Application of Python-Based Abaqus Secondary Development in Laser Shock Forming of Aluminum Alloy 6082-T6

Abstract

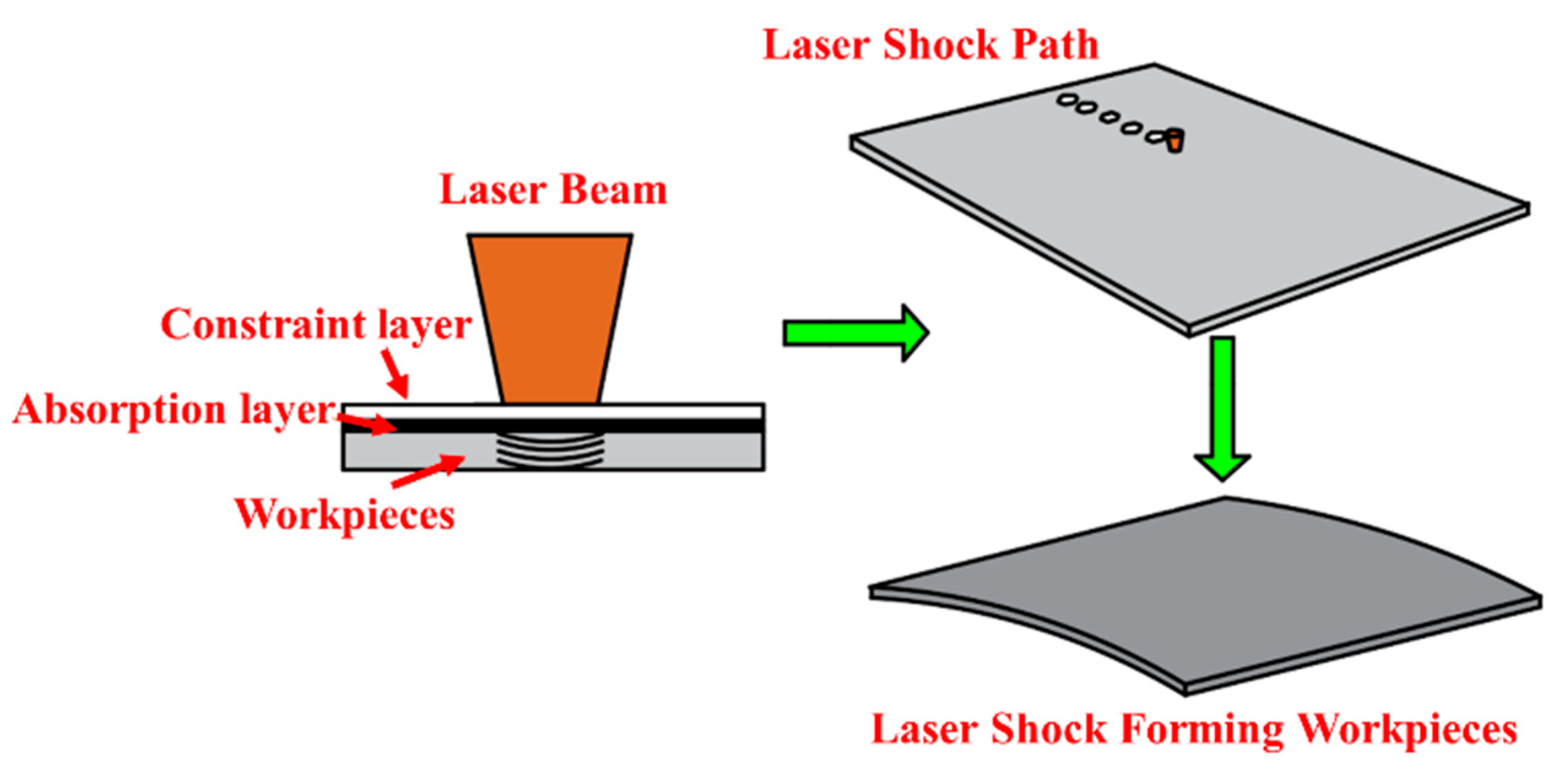

1. Introduction

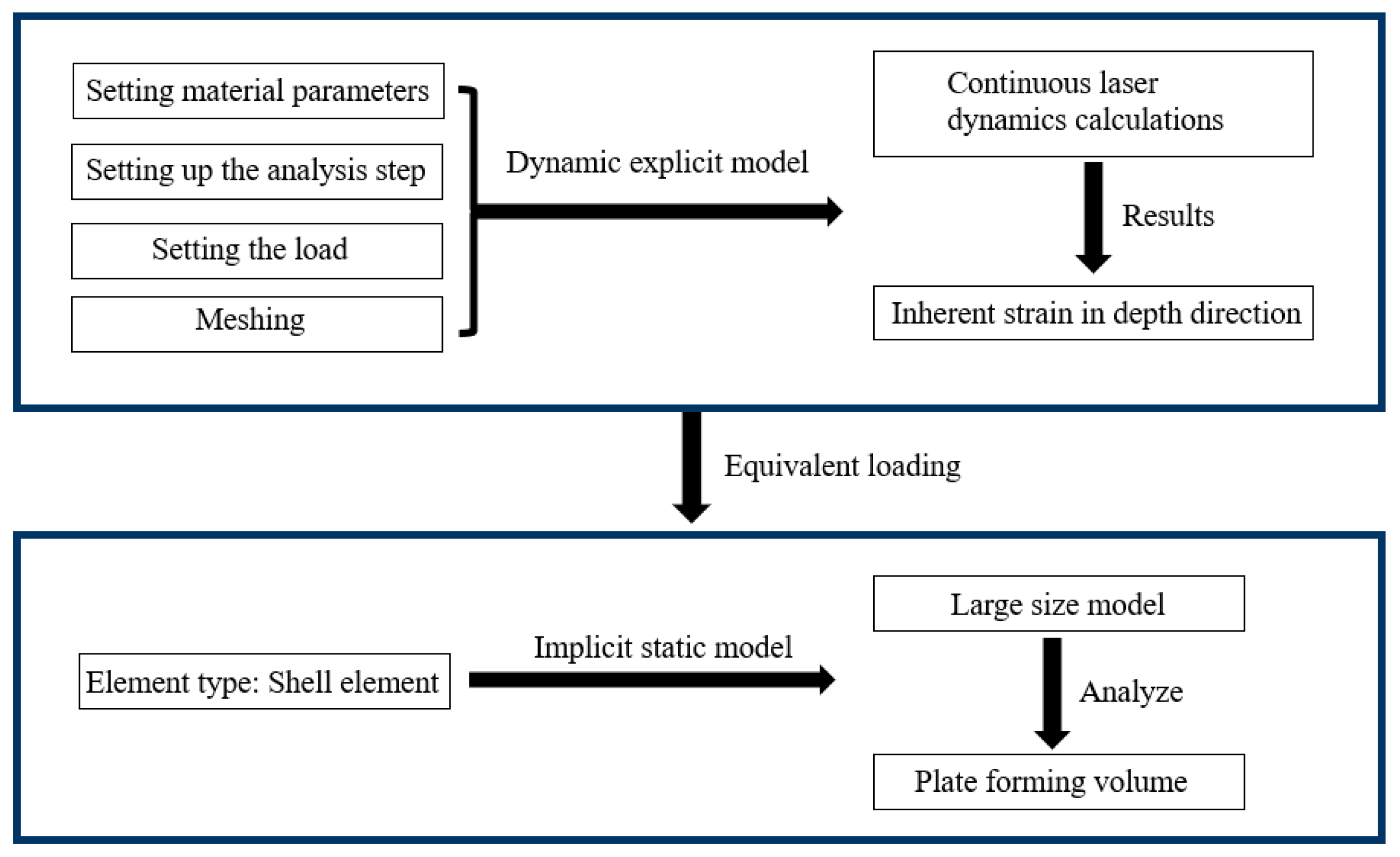

2. Finite Element Model

2.1. Inherent Strain Theory

