1. Research Background and Significance

1.1. Research Background

With the rapid advancements in material bonding technologies, welding has emerged as a pivotal connection method, playing a vital role across multiple industries, including electronics, automotive, and aerospace. Ultrasonic welding technology has gained prominence as a research focus due to its efficiency, energy efficiency, and environmental benefits. However, the welding process involves complex physical and mechanical phenomena, particularly at the atomic and microscopic scales. Critical challenges such as material diffusion behavior, interface structure evolution, and factors affecting welding quality have become key constraints hindering the further development and practical application of this technology.

From a theoretical perspective, ultrasonic welding challenges involve the interdisciplinary integration of materials science, physics, and mechanics. The inherent complexity and uncertainty pose significant challenges to traditional theoretical frameworks, necessitating innovative perspectives and solutions. In practical applications, inconsistent welding quality not only compromises product performance and reliability but also leads to increased production costs and resource wastage.

In recent years, scholars both domestically and internationally have conducted extensive research on ultrasonic welding, accumulating substantial survey data and contributions to the literature. Meanwhile, the introduction of relevant policies and regulations has provided crucial support and guidance for this field. However, despite numerous research outcomes, some fundamental issues in ultrasonic welding processes remain unresolved, such as atomic diffusion mechanisms, interface temperature evolution, and precise quality control. The underlying causes and mechanisms behind these challenges still require further investigation. Therefore, this study aims to thoroughly analyze the causes and impacts of ultrasonic welding problems, propose practical solutions, and provide theoretical support and practical guidance for the sustainable development of this field.

1.2. Significance of the Study

This study provides a comprehensive analysis of core challenges in ultrasonic welding technology, systematically tracing its theoretical evolution and practical applications. Through integrated methodologies, including molecular dynamics simulations and experimental investigations, researchers conducted rigorous data analysis to derive forward-looking conclusions with significant practical value. These findings not only validate the theoretical foundations for industrial implementation but also open new research pathways, offering crucial references for future studies. This study identifies the key factors affecting welding quality while proposing targeted solutions that enhance both efficiency and product integrity. These strategies will drive sustainable industry growth through improved welding processes. Furthermore, the research provides actionable insights for industry managers and researchers, playing a vital role in optimizing operational practices and fostering healthy development within the ultrasonic welding sector.

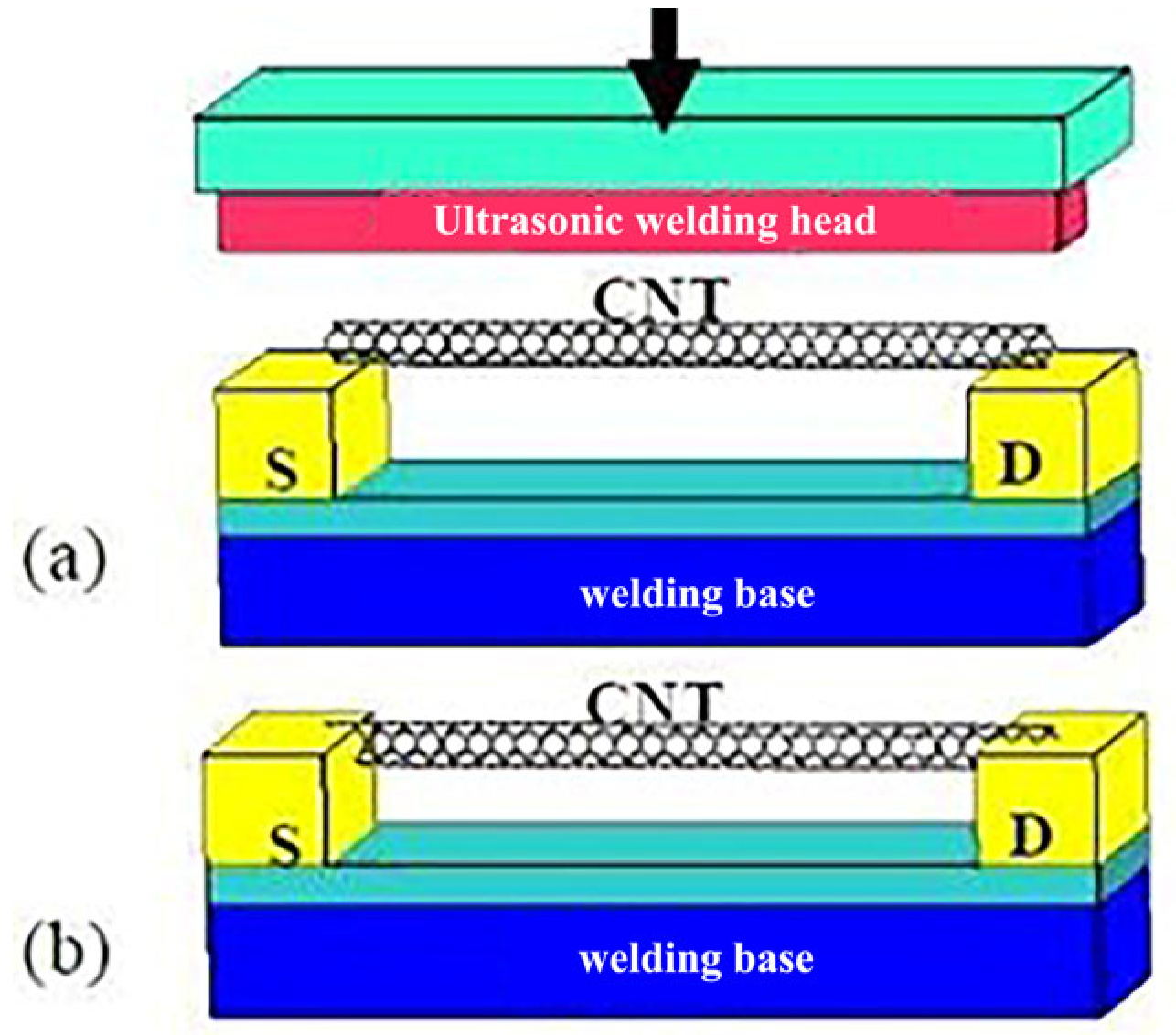

2. Model Simulation

The ultrasonic molecular dynamics simulation steps are shown below.

2.1. Establishment of Simulation Model

Molecular simulation is a crucial research method that studies molecular structures and properties through computer simulations, including Molecular Mechanics (MM), Monte Carlo (MC) simulations, and molecular dynamics simulations. Molecular Mechanics (MM) is a computational method that describes molecular structures and energies based on classical mechanics, typically used for optimizing molecular geometries and calculating conformational energies. Monte Carlo (MC) simulations utilize random sampling to explore the thermodynamic properties and equilibrium states of systems, making them particularly suitable for studying phase transitions and adsorption processes. In contrast, Molecular Dynamics (MD) simulations solve Newton’s equations of motion to track the time evolution of atomic trajectories, providing insights into dynamic processes and non-equilibrium phenomena.

For multi-atomic molecular systems, if all intermolecular interaction potentials—such as bond stretching potential and bond angle bending potential—are described by potential functions without constraints, the numerical solution of the system’s motion equation is essentially identical to that of single-atom systems. Common MD numerical integration methods include the Verlet algorithm, the predictive correction algorithm, and its derivatives like the frog-jump method and velocity Verlet method. De et al. [

1] proposed an implicit integration scheme based on variational integrators for the Discrete Element Method (DEM). This approach not only handles dynamic problems but also degrades into an energy minimization scheme under quasi-static conditions. Following Hamiltonian principles, it derives motion equations by identifying stationary points in the action. The application scope of variational integrators is expanded through Lagrange-D’ Alembert principles, making them applicable to systems with non-conservative forces (e.g., dissipative forces). This is particularly important for particle material simulations where inter-particle contact typically exhibits dissipative characteristics. A time-discrete framework was proposed to lay the foundation for applying the Quasi-Concrete (QC) method to particle systems. This enables full-resolution particle simulations in certain regions while employing more efficient continuum descriptions in others. The proposed integration method is benchmarked against the existing velocity Verlet method, and its equivalence in single collision, long-term stability, and statistics is verified.

Molecular dynamics simulation is based on classical Newtonian mechanics, and the evolution trajectory of the system is tracked by solving the equation of motion of atoms numerically:

Here, represent the atomic mass, the position vector, and the potential energy function, respectively. The simulation adheres to the law of conservation of energy, requiring temperature/pressure regulation to achieve the target ensemble.

Early MD simulations were confined within a fixed spatial volume. According to the law of conservation of energy, the total energy of the simulated system remains constant, allowing no fluctuations. From a statistical mechanics perspective, such MD systems are classified as microcanonical or NVE ensembles. However, many practical chemical and biological systems maintain constant temperatures but exhibit variable total energies when in contact with a constant heat source—these represent canonical systems or NVT ensembles. Furthermore, most real-world or engineered systems possess both fixed temperatures and pressures yet demonstrate variable total energy and volume, constituting NPT ensembles.

Common molecular dynamics software includes LAMMPS and GROMACS. LAMMPS, with its robust parallel computing capabilities, is particularly suitable for simulating large-scale systems. Among the commonly used MD software, LAMMPS (Large-scale Atomic/Molecular Massively Parallel Simulator) is highly regarded for its excellent parallel computing efficiency and flexibility, making it particularly suitable for simulating large-scale metallic and alloy systems. GROMACS, on the other hand, is optimized for biomolecular systems and soft matter, offering high performance in simulating proteins, lipids, and polymers, though it can also handle simpler material systems. When dealing with complex ultrasonic welding systems involving multiple materials or numerous atoms, LAMMPS demonstrates efficient computational performance. GROMACS is primarily used for simulating biomolecules and soft matter systems, though it can also handle simple material systems. This study focuses on plastic welding, emphasizing intermolecular interactions, and dynamic processes.

