Thermal Performance of Heat Sink Filled with Double-Porosity Porous Aluminum Skeleton/Paraffin Phase Change Material

Abstract

1. Introduction

2. Materials and Methods

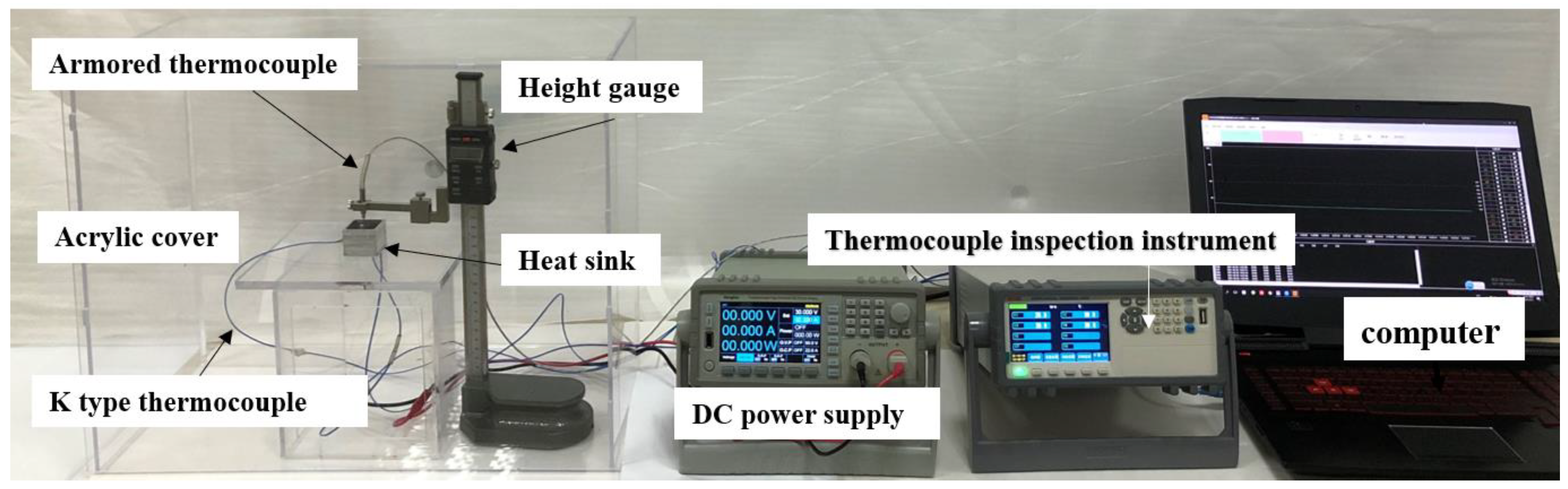

2.1. Experimental Platform

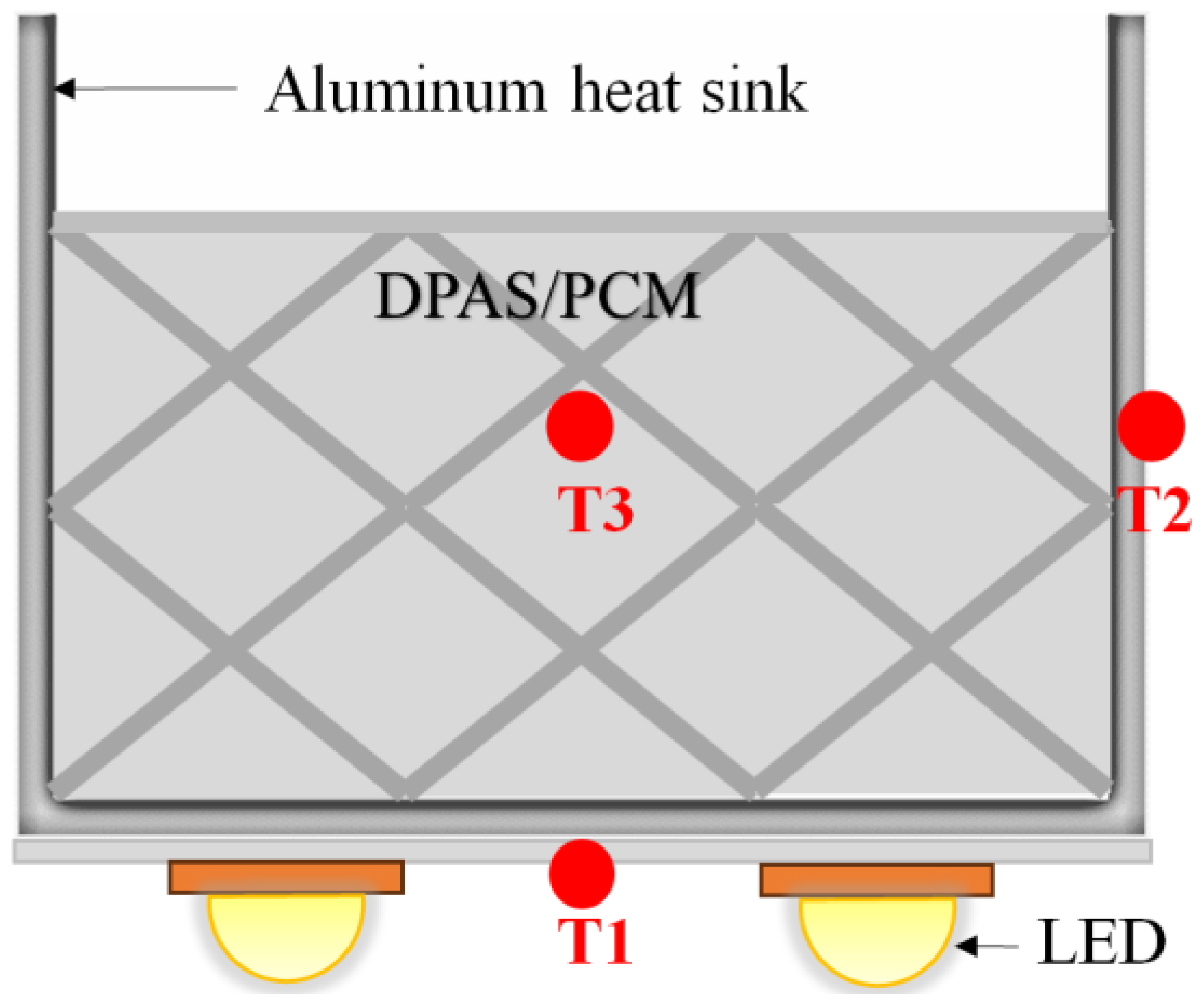

2.2. LED Heat Sink (HS) Cooling Device

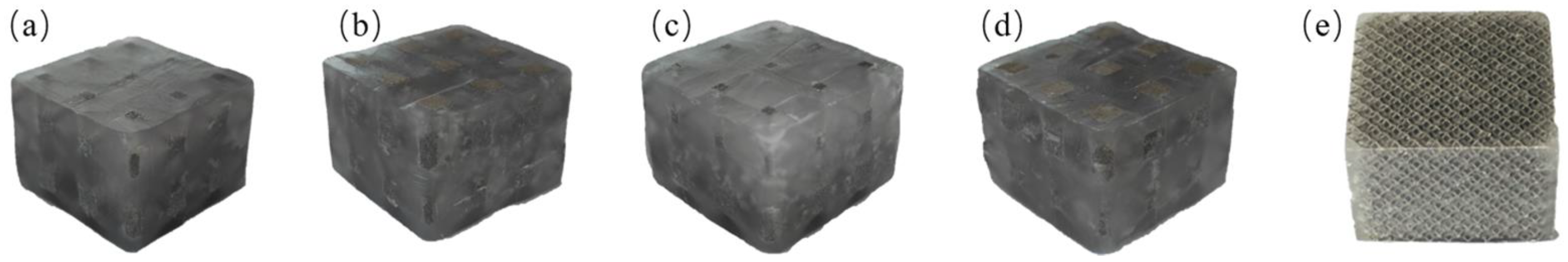

