Abstract

Acoustic hologram lenses enable the precise shaping of sound fields using plane wave inputs, with applications in biomedical imaging, targeted therapy, and acoustic manipulation. Recent advances in additive microfabrication technologies have greatly improved the design and fabrication of these lenses supporting materialization of complex phase profiles, miniaturization, and rapid prototyping. This review summarizes key progress in fabrication methods including stereolithography, material jetting, and fused deposition modeling that have expanded the versatility and performance of acoustic hologram lenses. We examine the fabrication techniques, operating frequencies, printing resolutions, and acoustic properties reported in the literature. This review provides an organized overview of the current state of acoustic hologram lens fabrication and highlights critical challenges and future opportunities for advancing research and practical applications.

1. Introduction

Acoustic holograms have emerged as a useful ultrasonic energy delivery tool for the precise manipulation of ultrasound fields, owing to the capability of reconstructing micro-resolution, multi-focal pressure distributions in an acoustic medium [1,2]. This pressure distribution shaping technique has stimulated intensive research activity in recent years and has enabled a wide spectrum of engineering applications [3], including transcranial ultrasound therapies [4], cavitation control [5,6], particle manipulation [7,8,9], tissue ablation [10], and bio-sample processing [11].

To realize acoustic holograms, most studies have relied on additive manufacturing (3D printing), which has become the dominant prototyping approach [3,12]. Among various techniques, stereolithography (SLA) has gained particular traction due to its ability to rapidly fabricate holographic lenses with high spatial resolution (<100 µm) while suppressing unintended porosity [13]. SLA is now regarded as a mature and efficient printing technology, offering both precision and cost-effectiveness. Using this method, many studies have demonstrated accurate pressure amplitude shaping within the excitation frequency range of 1–2 MHz [3,14]. Similar photopolymers have also been employed in material jetting, or PolyJet modeling, for acoustic hologram lens fabrication, extending the frequency range up to 3 MHz [15]. Both SLA and material jetting rely on photopolymer curing, enabling fine spatial resolution (<100 µm) in fabricated hologram lenses [16]. In contrast, fused deposition modeling (FDM) has been applied primarily in multifocal transcranial ultrasound treatments at 1–2 MHz [4]. Although simpler and more cost-efficient than SLA or material jetting, FDM typically offers lower resolution (hundreds of microns) than photopolymer prototypes [17].

Despite the dominance of additive manufacturing in acoustic hologram fabrication, clear technical limitations remain. The performance of fabricated lenses through SLA, material jetting, or FDM is fundamentally constrained by the acoustic properties of commercial resins and filaments. With densities of 1000–1300 kg/m3 and sound speeds of 1700–2300 m/s, their corresponding acoustic impedances fall within 1.7–3 MRayl. This limited impedance range contrasts with the broader material options available for conventional ultrasonic transducer assemblies [18,19], leading to significant impedance mismatch and reduced transmission efficiency, and these have been critical barriers to high-pressure output performance implementations. To overcome these challenges, recent studies have explored hybrid fabrication strategies that combine 3D printing with conventional composite molding methods, aiming to improve material versatility, acoustic efficiency, and device functionality [20]. These innovations continue to expand the design space and application potential of acoustic holograms [11,21].

Acoustic holograms have emerged as a significant branch of the broader research field of acoustic metamaterials and metasurfaces [22,23,24]. Despite rapid progress in the past decade, a systematic review that critically examines fabrication methods, advantages, limitations, and prototyping outcomes remains lacking. This review addresses that gap by providing a comprehensive survey of acoustic hologram microfabrication technologies, emphasizing their technical principles, trade-offs, and acoustic suitability for diverse application domains. By consolidating these insights, it aims to serve as a practical guideline for both hologram designers and engineers developing customized multifocal ultrasonic systems.

2. Background for Acoustic Holograms and Literature Survey

2.1. Design of Acoustic Holograms by Iterative Angular Spectrum Approach

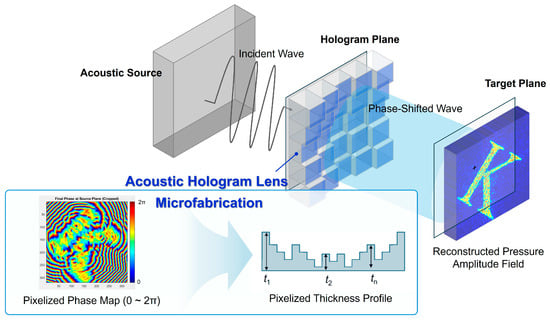

Acoustic holograms encode a specific phase distribution on a two-dimensional plane to generate a predefined multi-focal pressure amplitude distribution at a target plane, typically located within the Fresnel zone [1,25]. The design process generally involves simulating a two-dimensional planar wavefield, followed by layered propagation analysis, which aligns well with the angular spectrum method [26]. Among the various acoustic theories and algorithms for designing acoustic holograms, such as diffraction [27,28,29,30], the most widely used computational technique is the Iterative Angular Spectrum Approach (IASA), which performs repeated forward and backward propagations, often more than 50 iterations, to accurately reconstruct the target pressure field as demonstrated by our previous studies [20,21]. The acoustic pressure field is expressed as Equation (1) where is the harmonic pressure amplitude and is the harmonic phase function [31].

The phase function at the hologram plane (z = 0) is pixelized to yield the hologram map corresponding to the desired amplitude distribution at the target plane (z = zt). Once the target map accuracy is confirmed, the final phase map is converted into a lens thickness profile using the following relations, where k is the wavenumber, t is the lens thickness, and the subscripts m and h denote the propagation medium (typically water) and the hologram lens material, respectively [1].

An important factor in hologram design is the transmission coefficient, which governs acoustic energy transfer efficiency from the source to the target plane. After determining pixel thicknesses from the phase relation, the transmission coefficient at each pixel is calculated as Equation (4), where Z represents acoustic impedance, with subscripts t, h, and mmm referring to the source (e.g., piezoelectric transducer), the hologram lens, and the medium, respectively, Thus, the pressure amplitude at the hologram plane (z = 0) can be expressed as Equation (5) [21,31].

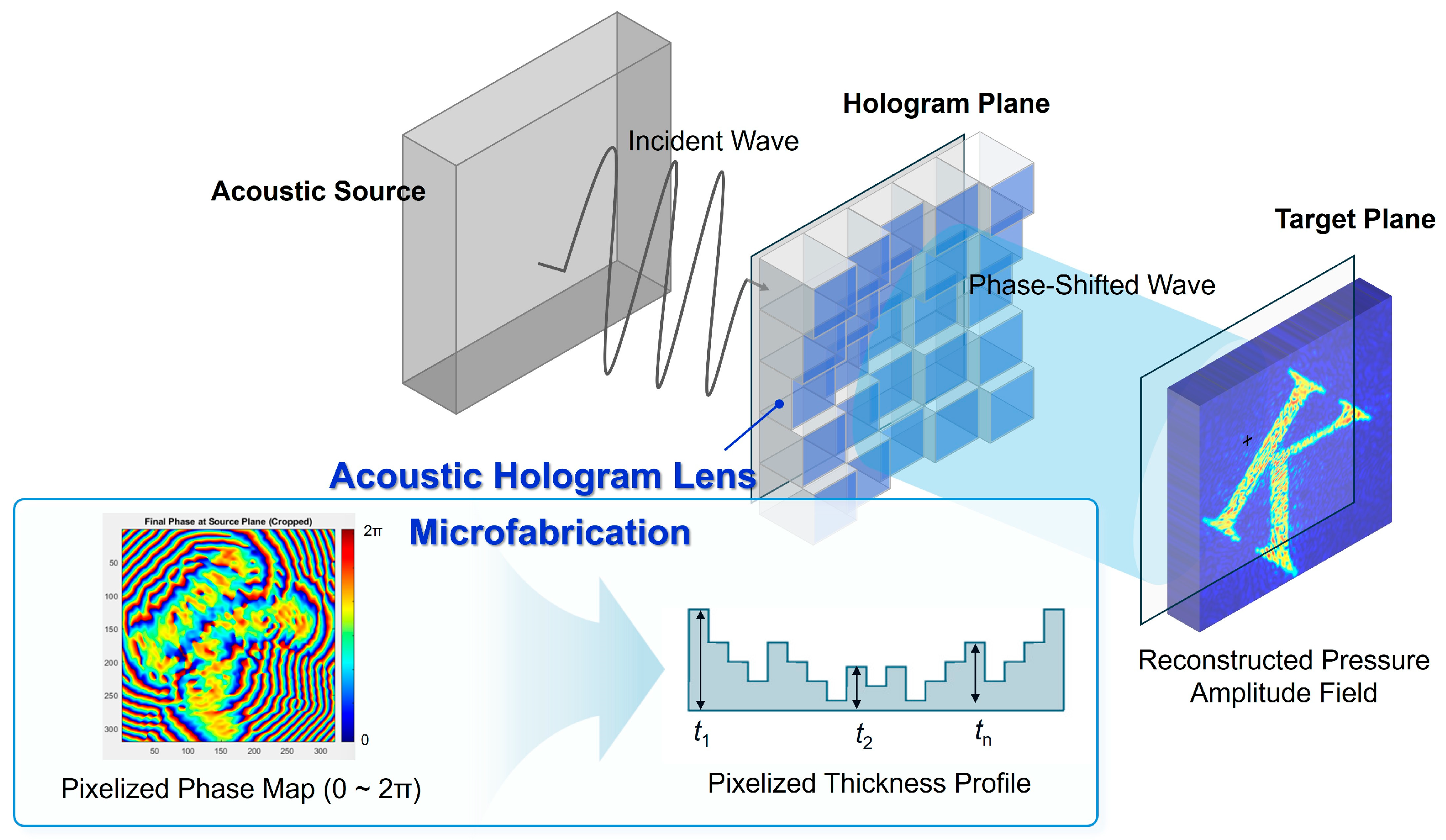

Recently, various machine learning (ML) techniques have been applied to design two-dimensional phase maps for acoustic hologram lenses. Compared to IASA or other theoretical or numerical simulation methods, ML-assisted design offers significantly (more than 100 times) faster computation and optimization [32,33,34,35,36,37]. Regardless of whether the design follows a theoretical simulation approach or an ML-assisted workflow, the resulting acoustic hologram lens is translated into a microscale thickness distribution, converted into a 3D model (STL file), and prepared as a layered structure (g-code) for additive manufacturing [5]. A schematic overview of the acoustic hologram lens is presented in Figure 1.