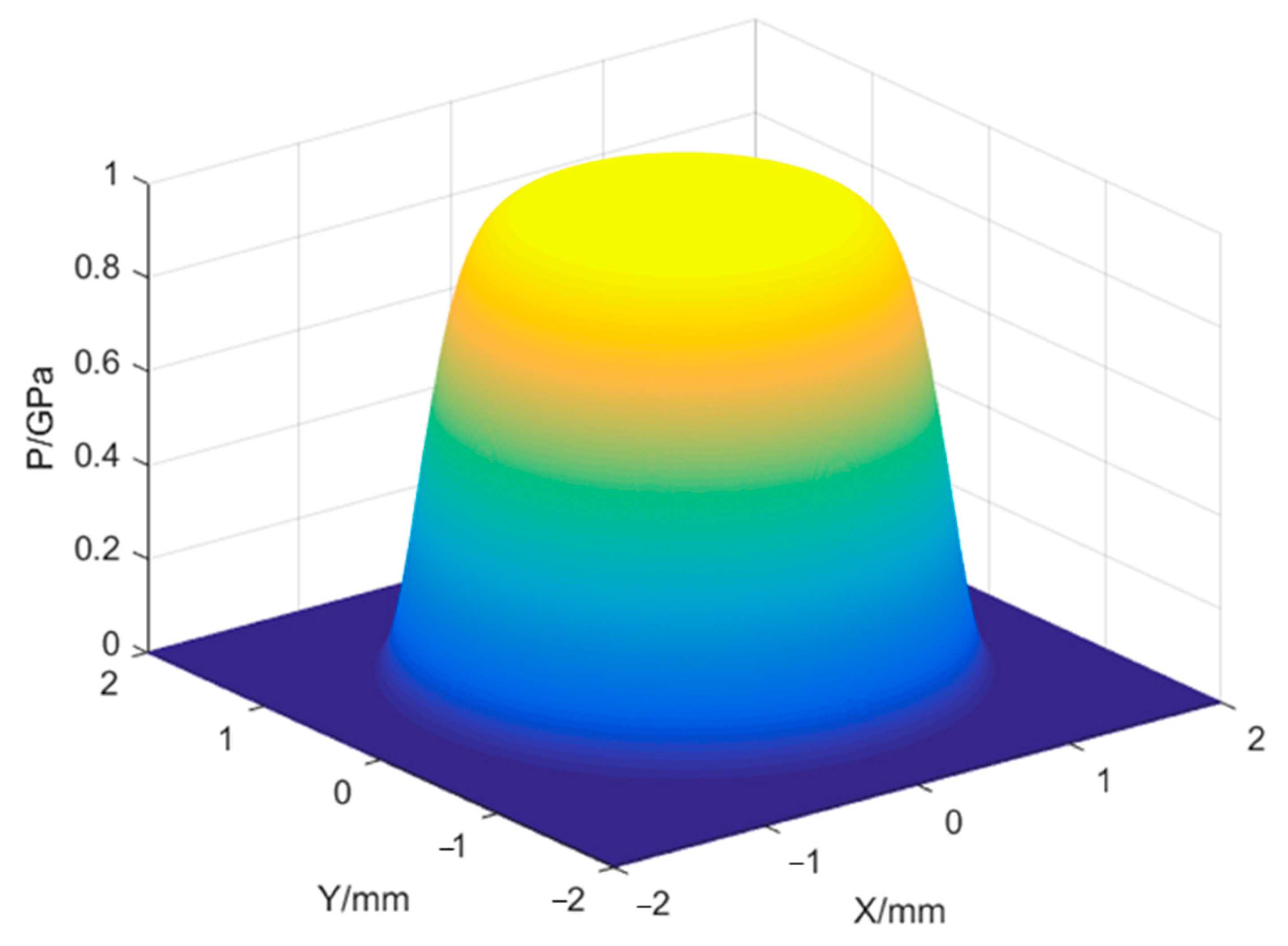

2.2. Shock Wave Pressure and Material Constitutive Model

2.2.1. Shock Wave Pressure Model

