A Rapid Fabrication Method of Large-Area MLAs with Variable Curvature for Retroreflectors Based on Thermal Reflow

Abstract

1. Introduction

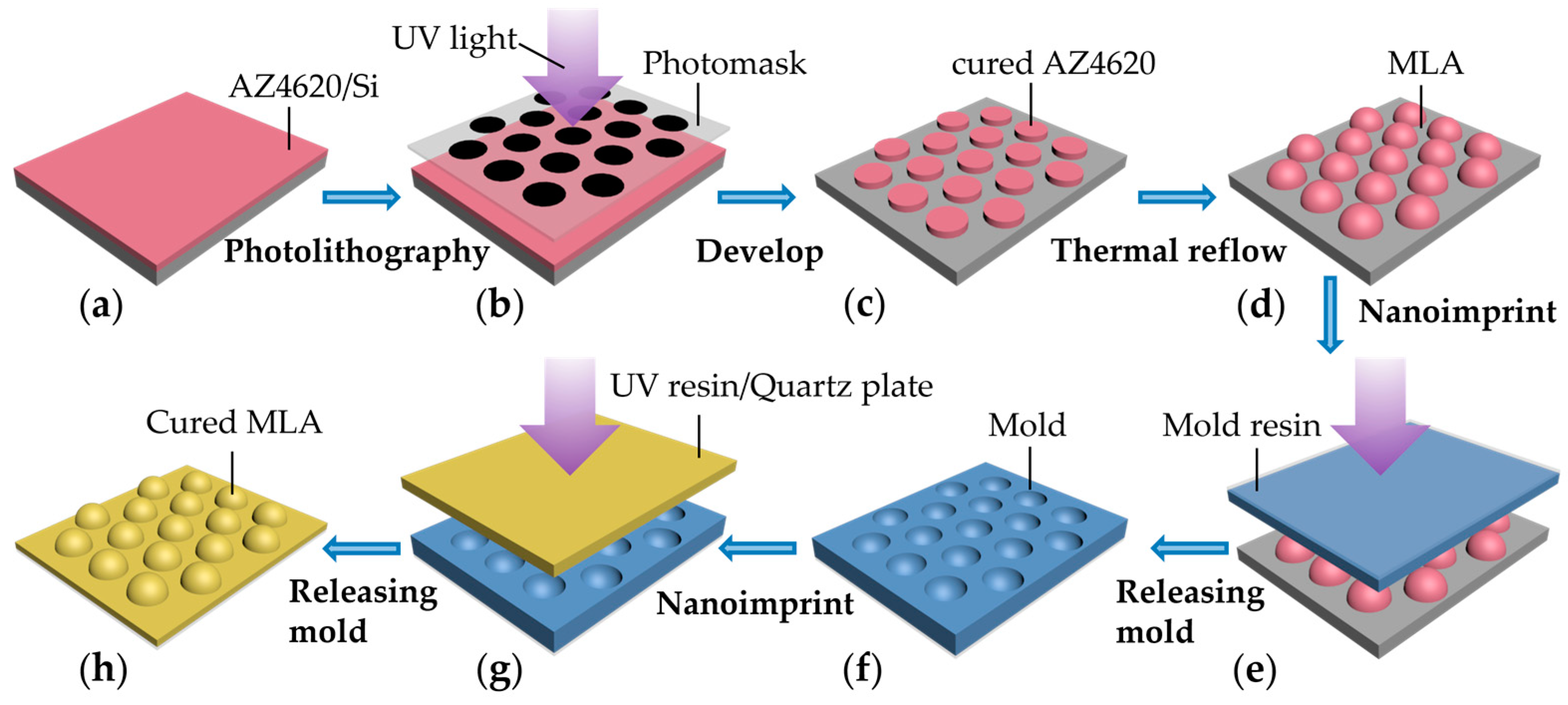

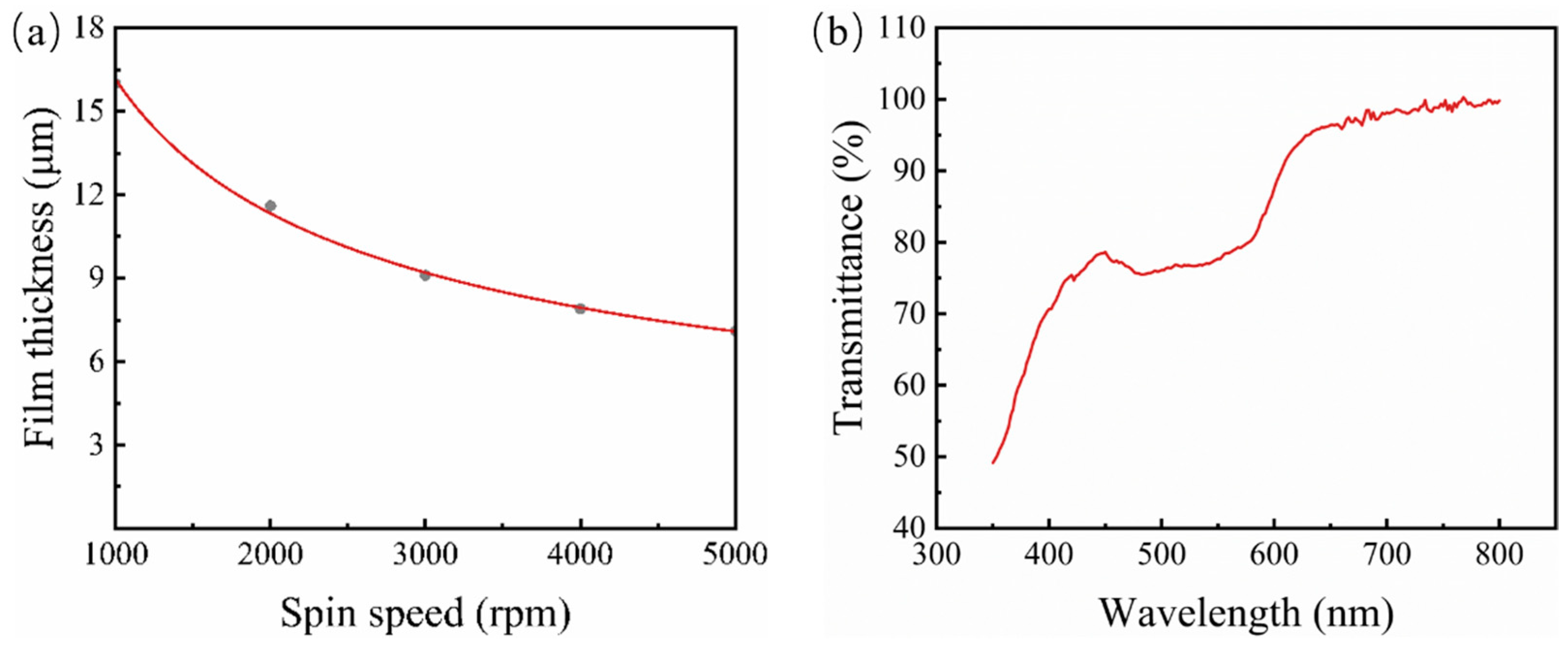

2. Materials and Methods

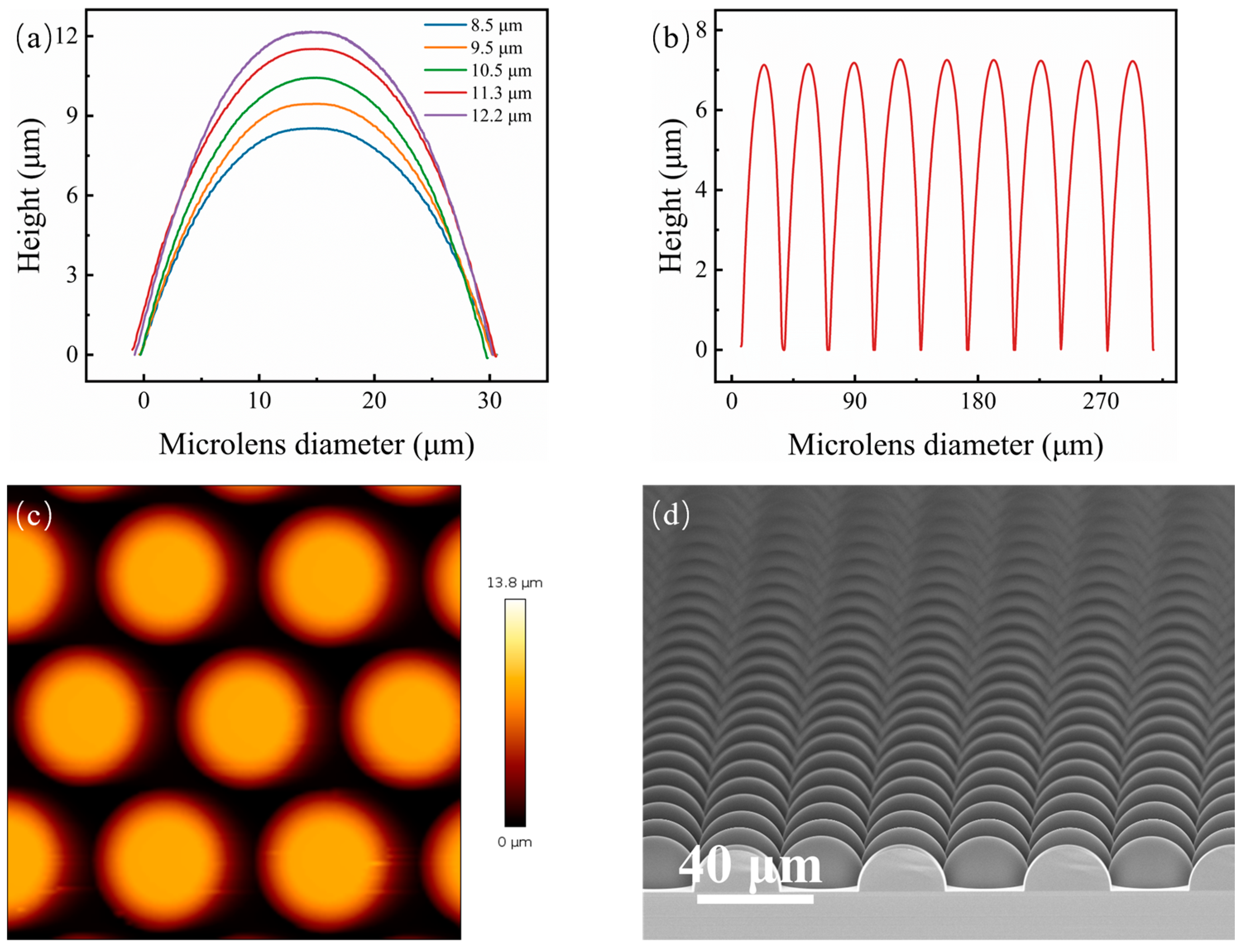

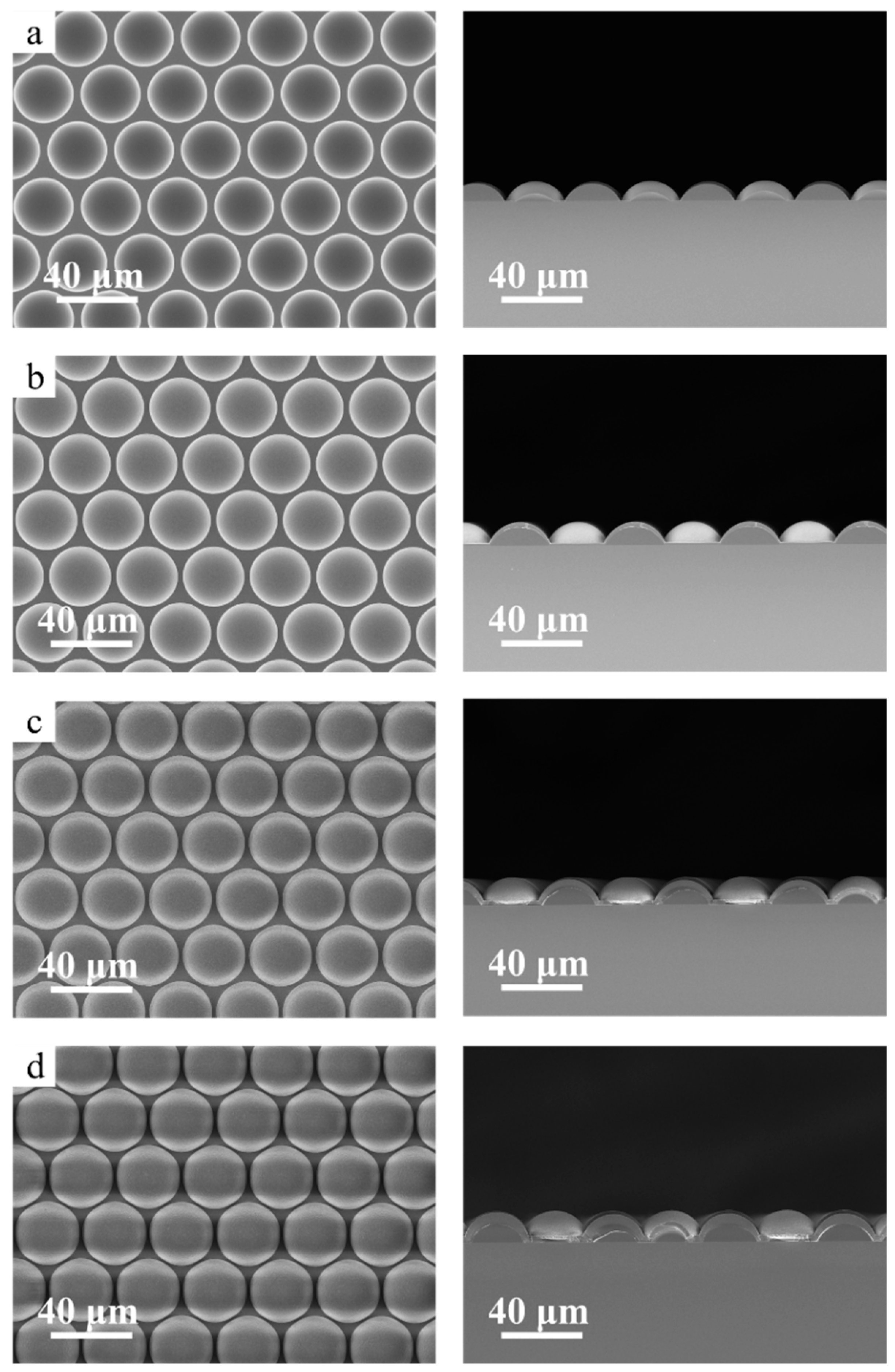

