Principles of Operation and Application Extensions of Triboelectric Nanogenerators: Structure and Material Optimization

Abstract

1. Introduction

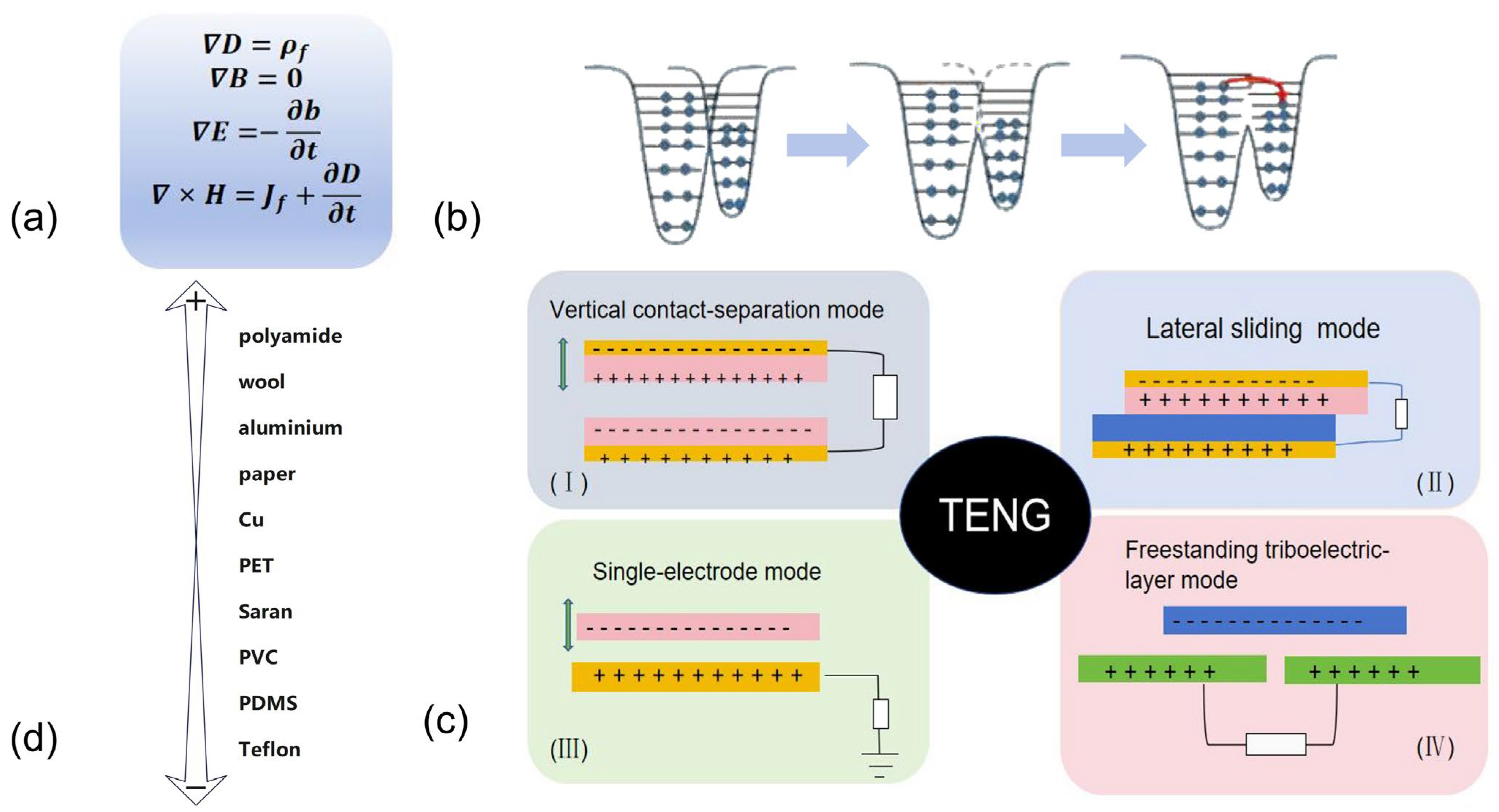

2. TENG Working Principle and Working Mode

2.1. Origin of TENG Theory

2.2. Vertical Contact-Separation Mode

2.3. Lateral Sliding Mode

| Lateral Sliding Mode | Practical Application | Pros. | Cons. | Refs. | |

|---|---|---|---|---|---|

| Rotating Disk Structure |  | wearable devices, Industrial Monitoring, Environmental energy harvesting | Efficient mechanical energy harvesting through continuous friction and charge separation, compact design, easy integration, and adjustable size and material to accommodate different rotational speeds and energy needs. | Long-term rotation may reduce efficiency due to friction material wear, high requirements for speed and stability, low speed or irregular motion efficiency decreases, and high-speed operation may produce noise and vibration. | [41] |

| Rotate the cylindrical structure |  | Wave Energy Harvesting, Wind power, Self-powered sensors | The large friction area is used to improve the efficiency of charge generation, adapt to complex dynamic environments such as ocean or wind power, and increase the output power through modular series connection. | The manufacturing process is complex and costly, and long-term operation may increase friction loss due to material fatigue or surface roughness, and it requires more space than the disk structure, which limits the miniaturization application | [42] |

| Tubular package construction |  | Medical implant devices, Pipeline monitoring, Portable devices, | Encapsulated to protect internal materials, suitable for liquid or wet environments, high durability and long life, and can be designed as flexible or rigid construction to suit a variety of applications. | The limited internal friction area and low output power require a precision packaging process that increases manufacturing costs and requires additional design optimization in the integration of small devices | [43] |

| Liquid metal construction |  | Flexible Electronics Biomedicine Extreme Environments | Adapting to complex shapes and dynamic deformations with high flexibility, excellent conductivity improves charge transfer efficiency and has the potential for self-healing. | Gallium-based alloys are costly, can cause corrosion due to chemical reactions, and require high-precision packaging to prevent leaks, limiting large-scale applications and increasing manufacturing complexity. | [44] |