2.2.2. Material Constitutive Model

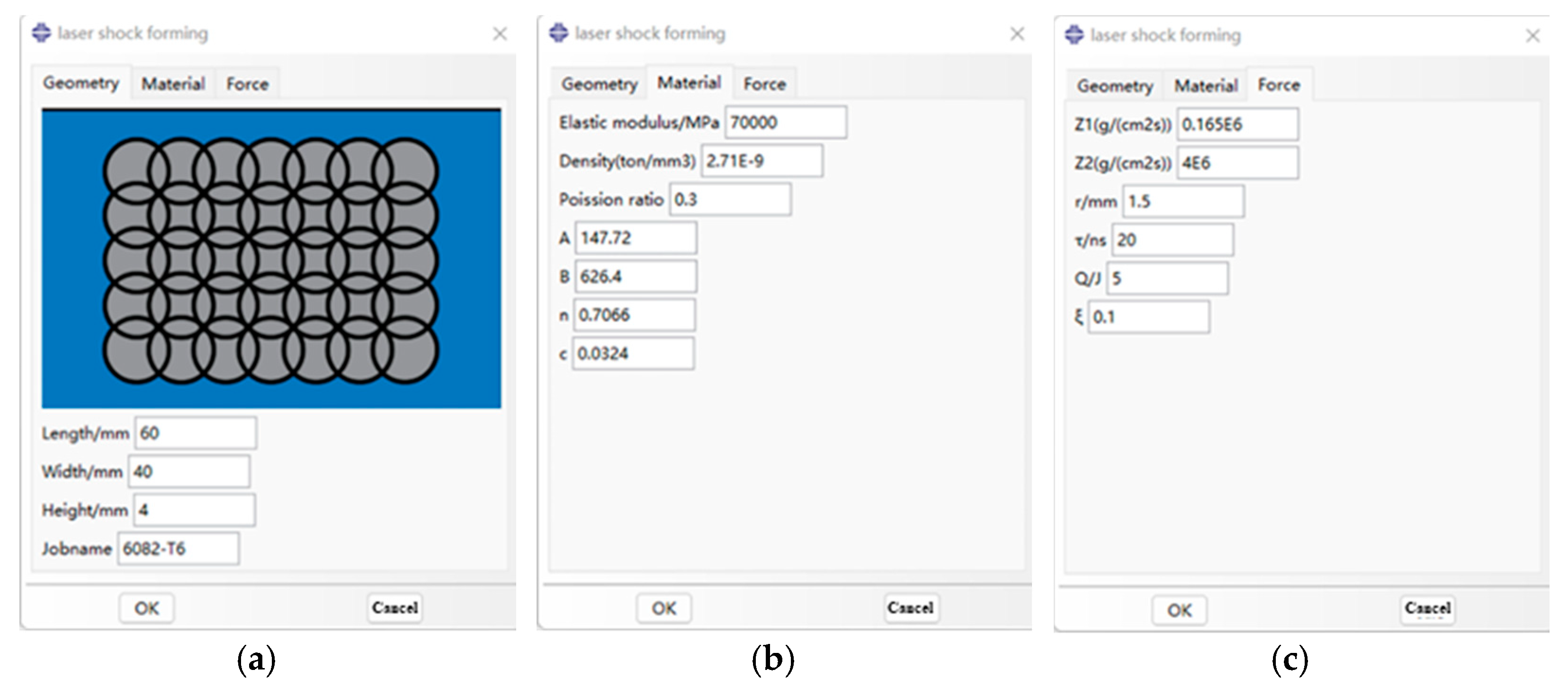

2.3. Design of Plugin Program for Aluminum Alloy 6082-T6

