Machining Accurate Deep Curved Forms on Tungsten Carbide–Cobalt (WC-Co) Eliminating Tool Wear in the Electrical Discharge Turning Operation

Abstract

1. Introduction

2. Material and Methods

3. Results and Discussion

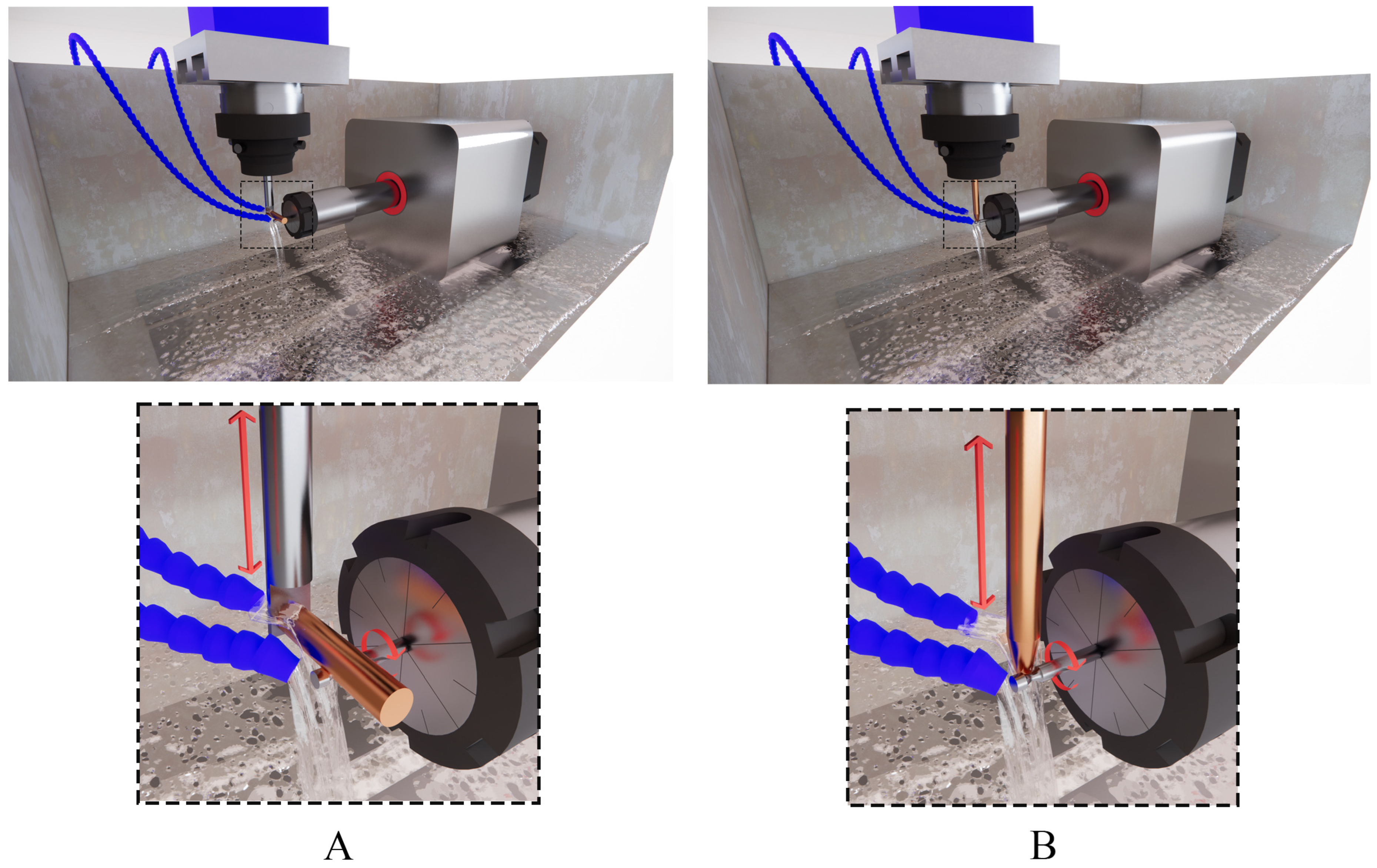

