Study on Microstructures and Properties of FeCoNiCuAlSix High-Entropy Alloy Composite Coatings by Laser Cladding

Abstract

1. Introduction

2. Materials and Methods

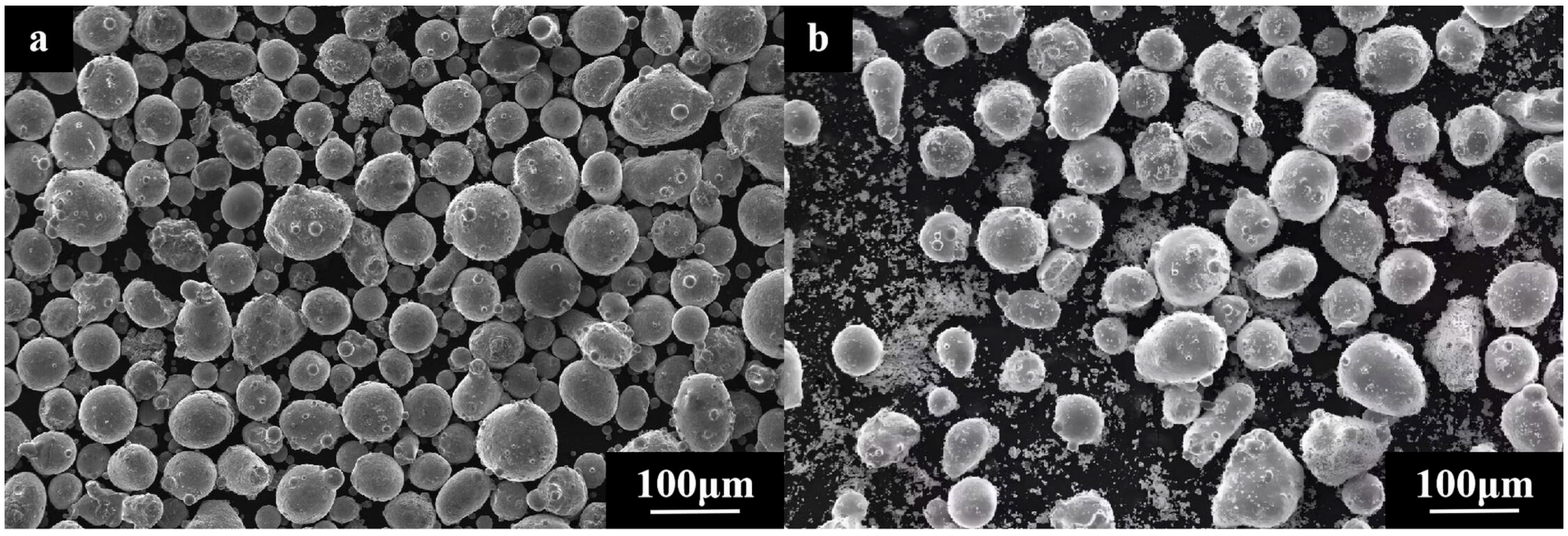

2.1. Experimental Materials

2.2. Test Methods and Characterization

3. Results and Discussion

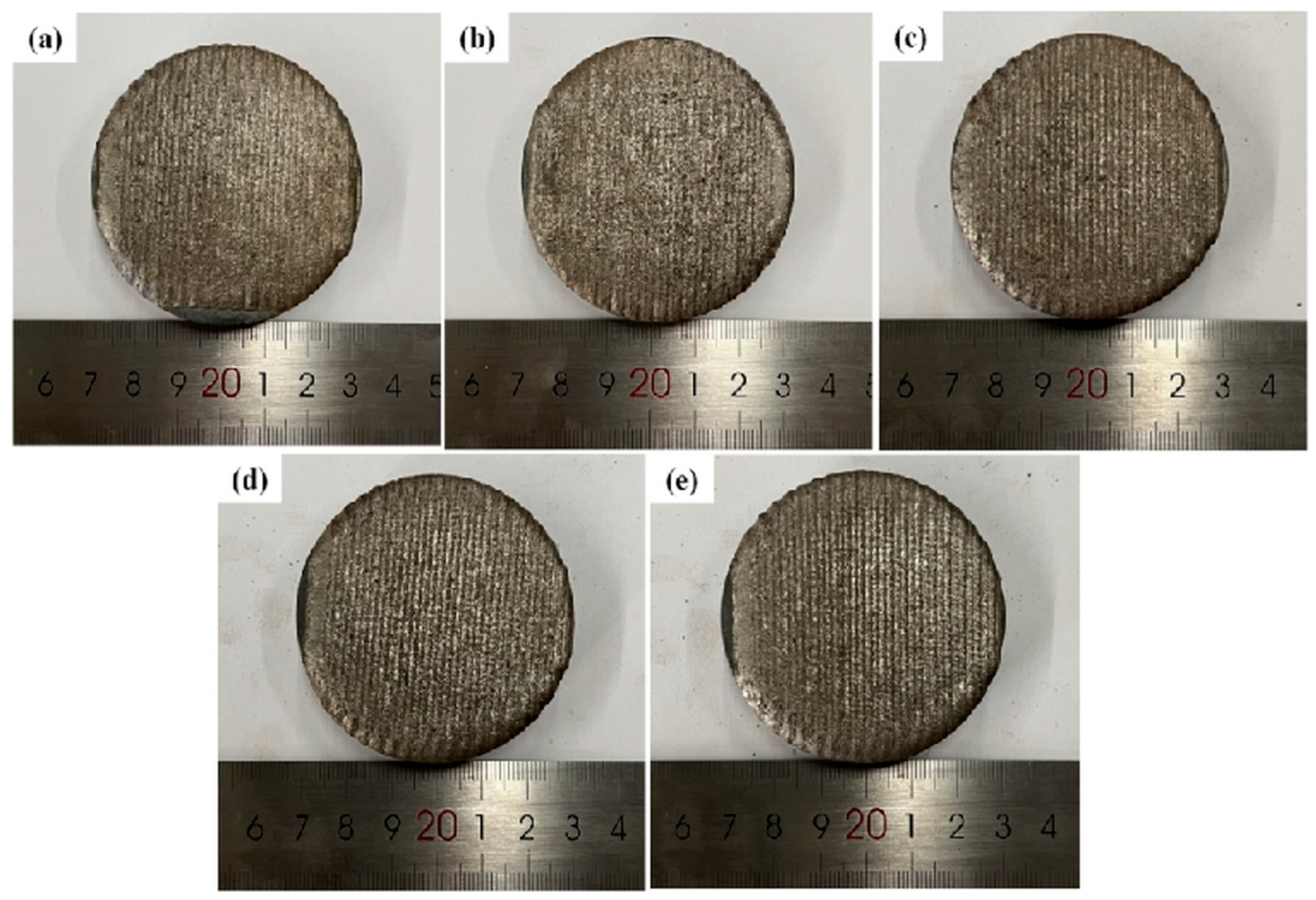

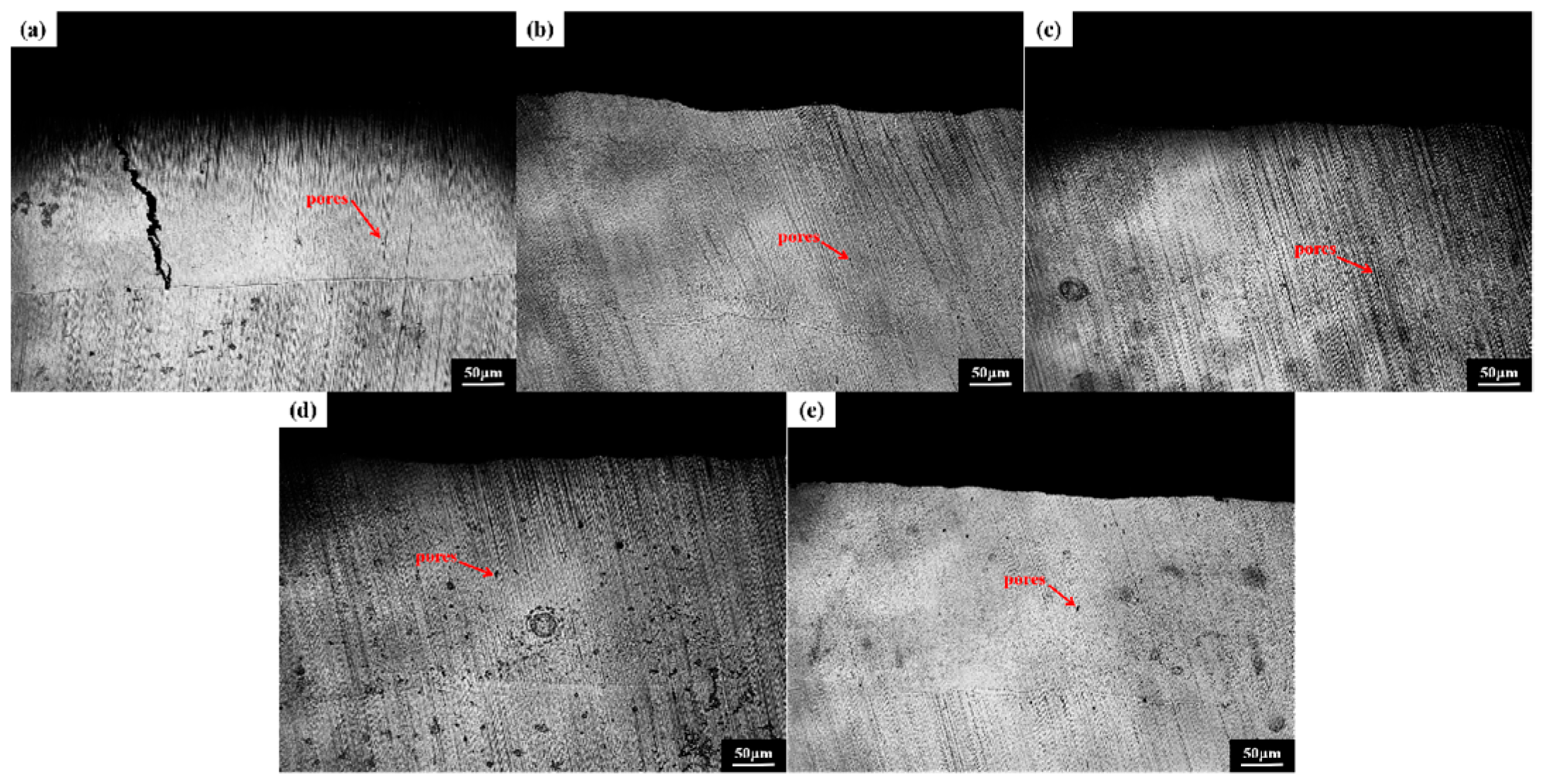

3.1. Morphology of Laser-Clad HEA Specimens

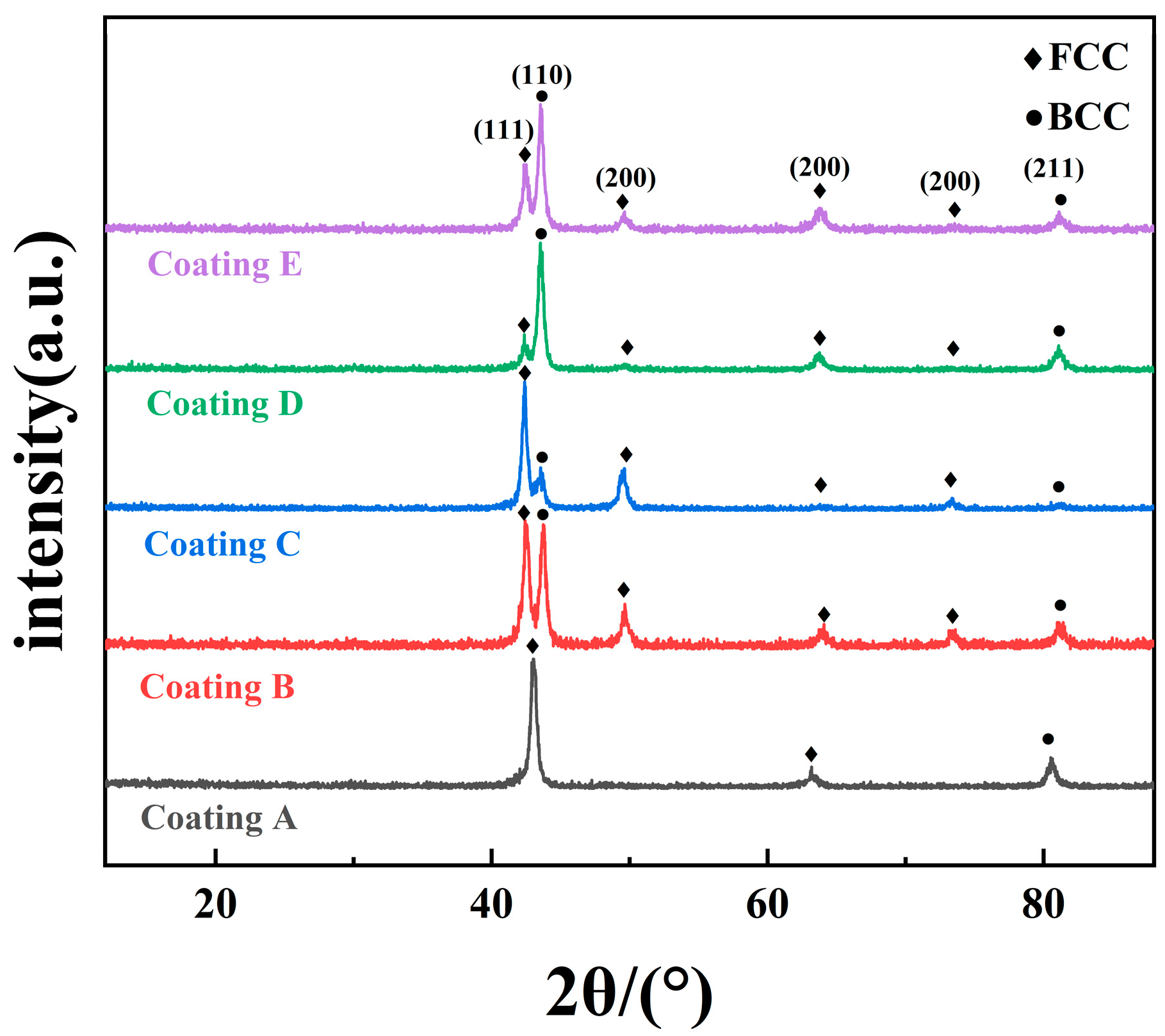