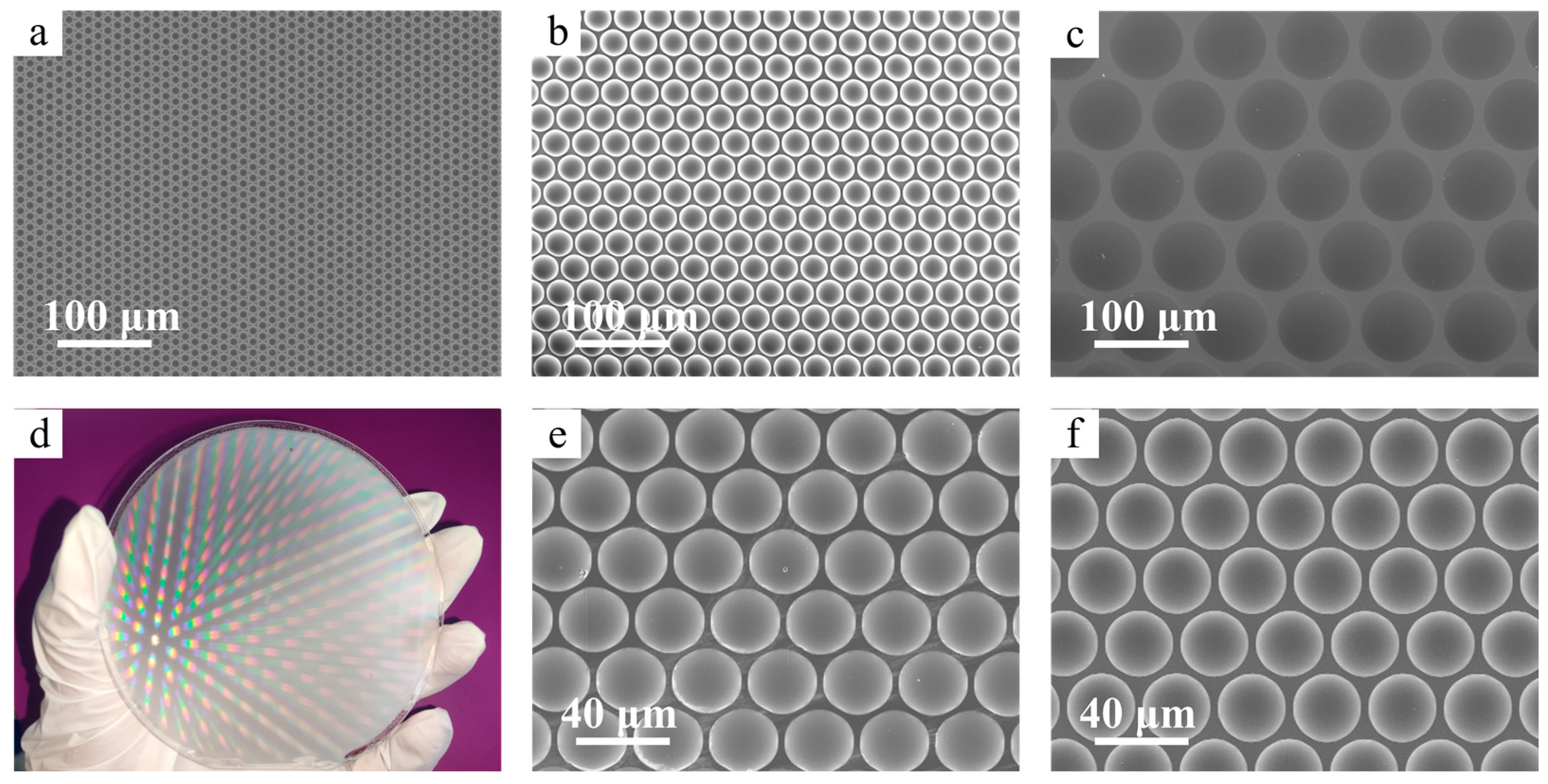

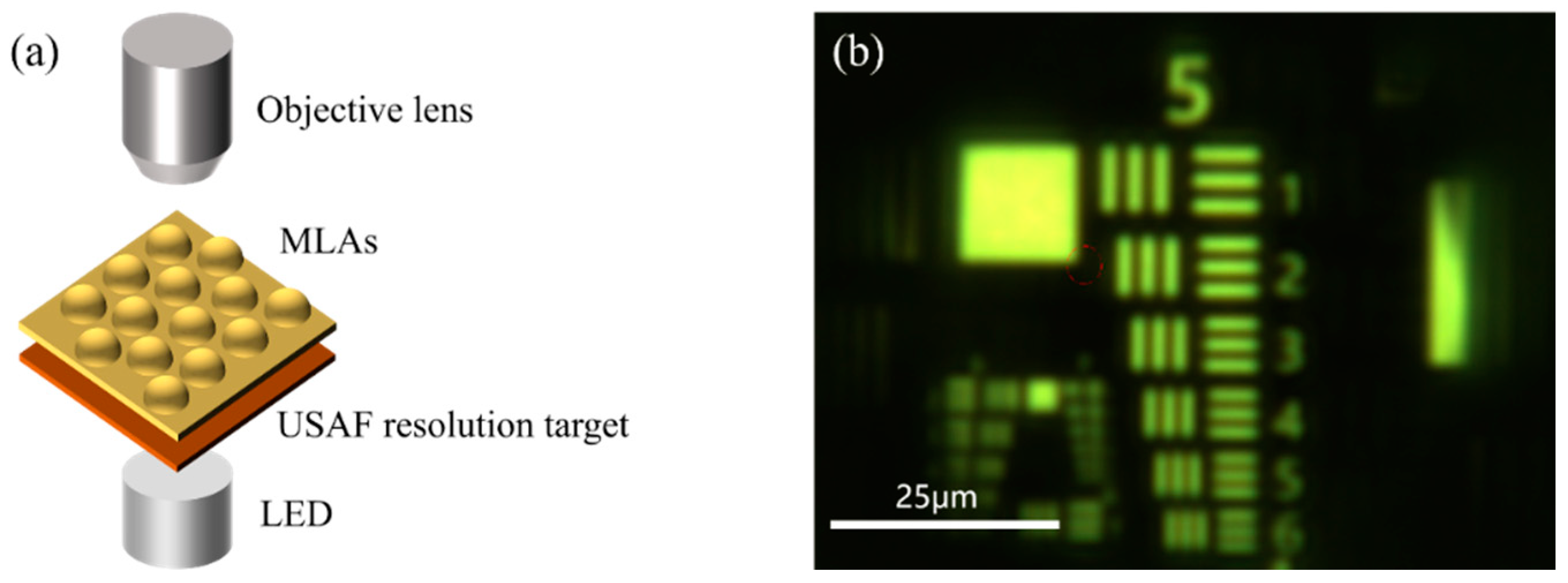

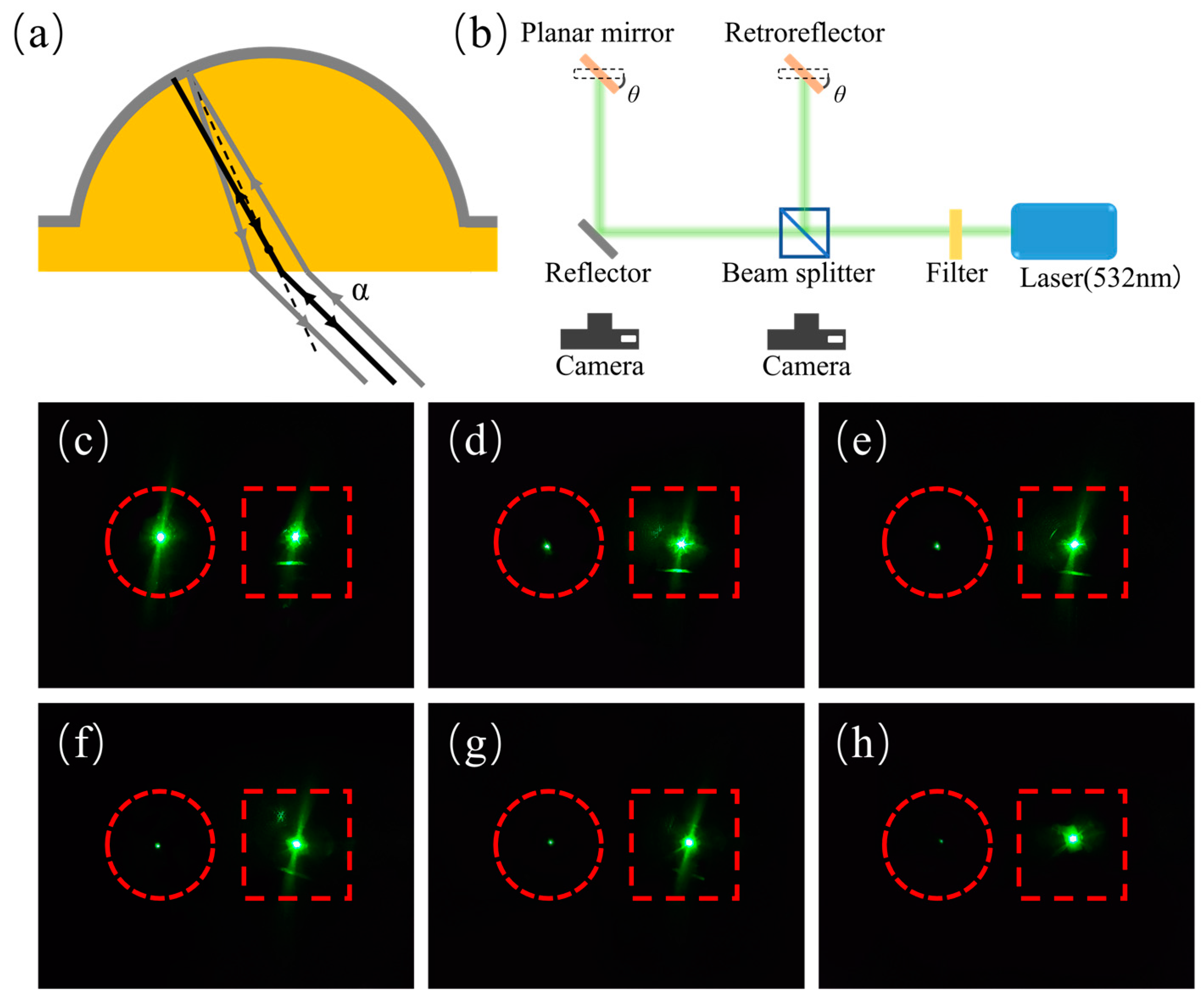

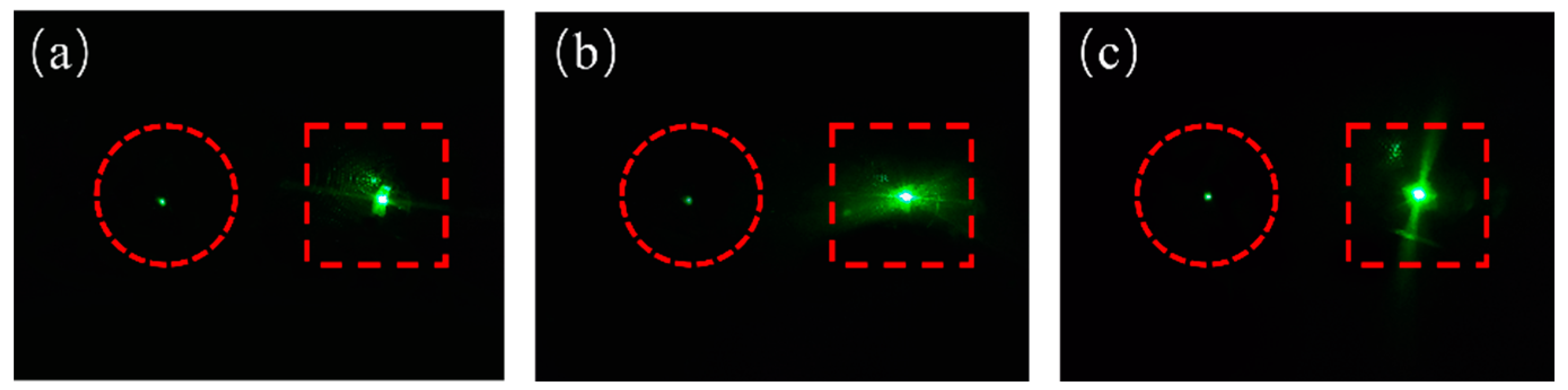

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lundvall, A.; Nikolajeff, F.; Lindstrom, T. High Performing Micromachined Retroreflector. Opt. Express 2003, 11, 2459–2473. [Google Scholar] [CrossRef]

- Saleh, R.; Fleyeh, H.; Alam, M. An Analysis of the Factors Influencing the Retroreflectivity Performance of In-Service Road Traffic Signs. Appl. Sci. 2022, 12, 2413. [Google Scholar] [CrossRef]

- Balali, V.; Sadeghi, M.A.; Golparvar-Fard, M. Image-Based Retro-Reflectivity Measurement of Traffic Signs in Day Time. Adv. Eng. Inform. 2015, 29, 1028–1040. [Google Scholar] [CrossRef]

- Lan, T.T.; Kanitpong, K.; Tomiyama, K.; Kawamura, A.; Nakatsuji, T. Effectiveness of Retro-Reflective Tape at the Rear of Heavy Trucks to Increase Visibility and Reduce Rear-End Collisions. IATSS Res. 2019, 43, 176–184. [Google Scholar] [CrossRef]

- Han, X.; Wang, R.; Wang, L.; Su, W. Research on Measurement Accuracy of Vehicle-Mounted Marking Retroreflective Measuring Instrument. In Proceedings of the 2021 4th International Symposium on Traffic Transportation and Civil Architecture (ISTTCA), Suzhou, China, 12–14 November 2021; pp. 51–54. [Google Scholar]