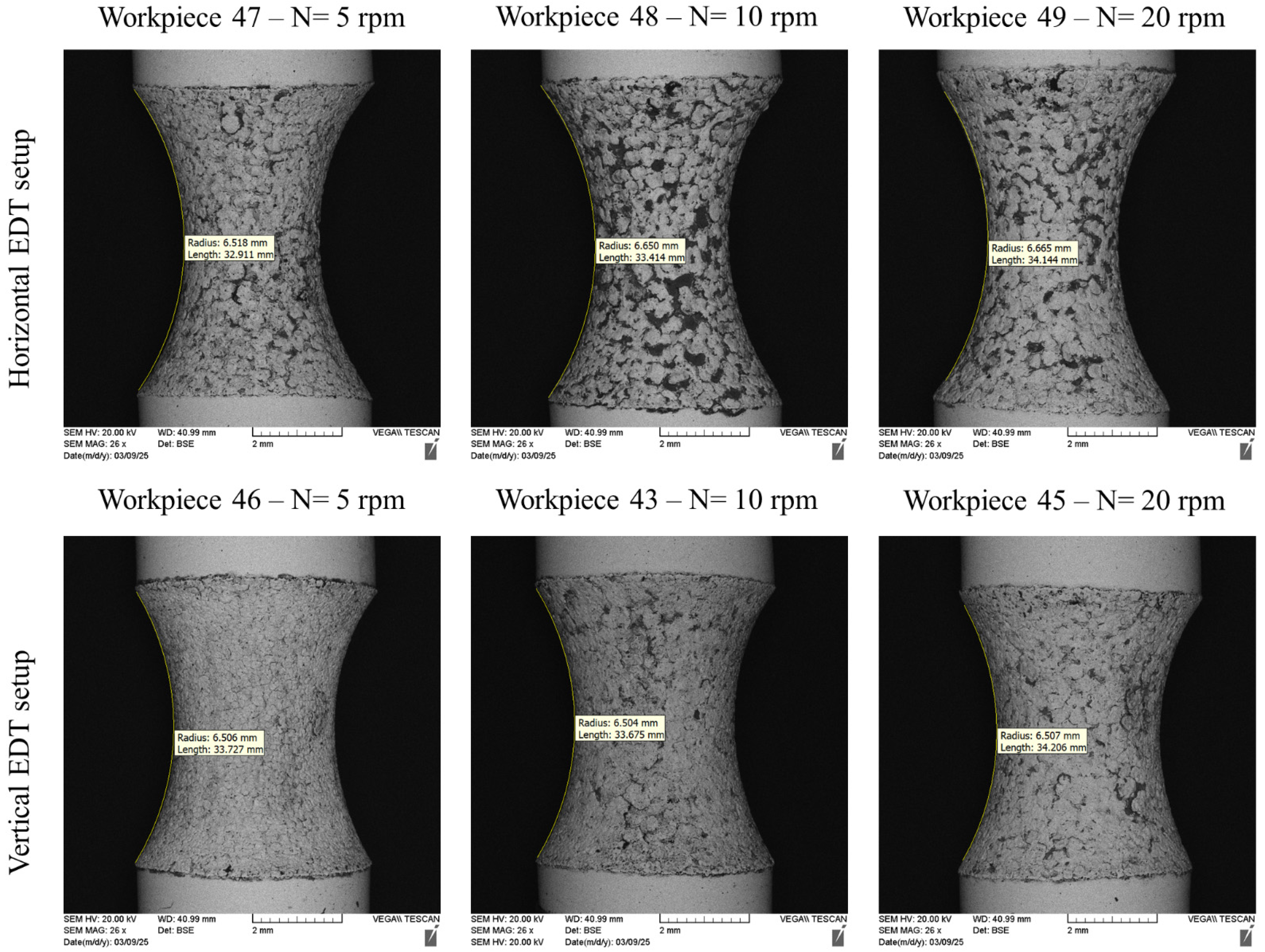

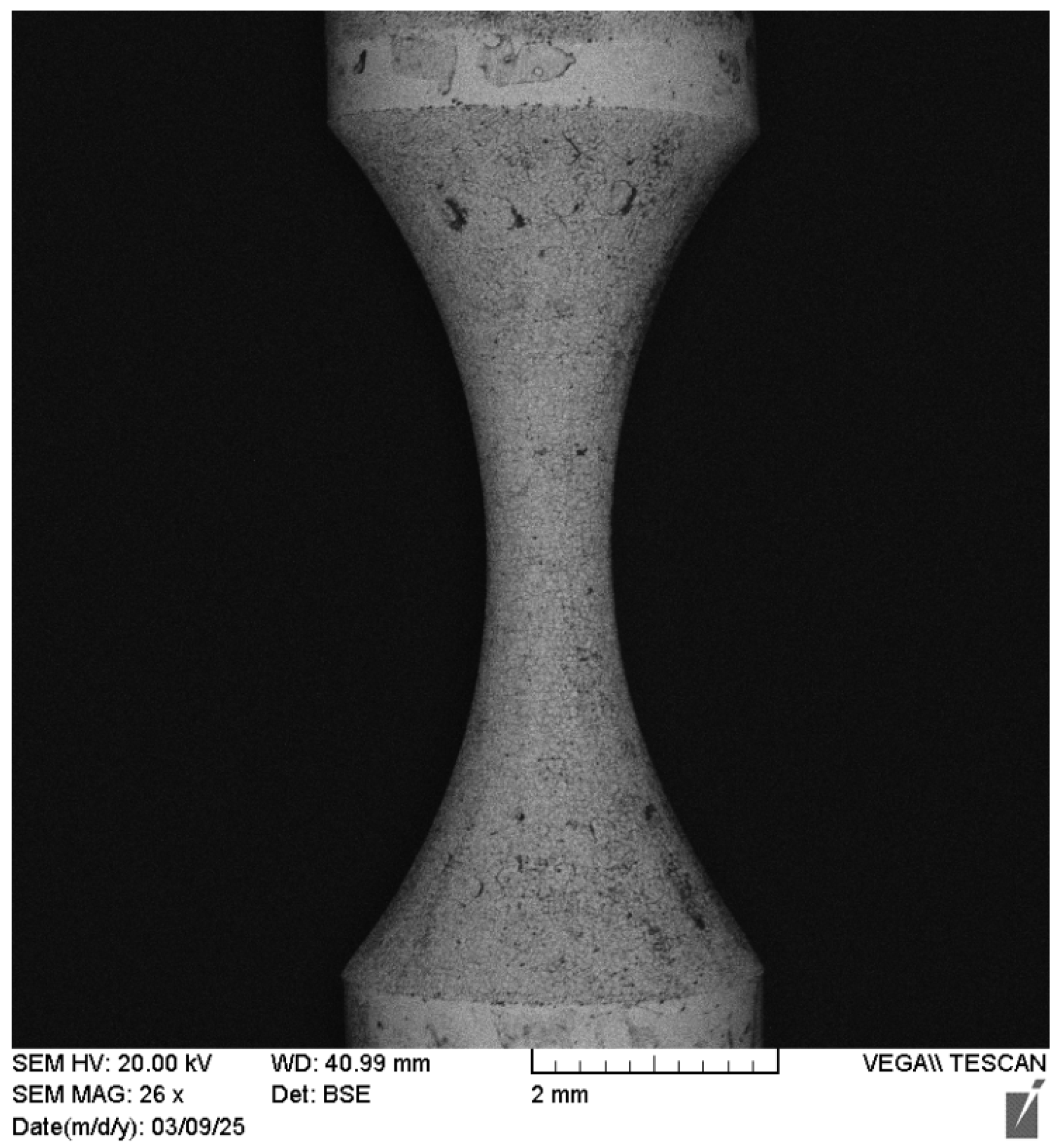

3.1. Horizontal and Vertical EDT

3.2. Vertical EDT in Roughing, Semi-Finishing, and Finishing

4. Conclusions

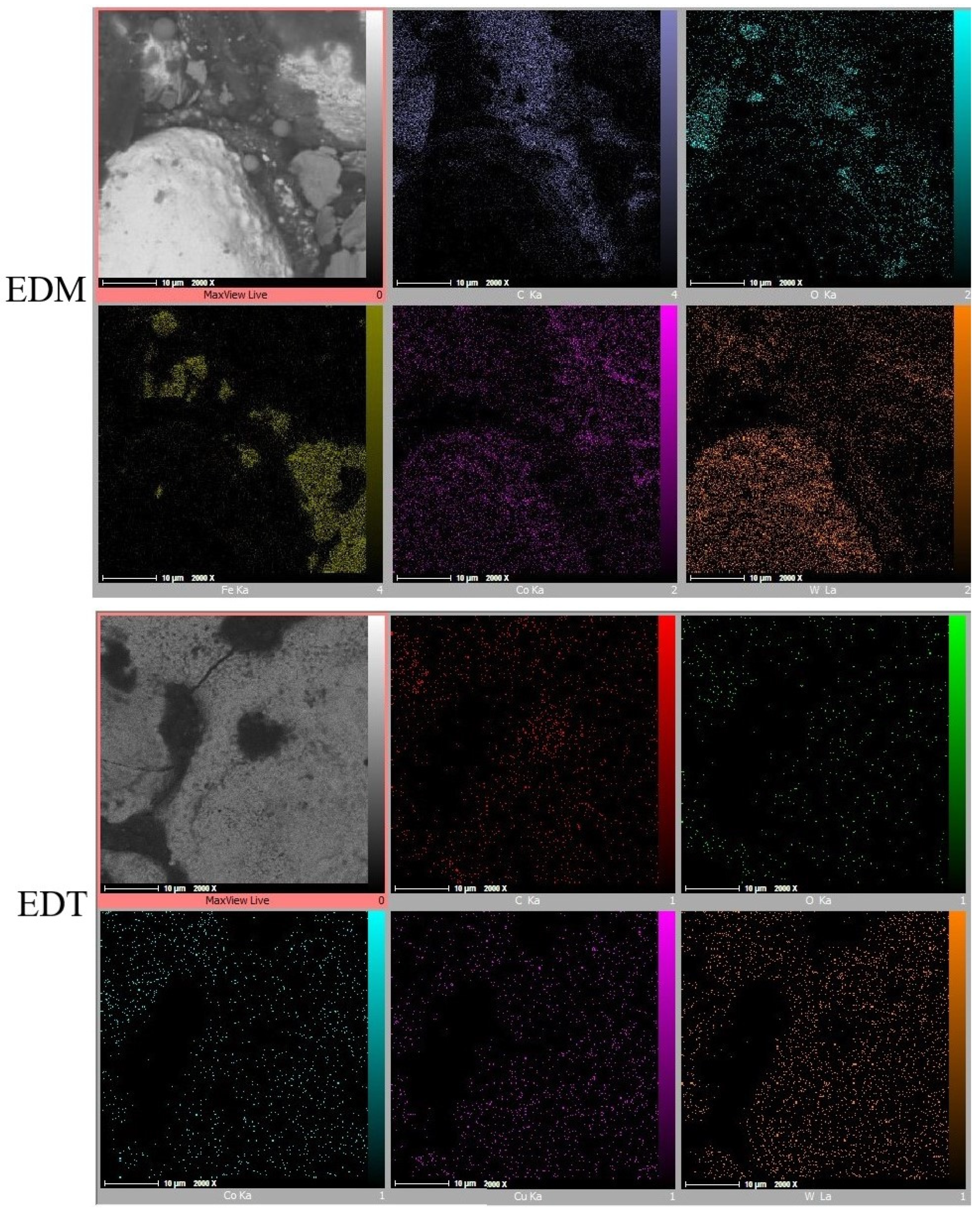