3.2. Physical Phase Analysis of Coatings

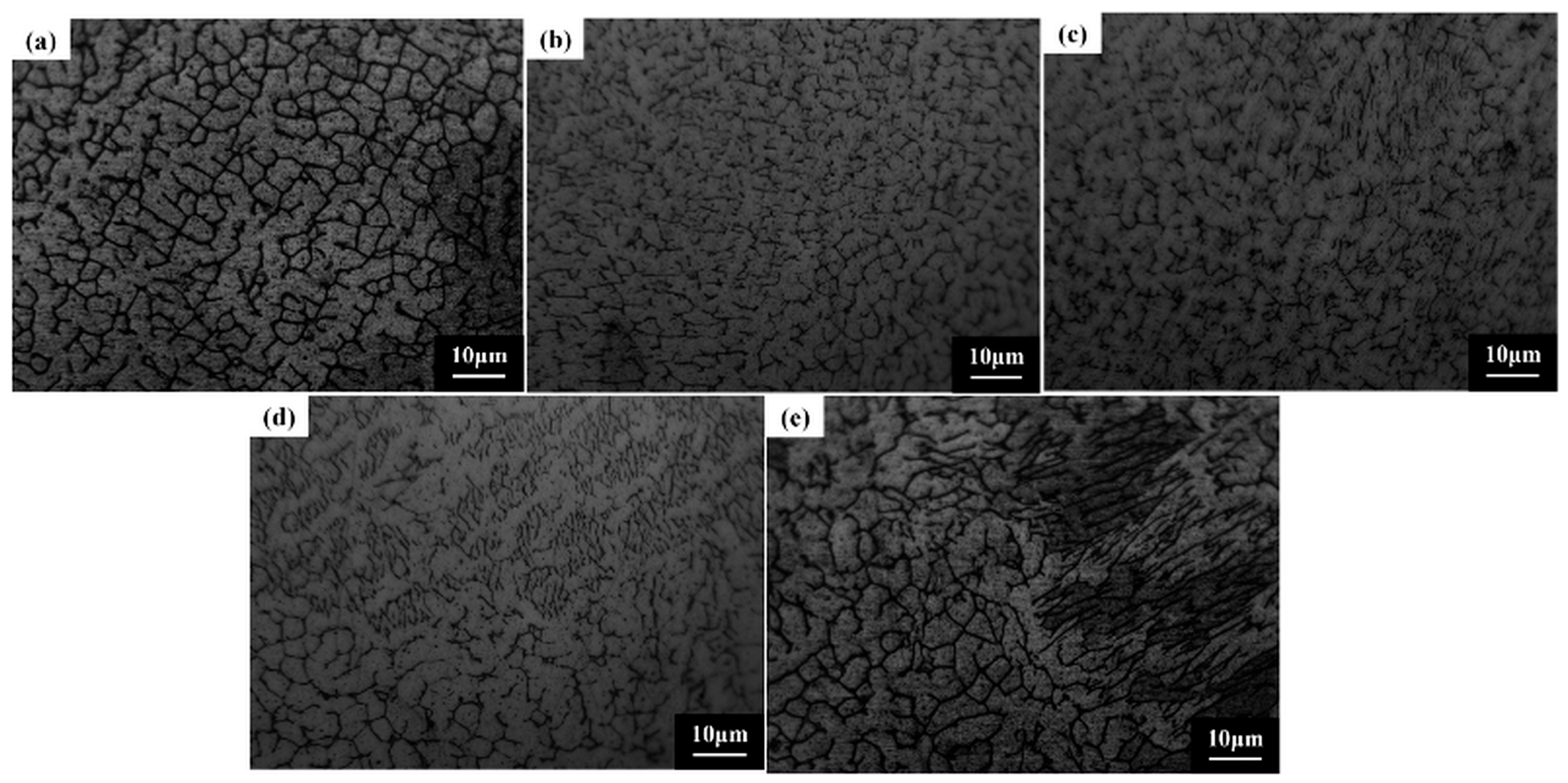

3.3. Microstructural Analysis of Coating

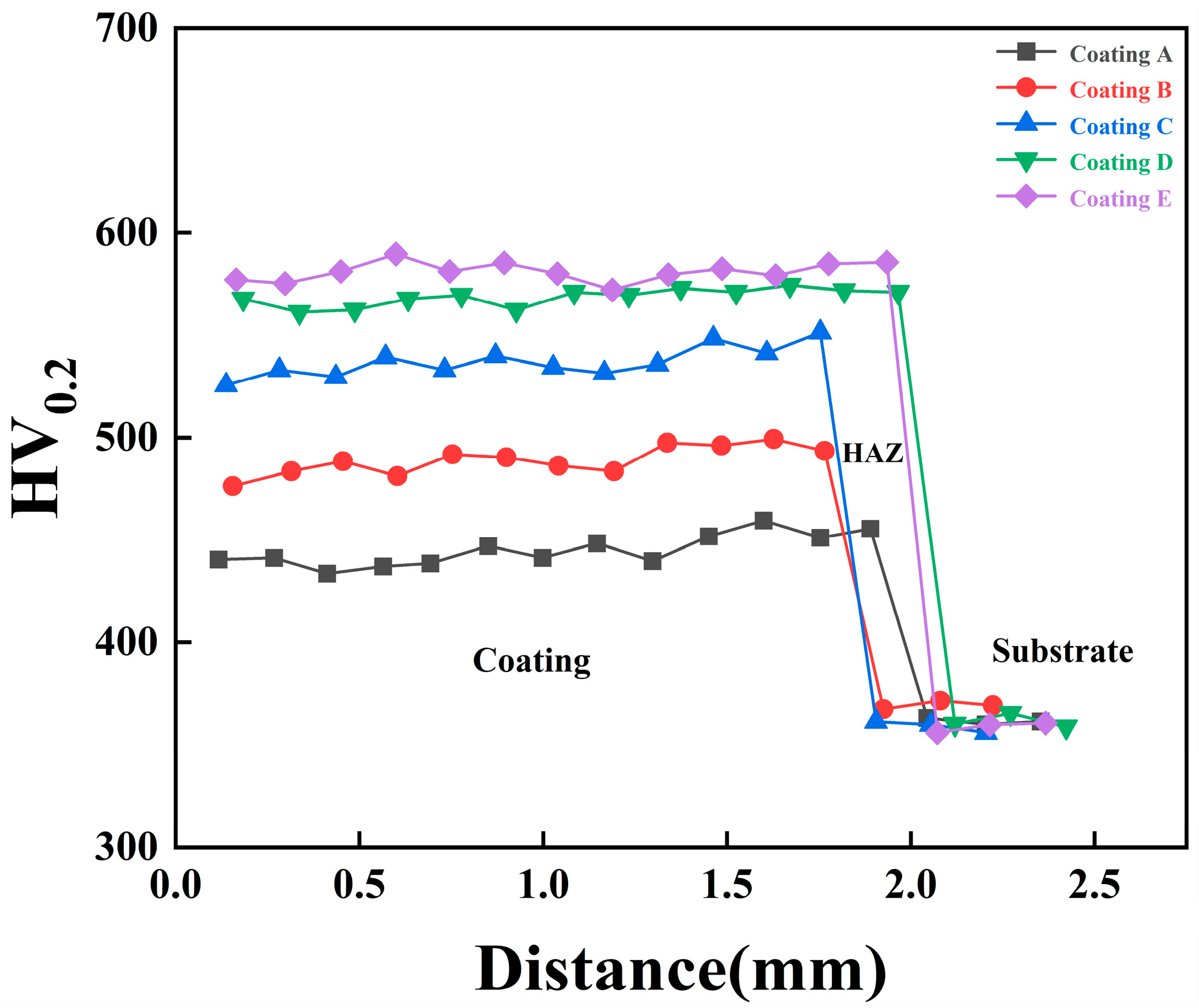

3.4. Microhardness of Coatings

3.5. Frictional Wear Behavior of Coatings

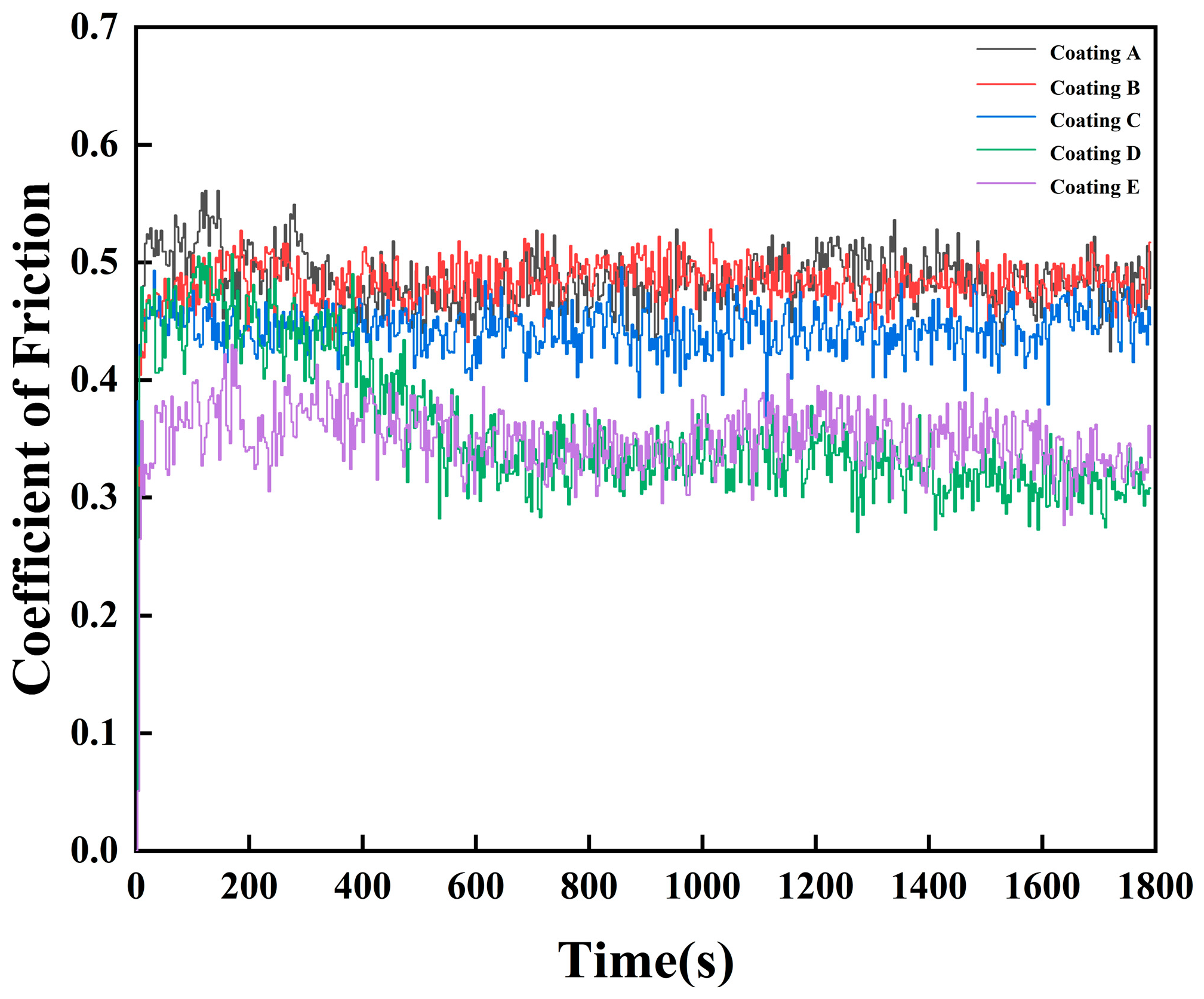

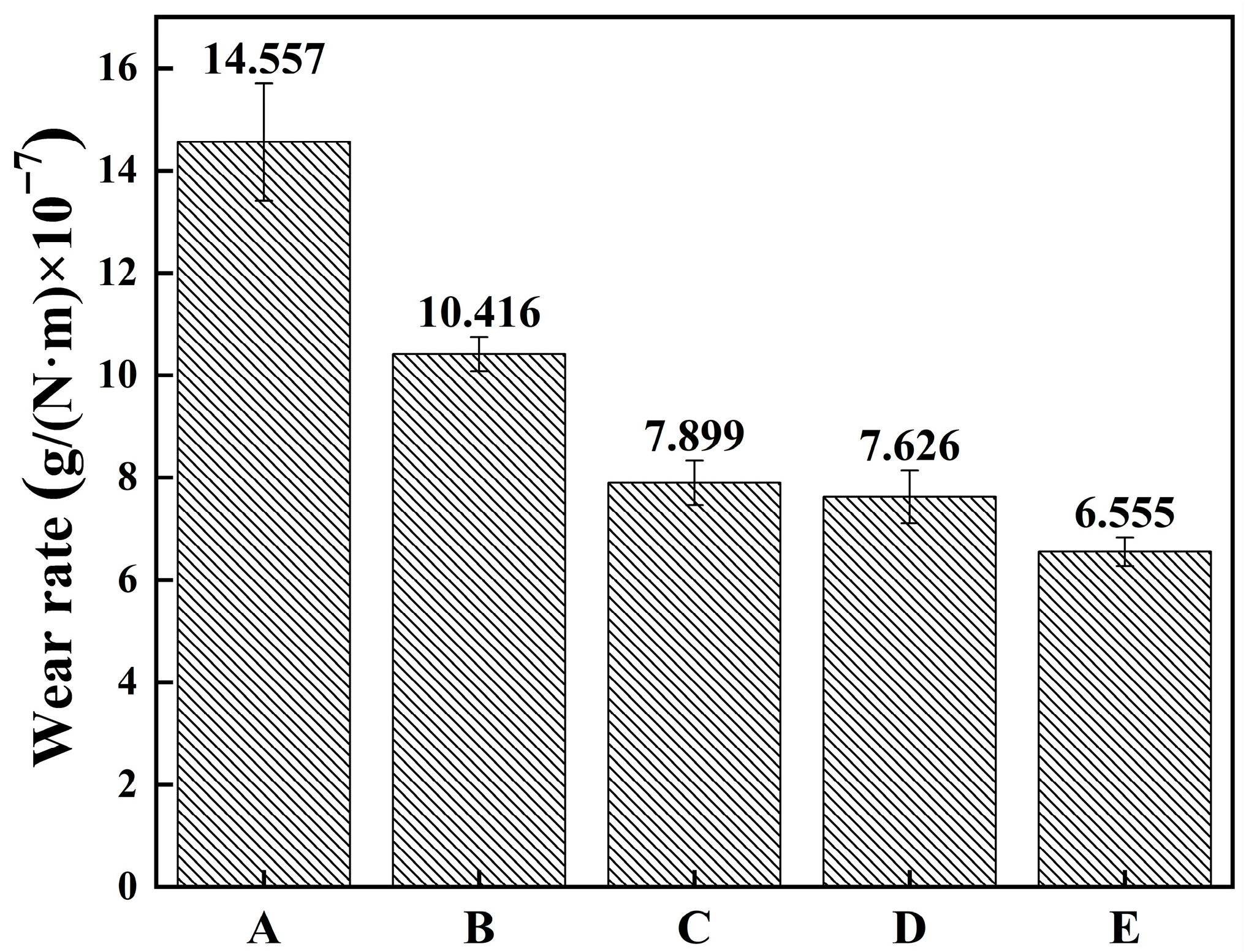

3.5.1. Average Coefficient of Friction and Wear Rate

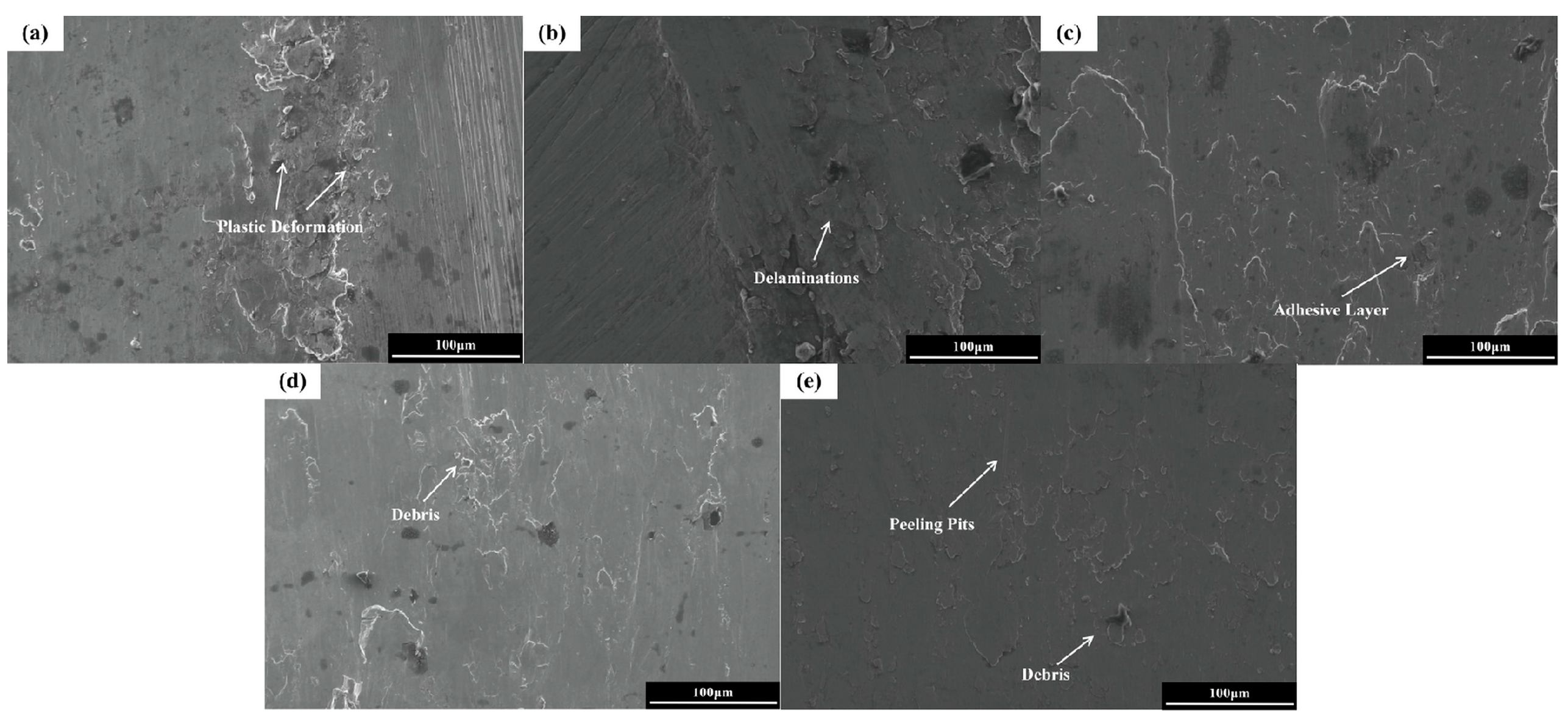

3.5.2. Coating Surface Wear Morphology and Mechanism