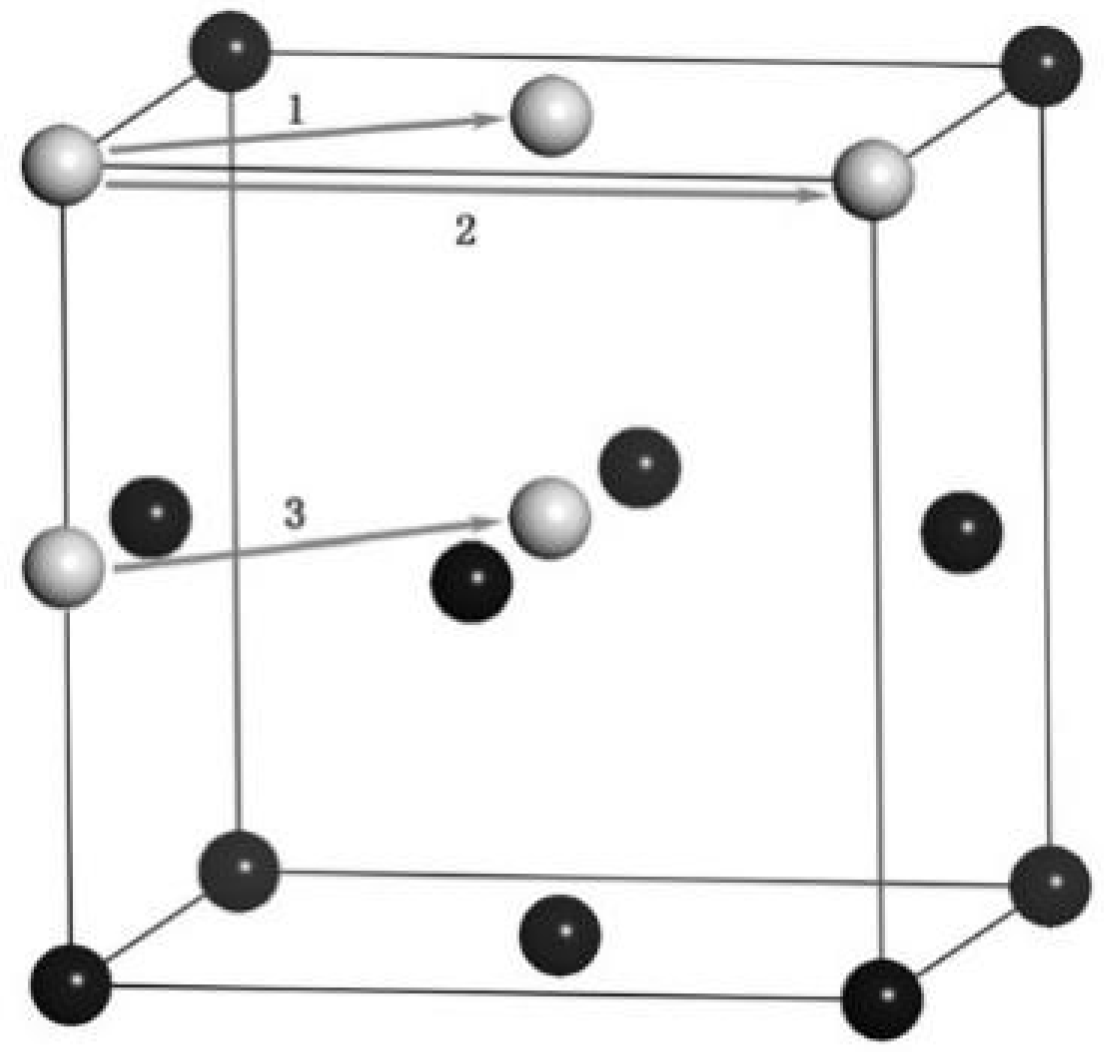

Different metals possess distinct crystal structures, with common examples including Face-Centered Cubic (FCC), Body-Centered Cubic (BCC), and Hexagonal Close-Packed (HCP). Determining a metal’s crystal structure forms the foundation for constructing atomic models. To determine the unit cell dimensions, lattice constants can be obtained through a literature review or experimental measurements.

2.2. Core Framework of Molecular Dynamics Simulation

2.2.1. Potential Function Selection

Potential function is the physical basis of molecular dynamics simulation. The accuracy of potential function determines the reliability of simulation results through mathematical formula to quantify the interactions between atoms.

The EAM (Embedded Atomic Method), a widely used potential energy model for simulating material properties like metals and alloys, is based on the concept of electron density. It treats metal atoms as embedded within surrounding electron clouds, where interatomic interactions depend not only on spatial proximity but also on the distribution of electron clouds. This approach allows the EAM potential function to describe the nature of metallic bonds more accurately. Compared with potential functions that only consider two-body interactions, the EAM accounts for multi-body interactions, better aligning with the actual interatomic interactions in metallic systems and effectively reflecting the structural and performance characteristics of metals.

In contrast, Tersoff [

2] developed a general form of empirical interatomic potential functions applicable to multi-component systems, primarily designed for covalent materials such as silicon and carbon. Unlike the EAM potential, the Tersoff potential represents a three-body function based on bond order concepts. It describes interactions in covalent bond systems through bond length, bond angle, and the spatial distribution of neighboring atoms. The key advantage of this potential lies in its dynamic reflection of chemical environment changes around atoms, enabling an accurate depiction of bond formation and breaking. By introducing bond angle dependencies, it precisely characterizes the directionality of covalent bonds. To enhance performance in molecular dynamics simulations, conventional models with overly steep cutoff functions often require optimization with smoother parameters. Compared to quantum mechanical methods, the Tersoff potential significantly reduces computational costs, making it ideal for large-scale simulations of covalent systems.

In potential function research, Mendelev et al. [

3] utilized first-principles calculations (VASP software) to obtain critical properties of Al-Mg alloys (e.g., lattice parameters, compound formation energy), combined with molecular dynamics simulations to validate solid–liquid phase equilibrium. They proposed a staged fitting strategy: first optimizing the pure metal potential function (based on existing Al/Mg potential functions) to ensure accurate elemental melting points, then incorporating liquid solution energy data and dilute solid solution formation energy through iterative refinement of cross-potential parameters. The study revealed that potential functions fitted solely for solid-state properties could not correctly predict solid/liquid lines in the Al-Mg phase diagram. Therefore, liquid thermodynamic data were incorporated into the fitting process to ensure accuracy of solid–liquid interface properties. This determined that liquid solution energy data must be integrated into alloy potential function development as a prerequisite for simulating solidification phenomena.

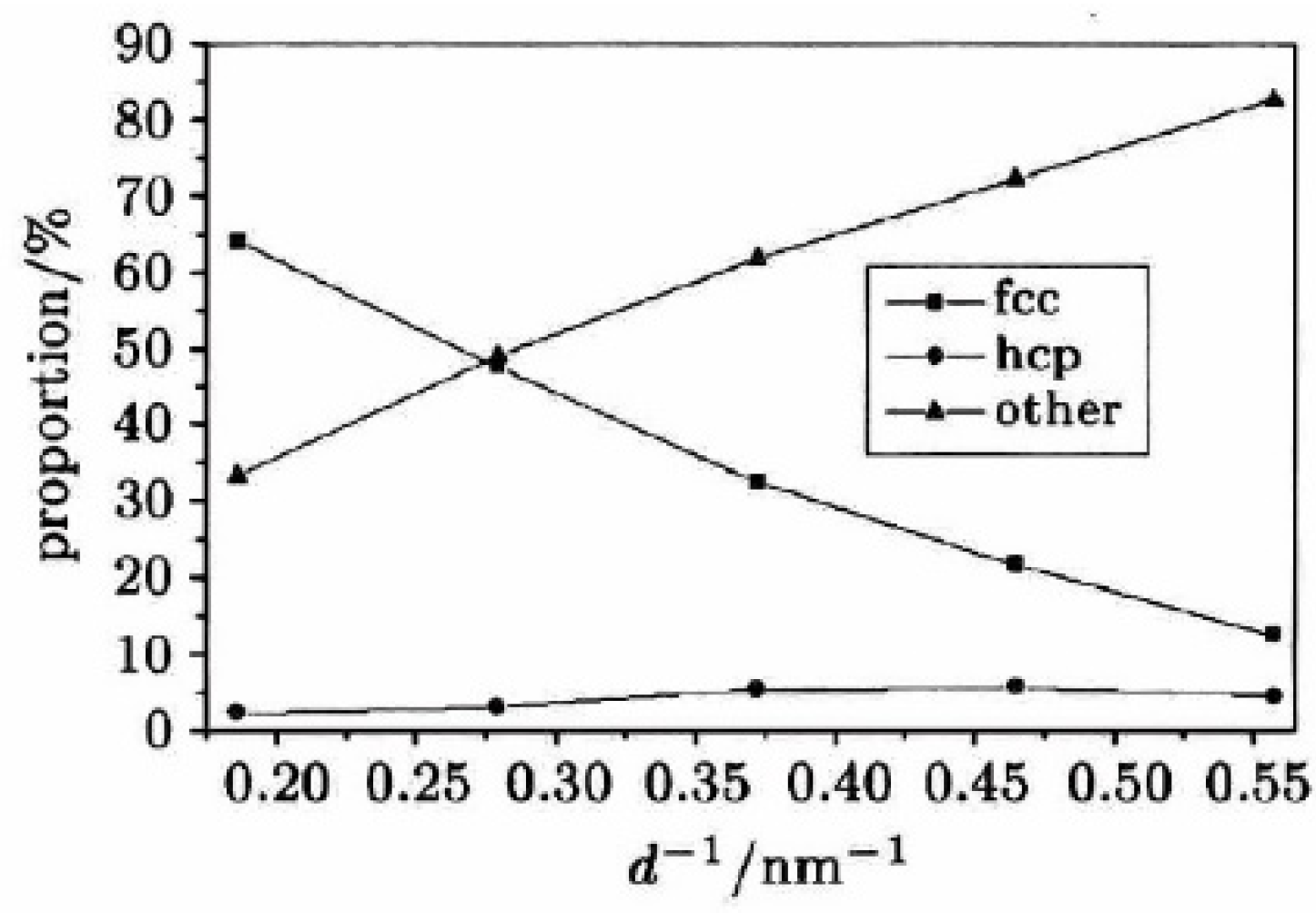

Faken et al. [

4] developed a common neighborhood analysis method that systematically investigates local atomic structures using 3D computer graphics. By analyzing radial distribution functions through atomic pair decomposition, this approach directly interprets the functional characteristics of these distributions from an atomic perspective and enables the identification of crystal types. The study demonstrated that while most atoms in copper melts were classified as Face-Centered Cubic (FCC) atoms, stacking faults were still observed—a phenomenon traceable to near-critical nuclei formation.

The choice of an appropriate interatomic potential is not merely a technical step but a foundational decision that directly governs the physical fidelity and reliability of the simulation outcomes discussed in subsequent sections. The conclusions drawn from the material-specific case studies (

Section 3 and

Section 4)—regarding mechanisms such as atomic diffusion, dislocation dynamics, and phase transformation—are strongly dependent on this choice. For example, the activation energy for diffusion or the critical stress for yielding is not an absolute value but one contingent upon the potential’s parameterization. A potential fitted exclusively to the properties of solid phases may fail to accurately model processes involving significant lattice distortion or local melting at the weld interface. Similarly, the ability of a potential to correctly reproduce stacking fault energies will critically affect the simulation of dislocation-mediated plasticity in FCC metals like Cu and Al. Therefore, discrepancies in reported mechanisms or quantitative values across different studies on similar material systems can often be attributed to the use of different empirical potentials. The reliability of any MD study hinges on the demonstrated accuracy of its chosen potential for the specific properties and conditions under investigation.

2.2.2. Boundary Conditions Design

In molecular dynamics simulation, the common types of boundary conditions are Periodic Boundary Conditions (PBC), Non-Periodic Boundary Conditions (NPB), and mixed boundary conditions. Different types of boundary conditions have different principles and application scenarios.

Periodic Boundary Conditions (PBC): These are the most widely used boundary conditions in molecular dynamics simulations. Under PBC, system boundaries are interconnected to form an infinitely repeating three-dimensional grid. This means when a particle exits one boundary, it immediately enters the opposite boundary, creating the illusion of an infinite system. Such boundary conditions effectively prevent boundary effects and are commonly employed to study macroscopic systems, including fluid dynamics and material properties such as crystal structures.

Non-Periodic Boundary Conditions (NPB): These apply to isolated systems such as individual molecules or clusters. In such cases, the system has no boundary connections. Particles that reach the boundary will not re-enter the system, requiring special treatment of particles at the boundary—such as applying fixed forces or implementing reflections.

Mixed boundary conditions: These combine the characteristics of periodic and non-periodic boundary conditions, with parameters tailored to specific simulation requirements. For example, when simulating a two-dimensional film, one might apply periodic boundary conditions in the horizontal plane while implementing non-periodic boundary conditions in the vertical direction.

2.2.3. Optimization of Time Step Length

In molecular dynamics simulations, the selection of time steps plays a crucial role in simulation accuracy. The motion states of molecules change rapidly within extremely short periods, and appropriate time steps can accurately capture these changes, making simulation results closer to real-world scenarios. Excessive time steps may reduce both simulation accuracy and stability. Therefore, it is essential to strike a balance between computational efficiency and precision. For high-precision requirements, smaller time steps are often necessary; when computational resources are limited and strict precision demands are not critical, appropriately increasing time steps is acceptable, provided that simulation stability and result reliability are maintained.

Tersoff [

2] developed a general form of empirical interatomic potential functions applicable to multi-component systems. This approach extends traditional single-component potential functions by enabling interpolation for heteronuclear bonds, thereby broadening their application scope in molecular dynamics simulations. In these simulations, the smoothness of potential functions is critical for accurate results. Conventional models often employ overly steep cutoff functions that require optimization with smoother parameters. This improvement significantly enhances the model’s performance in molecular dynamics simulations, particularly when dealing with complex structures or extended simulation durations.