2.4. Single-Electrode Mode

| Materials | VOC (V) | ISC (µA) | Applications | Ref. |

|---|---|---|---|---|

| PVDF/CNC | 2 | 0.155 | Sensor | [47] |

| PVDF/PZT | 0.44 | - | Vibration energy recovery | [48] |

| PVDF/KNN nanostructures | 1.9 | - | Nanomaterials | [49] |

| PVDF/KNN NRs | 17.5 | 0.522 | Wearable devices | [50] |

| PVDF/BT | 1.1 | - | Electrospun nanocomposite | [51] |

| PVDF/rGO/BT | 1.2 | 0.0025 | Wearable devices and sensors | [52] |

| PVDF/SM-KNN NRs | 21 | 22 | Electrospun nanocomposite based piezoelectric materials | [51] |

| PVDF/Ag-Nylon | 0.38 | 1750 | Wearable devices | [53] |

| PVDF-HFP/CNC/Fe-ZnO | 12 | 2.5 | Wearable devices | [54] |

| PVDF/KNN NRs | 3.7 | 0.000326 | Nanomaterials | [55] |

| PVDF-HFP/Co-ZnO | 2.8 | - | Nanofibers | [56] |

| PVDF-TrFE/BT NPs | 3.4 | 0.523 | Self powered sensor | [57] |

| PVDF/KNN-ZS | 25 | 2.11 | Nanofibers | [58] |

| PVDF-TrFE/MWCNTs | 18.23 | 2.14 | Wearable devices | [59] |

| PVDF/KNN/CNT | 23.24 | 9 | Carbon nanotubes | [60] |

2.5. Freestanding Triboelectric Layer Mode

3. Research Directions of TENG Application Extension, Structural Optimization, and Material Optimization

3.1. Application Extension

| Field | Structure Lype | Output Performance | Ref. |

|---|---|---|---|

| Blue Energy | Rolling Spherical Structure | 7.96 mW, 120 μA, 560 V, 15.20 Wm−3 | [69] |

| wind | Contact-separation | 300 V, 12 μA, 200 nC | [70] |

| Contact-separation | 400 V, 7 μA, 80 nC | [71] | |

| Human skin | Single electrode | 10 Pa, 1860 V, 1.1 μA/cm2 5200 mW/m2, 5.09 mW/N | [72] |

| Single electrode | 9.8 Pa, 28 V, 0.56 μA | [73] | |

| Machine learning | four-layer GNN | 1.12 J/cm | [74] |

| ground motion | Contact-separation | Minimum traction and compression forces of 35 N at minimum velocities of 10 mm/min for elongations up to 4 mm could be detected | [75] |

| Healthcare | Single electrode | 14.5 W m2 85 μA | [76] |

| Pervskites | Contact-separation | 17 V, 30 μA, 130 μW, 14.44 μW/cm2 | [77] |

| Mechanical energy | cylindrical rollers | 26.56 V, 2.45 μA | [78] |

| optics | Single electrode | achieving remarkable elasticity over 100% and a brightness of 139 cd/m2. | [38] |

| Unmanned aerial vehicle | Contact-separation | with a wide frequency detection range of 20–400 Hz, a maximum error of 0.0062%, and a linear fit goodness of fit (R2) close to 1.F | [79] |

3.2. Structure Optimization

3.3. Material Optimization

| Perovskite | VOC | Isc | Refs. |

|---|---|---|---|

| 127 V | 3.16 | [89] | |

| 192 V | 16.7 | [90] | |

| V-NaNb | −200 V | −5.7 | [91] |

| FTO/CsPbB | 240 V | 4.13 | [92] |

| ~662 V | ~18.7 | [87] | |

| Pb | 200 V | 16.3 | [93] |

| 67 V | 18 | [94] | |

| CsFAMA | 0.33 V | 2.1 | [95] |

| Materials | Open-Circuit Voltage (V) | Peak Power Density (W/cm2) | Ref. |

|---|---|---|---|

| PVDF-HFP+Mn-BNT-BT + AgNWs composite fiber mat/Al foil | 2172 | 47.3 | [96] |

| PVDF/ZnO NWs | 330 | 3 | [97] |

| PVDF/MXene nanocomposite fiber | 710 | 11.213 | [98] |

| PVDF nanofiber mat/conductive fabric | 400 | 7 | [99] |

| PVDF/printer ink (PI) nanocomposite fiber | 1600 | 22 | [85] |

| PVDF-MoS2/CNTs nanocomposite fiber | 300 | 0.134 | [86] |

| PVDF film /FTO/Co(OH)(CO3)0.5/Pt/CsPbIBr2 | 243 | 2.04 | [100] |

| Material | Voc (v) | Isc (μA) | Power (μW) | Power Density [W/cm2] | References |

|---|---|---|---|---|---|

| PZT/MFC@PVA | 16.5 | 0.86 | 3.3 | 1.5 | [86] |

| ZnTiO3/PDMS | 6.5 | 0.07 | 1.43 | 2.86 | [101] |

| Bi0.5Na0.5TiO3/PVDF | 19 | 1.2 | 1.4 | 0.35 | [86] |

| CaTiO3/PVDF | 12 | 0.1 | 1.71 | 0.19 | [102] |

| BaTiO3/PVDF | 25.7 | 0.68 | - | - | [103] |

| BSTO-MWCNTs/PVDF | 42 | 9 | 31.5 | 31.5 | [104] |

| BaTiO3/PVDF | 24.5 | 0.64 | 0.7 | 0.4 | [105] |

| SrTi2O5/PDMS | ~10 | 0.92 | 0.64 | 0.16 | [106] |

| SrTiO3/PVDF | 17 | 30 | 130 | 14.44 | [78] |

4. Conclusions and Extensions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shan, B.; Ai, T.; Wang, K. Triboelectric nanogenerator for ocean energy harvesting: A review of technological advances and future perspectives. Int. J. Electrochem. Sci. 2024, 19, 100694. [Google Scholar] [CrossRef]