2.3.1. Dynamic Display Model’s Secondary Development

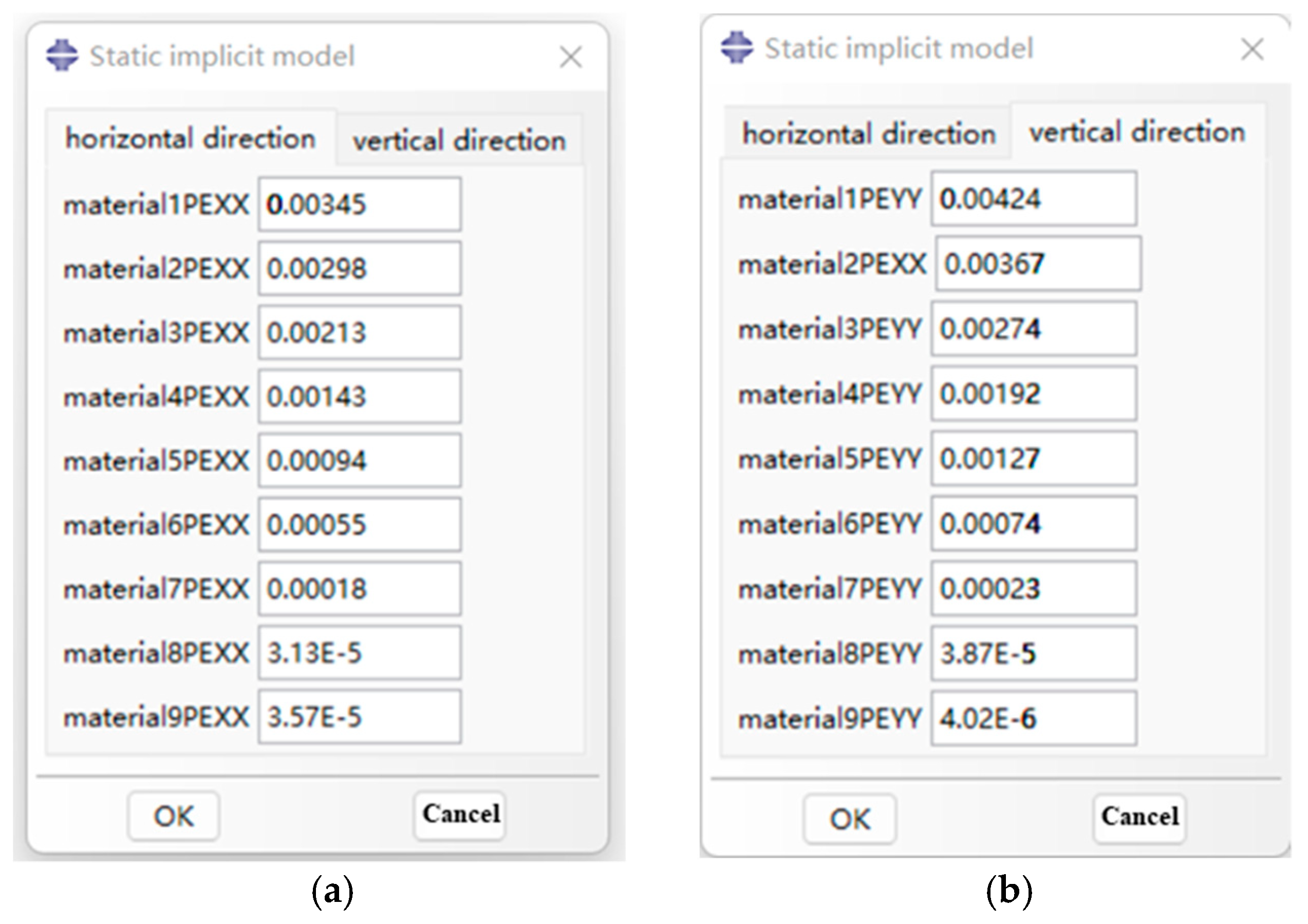

2.3.2. Implicit Static Layered Shell