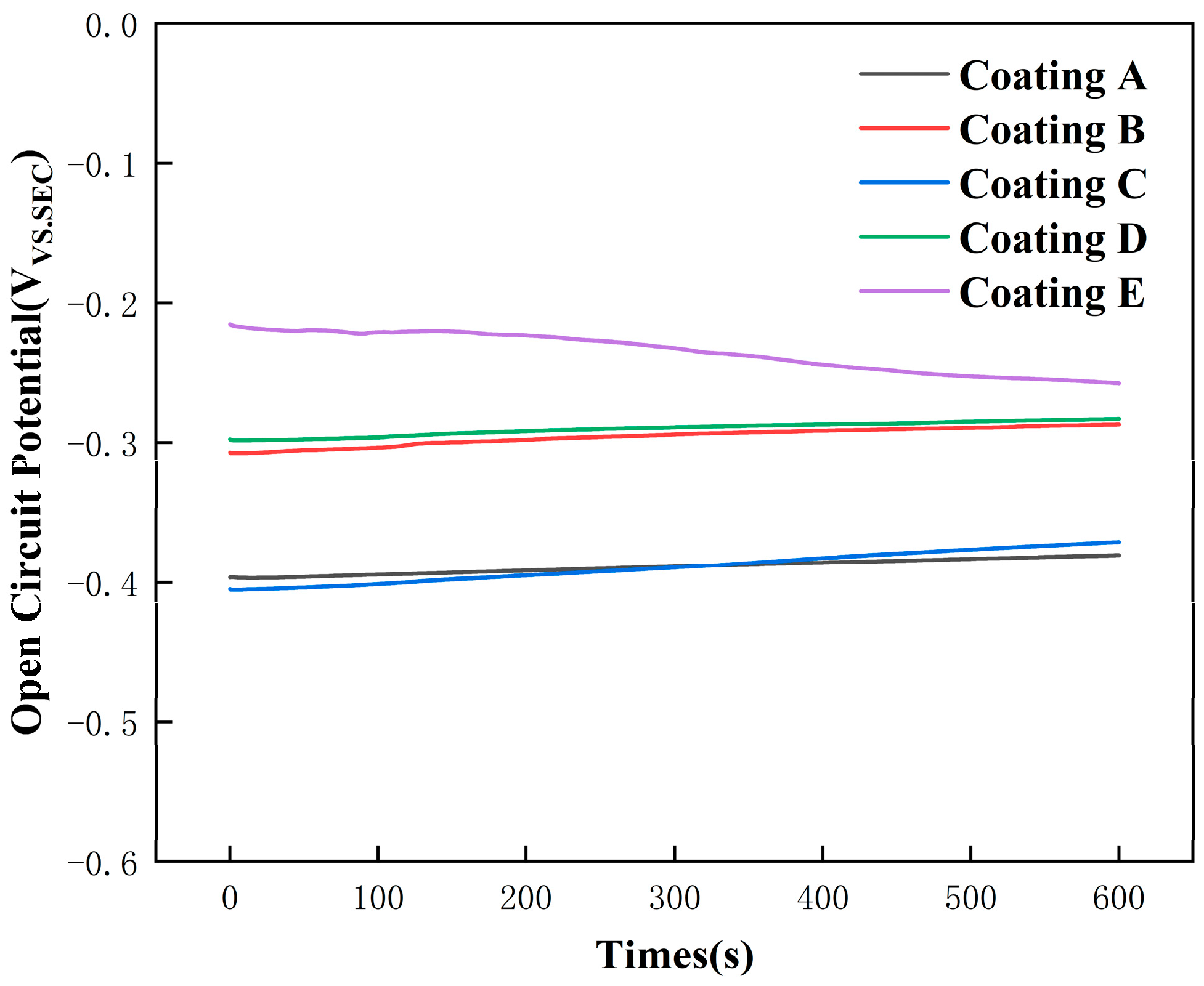

3.6. Corrosion Behavior of Coatings

Electrochemical

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, B.; Zhou, P.; Lv, Y. Research Progress in and Defect Improvement Measures for Laser Cladding. Materials 2025, 18, 3206. [Google Scholar] [CrossRef]

- Zheng, K.; Yu, D.; Liu, J.; Wu, C.; Zhang, S.; Zhang, C.; Wang, Q.; Zhang, D. Laser cladding of FeCoCrNiTi high-entropy alloy coatings to