- Wang, S.; Ding, L.; Fan, X.; Jiang, W.; Gong, X. A liquid metal-based triboelectric nanogenerator as stretchable electronics for safeguarding and self-powered mechanosensing. Nano Energy 2018, 53, 863–870. [Google Scholar] [CrossRef]

- Li, X.; Xu, L.; Lin, P.; Yang, X.; Wang, H.; Qin, H.; Wang, Z.L. Three-dimensional chiral networks of triboelectric nanogenerators inspired by metamaterial’s structure. Energy Environ. Sci. 2023, 16, 3040–3052. [Google Scholar] [CrossRef]

- Feng, Y.; Liang, X.; An, J.; Jiang, T.; Wang, Z.L. Soft-contact cylindrical triboelectric-electromagnetic hybrid nanogenerator based on swing structure for ultra-low frequency water wave energy harvesting. Nano Energy 2021, 81, 105625. [Google Scholar] [CrossRef]

- Iqbal, M.S.; Lu, H.; Khaladkar, S.; Wu, X.; Roy, S.; Ullah, Z.; Yan, Y.; Zhang, Y.; Guo, B. Recent advances in triboelectric nanogenerators: Mechanism, rational designing andapplications. Mater. Today Energy 2024, 46, 101732. [Google Scholar] [CrossRef]

- Lin, Z.; Chen, J.; Yang, J. Recent Progress in Triboelectric Nanogenerators as a Renewable and Sustainable Power Source. J. Nanomater. 2016, 2016, 5651613. [Google Scholar] [CrossRef]

- Ren, Z.; Wu, L.; Zhang, J.; Wang, Y.; Wang, Y.; Li, Q.; Wang, F.; Liang, X.; Yang, R. Trapezoidal Cantilever-Structure Triboelectric Nanogenerator Integrated with a Power Management Module for Low-Frequency Vibration Energy Harvesting. ACS Appl. Mater. Interfaces 2022, 14, 5497–5505. [Google Scholar] [CrossRef] [PubMed]

- Rehman, S.; Alhems, L.M.; Alam, M.M.; Wang, L.; Toor, Z. A review of energy extraction from wind and ocean: Technologies, merits, efficiencies, and cost. Ocean Eng. 2023, 267, 113192. [Google Scholar] [CrossRef]

- Wang, K.; Yao, Y.; Liu, Y.; Guan, X.; Yu, Y.; Wang, J.; Wang, Y.; Li, T.; Cheng, T. Self-powered system for real-time wireless monitoring and early warning of UAV motor vibration based on triboelectric nanogenerator. Nano Energy 2024, 129 Pt A, 110012. [Google Scholar] [CrossRef]

- Potu, S.; Kulandaivel, A.; Gollapelli, B.; Khanapuram, U.K.; Rajaboina, R.K. Oxide based triboelectric nanogenerators: Recent advances and future prospects in energy harvesting. Mater. Sci. Eng. R Rep. 2024, 161, 100866. [Google Scholar] [CrossRef]

- Yang, X.; Xu, L.; Lin, P.; Zhong, W.; Bai, Y.; Luo, J.; Chen, J.; Wang, W. Macroscopic self-assembly network of encapsulated high-performance triboelectric nanogenerators for water wave energy harvesting. Nano Energy 2019, 60, 404–412. [Google Scholar] [CrossRef]

- Lee, Y.; Ren, Z.; Hsiao, H.Y.; Kim, S.; Song, W.; Lee, C.; Chen, Y. Liftoff of a soft-actuated micro-aerial-robot powered by triboelectric nanogenerators. Nano Energy 2024, 126, 109602. [Google Scholar] [CrossRef]

- Stempflé, P.; Ratier, N. What does a sliding triboelectrical sensor really measure? Tribol. Int. 2023, 179, 108083. [Google Scholar] [CrossRef]

- Yu, Y.; Li, H.; Zhao, D.; Gao, Q.; Li, X.; Wang, J.; Wang, Z.L.; Cheng, T. Material’s selection rules for high performance triboelectric nanogenerators. Mater. Today 2023, 64, 61–71. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, S.; Dai, X.; Tu, Y.; Du, Z.; Wu, X.; Huang, Y.; Fan, J.; Hong, Z.; Jiang, T.; et al. Hybridized triboelectric-electromagnetic nanogenerators for efficient harvesting of wave energy for self-powered ocean buoy. Nano Energy 2024, 128 Pt B, 109929. [Google Scholar] [CrossRef]

- Prasanna, A.P.S.; Anithkumar, M.; Kim, S.J. Hybrid triboelectric nanogenerators: Revolutionizing the energy harvesting through material diversity and device architecture for different applications. Nano Energy 2024, 131 Pt A, 110253. [Google Scholar] [CrossRef]

- Jean, F.; Khan, M.U.; Anwer, S.; Alazzam, A.; Mohammad, B. Cobalt Ferrite@Barium titanate core-shell nanoparticles empowered triboelectric electromagnetic coupled nanogenerator for self-powered electronics. Chem. Eng. J. 2024, 501, 156787. [Google Scholar] [CrossRef]

- Feng, M.; Feng, Y.; Cheng, J.; Zhang, Z.; Yang, D.; Du, C.; Wang, D. Clothing comfort sensing system based on triboelectric and tribological behavior of fabrics. Nano Energy 2024, 127, 109721. [Google Scholar] [CrossRef]

- Luo, X.; Li, H.; Berbille, A.; Liu, L.; Gao, Y.; Han, G.; Wang, Z.; Zhu, L. Tribovoltaic nanogenerators based on n-n and p-p semiconductor homojunctions. Nano Energy 2024, 129 Pt A, 110043. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Ren, L.; Xue, H.; Li, B.; Niu, S.; Liu, Q.; Han, Z.; Ren, L. Reconfigurable Fiber Triboelectric Nanogenerator for Self-Powered Defect Detection. ACS Nano 2022, 16, 7721–7731. [Google Scholar] [CrossRef]