2.3. Preparation of Double-Porosity Porous Aluminum Skeleton/Paraffin Phase Change Material

3. Results and Discussion

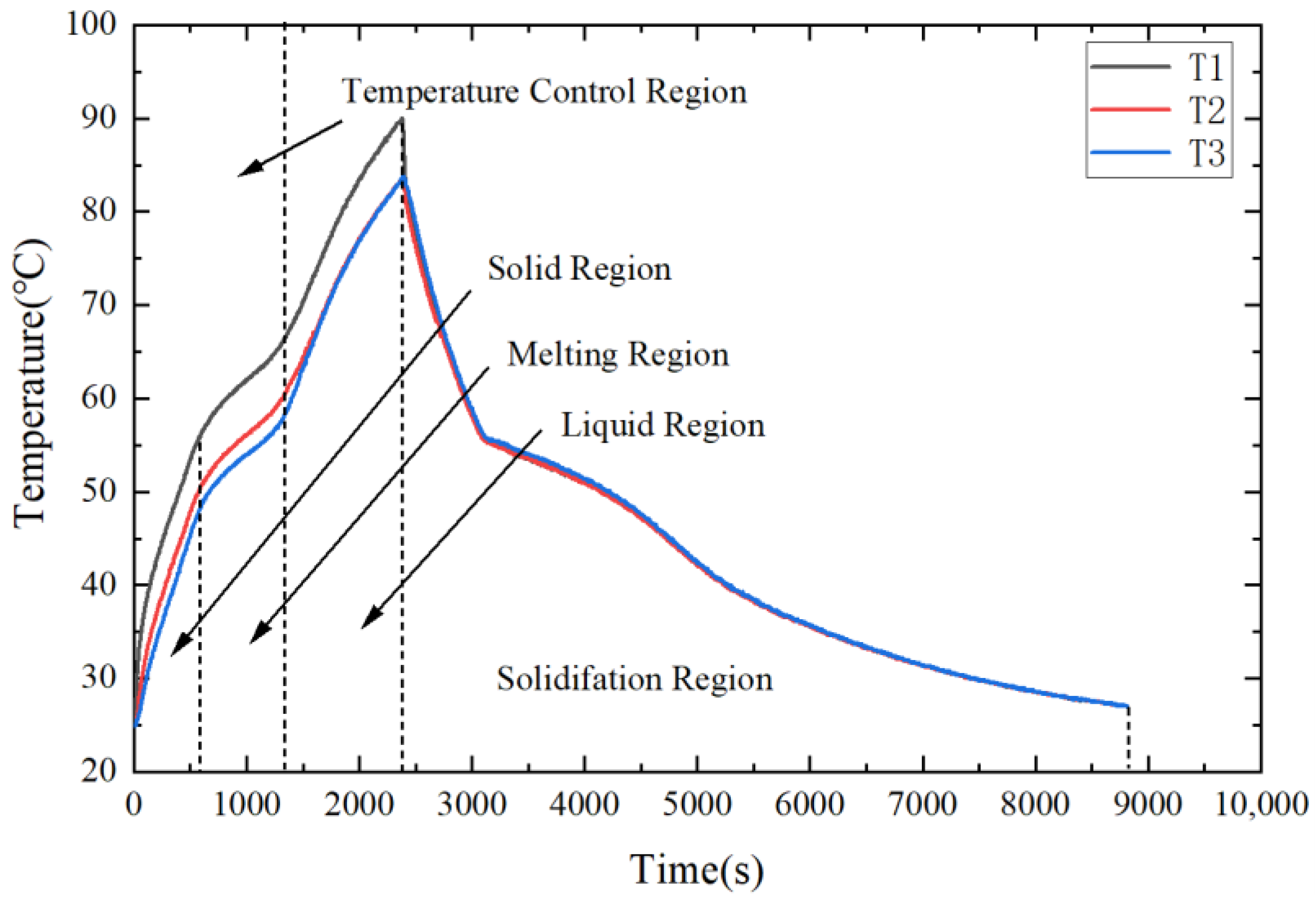

3.1. Thermal Performance Analysis of a Typical DPAS/PCM HS

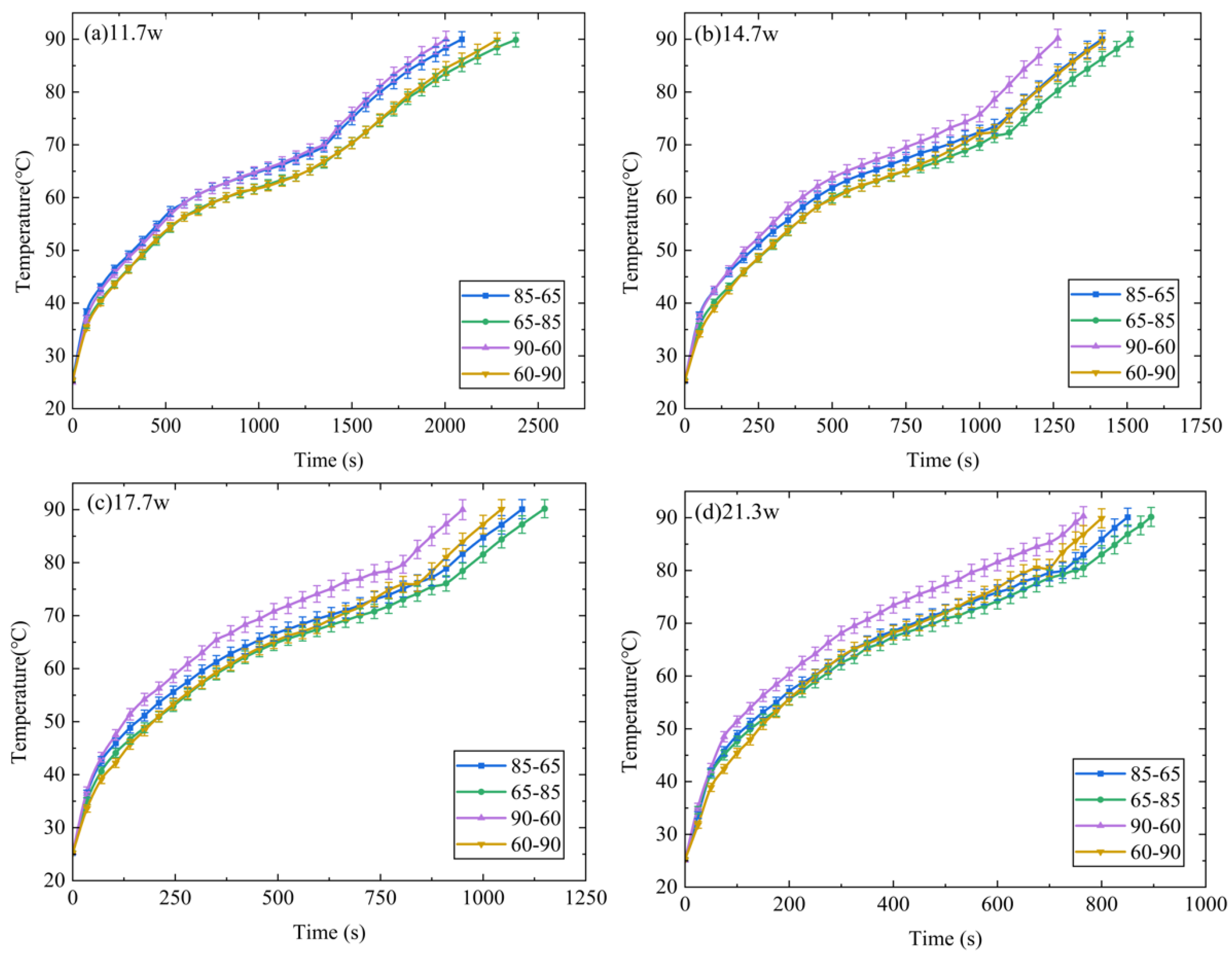

3.2. DPAS/PCM during the Heating Stage

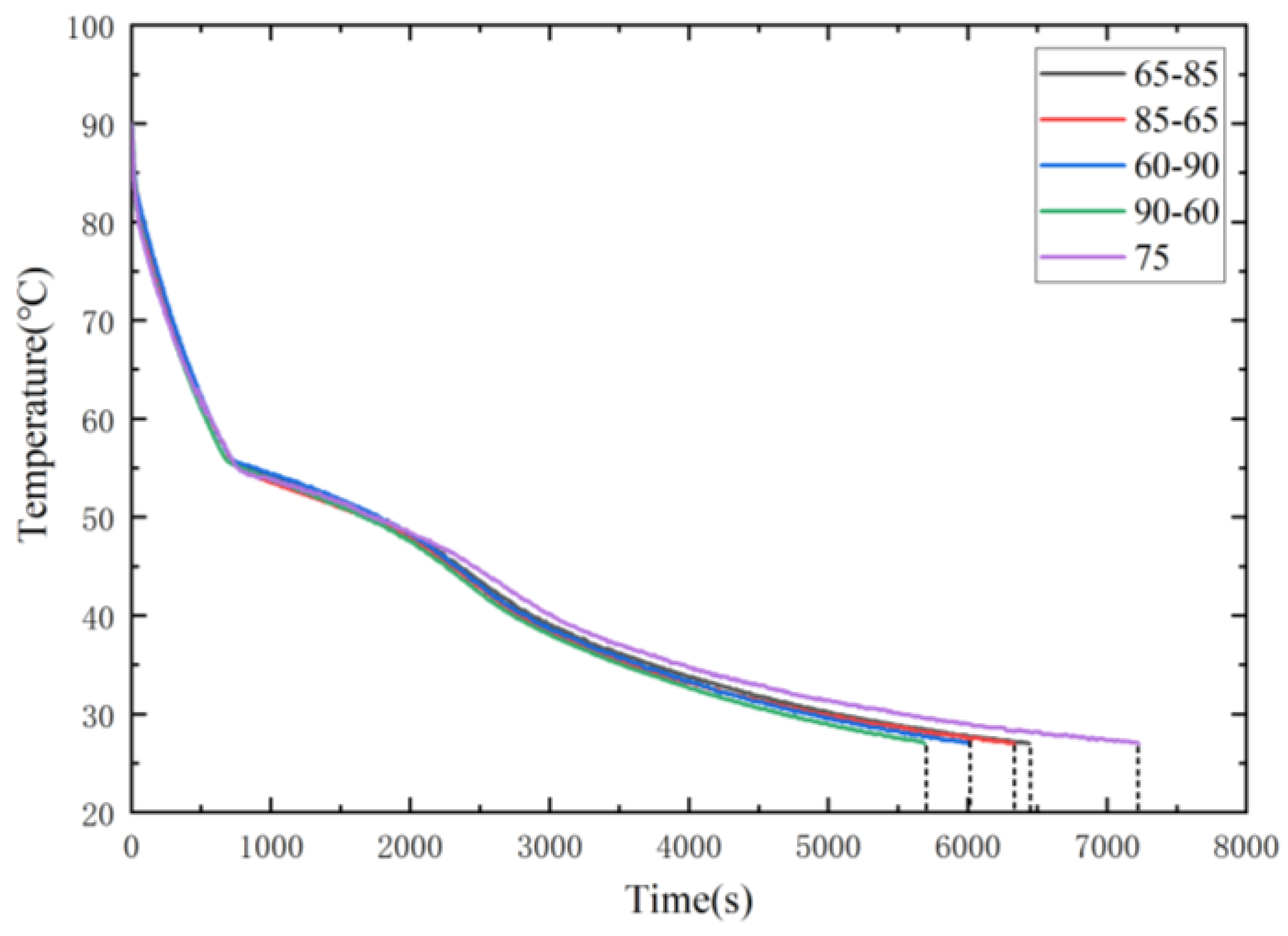

3.3. Temperature Control Time Analysis of DPAS/PCM

