AI-Based Model Estimation for a Precision Positioning Stage Employing Multiple Control Switching

Abstract

1. Introduction

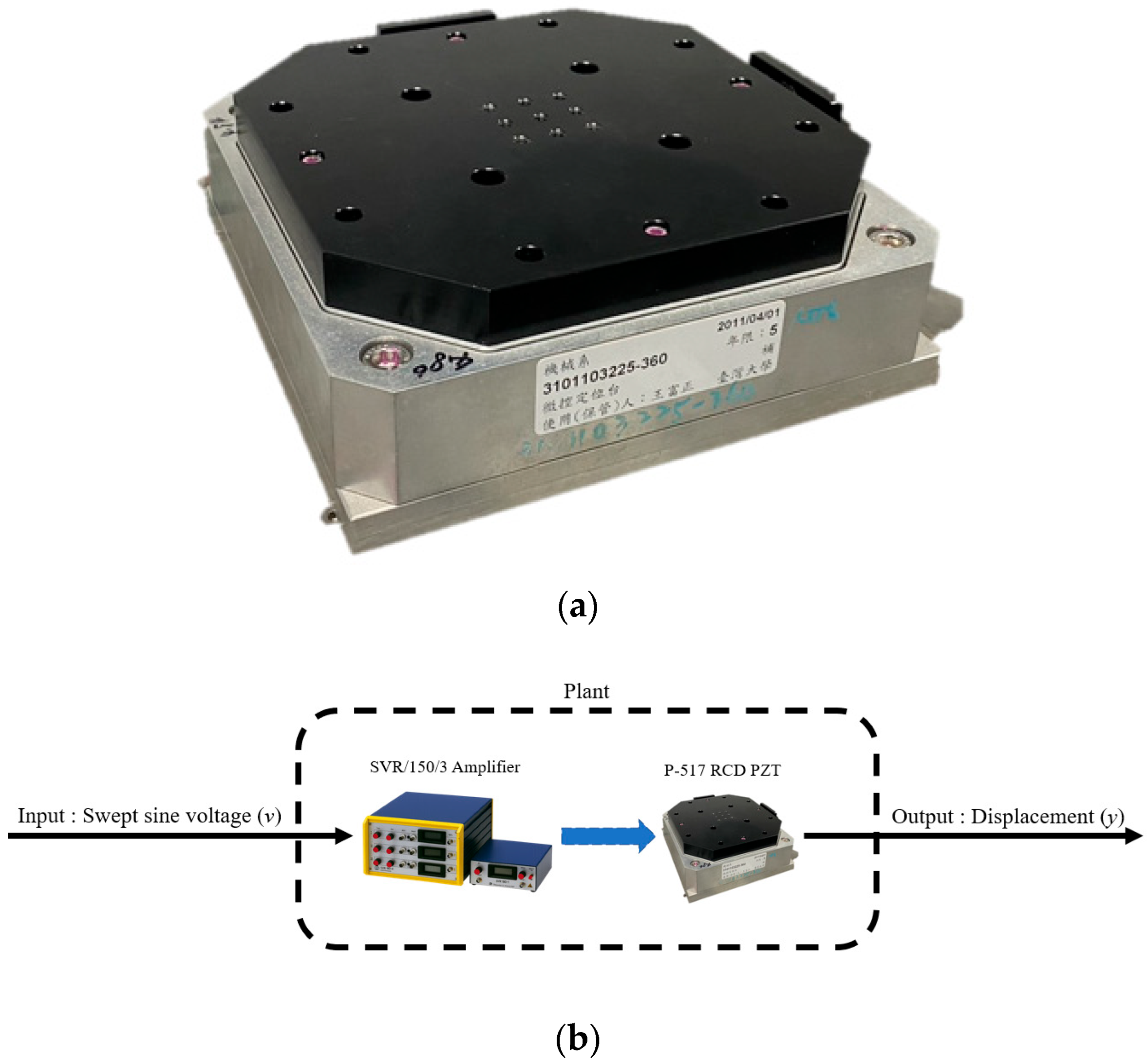

2. The Precision Positioning Stage