Figure 1.

Schematic of an acoustic hologram lens and microfabrication of lens structure.

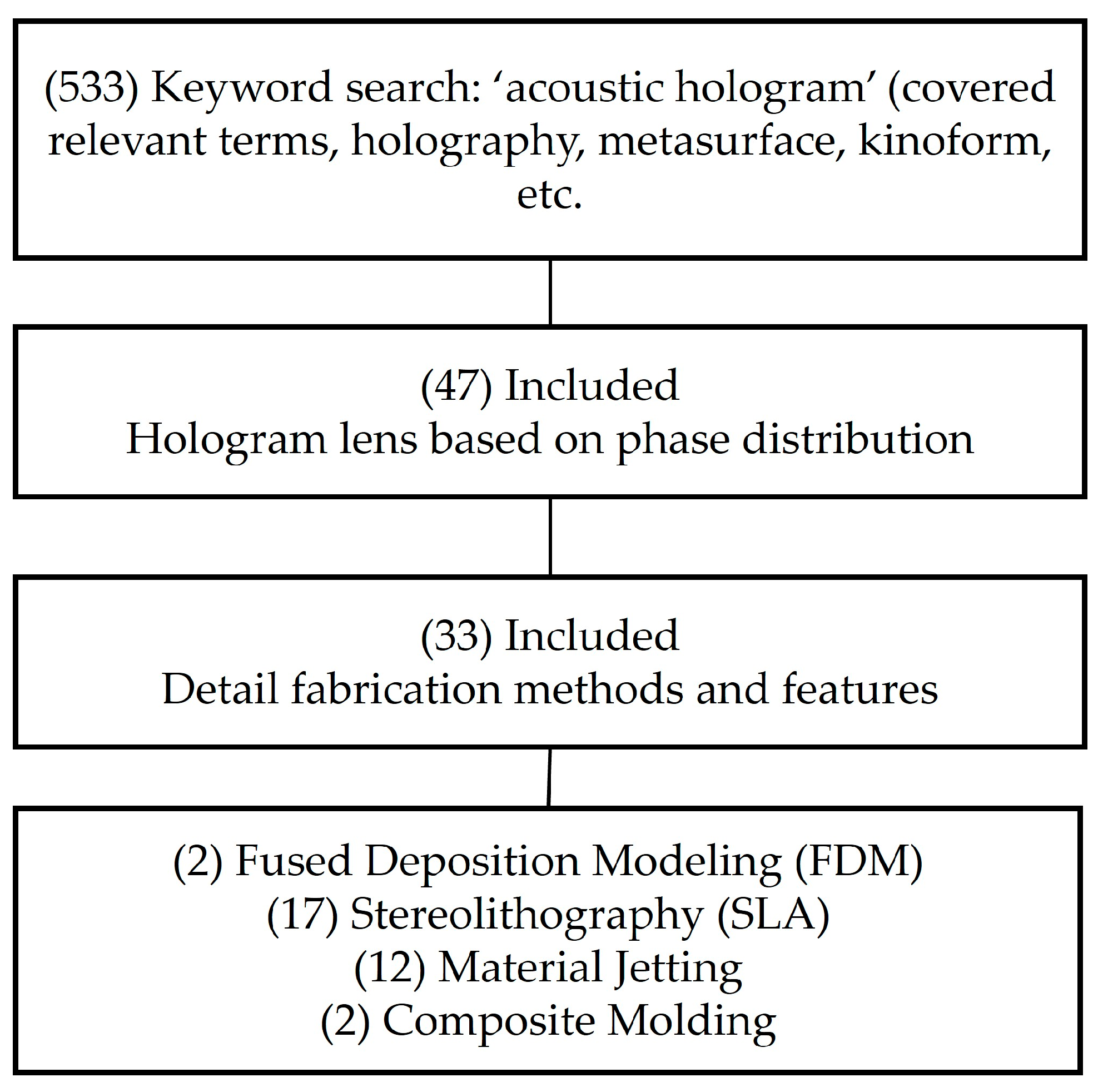

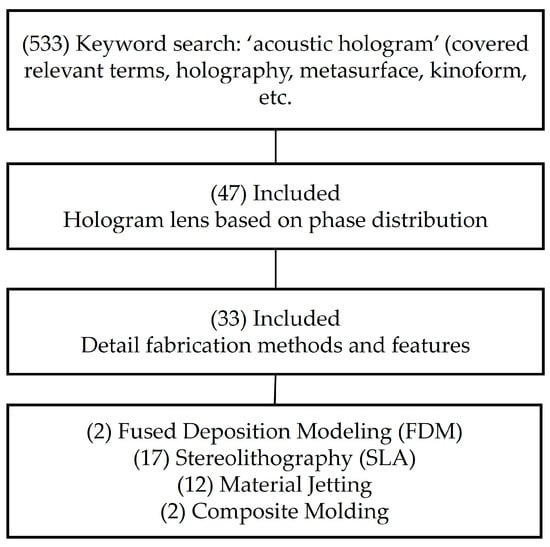

2.2. Lituerature Survey Approach

We initially searched ScienceDirect, Google Scholar, PubMed, and the public AI tool Perplexity using the keywords “acoustic hologram.” Google Scholar returned the largest number of results (533) including the searched results by other methods, which we then screened to identify papers that included an actual hologram lens as a thin phase-delay map, reducing the set to 47 papers. We excluded studies that did not employ hologram lens components, such as those relying solely on 2D matrix arrays with element-wise voltage/phase control [38], phased-array steering methods [10,39], or thick volumetric hologram structures that involves considerably higher complexity than the source-lens-medium layered propagation consideration [40]. Next, we examined the remaining papers for lens fabrication details, including additive manufacturing approaches, 3D printer models, resin types, and acoustic material properties (e.g., density, sound speed, and attenuation), which filtered out articles that focus on applications and techniques rather than lens microfabrication details [41,42,43]. This filtering yielded 31 papers with sufficient microfabrication details. We then tabulated the key parameters (e.g., operation frequency, printer model, resin properties) and distinctive features of each prototyped lens for its intended application. The survey workflow is summarized in Figure 2.

Figure 2.

Literature survey flow chart.

Overall, the results revealed a dominant trend toward SLA 3D printing and material jetting, both mature and widely adopted techniques capable of high-resolution fabrication (<50 µm). By contrast, only a few studies reported FDM-based methods or composite molding for hologram lens fabrication.