4. Comparative Study of DPAS/PCM and UAS/PCM

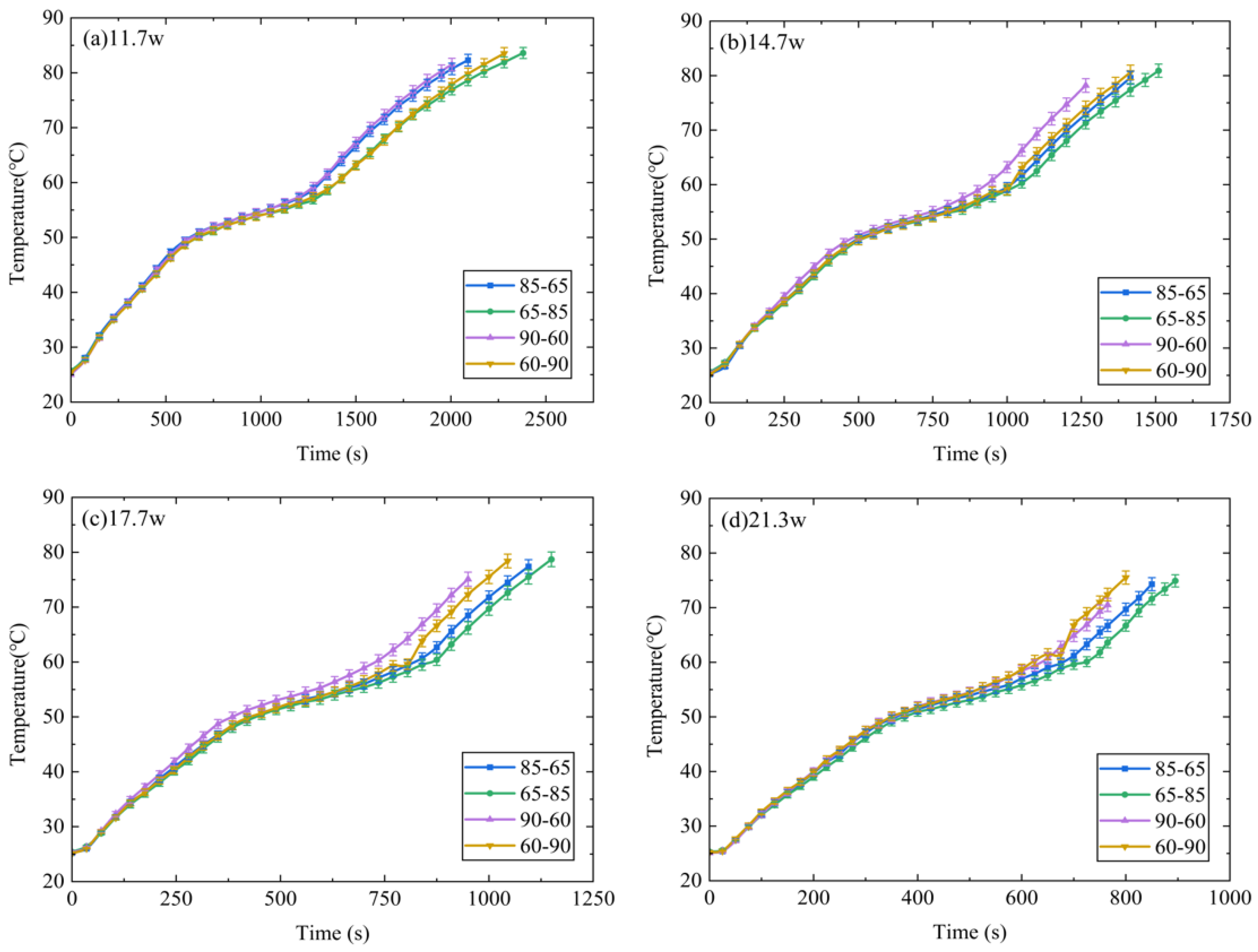

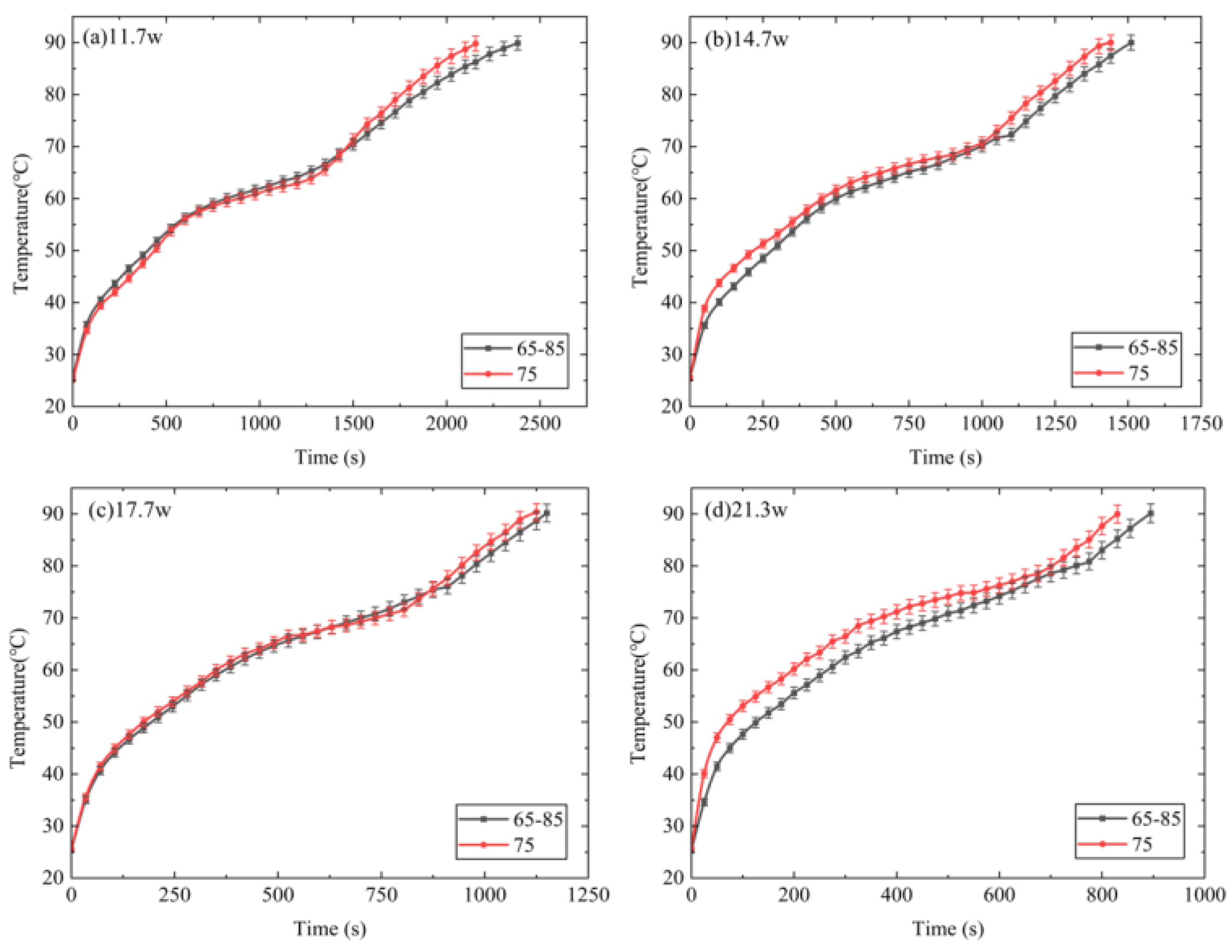

4.1. Comparison at Heating Stage

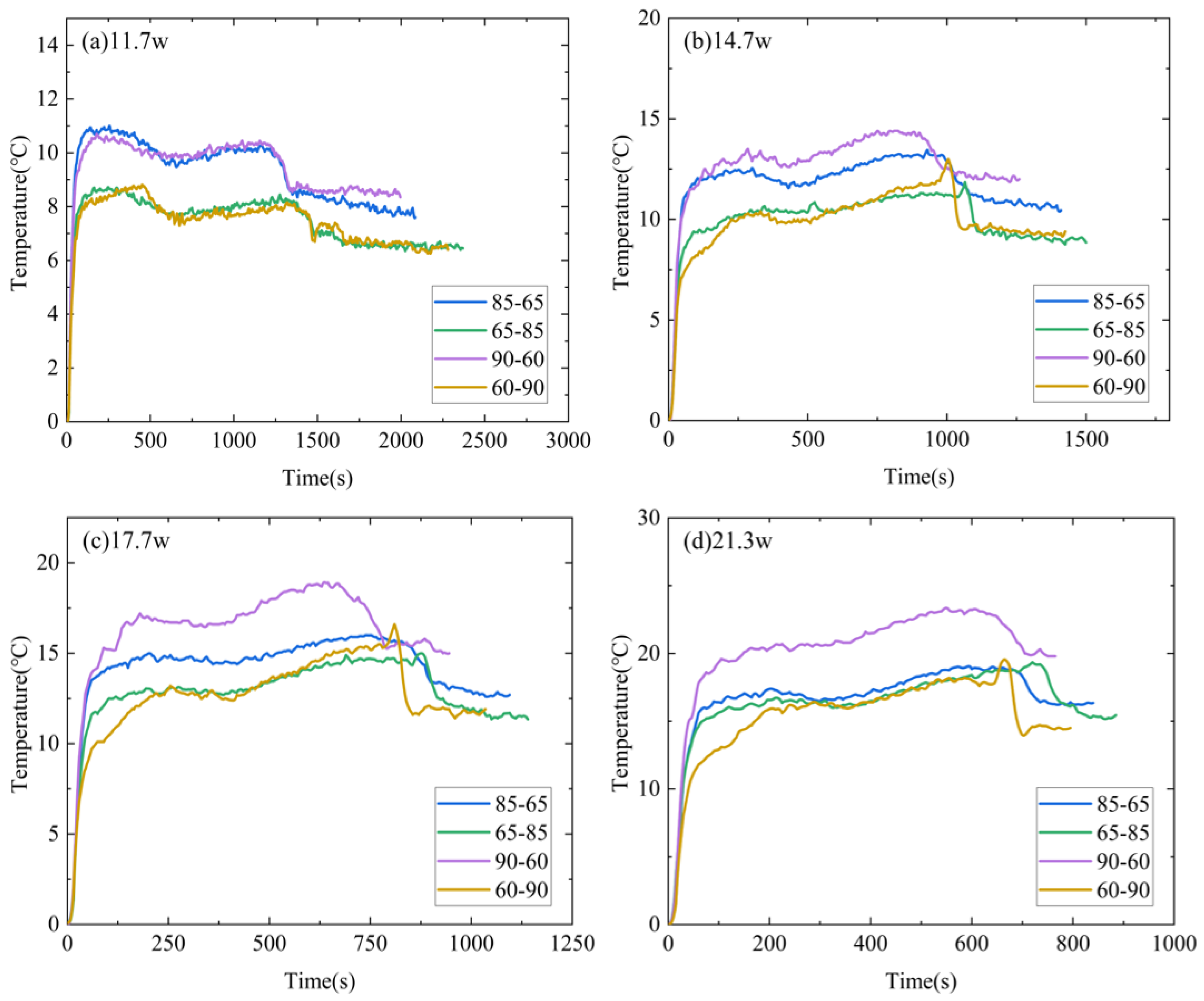

4.2. Comparison at Cooling Stage

4.3. Comparison of Temperature Control Times

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amano, H. Development