Cheng Hongtao et al. [

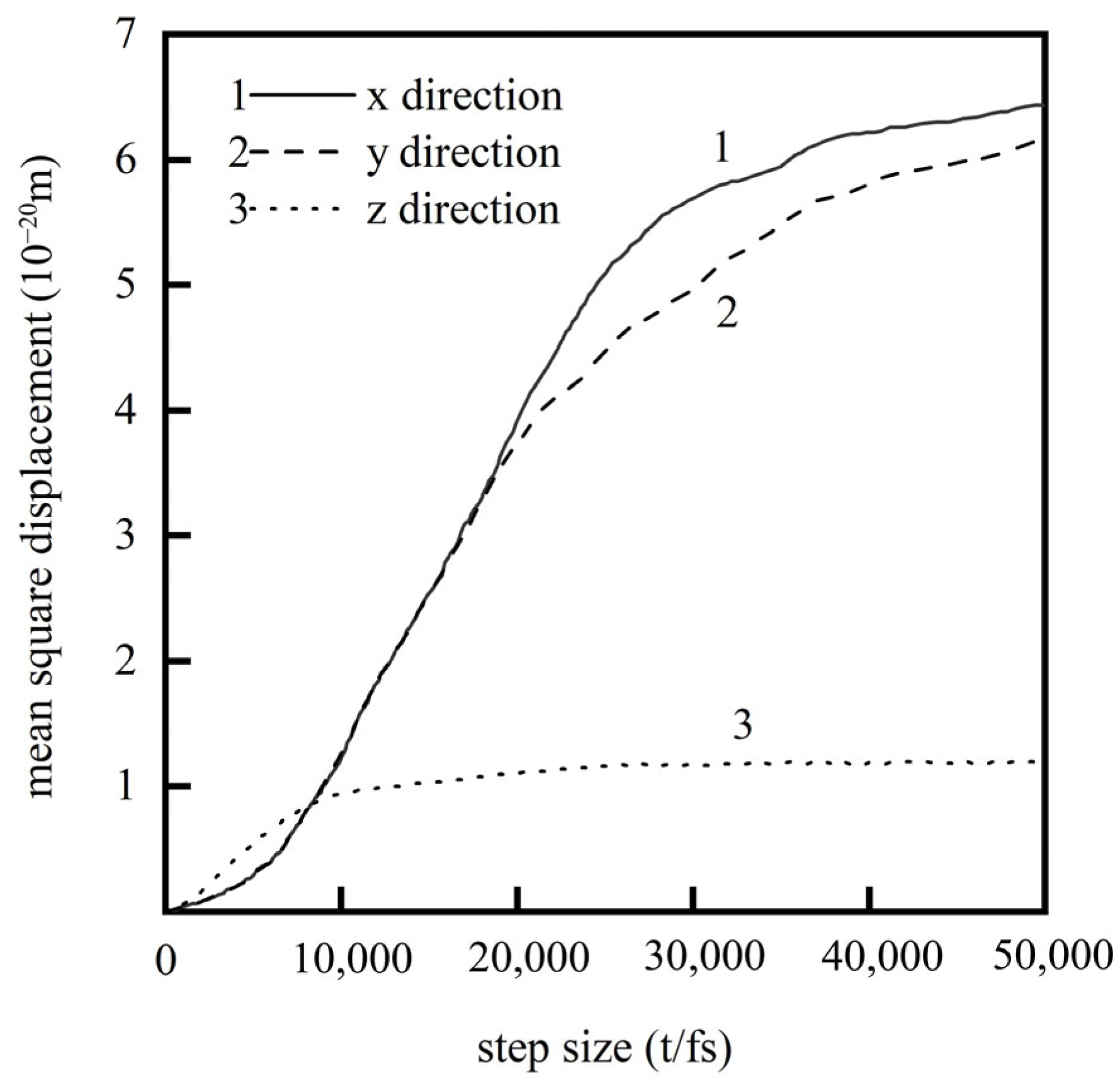

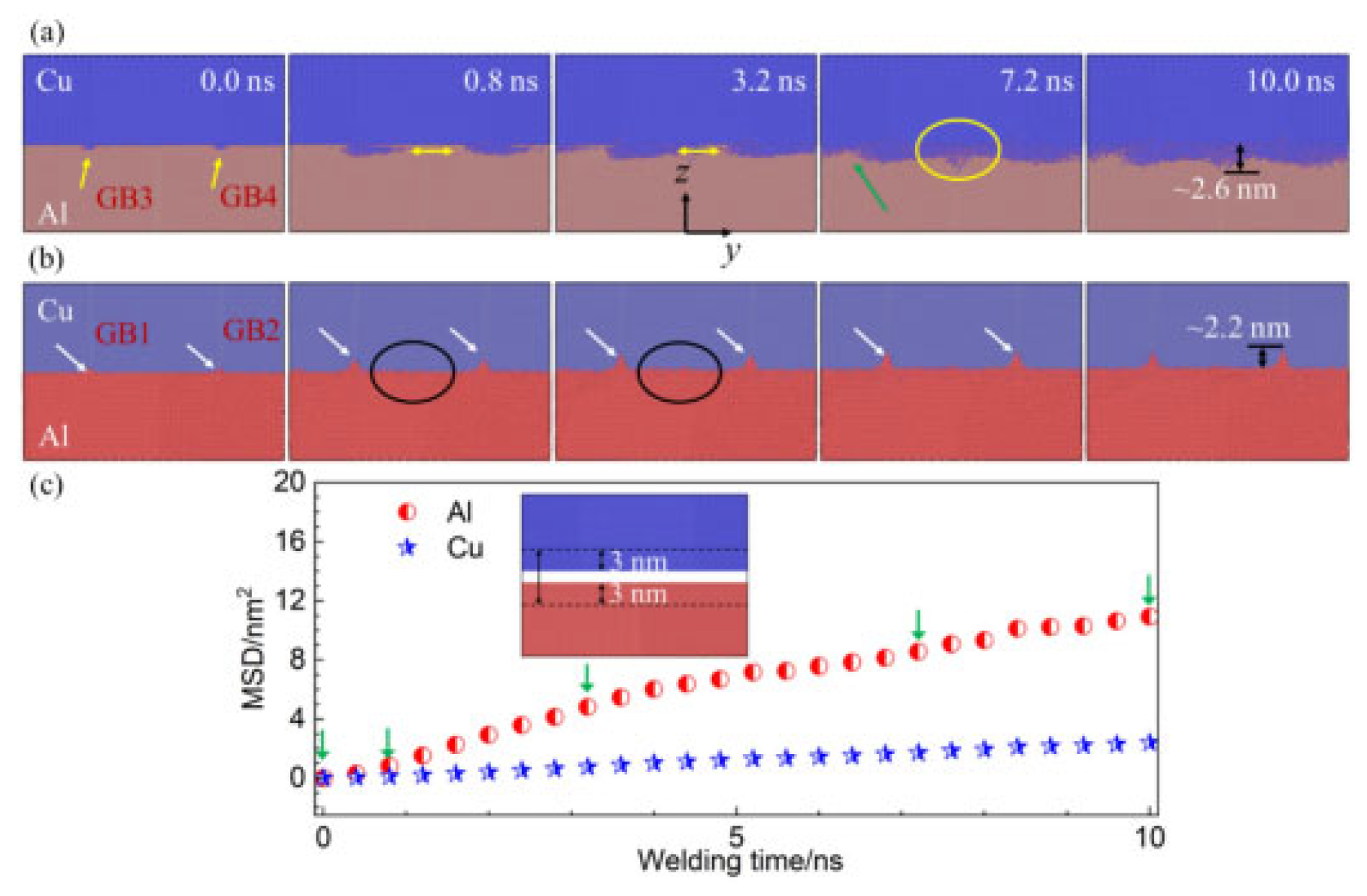

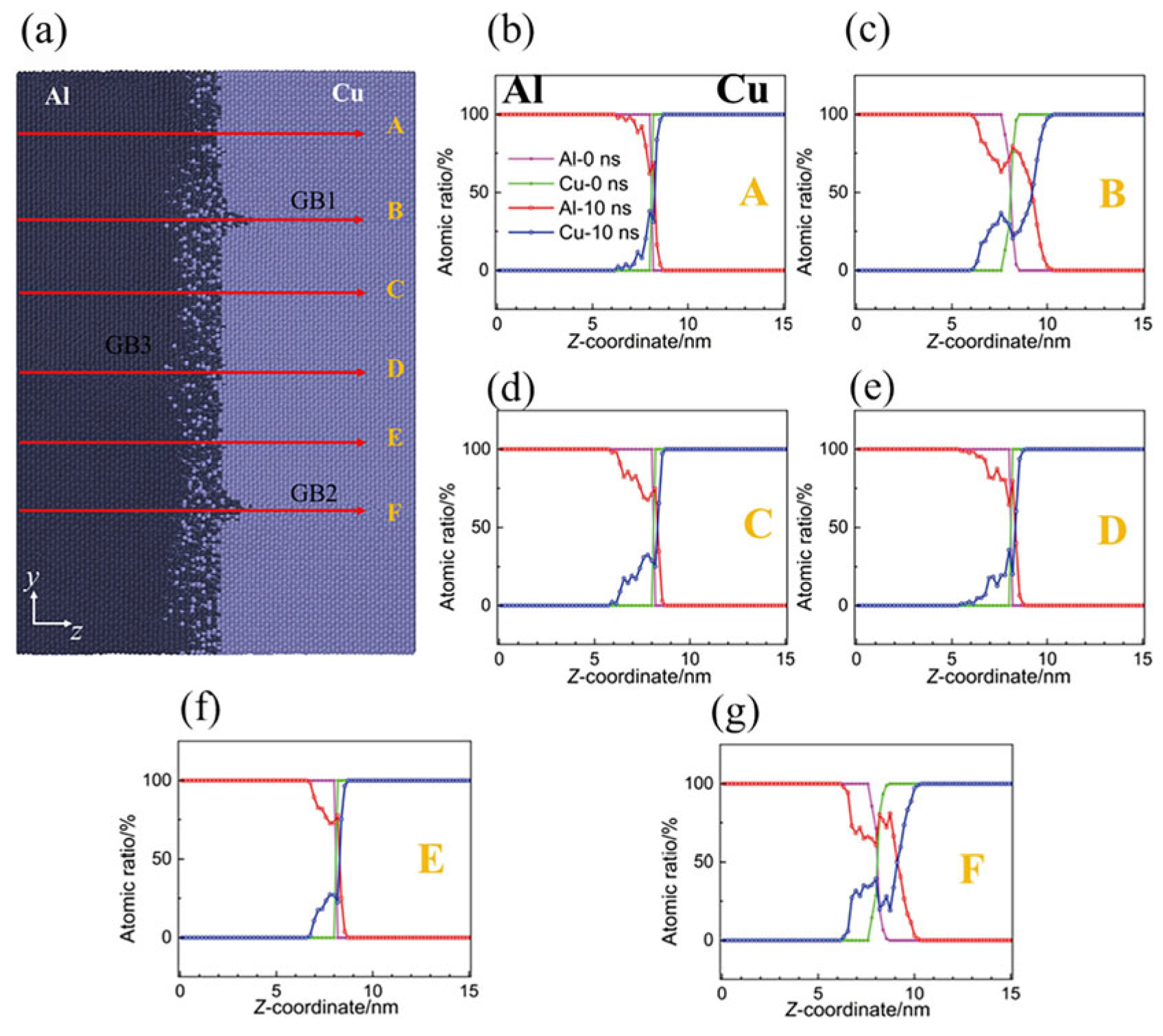

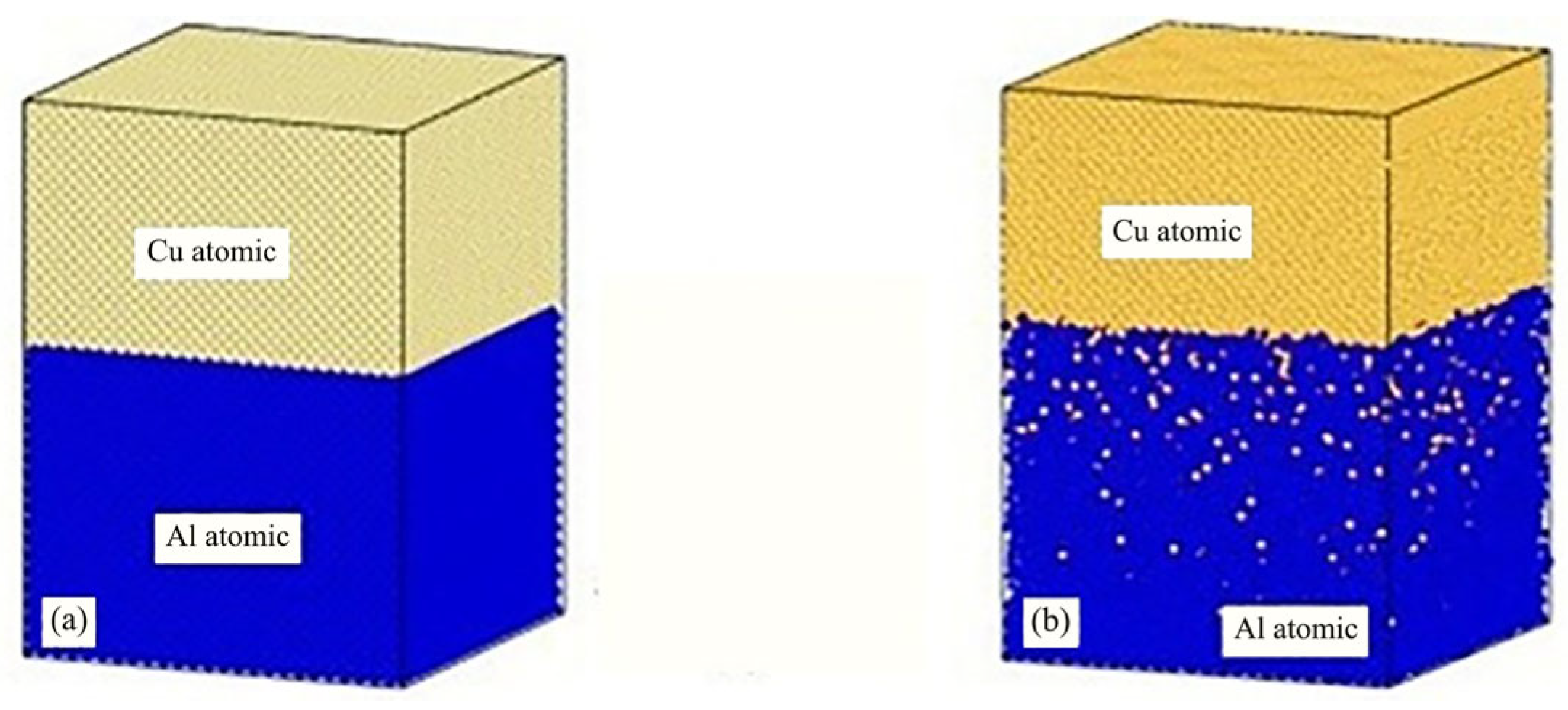

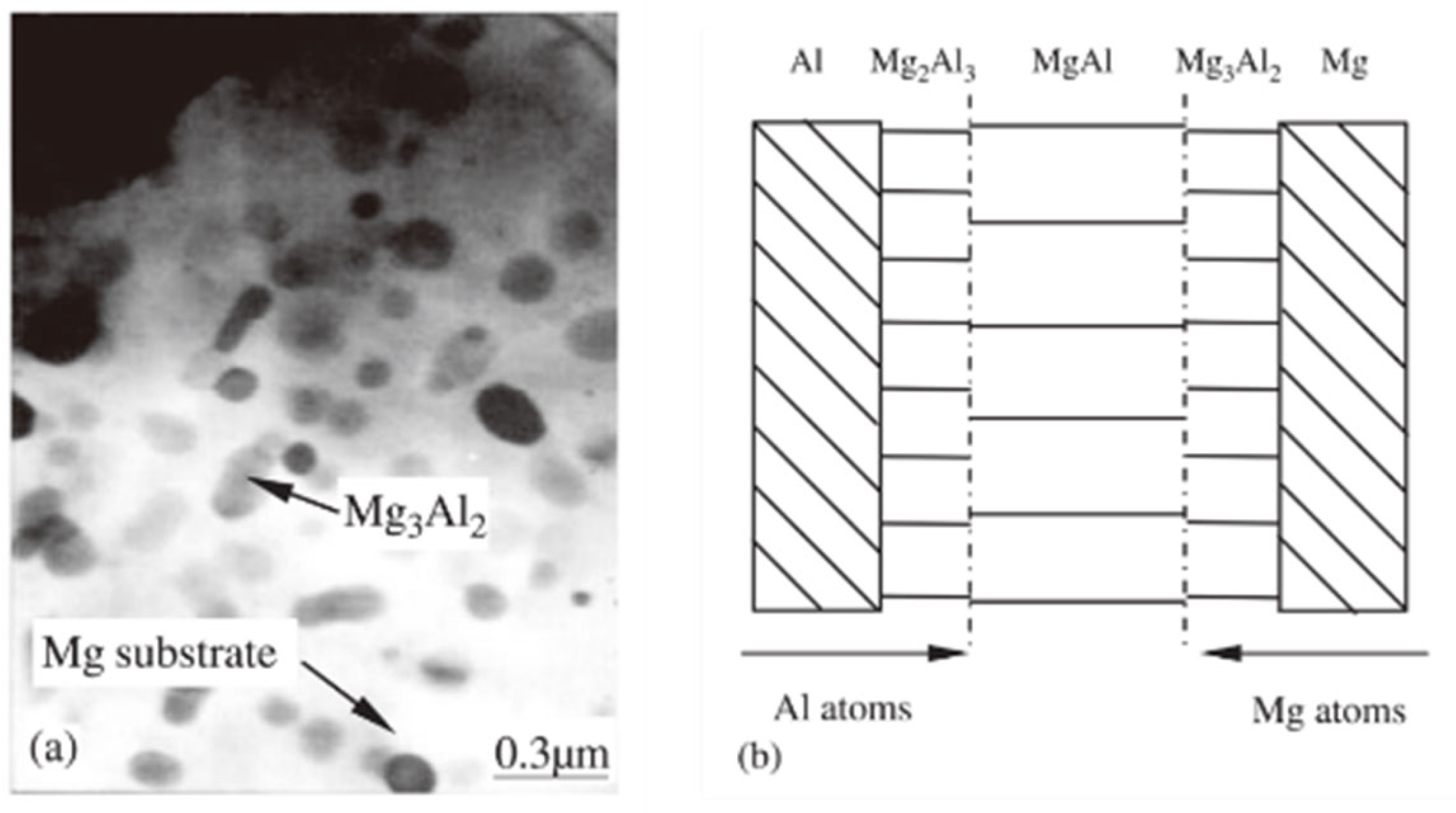

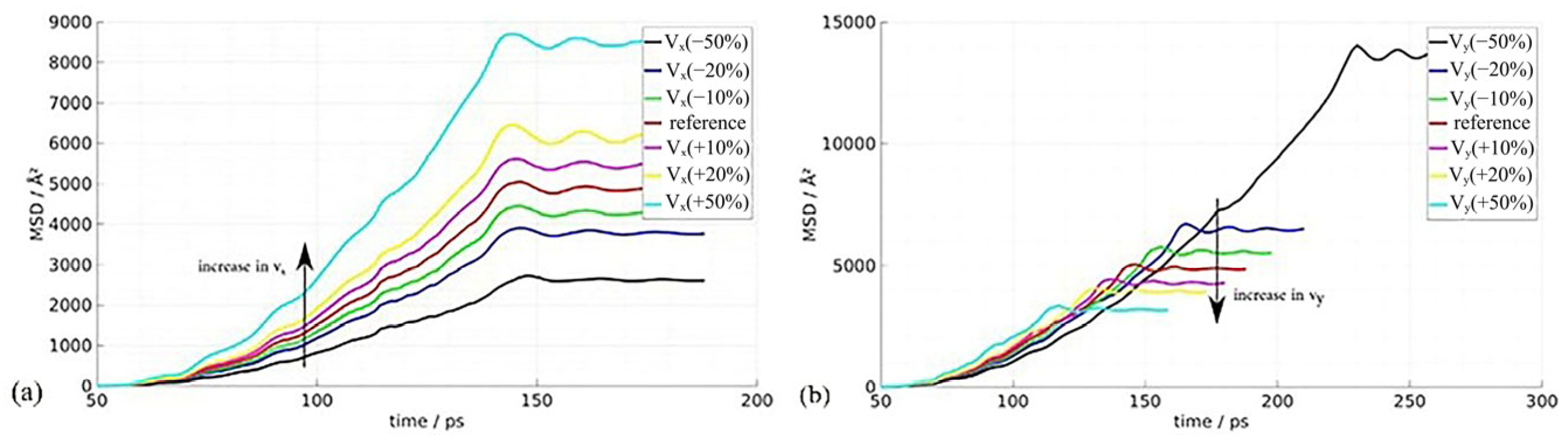

5] employed the Modified Embedded Atom Method (MEAM) potential energy model to describe intermetallic interactions, elucidating the diffusion behavior of brazing alloys in base materials at atomic scale. Their study conducted detailed analysis of diffusion mechanisms across different orientations: surface diffusion mechanisms dominated in x and y directions with comparable rates, while z-directional bulk diffusion exhibited significantly slower rates, as shown in

Figure 1. Simulation results demonstrated that as the reaction reached equilibrium, the Mean Square Displacement (MSD) showed a linear increase with reaction time. After approximately 9000 simulation steps, diffusion rates declined due to the formation of intermetallic compound layers that hindered further diffusion.

2.3. Limitations of Molecular Dynamics and Multi-Scale Modeling Approaches

While MD simulations provide unparalleled atomic-scale insights, it is crucial to critically assess their limitations, the most significant of which is the vast spatiotemporal scale gap. Conventional MD operates at the nanosecond (ns) to microsecond (µs) timescale and nanometer (nm) length scale. In stark contrast, experimental ultrasonic welding processes occur over milliseconds to seconds and involve components on the micrometer to millimeter scale. This disparity of several orders of magnitude means that MD cannot simulate a complete, macroscopic welding cycle.

Therefore, the primary value of MD in this context is not to replicate the entire experiment but to act as a “computational microscope” that reveals the fundamental initiation mechanisms, such as the very first atomic displacements, the nucleation of dislocations at the interface, the initial stages of atomic inter-diffusion, and the dynamic evolution of the interface under extreme shear and pressure. These mechanisms are often the root cause of macroscopic weld quality but are exceedingly difficult to observe directly in experiments. To bridge this scale gap, the computational materials science community has developed several strategies, among which multiscale modeling stands as the most comprehensive and necessary framework.

