Research Progress of Additively Manufactured Metallic Lattice Structures

Abstract

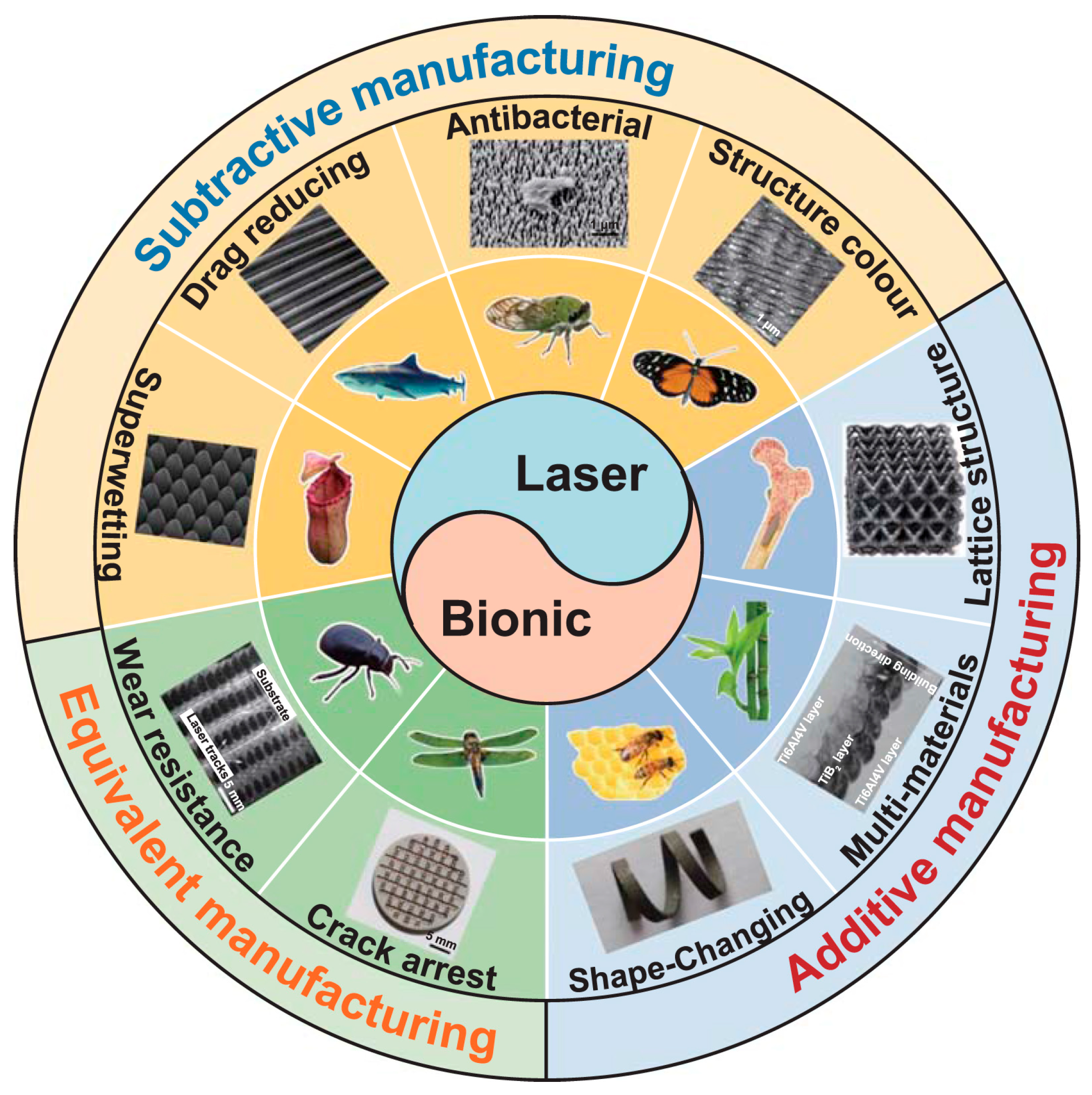

1. Introduction

2. Design of Metallic Lattice Structure for Additive Manufacturing

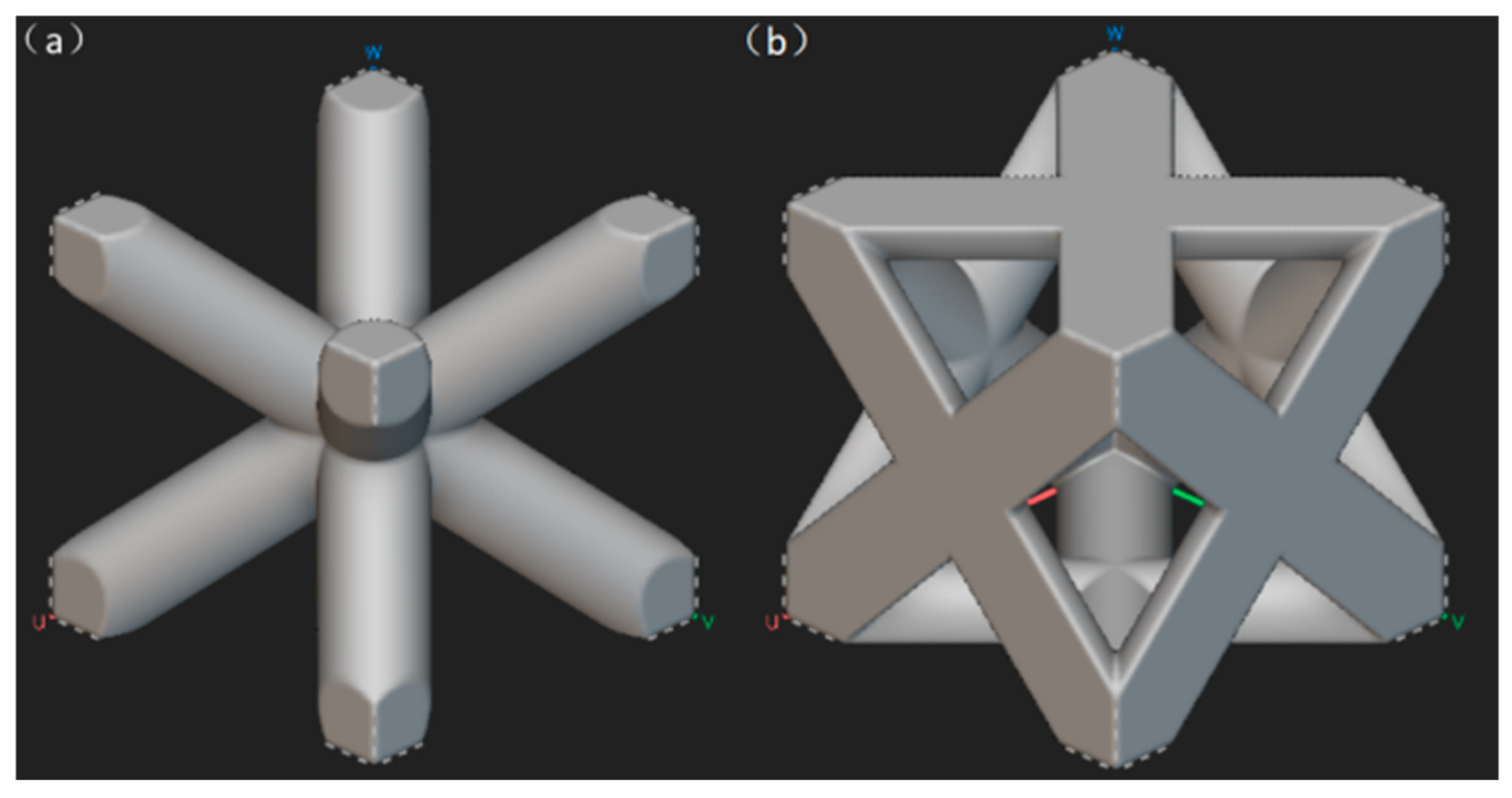

2.1. Design of Truss Lattice Structure

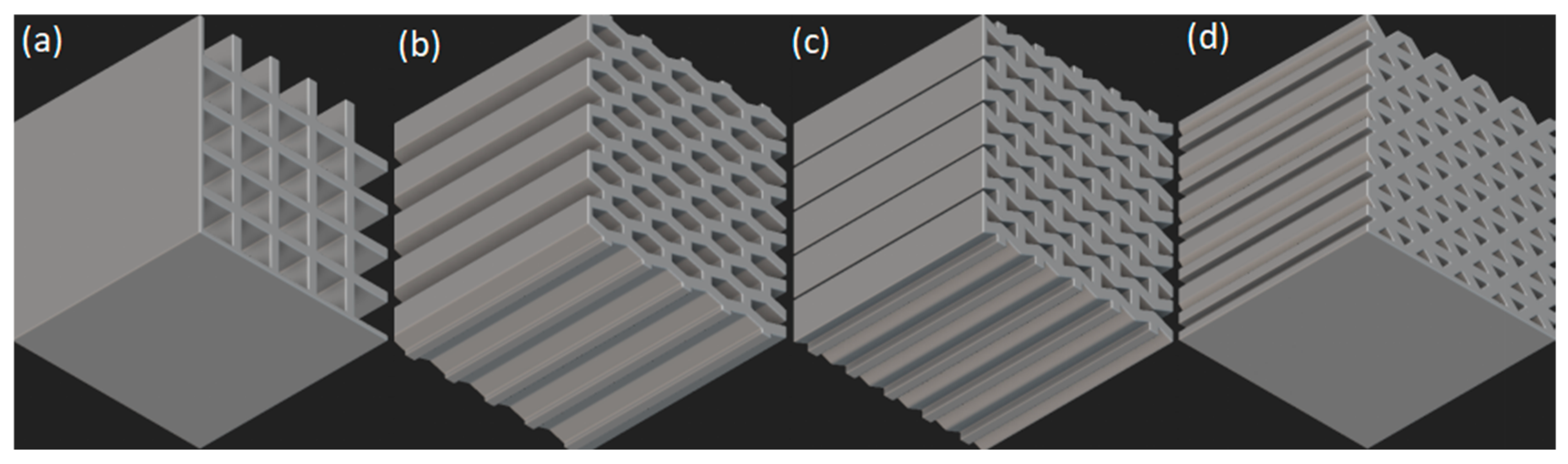

2.2. Design of Honeycomb Lattice Structure

2.3. Design of Surface Lattice Structure

2.4. Design of Biomimetic Lattice Structure

2.5. Design of Gradient Lattice Structure

2.6. Summary of the Advantages and Disadvantages of Different Types of Lattice Structures

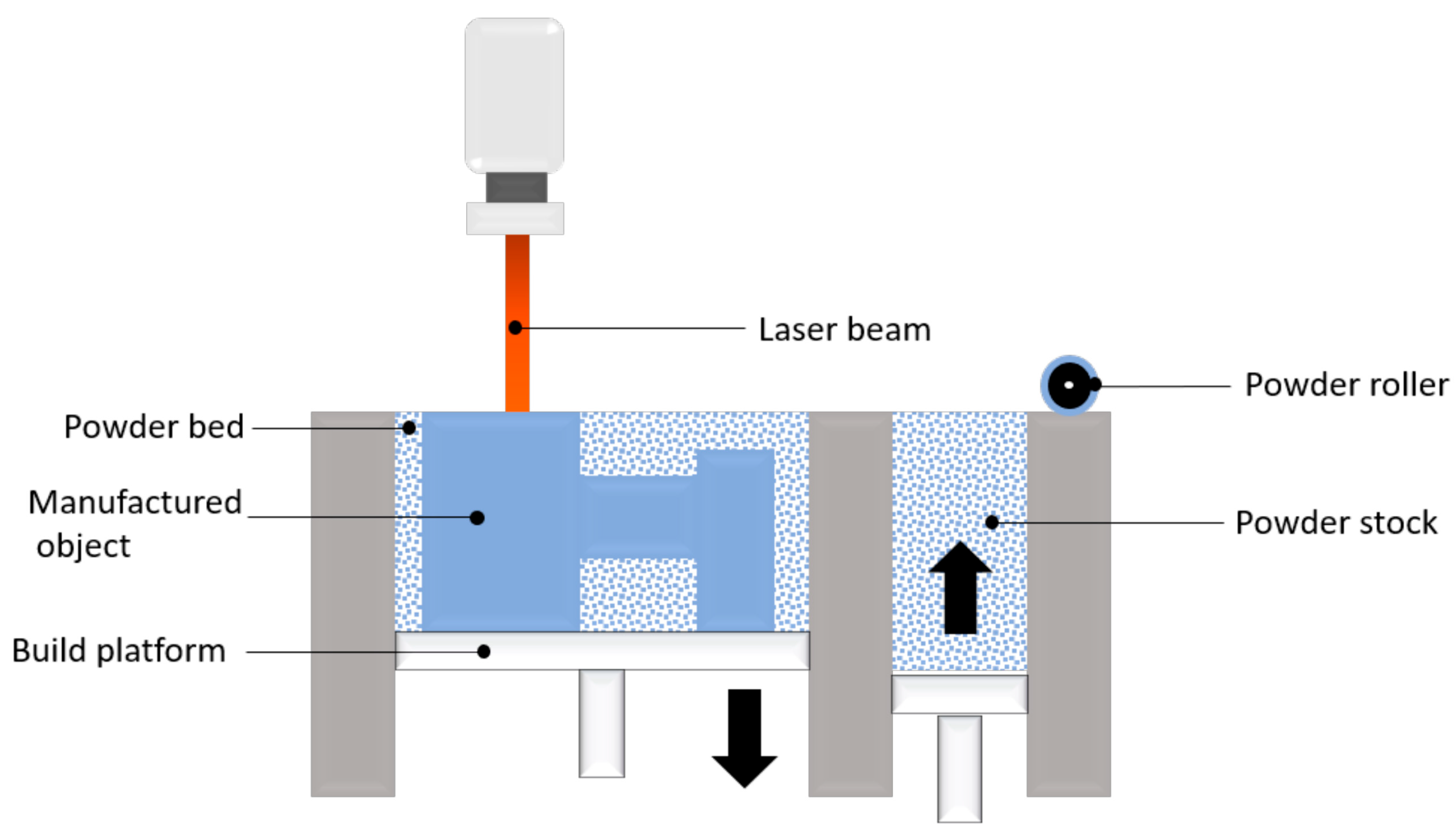

3. Metallic Lattice Structure Additive Manufacturing Process

3.1. Powder Bed Fusion (PBF) Process

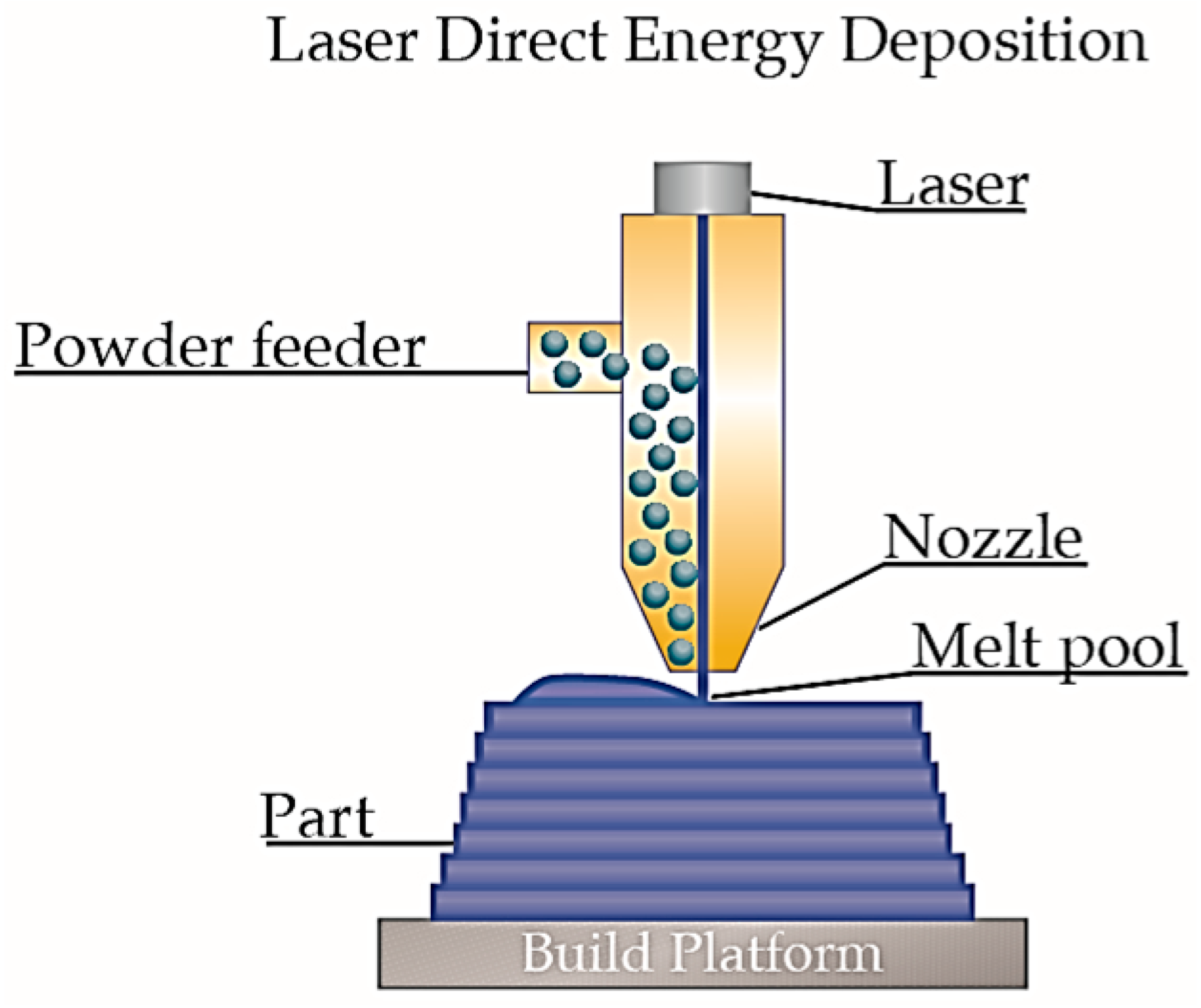

3.2. Direct Energy Deposition (DED) Process

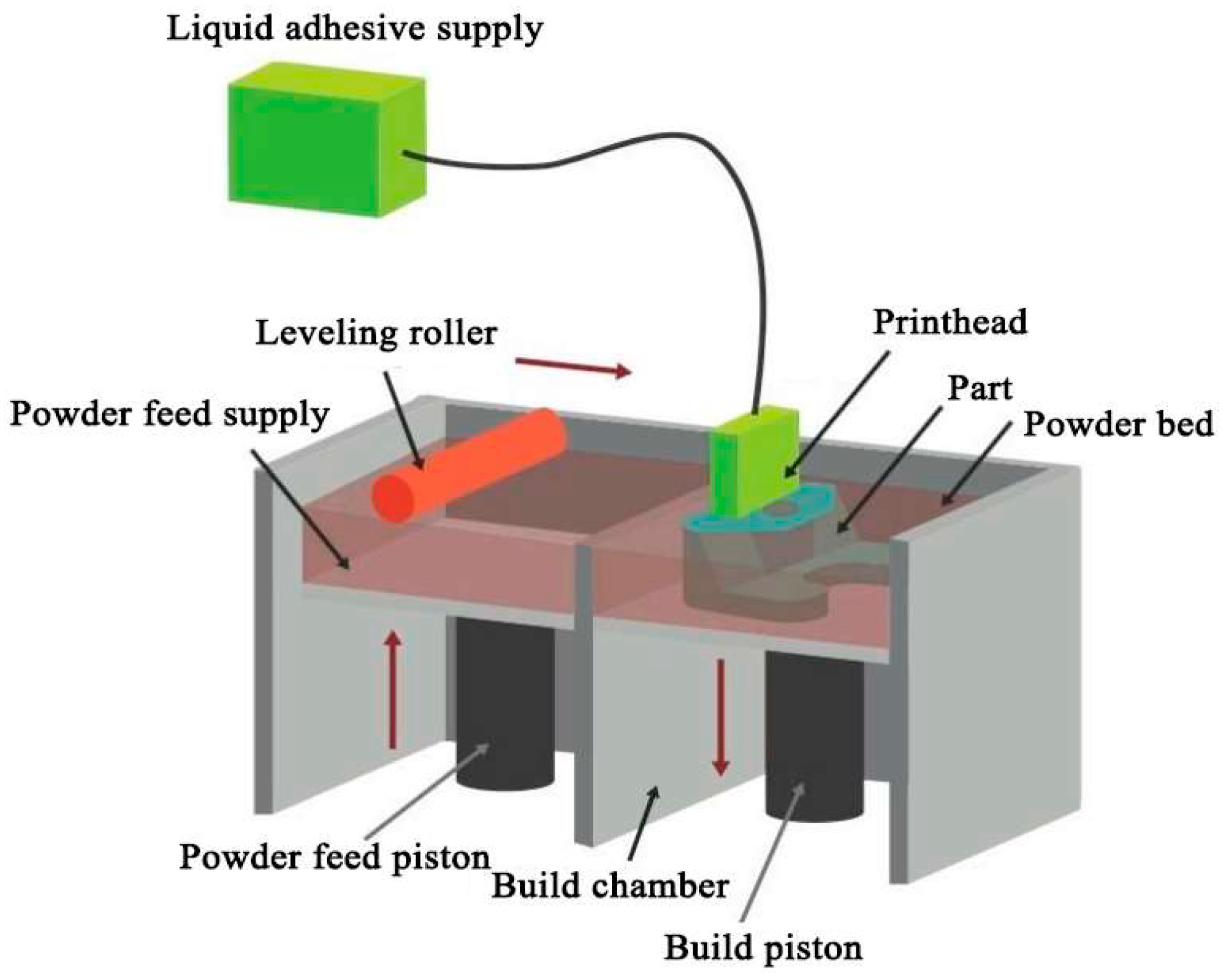

3.3. Binder Jetting (BJ) Process

3.4. Wire Arc Additive Manufacturing (WAAM) Process

3.5. Comparison of the Advantages and Disadvantages of Four Additive Manufacturing (AM) Processes

4. Performance and Application of Metallic Lattice Structure in Additive Manufacturing