modulate the microstructure and enhance the tribo-corrosion behavior on 304 stainless steel. Surf. Coat. Technol. 2025, 505, 132114. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Zha, X.; Lu, Y.; Li, K.; Xu, J.; Xie, T. Analysis and Prediction of Melt Pool Geometry in Rectangular Spot Laser Cladding Based on Ant Colony Optimization–Support Vector Regression. Micromachines 2025, 16, 224. [Google Scholar] [CrossRef]

- Wang, K.; Liu, W.; Hong, Y.; Sohan, H.S.; Tong, Y.; Hu, Y.; Zhang, M.; Zhang, J.; Xiang, D.; Fu, H.; et al. An overview of technological parameter optimization in the case of laser cladding. Coatings 2023, 13, 496. [Google Scholar] [CrossRef]

- Wang, W.; He, Q.; Shi, W.; Wu, W. Research on Modification Technology of Laser Cladding Stellite6/Cu Composite Coating on the Surface of 316L Stainless Steel Plow Teeth. Micromachines 2025, 16, 827. [Google Scholar] [CrossRef]

- Manoj, A.; Saurabh, A.; Narala, S.K.R.; Saravanan, P.; Natu, H.P.; Verma, P.C. Surface modification of grey cast iron by laser cladding for automotive brake disc application. Wear 2023, 532, 205099. [Google Scholar] [CrossRef]

- Zhu, Z.-X.; Liu, X.-B.; Liu, Y.-F.; Zhang, S.-Y.; Meng, Y.; Zhou, H.-B.; Zhang, S.-H. Effects of Cu/Si on the microstructure and tribological properties of FeCoCrNi high entropy alloy coating by laser cladding. Wear 2023, 512, 204533. [Google Scholar] [CrossRef]