- Wu, H.; Xu, X.A.; Xin, C.; Liu, Y.; Rao, R.; Li, Z.; Zhang, D.; Wu, Y.; Han, S. Intelligent fault diagnosis for triboelectric nanogenerators via a novel deep learning framework. Expert Syst. Appl. 2023, 226, 120244. [Google Scholar] [CrossRef]

- Ahmed, A.; Hassan, I.; El-Kady, M.F.; Radhi, A.; Jeong, C.K.; Selvaganapathy, P.R.; Zu, J.; Ren, S.; Wang, Q.; Kaner, R.B. Integrated Triboelectric Nanogenerators in the Era of the Internet of Things. Adv. Sci. 2019, 6, 1802230. [Google Scholar] [CrossRef]

- Xiao, T.; Bing, Z.; Wu, Y.; Chen, W.; Zhou, Z.; Fang, F.; Liang, S.; Guo, R.; Tu, S.; Pan, G.; et al. A multi-dimensional tactile perception system based on triboelectric sensors: Towards intelligent sorting without seeing. Nano Energy 2024, 123, 109398. [Google Scholar] [CrossRef]

- Nguyen, M.P.; Huynh, N.D.; Luu, T.T.; Cho, D. Recent progress towards smart transportation systems using triboelectric nanogenerators. J. Phys. Energy 2024, 6, 022001. [Google Scholar] [CrossRef]

- Willatzen, M.; Zhang, Z.; Wang, Z.L. Theory of Tribovoltaics: Direct Current Generation at a p-n Semiconductor Interface. PRX Energy 2024, 3, 14. [Google Scholar] [CrossRef]

- An, C.; Qi, H.; Wang, L.; Fu, X.; Wang, A.; Wang, Z.L.; Liu, J. Piezotronic and piezo-phototronic effects of atomically-thin ZnO nanosheets. Nano Energy 2021, 82, 105653. [Google Scholar] [CrossRef]

- Wang, Z.L. On Maxwell’s displacement current for energy and sensors: The origin of nanogenerators. Mater. Today 2016, 20, 74–82. [Google Scholar] [CrossRef]

- Bairagi, S.; Khandelwal, G.; Karagiorgis, X.; Gokhool, S.; Kumar, C.; Min, G.; Mulvihill, D.M. High-Performance Triboelectric Nanogenerators Based on Commercial Textiles: Electrospun Nylon 66 Nanofibers on Silk and PVDF on Polyester. ACS Appl. Mater. Interfaces 2022, 14, 44591–44603. [Google Scholar] [CrossRef]

- Liang, X.; Jiang, T.; Liu, G.; Xiao, T.; Xu, L.; Li, W.; Xi, F.; Zhang, C.; Wang, Z.L. Triboelectric Nanogenerator Networks Integrated with Power Management Module for Water Wave Energy Harvesting. Adv. Funct. Mater. 2019, 29, 1807241. [Google Scholar] [CrossRef]

- Almardi, J.M.; Bo, X.; Shi, J.; Firdous, I.; Daoud, W.A. Drone rotational triboelectric nanogenerator for supplemental power generation and RPM sensing. Nano Energy 2025, 135, 110614. [Google Scholar] [CrossRef]

- Li, F.; Sun, S.; Wan, X.; Sun, M.; Zhang, S.L.; Xu, M. A self-powered soft triboelectric-electrohydrodynamic pump. Nat. Commun. 2025, 16, 1315. [Google Scholar] [CrossRef]

- Fu, J.; Xia, K.; Xu, Z. Double helix triboelectric nanogenerator for self-powered weight sensors. Sens. Actuators A Phys. 2021, 323, 112650. [Google Scholar] [CrossRef]

- Lin, S.; Chen, X.; Wang, Z.L. Contact Electrification at the Liquid−Solid Interface. Chem. Rev. 2021, 122, 5209–5232. [Google Scholar] [CrossRef]

- Tang, W.; Fan, R.F.; Berbille, A.; Wang, L.Z. Contact-electro-catalysis. MRS Bull. 2025, 50, 503–511. [Google Scholar] [CrossRef]

- Cheng, B.; Xu, Q.; Ding, Y.; Bai, S.; Jia, X.; Yu, Y.; Wen, J.; Qin, Y. High performance temperature difference triboelectric nanogenerator. Nat. Commun. 2021, 12, 4782. [Google Scholar] [CrossRef]

- Nie, J.; Wang, Z.; Ren, Z.; Li, S.; Chen, X.; Wang, L.Z. Power generation from the interaction of a liquid droplet and a liquid membrane. Nat. Commun. 2019, 10, 2264. [Google Scholar] [CrossRef]

- Suh, I.-Y.; Jeon, J.; Park, M.J.; Ryu, H.; Park, J.Y.; Kim, S.-W. Recent Studies on Solid–Liquid Contact Electrification. ACS Appl. Electron. Mater. 2024, 6, 4826–4842. [Google Scholar] [CrossRef]

- Xin, Y.; Du, T.; Liu, T.; Sun, P.; Zhu, M.; Zheng, L.; Du, H.; Zou, Y.; Xu, M. Triboelectric nanogenerator embedded cylindrical roller bearing for rotational energy harvesting and self-powered fault diagnosis. Sens. Actuators A Phys. 2023, 362, 114664. [Google Scholar] [CrossRef]

- Tang, C.; Liu, Z.; Hu, Q.; Jiang, Z.; Zheng, M.; Xiong, C.; Wang, S.; Yao, S.; Zhao, Y.; Wan, X.; et al. Unconstrained Piezoelectric Vascular Electronics for Wireless Monitoring of Hemodynamics and Cardiovascular Health. Small 2023, 20, e2304752. [Google Scholar] [CrossRef]

- Li, C.; Guo, H.; Liao, J.; Wang, Y.; Qin, Y.; Tian, Q.Z. Gas-driven triboelectric nanogenerator for mechanical energy harvesting and displacement monitoring. Nano Energy 2024, 126, 109681. [Google Scholar] [CrossRef]