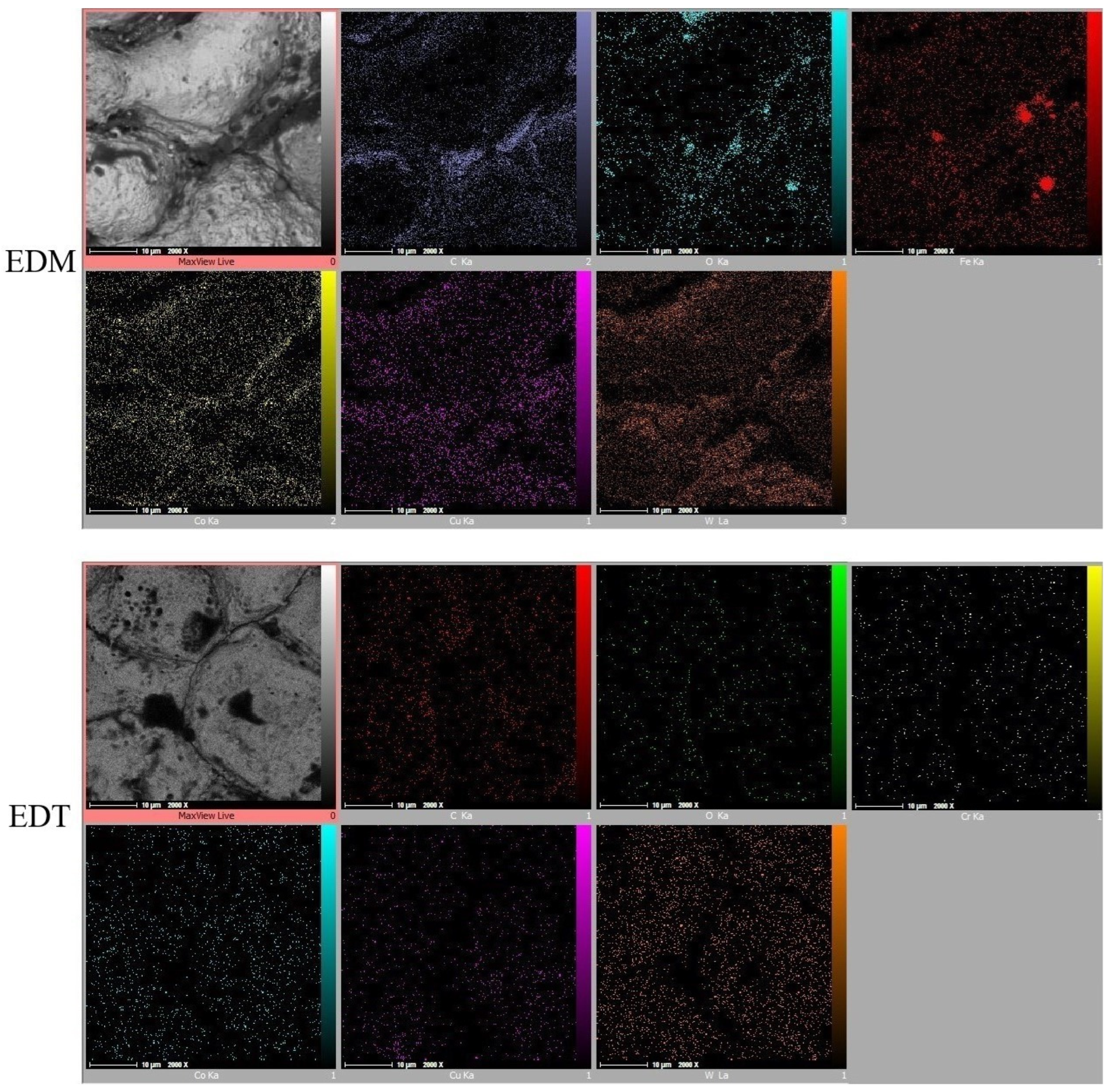

- Applying the vertical EDT resulted in significantly higher geometrical accuracy compared to the horizontal EDT when machining arc forms on WC-Co bars. In the horizontal EDT setup, tool electrode erosion adversely affected the final geometry on the final machined geometry. However, in the vertical EDT setup, the wear of the tool electrode had almost no negative effect on the final geometry, as the worn regions were continuously replaced by fresh regions during the machining process.