- Ji, F.; Li, X.; Zhang, S.; Pang, M. Influence of Cu Content Variation on the Tribological Properties of Ni60CuMo with Sandwich-Structured Composite Coatings by Laser Cladding. Micromachines 2024, 15, 1429. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Zhao, W.; Li, Z.; Guo, N.; Xiao, G.; Zhang, H. High-temperature oxidation behavior and corrosion resistance of in-situ TiC and Mo reinforced AlCoCrFeNi-based high entropy alloy coatings by laser cladding. Ceram. Int. 2023, 49, 10151–10164. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, X.; Lou, C.; Kang, L.; Hou, Q.; Ma, C. Influence of WC ceramic particles on structures and properties of laser cladding Ni50-WC coatings. J. Mater. Res. Technol. 2023, 26, 14–21. [Google Scholar] [CrossRef]

- Li, X.; Zhang, S.; Liu, W.; Pang, X.; Tong, Y.; Zhang, M.; Zhang, J.; Wang, K. Effect of WC Content on the Wear and Corrosion Properties of Oscillating Laser-Cladding-Produced Nickel-Based Coating. Coatings 2023, 13, 1614. [Google Scholar] [CrossRef]

- Hu, Z.; Li, Y.; Lu, B.; Tan, N.; Cai, L.; Yong, Q. Effect of WC content on microstructure and properties of high-speed laser cladding Ni-based coating. Opt. Laser Technol. 2022, 155, 108449. [Google Scholar] [CrossRef]

- He, Q.; Zhang, Y.; Shi, W.; Wang, W. Effect of Cu content on the microstructure and properties of 316L laser cladding cobalt based coatings. Laser Technol. 2024, 48, 527–533. [Google Scholar] [CrossRef]

- Li, Q.; Liang, J.; Chen, M.; Yang, Z.; Peng, H.; Li, D. Effect of Ti on defects in Nb-Mo-Ta-W high-entropy alloy prepared by laser metal deposition. J. Aeronaut. Mater. 2023, 43, 86–93. [Google Scholar] [CrossRef]

- Liang, H.; Hou, J.; Cao, Z.; Jiang, L. Interesting ‘island-like’ microstructure and tribological evaluation of Al1.5CrFeNiWTi0.5 high entropy alloy coating manufactured by laser cladding. Tribol. Int. 2023, 179, 108171. [Google Scholar] [CrossRef]

- Duan, X.; Wang, S.; Wang, G.; Gao, S.; Wang, L.; Yang, X. Microstructure evolution and frictional wear behavior of laser cladding FeCrCoNiMo0.5Wx high-entropy alloy coatings. Intermetallics 2023, 158, 107888. [Google Scholar] [CrossRef]

- Jian, S.; Liu, K.; Li, J.; Xu, C. A new test for evaluating the cracking susceptibility of laser cladding coatings and its validity on assessing the effect of laser power. Opt. Laser Technol. 2025, 180, 111609. [Google Scholar] [CrossRef]

- Yuan, S.; Li, H.; Han, C.; Li, W.; Xu, X.; Chen, C.; Wei, R.; Wang, T.; Wu, S.; Li, F. FeCoNiCrAl0.6 high-entropy alloy coating on Q235 steel fabricated by laser cladding. Mater. Sci. Technol. 2023, 39, 705–713. [Google Scholar] [CrossRef]

- Hao, X.; Liu, H.; Zhang, X.; Tao, J.; Wang, Y.; Yang, C.; Liu, Y. Microstructure and wear resistance of in-situ TiN/(Nb, Ti)5Si3 reinforced MoNbTaWTi-based refractory high entropy alloy composite coatings by laser cladding. Appl. Surf. Sci. 2023, 626, 157240. [Google Scholar] [CrossRef]

- Li, X.; Feng, Y.; Wang, X.; Xie, H.; Yang, X.; Liu, B.; Cao, Y. Microstructures and properties of AlCrFeNiMnx high-entropy alloy coatings fabricated by laser cladding on a copper substrate. J. Alloys Compd. 2022, 926, 166778. [Google Scholar] [CrossRef]

- Liu, H.; Sun, S.; Zhang, T.; Zhang, G.; Yang, H.; Hao, J. Effect of Si addition on microstructure and wear behavior of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. Surf. Coat. Technol. 2021, 405, 126522. [Google Scholar] [CrossRef]

- Shirali, M.; Gheisari, K.; Reihanian, M. Phase Evolution, Mechanical Properties, and Corrosion Behavior of FeCoNiCu-Based High-Entropy Alloys. J. Mater. Res. Technol. 2025, 37, 4275–4290. [Google Scholar] [CrossRef]

- Ning, H.; Liu, Z.; Kong, Y.; Li, J.; Shen, Y. Study on the dealloying of binary Cu-Fe laser cladding layer with Fe content less than 20 at.%. Acta Mater. 2025, 297, 121342. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, T.; Sun, S.; Zhang, G.; Tian, X.; Chen, P. Microstructure and dislocation density of AlCoCrFeNiSix high entropy alloy coatings by laser cladding. Mater. Lett. 2021, 283, 128746. [Google Scholar] [CrossRef]

- Zhang, L.; Ji, Y.; Yang, B. Thermal Stability and Hot Corrosion Performance of the AlCoCrFeNi2.1 High-Entropy Alloy Coating by Laser Cladding. Materials 2023, 16, 5747. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Bai, P.; Li, Z.; Zhang, J. A review of laser cladding monitoring and control based on the molten pool images. Int. J. Adv. Manuf. Technol. 2025, 140, 2317–2340. [Google Scholar] [CrossRef]

- Guo, J.; Liu, C.; Wang, D.; Xu, L.; Song, K.; Gao, M. Structure and Wear Resistance of TiC-Reinforced Al1.8CrCuFeNi2 High-Entropy Alloy Coating Using Laser Cladding. Materials 2023, 16, 3422. [Google Scholar] [CrossRef]

- Ou, W.; Yuan, X.; Li, Z.; Zuo, X.; Li, X.; Zhang, L.; Li, T. Novel eutectic high-entropy alloy surfacing of flower-pot structure with outstanding wear resistance manufactured by laser cladding. Surf. Interfaces 2023, 40, 103068. [Google Scholar] [CrossRef]

- De Oliveira, U.; Ocelík, V.; De Hosson, J.T.M. Analysis of coaxial laser cladding processing conditions. Surf. Coat. Technol. 2005, 197, 127–136. [Google Scholar] [CrossRef]