3. Acoustic Hologram Microfabrication Methods

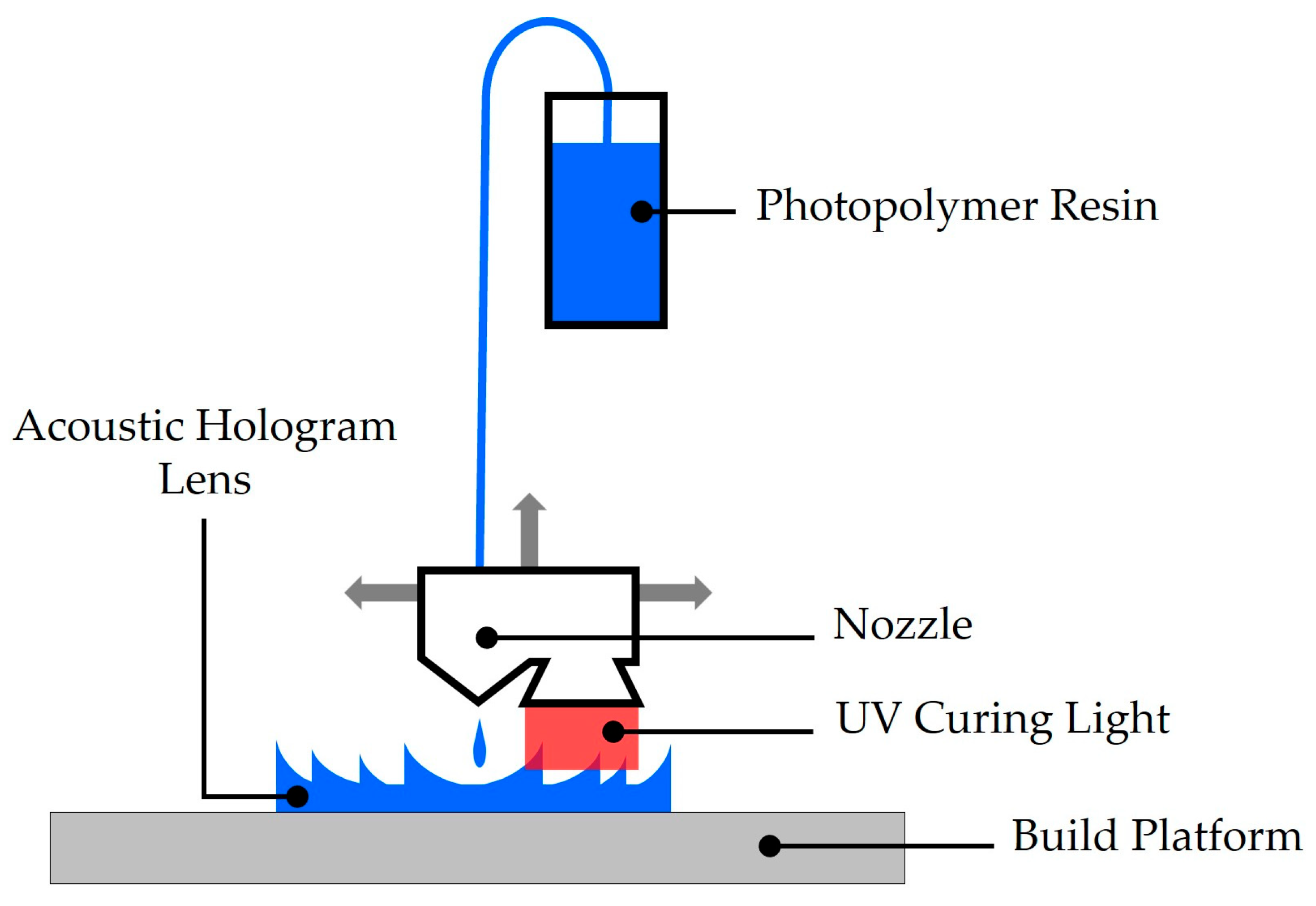

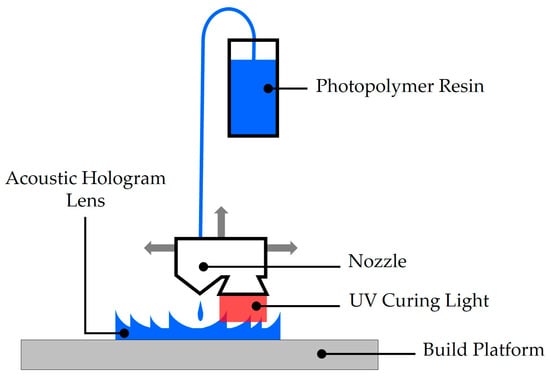

3.1. Material Jetting 3D Printing

Since the first demonstration of acoustic holograms with the terminology “holograms” in 2016, material jetting 3D printing has been widely adopted for fabricating acoustic hologram lenses. Material jetting, often referred to as PolyJet modeling, is an additive manufacturing technique in which liquid photopolymers are jetted as tiny droplets, layer by layer, using a print head similar to that of an inkjet printer [44]. Each deposited layer is immediately cured by ultraviolet (UV) light, allowing precise control over feature resolution. In this process, the photopolymer is stored in an airtight reservoir, heated, and then delivered through a transmission line to the nozzle, where it is deposited as an ultra-thin film on the build platform (Figure 3). The photo-curing step relies on a UV light source of specific wavelength to polymerize monomers and oligomers in the liquid state, solidifying them into the desired structure. This combination of high-precision droplet deposition and rapid photopolymerization enables the fabrication of complex hologram lenses with microscale accuracy [44,45]. The surveyed results on acoustic hologram lens fabrication by material jetting are summarized in Table 1. All the abbreviations are defined the ‘Abbreviations’ at the end of the manuscript.

Figure 3.

Schematic of acoustic hologram lens fabrication by Material Jetting 3D printing.

Table 1.

Survey summary for acoustic hologram lens fabrication results by using material jetting. ρ, v, and α denote the density, wave speed, and attenuation, respectively. * The used abbreviation list is tabulated in ‘Abbreviation’. N/A denotes ‘not applicable.’

The key advantages of material jetting, such as multi-material capability, high resolution, and smooth surface finishes, have directly contributed to the high fabrication quality and performance of acoustic hologram lenses [53]. The used frequency range spans from 1.1 MHz to ~4 MHz, and the reported acoustic impedance of the used photopolymer resin ranges from 2.36 MRayl to 2.98 MRayl. With an averaged operating frequency of ~2.4 MHz and the averaged resin wave speed of ~2445 m/s, the reported lateral resolution limit of ~42 µm corresponds to ~0.04λ, which is sufficiently precise for materializing the designed phase profiles. This precision has enabled diffraction-limited focusing and multiplexing of acoustic fields in multiple studies [40].

In addition, the solid, non-porous, and homogeneous structure of lenses fabricated via material jetting has been consistently advantageous. Its multi-material printing capability has also been leveraged for binary and volumetric holograms, where combining waveguide materials with tailored acoustic impedances allows highly accurate wavefront manipulation [40,51].

One common limitation of thin plates produced by material jetting is their susceptibility to out-of-plane bending, warping, or curling, which can arise from thermal gradients during curing. These deformations may be further influenced by build orientation, small thickness, and rapid energy input [54]. Interestingly, in summarized studies (see Table 1), no thermal bending issues were reported for thin acoustic hologram lenses fabricated using this technique, indicating that such challenges may be mitigated under carefully optimized printing conditions.

Certain photopolymers exhibit high acoustic attenuation and suboptimal impedance (determined by density and sound speed), which reduces transmission efficiency through the lens [40,54]. The restricted range of available printable materials poses another challenge, since polymers with higher acoustic impedance would provide better matching between ceramic transducer surfaces and water. In addition, material jetting is generally more expensive than SLA or FDM, and its printed parts are relatively fragile, making them less suitable for pre-stressed applications [1,40,55].

As summarized in Table 1, even the same resin printed on the same machine has been reported to yield slightly different density and wave speed values. Attenuation can vary even more strongly, depending on testing excitation frequency and measurement technique. Such variability introduces uncertainty in acoustic hologram lens design, as accurate material properties are essential for determining the phase-delay map. Consequently, imperfections and performance inconsistencies may arise due to fabrication variability and material property uncertainty [55].