- Hu, Y.; Qiu, H.; Sun, Q.; Wang, Z.L.; Xu, L. Wheel-structured Triboelectric Nanogenerators with Hyperelastic Networking for High-Performance Wave Energy Harvesting. Small Methods 2023, 7, e2300582. [Google Scholar] [CrossRef]

- Pang, H.; Feng, Y.; An, J.; Chen, P.; Han, J.; Jiang, T.; Wang, Z.L. Segmented Swing-Structured Fur-Based Triboelectric Nanogenerator for Harvesting Blue Energy toward Marine Environmental Applications Advanced. Funct. Mater. 2021, 31, 2106398. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, B.; Zou, H.; Lin, Z.; Liu, G.; Wang, Z. Multifunctional Sensor Based on Translational-Rotary Triboelectric Nanogenerator. Energy Mater. 2019, 9, 1901124. [Google Scholar] [CrossRef]

- Dai, Y.; Yu, K.; Li, H.; Zhu, H.; He, Q.; Zhang, T.; Liu, T.; Luo, B.; Zhang, S.; Cai, C.; et al. Efficient removal of oil mist via triboelectric negative air ions. Nano Energy 2024, 126, 109692. [Google Scholar] [CrossRef]

- Jiao, H.; Lin, X.; Xiong, Y.; Han, J.; Liu, Y.; Yang, J.; Wu, S.; Jiang, T.; Wang, Z.L.; Sun, Q. Thermal insulating textile based triboelectric nanogenerator for outdoor wearable sensing and interaction. Nano Energy 2024, 120, 109134. [Google Scholar] [CrossRef]

- Ouyang, H.; Liu, Z.; Li, N.; Shi, B.; Zou, Y.; Xie, F.; Ma, Y.; Li, Z.; Li, H.; Zheng, Q.; et al. Symbiotic cardiac pacemaker. Nat. Commun. 2019, 10, 1821. [Google Scholar] [CrossRef]

- Lee, J.E.; Shin, Y.E.; Lee, G.H.; Kim, J.; Ko, H.; Chae, H.G. Polyvinylidene fluoride (PVDF)/cellulose nanocrystal (CNC) nanocomposite fiber and triboelectric textile sensors. Compos. Part B 2021, 223, 109098. [Google Scholar] [CrossRef]

- Koç, M.; Paralı, L.; Şan, O. Fabrication and vibrational energy harvesting characterization of flexible piezoelectric nanogenerator (PEN) based on PVDF/PZT. Polym. Test. 2020, 90, 106695. [Google Scholar] [CrossRef]

- Teka, A.; Bairagi, S.; Shahadat, M.; Joshi, M.; Ziauddin Ahammad, S.K.; Wazed Ali, S. Poly (vinylidene fluoride) (PVDF)/potassium sodium niobate (KNN)–based nanofibrous web: A unique nanogenerator for renewable energy harvesting and investigating the role of KNN nanostructures. Polym. Adv. Technol. 2018, 29, 2537–2544. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Fay, C.; Cheng, Z.; Raad, R.; Xi, J.; Foroughi, J. Wearable Electronic Textiles from Nanostructured Piezoelectric Fibers. Adv. Mater. Technol. 2020, 5, 1900900. [Google Scholar] [CrossRef]

- Bairagi, S.; Ali, W.S. Flexible lead-free PVDF/SM-KNN electrospun nanocomposite based piezoelectric materials: Significant enhancement of energy harvesting efficiency of the nanogenerator. Energy 2020, 198, 117385. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Sayyar, S.; Cheng, Z.; Ruhparwar, A.; Foroughi, J. Highly Stretchable Self-Powered Wearable Electrical Energy Generator and Sensors. Adv. Mater. Technol. 2020, 6, 2000841. [Google Scholar] [CrossRef]

- Mokhtari, F.; Foroughi, J.; Zheng, T.; Cheng, Z.; Spinks, G.M. Triaxial braided piezo fiber energy harvesters for self-powered wearable technologies. J. Mater. Chem. A 2019, 7, 8245–8257. [Google Scholar] [CrossRef]

- Ponnamma, D.; Parangusan, H.; Tanvir, A.; AlMa’adeed, A.A.M. Smart and robust electrospun fabrics of piezoelectric polymer nanocomposite for self-powering electronic textiles. Mater. Des. 2019, 184, 108176. [Google Scholar] [CrossRef]

- Bairagi, S.; Ali, W.S. A unique piezoelectric nanogenerator composed of melt-spun PVDF/KNN nanorod-based nanocomposite fibre. Eur. Polym. J. 2019, 116, 554–561. [Google Scholar] [CrossRef]

- Parangusan, H.; Ponnamma, D.; Al-Maadeed, M.A. Stretchable Electrospun PVDF-HFP/Co-ZnO Nanofibers as Piezoelectric Nanogenerators. Sci. Rep. 2018, 8, 754. [Google Scholar] [CrossRef]

- Siddiqui, S.; Kim, D.I.; Roh, E.; Duy, L.T.; Trung, T.Q.; Nguyen, M.T.; Lee, N.E. A durable and stable piezoelectric nanogenerator with nanocomposite nanofibers embedded in an elastomer under high loading for a self-powered sensor system. Nano Energy 2016, 30, 434–442. [Google Scholar] [CrossRef]

- Banerjee, S.; Bairagi, S.; Ali, S.W. A lead-free flexible piezoelectric-triboelectric hybrid nanogenerator composed of uniquely designed PVDF/KNN-ZS nanofibrous web. Energy 2022, 244 Pt B, 123102. [Google Scholar] [CrossRef]

- Zhao, C.; Niu, J.; Zhang, Y.; Li, C.; Hu, P. Coaxially aligned MWCNTs improve performance of electrospun P(VDF-TrFE)-based fibrous membrane applied in wearable piezoelectric nanogenerator. Compos. Part B 2019, 178, 107447. [Google Scholar] [CrossRef]