of GaN-based blue LEDs and metalorganic vapor phase epitaxy of GaN and related materials. Prog. Cryst. Growth Charact. Mater. 2016, 62, 126–135. [Google Scholar] [CrossRef]

- Qi, Z.; Wang, L.; Liang, Y.; Liu, P.; Zhu, H.; Wang, Y. Deep-ultraviolet light communication in sunlight using 275-nm LEDs. Appl. Phys. Lett. 2023, 123, 161109. [Google Scholar] [CrossRef]

- Zhang, S.; Li, W.; Wang, K.; Guo, Y.; Gong, Z.; Zhang, Z.; Zhang, Y.; Zhou, X.; Guo, T.; Wu, C. Noncarrier Injection Mode for Realizing One Line-to-Three LEDs Driving Method. IEEE Trans. Electron Devices 2024, 71, 2486–2490. [Google Scholar] [CrossRef]

- Liu, J.; Tang, M.; Deng, H.; Shutts, S.; Wang, L.; Smowton, P.; Jin, C.-Y.; Chen, S.; Seeds, A.; Liu, H. Theoretical Analysis and Modelling of Degradation for III-V Lasers on Si. J. Phys. D Appl. Phys. 2022, 55, 404006. [Google Scholar] [CrossRef]

- Hosseinizadeh, S.F.; Tan, F.L.; Moosania, S.M. Experimental and Numerical Studies on Performance of PCM-Based Heat Sink with Different Configurations of Internal Fins. Appl. Therm. Eng. 2011, 31, 3827–3838. [Google Scholar] [CrossRef]

