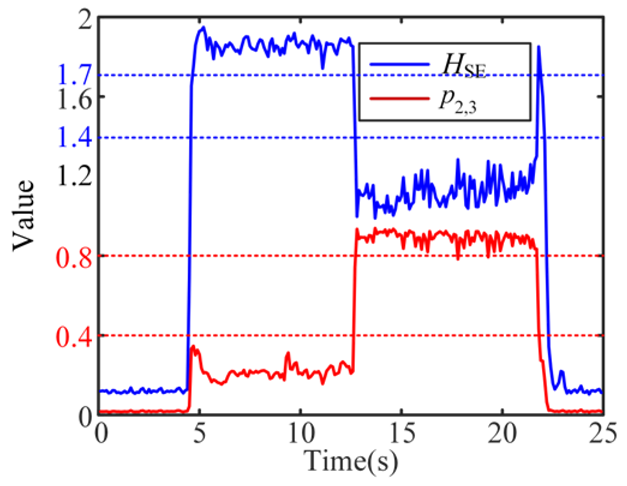

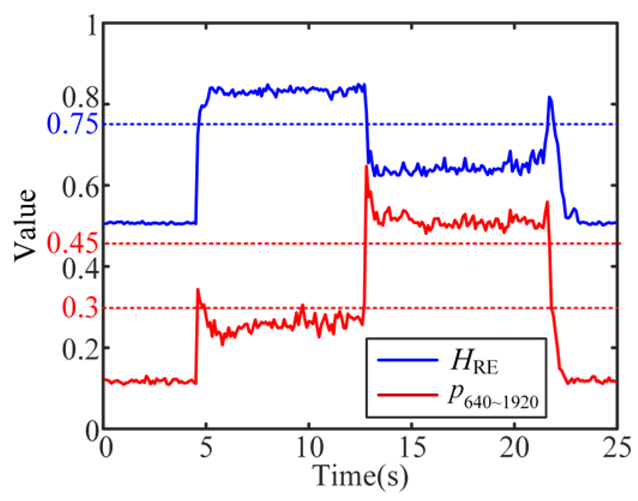

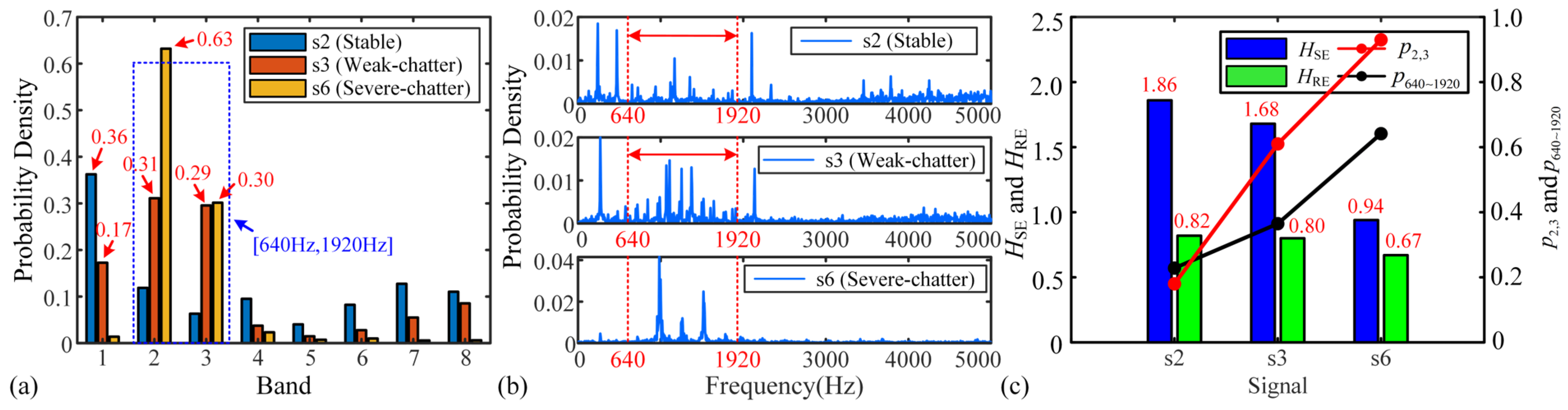

3.2. TD and FD Analysis of Experimental Tests

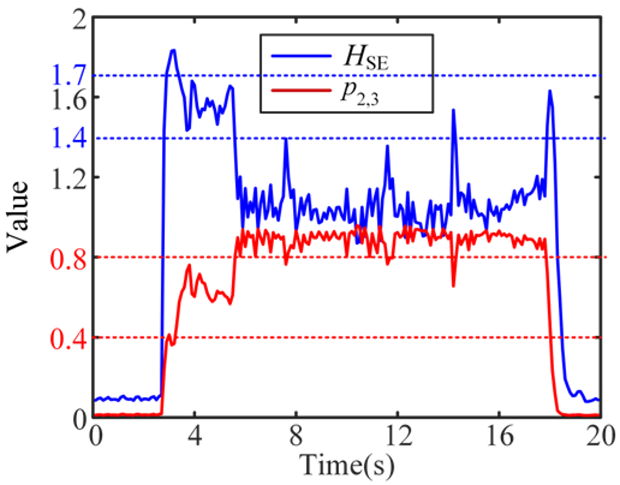

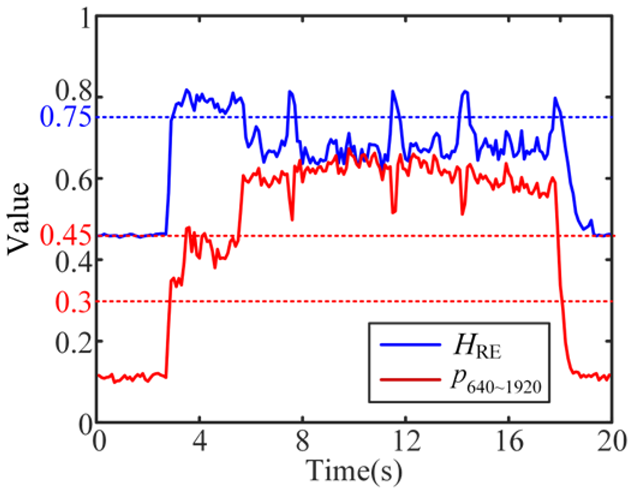

3.3. Assessment of Proposed Features from Shannon Entropy and Rényi Entropy

4. Conclusions

- Four features that can be used for real-time chatter detection are extracted from the Shannon entropy and Rényi entropy algorithms and their thresholds are given separately.

- The probability-related feature () extracted from the Shannon entropy algorithm exhibits the highest chatter sensitivity in a variety of situations.

- The results show that probability-related features are more sensitive and have the potential to be applied in chatter detection rather than entropy-related features for the same algorithm.