- Bairagi, S.; Ali, S.W. Investigating the role of carbon nanotubes (CNTs) in the piezoelectric performance of a PVDF/KNN-based electrospun nanogenerator. Soft Matter 2020, 16, 4876–4886. [Google Scholar] [CrossRef]

- Wang, S.; Xie, Y.; Niu, S.; Long, L.; Lin, Z.W. Freestanding triboelectric-layer-based nanogenerators for harvesting energy from a moving object or human motion in contact and non-contact modes. Adv. Mater. 2014, 26, 2818–2824. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, Y.; Du, X.; Yang, Y.; Li, S.; Fan, D.; Xiao, X.; Mutsuda, H.; Jiao, P. Self-powered and self-sensing blue carbon ecosystems by hybrid fur triboelectric nanogenerators (F-TENG). Nano Energy 2024, 119, 109091. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, J.; Li, H.; Yu, Y.; Zhang, X.; Wang, Y.; Wen, J.; Wang, L.Z.; Cheng, T. High performance triboelectric nanogenerator for wave energy harvesting through the gas-assisted method. Chem. Eng. J. 2024, 493, 152730. [Google Scholar] [CrossRef]

- Ali, M.; Khan, S.A.; Ali, A.; Ali, S.; ul Hassan, R.; Cho, D.H.; Byun, D. Low profile wind savonius turbine triboelectric nanogenerator for powering small electronics. Sens. Actuators A Phys. 2023, 363, 114535. [Google Scholar] [CrossRef]

- Qu, H.; Wan, L.; Tian, Z.; Liu, G.; Wang, Z.L. Evaporation Triboelectric-Nanogenerator: Harvesting Low-Grade Heat Energy from Ambient Environment. Adv. Mater. Technol. 2024, 9, 2301409. [Google Scholar] [CrossRef]

- Lin, S.; Zhu, L.; Qiu, Y.; Jiang, Z.; Wang, Y.; Zhu, J.; Wu, H. A self-powered multi-functional sensor based on triboelectric nanogenerator for monitoring states of rotating motion. Nano Energy 2021, 83, 105857. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Liu, D.; Zhang, Z.; Li, W.; Liu, C.; Du, T.; Xiao, X.; Song, L.; Pang, H.; et al. A robust and self-powered tilt sensor based on annular liquid-solid interfacing triboelectric nanogenerator for ship attitude sensing. Sens. Actuators A Phys. 2021, 317, 112459. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Liu, T.; Wei, Z.; Luo, B.; Chi, M.; Zhang, S.; Cai, C.; Gao, C.; Zhao, T.; et al. Triboelectric tactile sensor for pressure and temperature sensing in high-temperature applications. Nat. Commun. 2025, 16, 383. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Cheng, L.; Wan, N.; Ma, J.; Hu, Y.; Wen, J. Hybrid harvesting of wind and wave energy based on triboelectric-piezoelectric nanogenerators. Sustain. Energy Technol. Assess. 2023, 60, 103466. [Google Scholar] [CrossRef]

- Liang, X.; Jiang, T.; Liu, G.; Feng, Y.; Zhang, C.; Wang, Z.L. Spherical triboelectric nanogenerator integrated with power management module for harvesting multidirectional water wave energy. Energy Environ. 2020, 13, 277–285. [Google Scholar] [CrossRef]

- Li, H.; Wen, J.; Ou, Z.; Su, E.; Xing, F.; Yang, Y.; Sun, Y.; Wang, Z.L.; Chen, B. Leaf-Like TENGs for Harvesting Gentle Wind Energy at an Air Velocity as Low as 0.2 m s−1. Adv. Funct. Mater. 2023, 33, 57. [Google Scholar] [CrossRef]

- Zhang, L.; Meng, B.; Tian, Y.; Meng, X.; Lin, X.; He, Y.; Xing, C.; Dai, H.; Wang, L. Vortex-induced vibration triboelectric nanogenerator for low speed wind energy harvesting. Nano Energy 2022, 95, 47. [Google Scholar] [CrossRef]

- Xiong, J.; Cui, P.; Chen, X.; Wang, J.; Parida, K.; Lin, M.F.; Lee, P.S. Skin-touch-actuated textile-based triboelectric nanogenerator with black phosphorus for durable biomechanical energy harvesting. Nat. Commun. 2018, 9, 4280. [Google Scholar] [CrossRef]

- Park, J.; Choi, A.Y.; Lee, C.J.; Kim, D.; Kim, Y.T. Highly stretchable fiber-based single-electrode triboelectric nanogenerator for wearable devices. RSC Adv. 2017, 7, 54829–54834. [Google Scholar] [CrossRef]

- Xu, G.; Zhao, Z.; Wang, L.Z.; Li, F.H. Integrating machine learning with triboelectric nanogenerators: Optimizing electrode materials and doping strategies for intelligent energy harvesting. Nano Energy 2025, 142 Pt A, 111131. [Google Scholar] [CrossRef]

- del Río, J.S.; Vázquez-López, A.; Laguna, A.L.; Andolfi, M.; Cascón, R.; Olalla, F.S.; Paramio, S.; Ballesteros, Y.; Cruz, C.; Martínez, V.; et al. A low frequency seismic triboelectric energy triboelectric nanogenerators used in slow and higher ground motion. Results Eng. 2025, 27, 105845. [Google Scholar] [CrossRef]

- Bui, V.T.; Le, T.H.; Jeong, H.M.; Do, L.C.; Bui, V.T.; Van Khai, T.; Dao, V.D.; Doan, T.C.; Hoang, D. Antagonistic-structured breathable triboelectric nanogenerator based on sponge PMMA-GO/electrode mesh hybrid for wearable healthcare applications. Nano Energy 2025, 142 Pt B, 111242. [Google Scholar] [CrossRef]