4.1. Mechanical Properties

4.2. Energy Absorption Performance

4.3. Thermal Properties

4.4. Biocompatibility

5. Summary

5.1. Summary of Research Status

5.2. Development Trend Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gao, Z.; Liu, Y.X.; Zhu, M.L.; Xuan, F.Z. Research Progress on Design, Manufacturing and Fatigue Properties of Lattice Structures. J. Mech. Eng. 2025, 61, 347–375. [Google Scholar]

- Vyatskikh, A.; Delalande, S.; Kudo, A.; Zhang, X.; Portela, C.M.; Greer, J.R. Additive manufacturing of 3D nano-architected metals. Nat. Commun. 2018, 9, 593. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, T.; Wen, T. Processes in the study on enhanced mechanical properties of high-performance lightweight lattice metallic materials. Adv. Mech. 2010, 40, 157–169. [Google Scholar]

- Gu, D.; Zhang, H.; Chen, H.; Zhang, H.; Xi, L. Laser Additive Manufacturing of High-Performance Metallic Aerospace Components. Chin. J. Lasers 2020, 47, 0500002. (In Chinese) [Google Scholar] [CrossRef]

- Han, Y.; Jiang, W.; Wang, J.; Gong, S.; Li, Y.; Zheng, L.; Zhang, J.; Zhang, A.; Qu, S. Multi-functional sandwich structure with metamaterial antenna lattice cores: Protection, radiation and absorption. IET Microw. Antennas Propag. 2020, 14, 593–599. [Google Scholar] [CrossRef]

- Lei, H.S.; Zhao, Z.A.; Guo, X.G. Research Progress on the Design and Manufacture Technology of Lightweight Multifunctional Spacecraft Structures. Aerosp. Mater. Technol. 2021, 51, 10–22. [Google Scholar]

- Xu, T.; Jing, C.; Mao, H.; Li, K.; Han, X.; Lu, T.; Ma, S.; Liu, C. Research Progress of Metal Lattice Structure Based on Wire ArcAdditive Manufacturing. Electr. Weld. Mach. 2023, 53, 76–86. [Google Scholar] [CrossRef]

- Feng, J.; Fu, J.; Yao, X.; He, Y. Triply periodic minimal surface (TPMS) porous structures: From multi-scale design, precise additive manufacturing to multidisciplinary applications. Int. J. Extrem. Manuf. 2022, 4, 022001. [Google Scholar] [CrossRef]

- Ming, X.; Tang, J.; Dang, Y.; Tang, Y.; Tan, H. Technology development direction and industrialization suggestions of metal 3D printing in aerospace field. MW Met. Form. 2025, 8, 140–148. [Google Scholar]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xiong, J. Integrated design of novel composite plate-truss hybrid lattice structures for superior energy absorption. Int. J. Solids Struct. 2025, 318, 113447. [Google Scholar] [CrossRef]

- Feng, J.; Liu, B.; Lin, Z.; Fu, J. Isotropic octet-truss lattice structure design and anisotropy control strategies for implant application. Mater. Des. 2021, 203, 109595. [Google Scholar] [CrossRef]

- Jin, Q.Y.; Yu, J.H.; Ha, K.S.; Lee, W.J.; Park, S.H. Multi-dimensional lattices design for ultrahigh specific strength metallic structure in additive manufacturing. Mater. Des. 2021, 201, 109479. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, F.; Li, P.; Bian, Y.; Zhao, J.; Fan, H. A topologically gradient body centered lattice design with enhanced stiffness and energy absorption properties. Eng. Struct. 2022, 263, 114384. [Google Scholar] [CrossRef]

- Vaissier, B.; Pernot, J.P.; Chougrani, L.; Véron, P. Parametric design of graded truss lattice structures for enhanced thermal dissipation. Comput. Aided Des. 2019, 115, 1–12. [Google Scholar] [CrossRef]