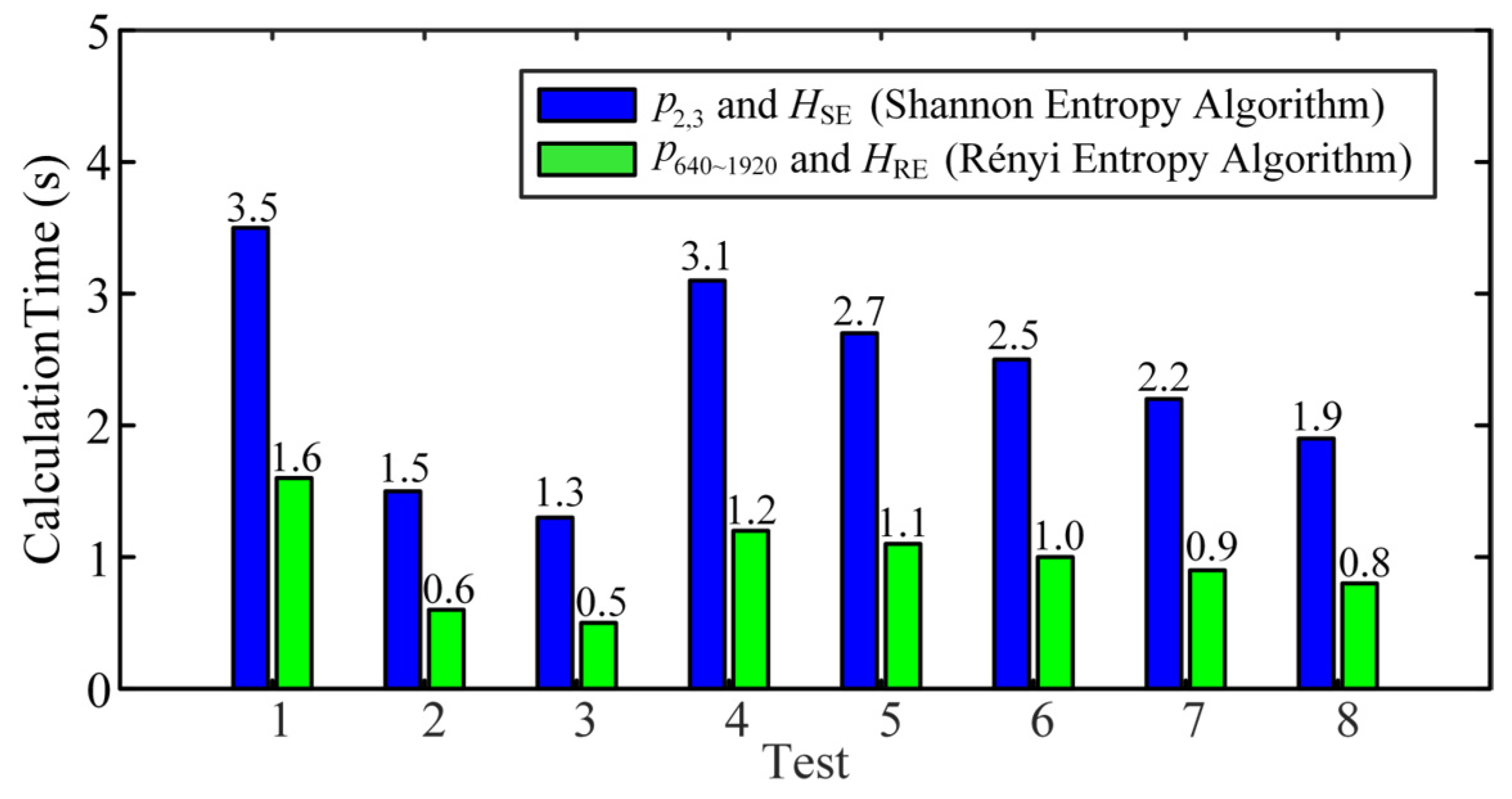

- The features extracted from Shannon entropy algorithm are more sensitive to chatter, while the features extracted from the Rényi entropy algorithm show some applicability to chatter detection with minimum computation time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms | |

| EMD | empirical mode decomposition |

| FD | frequency domain |

| FFT | fast Fourier transform |

| RE | Rényi entropy |

| SE | Shannon entropy |

| SF | spindle frequency |

| SLD | stability lobe diagram |

| TD | time domain |

| TFD | time-frequency domain |

| TPF | tool passing frequency |

| VMD | variational mode decomposition |

| WPD | wavelet packet decomposition |

| WT | wavelet transform |

| Symbols | |

| c1, c2 | the two states before and after the change in machining state |

| E | energy of signal |

| f | frequency component |

| fs | sampling frequency |

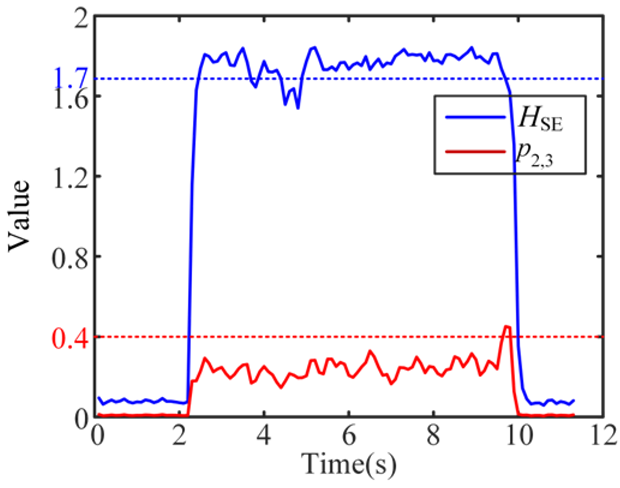

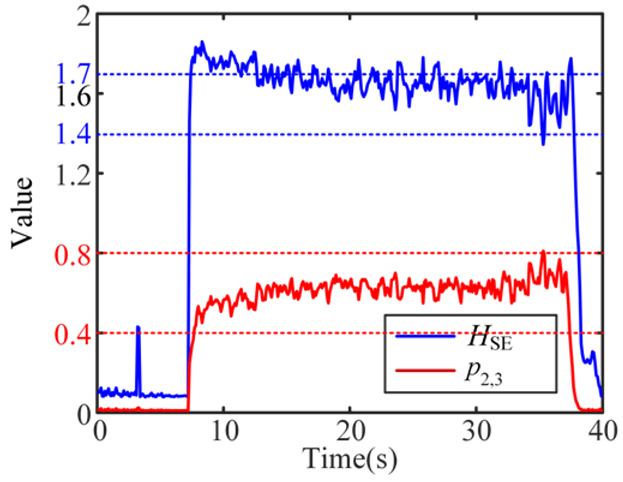

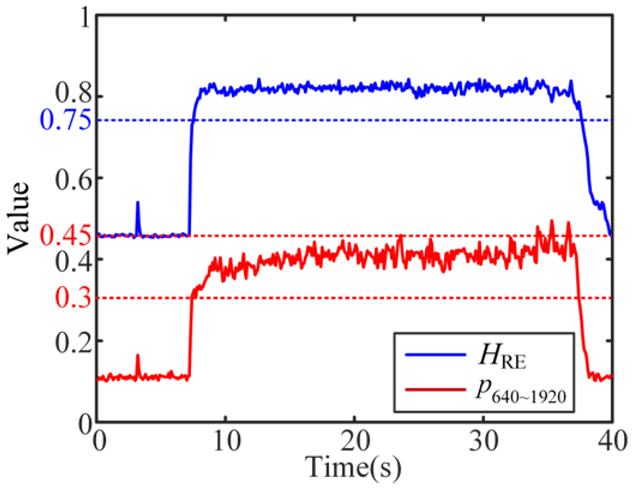

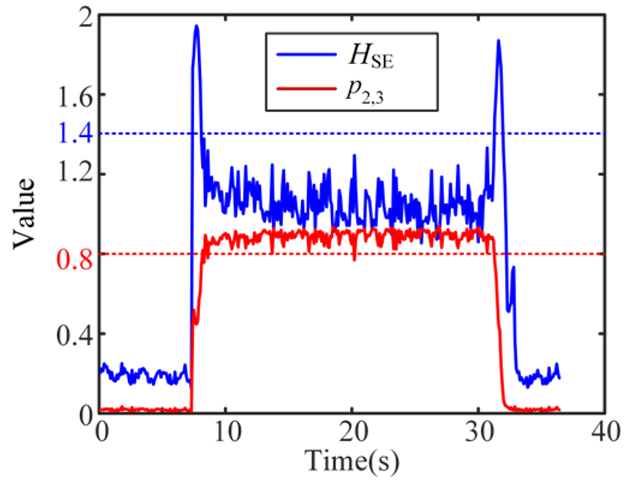

| HSE | Shannon entropy |

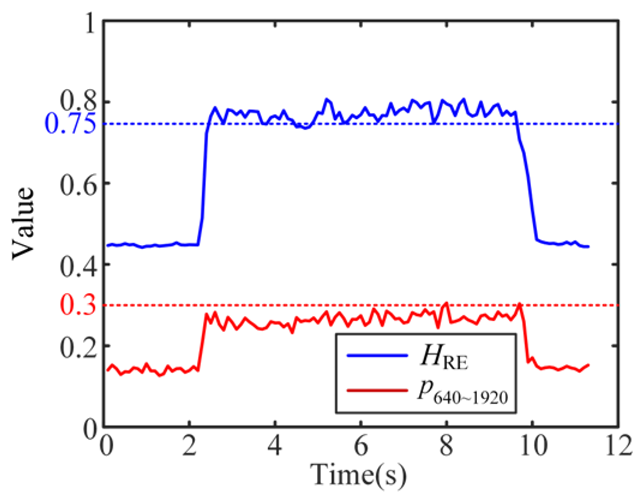

| HRE | Rényi entropy |

| L | length of X(t) |

| n | layer of WPD |

| M | the number of frequency component of the spectrum |

| p | probability |

| p2,3 | the sum of probability densities for bands 2 and 3 |

| p640~1920 | the sum of the probability densities in the frequency intervals [640 Hz, 1920 Hz] |