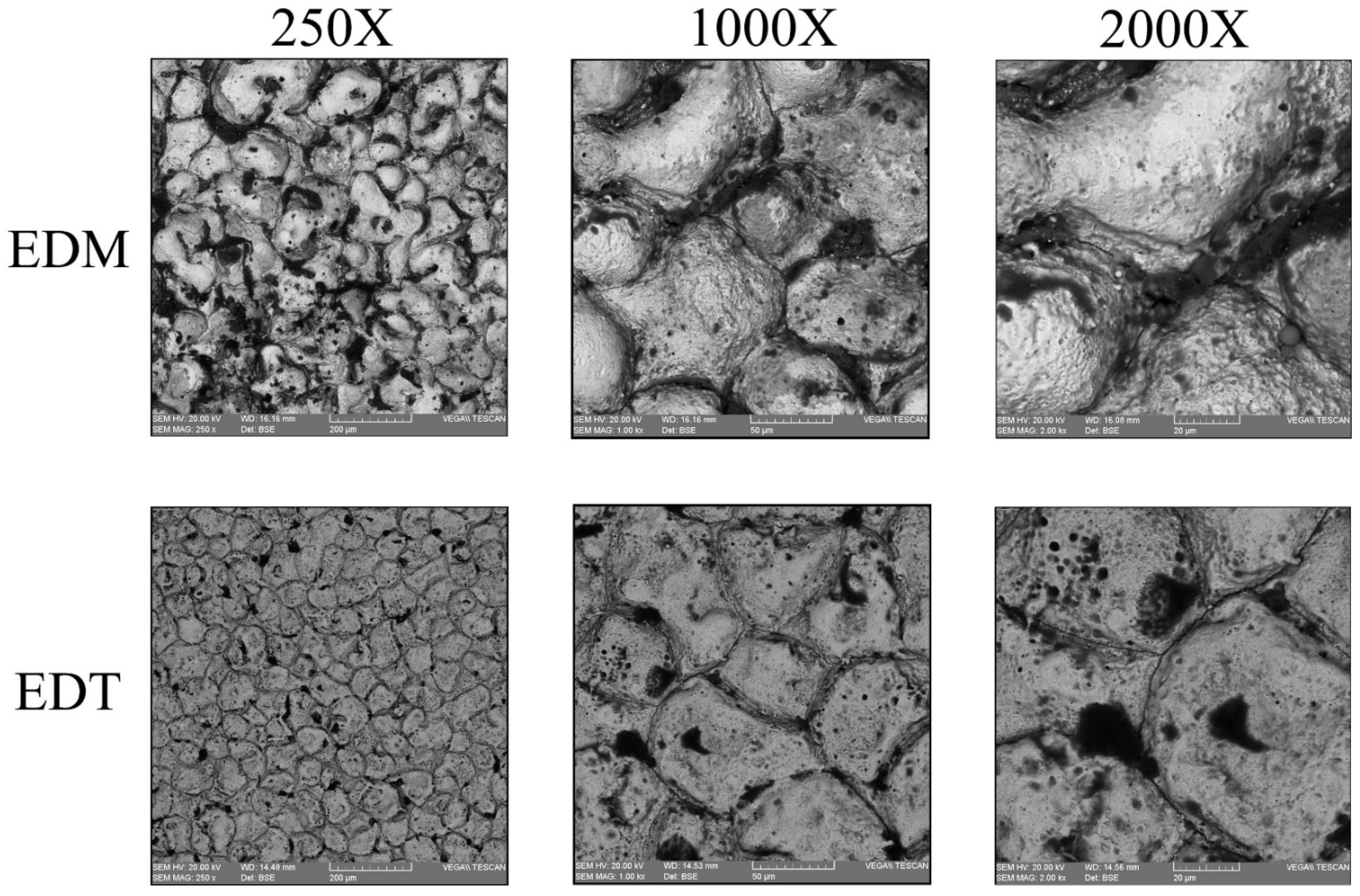

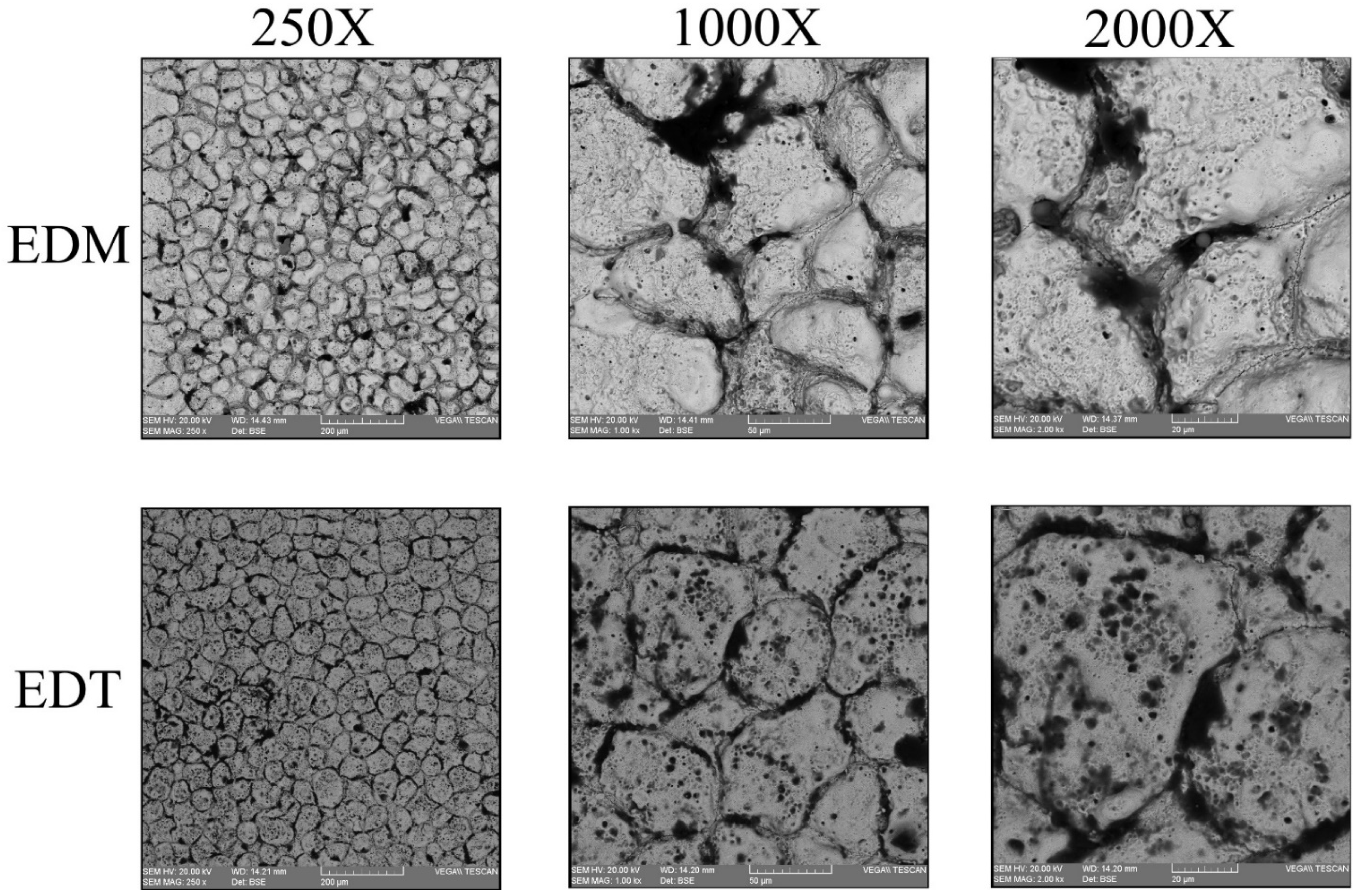

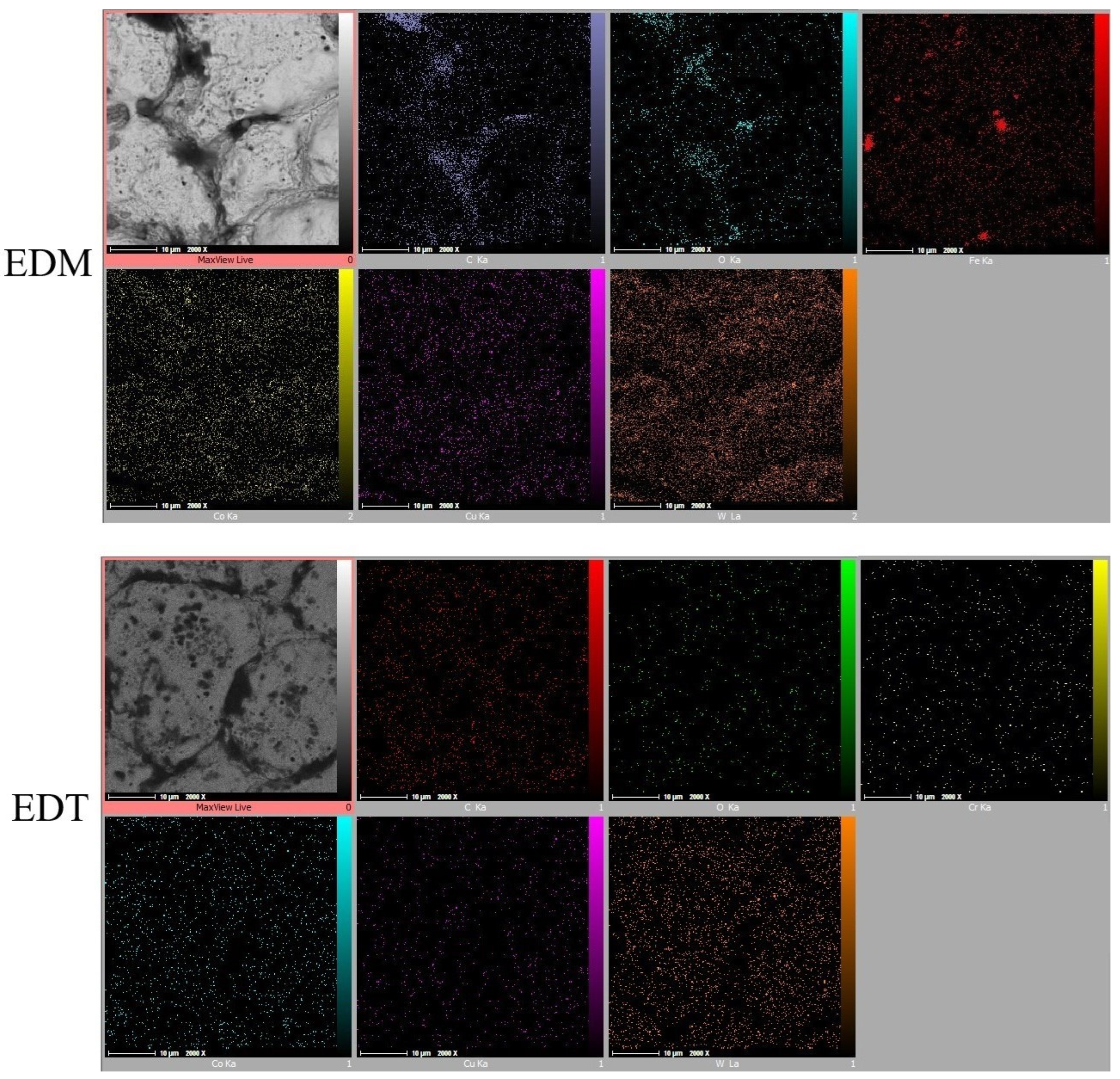

- The surfaces machined by the vertical EDT were cleaner and exhibited fewer residuals compared to those machined by the horizontal EDT. In the vertical setup, gravity is aligned with the machining gap, which aids in evacuating the extracted molten material from the machining area.

- The rotational speed applied in the EDT process improved the flushing performance. This improvement was more noticeable during roughing compared to semi-finishing and finishing, due to the higher discharge energy in roughing, which generates more molten material and therefore requires more effective flushing. Reducing the rotational speed to zero resulted in a high accumulation of carbon-based and oxygen-based phases on the machined surface due to reduced flushing performance. At very low rotational speeds, even suspended particles remaining in the dielectric from previous machining operations can adhere to the machined surface as a result of poor flushing.