Model’s Secondary Development

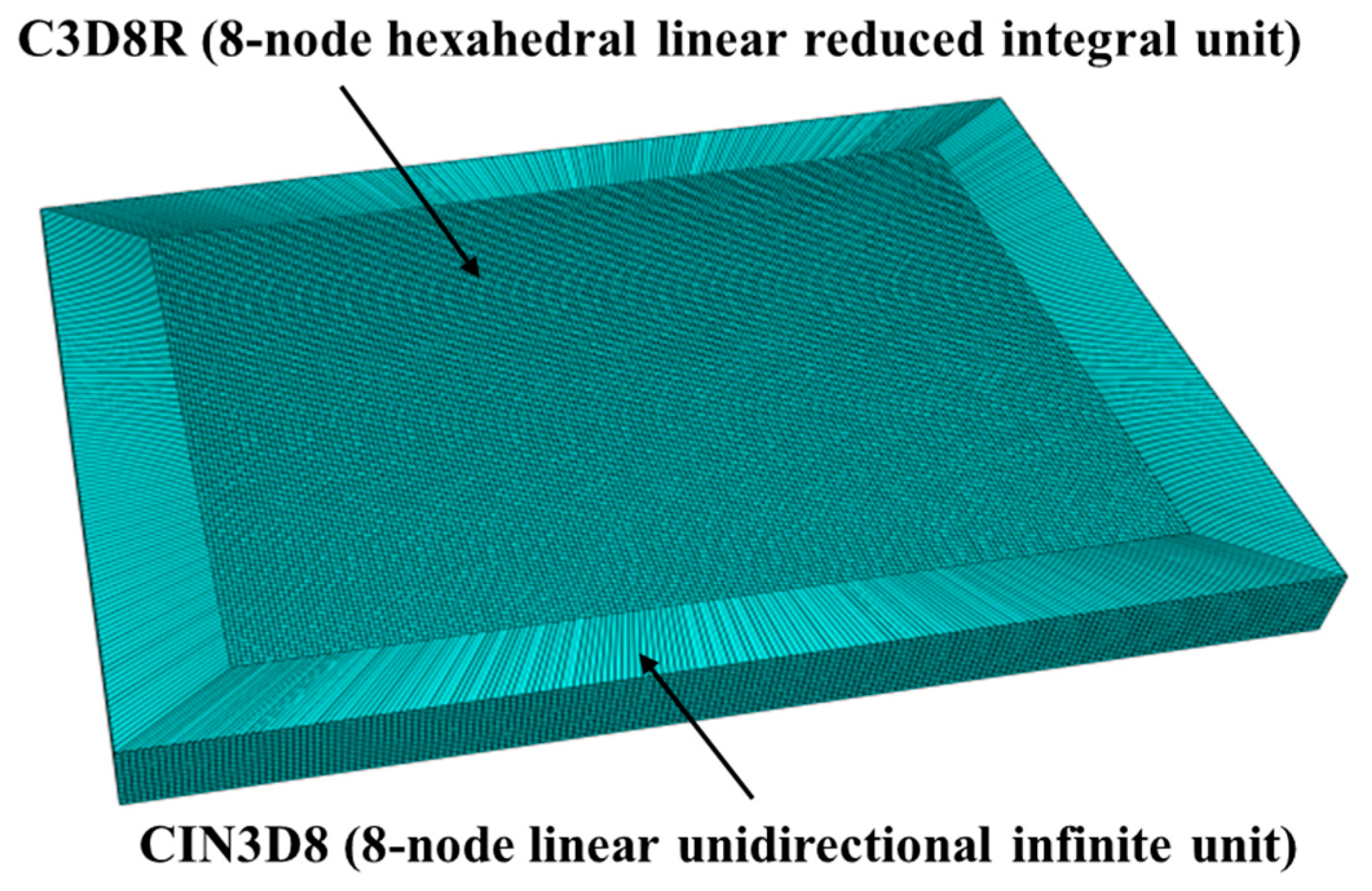

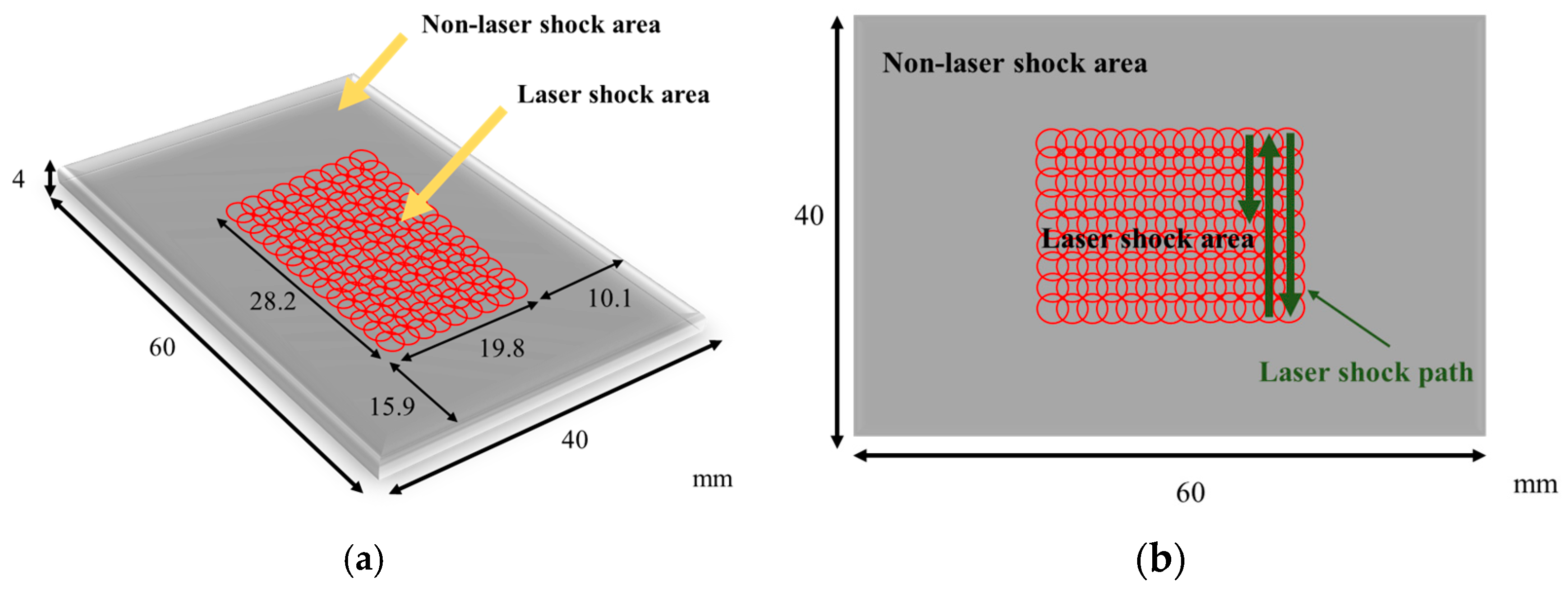

2.4. Model Geometry and Meshing