- Chen, H.; Tang, L.; Zhang, S.; Song, H.; Shi, Z. Effects of Incident Beam Deviation from the Center of a Cat’s Eye Retro-Reflector on the Measurement Accuracy of a Laser Tracing System. Opt. Lasers Eng. 2021, 137, 106387. [Google Scholar] [CrossRef]

- Turyshev, S.G.; Williams, J.G.; Folkner, W.M.; Gutt, G.M.; Baran, R.T.; Hein, R.C.; Somawardhana, R.P.; Lipa, J.A.; Wang, S. Corner-Cube Retro-Reflector Instrument for Advanced Lunar Laser Ranging. Exp. Astron. 2013, 36, 105–135. [Google Scholar] [CrossRef]

- Goetz, P.G.; Rabinovich, W.S.; Mahon, R.; Murphy, J.L.; Ferraro, M.S.; Suite, M.R.; Smith, W.R.; Burris, H.R.; Moore, C.I.; Schultz, W.W. Modulating Retro-Reflector Lasercom Systems for Small Unmanned Vehicles. IEEE J. Sel. Areas Commun. 2012, 30, 986–992. [Google Scholar] [CrossRef]

- Moon, H.-J.; Chae, C.-B.; Alouini, M.-S. Performance Analysis of Passive Retro-Reflector Based Tracking in Free-Space Optical Communications with Pointing Errors. IEEE Trans. Veh. Technol. 2023, 72, 10982–10987. [Google Scholar] [CrossRef]

- Tian, J.; Guo, T.; He, N.; Du, J.; Huang, Q.; Hong, X.; Fei, C.; Wang, Y.; Zhang, T.; Zhang, J.; et al. Wide-Field-of-View Modulating Retro-Reflector System Based on a Telecentric Lens for High-Speed Free-Space Optical Communication. IEEE Photonics J. 2023, 15, 1–8. [Google Scholar]

- Qin, Y.; Xu, Z.; Wang, J.; Li, J.; Xie, M.; Zhao, J.; Qi, A. Performance Analysis of Modulating Retro-Reflector Optical Communication System Based on an Airy Beam. J. Mod. Opt. 2023, 70, 435–442. [Google Scholar] [CrossRef]

- Hussein, S.; Hamilton, B.; Tutunea-Fatan, O.R.; Bordatchev, E. Novel Retroreflective Micro-Optical Structure for Automotive Lighting Applications. SAE Int. J. Passeng. Cars-Mech. Syst. 2016, 9, 497–506. [Google Scholar] [CrossRef]

- Solanki, R.S.; Khurana, V. Studies on Retro-Reflection for Optical Target Detection. J. Opt. 2023, 53, 336–341. [Google Scholar] [CrossRef]

- Goetz, P.G.; Rabinovich, W.S.; Mahon, R.; Ferraro, M.S.; Murphy, J.L.; Burris, H.R.; Stell, M.F.; Moore, C.I.; Suite, M.R.; Freeman, W. Modulating Retro-Reflector Devices and Current Link Performance at the Naval Research Laboratory. In Proceedings of the MILCOM 2007-IEEE Military Communications Conference, Orlando, FL, USA, 29–31 October 2007; pp. 1–7. [Google Scholar]

- Egidi, A. Review of Main Optical Retroreflectors. Ist. Naz. Ric. Metrol. Turin Italy Tech. Rep. RT 2018, 31, 2018. [Google Scholar]

- Chan, T.K.; Ford, J.E. Retroreflecting Optical Modulator Using an MEMS Deformable Micromirror Array. J. Light. Technol. 2006, 24, 516–525. [Google Scholar] [CrossRef]

- Chu, G.; Chen, F.; Zhao, B.; Zhang, X.; Zussman, E.; Rojas, O.J. Self-assembled Nanorods and Microspheres for Functional Photonics: Retroreflector Meets Microlens Array. Adv. Opt. Mater. 2021, 9, 2002258. [Google Scholar] [CrossRef]

- Tian, L.-L.; Chu, F.; Zhao, W.-X.; Li, L.; Wang, Q.-H. Fast Responsive 2D/3D Switchable Display Using a Liquid Crystal Microlens Array. Opt. Lett. 2021, 46, 5870–5873. [Google Scholar] [CrossRef]

- Ratcliff, J.; Supikov, A.; Alfaro, S.; Azuma, R. ThinVR: Heterogeneous Microlens Arrays for Compact, 180 Degree FOV VR near-Eye Displays. IEEE Trans. Vis. Comput. Graph. 2020, 26, 1981–1990. [Google Scholar] [CrossRef]

- Zhou, X.; Peng, Y.; Peng, R.; Zeng, X.; Zhang, Y.; Guo, T. Fabrication of Large-Scale Microlens Arrays Based on Screen Printing for Integral Imaging 3D Display. ACS Appl. Mater. Interfaces 2016, 8, 24248–24255. [Google Scholar] [CrossRef]

- Heo, D.; Kim, B.; Lim, S.; Moon, W.; Lee, D.; Hahn, J. Large Field-of-View Microlens Array with Low Crosstalk and Uniform Angular Resolution for Tabletop Integral Imaging Display. J. Inf. Disp. 2023, 24, 81–92. [Google Scholar] [CrossRef]

- Zhao, N.-Q.; Liu, J.; Zhao, Z.-F. High Performance Integral Imaging 3D Display Using Quarter-Overlapped Microlens Arrays. Opt. Lett. 2021, 46, 4240–4243. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Xue, Y.; Li, J.; Zhang, L.; Lu, H.; Wang, Z. Large-Area and Rapid Fabrication of a Microlens Array on a Flexible Substrate for an Integral Imaging 3D Display. ACS Appl. Mater. Interfaces 2023, 15, 10219–10227. [Google Scholar] [CrossRef] [PubMed]