- Challapalli, A.; Li, G. Machine learning assisted design of new lattice core for sandwich structures with superior load carrying capacity. Sci. Rep. 2021, 11, 18552. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Feng, G.; Li, S.; Mu, K.; Qin, Q.; Song, W. Mechanical characterization of additively-manufactured metallic lattice structures with hollow struts under static and dynamic loadings. Int. J. Impact Eng. 2022, 169, 104333. [Google Scholar] [CrossRef]

- Cho, J.; Kim, E.; Kim, J.H.; Lee, C.Y.; Cho, J.Y. Enhancement of Energy Absorption Capability of 3D Printed Ti-6Al-4V BCC Lattice Structures by Adding Auxiliary Struts. Materials 2025, 18, 732. [Google Scholar] [CrossRef] [PubMed]

- Pham, M.S.; Creuziger, A.; Iadicola, M.; Rollett, A.D. Roles of texture and latent hardening on plastic anisotropy of face-centered-cubic materials during multi-axial loading. J. Mech. Phys. Solids 2017, 99, 50–69. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Cang, M.; Ding, J.; Ma, W.; Zhu, X.; Lu, Y.; Song, X.; Cui, H.C.; Wang, M.Y. Metallic perforated plate lattices with superior buckling strength. Mater. Des. 2025, 249, 113544. [Google Scholar] [CrossRef]

- Wei, Y.C.; Huang, C.Y.; Yuan, M.Q. Research on Mechanical Properties and Parameter Optimization of Three Typical Honeycomb Structures under High Strain Rates. Sci. Found. China 2022, 36, 530–535. [Google Scholar]

- Yin, S.; Li, J.; Liu, B.; Meng, K.; Huan, Y.; Nutt, S.R.; Xu, J. Honeytubes: Hollow lattice truss reinforced honeycombs for crushing protection. Compos. Struct. 2017, 160, 1147–1154. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Y.; Wang, L.; Li, J.; Yang, Y.; Tian, Y.; Gong, Z.; Zhang, P.; Nutt, S.; Yin, S. Compressive properties of hollow lattice truss reinforced honeycombs (Honeytubes) by additive manufacturing: Patterning and tube alignment effects. Mater. Des. 2018, 156, 446–457. [Google Scholar] [CrossRef]

- Zou, Z.; Xu, F.; Xu, Z.; Niu, X.; Fang, T. Parametric design and energy absorption of non-uniform classic honeycombs mapped by topology optimization. Mech. Adv. Mater. Struct. 2024, 31, 8501–8515. [Google Scholar] [CrossRef]

- Xing, H.; Jing, S.; Zhang, H.; Zhao, F.; Li, P. A non-uniform honeycomb design method based on topology optimization density mapping. J. Comput.-Aided Des. Comput. Graph. 2017, 29, 734–741. [Google Scholar]

- Feng, X.; Wang, B.; Wu, X.; Wang, X.; Guo, Y. In-plane compression behavior of sinusoidal honeycomb with circular nodes. Chin. J. Theor. Appl. Mech. 2023, 55, 1910–1920. [Google Scholar]

- Ma, R.; Li, M.; Xu, Y.; Meloni, M.; Feng, J.; Cai, J. Geometry design and in-plane compression performance of novel origami honeycomb material. Thin-Walled Struct. 2022, 181, 110111. [Google Scholar] [CrossRef]

- Montazeri, A.; Ahmadian, I.; Bahmanpour, E.; Saeedi, A.; Safarabadi, M. Mechanical behaviors of star honeycombs with symmetry-broken lattices. Eur. J. Mech. A/Solids 2025, 113, 105709. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, X.; Han, Y.; Tian, Y.; Zhang, D.; Yan, L. Failure mechanisms and process defects of 3D-printed continuous carbon fiber-reinforced composite circular honeycomb structures with different stacking directions. Aerosp. Sci. Technol. 2024, 148, 109075. [Google Scholar] [CrossRef]

- Ouyang, S.; Deng, Z.; Hou, X. Stress concentration in octagonal honeycombs due to defects. Compos. Struct. 2018, 204, 814–821. [Google Scholar] [CrossRef]

- Benedetti, M.; Du Plessis, A.; Ritchie, R.O.; Dallago, M.; Razavi, M.; Berto, F. Architected cellular materials: A review on their mechanical properties towards fatigue-tolerant design and fabrication. Mater. Sci. Eng. R Rep. 2021, 144, 100606. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Wang, Z.; Liu, Z.; Li, S. Hybrid Design of Triply Periodic Minimal Surface Structure and Its Mechanical Behavior under Impact Loading. High Press. Phys. 2024, 38, 054102. [Google Scholar]

- Li, Y.; Xia, Q.; Yoon, S.; Lee, C.; Lu, B.; Kim, J. Simple and efficient volume merging method for triply periodic minimal structures. Comput. Phys. Commun. 2021, 264, 107956. [Google Scholar] [CrossRef]

- Wei, Q.; Jiang, L.; Liu, Z.; Zhu, L.; Fan, L.; Wang, G.; Zhao, M.; Guo, Z. Lattice structure and mechanical properties of TPMS prepared by selective laser melting. Acta Aeronaut. Astronaut. Sin. 2025, 46, 430593. [Google Scholar]

- Liu, W.H. Inverse Design of Triply Periodic Minimal Surface Structures Based on Machine Learning. Master’s Thesis, Dalian University of Technology, Dalian, China, 2024. [Google Scholar]

- Sychov, M.M.; Lebedev, L.A.; Dyachenko, S.V.; Nefedova, L.A. Mechanical properties of energy-absorbing structures with triply periodic minimal surface topology. Acta Astronaut. 2018, 150, 81–84. [Google Scholar] [CrossRef]

- Zhao, Y.; Wei, M.; Dan, D.; Zheng, S.; Tian, R.; Meng, S.; Nan, X. Hybrid design of triply periodic minimal surface (TPMS) structures for loop heat pipe wicks to enhance heat and mass transfer. Int. J. Heat Mass Transf. 2025, 242, 126874. [Google Scholar] [CrossRef]

- Gao, T.; Liu, K.; Wang, X.; Li, Z.; Wang, Z. Elastic mechanical property hybridization of configuration-varying TPMS with geometric continuity. Mater. Des. 2022, 221, 110995. [Google Scholar] [CrossRef]

- Wang, Y. Topology Optimization and Compressive Performance Verification of TPMS Gradient Lattice Structure Based on Stress Field Driven. Model. Simul. 2025, 14, 315. [Google Scholar] [CrossRef]