2.1. Stage Identification

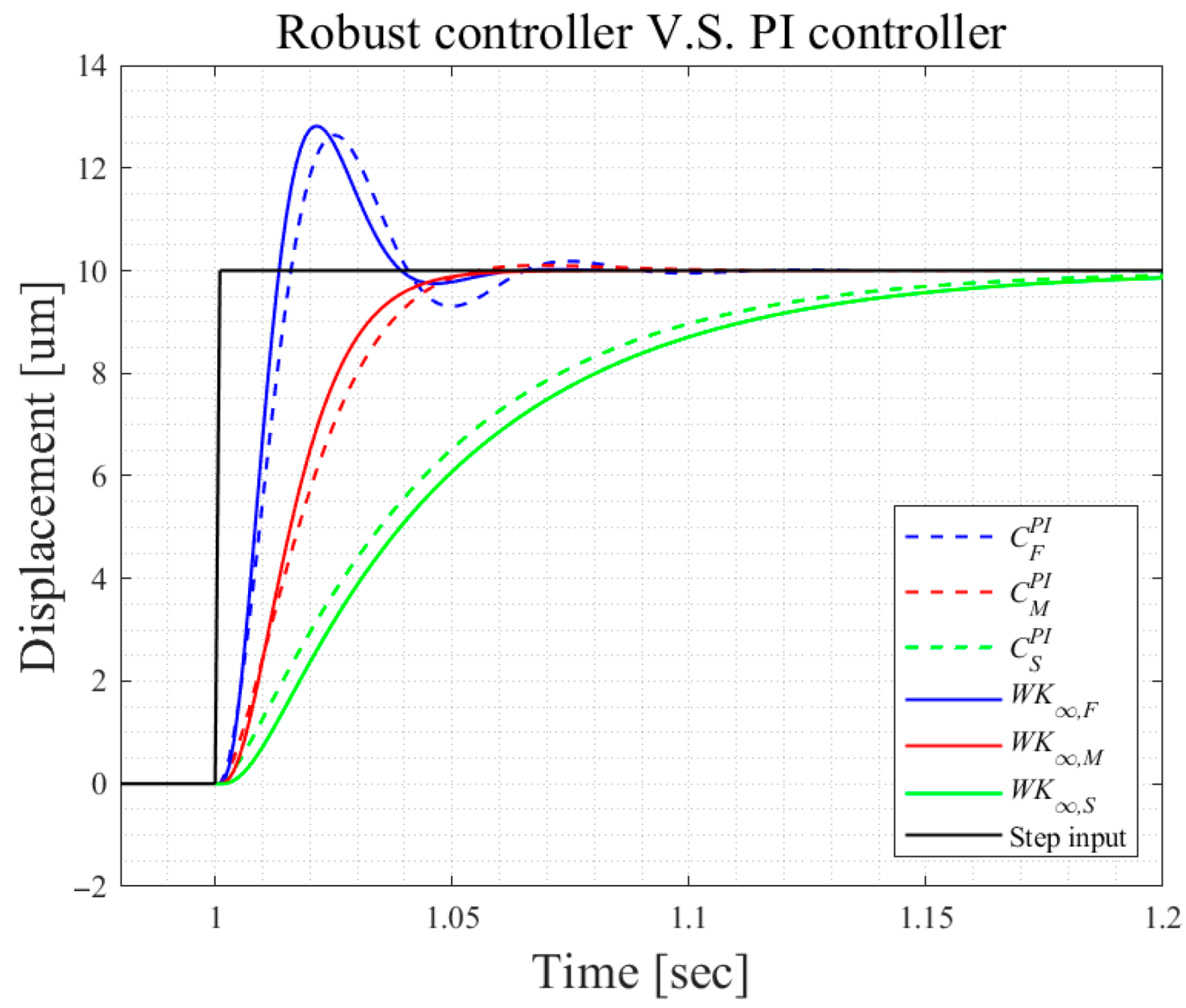

2.2. Control Design

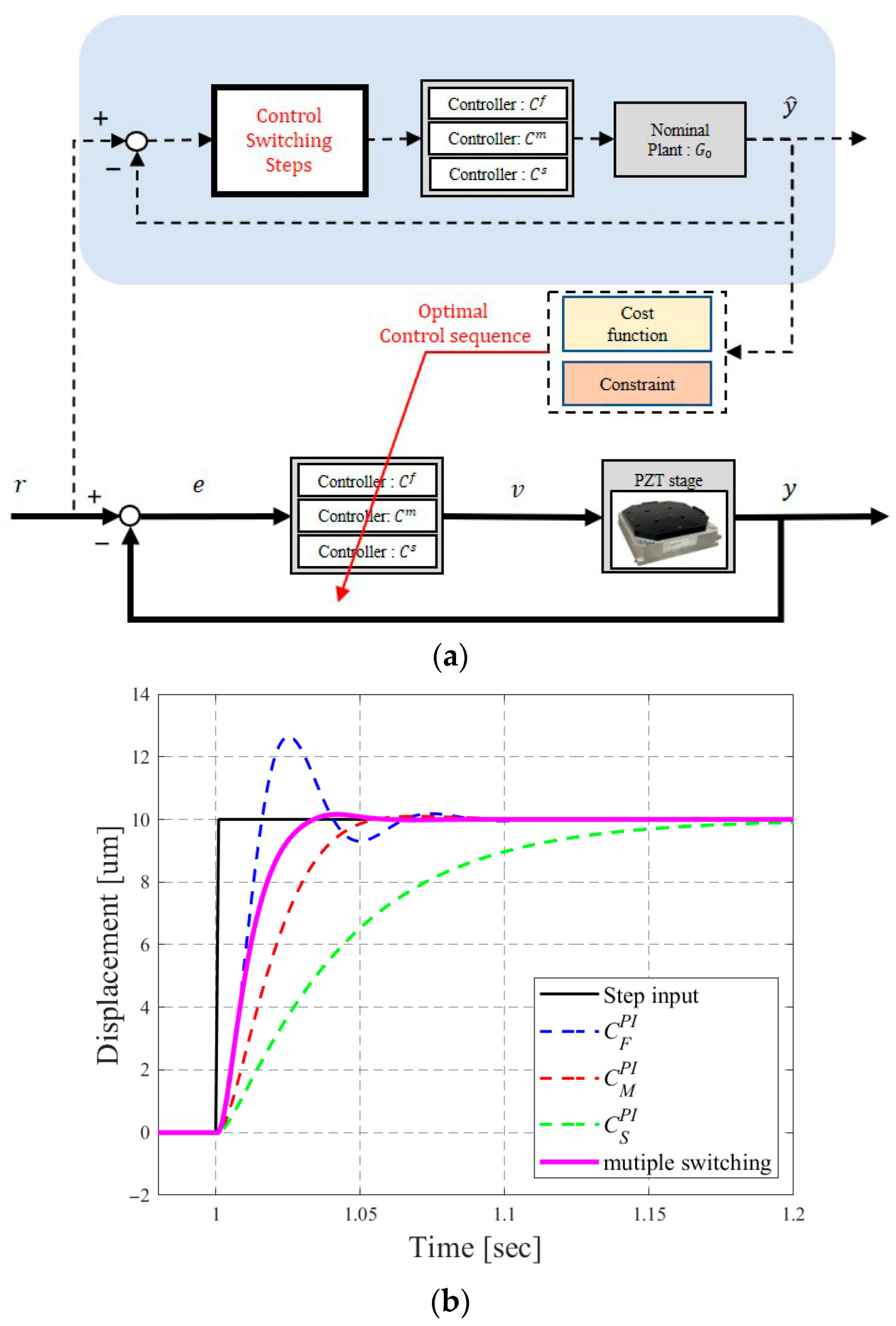

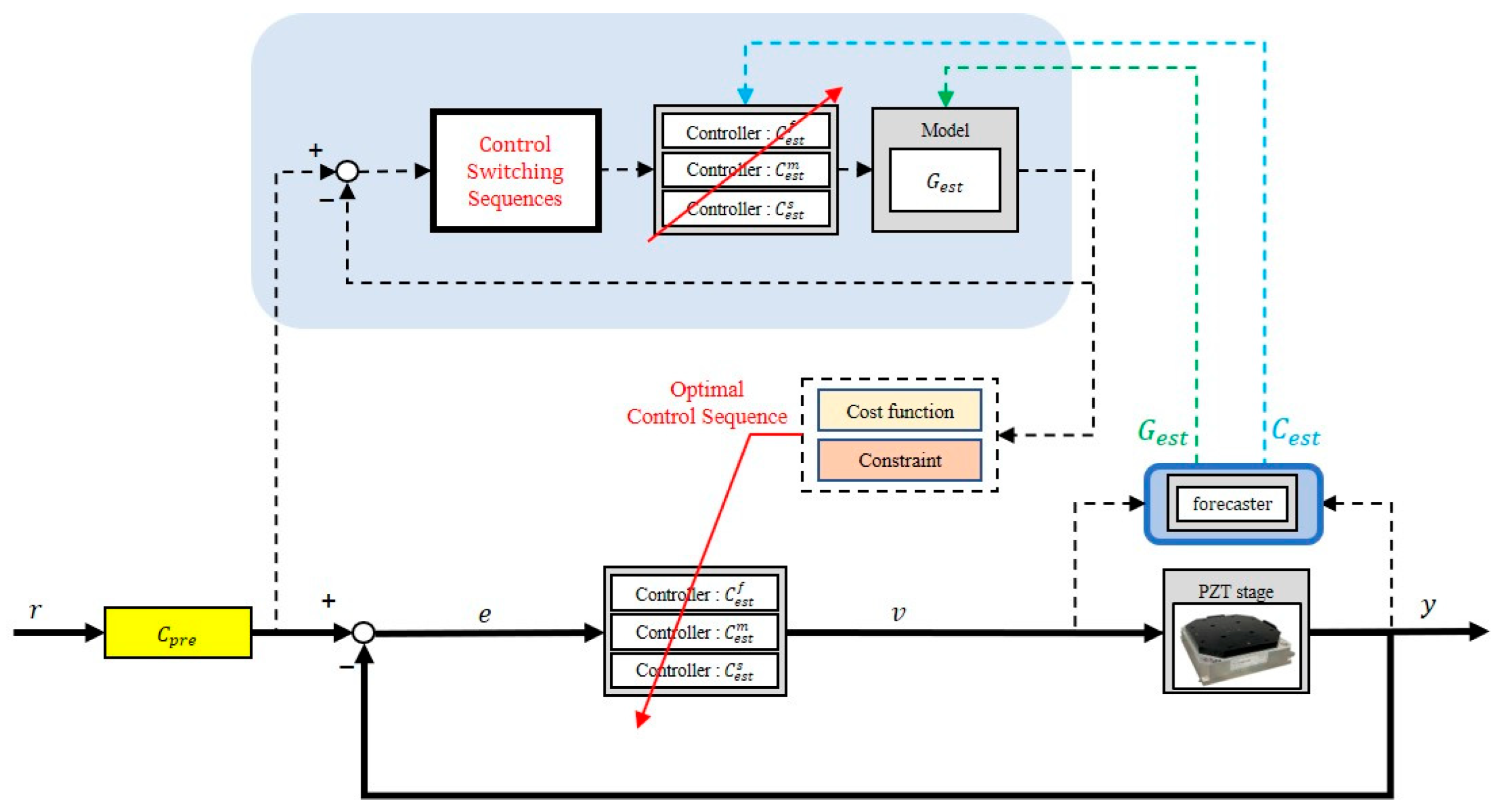