5. Results and Future Prospects

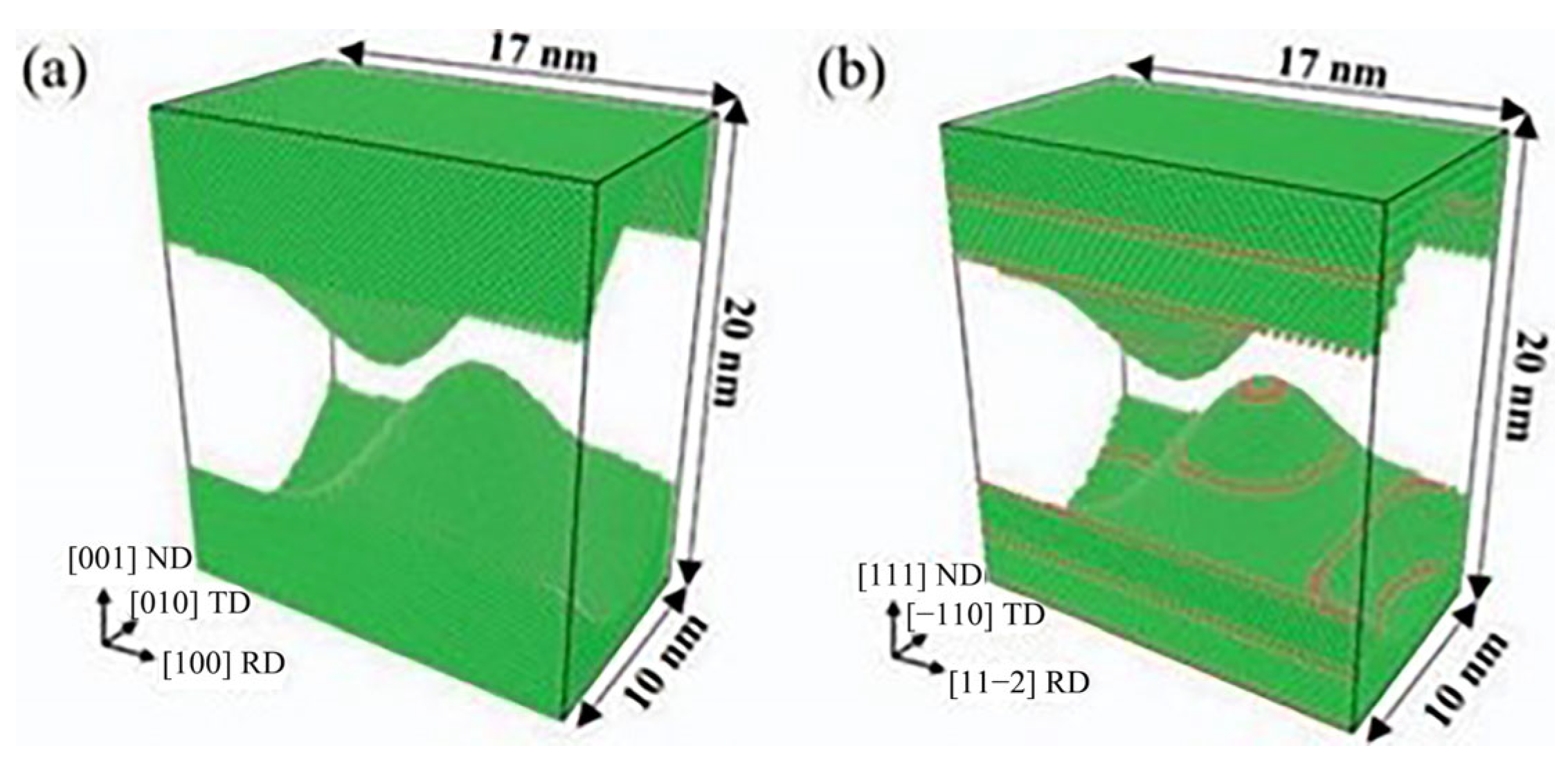

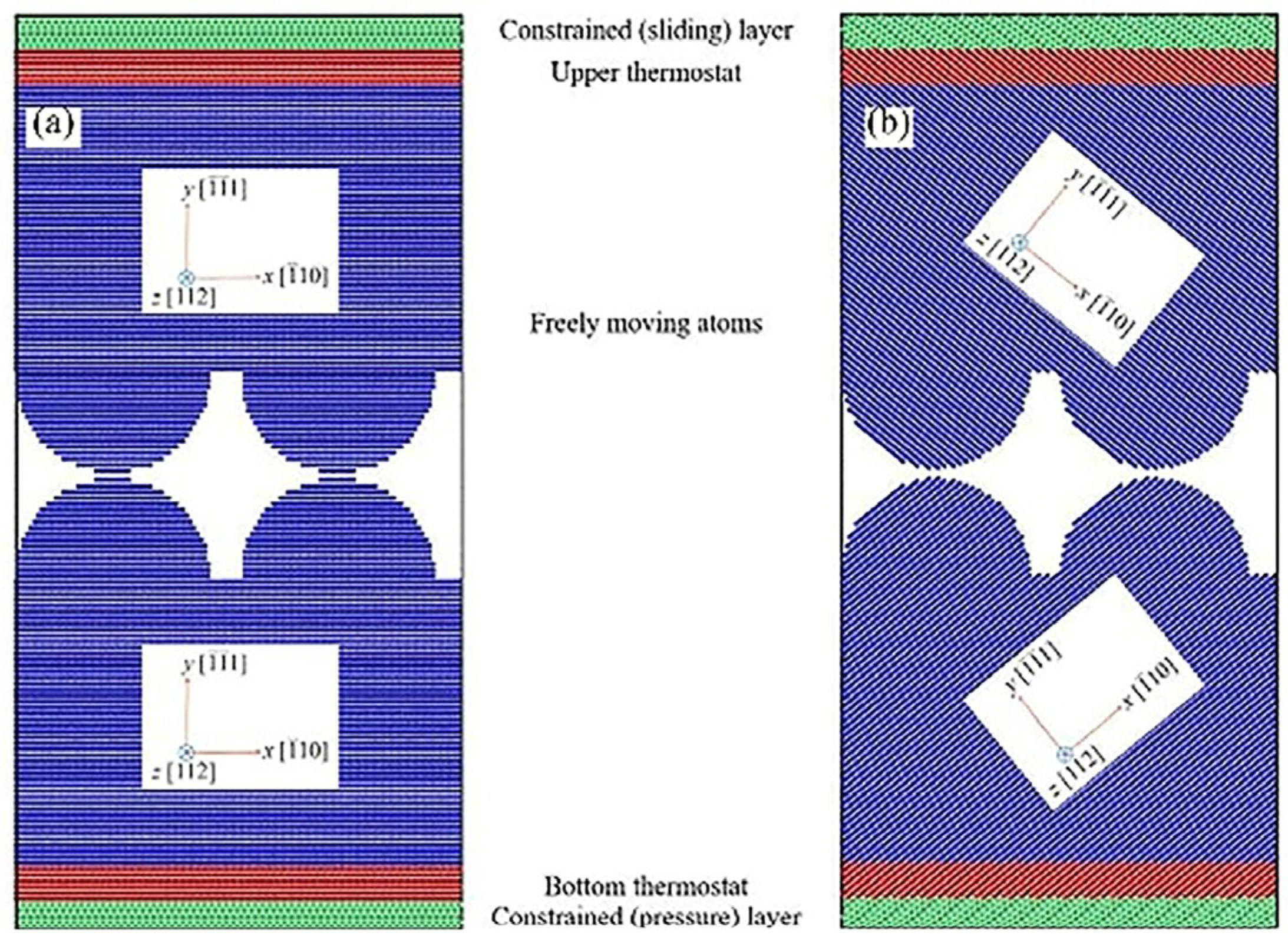

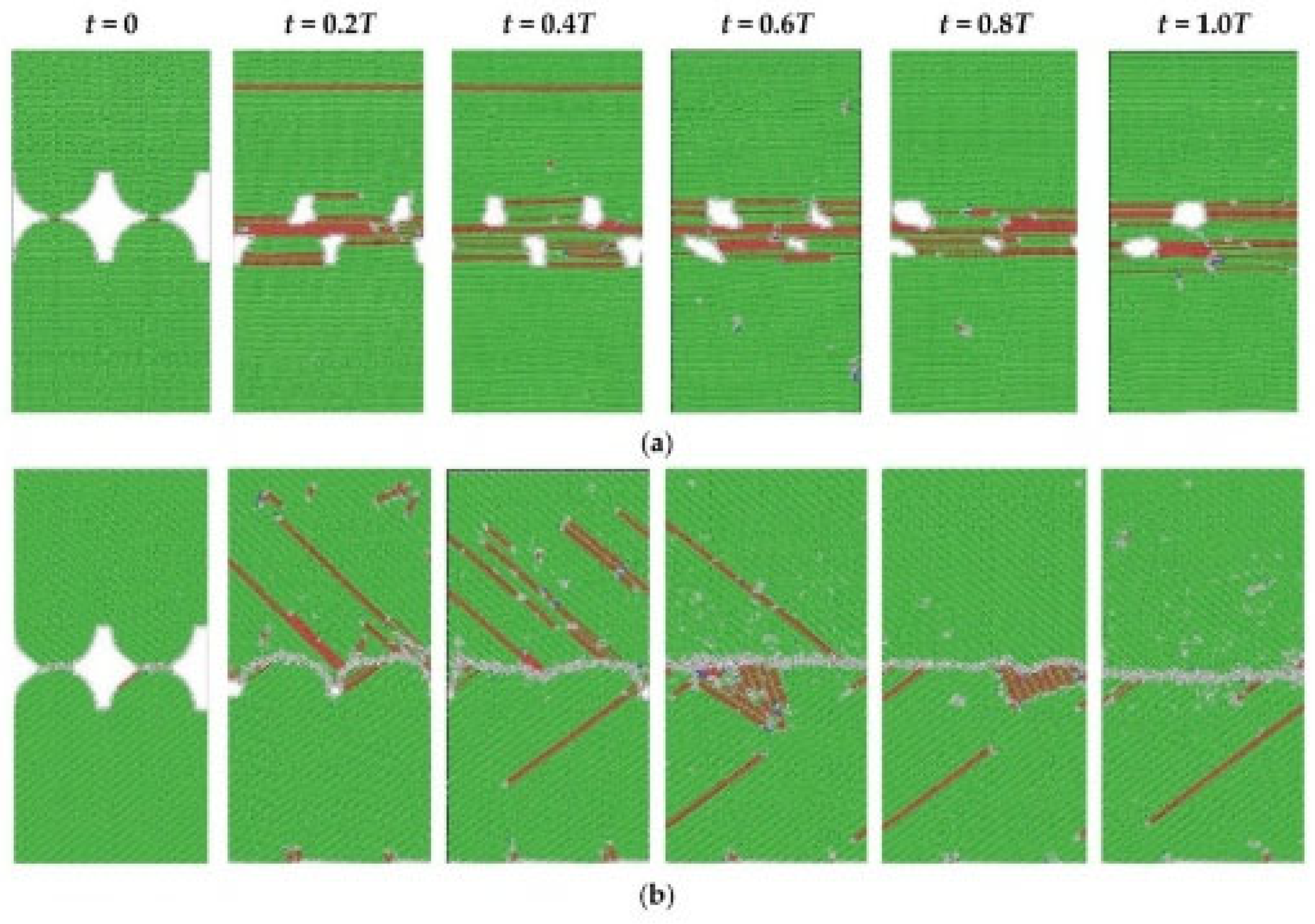

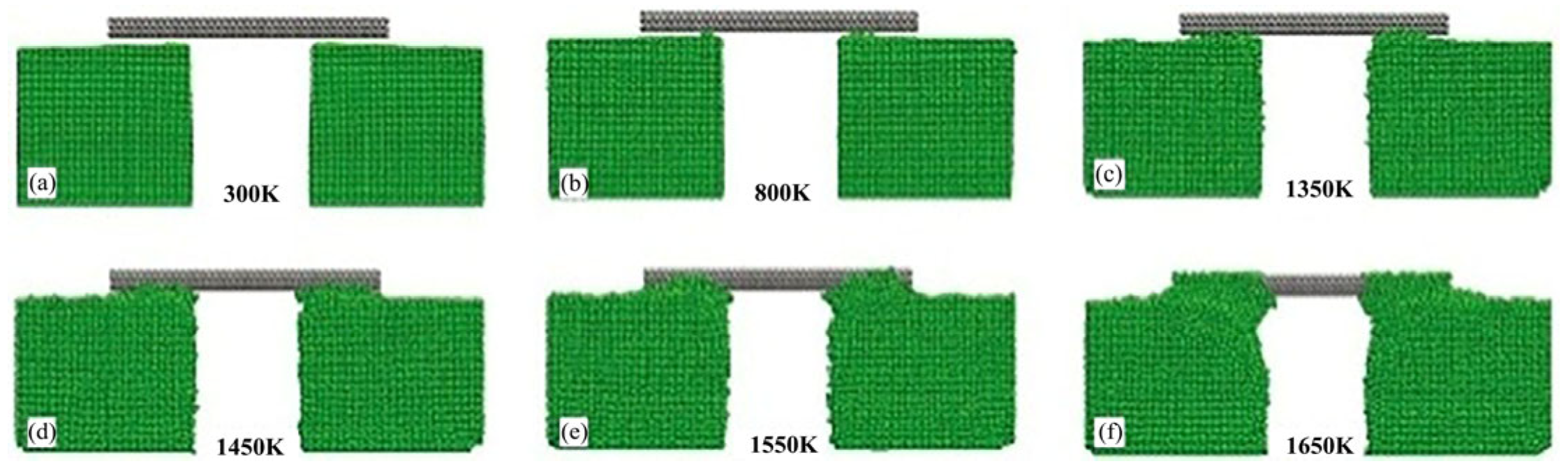

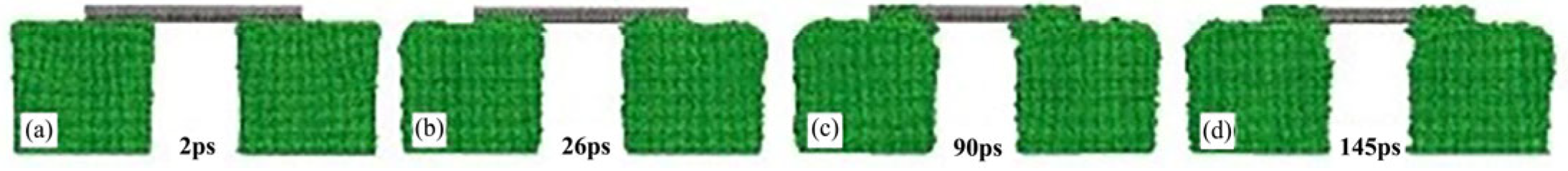

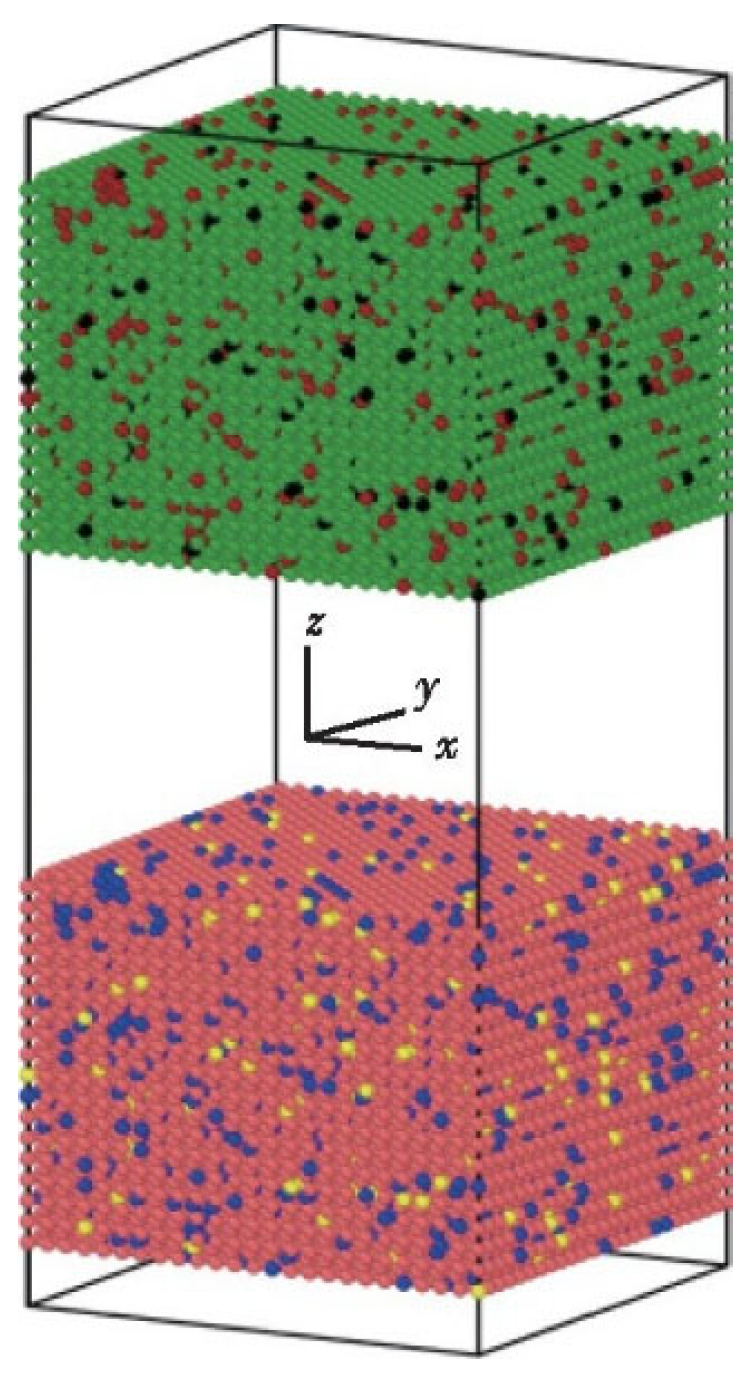

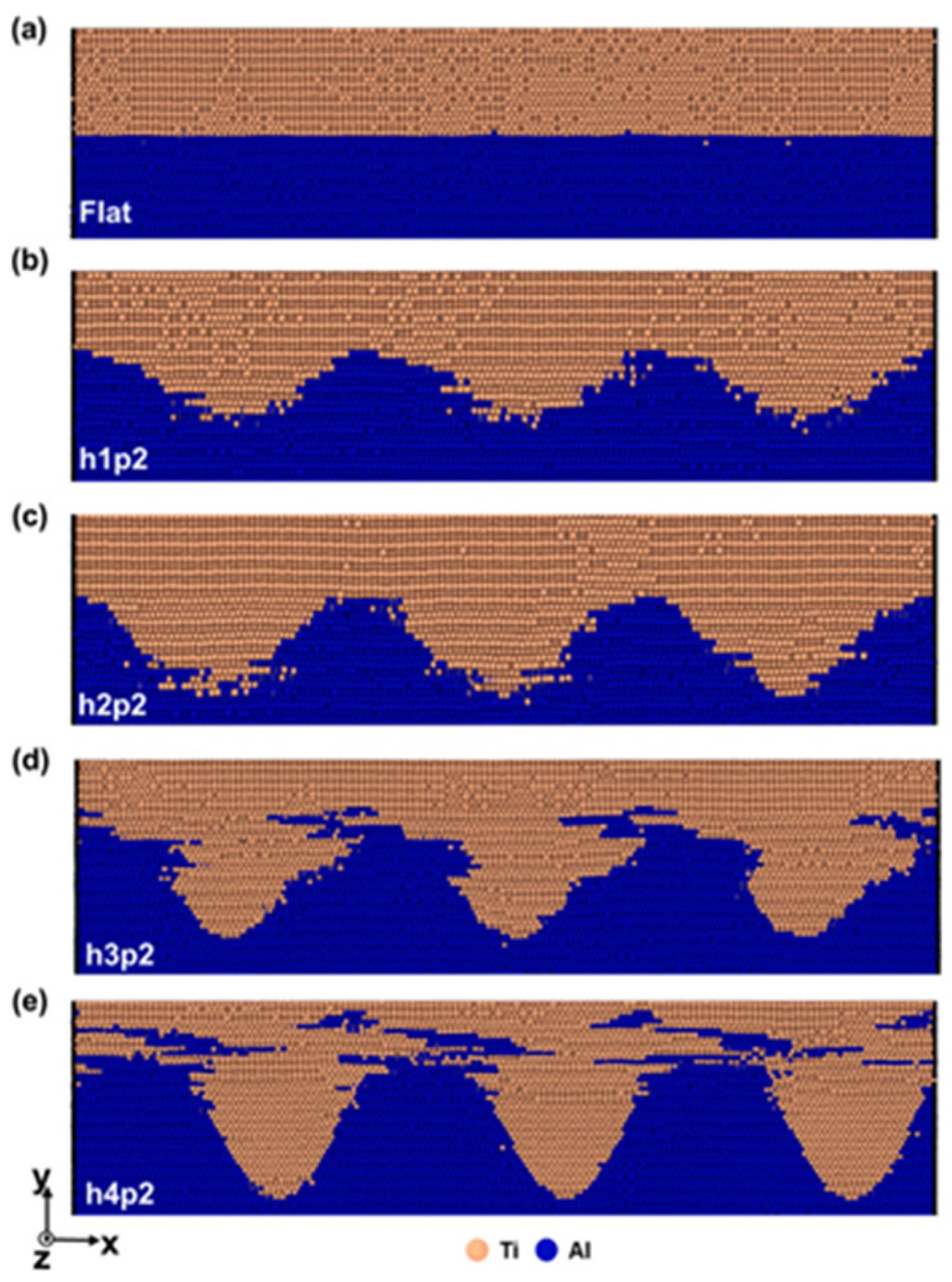

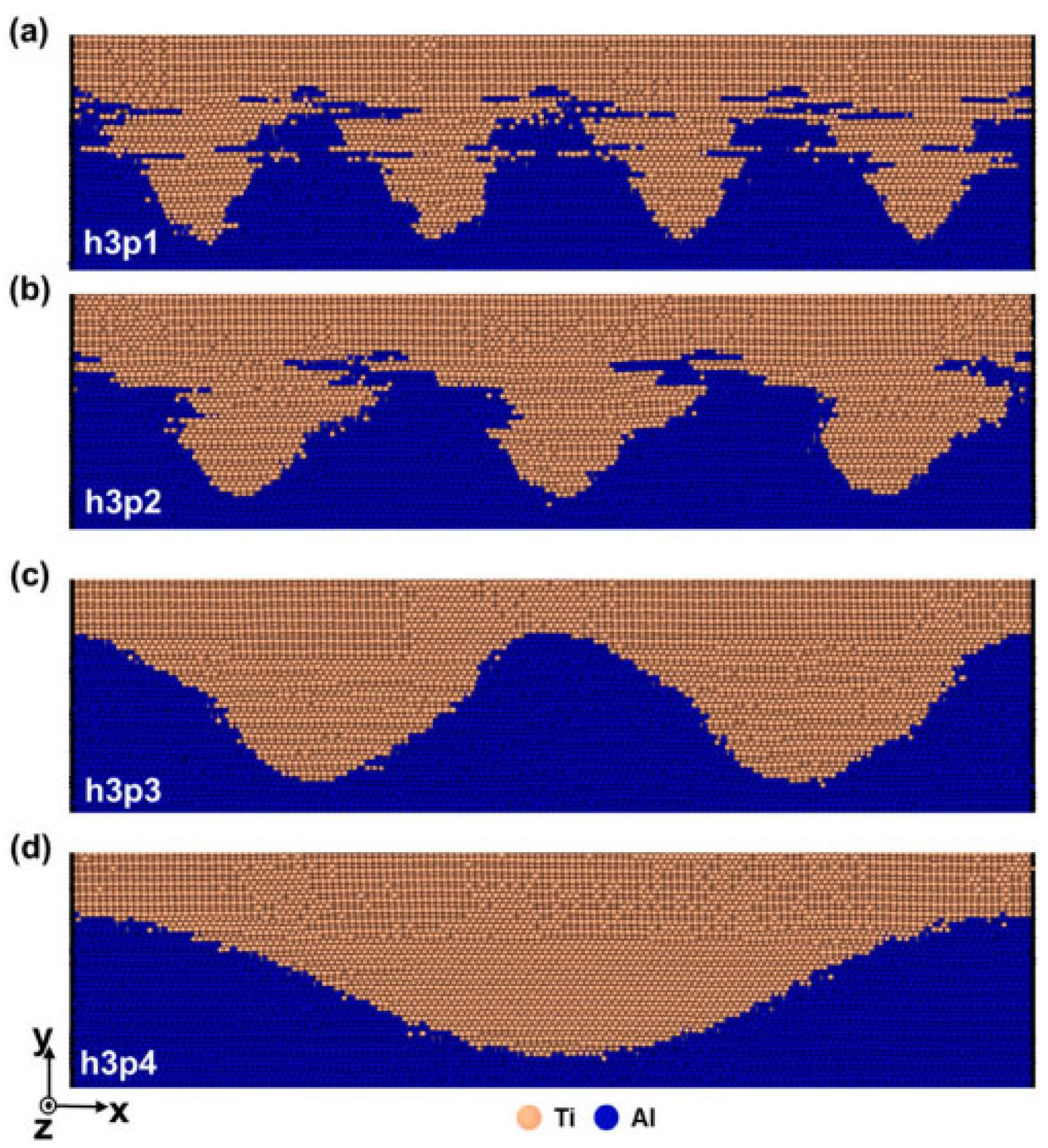

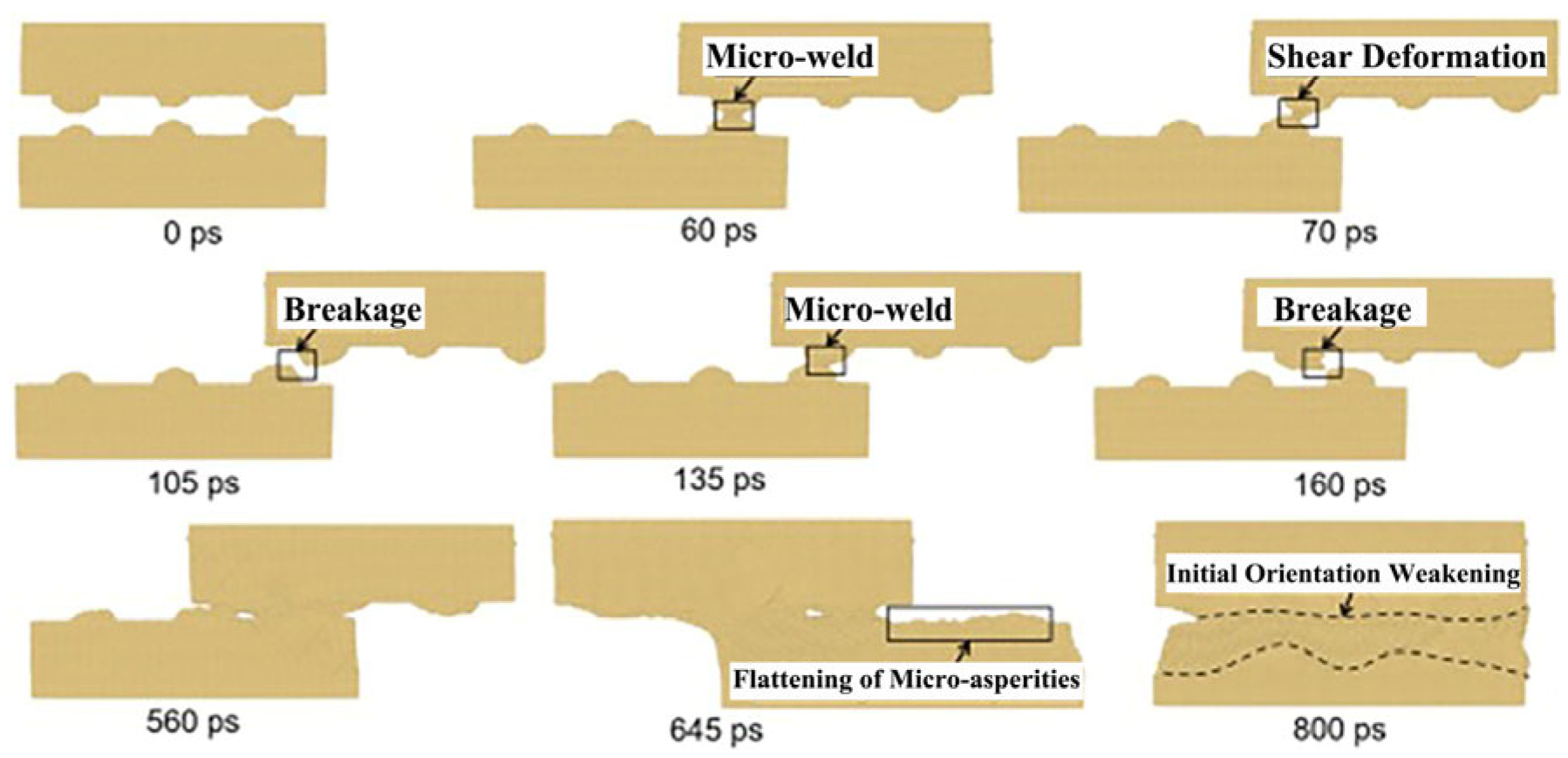

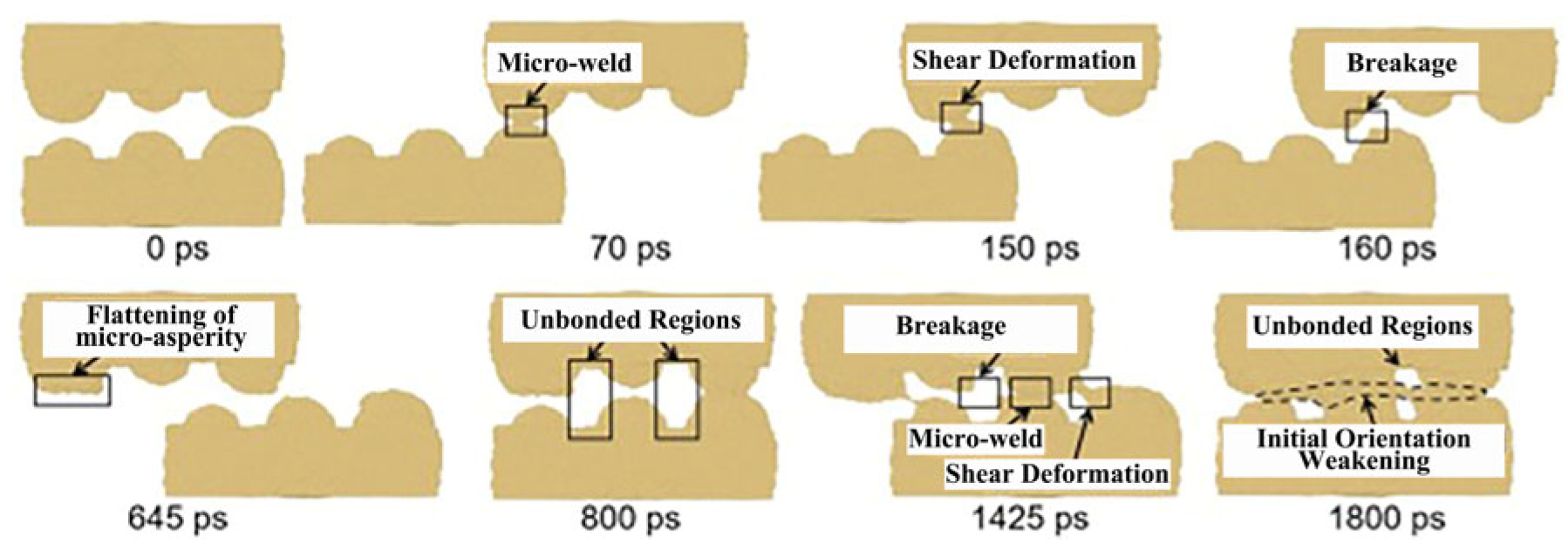

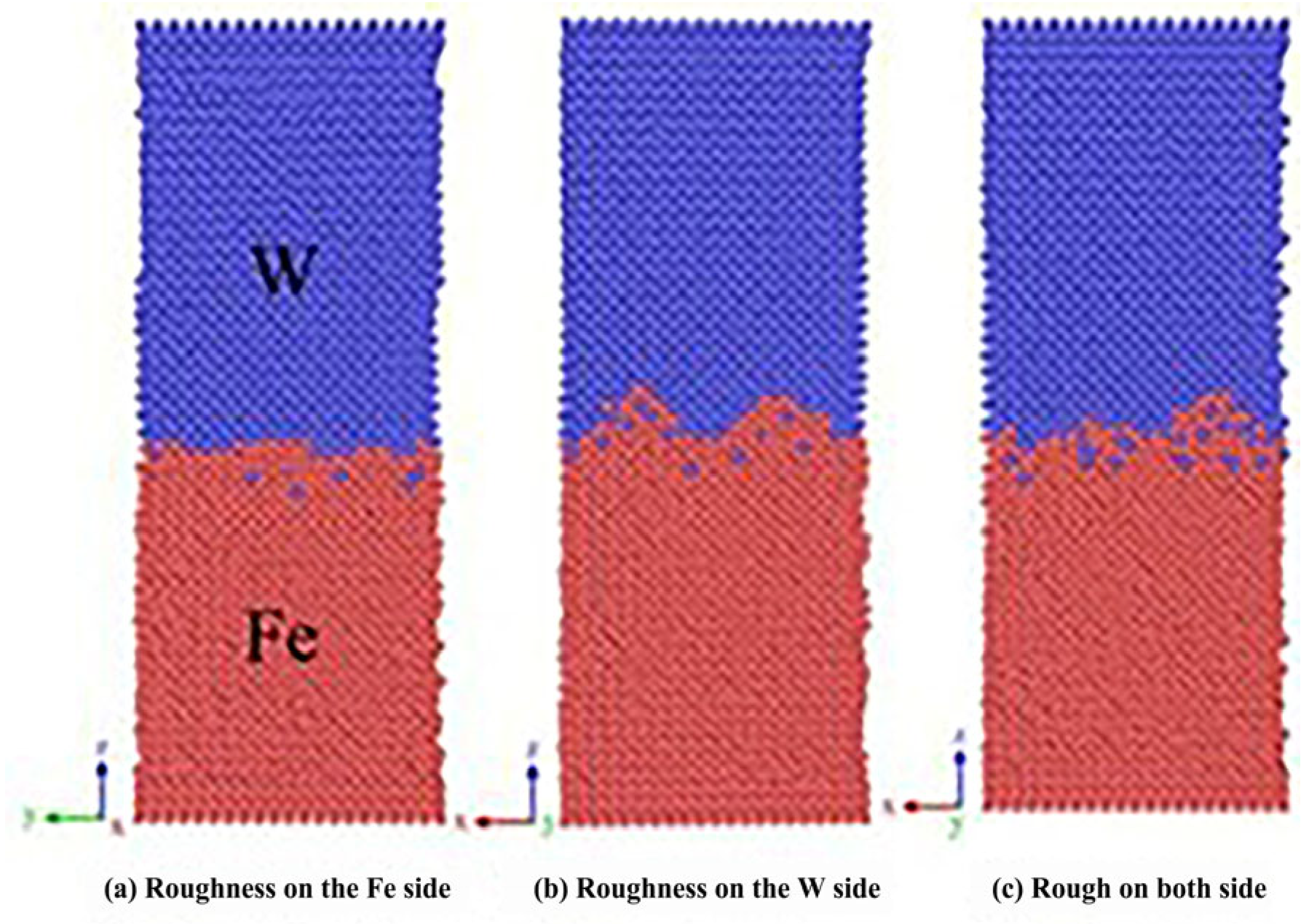

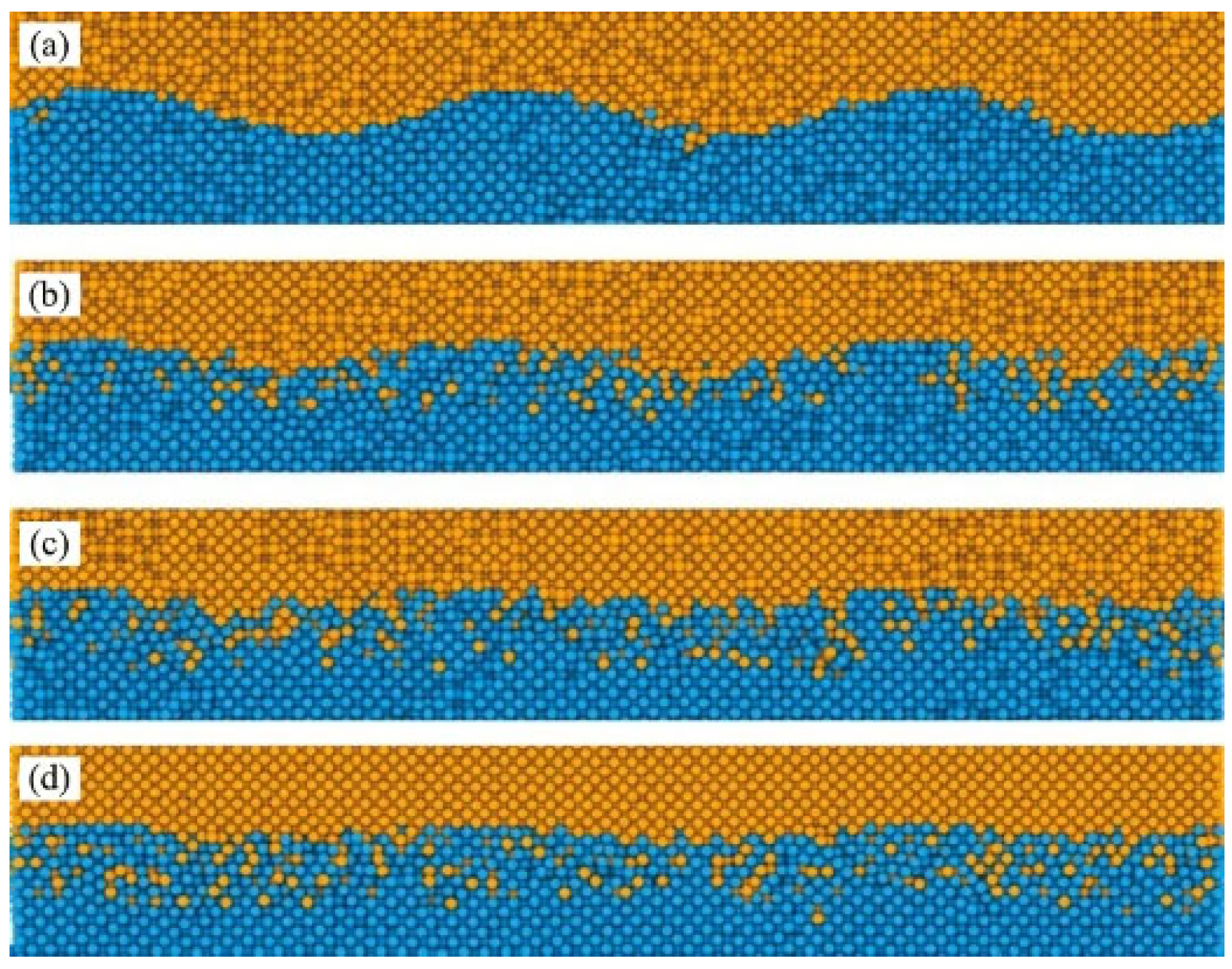

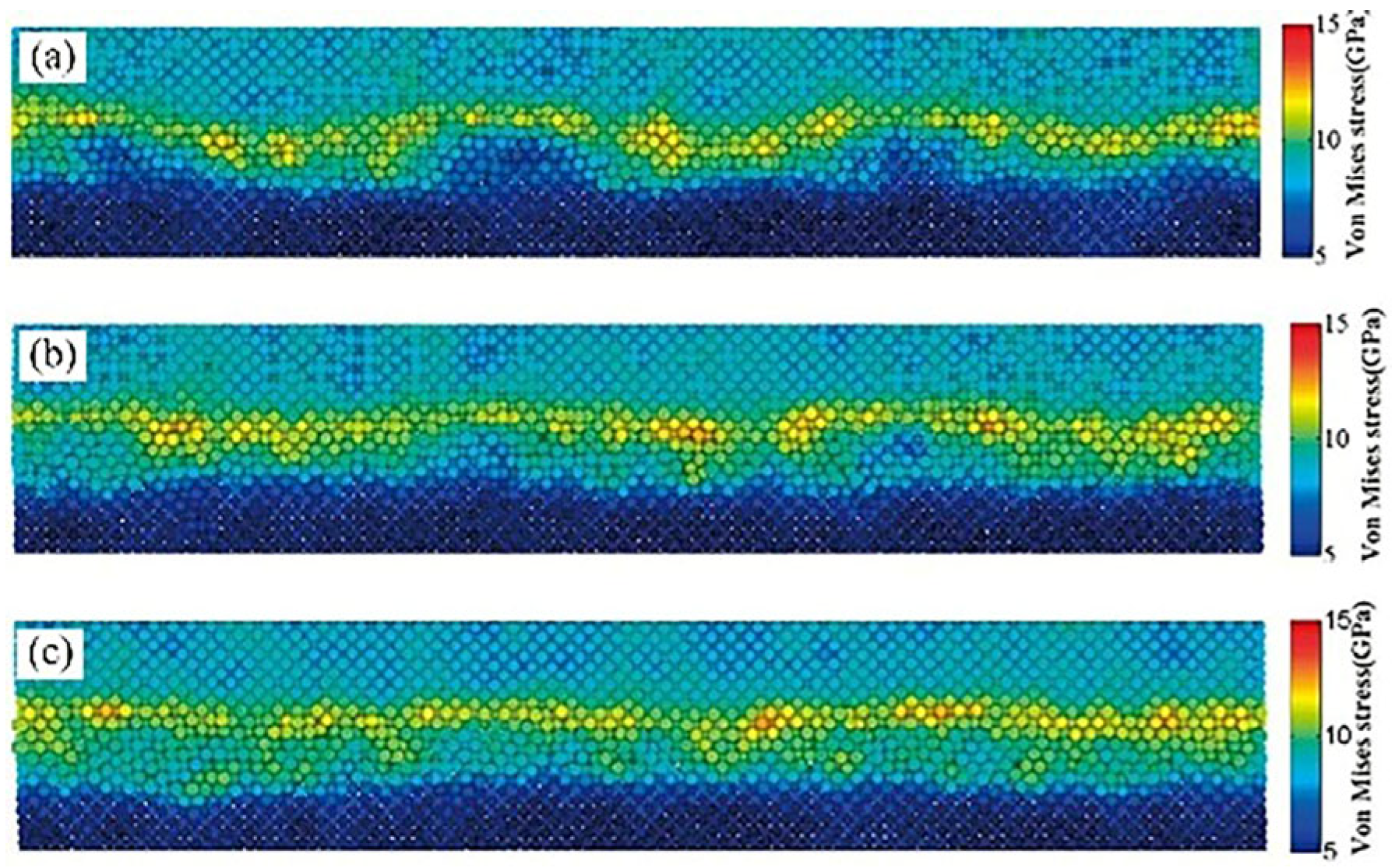

This comprehensive review has synthesized the molecular dynamics (MD) simulation research in the field of metal ultrasonic welding. Through a detailed examination of the literature, we have delved into the core theoretical issues, demonstrating that MD simulations provide an indispensable atomic-scale perspective on the complex physical mechanisms governing the process. Key insights revealed through this review include the critical roles of atomic diffusion, dislocation dynamics, grain boundary interactions, and the acoustic softening effect in determining weld formation and quality. Furthermore, the review has systematically analyzed how MD simulations elucidate the influence of crucial factors such as grain boundaries, temperature, surface morphology, time, and displacement rate on the welding outcome.

The integration of findings from studies on various material systems (e.g., Cu-Cu, Al-Al, Cu-Al) underscores the power of MD in not only visualizing and explaining experimental phenomena but also in predicting optimal process windows and guiding parameter optimization. This aligns with the stated objective of providing robust theoretical support for practical applications, offering a pathway to reduce experimental iterations and R&D costs.