- Mikulics, M.; Kordoš, P.; Fox, A.; Kočan, M.; Lüth, H.; Sofer, Z.; Hardtdegen, H. Efficient heat dissipation in AlGaN/GaN heterostructure grown on silver substrate. Appl. Mater. Today 2017, 7, 134–137. [Google Scholar] [CrossRef]

- Zhao, M.; Tang, X.; Huo, W.; Han, L.; Deng, Z.; Jiang, Y.; Wang, W.; Chen, H.; Du, C.; Jia, H. Characteristics of AlGaN/GaN high electron mobility transistors on metallic substrate. Chin. Phys. B 2020, 29, 048104. [Google Scholar] [CrossRef]

- Peng, Y.; Mou, Y.; Wang, T.; Wang, H.; Liang, R.; Wang, X.; Chen, M.; Luo, X. Effective Heat Dissipation of QD-Based WLEDs by Stacking QD Film on Heat-Conducting Phosphor-Sapphire Composite. IEEE Trans. Electron Devices 2019, 66, 2637–2642. [Google Scholar] [CrossRef]

- Sajjad, U.; Sadeghianjahromi, A.; Ali, H.M.; Wang, C.C. Enhanced pool boiling of dielectric and highly wetting liquids—A review on surface engineering. Appl. Therm. Eng. 2021, 195, 117074. [Google Scholar] [CrossRef]

- McGlen, R.J.; Jachuck, R.; Lin, S. Integrated thermal management techniques for high power electronic devices. Appl. Therm. Eng. 2004, 24, 11431156. [Google Scholar] [CrossRef]

- Yin, Z.; Zhang, X.; Huang, Z.; Liu, S.; Zhang, W.; Liu, Y.; Wu, X.; Fang, M.; Min, X. Paraffin/expanded graphite phase change composites with enhanced thermal conductivity prepared by implanted β-SiC nanowires with chemical vapor deposition method. Mater. Res. Express 2018, 5, 025503. [Google Scholar] [CrossRef]

- Wang, H.; Wang, F.; Li, Z.; Tang, Y.; Yu, B.; Yuan, W. Experimental Investigation on the Thermal Performance of a Heat Sink Filled with Porous Metal Fiber Sintered Felt/Paraffin Composite Phase Change Material. Appl. Energy 2016, 176, 221–232. [Google Scholar] [CrossRef]

- Meng, E.; Cai, R.; Sun, Z.; Yang, J.; Wang, J. Experimental Study of the Passive and Active Performance of Real-Scale Composite PCM Room in Winter. Appl. Therm. Eng. 2021, 185, 116418. [Google Scholar] [CrossRef]

- Samimi, F.; Babapoor, A.; Azizi, M.; Karimi, G. Thermal Management Analysis of a Li-Ion Battery Cell Using Phase Change Material Loaded with Carbon Fibers. Energy 2016, 96, 355–371. [Google Scholar] [CrossRef]

- Mousavi, S.; Siavashi, M.; Zadehkabir, A. A New Design for Hybrid Cooling of Li-Ion Battery Pack Utilizing PCM and Mini Channel Cold Plates. Appl. Therm. Eng. 2021, 197, 117398. [Google Scholar] [CrossRef]

- Raj, C.R.; Suresh, S.; Singh, V.K.; Bhavsar, R.R.; Vasudevan, S.; Archita, V. Experimental Investigation on Nanoalloy Enhanced Layered Perovskite PCM Tamped in a Tapered Triangular Heat Sink for Satellite Avionics Thermal Management. Int. J. Therm. Sci. 2021, 167, 107007. [Google Scholar] [CrossRef]

- Li, Z.; Wu, Y.; Zhuang, B.; Zhao, X.; Tang, Y.; Ding, X.; Chen, K. Preparation of Novel Copper-Powder-Sintered Frame/Paraffin Form-Stable Phase Change Materials with Extremely High Thermal Conductivity. Appl. Energy 2017, 206, 1147–1157. [Google Scholar] [CrossRef]

- Fang, X.; Fan, L.-W.; Ding, Q.; Yao, X.-L.; Wu, Y.-Y.; Hou, J.-F.; Wang, X.; Yu, Z.-T.; Cheng, G.-H.; Hu, Y.-C. Thermal Energy Storage Performance of Paraffin-Based Composite Phase Change Materials Filled with Hexagonal Boron Nitride Nanosheets. Energy Convers. Manag. 2014, 80, 103–109. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Lohrasbi, S.; Ganji, D.D.; Nsofor, E.C. Accelerated Melting of PCM in Energy Storage Systems via Novel Configuration of Fins in the Triplex-Tube Heat Exchanger. Int. J. Heat Mass Transf. 2018, 124, 663–676. [Google Scholar] [CrossRef]

- Tamraparni, A.; Hoe, A.; Deckard, M.; Zhang, C.; Elwany, A.; Shamberger, P.J.; Felts, J.R. Design and Optimization of Lamellar Phase Change Composites for Thermal Energy Storage. Adv. Eng. Mater. 2021, 23, 2001052. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, J.; Li, H.; Cui, Y.; Li, X. Enhanced Thermal Properties for Nanoencapsulated Phase Change Materials with Functionalized Graphene Oxide (FGO) Modified PMMA. Nanotechnology 2020, 31, 295704. [Google Scholar] [CrossRef] [PubMed]