2.3. Multiple Control Switching

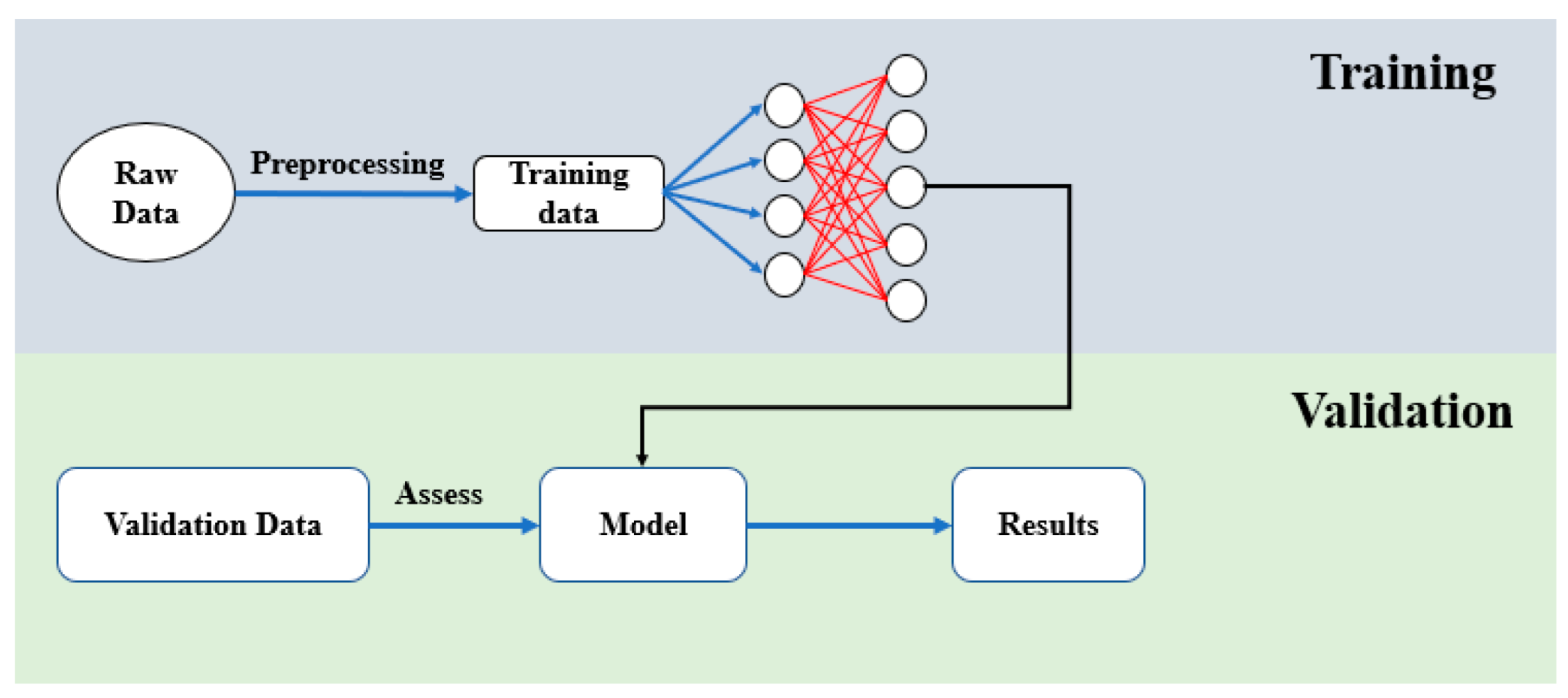

3. AI-Based Model Estimation

3.1. The eXtreme Gradient Boosting Algorithm

3.2. Model Estimation

- (1)