- Park, C.; Lim, W.; Joshi, B.; Kim, T.; Samuel, E.; Aldalbahi, A.; Periyasami, G.; Ding, B.; Yoon, S.S. Enhancing the piezoelectric coefficient of SrTiO3 nanocubes and PVDF film deposited by supersonic spraying for energy-harvesting nanogenerators. Chem. Eng. J. 2024, 491, 151945. [Google Scholar] [CrossRef]

- Jeong, H.I.; Jung, H.S.; Dubajic, M.; Kim, G.; Jeong, W.H.; Song, H.; Lee, Y.; Biswas, S.; Kim, H.; Lee, B.R.; et al. Super elastic and negative triboelectric polymer matrix for high performance mechanoluminescent platforms. Nat. Commun. 2025, 16, 854. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.; He, W.; Tang, Q.; Wang, Z.; Liu, W.; Li, Q.; Shan, C.; Long, L.; Hu, C.; Liu, H. An Ultrarobust and High-Performance Rotational Hydrodynamic Triboelectric Nanogenerator Enabled by Automatic Mode Switching and Charge Excitation. Adv. Mater. 2022, 34, 2105882. [Google Scholar] [CrossRef]

- Fu, X.; Xu, S.; Gao, Y.; Zhang, X.; Liu, G.; Zhou, H.; Lv, Y.; Zhang, C.; Wang, Z.L. Breeze-Wind-Energy-Powered Autonomous Wireless Anemometer Based on Rolling Contact-Electrification. ACS Energy Lett. 2021, 6, 2343–2350. [Google Scholar] [CrossRef]

- Luo, Y.; Chen, P.; Cao, L.N.Y.; Xu, Z.; Wu, Y.; He, G.; Jiang, T.; Wang, Z.L. Durability Improvement of Breeze-Driven Triboelectric-Electromagnetic Hybrid Nanogenerator by a Travel-Controlled Approach. Adv. Funct. Mater. 2022, 32, 2205710. [Google Scholar] [CrossRef]

- Shu, L.; Fang, L.; Wang, F.; Li, Z.; Guo, Y.; Zhang, H.; Wang, Z.; He, W.; Rasheed, A.; Fan, K.; et al. Wind speed adaptive triboelectric nanogenerator with low start-up wind speed, enhanced durability and high power density via the synergistic mechanism of magnetic and centrifugal forces for intelligent street lamp system. Nano Energy 2025, 133, 110487. [Google Scholar] [CrossRef]

- Li, J.; Zhu, L.; Zhang, Z.; Wang, A.; Wang, L.Z.; Wang, L.; Yang, D. Triboelectrification-induced electroluminescent skin for real-time information recording at a record low pressure threshold of 0.125 kPa. Mater. Today 2024, 78, 10–19. [Google Scholar] [CrossRef]

- Tayyab, M.; Wang, J.; Wang, J.; Maksutoglu, M.; Yu, H.; Sun, G.; Yildiz, F.; Eginligil, M.; Huang, W. Enhanced output in polyvinylidene fluoride nanofibers based triboelectric nanogenerator by using printer ink as nano-fillers. Nano Energy 2020, 77, 105178. [Google Scholar] [CrossRef]

- Sun, C.; Zu, G.; Wei, Y.; Song, X.; Yang, X. Flexible Triboelectric Nanogenerators Based on Electrospun Poly(vinylidene flu-oride) with MoS2/Carbon Nanotube Composite Nanofibers. Langmuir ACS J. Surf. Colloids 2022, 38, 1479–1487. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Kim, J.; Hong, S.; Kim, H.S.; Yoon, S.G. High-power nanogenerator of 2D-layered perovskite in a polymer matrix for self-charging battery-powered electronics. Nano Energy 2022, 103 Pt A, 107781. [Google Scholar] [CrossRef]

- Sahu, M.; Hajra, S.; Bijelić, J.; Oh, D.; Djerdj, I.; Kim, J.H. Triple perovskite-based triboelectric nanogenerator: A facile method of energy harvesting and self-powered information generator. Mater. Today Energy 2021, 20, 100639. [Google Scholar] [CrossRef]

- Xie, B.; Yin, R.; Miao, S.; Jia, H.; Ma, Y.; Liu, Y. Thermal-stable and high-dielectric Ba(Cu0.5W0.5)O3-based ceramic Powder/PMDS films for triboelectric nanogenerator. Ceram. Int. 2024, 50, 12778–12786. [Google Scholar] [CrossRef]

- Wang, Y.; Duan, J.; Yang, X.; Liu, L.; Zhao, L.; Tang, Q. The unique dielectricity of inorganic perovskites toward high-performance triboelectric nanogenerators. Nano Energy 2020, 69, 104418. [Google Scholar] [CrossRef]

- Paranjape, M.V.; Kim, J.; Kim, Y.; Jo, E.; Graham, S.A.; Manchi, P.; Lee, J.K.; Yu, J.S. Perovskite V–NaNbO3 embedded PDMS composite film-based robust hybrid nanogenerator for efficient mechanical energy harvesting. Compos. Sci. Technol. 2023, 242, 110195. [Google Scholar] [CrossRef]

- Wang, M.; Duan, J.; Yang, X.; Wang, Y.; Duan, Y.; Tang, Q. Interfacial electric field enhanced charge density for robust triboelectric nanogenerators by tailoring metal/perovskite Schottky junction. Nano Energy 2020, 73, 104747. [Google Scholar] [CrossRef]

- Jiao, Y.; Lin, Z.; Ma, X.; Zhou, L.; Guo, X.; Hu, Z.; Hu, X.; Zhao, X.; Ding, L.; Hao, Y.; et al. High-performance triboelectric nanogenerators based on blade-coating lead halide perovskite film and electrospinning PVDF/graphene nanofiber. Chem. Eng. J. 2024, 483, 149442. [Google Scholar] [CrossRef]

- He, X.; Zheng, J.; Yang, T.; Ou, D.; Bowen, C.R.; Shi, S.; Chen, Q.; Fu, H.; Huang, S.; Ye, Y.; et al. High-performance piezoelectric nanogenerators based on Cs2Ag0.3Na0.7InCl6 double perovskites with high polarity induced by Zr/Te codoping. Nano Energy 2023, 115, 108741. [Google Scholar] [CrossRef]