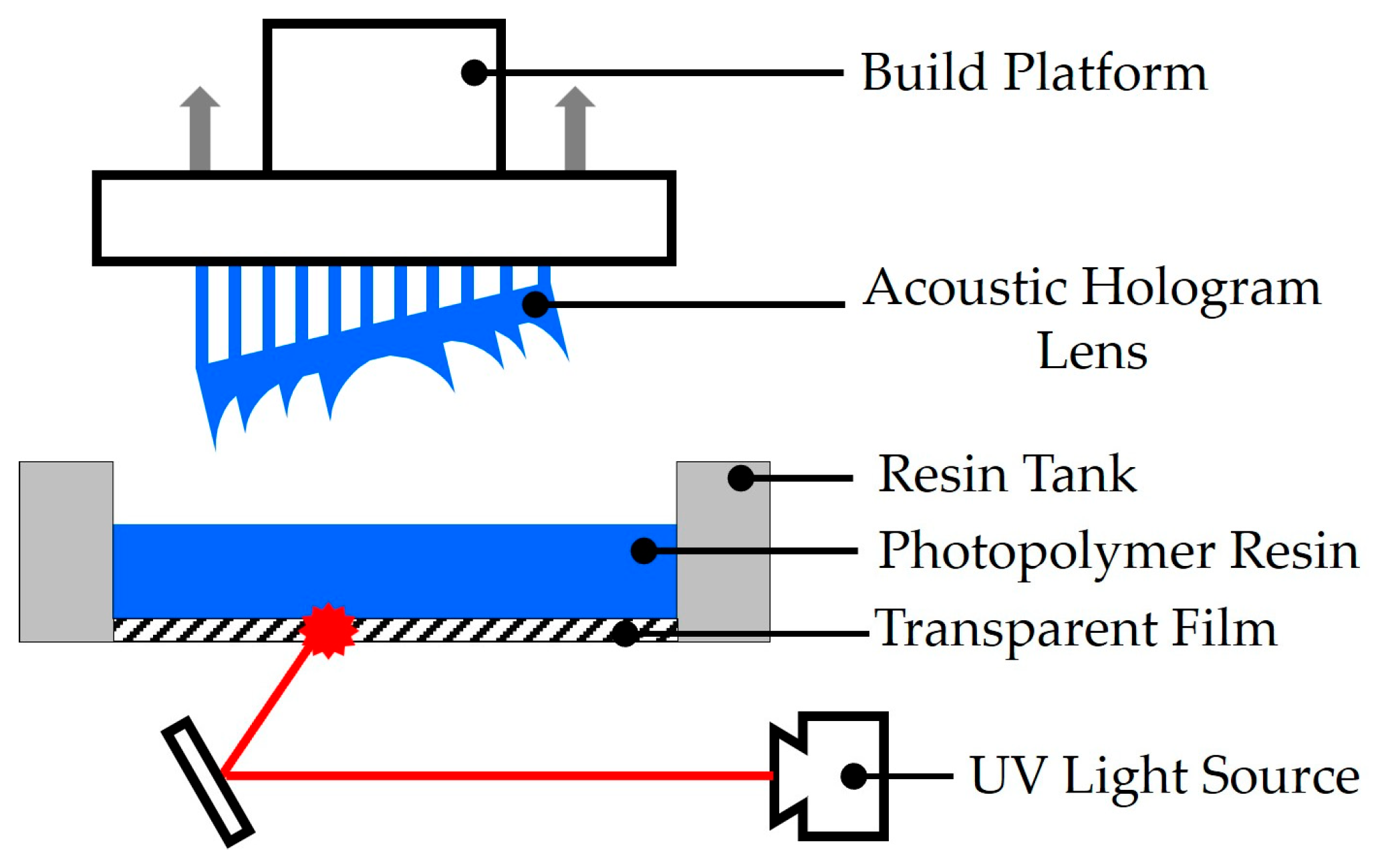

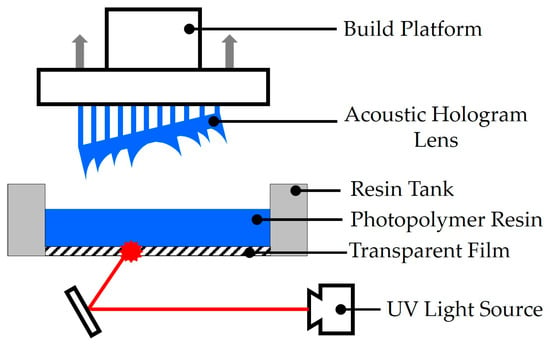

3.2. Stereolithography

SLA printing can be classified into top-down and bottom-up approaches, with most modern systems adopting the bottom-up method. All the surveyed acoustic hologram lenses were fabricated using this approach, so our discussion focuses on its mechanism. In bottom-up SLA, a transparent resin tank is filled with liquid photopolymer, and a UV laser selectively cures the resin layer by layer [56]. Printing resolution can be improved by tilting the model during slicing, which reduces the cross-sectional area of each layer (Figure 4). Since the UV laser beam diameter in SLA is typically on the micrometer scale [57,58], this method achieves high spatial resolution and enables the precise fabrication of acoustic hologram lenses.

Figure 4.

Schematic of acoustic hologram lens fabrication by stereolithography 3D printing.

SLA 3D printing offers key advantages including high resolution, smooth surface finishes, and solid, non-porous, homogeneous structures comparable to those of material jetting [59]. Reported applications span frequencies from 0.5 to ~4.5 MHz, with photopolymer resins exhibiting acoustic impedances between 2.67 and 3.12 MRayl. At an average operating frequency of ~1.4 MHz and an average resin sound speed of ~2503 m/s, the lateral resolution limit of ~50 µm corresponds to ~0.028 λ, providing sufficient precision to accurately reproduce the designed phase profiles.

The main limitations of SLA-fabricated acoustic hologram lenses are the restricted range of printable materials and shrinkage-induced deformation during curing. Achieving efficient ultrasound transmission requires proper acoustic impedance matching between the lens, the ceramic transducer surface, and the coupling medium (e.g., water) [60]. However, SLA resins generally exhibit limited acoustic impedance, and adjusting this property is highly challenging. Material jetting partially overcomes this issue by allowing multi-resin combinations with tailored impedances. Another drawback of SLA is shrinkage deformation, where the thin plate structure of acoustic hologram lenses tends to warp at the edges during photocuring [21,61]. While SLA is typically less expensive than material jetting, it remains costlier than FDM.

As summarized in Table 2, SLA has been widely adopted for acoustic hologram lens fabrication due to its accessibility, relatively high resolution, and overall quality. However, similar to material jetting, studies using even identical resins printed on the same machine reported variations in acoustic properties of acoustic hologram lenses. Such variability undermines consistency and reliability, both of which are crucial for accurate hologram lens fabrication [13,61].

Table 2.

Survey summary for acoustic hologram lens fabrication results by using stereolithography. ρ, v, and α denote the density, wave speed, and attenuation, respectively. * The used abbreviation list is tabulated in ‘Abbreviation’. N/A denotes ‘not applicable.’

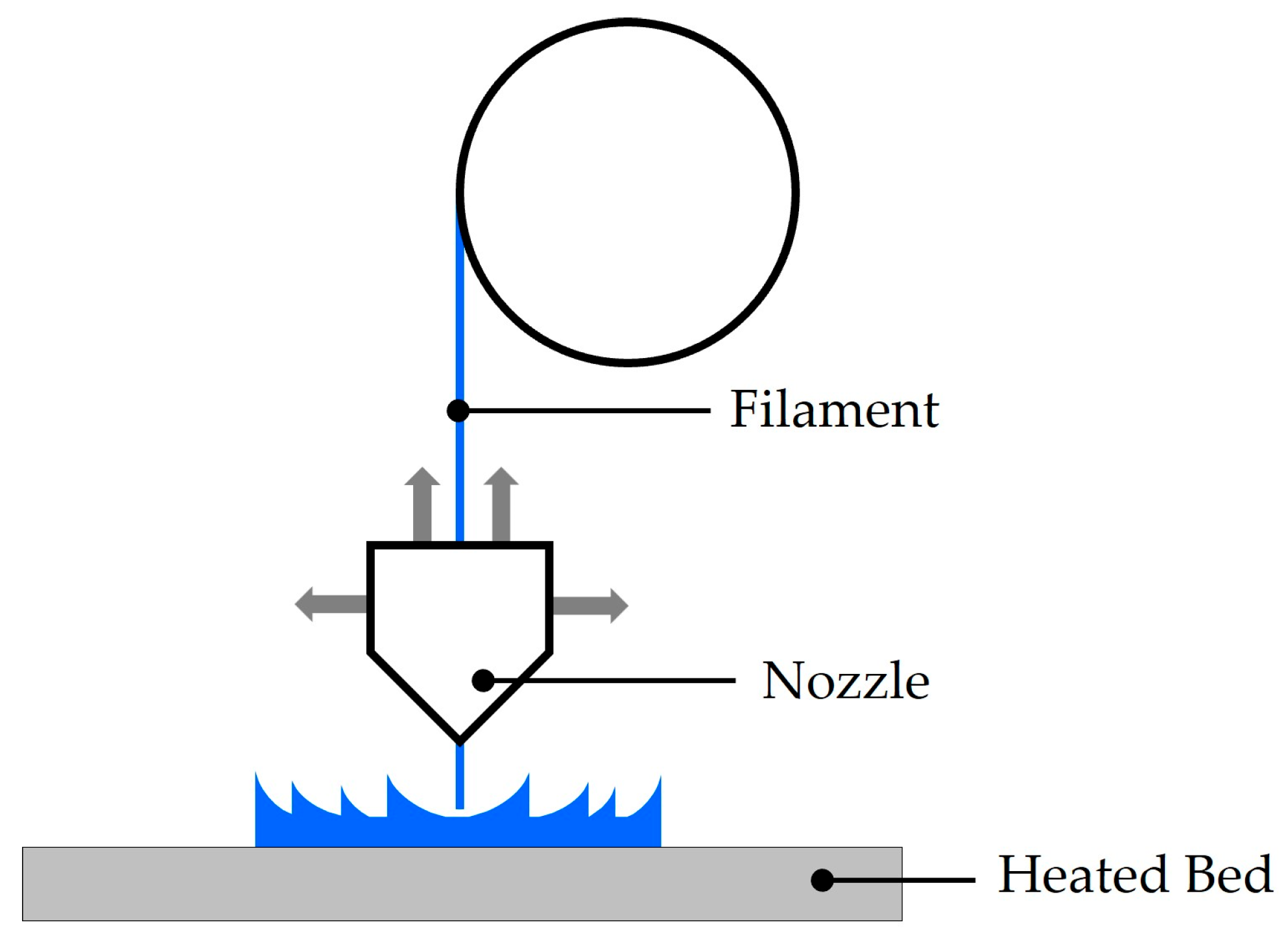

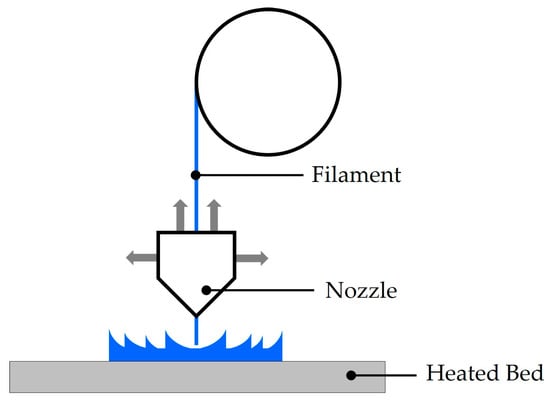

3.3. Fused Deposition Modeling

Fused deposition modeling (FDM) 3D printing builds structures by extruding melted thermoplastic filament through a heated nozzle, which moves in the X–Y plane while the build platform shifts in the Z direction to form successive layers (Figure 5) [75,76]. The process allows adjustment of infill density and the use of various internal infill patterns, such as gyroid, grid, or cubic to tailor structural properties. A key advantage of FDM is its relatively low cost compared to SLA and material jetting.