| s(f) | amplitude of the frequency component f |

| ui(t) | sub-signal of X after WPD |

| U | features |

| X, X(t), s1–s6 | signal |

| X(ω) | Fourier transform of X(t) |

| Y | random variable |

Appendix A

| Test and Containing State | Time Domain of Signals | Features of Shannon Entropy Algorithm | Features of Rényi Entropy Algorithm |

| 1 Stable |  |  |  |

| 2 Stable |  |  |  |

| 3 Stable |  |  |  |

| 4 Weak-chatter |  |  |  |

| 5 Severe-chatter |  |  |  |

| 6 Severe-chatter |  |  |  |

| 7 Stable and Severe-chatter |  |  |  |

| 8 Weak-chatter and Severe-chatter |  |  |  |

References

- Chen, N.; Li, H.N.; Wu, J.; Li, Z. Advances in micro milling: From tool fabrication to process outcomes. Int. J. Mach. Tools Manuf. 2021, 160, 103670. [Google Scholar] [CrossRef]

- Balazs, B.Z.; Geier, N.; Takacs, M.; Davim, J.P. A review on micro-milling: Recent advances and future trends. Int. J. Adv. Manuf. Technol. 2021, 112, 655–684. [Google Scholar] [CrossRef]

- Zhang, X.; Ehmann, K.F.; Yu, T.; Wang, W. Cutting forces in micro-end-milling processes. Int. J. Mach. Tools Manuf. 2016, 107, 21–40. [Google Scholar] [CrossRef]

- Shekhar, S.; Bediz, B.; Ozdoganlar, O.B. Tool-tip dynamics in micromachining with arbitrary tool geometries and the effect of spindle speed. Int. J. Mach. Tools Manuf. 2023, 185, 103981. [Google Scholar] [CrossRef]

- Shekhar, S.; Nahata, S.; Ozdoganlar, O.B. The effect of spindle dynamics on tool-tip radial throw in micromachining. J. Manuf. Process. 2020, 56, 1397–1403. [Google Scholar] [CrossRef]

- Özşahin, O.; Budak, E.; Özgüven, H.N. In-process tool point FRF identification under operational conditions using inverse stability solution. Int. J. Mach. Tools Manuf. 2015, 89, 64–73. [Google Scholar] [CrossRef]

- Ding, P.; Huang, X.; Miao, X.; Li, S.; Liu, H. Dynamic stability simulation of micro-milling under the condition of multi-parameter uncertainty. Probabilistic Eng. Mech. 2023, 74, 103499. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Matuszak, M.; Powałka, B.; Madajewski, M.; Maruda, R.W.; Królczyk, G.M. Prediction of cutting forces during micro end milling considering chip thickness accumulation. Int. J. Mach. Tools Manuf. 2019, 147, 103466. [Google Scholar] [CrossRef]

- Wang, P.; Bai, Q.; Cheng, K.; Zhao, L.; Ding, H. The Modelling and Analysis of Micro-Milling Forces for Fabricating Thin-Walled Micro-Parts Considering Machining Dynamics. Machines 2022, 10, 217. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Mrozek, K. Mechanical and technological aspects of micro ball end milling with various tool inclinations. Int. J. Mech. Sci. 2017, 134, 424–435. [Google Scholar] [CrossRef]

- Yesilli, M.C.; Khasawneh, F.A.; Otto, A. On transfer learning for chatter detection in turning using wavelet packet transform and ensemble empirical mode decomposition. CIRP J. Manuf. Sci. Technol. 2020, 28, 118–135. [Google Scholar] [CrossRef]

- Cao, H.; Zhang, X.; Chen, X. The concept and progress of intelligent spindles: A review. Int. J. Mach. Tools Manuf. 2017, 112, 21–52. [Google Scholar] [CrossRef]

- Postel, M.; Özsahin, O.; Altintas, Y. High speed tooltip FRF predictions of arbitrary tool-holder combinations based on operational spindle identification. Int. J. Mach. Tools Manuf. 2018, 129, 48–60. [Google Scholar] [CrossRef]