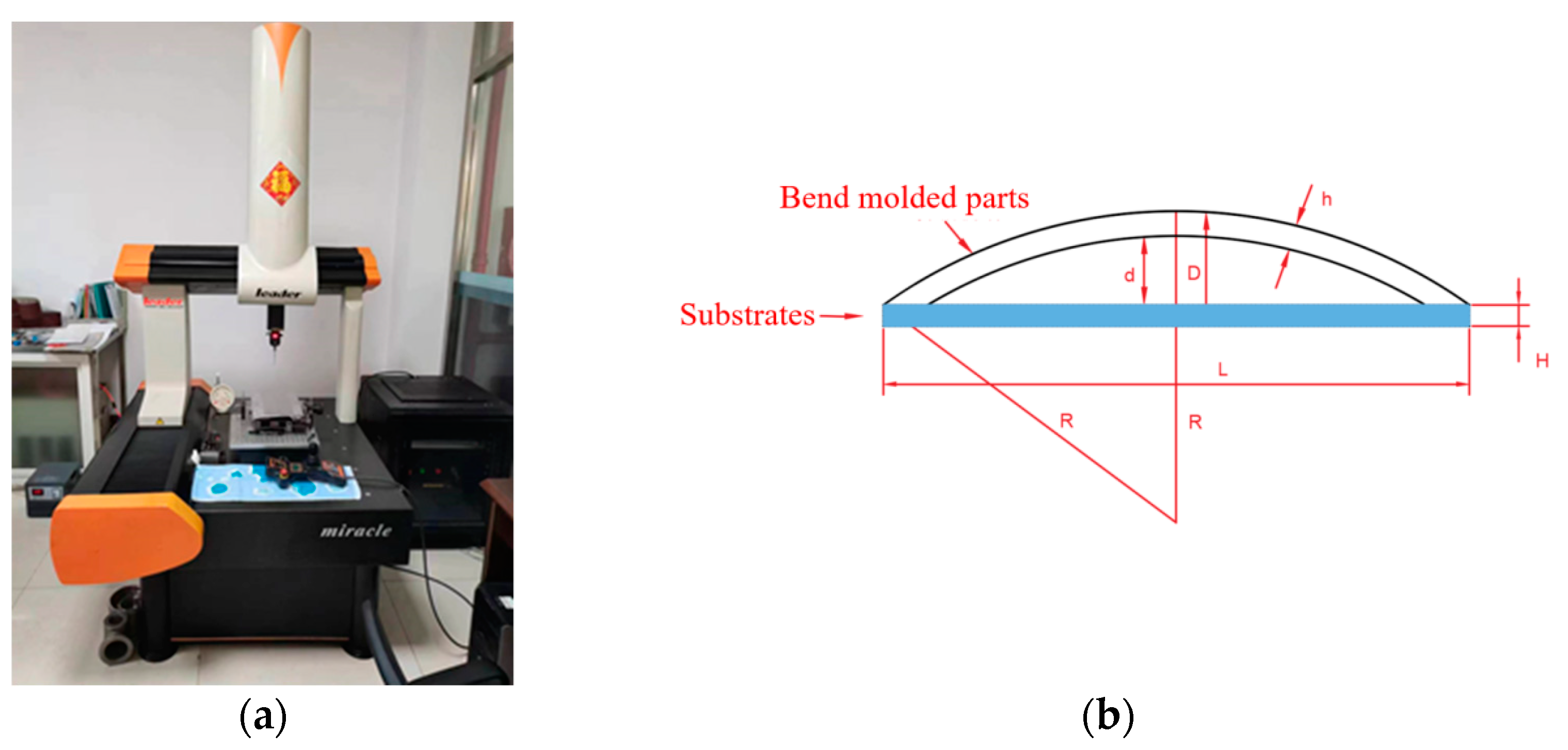

2.5. Methodology for Experimental Validation of Finite Element Models

3. Results and Analysis