Figure 5.

Schematic of acoustic hologram lens fabrication by fused deposition modeling 3D printing.

Despite the distinctive benefits, FDM faces major limitations, including thermal deformation, high porosity, non-homogeneous structures, relatively low resolution, and high sensitivity to process parameters [76,77]. Thermal deformation arises because extruded filaments exit the nozzle at a much higher temperature than the heated bed, cooling rapidly and generating residual stresses that distort the printed part [78]. Furthermore, typical FDM structures are not fully dense but porosities exceeding 50% are common, which excessively reduces acoustic impedance, increases attenuation, and can even allow water leakage when used in underwater experiments. Resolution is also constrained by nozzle diameter, making it lower than SLA or material jetting. Finally, numerous parameters, such as nozzle temperature and bed temperature, must be precisely controlled, adding further complexity.

As summarized in Table 3, only a few studies have employed FDM for acoustic hologram lens fabrication, and the method remains less suitable compared to SLA or material jetting due to its inherent limitations in printing resolution and acoustic properties of thermoplastics [79]. Reported resolutions are the lowest among the three techniques, while the average acoustic impedance of ~2.5 MRayl is slightly lower than that of photopolymers. Combined with the lower wave speed and larger printing resolution, this results in significantly reduced phase profile accuracy relative to the acoustic wavelength. Furthermore, the reported attenuation of 13.72 dB/cm is substantially higher than values observed in SLA and material jetting lenses, further limiting FDM’s effectiveness for acoustic hologram lens fabrication.

Table 3.

Survey summary for acoustic hologram lens fabrication results by using fused deposition modeling. ρ, v, and α denote the density, wave speed, and attenuation, respectively. * The used abbreviation list is tabulated in ‘Abbreviation’. N/A denotes ‘not applicable.’

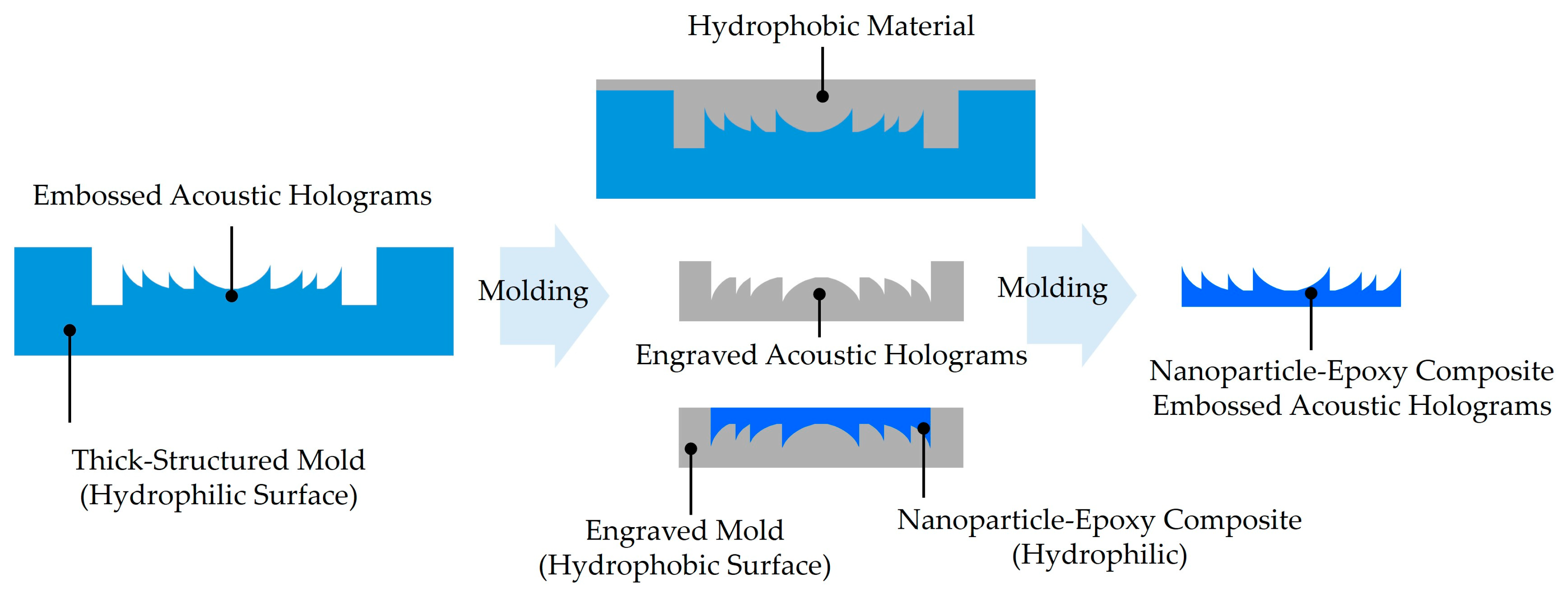

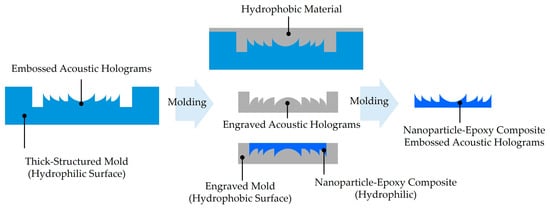

3.4. Nanoparticle–Epoxy Composite Molding

The 3D printing technology offers cost efficiency and the ability to fabricate complex geometries, which are major advantages over conventional metal machining. However, their utility is limited by the acoustic properties of photopolymers, which are (1) typically not sufficient for optimal wave transmission between hard ceramic transducers and water or air, and by (2) the vulnerability of thin-plate structures, such as acoustic hologram lenses, to thermal deformation during printing. To address these challenges, we previously introduced the nanoparticle–epoxy (NPEC) molding method for acoustic hologram lens fabrication [20,21].

NPEC molding approach is designed to utilize the advantages of both cost-efficient, versatile, high-resolution fabrication by SLA printing and acoustic property controllable nanoparticle-epoxy composites. The schematic of NPEC lens fabrication method is depicted in Figure 6.

Figure 6.

Schematic of acoustic hologram lens fabrication by epoxy composite molding.

Briefly, an acoustic hologram surface is designed on the bottom of the bath with a thick back-support, and the bath is 3D printed by SLA printing. After that, the silicone rubber is poured and molded for making a hydrophobic engraved surface for an acoustic hologram mold. Finally, the low-viscosity epoxy and nanoparticle mixture is used through a degassing process to fabricate the NPEC acoustic hologram lens. Despite the one additional molding process included, this subsequent molding approach demonstrated improved lens materialization accuracy with more suitable impedance matched acoustic transmission compared to conventional photopolymer clear resin [11,21]. For the literature survey focusing on this technique, we surveyed using expanded keyword options including ‘epoxy composite, molding, nanoparticle composite’ with acoustic holograms, but the main search results included only our previous studies as summarized in Table 4.

Table 4.

Survey summary for acoustic hologram lens fabrication results by using nanoparticle–epoxy composite molding. ρ, v, and α denote the density, wave speed, and attenuation, respectively. * The used abbreviation list is tabulated in ‘Abbreviation’.

By varying the alumina nanoparticle volume fraction (6.8–22.5%), the acoustic impedance of NPEC lenses was characterized in the range of 2.99–4.64 MRayl, representing a substantial increase over conventional photopolymers while also demonstrating tunability [20,21]. Achieving an impedance of up to 4.64 MRayl without compromising phase-profile accuracy or fabrication speed highlights the overall merit of the NPEC approach for acoustic hologram lens fabrication. The resulting lenses maintained their designed geometry without deformation and exhibited a 1.55-fold higher acoustic impedance compared to standard photopolymers. Experimental demonstrations also showed over 20% enhancement in output acoustic pressure relative to photopolymer-based lenses.

The use of low-viscosity epoxy nanocomposites for acoustic impedance tuning is a well-established method in matching layer and lens fabrication [18,80]. Both heavy-metal and lightweight glass nanoparticles have been explored to achieve a wide impedance range [81]. Extending beyond current results, this strategy enables broader applicability for acoustic hologram lenses, such as in airborne particle trapping or acoustic assembly, which are not feasible with conventional photopolymer lenses [82]. Furthermore, direct nanocomposite printing via SLA offers a promising route to bypass additional molding steps [83]. Incorporating nanoparticles into photocurable resins can enable impedance values exceeding 4 MRayl and introduce additional functionalities, including gradient–impedance structures. However, suspended nanoparticles alter light scattering and absorption during curing, which affects resolution and curing accuracy. Therefore, further optimization of nanocomposite SLA processes is critical to fully realize their potential [83].