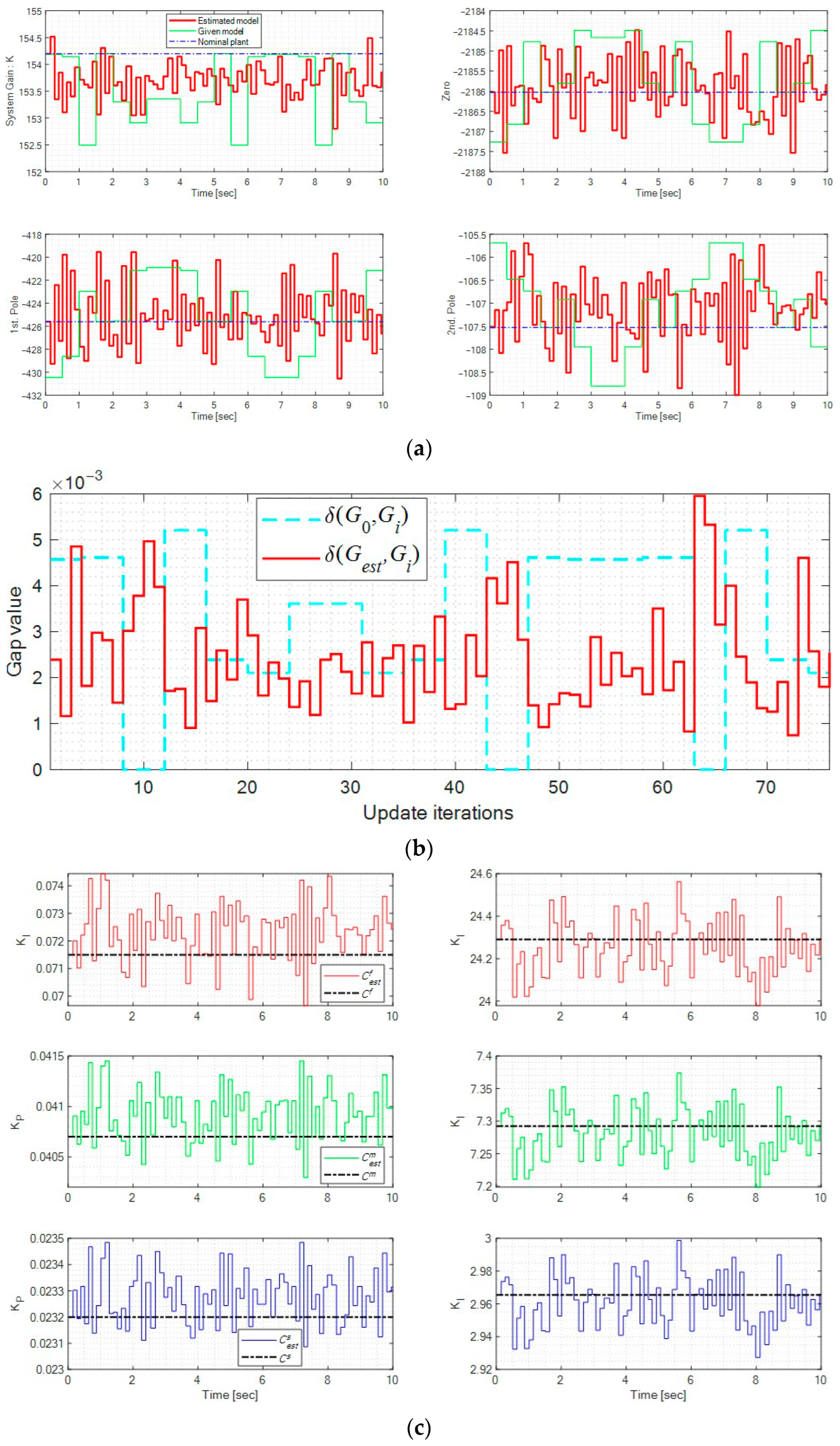

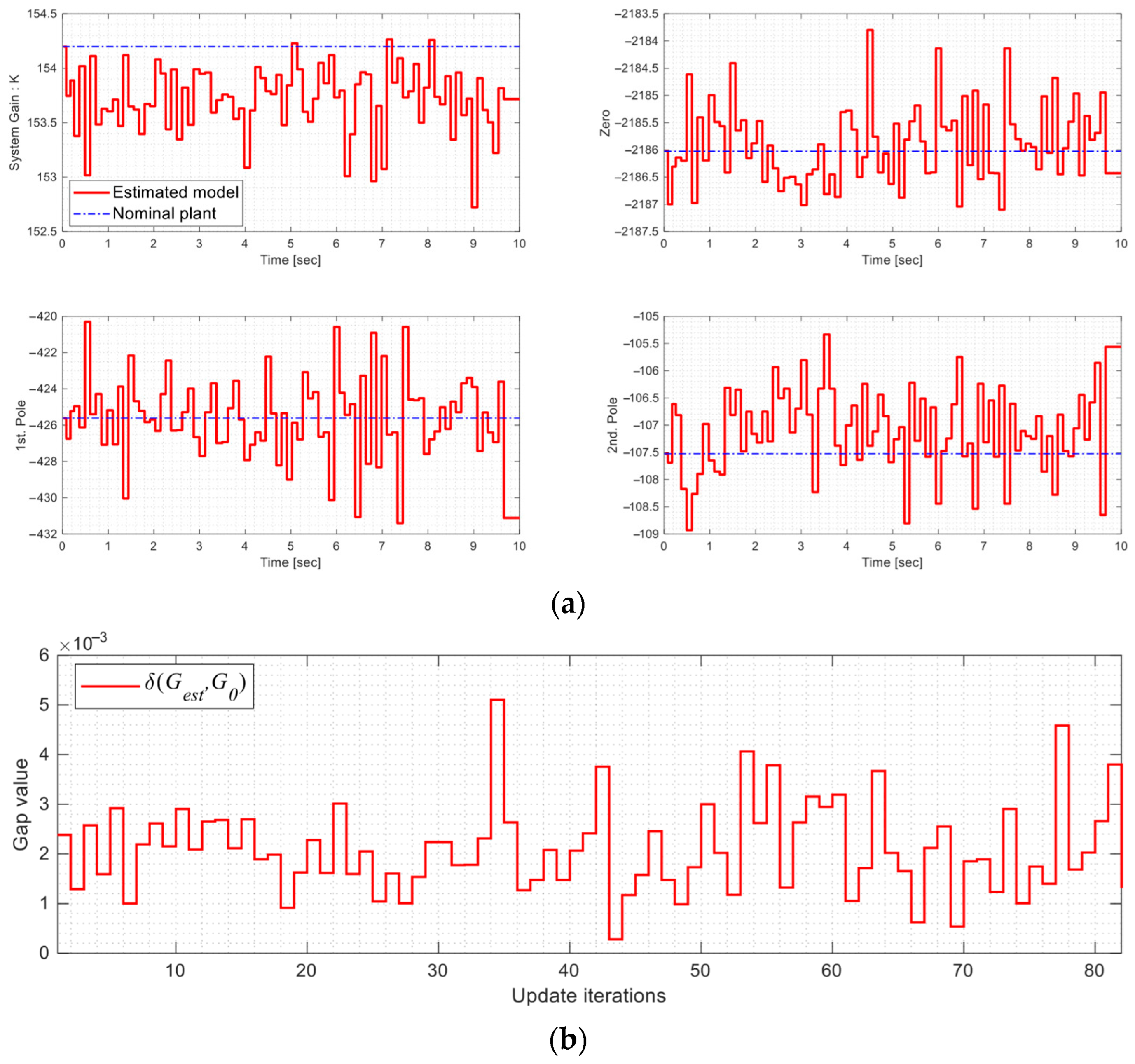

- Data splitting: For each model , we labeled its poles, zero, and gains, as shown in Figure 6, along with the corresponding input voltages v and output displacements y. Since the models in Section 2.1 are second-order strictly proper transfer functions, the input features were set as , while the poles, zero, and gain of served as the outputs for the model estimator.

- (2)

- Estimator training: The dataset contained 100,000 data points, as shown in Figure 6. Two-thirds of the data used to train the model estimator with the Python (version 3.12.3) command XGBRegressor from the XGBoost library, as illustrated in Figure 7. During training, we performed grid search to optimize hyperparameters. The final configuration set the learning rate to 0.4, limited the number of trees to 100, and restricted each tree to a maximum of 16 leaves.

- (3)