A particularly powerful application of multiscale modeling is the coupling of MD with the Phase-Field (PF) method and Finite Element Models (FEMs). MD can provide the crucial kinetic parameters—such as interface mobility, grain boundary energy, and diffusion coefficients—required by PF models to simulate the dynamic microstructural evolution (e.g., recrystallization and grain growth) in the thermomechanically affected zone of the weld. Simultaneously, MD-derived data on interface strength and constitutive behavior can be integrated into FEM simulations. This enables the prediction of macroscopic weld attributes, such as joint morphology, residual stress distribution, and ultimate shear strength, based on fundamental atomic-scale processes, thereby creating a truly predictive digital twin of the welding process.

Looking forward, a paramount challenge for MD simulations is to move beyond idealized clean interfaces and incorporate the complex chemistry of real-world surfaces. Realistic interface effects such as hydrogen embrittlement, native oxide layers, and organic contaminants or impurities are often decisive for weld quality but remain largely unaddressed in current atomistic studies. Future research must pioneer simulations that include these factors. For instance, simulations could investigate how hydrogen atoms segregate to grain boundaries and dislocation cores under ultrasonic stress, potentially leading to embrittlement. Similarly, modeling the fragmentation and dissolution of thin oxide films on metals like aluminum and copper is crucial to understand the conditions for achieving metallurgical bonding. Furthermore, the presence of surface hydrocarbons or other impurities could significantly alter frictional behavior and atomic diffusion. Developing robust simulation methodologies to account for these phenomena is essential for bridging the gap between idealized models and industrial practice, ultimately enabling the prediction and mitigation of welding defects.

This comprehensive review has synthesized the research status of Molecular Dynamics (MD) simulation in the field of metallic ultrasonic welding. The body of work demonstrates MD’s unparalleled capability in elucidating atomistic mechanisms such as atomic diffusion, dislocation dynamics, grain boundary interactions, and the acoustic softening effect. However, to advance the field from mechanistic understanding to predictive science, several concrete scientific challenges must be addressed, pointing to key future research directions.

(1) Development and Validation of Machine-Learning Interatomic Potentials (ML-IAPs): The reliability of MD simulations is fundamentally constrained by the accuracy of empirical potentials. The development of ML-IAPs trained on high-quality quantum mechanical data represents a paradigm shift. Future work should focus on creating and validating ML-IAPs for complex, multi-component alloy systems relevant to welding. These potentials promise to achieve near-density functional theory (DFT) accuracy while maintaining computational efficiency, enabling realistic simulations of chemical complexity, phase transformations, and defect interactions at the weld interface that are currently beyond the reach of traditional potentials.