4. Summary and Discussion

Our survey results clearly indicate that the advancement of acoustic hologram lenses has closely paralleled progress in 3D-printing technologies, particularly in material jetting and SLA [3,17]. By contrast, only a few studies have employed FDM, and while this method shows limited advantages, unexplored opportunities may exist for hybrid lens structures or porosity-assisted lightweight designs. Based on the literature survey, the representative advantages and limitations of additive manufacturing for acoustic hologram lenses can be summarized as follows:

- (1)

- Rapid, one-step fabrication: although post-processing steps such as cleaning and surface polishing are required, current photopolymer-based 3D printing techniques provide sufficiently high resolution (<50 µm) for the typical operating frequency range of 0.5–5 MHz. This resolution is competitive with conventional machining while offering greater accessibility, enabling engineers to fabricate lenses without specialized machining skills [31].

- (2)

- Reliable translation from design to performance: nearly all surveyed studies demonstrated successful realization of predefined multi-focal pressure fields. The accuracy of reconstruction strongly depends on operating frequency and axial alignment, yet both IASA- and ML-assisted design processes combined with 3D printing have proven reliable for custom transducer development, supporting their potential in future applications.

- (3)

- Limited material availability: despite ongoing advances in printable polymers, acoustically optimal material properties remain difficult to achieve with standard 3D printing resins. Workarounds such as NPEC molding illustrate that enhanced material control often comes at the expense of fabrication simplicity and speed [21].

- (4)

- Insufficient thermal stability data: Few studies report detailed thermal reliability of fabricated lenses. Photopolymers typically used in SLA exhibit glass transition temperatures (Tg) in the range of 50–120 °C [84]. Under long-duty, high-voltage operation, lens heating may approach Tg, raising concerns about performance stability in high-power applications. Systematic reliability testing is therefore needed.

Considering these current advantages and limitations, several research opportunities can be identified:

- (1)

- High-power applications: for surgical ultrasound, materials processing, or acoustic manipulation [85,86], high-impedance lens materials (e.g., heavy-particle/epoxy composites, aluminum, stainless steel) may provide improved energy transmission. NPEC molding is one viable approach, while composite SLA or metal 3D printing hold promise for fabricating high-impedance hologram lenses [83,87]. Further analysis of averaged transmission coefficient values across all pixels on the hologram plane for different lens materials could provide useful insights for high-power lens design.

- (2)

- Multi-layered acoustic holograms: inspired by stackable hologram [51], lenses with gradient acoustic impedance across layers could enhance precision and pressure output. Integration with advanced 3D printing techniques may enable further optimization of acoustic transmission.

- (3)

- Dynamic morphing holograms: Additive microfabrication with tissue-like or stimulus-responsive materials could enable lenses capable of reconfigurable focusing. Acoustic properties sensitive to pressure, temperature, magnetic fields, or electric fields could be exploited to create dynamic, adaptive acoustic holograms building upon recent findings on wave speed variation by temperature change [30,88]. This functionality would unlock greater controllability of pressure field distributions at the target volume, expanding the scope of high-precision non-contact excitation applications.

5. Conclusions

This review summarized recent advances in microfabrication methods for acoustic hologram lenses, highlighting the strengths and limitations of SLA, material jetting, FDM, and composite molding. SLA and material jetting provide high-resolution, homogeneous structures but remain costly, while FDM is cost-efficient yet limited by porosity and low resolution. Composite molding enables tailored impedance and stable fabrication, though with added complexity. Future directions such as dynamic focusing, metal-based printing, and diverse material integration promise to overcome current trade-offs and further expand applications in biomedical ultrasound, acoustic manipulation, and next-generation multifunctional acoustic devices.

Author Contributions

Conceptualization, J.K.; methodology, J.K., H.K., S.C. and D.K.; investigation, J.K., H.K., S.C. and D.K.; writing—original draft preparation, J.K. and H.K.; writing—review and editing, J.K., H.K., S.C. and D.K.; visualization, J.K. and H.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Research Foundation of Korea (NRF) through Korean Government [Ministry of Science and ICT (MSIT)] under Grant RS-2025-16072488.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank Sandeep Kasoji of Triangle Biotechnology, Inc. for his support and valuable insights on acoustic hologram lens design technologies and potential applications.

Conflicts of Interest

J.K. is a co-inventor on patents related to the development and application of acoustic hologram lenses for biomedical treatments and has a financial interest in their commercialization.

Abbreviations

The following abbreviations are used in this manuscript:

| SNR | Signal to noise ratio |

| PSNR | Peak signal to noise ratio |

| FWHM | Full width half maximum |

| MSE | Mean square error |

| RMSE | Root mean square error |

| SSIM | Structural similarity index |

| CSIM | Color similarity index |

| PNP | Peak negative pressure |

| MI | Mechanical index |

References

- Melde, K.; Mark, A.G.; Qiu, T.; Fischer, P. Holograms for Acoustics. Nature 2016, 537, 518–522. [Google Scholar] [CrossRef]

- Brown, M.D.; Cox, B.T.; Treeby, B.E. Design of Multi-Frequency Acoustic Kinoforms. Appl. Phys. Lett. 2017, 111, 244101. [Google Scholar] [CrossRef]

- Burstow, R.; Andrés, D.; Jiménez, N.; Camarena, F.; Thanou, M.; Pouliopoulos, A.N. Acoustic Holography in Biomedical Applications. Phys. Med. Biol. 2025, 70, 06TR01. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Gambín, S.; Jiménez, N.; Benlloch, J.M.; Camarena, F. Holograms to Focus Arbitrary Ultrasonic Fields through the Skull. Phys. Rev. Appl. 2019, 12, 014016. [Google Scholar] [CrossRef]

- Kim, J.; Kasoji, S.; Durham, P.G.; Dayton, P.A. Acoustic Holograms for Directing Arbitrary Cavitation Patterns. Appl. Phys. Lett. 2021, 118, 051902. [Google Scholar] [CrossRef]

- Ma, Z.; Melde, K.; Athanassiadis, A.G.; Schau, M.; Richter, H.; Qiu, T.; Fischer, P. Spatial Ultrasound Modulation by Digitally Controlling Microbubble Arrays. Nat. Commun. 2020, 11, 4537. [Google Scholar] [CrossRef] [PubMed]

- Melde, K.; Kremer, H.; Shi, M.; Seneca, S.; Frey, C.; Platzman, I.; Degel, C.; Schmitt, D.; Schölkopf, B.; Fischer, P. Compact Holographic Sound Fields Enable Rapid One-Step Assembly of Matter in 3D. Sci. Adv. 2023, 9, eadf6182. [Google Scholar] [CrossRef]

- Ma, Z.; Holle, A.W.; Melde, K.; Qiu, T.; Poeppel, K.; Kadiri, V.M.; Fischer, P. Acoustic Holographic Cell Patterning in a Biocompatible Hydrogel. Adv. Mater. 2020, 32, 1904181. [Google Scholar] [CrossRef]

- Ghanem, M.A.; Maxwell, A.D.; Dalecki, D.; Sapozhnikov, O.A.; Bailey, M.R. Phase Holograms for the Three-Dimensional Patterning of Unconstrained Microparticles. Sci. Rep. 2023, 13, 9160. [Google Scholar] [CrossRef]

- Glickstein, B.; Shaul, O.; Ilovitsh, T. Rationally Designed Acoustic Holograms for Uniform Nanodroplet-Mediated Tissue Ablation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2024, 71, 1606–1615. [Google Scholar] [CrossRef]

- Kim, J.; Kasoji, S.; Dayton, P.A. Acoustic Metastructure-Lensed Multi-Focal Sonicator Designs for High-Throughput Therapeutic Ultrasound Testing In Vitro. In Proceedings of the 2024 IEEE Ultrasonics, Ferroelectrics, and Frequency Control Joint Symposium (UFFC-JS), Taipei, Taiwan, 22–26 September 2024; pp. 1–4. [Google Scholar]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-Curing 3D Printing Technique and Its Challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Bakhtiari-Nejad, M.; Elnahhas, A.; Hajj, M.R.; Shahab, S. Acoustic Holograms in Contactless Ultrasonic Power Transfer Systems: Modeling and Experiment. J. Appl. Phys. 2018, 124, 244901. [Google Scholar] [CrossRef]

- Cengiz, C.; Shahab, S. Holographic Thermal Mapping in Volumes Using Acoustic Lenses. J. Phys. D Appl. Phys. 2024, 57, 365501. [Google Scholar] [CrossRef]

- Brown, M.D.; Nikitichev, D.I.; Treeby, B.E.; Cox, B.T. Generating Arbitrary Ultrasound Fields with Tailored Optoacoustic Surface Profiles. Appl. Phys. Lett. 2017, 110, 094102. [Google Scholar] [CrossRef]

- Sanders, J.; Wei, X.; Pei, Z. Experimental Investigation of PolyJet 3D Printing: Effects of Sample Location and Volume on Power Consumption. Manuf. Lett. 2022, 31, 83–86. [Google Scholar] [CrossRef]

- Shakibania, S.; Khakbiz, M.; Bektas, C.K.; Ghazanfari, L.; Banizi, M.T.; Lee, K.-B. A Review of 3D Printing Technology for Rapid Medical Diagnostic Tools. Mol. Syst. Des. Eng. 2022, 7, 315–324. [Google Scholar] [CrossRef]

- Zhou, Q.; Cha, J.H.; Huang, Y.; Zhang, R.; Cao, W.; Shung, K.K. Alumina/Epoxy Nanocomposite Matching Layers for High-Frequency Ultrasound Transducer Application. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 213–219. [Google Scholar] [CrossRef]