- El Khadiri, I.; Abouelmajd, M.; Zemzami, M.; Hmina, N.; Lagache, M.; AIMangour, B. TPMS Lattice Structure derived using Topology Optimization for the Design of Additive Manufactured Components. In Proceedings of the 8th International Conference on Optimization and Applications (ICOA), Genoa, Italy, 6–7 October 2022; pp. 1–4. [Google Scholar]

- Strömberg, N. A new multi-scale topology optimization framework for optimal combinations of macro-layouts and local gradings of TPMS-based lattice structures. Mech. Based Des. Struct. Mach. 2024, 52, 257–274. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, H.; Sun, H.; Sun, T.; Wu, Y.; Leung, C.; Wang, H. Additively manufactured high-energy-absorption metamaterials with artificially engineered distribution of bio-inspired hierarchical microstructures. Compos. Part B Eng. 2022, 247, 110345. [Google Scholar] [CrossRef]

- Lu, Y.; Zhou, J.; Wang, Q.; Cai, J.; Yu, B.; Dai, Q.; Bao, Y.; Chen, R.; Zhang, D. Glucocorticoid-loaded pH/ROS dual-responsive nanoparticles alleviate joint destruction by downregulating the NF-κB signaling pathway. Acta Biomater. 2023, 164, 458–473. [Google Scholar] [CrossRef]

- Wiese, M.; Thiede, S.; Herrmann, C. Rapid manufacturing of automotive polymer series parts: A systematic review of processes, materials and challenges. Addit. Manuf. 2020, 36, 101582. [Google Scholar] [CrossRef]

- Wu, G.; He, Z.; Wang, Q.; Wang, H.; Wang, Z.; Sun, P.; Mo, Z.; Liu, H.; Hu, H. Non-metal inducing charge rearrangement in carbon nitride to promote photocatalytic hydrogen production. J. Mater. Sci. Technol. 2024, 195, 1–8. [Google Scholar] [CrossRef]

- Kong, X.; Chang, Y.; Zhang, N.; Zhang, M.; Zhang, R.; Ding, X. Numerical investigation on dynamic response of bio-inspired bi-directional corrugated lattice structure under impact loading. Acta Mater. Compos. Sin. 2025, 42, 2282–2301. [Google Scholar] [CrossRef]

- San Ha, N.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar]

- Du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and functional: A review of biomimetic design in additive manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Ahamed, M.K.; Wang, H.; Hazell, P.J. From biology to biomimicry: Using nature to build better structures–A review. Constr. Build. Mater. 2022, 320, 126195. [Google Scholar] [CrossRef]

- Siddique, S.H.; Hazell, P.J.; Wang, H.; Escobedo, J.P.; Ameri, A. Lessons from nature: 3D printed bio-inspired porous structures for impact energy absorption–A review. Addit. Manuf. 2022, 58, 103051. [Google Scholar] [CrossRef]

- Tuninetti, V.; Narayan, S.; Ríos, I.; Menacer, B.; Valle, R.; Al-lehaibi, H.; Kaisan, M.; Samuel, J.; Oñate, A.; Pincheira, A. Biomimetic Lattice Structures Design and Manufacturing for High Stress, Deformation, and Energy Absorption Performance. Biomimetics 2025, 10, 458. [Google Scholar] [CrossRef]

- Li, X.; Zhang, B.; Jakobi, T.; Yu, Z.; Ren, L.; Zhang, Z. Laser-based bionic manufacturing. Int. J. Extrem. Manuf. 2024, 6, 042003. [Google Scholar] [CrossRef]

- Doodi, R.; Gunji, B.M. An experimental and numerical investigation on the performance of novel hybrid bio-inspired 3D printed lattice structures for stiffness and energy absorption applications. Mech. Adv. Mater. Struct. 2024, 31, 3970–3979. [Google Scholar] [CrossRef]

- Doodi, R.; Gunji, B.M. Experimental and numerical investigation on novel three-dimensional printed bio-inspired hexagonal lattices for energy absorption and stiffness behavior. Mech. Based Des. Struct. Mach. 2024, 52, 8727–8743. [Google Scholar] [CrossRef]

- Meng, L.; Shi, J.; Yang, C.; Gao, Y.; Song, L.; Gu, D.; Zhu, J.; Breitkopf, P.; Zhang, W. An emerging class of hyperbolic lattice exhibiting tunable elastic properties and impact absorption through chiral twisting. Extrem. Mech. Lett. 2020, 40, 100869. [Google Scholar] [CrossRef]

- Li, Q.; Zhan, L.; Miao, X.; Hu, L.; Li, E.; Zou, T. Morning glory-inspired lattice structure with negative Poisson’s ratio effect. Int. J. Mech. Sci. 2022, 232, 107643. [Google Scholar] [CrossRef]

- Li, Q.W.; Sun, B.H. Optimization of a lattice structure inspired by glass sponge. Bioinspir. Biomim. 2022, 18, 016005. [Google Scholar] [CrossRef]

- Santos, J.; Sohouli, A.; Suleman, A. Micro-and macro-scale topology optimization of multi-material functionally graded lattice structures. J. Compos. Sci. 2024, 8, 124. [Google Scholar] [CrossRef]

- Zeng, Y.H.; Zhao, M.; Zhang, Z.W.; Zhou, H.L. Optimization design for TPMS lattice structures combining density gradient with hybridization. J. Chongqing Univ. 2024, 47, 76–86. [Google Scholar]

- Yue, L.; Liu, H.; Cheng, Z.; Kan, Q.; Kang, G. Yield surface of multi-directional gradient lattices with octet architectures. Int. J. Plast. 2024, 182, 104140. [Google Scholar] [CrossRef]

- Huang, K.; Ding, Z.; Zhang, Y.; Li, X. Topological optimization design method of layer-wise graded lattice structures with high load-bearing. Chin. J. Theor. Appl. Mech. 2023, 55, 433–444. [Google Scholar]

- Zhao, S.; Zhang, Y.; Fan, S.; Yang, N.; Wu, N. Design and optimization of graded lattice structures with load path-oriented reinforcement. Mater. Des. 2023, 227, 111776. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Lee, D.W.; Rowshan, R.; Al-Rub, R.K.A. Functionally graded and multi-morphology sheet TPMS lattices: Design, manufacturing, and mechanical properties. J. Mech. Behav. Biomed. Mater. 2020, 102, 103520. [Google Scholar] [CrossRef]

- Pal, R.; Basak, A. Linking powder properties, printing parameters, post-processing methods, and fatigue properties in additive manufacturing of AlSi10Mg. Alloys 2022, 1, 149–179. [Google Scholar] [CrossRef]