- Increasing the rotational speed of the workpiece up to 45 rpm improved surface roughness by approximately 67% in roughing, 75% in semi-finishing, and 75% in the finishing regime. The enhanced flushing conditions at higher rotational speeds help remove debris and molten material from the machining gap, preventing them from solidifying inconsistently on the machined surface and thereby reducing surface coarseness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jahan, M.P.; Rahman, M.; Wong, Y.S. A review on the conventional and micro-electrodischarge machining of tungsten carbide. Int. J. Mach. Tools Manuf. 2011, 51, 837–858. [Google Scholar] [CrossRef]

- Mahdavinejad, R.A.; Mahdavinejad, A. ED machining of WC–Co. J. Mater. Process. Technol. 2005, 162, 637–643. [Google Scholar] [CrossRef]

- Lassner, E.; Schubert, W.-D.; Lassner, E.; Schubert, W.-D. Tungsten in hardmetals. In Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds; Springer: New York, NY, USA, 1999; pp. 321–363. [Google Scholar]

- Prakash, L. Fundamentals and general applications of hardmetals; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Vilhena, L.M.; Fernandes, C.M.; Soares, E.; Sacramento, J.; Senos, A.M.R.; Ramalho, A. Abrasive wear resistance of WC–Co and WC–AISI 304 composites by ball-cratering method. Wear 2016, 346, 99–107. [Google Scholar] [CrossRef]

- Belouettar, K.; Louar, M.A. Experimental investigation of the influence of electrical discharge machining process parameters using response surface methodology. Int. J. Adv. Manuf. Technol. 2024, 135, 5287–5299. [Google Scholar] [CrossRef]

- Alshaer, A.W.; Abdallah, R.; Rajab, F.H.; Barzinjy, A.A.; Otanocha, O.B. Understanding the machined material’s behaviour in electro-discharge machining (EDM) using a multi-phase smoothed particle hydrodynamics (SPH) modelling. Int. J. Adv. Manuf. Technol. 2024, 134, 369–387. [Google Scholar] [CrossRef]

- Guu, Y.H.; Hocheng, H. Effects of workpiece rotation on machinability during electrical-discharge machining. Mater. Manuf. Process. 2001, 16, 91–101. [Google Scholar] [CrossRef]

- Matoorian, P.; Sulaiman, S.; Ahmad, M. An experimental study for optimization of electrical discharge turning (EDT) process. J. Mater. Process. Technol. 2008, 204, 350–356. [Google Scholar] [CrossRef]

- Gohil, V.; Puri, Y.M. Experimental investigation of surface roughness in electrical discharge turning process. In AIP Conference Proceedings, Proceedings of the 19th International ESAFORM Conference on Material Forming, Nantes, France, 27–29 April 2016; AIP Publishing LLC: Melville, NY, USA, 2006; Volume 1769, p. 50001. [Google Scholar]

- Gohil, V.; Puri, Y.M. A study on the effect of tool electrode thickness on MRR, and TWR in electrical discharge turning process. In IOP Conference Series: Materials Science and Engineering; Proceedings of the International Conference on Recent Advances in Materials & Manufacturing Technologies, Dubai, UAE, 28–29 November 2017; IOP Publishing: Bristol, UK, 2018; Volume 346, p. 12036. [Google Scholar]

- Gohil, V.; Puri, Y.M. Statistical analysis of material removal rate and surface roughness in electrical discharge turning of titanium alloy (Ti-6Al-4V). Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1603–1614. [Google Scholar] [CrossRef]

- Gohil, V.; Puri, Y.M. Experimental Investigation on Surface Roughness in Electrical Discharge Turning of Ti-6Al-4V Alloy. Trans. FAMENA 2016, 40, 1–10. [Google Scholar] [CrossRef][Green Version]

- Gohil, V.; Puri, Y.M. Optimization of electrical discharge turning process using Taguchi-Grey relational approach. Procedia CIRP 2018, 68, 70–75. [Google Scholar] [CrossRef]

- Puri, Y.M.; Gohil, V. Experimental Study of Material Removal Rate in Electrical Discharge Turning of Titanium Alloy (Ti-6al-4v). In IOP Conference Series: Materials Science and Engineering; Proceedings of the 2016 Second International Conference on Mechanical and Aeronautical Engineering (ICMAE 2016), Hong Kong, China, 28–30 December 2016; IOP Publishing: Bristol, UK, 2017; Volume 187, p. 12036. [Google Scholar]

- Azhiri, R.B.; Bideskan, A.S.; Javidpour, F.; Tekiyeh, R.M. Study on material removal rate, surface quality, and residual stress of AISI D2 tool steel in electrical discharge machining in presence of ultrasonic vibration effect. Int. J. Adv. Manuf. Technol. 2019, 101, 2849–2860. [Google Scholar] [CrossRef]

- Azhiri, R.B.; Jadidi, A.; Teimouri, R. Electrical discharge turning by assistance of external magnetic field, part II: Study of surface integrity. Int. J. Light. Mater. Manuf. 2020, 3, 305–315. [Google Scholar] [CrossRef]

- Çakıroğlu, R.; Günay, M. Comprehensive analysis of material removal rate, tool wear and surface roughness in electrical discharge turning of L2 tool steel. J. Mater. Res. Technol. 2020, 9, 7305–7317. [Google Scholar] [CrossRef]