- Zhou, Q.; Lam, K.H.; Zheng, H.; Qiu, W.; Shung, K.K. Piezoelectric Single Crystal Ultrasonic Transducers for Biomedical Applications. Prog. Mater. Sci. 2014, 66, 87–111. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kasoji, S.; Durham, P.G.; Dayton, P.A. Acoustic Hologram Lens Made of Nanoparticle-Epoxy Composite Molding for Directing Predefined Therapeutic Ultrasound Beams. In Proceedings of the 2022 IEEE International Ultrasonics Symposium (IUS), Venice, Italy, 10–13 October 2022; pp. 1–4. [Google Scholar]

- Kim, J.; Kasoji, S.; Durham, P.G.; Dayton, P.A. Nanoparticle-Epoxy Composite Molding for Undeformed Acoustic Holograms with Tailored Acoustic Properties. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2023, 70, 1554–1562. [Google Scholar] [CrossRef]

- Hsu, J.-C.; Alwi, H.; Wei, C.-H.; Liao, K.-L.; Huang, C.-T. Reflections of High-Frequency Pulsed Ultrasound by Underwater Acoustic Metasurfaces Composed of Subwavelength Phase-Gradient Slits. Crystals 2023, 13, 846. [Google Scholar] [CrossRef]

- Zeng, L.-S.; Shen, Y.-X.; Fang, X.-S.; Li, Y.; Zhu, X.-F. Experimental Realization of Ultrasonic Retroreflection Tweezing via Metagratings. Ultrasonics 2021, 117, 106548. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.-T.; Fu, W.-X.; Wang, Y.-F.; Wang, Y.-S. High-Efficiency Ultrathin Nonlocal Waterborne Acoustic Metasurface. Phys. Rev. Appl. 2021, 15, 44046. [Google Scholar] [CrossRef]

- Rossing, T.D. (Ed.) Handbook of Acoustics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Liu, D.-L.; Waag, R.C. Propagation and Backpropagation for Ultrasonic Wavefront Design. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 1–13. [Google Scholar] [CrossRef]

- Fushimi, T.; Yamamoto, K.; Ochiai, Y. Acoustic Hologram Optimisation Using Automatic Differentiation. Sci. Rep. 2021, 11, 12678. [Google Scholar] [CrossRef] [PubMed]

- Raymond, S.J.; Collins, D.J.; O’Rorke, R.; Tayebi, M.; Ai, Y.; Williams, J. A Deep Learning Approach for Designed Diffraction-Based Acoustic Patterning in Microchannels. Sci. Rep. 2020, 10, 8745. [Google Scholar] [CrossRef]

- Liu, B.; Zhou, Z.; Wang, Y.; Zentgraf, T.; Li, Y.; Huang, L. Experimental Verification of the Acoustic Geometric Phase. Appl. Phys. Lett. 2022, 120, 211702. [Google Scholar] [CrossRef]

- Xu, M.; Wang, J.; Harley, W.S.; Lee, P.V.S.; Collins, D.J. Programmable Acoustic Holography Using Medium-Sound-Speed Modulation. Adv. Sci. 2023, 10, 2301489. [Google Scholar] [CrossRef]

- Kim, J.; Menichella, B.; Lee, H.; Dayton, P.A.; Pinton, G.F. A Rapid Prototyping Method for Sub-MHz Single-Element Piezoelectric Transducers by Using 3D-Printed Components. Sensors 2023, 23, 313. [Google Scholar] [CrossRef]

- Wang, S.; You, F.; Wang, X.; Xiao, H. A Knowledge-Driven Method for Real-Time Acoustic Holographic Field Reconstruction Using Physical Modeling and Semi-Supervised Neural Networks. Knowl.-Based Syst. 2025, 311, 113044. [Google Scholar] [CrossRef]

- Li, B.; Lu, M.; Liu, C.; Liu, X.; Ta, D. Acoustic Hologram Reconstruction with Unsupervised Neural Network. Front. Mater. 2022, 9, 916527. [Google Scholar] [CrossRef]

- Lee, M.H.; Lew, H.M.; Youn, S.; Kim, T.; Hwang, J.Y. Deep Learning-Based Framework for Fast and Accurate Acoustic Hologram Generation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2022, 69, 3353–3366. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, J.; Cai, F.; Zhang, R.; Zhao, D.; Xia, X.; Wang, J.; Zheng, H. A Deep Learning Approach for the Fast Generation of Acoustic Holograms. J. Acoust. Soc. Am. 2021, 149, 2312–2322. [Google Scholar] [CrossRef]

- Lin, Q.; Zhang, R.; Cai, F.; Chen, Y.; Ye, J.; Wang, J.; Zheng, H.; Zhang, H. Multi-Frequency Acoustic Hologram Generation with a Physics-Enhanced Deep Neural Network. Ultrasonics 2023, 132, 106970. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J. Multiphysics Simulation of Acoustic Hologram-Lensed Piezoelectric Ultrasound Transducers. In Proceedings of the 2024 IEEE Ultrasonics, Ferroelectrics, and Frequency Control Joint Symposium (UFFC-JS), Taipei, Taiwan, 22–26 September 2024; pp. 1–4. [Google Scholar]

- Li, Z.; Yang, Y.; Lu, Q.; Wei, X.; Hou, C.; Quan, Y.; Lü, X.; Bao, W.; Yang, Y.; Fei, C. Dynamic Acoustic Holography: One-Shot High-Precision and High-Information Methodology. Micromachines 2024, 15, 1316. [Google Scholar] [CrossRef] [PubMed]

- Schein, D.; Grutman, T.; Ilovitsh, T. Deep Learning-Based Ultrasound Beam Shaping for Spatiotemporal Acoustic Holograms Generation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2023, 70, 551–561. [Google Scholar] [CrossRef] [PubMed]

- Brown, M.D.; Cox, B.T.; Treeby, B.E. Binary Volume Acoustic Holograms. Phys. Rev. Appl. 2023, 19, 44032. [Google Scholar] [CrossRef]

- Melde, K.; Choi, E.; Wu, Z.; Palagi, S.; Qiu, T.; Fischer, P. Acoustic Fabrication via the Assembly and Fusion of Particles. Adv. Mater. 2018, 30, 1704507. [Google Scholar] [CrossRef] [PubMed]

- Marzo, A.; Drinkwater, B.W. Holographic Acoustic Tweezers. Proc. Natl. Acad. Sci. USA 2019, 116, 84–89. [Google Scholar] [CrossRef]

- Zou, H.-Y.; Ge, Y.; Zhao, K.-Q.; Lu, Y.-J.; Si, Q.-R.; Yuan, S.-Q.; Chen, H.; Sun, H.-X.; Yang, Y.; Zhang, B. Acoustic Metagrating Holograms. Adv. Mater. 2024, 36, 2401738. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Tamer, A. The State of the Art of Material Jetting—A Critical Review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef]

- Pilipović, A.; Baršić, G.; Katić, M.; Rujnić Havstad, M. Repeatability and Reproducibility Assessment of a PolyJet Technology Using X-Ray Computed Tomography. Appl. Sci. 2020, 10, 7040. [Google Scholar] [CrossRef]

- Yao, X.; Piao, X.; Hong, S.; Ji, C.; Wang, M.; Wei, Y.; Xu, Z.; Pan, J.-J.; Pei, Y.; Cheng, B. Acoustic Hologram-Enabled Simultaneous Multi-Target Blood-Brain Barrier Opening (AH-SiMBO). Commun. Eng. 2025, 4, 99. [Google Scholar] [CrossRef] [PubMed]

- Cox, L.; Melde, K.; Croxford, A.; Fischer, P.; Drinkwater, B.W. Acoustic Hologram Enhanced Phased Arrays for Ultrasonic Particle Manipulation. Phys. Rev. Appl. 2019, 12, 64055. [Google Scholar] [CrossRef]

- Andrés, D.; Rivens, I.; Mouratidis, P.; Jiménez, N.; Camarena, F.; ter Haar, G. Holographic Focused Ultrasound Hyperthermia System for Uniform Simultaneous Thermal Exposure of Multiple Tumor Spheroids. Cancers 2023, 15, 2540. [Google Scholar] [CrossRef]

- Brown, M.D. Phase and Amplitude Modulation with Acoustic Holograms. Appl. Phys. Lett. 2019, 115, 053701. [Google Scholar] [CrossRef]

- Bakhtiari-Nejad, M. Multi-Focal Transmission Acoustic Phase Holograms in Contactless Ultrasonic Power Transfer Systems. Sens. Actuators A Phys. 2022, 340, 113551. [Google Scholar] [CrossRef]

- Brown, M.D.; Cox, B.T.; Treeby, B.E. Stackable Acoustic Holograms. Appl. Phys. Lett. 2020, 116, 261901. [Google Scholar] [CrossRef]

- Gu, Y.; Chen, C.; Rufo, J.; Shen, C.; Wang, Z.; Huang, P.-H.; Fu, H.; Zhang, P.; Cummer, S.A.; Tian, Z.; et al. Acoustofluidic Holography for Micro- to Nanoscale Particle Manipulation. ACS Nano 2020, 14, 14635–14645. [Google Scholar] [CrossRef]