- Wang, W.-K.; Wan, M.; Zhang, W.-H.; Yang, Y. Chatter detection methods in the machining processes: A review. J. Manuf. Process. 2022, 77, 240–259. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Souflas, T.; Manitaras, D.; Papaioannou, C.; Bikas, H. Optimization of Milling Processes: Chatter Detection via a Sensor-Integrated Vice. Machines 2023, 11, 52. [Google Scholar] [CrossRef]

- Shao, Y.; Deng, X.; Yuan, Y.; Mechefske, C.K.; Chen, Z. Characteristic recognition of chatter mark vibration in a rolling mill based on the non-dimensional parameters of the vibration signal. J. Mech. Sci. Technol. 2014, 28, 2075–2080. [Google Scholar] [CrossRef]

- Lamraoui, M.; Barakat, M.; Thomas, M.; el Badaoui, M.M. Chatter detection in milling machines by neural network classification and feature selection. J. Vib. Control 2015, 21, 1251–1266. [Google Scholar] [CrossRef]

- Shao, Q.; Feng, C. Pattern recognition of chatter gestation based on Hybrid PCA-SVM. Appl. Mech. Mater. 2011, 120, 190–194. [Google Scholar] [CrossRef]

- Chang, L.; Weiwei, X.; Lei, G. Identification of milling chatter based on a novel frequency-domain search algorithm. Int. J. Adv. Manuf. Technol. 2020, 109, 2393–2407. [Google Scholar] [CrossRef]

- Yang, K.; Wang, G.; Dong, Y.; Zhang, Q.; Sang, L. Early chatter identification based on an optimized variational mode decomposition. Mech. Syst. Signal Process. 2019, 115, 238–254. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, H.; Meng, G.; Tu, X.; Cheng, C. Chatter detection in milling process based on the energy entropy of VMD and WPD. Int. J. Mach. Tools Manuf. 2016, 108, 106–112. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, L.; Ni, C. Chatter detection in milling process based on VMD and energy entropy. Mech. Syst. Signal Process. 2018, 105, 169–182. [Google Scholar] [CrossRef]

- Ji, Y.; Wang, X.; Liu, Z.; Wang, H.; Jiao, L.; Wang, D.; Leng, S. Early milling chatter identification by improved empirical mode decomposition and multi-indicator synthetic evaluation. J. Sound Vib. 2018, 433, 138–159. [Google Scholar] [CrossRef]

- Tao, J.; Qin, C.; Xiao, D.; Shi, H.; Liu, C. A pre-generated matrix-based method for real-time robotic drilling chatter monitoring. Chin. J. Aeronaut. 2019, 32, 2755–2764. [Google Scholar] [CrossRef]

- Rusinek, R.; Lajmert, P. Chatter Detection in Milling of Carbon Fiber-Reinforced Composites by Improved Hilbert–Huang Transform and Recurrence Quantification Analysis. Materials 2020, 13, 4105. [Google Scholar] [CrossRef]

- Rajesh, V.G.; Narayanan Namboothiri, V.N. Utilizing recurrence quantification analysis for chatter detection in turning. In Proceedings of the ASME 2010 International Manufacturing Science and Engineering Conference, Erie, PA, USA, 12–15 October 2020; Volume 2, pp. 149–156. [Google Scholar]

- Elias, J.; Narayanan Namboothiri, V.N. Cross-recurrence plot quantification analysis of input and output signals for the detection of chatter in turning. Nonlinear Dyn. 2014, 76, 255–261. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H.Z.; Hou, L.; Bu, X.J.; Ye, S.G.; Chen, D. Chatter detection for milling using novel p-leader multifractal features. J. Intell. Manuf. 2022, 33, 121–135. [Google Scholar] [CrossRef]

- Jing, X.; Zheng, Z.; Xu, J.; Wang, F.; Jaffery, S.H.I.; Li, H. Stability analysis in micro milling based on p-leader multifractal method. J. Manuf. Process. 2022, 77, 495–507. [Google Scholar] [CrossRef]

- Ji, Y.; Wang, X.; Liu, Z.; Yan, Z.; Jiao, L.; Wang, D.; Wang, J. EEMD-based online milling chatter detection by fractal dimension and power spectral entropy. Int. J. Adv. Manuf. Technol. 2017, 92, 1185–1200. [Google Scholar] [CrossRef]