- Jadidi, A.; Azhiri, R.B.; Teimouri, R. Electrical discharge turning by assistance of external magnetic field, part I: Study of MRR and dimensional accuracy. Int. J. Light. Mater. Manuf. 2020, 3, 265–276. [Google Scholar] [CrossRef]

- Phang, Y.M.; Asmelash, M.; Hamedon, Z.; Azhari, A. Investigation on turning operation using die sinking EDM process. Mater. Today Proc. 2021, 46, 1569–1573. [Google Scholar] [CrossRef]

- Rehman, S.; Alam, M.M.; Alhems, L.M.; Alimoradi, A. Experimental modeling and optimization of magnetic field assisted electrical discharge turning: Applicable for wind power turbine elements. Alexandria Eng. J. 2021, 60, 2209–2223. [Google Scholar] [CrossRef]

- Talebizadehsardari, P.; Eyvazian, A.; Khan, A.; Sebaey, T.A. Measurement and evaluation of magnetic field assistance on fatigue life and surface characterization of Inconel 718 alloy processed by dry electrical discharge turning. Measurement 2021, 173, 108578. [Google Scholar] [CrossRef]

- Haja Syeddu Masooth, P.; Arunnath, A. Experimental investigations on machining performance of tungsten carbide (WC) by modification of wire-cut electric discharge machining work holding setup into turning process. Mater. Today Proc. 2021, 45, 6064–6071. [Google Scholar] [CrossRef]

- Digimizer Software. Available online: https://www.digimizer.com/ (accessed on 20 February 2025).

| Element | W | C | Co |

|---|---|---|---|

| W% | 80.43 | 16.12 | 3.45 |

| Experience | Workpiece | Electrode | Rotational Speed (RPM) | Workpiece Diameter (mm) | Tool Electrode Diameter (mm) | Discharge Current (A) | Pulse On-Time (ms) | Pulse Off-Time (ms) | Voltage (V) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Horizontal Setup | 1 | 47 | 11 | 5 | 6 | 12 | 5 | 300 | 20 | 80 |

| 2 | 48 | 12 | 10 | 6 | 12 | 5 | 300 | 20 | 80 | |

| 3 | 49 | 13 | 20 | 6 | 12 | 5 | 300 | 20 | 80 | |

| 6 | 12 | |||||||||

| Vertical Setup | 4 | 46 | 23 | 5 | 6 | 12 | 5 | 300 | 20 | 80 |

| 5 | 43 | 21 | 10 | 6 | 12 | 5 | 300 | 20 | 80 | |

| 6 | 45 | 22 | 20 | 6 | 12 | 5 | 300 | 20 | 80 |

| Test | Workpiece | Depth of Cut (mm) | Rotational Speed (rpm) | Workpiece Radius (mm) | Tool Electrode Radius (mm) | Discharge Current (A) | Pulse On-Time (µs) | Pulse Off-Time (µs) | Voltage (V) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Roughing | 1 | 71 | 0.5 | 0 45 | 3 | 6 | 4 | 300 | 20 | 80 |

| 2 | 72 | 0.5 | 0 45 | 3 | 6 | 4 | 300 | 20 | 80 | |

| 3 | 73 | 0.5 | 0 45 | 3 | 6 | 4 | 300 | 20 | 80 | |

| Semi-Finishing | 4 | 71 | 0.3 0.2 | 0 45 | 3 | 6 | 4 2 | 300 150 | 20 | 80 |

| 5 | 72 | 0.3 0.2 | 0 45 | 3 | 6 | 4 2 | 300 150 | 20 | 80 | |

| 6 | 73 | 0.3 0.2 | 0 45 | 3 | 6 | 4 2 | 300 150 | 20 | 80 | |

| Finishing | 7 | 71 | 0.25 0.15 0.1 | 0 45 | 3 | 6 | 4 2 1 | 300 150 50 | 20 | 80 |

| 8 | 72 | 0.25 0.15 0.1 | 0 45 | 3 | 6 | 4 2 1 | 300 150 50 | 20 | 80 | |

| 9 | 73 | 0.25 0.15 0.1 | 0 45 | 3 | 6 | 4 2 1 | 300 150 50 | 20 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadad, M.; Soleymani, M.; Alinaghizadeh, A. Machining Accurate Deep Curved Forms on Tungsten Carbide–Cobalt (WC-Co) Eliminating Tool Wear in the Electrical Discharge Turning Operation. Micromachines 2025, 16, 1167. https://doi.org/10.3390/mi16101167

Hadad M, Soleymani M, Alinaghizadeh A. Machining Accurate Deep Curved Forms on Tungsten Carbide–Cobalt (WC-Co) Eliminating Tool Wear in the Electrical Discharge Turning Operation. Micromachines. 2025; 16(10):1167. https://doi.org/10.3390/mi16101167

Chicago/Turabian StyleHadad, Mohammadjafar, Mehdi Soleymani, and Amir Alinaghizadeh. 2025. "Machining Accurate Deep Curved Forms on Tungsten Carbide–Cobalt (WC-Co) Eliminating Tool Wear in the Electrical Discharge Turning Operation" Micromachines 16, no. 10: 1167. https://doi.org/10.3390/mi16101167

APA StyleHadad, M., Soleymani, M., & Alinaghizadeh, A. (2025). Machining Accurate Deep Curved Forms on Tungsten Carbide–Cobalt (WC-Co) Eliminating Tool Wear in the Electrical Discharge Turning Operation. Micromachines, 16(10), 1167. https://doi.org/10.3390/mi16101167