- Ghalambaz, M.; Zhang, J. Conjugate Solid-Liquid Phase Change Heat Transfer in Heatsink Filled with Phase Change Material-Metal Foam. Int. J. Heat Mass Transf. 2020, 146, 118832. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, Z.; Zhang, H.; Sun, X.; Dou, B.; Wu, W.; Zhang, G.; Jiang, L. Experimental Investigation of the Comprehensive Heat Transfer Performance of PCMs Filled with CMF in a Heat Storage Device. Int. J. Heat Mass Transf. 2022, 188, 122582. [Google Scholar] [CrossRef]

- Yu, S.; Wang, X.; Wu, D. Microencapsulation of n-octadecane Phase Change Material with Calcium Carbonate Shell for Enhancement of Thermal Conductivity and Serving Durability: Synthesis, Microstructure, and Performance Evaluation. Appl. Energy 2014, 114, 632–643. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Das, M.K.; Rath, P. Application of TCE-PCM Based Heat Sinks for Cooling of Electronic Components: A Review. Renew. Sustain. Energy Rev. 2016, 59, 550–582. [Google Scholar] [CrossRef]

- Ali, H.M.; Arshad, A.; Jabbal, M.; Verdin, P.G. Thermal Management of Electronics Devices with PCMs Filled Pin-Fin Heat Sinks: A Comparison. Int. J. Heat Mass Transf. 2018, 117, 1199–1204. [Google Scholar] [CrossRef]

- Arshad, A.; Ali, H.M.; Yan, W.-M.; Hussein, A.K.; Ahmadlouydarab, M. An Experimental Study of Enhanced Heat Sinks for Thermal Management Using n-eicosane as Phase Change Material. Appl. Therm. Eng. 2018, 132, 52–66. [Google Scholar] [CrossRef]

- Qureshi, F.A.; Ahmad, N.; Ali, H.M. Heat Dissipation in Bituminous Asphalt Catalyzed by Different Metallic Oxide Nanopowders. Constr. Build. Mater. 2021, 276, 122220. [Google Scholar] [CrossRef]

- Khan, M.A.; Imam, M.K.; Irshad, K.; Ali, H.M.; Hasan, M.A.; Islam, S. Comparative Overview of the Performance of Cementitious and Non-cementitious Nanomaterials in Mortar at Normal and Elevated Temperatures. Nanomaterials 2021, 11, 911. [Google Scholar] [CrossRef]

- Mishra, S.R.; Mathur, P.; Ali, H.M. Analysis of Homogeneous–Heterogeneous Reactions in a Micropolar Nanoflid past a Nonlinear Stretching Surface: Semi-analytical Approach. J. Therm. Anal. Calorim. 2021, 144, 2247–2257. [Google Scholar] [CrossRef]

- Zehri, A.; Samani, M.K.; Latorre, M.G.; Nylander, A.; Nilsson, T.; Fu, Y.; Wang, N.; Ye, L.; Liu, J. High Porosity and Light Weight Graphene Foam Heat Sink and Phase Change Material Container for Thermal Management. Nanotechnology 2020, 31, 424003. [Google Scholar] [CrossRef] [PubMed]

- Baby, R.; Balaji, C. Experimental Investigations on Thermal Performance Enhancement and Effect of Orientation on Porous Matrix Filled PCM Based Heat Sink. Int. Commun. Heat Mass Transf. 2013, 46, 27–30. [Google Scholar] [CrossRef]

- Rehman, T.; Ali, H.M. Experimental Study on the Thermal Behavior of RT-35HC Paraffi Within Copper and Iron-Nickel Open Cell Foams: Energy Storage for Thermal Management of Electronics. Int. J. Heat Mass Transf. 2020, 146, 118852. [Google Scholar] [CrossRef]

- Rehman, T.; Ali, H.M. Thermal Performance Analysis of Metallic Foam-Based Heat Sinks Embedded with RT-54HC Paraffi: An Experimental Investigation for Electronic Cooling. J. Therm. Anal. Calorim. 2020, 140, 979–990. [Google Scholar] [CrossRef]

| AS/PCM | DPAS6585/PCM | DPAS8565/PCM | DPAS6090/PCM | DPAS9060/PCM | UAS/PCM |

|---|---|---|---|---|---|

| k (W/m·K) | 12.23 | 10.92 | 11.74 | 8.7 | 11.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Long, C.; Hu, Z.; Xu, Y.; Zhang, B.; Zhi, C. Thermal Performance of Heat Sink Filled with Double-Porosity Porous Aluminum Skeleton/Paraffin Phase Change Material. Micromachines 2024, 15, 806. https://doi.org/10.3390/mi15060806

Huang S, Long C, Hu Z, Xu Y, Zhang B, Zhi C. Thermal Performance of Heat Sink Filled with Double-Porosity Porous Aluminum Skeleton/Paraffin Phase Change Material. Micromachines. 2024; 15(6):806. https://doi.org/10.3390/mi15060806

Chicago/Turabian StyleHuang, Shufeng, Chuanshun Long, Zhihan Hu, Yingshuai Xu, Bin Zhang, and Changjian Zhi. 2024. "Thermal Performance of Heat Sink Filled with Double-Porosity Porous Aluminum Skeleton/Paraffin Phase Change Material" Micromachines 15, no. 6: 806. https://doi.org/10.3390/mi15060806

APA StyleHuang, S., Long, C., Hu, Z., Xu, Y., Zhang, B., & Zhi, C. (2024). Thermal Performance of Heat Sink Filled with Double-Porosity Porous Aluminum Skeleton/Paraffin Phase Change Material. Micromachines, 15(6), 806. https://doi.org/10.3390/mi15060806