- Li, K.; He, S.; Li, B.; Liu, H.; Mao, X.; Shi, C. A novel online chatter detection method in milling process based on multiscale entropy and gradient tree boosting. Mech. Syst. Signal Process. 2020, 135, 106385. [Google Scholar] [CrossRef]

- Zheng, Z.; Jing, X.; Wang, Y.; Song, X.; Li, H. A Comparison of Wavelet Packet, Wavelet Leaders Multifractal, and p-Leader Multifractal Method in Chatter Detection. Nanomanuf. Metrol. 2023, 6, 10. [Google Scholar] [CrossRef]

- Rahimi, M.H.; Huynh, H.N.; Altintas, Y. On-line chatter detection in milling with hybrid machine learning and physics-based model. CIRP J. Manuf. Sci. Technol. 2021, 35, 25–40. [Google Scholar] [CrossRef]

- Cao, H.; Lei, Y.; He, Z. Chatter identification in end milling process using wavelet packets and Hilbert–Huang transform. Int. J. Mach. Tools Manuf. 2013, 69, 11–19. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, D.; Lu, Y.; Kong, L.; Ma, Z. Online chatter detection in milling process based on fast iterative VMD and energy ratio difference. Measurement 2022, 194, 111060. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Niu, J.; Zhu, L. Chatter detection in milling processes using frequency-domain Rényi entropy. Int. J. Adv. Manuf. Technol. 2020, 106, 877–890. [Google Scholar] [CrossRef]

- Matthew, D.E.; Cao, H.; Shi, J. Advancing chatter detection: Harnessing the strength of wavelet synchrosqueezing transform and Hilbert-Huang transform techniques. J. Manuf. Process. 2024, 127, 613–630. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, C.; Ju, C.; Guo, M. Vibration recognition for peripheral milling thin-walled workpieces using sample entropy and energy entropy. Int. J. Adv. Manuf. Technol. 2020, 108, 3251–3266. [Google Scholar] [CrossRef]

- Hao, Y.; Zhu, L.; Yan, B.; Qin, S.; Cui, D.; Lu, H. Milling chatter detection with WPD and power entropy for Ti-6Al-4V thin-walled parts based on multi-source signals fusion. Mech. Syst. Signal Process. 2022, 177, 109225. [Google Scholar] [CrossRef]

- Shannon, C.E. A mathematical theory of communication. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Zhuo, R.; Deng, Z.; Li, Y.; Liu, T. An online chatter detection and recognition method for camshaft non-circular contour high-speed grinding based on improved LMD and GAPSO-ABC-SVM. Mech. Syst. Signal Process. 2024, 216, 111487. [Google Scholar] [CrossRef]

- Rényi, A. On Measures of Entropy and Information. In Proceedings of the Fourth Berkeley Symposium on Mathematical Statistics and Probability, Volume 1: Contributions to the Theory of Statistics; University of California Press: Berkeley, CA, USA, 1961; pp. 547–561. [Google Scholar]

- Wei, L.; Wang, D.; Wang, Y. Generalized relative entropy: New look at Rényi entropy and its exploration from complexity measures to sparsity measures with applications in machine condition monitoring. Mech. Syst. Signal Process. 2025, 223, 111917. [Google Scholar] [CrossRef]

- Florindo, J.B. Renyi entropy analysis of a deep convolutional representation for texture recognition. Appl. Soft Comput. 2023, 149, 110974. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, D.; Hong, D.; Lu, Y.; Wu, Q.; Zan, S.; Liao, Z. Improving generalisation and accuracy of on-line milling chatter detection via a novel hybrid deep convolutional neural network. Mech. Syst. Signal Process. 2023, 193, 110241. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, M.; Tang, X.; Peng, F.; Yan, R. A kMap optimized VMD-SVM model for milling chatter detection with an industrial robot. J. Intell. Manuf. 2022, 33, 1483–1502. [Google Scholar] [CrossRef]

- Tran, M.-Q.; Liu, M.-K.; Elsisi, M. Effective multi-sensor data fusion for chatter detection in milling process. ISA Trans. 2022, 125, 514–527. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Huang, X.; Zhao, J.; Wang, X.; Ma, M. An intelligent chatter detection method for high-speed milling under variable tool-workpiece systems and cutting parameters. Mech. Syst. Signal Process. 2025, 224, 111960. [Google Scholar] [CrossRef]