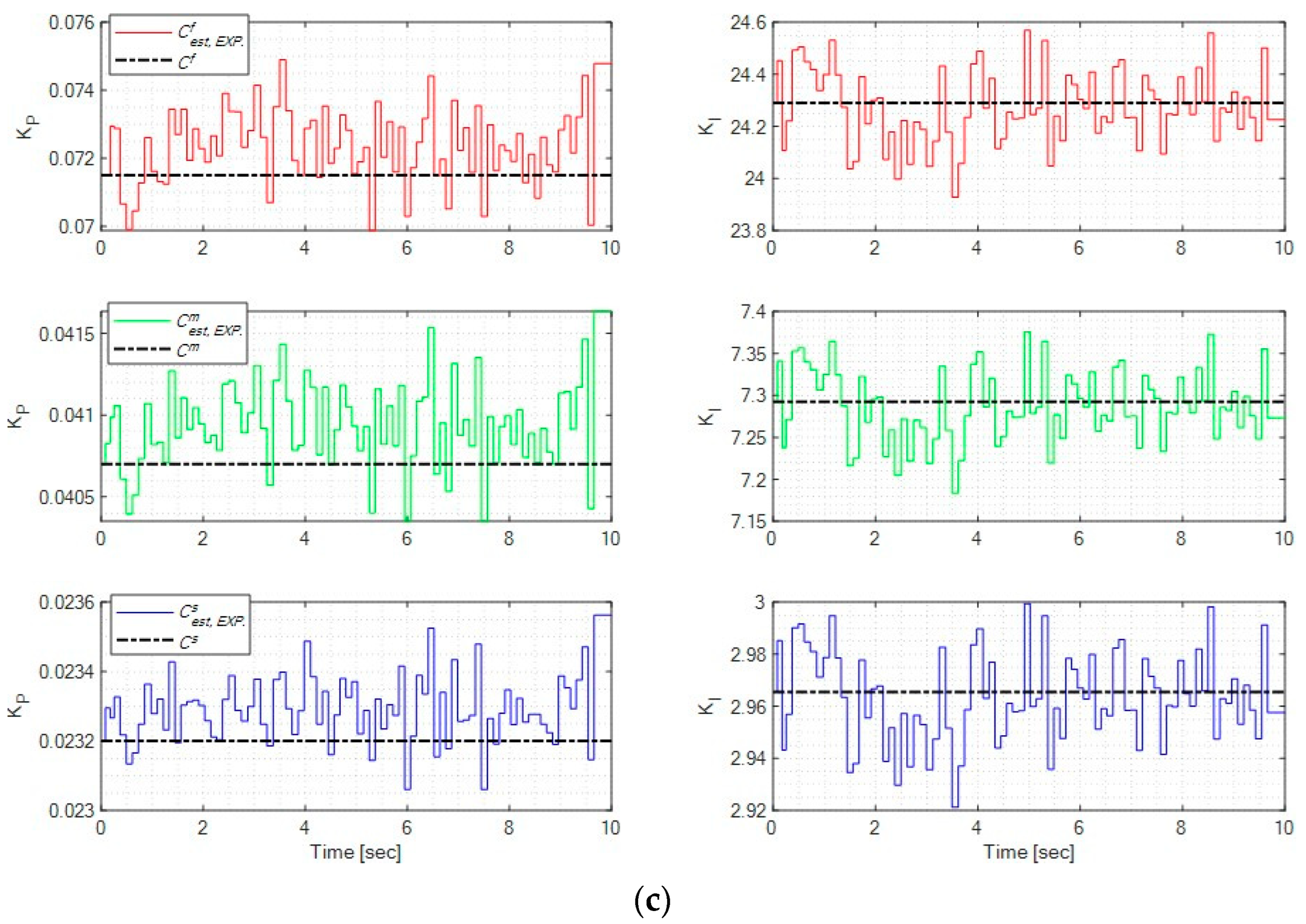

- Estimator validation: The remaining one-third of the dataset was used to validate the model estimator, as shown in Figure 6 and Figure 7. The input v and output y were fed into the trained XGBoost model to obtain an estimated stage model . The gap between and the actual model is denoted as , while the gap between and is . The estimation is considered effective if is significantly smaller than . Validation results show that the average gap for is 0.0004, compared to , which is substantially larger. This demonstrates that the estimated model captures system dynamics more accurately than the nominal model , confirming the effectiveness of the XGBoost estimator. Furthermore, the estimated gaps are well below the stability margins, ensuring closed-loop stability.

3.3. Real-Time Controller Modification

3.4. Phase Compensator Design

4. Simulation and Experiments

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Saleem, A.; Al-Ratrout, S.; Mesbah, M. A fitness function for parameters identification of Bouc-Wen hysteresis model for piezoelectric actuators. In Proceedings of the 2018 5th International Conference on Electrical and Electronic Engineering, Istanbul, Turkey, 3–5 May 2018. [Google Scholar] [CrossRef]

- Gan, J.; Zhang, X. Nonlinear Hysteresis Modeling of Piezoelectric Actuators Using a Generalized Bouc–Wen Model. Micromachines 2025, 10, 183. [Google Scholar] [CrossRef]

- Sumitha, C.; Anandaraju, M.B. Bouc-Wen model for SISO Nano-Positioning System with Kalman Filtering. In Proceedings of the 2021 International Conference on Intelligent Technologies, Hubli, India, 25–27 June 2021. [Google Scholar] [CrossRef]

- Ming, M.; Feng, Z.; Ling, J.; Xiao, X.H. Hysteresis modelling and feedforward compensation of piezoelectric nanopositioning stage with a modified Bouc-Wen model. Nanomicro. Lett. 2018, 13, 1170–1174. [Google Scholar] [CrossRef]

- McCartney, L.N.; Crocker, L.E.; Wright, L.; Rungger, I. A Compact Device Model for a Piezoelectric Nano-Transistor. Micromachines 2025, 16, 114. [Google Scholar] [CrossRef]

- Nafea, M.; Mohamed, Z.; Ali, M.S.M.; Mehranzamir, K.; Rehman, T. Hybrid PSO-Tuned PID and hysteresis-observer based control for piezoelectric micropositioning stages. In Proceedings of the 2019 IEEE International Conference on Smart Instrumentation, Measurement and Application, Kuala Lumpur, Malaysia, 27–29 August 2019. [Google Scholar] [CrossRef]

- Shi, B.; Shi, R.; Wang, F. Design of an adaptive feedforward/feedback combined control for piezoelectric actuated micro positioning stage. Precis. Eng. 2022, 78, 199–205. [Google Scholar] [CrossRef]

- Ahmad, I. Two degree-of-freedom robust digital controller design with Bouc-Wen hysteresis compensator for piezoelectric positioning stage. IEEE Access 2018, 6, 17275–17283. [Google Scholar] [CrossRef]

- Al-Jodah, A.A.L.; Shirinzaden, B.; Pinskier, J.; Ghafarian, M.; Das, T.K. Antlion optimized robust control approach for micropositioning trajectory tracking tasks. IEEE Access 2020, 8, 220889–220907. [Google Scholar] [CrossRef]

- Makarem, S.; Delibas, B.; Koc, B. Data-driven tuning of PID controlled piezoelectric ultrasonic motor. Actuators 2021, 10, 148. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, M.; Hou, D.; Cao, W.; Huang, X. Composite data driven-based adaptive control for a piezoelectric linear motor. IEEE Trans. Instrum. Meas. 2022, 71, 3527912. [Google Scholar] [CrossRef]