- Esquivel, A.; Marcelino, S.; Veiga, F.; Olvera-Trejo, D. Machinability of Sintered Metallic Materials in Additive Manufacturing. Appl. Sci. 2025, 15, 12455. [Google Scholar] [CrossRef]

- Shan, L.; Shi, Y.; Su, X.; Li, W.; Liu, C. Fabrication and Parameter Optimization of High-Melting-Point Pure Cr by Binder Jetting Additive Manufacturing. Crystals 2025, 15, 1012. [Google Scholar] [CrossRef]

- Huang, R.; Ding, D.; Liang, J.; Zou, Z.; Zhang, Y.; Liu, J. Research progress and challenges in forming control of wire arc additive manufacturing. Manuf. Technol. Mach. Tool 2025, 103–119. [Google Scholar] [CrossRef]

- McAndrew, A.R.; Rosales, M.A.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V wire+ arc additively manufactured features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, J.; Zhu, Z.W.; Lu, P.L.; Shi, Y. Improving accuracy and precisely controlling molten pool of stepped filling wire–assisted DP-GTA-AM. Weld. World 2025, 69, 1255–1266. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.; Jia, D. Lightweight design and static analysis of lattice compressor impeller. Sci. Rep. 2020, 10, 18394. [Google Scholar] [CrossRef]

- Tariq, U.; Mazhar, F. Static Structural Analysis of Fighter Aircraft’s Wing Spars. In Proceedings of the 2021 International Bhurban Conference on Applied Sciences and Technologies (IBCAST), Islamabad, Pakistan, 12–16 January 2021; pp. 221–243. [Google Scholar]

- Khan, N.; Acanfora, V.; Riccio, A. Non-conventional wing structure design with lattice infilled through design for additive manufacturing. Materials 2024, 17, 1470. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Macera, L.; Vatanparast, S. Additive manufacturing for lightweighting satellite platform. Appl. Sci. 2023, 13, 2809. [Google Scholar] [CrossRef]

- Yao, Y.; Cong, L.; Wang, H.; Wang, J. Modeling active adjustment of negative Poisson’s ratio mechanical metamaterials. Acta Mater. Compos. Sin. 2024, 41, 467–476. [Google Scholar]

- Luo, Y.; Dai, F.; Shen, J.; Wang, A.; Jiang, X.; Li, Y. Negative poisson’s ratio lattice structure with chiral and re-entrant properties. Appl. Sci. 2023, 13, 13097. [Google Scholar]

- Kang, M.; Choi, H.G.; Park, K.; Pyo, S. Additively Manufactured 3D Auxetic Metamaterials for Structurally Guided Capacitive and Resistive Tactile Sensing. Adv. Funct. Mater. 2025, 35, e09704. [Google Scholar]

- Li, F.; Zhang, Q.; Shi, H.; Zheng, L. A modified three-dimensional negative-poisson-ratio metal metamaterial lattice structure. Materials 2022, 15, 3752. [Google Scholar]

- Gao, M.; He, D.; Wu, X.; Tan, Z.; Guo, X. Design, Preparation, and Mechanical Property Investigation of Ti–Ta 3D-Auxetic Structure by Laser Powder Bed Fusion. Adv. Eng. Mater. 2023, 25, 2300242. [Google Scholar]

- Liu, Z.P.; Xu, F.X.; Zhu, Y.F.; Zou, Z. Compression mechanics and energy absorption characteristics of multi-bionic hollow curved lattice structure. Acta Mater. Compos. Sin. 2025, 42, 5351–5365. [Google Scholar]

- Nasrullah, A.I.H.; Santosa, S.P.; Dirgantara, T. Design and optimization of crashworthy components based on lattice structure configuration. Elsevier 2020, 26, 969–981. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, X.; Hou, B.; Jarlöv, A.; Du, C.; Zhou, K. Programmable heterogeneous lamellar lattice architecture for dual mechanical protection. Proc. Natl. Acad. Sci. USA 2024, 121, e2407362121. [Google Scholar] [PubMed]

- Wang, G.; Ma, S.; Wang, C.; Ma, B.; Zeng, F. Design and optimization of lattice infilled landing impact absorbing structure for a reentry capsule. In Proceedings of the 12th International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (QR2MSE 2022), Emeishan, China, 27–30 July 2022; The Institution of Engineering and Technology: Stevenage, UK, 2022; pp. 1427–1431. [Google Scholar]

- Gong, C.; Ritchie, R.O.; Wei, X.; Liu, Q.; Xiong, J. Mechanical properties of modular assembled composite lattice architecture. J. Mech. Phys. Solids 2025, 195, 105967. [Google Scholar] [CrossRef]

- Zhang, P.; Qi, D.; Xia, Y.; Wu, W. Impact energy-absorption performances of an automobile energy-absorbing-box with plate cubic-lattice core filled. J. Automot. Saf. Energy 2020, 11, 287. [Google Scholar]

- Liang, H.; Liu, B.; Ma, F.; Wang, D. Research on Design Strategy of Lattice Structure Filled Crash Box Under Multi-angle Impact Loading. Automot. Eng. 2023, 45, 293–303. [Google Scholar]

- Wu, X.; Zhang, S.; Shao, J. Studies on Impact Performance of Gradient Lattice Structure Applied to Crash Box. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Rajpura, A.; Prajapati, H.; Sur, A.; Jatti, V.; Kale, G.; Razoumny. Performance evaluation of lattice structured bumper beam for automobile. AIMS Mater. Sci. 2025, 12, 395–422. [Google Scholar] [CrossRef]

- Cresswell, N.D.; Ameri, A.A.H.; Wang, J.; Wang, H.; Hazell, P.; Escobedo, J.P. Characterization and modelling of triply periodic minimum surface (TPMS) lattice structures for energy absorption in automotive applications. In Characterization of Minerals, Metals, and Materials; Springer Nature: Cham, Switzerland, 2024; pp. 295–305. [Google Scholar]

- Liang, J.; Zhang, W.; Liu, W.; Chen, B. Optimization and Laser Selective Melting for Lattice Structure of Heat Exchanger. Laser Optoelectron. Prog. 2022, 59, 1914006. [Google Scholar]

- Ding, Y.; Wu, W.T.; Feng, F.; Li, S.L.; Yan, H.B. Topology Review and Convective Heat Transfer Comparison of 3D Lattice Structures. Appl. Math. Mech. 2024, 45, 1001–1023. [Google Scholar]

- Chen, J.; Liu, L.; Xu, W.; Huang, X.; Sheng, H. Design and Analysis of a Hollow Metallic Microlattice Active Cooling System for Microsatellites. Nanomaterials 2022, 12, 1485. [Google Scholar] [CrossRef] [PubMed]