- Bai, Q.; Wang, P.; Cheng, K.; Zhao, L.; Zhang, Y. Machining dynamics and chatters in micro-milling: A critical review on the state-of-the-art and future perspectives. Chin. J. Aeronaut. 2024, 37, 59–80. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, P.; Wang, Z. Real-time fault diagnosis method of battery system based on shannon entropy. Energy Procedia 2017, 105, 2354–2359. [Google Scholar] [CrossRef]

- Bai, H.; Zhao, Y.; Shen, W. Radar radiation source identification based on the Rényi entropy feature of time-frequency distribution. J. Circuits Syst. 2013, 18, 437–442. [Google Scholar]

- Kim, C.-J.; Mayor, J.R.; Ni, J. A static model of chip formation in microscale milling. J. Manuf. Sci. Eng. 2005, 126, 710–718. [Google Scholar] [CrossRef]

- Filiz, S.; Conley, C.M.; Wasserman, M.B.; Ozdoganlar, O.B. An experimental investigation of micro-machinability of copper 101 using tungsten carbide micro-endmills. Int. J. Mach. Tools Manuf. 2007, 47, 1088–1100. [Google Scholar] [CrossRef]

| Test | Depth of Cut (μm) | Feed Per Tooth (μm/Tooth) | Spindle Speed (rpm) |

|---|---|---|---|

| 1 | 50 | 0.5 | 14,000 |

| 2 | 50 | 2.0 | 14,000 |

| 3 | 50 | 2.0 | 16,000 |

| 4 | 50 | 0.5 | 16,000 |

| 5 | 50 | 1.0 | 10,000 |

| 6 | 50 | 1.0 | 12,000 |

| 7 | 50 | 1.0 | 14,000 |

| 8 | 50 | 1.0 | 16,000 |

| Direction | Natural Frequency (Hz) | |

|---|---|---|

| Tool-spindle | X, Y | 1344, 1920, 2896, 4768 |

| SE and RE | HSE | HRE | |||

|---|---|---|---|---|---|

| Cutting States and Change Rates | |||||

| Cutting states | Stable | 0.2 | 0.23 | 1.9 | 0.84 |

| Weak-chatter | 0.6 | 0.4 | 1.6 | - | |

| Severe-chatter | 0.9 | 0.6 | 1.0 | 0.65 | |

| Change rates for probability distribution and entropy (%) | Stable to weak-chatter | 100 | 53.97 | 17.14 | - |

| Weak-chatter to severe-chatter | 40 | 40 | 46.15 | - | |

| Stable to severe-chatter | 127.27 | 89.16 | 62.07 | 25.5 | |

| HSE | HRE | |||

|---|---|---|---|---|

| Stable | <0.4 | <0.3 | >1.7 | >0.75 |

| Weak-chatter | 0.4~0.8 | 0.3~0.45 | 1.4~1.7 | - |

| Severe-chatter | >0.8 | >0.45 | <1.4 | <0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; Jing, X.; Song, B.; Song, X.; Chen, Y.; Li, H. Extraction and Assessment of Features Using Shannon Entropy and Rényi Entropy for Chatter Detection in Micro Milling. Micromachines 2025, 16, 161. https://doi.org/10.3390/mi16020161

Zheng Z, Jing X, Song B, Song X, Chen Y, Li H. Extraction and Assessment of Features Using Shannon Entropy and Rényi Entropy for Chatter Detection in Micro Milling. Micromachines. 2025; 16(2):161. https://doi.org/10.3390/mi16020161

Chicago/Turabian StyleZheng, Zehui, Xiubing Jing, Bowen Song, Xiaofei Song, Yun Chen, and Huaizhong Li. 2025. "Extraction and Assessment of Features Using Shannon Entropy and Rényi Entropy for Chatter Detection in Micro Milling" Micromachines 16, no. 2: 161. https://doi.org/10.3390/mi16020161

APA StyleZheng, Z., Jing, X., Song, B., Song, X., Chen, Y., & Li, H. (2025). Extraction and Assessment of Features Using Shannon Entropy and Rényi Entropy for Chatter Detection in Micro Milling. Micromachines, 16(2), 161. https://doi.org/10.3390/mi16020161