- Hao, J.; Gao, Y.; Dong, C.; Meng, Z.; Chen, G. The Design of a Fiber-Coupling Micro-Lens Array for an M × N Wavelength-Selective Switch. Micromachines 2024, 15, 307. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Geng, C.; Li, F.; Li, X.; Zuo, J.; Jiang, J.; Li, B.; Li, X. High-Resolution Beam Scanning Technique with Microlens Array and Adaptive Fiber-Optics Collimator. Opt. Express 2021, 29, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Ko, C.-H.; Lin, C.-H.; Tsai, B.-C.; Shih, H.-H.; Wu, C.-T.; Chao, Y.-L.; Chou, Y.-K.; Chu, C.-H.; Chiou, Y.-T.; Chen, R. Development of Microlens Arrays for High-Speed Optical Communication. In Proceedings of the Micro-Optics: Fabrication, Packaging, and Integration, Strasbourg, France, 29–30 April 2004; SPIE: Bellingham, WA, USA, 2004; Volume 5454, pp. 121–128. [Google Scholar]

- Zhao, Z.; Liang, Y. Cutting Force and Energy Modelling in Ultra-Precision Machining of Micro-Structures. In Fabrication of Micro/Nano Structures via Precision Machining: Modelling, Processing and Evaluation; Springer: Singapore, 2023; pp. 129–161. [Google Scholar]

- Wang, S.; Kong, L.; Wang, C.; Cheung, C. Ultra-Precision Manufacturing of Microlens Arrays Using an Optimum Machining Process Chain. Opt. Express 2023, 31, 2234–2247. [Google Scholar] [CrossRef] [PubMed]

- Kwok, T.C.; Cheung, C.F.; Kong, L.B.; To, S.; Lee, W.B. Analysis of Surface Generation in Ultra-Precision Machining with a Fast Tool Servo. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 1351–1367. [Google Scholar] [CrossRef]

- Li, D.; Wang, B.; Qiao, Z.; Jiang, X. Ultraprecision Machining of Microlens Arrays with Integrated On-Machine Surface Metrology. Opt. Express 2019, 27, 212–224. [Google Scholar] [CrossRef] [PubMed]

- Nam, M.; Oh, H.; Kim, G.; Yang, S.; Lee, K. Development of a Microlens Array (MLA) for Maskless Photolithography Application. In Proceedings of the Reliability, Packaging, Testing, and Characterization of MEMS/MOEMS and Nanodevices IX, San Francisco, CA, USA, 25–26 January 2010; SPIE: Bellingham, WA, USA, 2010; Volume 7592, pp. 248–255. [Google Scholar]

- Huang, K.-Y.; Chang, K.-P.; Chang, Y.-P.; Liu, C.-N.; Cheng, W.-H. Microlens Array Device for Laser Light Shaping in Laser Scanning Smart Headlights. Opt. Express 2023, 31, 25307–25317. [Google Scholar] [CrossRef] [PubMed]

- Oh, H.; Kim, G.; Seo, H.; Song, Y.; Lee, K.; Yang, S.S. Fabrication of Micro-Lens Array Using Quartz Wet Etching and Polymer. Sens. Actuators Phys. 2010, 164, 161–167. [Google Scholar] [CrossRef]

- Zhang, Q.; Schambach, M.; Schlisske, S.; Jin, Q.; Mertens, A.; Rainer, C.; Hernandez-Sosa, G.; Heizmann, M.; Lemmer, U. Fabrication of Microlens Arrays with High Quality and High Fill Factor by Inkjet Printing. Adv. Opt. Mater. 2022, 10, 2200677. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, L.; Ding, Y.; Wei, H.; Hao, X.; Wang, D.; Dai, Y.; Shi, J. Direct Fabrication of Microlens Arrays with High Numerical Aperture by Ink-Jetting on Nanotextured Surface. Appl. Surf. Sci. 2013, 279, 36–40. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, G.; Ye, H.; Wei, M.; Guo, Z.; Chen, K.; Liu, C.; Tang, B.; Zhou, G. Mold-Free Self-Assembled Scalable Microlens Arrays with Ultrasmooth Surface and Record-High Resolution. Light Sci. Appl. 2023, 12, 143. [Google Scholar] [CrossRef] [PubMed]

- Ding, H.; Yue, Y.; Han, C.; Chen, S. Self-Assembly Three-Dimensional Optical Devices: From Microsphere to Microlens Array. Opt. Lett. 2018, 43, 2619–2622. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Sheng, B.; Wang, D.; Shi, J.; Ni, Z.; Huang, Y. Soft Mold of Microlens Arrays Fabricated by Surface Self-Assembly. Opt. Mater. 2020, 99, 109602. [Google Scholar] [CrossRef]

- Xu, R.; Zhou, T.; Cheung, R. Fabrication of SiC Concave Microlens Array Mold Based on Microspheres Self-Assembly. Microelectron. Eng. 2021, 236, 111481. [Google Scholar] [CrossRef]

- Guo, R.; Xiao, S.; Zhai, X.; Li, J.; Xia, A.; Huang, W. Micro Lens Fabrication by Means of Femtosecond Two Photon Photopolymerization. Opt. Express 2006, 14, 810. [Google Scholar] [CrossRef]

- He, Z.; Lee, Y.-H.; Chanda, D.; Wu, S.-T. Adaptive Liquid Crystal Microlens Array Enabled by Two-Photon Polymerization. Opt. Express 2018, 26, 21184. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Zhang, W.; Guo, L.; Zhuang, L. Sub-10 Nm Imprint Lithography and Applications. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1997, 15, 2897–2904. [Google Scholar] [CrossRef]