- Elkaseer, A.; Chen, K.J.; Janhsen, J.C.; Refle, O.; Hagenmeyer, V.; Scholz, S.G. Material Jetting for Advanced Applications: A State-of-the-Art Review, Gaps and Future Directions. Addit. Manuf. 2022, 60, 103270. [Google Scholar] [CrossRef]

- Xie, D.; Lv, F.; Yang, Y.; Shen, L.; Tian, Z.; Shuai, C.; Chen, B.; Zhao, J. A Review on Distortion and Residual Stress in Additive Manufacturing. Chinese J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100039. [Google Scholar] [CrossRef]

- Bakaric, M.; Miloro, P.; Javaherian, A.; Cox, B.T.; Treeby, B.E.; Brown, M.D. Measurement of the Ultrasound Attenuation and Dispersion in 3D-Printed Photopolymer Materials from 1 to 3.5 MHz. J. Acoust. Soc. Am. 2021, 150, 2798–2805. [Google Scholar] [CrossRef] [PubMed]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous Liquid Interface Production of 3D Objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Sager, B.; Rosen, D.W.; Shilling, M.; Kurfess, T.R. Experimental Studies in Stereolithography Resolution; University of Texas at Austin: Austin, TX, USA, 2003. [Google Scholar]

- Andres, D.; Carrión García, A.; Camarena, F.; Jiménez, N. Methods to Design and Evaluate Transcranial Ultrasonic Lenses Using Acoustic Holography. Phys. Rev. Appl. 2023, 20, 044071. [Google Scholar] [CrossRef]

- Li, Z.; Danfeng, W.; Fei, C.; Jiang, P.; Zhang, S.; Chen, D.-D.; Di, L.; Zhen, C.; Wu, R.; Peng, X.; et al. Acoustic Hole-Hologram for Ultrasonic Focusing With High Sensitivity. IEEE Sens. J. 2021, 21, 8935–8942. [Google Scholar] [CrossRef]

- Derayatifar, M.; Habibi, M.; Bhat, R.; Packirisamy, M. Holographic Direct Sound Printing. Nat. Commun. 2024, 15, 6691. [Google Scholar] [CrossRef]

- Sallam, A.; Cengiz, C.; Pewekar, M.; Hoffmann, E.; Legon, W.; Vlaisavljevich, E.; Shahab, S. Gradient Descent Optimization of Acoustic Holograms for Transcranial Focused Ultrasound. J. Appl. Phys. 2024, 136, 144901. [Google Scholar] [CrossRef]

- Ellouzi, C.; Zabihi, A.; Aghdasi, F.; Kayes, A.; Rivera, M.; Zhong, J.; Miri, A.; Shen, C. Underwater Double Vortex Generation Using 3D Printed Acoustic Lens and Field Multiplexing. APL Mater. 2024, 12, 31130. [Google Scholar] [CrossRef]

- Jiménez-Gambín, S.; Jiménez, N.; Camarena, F. Transcranial Focusing of Ultrasonic Vortices by Acoustic Holograms. Phys. Rev. Appl. 2020, 14, 54070. [Google Scholar] [CrossRef]

- Zhou, M.-Q.; Li, Z.; Li, Y.; Wang, Y.-C.; Zhang, J.; Chen, D.-D.; Quan, Y.; Yang, Y.-T.; Fei, C.-L. Discrete Multi-Step Phase Hologram for High Frequency Acoustic Modulation. Chin. Phys. B 2024, 33, 014303. [Google Scholar] [CrossRef]

- Lin, Q.; Cai, F.; Ye, J.; Liu, Y.; Zhang, R.; Wang, J.; Chen, Y.; Zheng, H.; Zhang, H. Acoustic Encryption with Cascaded Acoustic Holography. Sci. China Phys. Mech. Astron. 2025, 68, 274311. [Google Scholar] [CrossRef]

- Andrés, D.; Jiménez-Gambín, S.; Jiménez, N.; Camarena, F. Multifocal Acoustic Holograms for Deep-Brain Neuromodulation and BBB Opening. In Proceedings of the 2020 IEEE International Ultrasonics Symposium (IUS), Las Vegas, NV, USA, 7–11 September 2020; pp. 1–3. [Google Scholar]

- Andrés, D.; Vappou, J.; Jiménez, N.; Camarena, F. Ultrasonic Holograms to Enhance Hyperthermia Volumes. In Proceedings of the 2021 IEEE International Ultrasonics Symposium (IUS), Xi’an, China, 11–16 September 2021; pp. 1–4. [Google Scholar]

- Andrés, D.; Vappou, J.; Jiménez, N.; Camarena, F. Thermal Holographic Patterns for Ultrasound Hyperthermia. Appl. Phys. Lett. 2022, 120, 84102. [Google Scholar] [CrossRef]

- Namin, B.; Hojjat, Y. Design and Experimental Evaluation of a Non-Contact Ultrasonic Motor Using Acoustic Phase Holography. Eng. Res. Express 2024, 6, 045543. [Google Scholar] [CrossRef]

- Ghavami Namin, B.; Hojjat, Y. Remote Control of Fluid Motion in a Channel by Acoustic Holography. Ultrasonics 2024, 140, 107303. [Google Scholar] [CrossRef]

- Jiménez-Gambín, S.; Jiménez, N.; Pouliopoulos, A.N.; Benlloch, J.M.; Konofagou, E.E.; Camarena, F. Acoustic Holograms for Bilateral Blood-Brain Barrier Opening in a Mouse Model. IEEE Trans. Biomed. Eng. 2022, 69, 1359–1368. [Google Scholar] [CrossRef]

- Weerasinghe, G.; Servais, B.; Heath, D.; Martin, S.T.; Collins, D.J. Improved Acoustic Holograms Using Simulated Annealing. Biomicrofluidics 2025, 19, 24105. [Google Scholar] [CrossRef]

- Huang, J.; Qin, Q.; Wang, J. A Review of Stereolithography: Processes and Systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive Manufacturing Methods and Modeling Approaches: A Critical Review. Int. J. Adv. Manuf. Technol. 2015, 83, 389–405. [Google Scholar] [CrossRef]

- Kristiawan, R.; Imaduddin, F.; Ariawan, D.; Sabino, U.; Arifin, Z. A Review on the Fused Deposition Modeling (FDM) 3D Printing: Filament Processing, Materials, and Printing Parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Zhu, Q.; Bu, M.; Li, B.; Jiang, X.; Liu, X. Acoustic Holographic Lenses for Transcranial Focusing in an Ex Vivo Human Skull. Appl. Phys. Lett. 2024, 125, 194104. [Google Scholar] [CrossRef]

- Wang, T.-M.; Xi, J.-T.; Jin, Y. A Model Research for Prototype Warp Deformation in the FDM Process. Int. J. Adv. Manuf. Technol. 2007, 33, 1087–1096. [Google Scholar] [CrossRef]

- Antoniou, A.; Evripidou, N.; Giannakou, M.; Constantinides, G.; Damianou, C. Acoustical Properties of 3D Printed Thermoplastics. J. Acoust. Soc. Am. 2021, 149, 2854–2864. [Google Scholar] [CrossRef]

- Wang, H.; Ritter, T.A.; Cao, W.; Shung, K.K. High Frequency Properties of Passive Materials for Ultrasonic Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2001, 48, 78–84. [Google Scholar] [CrossRef]

- Liu, Q.; Zhou, J.; Jia, Z.; Zhou, P. Design and Fabrication of an Epoxy/Glass Microbeads-Based 1-3 Piezoelectric Composite. Micromachines 2025, 16, 361. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, Y.; Cheng, Y.; Liu, X. Acoustic Holography Using Composite Metasurfaces. Appl. Phys. Lett. 2020, 116, 30501. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D Printing of Polymer Nanocomposites via Stereolithography. Macromol. Mater. Eng. 2017, 302, 1600553. [Google Scholar] [CrossRef]

- Ye, S.; Cramer, N.B.; Bowman, C.N. Relationship between Glass Transition Temperature and Polymerization Temperature for Cross-Linked Photopolymers. Macromolecules 2011, 44, 490–494. [Google Scholar] [CrossRef]

- Kondo, S.; Okubo, K. Mid-Air Acoustic Tweezers for Non-Contact Pick up Using Multi-Channel Controlled Ultrasonic Transducer Arrays. Jpn. J. Appl. Phys. 2021, 60, SDDD16. [Google Scholar] [CrossRef]

- Jiménez-Gambín, S.; Jiménez, N.; Benlloch, J.M.; Camarena, F. Generating Bessel Beams with Broad Depth-of-Field by Using Phase-Only Acoustic Holograms. Sci. Rep. 2019, 9, 20104. [Google Scholar] [CrossRef]

- Velásquez-García, L.F.; Kornbluth, Y. Biomedical Applications of Metal 3D Printing. Annu. Rev. Biomed. Eng. 2021, 23, 307–338. [Google Scholar] [CrossRef] [PubMed]

- Sayed Ahmed, M.; Shahab, S. Dynamic and Reconfigurable Acoustic Fields Enabled by Morphing Fluidic Holographic Lenses. Adv. Mater. Technol. 2025, e00741. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).