- Du, J.; Yang, X.; Duan, J.; Wang, Y.; Tang, Q. Tailoring all-inorganic cesium lead halide perovskites for robust triboelectric nanogenerators. Nano Energy 2020, 70, 104514. [Google Scholar] [CrossRef]

- He, Y.; Wang, H.; Sha, Z.; Boyer, C.; Wang, C.H.; Zhang, J. Enhancing output performance of PVDF-HFP fiber-based nanogenerator by hybridizing silver nanowires and perovskite oxide nanocrystals. Nano Energy 2022, 98, 107343. [Google Scholar] [CrossRef]

- Pu, X.; Zha, J.W.; Zhao, C.L.; Gong, S.B.; Gao, J.F.; Li, R.K. Flexible PVDF/nylon-11 electrospun fibrous membranes with aligned ZnO nanowires as potential triboelectric nanogenerators. Chem. Eng. J. 2020, 398, 125526. [Google Scholar] [CrossRef]

- Bhatta, T.; Maharjan, P.; Cho, H.; Park, C.; Yoon, S.H.; Sharma, S.; Salauddin, M.; Rahman, M.T.; Rana, S.S.; Park, J.Y. High-performance triboelectric nanogenerator based on MXene functionalized polyvinylidene fluoride composite nanofibers. Nano Energy 2021, 81, 105670. [Google Scholar] [CrossRef]

- Chen, F.; Wu, Y.; Ding, Z.; Chen, F.; Wu, Y.; Ding, Z.; Xia, X.; Li, S.; Zheng, H.; Diao, C.; et al. A Novel Triboelectric Nanogenerator Based on Electrospun Polyvinylidene Fluoride Nanofibers for Effective Acoustic Energy Harvesting and Self-powered Multifunctional Sensing. Nano Energy 2018, 56, 241–251. [Google Scholar] [CrossRef]

- Du, J.; Duan, J.; Yang, X.; Wang, Y.; Duan, Y.; Tang, Q. Charge boosting and storage by tailoring rhombus all-inorganic perovskite nanoarrays for robust triboelectric nanogenerators. Nano Energy 2020, 74, 104845. [Google Scholar] [CrossRef]

- Barman, S.; Paul, S.; Ranjan, P.; Das, S.; Datta, A. Emerging ferroelectricity and piezoelectric energy harvesting properties in lead-free zinc titanate nanocrystals. J. Mater. Sci. 2023, 58, 7060–7075. [Google Scholar] [CrossRef]

- Kurakula, A.; Graham, S.A.; Manchi, P.; Paranjape, M.V.; Yu, J.S. Enhanced energy harvesting ability of bismuth sodium titanate/polyvinylidene fluoride composite film-based piezoelectric nanogenerators for mechanical energy scavenging and safety-walker applications. Mater. Today Sustain. 2024, 25, 100616. [Google Scholar] [CrossRef]

- Panda, S.; Hajra, S.; Jeong, H.; Panigrahi, B.K.; Pakawanit, P.; Dubal, D.; Hong, S.; Kim, H.J. Biocompatible CaTiO3-PVDF composite-based piezoelectric nanogenerator for exercise evaluation and energy harvesting. Nano Energy 2022, 102, 107682. [Google Scholar] [CrossRef]

- Jiang, H.; Song, L.; Huang, Z.X.; Liu, M.; Zhao, Y.; Zhang, S.; Guo, J.; Li, Y.; Wang, Q.; Qu, J.P. A novel concept of hierarchical porous structural design on enhancing output performance of piezoelectric nanogenerator. Nano Energy 2022, 104 Pt A, 107921. [Google Scholar] [CrossRef]

- Das, T.; Biswas, P.; Dev, A.; Mallick, J.; Kar, M. Multi-functional piezoelectric nanogenerator based on relaxor ferroelectric materials (BSTO) and conductive fillers (MWCNTs) for self-powered memristor and optoelectronic devices. Chem. Eng. J. 2024, 479, 147900. [Google Scholar] [CrossRef]

- Panda, S.; Shin, H.; Hajra, S.; Oh, Y.; Oh, W.; Lee, J.; Rajaitha, P.M.; Panigrahi, B.K.; Shukla, J.; Sahu, A.K.; et al. Ferroelectric composite-based piezoelectric energy harvester for self-powered detection of obstructive sleep. J. Mater. 2023, 9, 609–617. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, L.; Chen, T.; Wu, J.; Zhang, T.; Shao, L.; Zhang, H.; Liu, L.; Wu, H.; Chen, T.; Ji, J. Principles of Operation and Application Extensions of Triboelectric Nanogenerators: Structure and Material Optimization. Micromachines 2025, 16, 1127. https://doi.org/10.3390/mi16101127

Tao L, Chen T, Wu J, Zhang T, Shao L, Zhang H, Liu L, Wu H, Chen T, Ji J. Principles of Operation and Application Extensions of Triboelectric Nanogenerators: Structure and Material Optimization. Micromachines. 2025; 16(10):1127. https://doi.org/10.3390/mi16101127

Chicago/Turabian StyleTao, Li, Tianyu Chen, Jiale Wu, Teng Zhang, Lei Shao, Haoliang Zhang, Litao Liu, Hongbo Wu, Tao Chen, and Jingdong Ji. 2025. "Principles of Operation and Application Extensions of Triboelectric Nanogenerators: Structure and Material Optimization" Micromachines 16, no. 10: 1127. https://doi.org/10.3390/mi16101127

APA StyleTao, L., Chen, T., Wu, J., Zhang, T., Shao, L., Zhang, H., Liu, L., Wu, H., Chen, T., & Ji, J. (2025). Principles of Operation and Application Extensions of Triboelectric Nanogenerators: Structure and Material Optimization. Micromachines, 16(10), 1127. https://doi.org/10.3390/mi16101127