- Kilic, G.A. Performance Evaluation of Triply Periodic Minimal Surface Heat Exchangers Using Nanofluids at High Flow Rates for Enhanced Energy Efficiency. Appl. Sci. 2025, 15, 4140. [Google Scholar] [CrossRef]

- Maloney, K.J.; Fink, K.D.; Schaedler, T.A.; Kolodziejska, J.A.; Jacobsen, A.J.; Roper, C.J. Multifunctional heat exchangers derived from three-dimensional micro-lattice structures. Int. J. Heat Mass Transf. 2012, 55, 2486–2493. [Google Scholar] [CrossRef]

- Wang, X.; Li, A.; Liu, X.; Wan, X. Thermal Insulation and Compressive Performances of 3D Printing Flexible Load-Bearing and Thermal Insulation Integrated Lattice. Materials 2022, 15, 8625. [Google Scholar] [CrossRef]

- Steeves, C.A.; He, M.; Maxwell, P.T.; Evans, A.G. Design of a robust, multifunctional thermal protection system incorporating zero expansion lattices. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Seattle, WA, USA, 11–15 November 2007; pp. 255–260. [Google Scholar]

- Rezapourian, M.; Jasiuk, I.; Saarna, M.; Hussainova, I. Selective laser melted Ti6Al4V split-P TPMS lattices for bone tissue engineering. Int. J. Mech. Sci. 2023, 251, 108353. [Google Scholar] [CrossRef]

- Alaña, M.; Lopez-Arancibia, A.; Ghouse, S.; Rodriguez-Florez, N.; Galarreta, S. Additively manufactured lattice structures with controlled transverse isotropy for orthopedic porous implants. Comput. Biol. Med. 2022, 150, 105761. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Han, Q.; Wang, C.; Liu, Y.; Chen, B.; Wang, J. Porous scaffold design for additive manufacturing in orthopedics: A review. Front. Bioeng. Biotechnol. 2020, 8, 609. [Google Scholar] [CrossRef]

- Sun, Y.; Ma, J.; Wang, Y.; Dong, B.; Yang, P.; Li, Y.; Li, Y.; Zhou, L.; Shen, J.; Ma, X. Research progress in influence of microstructure on performance of triply-periodic minimal surface bone scaffolds. Chin. J. Reparative Reconstr. Surg. 2023, 37, 1314–1318. (In Chinese) [Google Scholar]

- Jing, L.; Hai, J.; Shan, C.; Xu, Q.; Lei, Y.; Li, H. Fabrication of Functionally Fused Porous Tantalum/Lithium Magnesium Silicate Polymer Bone Repair Scaffolds. J. Shanghai Jiaotong Univ. (Sci.) 2025, 1–12. [Google Scholar] [CrossRef]

- Xiao, R.; Feng, X.; Liu, W.; Zhou, W.; Li, X.; Song, I.; Ding, M.; Pu, Y.; Zhang, D.; Fan, R. Direct 3D printing of thin-walled cardiovascular stents with negative Poisson’s ratio (NPR) structure and functional metallic coating. Compos. Struct. 2023, 306, 116572. [Google Scholar] [CrossRef]

| TPMS | Entity Class | Thin-Walled Class | Implicit Function Equation |

|---|---|---|---|

| Gyroid |  |  | sin x ∗ cos y + sin y ∗ cos z + sin z ∗ cos x = c |

| Schwarz |  |  | cos x + cos y + cos z = c |

| Diamond |  |  | sin x ∗ sin y ∗ sin z + sin x ∗ cos y * cos z + cos x ∗ sin y ∗ cos z + cos x ∗ cos y ∗ sin z = c |

| Structure Type | Specific Strength | Energy Absorption Efficiency | Manufacturability | Typical Applications |

|---|---|---|---|---|

| Truss Lattice Structures | High specific strength; vulnerable to stress concentration at joints. | Moderate energy absorption efficiency. | Good manufacturability. | Lightweight aerospace components, heat exchangers, orthopedic implants (when optimized), mechanical metamaterials. |

| Honeycomb Lattice Structures | High in-plane specific strength; lower out-of-plane strength. | High in-plane energy absorption. | Good manufacturability. | Aerospace sandwich panels, protective packaging, automotive crash absorbers. |

| TPMS Structures | High and uniform specific strength. | Excellent energy absorption efficiency. | The structure is com-plex, requiring high precision from additive manufacturing technology. | Biomedical implants (porous scaffolds), thermal management, acoustic damping, multifunctional metamaterials. |

| Biomimetic Lattice Structures | High specific strength can be achieved by mimicking natural structures. | By mimicking natural structures, high energy absorption efficiency can be achieved. | The structure is more complex, requiring more stringent requirements for the additive manufacturing process. | Bone-mimicking scaffolds, impact-resistant structures, architected materials with superior stiffness-to-weight ratios. |

| Gradient Lattice Structures | Strength can be optimized by spatially varying density or topology. | Very high; gradients promote sequential crushing and superior energy absorption. | The structure is more complex, requiring more stringent requirements for the additive manufacturing process. | Functionally graded implants, heat exchangers, crashworthy structures with tailored deformation behavior. |

| AM Processes | Feature Resolution | Surface Roughness | Build Rate | Relative Cost | Suitability for Different Lattice Types |

|---|---|---|---|---|---|

| PBF | Very high: best for fine and intricate features | Moderate to rough | Low | High | TPMS; Complex truss lattices and honeycomb lattice; biomimetic structures; Gradient lattices |

| DED | Moderate: limited by melt pool size | Rough | High | High | large-scale lattices |

| BJ | Moderate to high: depending on powder size | Moderate to good | Very high | Moderate | TPMS; Honeycomb lattice |

| WAAM | Low: large bead width limits fine features | Very rough | Very high | Low | large-scale lattice structures |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, C.; Wang, Y.; Fan, H.; Li, X. Research Progress of Additively Manufactured Metallic Lattice Structures. Micromachines 2025, 16, 1418. https://doi.org/10.3390/mi16121418

Tian C, Wang Y, Fan H, Li X. Research Progress of Additively Manufactured Metallic Lattice Structures. Micromachines. 2025; 16(12):1418. https://doi.org/10.3390/mi16121418

Chicago/Turabian StyleTian, Chenchen, Yongjian Wang, Haiyang Fan, and Xuekun Li. 2025. "Research Progress of Additively Manufactured Metallic Lattice Structures" Micromachines 16, no. 12: 1418. https://doi.org/10.3390/mi16121418

APA StyleTian, C., Wang, Y., Fan, H., & Li, X. (2025). Research Progress of Additively Manufactured Metallic Lattice Structures. Micromachines, 16(12), 1418. https://doi.org/10.3390/mi16121418