- Wolmuth, L.D.; Alves, U.N.L.T.; Krindges, A.; Cardim, R.; Assunção, E.; Teixeira, M.C.M. Switched Controller Design for a Class of Uncertain Linear Systems Using Derivative Feedback. IEEE Access 2025, 13, 95034–95053. [Google Scholar] [CrossRef]

- Sharma, N.K.; Roy, S.; Janardhanan, S. New design methodology for adaptive switching gain based discrete-time sliding mode control. Int. J. Control 2021, 94, 1081–1088. [Google Scholar] [CrossRef]

- Wang, F.C.; Lu, J.F.; Su, W.J.; Yen, J.Y. Precision positioning control of a long-stroke stage employing multiple switching control. Microsyst. Technol. 2022, 28, 319–332. [Google Scholar] [CrossRef]

- Sarker, I.H. AI-Based Modeling: Techniques, Applications and Research Issues Towards Automation, Intelligent and Smart Systems. SN Comput. Sci. 2022, 3, 158. [Google Scholar] [CrossRef] [PubMed]

- Hosseinzadeh, A.; Chen, F.F.; Shahin, M.; Bouzary, H. A predictive maintenance approach in manufacturing systems via AI-based early failure detection. Manuf. Lett. 2023, 35, 319–332. [Google Scholar] [CrossRef]

- Wang, F.C.; Wang, J.Z. Superior Optimization for a Hybrid PEMFC Power System Employing Model Predictions. Int. J. Energy Res. 2023, 2023, 9984961. [Google Scholar] [CrossRef]

- Kong, S.F.; Guevarra, D.; Gomes, C.P.; Gregoire, J.M. Materials representation and transfer learning for multi-property prediction. Appl. Phys. Rev. 2021, 8, 021409. [Google Scholar] [CrossRef]

- Ye, X.W.; Tao, J.; Yun, C.B. A review on deep learning-based structural health monitoring of civil infrastructures. Smart Struct. Syst. 2019, 24, 567–585. [Google Scholar] [CrossRef]

- Uralde, J.; Artetxe, E.; Barambones, O.; Calvo, I.; Fernández-Bustamante, P.; Martin, I. Ultraprecise Controller for Piezoelectric Actuators Based on Deep Learning and Model Predictive Control. Sensors 2023, 23, 1690. [Google Scholar] [CrossRef] [PubMed]

- Baziyad, A.G.; Ahmad, I.; Salamah, Y.B. Precision Motion Control of a Piezoelectric Actuator via a Modified Preisach Hysteresis Model and Two-Degree-of-Freedom H-Infinity Robust Control. Micromachines 2023, 14, 1208. [Google Scholar] [CrossRef]

- Artetxe, E.; Barambones, O.; Calvo, I.; del Rio, A.; Uralde, J. Combined Control for a Piezoelectric Actuator Using a Feed-Forward Neural Network and Feedback Integral Fast Terminal Sliding Mode Control. Micromachines 2024, 15, 757. [Google Scholar] [CrossRef]

- Dong, A.; Starr, A.; Zhao, Y. Neural network-based parametric system identification: A review. Int. J. Syst. Sci. 2023, 13, 2676–2688. [Google Scholar] [CrossRef]

- Multi-Axis Piezo Scanner High Dynamics Nanopositioner/Scanner with Direct Position Measuring. Available online: https://reurl.cc/Om69QA (accessed on 22 October 2025).

- Glover, K.; Mcfarlane, D. Robust Stabilization of Normalized Coprime Factor Plant Descriptions with H-Infinity-Bounded Uncertainty. IEEE Trans. Autom. Control 1989, 34, 821–830. [Google Scholar] [CrossRef]

- Mcfarlane, D.; Glover, K. A Loop Shaping Design Procedure Using H-Infinity-Synthesis. IEEE Trans. Autom. Control 1992, 37, 759–769. [Google Scholar] [CrossRef]

- Wang, F.C.; Chen, L.S.; Tsai, Y.C.; Hsieh, C.H.; Yen, J.Y. Robust loop-shaping control for a nano-positioning stage. J. Vib. Control. 2014, 20, 885–900. [Google Scholar] [CrossRef]

- Zhou, K.; Doyle, J.C. Essentials of Robust Control; Prentice-Hall: Upper Saddle River, NJ, USA, 1998. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995. [Google Scholar] [CrossRef]

- The Introduction of XGBoost. Available online: https://blog.csdn.net/wujianing_110117/article/details/115410996 (accessed on 22 October 2025).

- Kung, S.Y.; Lin, D.W. Optimal Hankel-Norm Model Reductions—Multivariable Systems. IEEE Trans. Autom. Control 1981, 26, 832–852. [Google Scholar] [CrossRef]

- Schöning, J.; Riechmann, A.; Pfisterer, H.J. AI for Closed-Loop Control Systems: New Opportunities for Modeling, Designing, and Tuning Control Systems. In Proceedings of the 14th International Conference on Machine Learning and Computing, Guangzhou, China, 18–21 February 2022. [Google Scholar] [CrossRef]

- Park, J.; Jung, H.; Kim, J.W.; Lee, J.M. Reinforcement Learning for Process Control: Review and Benchmark Problems. Int. J. Control Auto. Syst. 2025, 23, 1–40. [Google Scholar] [CrossRef]