(2) Multi-Scale Frameworks to Bridge Time and Length Scales: As highlighted in

Section 2.3, the inherent scale gap of MD remains a primary challenge. Future efforts must prioritize the development and application of multi-scale modeling frameworks. This includes using coarse-grained MD to simulate larger material volumes, employing accelerated dynamics (e.g., hyperdynamics, metadynamics) to access experimental timescales for rare events like nucleation, and, most critically, establishing robust MD-to-continuum coupling schemes. The integration of atomistically informed parameters—such as interface strength, diffusion coefficients, and constitutive laws—into Crystal Plasticity Finite Element Models (CPFEM) or phase-field models will be essential for predicting the macroscopic performance and reliability of welded joints.

(3) Strategies for Experimental Validation and Integration: The ultimate test of any simulation lies in its agreement with experimental reality. A critical future direction is the design of dedicated experiments for the direct validation of MD predictions. This can be achieved through synergies with in situ characterization techniques, such as High-Resolution Transmission Electron Microscopy (HR-TEM) for observing interface structures, or synchrotron X-ray diffraction for measuring stress and strain fields at the micro-scale. Furthermore, MD should be used not in isolation but as an integral part of an iterative loop with continuum models and experiments, where simulation insights guide experimental design, and experimental data, in turn, validates and refines the simulation models.