- Resnick, D.J.; Iwasa, J. Nanoimprint Lithography and a Perspective on Cost of Ownership. In Proceedings of the Photomask Technology 2018, Monterey, CA, USA, 17–19 September 2018; SPIE: Bellingham, WA, USA, 2018; Volume 10810, pp. 53–59. [Google Scholar]

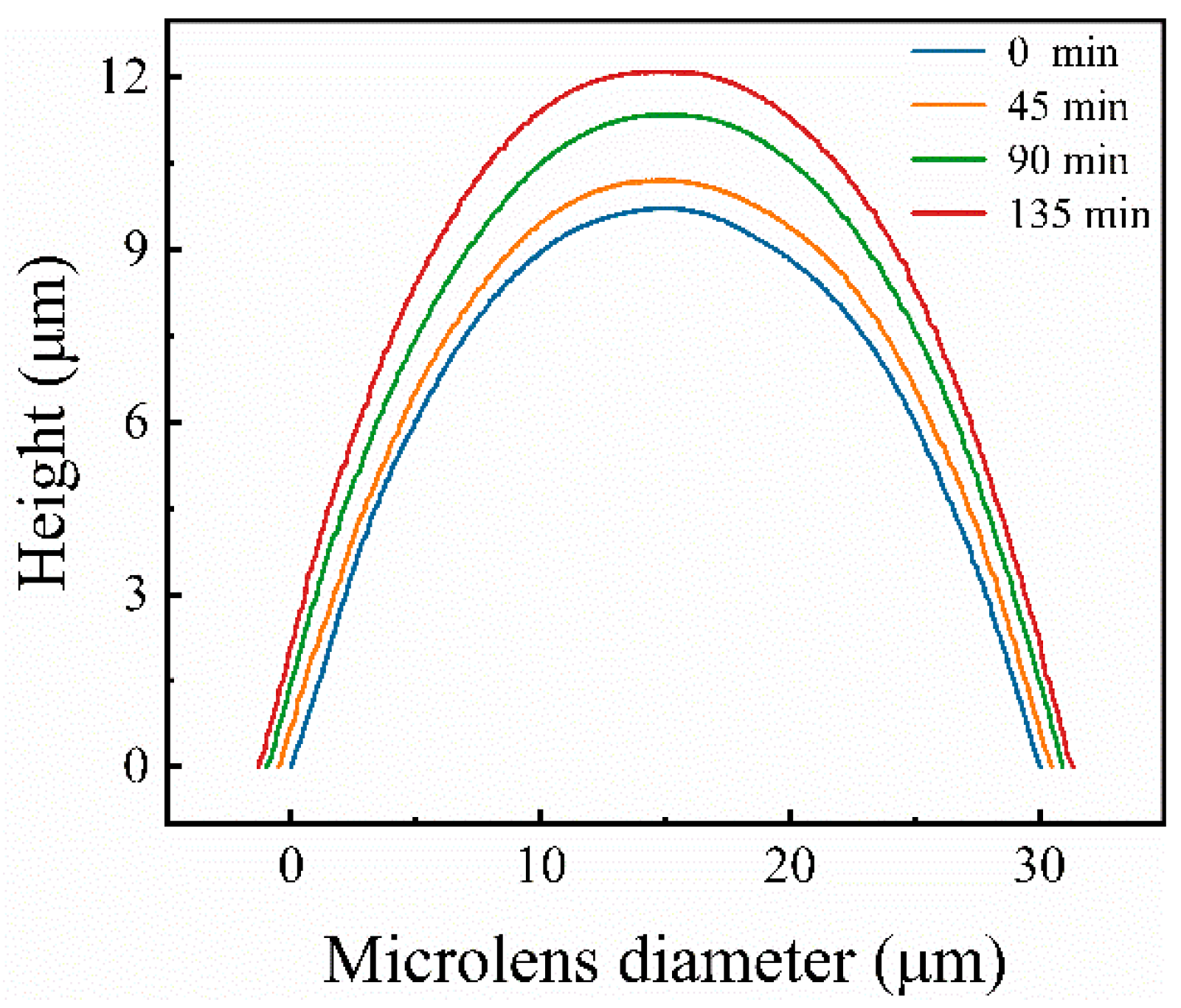

| Microlens Height (μm) | Diameter (μm) | Curvature Radius (μm) | Fill Factor | |

|---|---|---|---|---|

| R1 | 8.1 | 30.9 | 18.8 | 79.3% |

| R2 | 10.5 | 31.6 | 17.1 | 82.9% |

| R3 | 15.7 | 31.7 | 15.9 | 83.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yong, Y.; Chen, S.; Chen, H.; Ge, H.; Hao, Z. A Rapid Fabrication Method of Large-Area MLAs with Variable Curvature for Retroreflectors Based on Thermal Reflow. Micromachines 2024, 15, 816. https://doi.org/10.3390/mi15070816

Yong Y, Chen S, Chen H, Ge H, Hao Z. A Rapid Fabrication Method of Large-Area MLAs with Variable Curvature for Retroreflectors Based on Thermal Reflow. Micromachines. 2024; 15(7):816. https://doi.org/10.3390/mi15070816

Chicago/Turabian StyleYong, Yiqiu, Si Chen, Hao Chen, Haixiong Ge, and Zongbin Hao. 2024. "A Rapid Fabrication Method of Large-Area MLAs with Variable Curvature for Retroreflectors Based on Thermal Reflow" Micromachines 15, no. 7: 816. https://doi.org/10.3390/mi15070816

APA StyleYong, Y., Chen, S., Chen, H., Ge, H., & Hao, Z. (2024). A Rapid Fabrication Method of Large-Area MLAs with Variable Curvature for Retroreflectors Based on Thermal Reflow. Micromachines, 15(7), 816. https://doi.org/10.3390/mi15070816