- Li, T.; Wang, S.; Lu, Y.; Cao, Z.; Wang, T.; Li, T. Research progress and prospect of high-entropy alloy materials. Strateg. Study Chin. Acad. Eng. 2023, 25, 170–181. [Google Scholar] [CrossRef]

- Yang, Y.; Ren, Y.; Tian, Y.; Li, K.; Bai, L.; Huang, Q.; Shan, Q.; Tian, Y.; Wu, H. Microstructure and tribological behaviors of FeCoCrNiMoSix high-entropy alloy coatings prepared by laser cladding. Surf. Coat. Technol. 2022, 432, 128009. [Google Scholar] [CrossRef]

- Feng, M.; Yang, X.; Lian, G.; Chen, C. Microstructure and properties of laser cladding CoCrNi-based medium-entropy alloy enhanced by Nb. J. Mater. Res. Technol. 2025, 35, 5015–5033. [Google Scholar] [CrossRef]

- Chen, M.; Yang, X.; Zhang, Z.; Gu, Y.; Li, K.; Liu, Y.; Ma, J. Research status of laser cladding technology on aluminum alloy surface. Int. J. Adv. Manuf. Technol. 2025, 137, 1–21. [Google Scholar] [CrossRef]

- Li, X.-C.; Liang, H.; Zhao, Y.-Z.; Gao, L.; Jiang, L.; Cao, Z.-Q. Microstructure and wear resistance of AlCrFeNiMo0.5Six high-entropy alloy coatings prepared by laser cladding. China Foundry 2022, 19, 473–480. [Google Scholar] [CrossRef]

- Wang, Z.; Peng, B.; Ning, H.; Zhang, J.; Han, Z.; Li, J. Effect of Si on the mechanical properties of Inconel 625 laser cladding layer. Mater. Lett. 2024, 354, 135380. [Google Scholar] [CrossRef]

- Tabrizi, A.T.; Aghajani, H.; Saghafian, H.; Laleh, F.F. Correction of Archard equation for wear behavior of modified pure titanium. Tribol. Int. 2021, 155, 106772. [Google Scholar] [CrossRef]

- Gonela, K.K.; Vijayavarman, C.; Palanivel, M.; Mariappan, L.; Ramasubramanian, L.N.; Kannan, A.R. Effect of robotic weaving motion on mechanical and microstructural characteristics of wire arc additively manufactured NiTi shape memory alloy. Int. J. Mater. Res. 2023, 114, 947–954. [Google Scholar] [CrossRef]

- Miao, J.; Wang, M.; Zhang, A.; Lu, Y.; Wang, T.; Li, T. Tribological properties and wear mechanism of AlCr1.3TiNi2 eutectic high-entropy alloy at elevated temperature. Acta Metall. Sin. 2022, 59, 267–276. [Google Scholar] [CrossRef]

- Savinov, R.; Shi, J. Microstructure, mechanical properties, and corrosion performance of additively manufactured CoCrFeMnNi high-entropy alloy before and after heat treatment. Mater. Sci. Addit. Manuf. 2023, 2, 42. [Google Scholar] [CrossRef]

- Song, C.; Zhao, W.; Bi, J.; Li, S.; Gao, H.; Zhang, H.; Gao, S.; Lv, Y.; Rao, W. Effect of V addition on the microstructure and wear resistance of CoCrFeNiNb high-entropy alloy laser cladding layers. Intermetallics 2025, 179, 108654. [Google Scholar] [CrossRef]

- Liu, Y.; Xiang, D.; Wang, K.; Yu, T. Corrosion of laser cladding high-entropy alloy coatings: A review. Coatings 2022, 12, 1669. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Ni | Al | Co | |

|---|---|---|---|---|---|---|

| 0 Si | 0 | 21.42 | 24.12 | 22.47 | 10.49 | Bal. |

| 0.5% Si | 0.5 | 21.42 | 24.12 | 22.47 | 10.49 | Bal. |

| 1% Si | 1 | 21.42 | 24.12 | 22.47 | 10.49 | Bal. |

| 1.5% Si | 1.5 | 21.42 | 24.12 | 22.47 | 10.49 | Bal. |

| 2% Si | 2 | 21.42 | 24.12 | 22.47 | 10.49 | Bal. |

| Coating | Average Coefficient of Friction | Amount of Wear/g | Wear Rate g/(N·m) |

|---|---|---|---|

| FeCoNiCuAl | 0.485 | 0.0354 | 1.566 × 10−6 |

| FeCoNiCuAlSi0.5 | 0.481 | 0.0239 | 1.057 × 10−6 |

| FeCoNiCuAlSi1.0 | 0.442 | 0.0171 | 7.564 × 10−7 |

| FeCoNiCuAlSi1.5 | 0.357 | 0.0166 | 7.342 × 10−7 |

| FeCoNiCuAlSi2.0 | 0.349 | 0.0142 | 6.281 × 10−7 |

| Coatings | Ecorr/V | Icorr/A/cm2 |

|---|---|---|

| FeCoNiCuAl | −0.471 | 1.039 × 10−5 |

| FeCoNiCuAlSi0.5 | −0.436 | 6.442 × 10−6 |

| FeCoNiCuAlSi1.0 | −0.395 | 4.823 × 10−6 |

| FeCoNiCuAlSi1.5 | −0.347 | 4.169 × 10−6 |

| FeCoNiCuAlSi2.0 | −0.344 | 4.073 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Guo, C.; Huang, G.; Peng, Z.; Hu, R.; Lin, Q.; Lu, T. Study on Microstructures and Properties of FeCoNiCuAlSix High-Entropy Alloy Composite Coatings by Laser Cladding. Micromachines 2025, 16, 1211. https://doi.org/10.3390/mi16111211

Zhang X, Guo C, Huang G, Peng Z, Hu R, Lin Q, Lu T. Study on Microstructures and Properties of FeCoNiCuAlSix High-Entropy Alloy Composite Coatings by Laser Cladding. Micromachines. 2025; 16(11):1211. https://doi.org/10.3390/mi16111211

Chicago/Turabian StyleZhang, Xinyu, Chun Guo, Guangcan Huang, Zheng Peng, Ruizhang Hu, Qingcheng Lin, and Tianyuan Lu. 2025. "Study on Microstructures and Properties of FeCoNiCuAlSix High-Entropy Alloy Composite Coatings by Laser Cladding" Micromachines 16, no. 11: 1211. https://doi.org/10.3390/mi16111211

APA StyleZhang, X., Guo, C., Huang, G., Peng, Z., Hu, R., Lin, Q., & Lu, T. (2025). Study on Microstructures and Properties of FeCoNiCuAlSix High-Entropy Alloy Composite Coatings by Laser Cladding. Micromachines, 16(11), 1211. https://doi.org/10.3390/mi16111211