| Simulation | Experiment | ||||||

|---|---|---|---|---|---|---|---|

| C.S. | M.E. + C.S. | M.E. | C.S. | M.E. + C.S. | M.E. | ||

| Square input | Rising time (s) | 0.0117 | 0.0102 | - | 0.0065 | 0.0073 | - |

| Settling time (s) | 1.5392 | 1.5400 | - | 1.5260 | 1.5265 | - | |

| Overshoot (%) | 6.4577 | 12.4754 | - | 13.4140 | 8.3308 | - | |

| RMSE (μm) | 0.8808 | 0.8784 | - | 0.9933 | 0.9521 | - | |

| Ramp 20 μm/s | MAE (μm) | 0.1823 | 0.1826 | - | 0.2360 | 0.1340 | - |

| RMSE (μm) | 0.0673 | 0.0669 | - | 0.0959 | 0.0946 | - | |

| Ramp 50 μm/s | MAE (μm) | 0.4565 | 0.4558 | - | 0.3470 | 0.3360 | - |

| RMSE (μm) | 0.1583 | 0.1573 | - | 0.1524 | 0.1511 | - | |

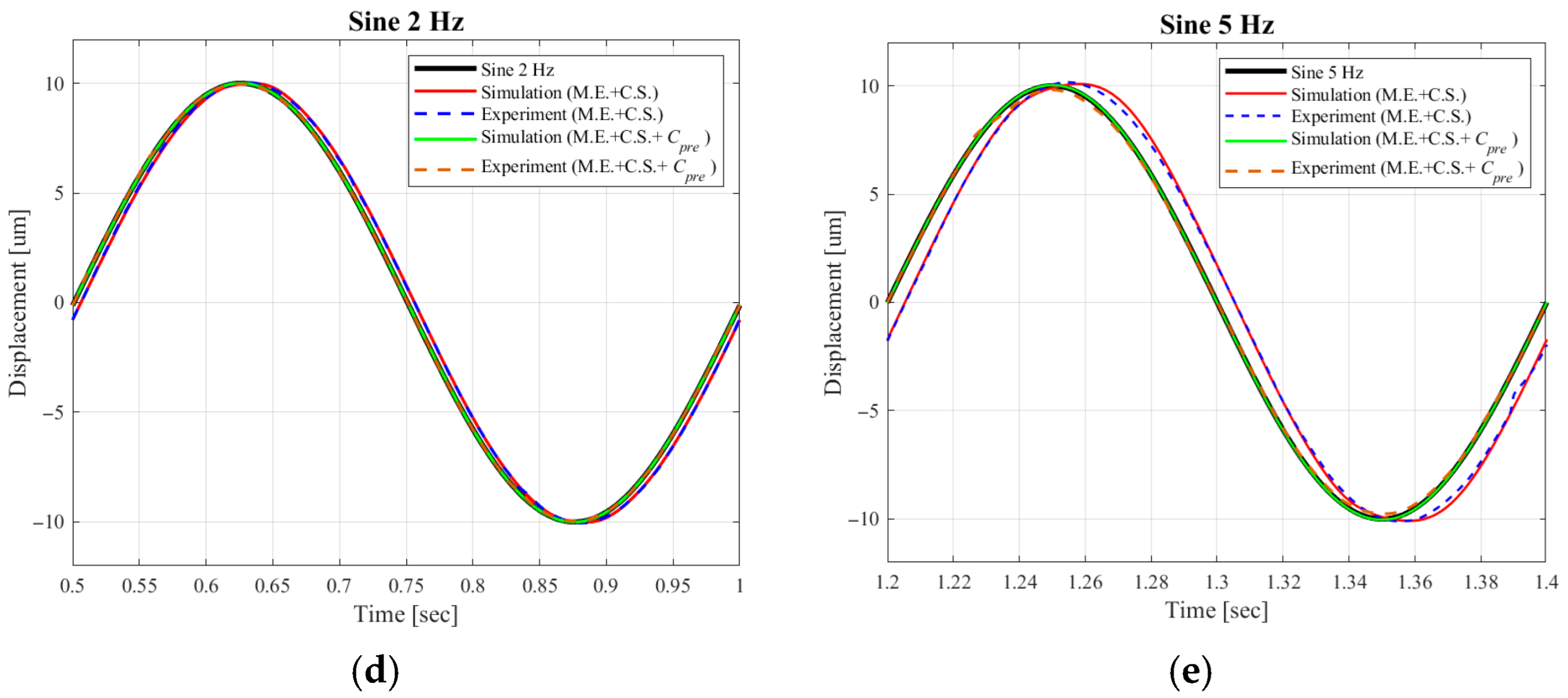

| Sinusoidal 2 Hz | Phase lag (º) | 6.480 | 5.7600 | 0.0000 | 4.3200 | 3.6000 | 0.0000 |

| MAE (μm) | 0.6648 | 0.6628 | 0.0191 | 0.7283 | 0.6807 | 0.3157 | |

| RMSE (μm) | 0.4706 | 0.4690 | 0.0116 | 0.4644 | 0.4581 | 0.0385 | |

| Sinusoidal 5 Hz | Phase lag (º) | 16.200 | 14.400 | 0.0000 | 10.800 | 9.0000 | 0.0000 |

| MAE (μm) | 1.7288 | 1.7225 | 0.1114 | 1.7879 | 1.7752 | 0.5065 | |

| RMSE (μm) | 1.2569 | 1.2513 | 0.0796 | 1.1644 | 1.1590 | 0.1633 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.-C.; Zhong, B.-X.; Wen, C.-W.; Tsai, I.-H.; Yen, J.-Y. AI-Based Model Estimation for a Precision Positioning Stage Employing Multiple Control Switching. Micromachines 2025, 16, 1305. https://doi.org/10.3390/mi16121305

Wang F-C, Zhong B-X, Wen C-W, Tsai I-H, Yen J-Y. AI-Based Model Estimation for a Precision Positioning Stage Employing Multiple Control Switching. Micromachines. 2025; 16(12):1305. https://doi.org/10.3390/mi16121305

Chicago/Turabian StyleWang, Fu-Cheng, Bo-Xuan Zhong, Chi-Wei Wen, I-Haur Tsai, and Jia-Yush Yen. 2025. "AI-Based Model Estimation for a Precision Positioning Stage Employing Multiple Control Switching" Micromachines 16, no. 12: 1305. https://doi.org/10.3390/mi16121305

APA StyleWang, F.-C., Zhong, B.-X., Wen, C.-W., Tsai, I.-H., & Yen, J.-Y. (2025). AI-Based Model Estimation for a Precision Positioning Stage Employing Multiple Control Switching. Micromachines, 16(12), 1305. https://doi.org/10.3390/mi16121305