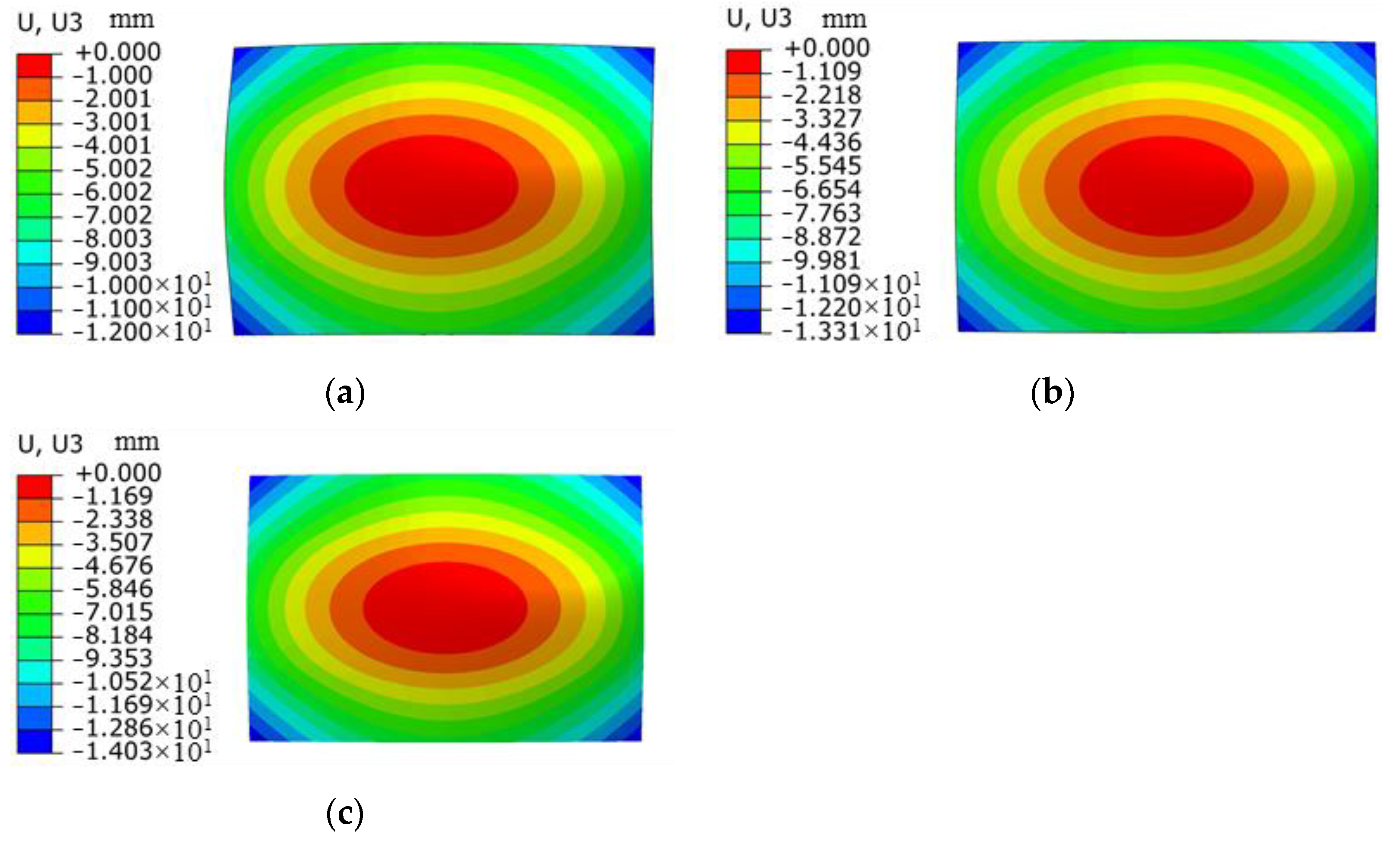

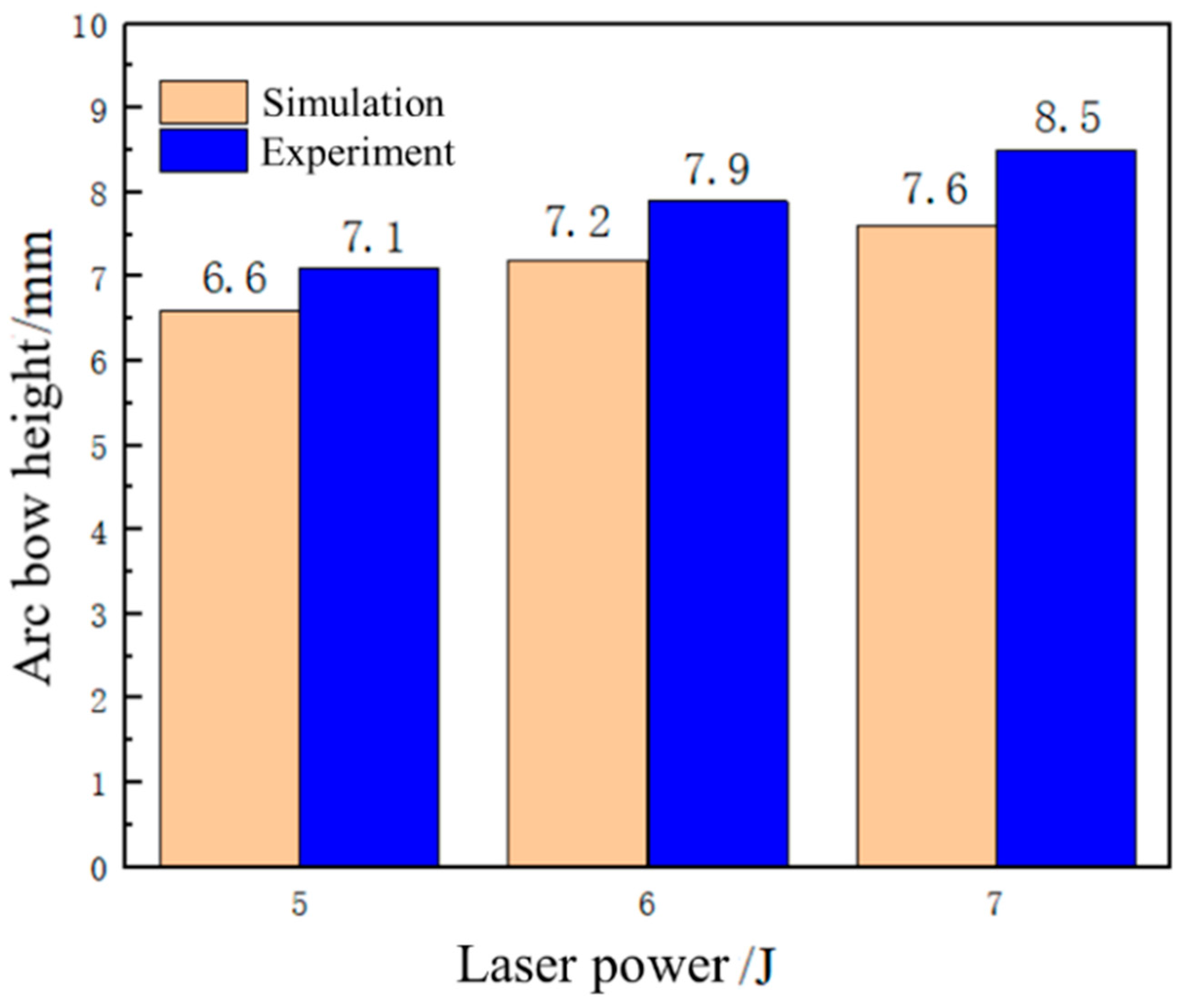

3.1. Finite Element Model Verification

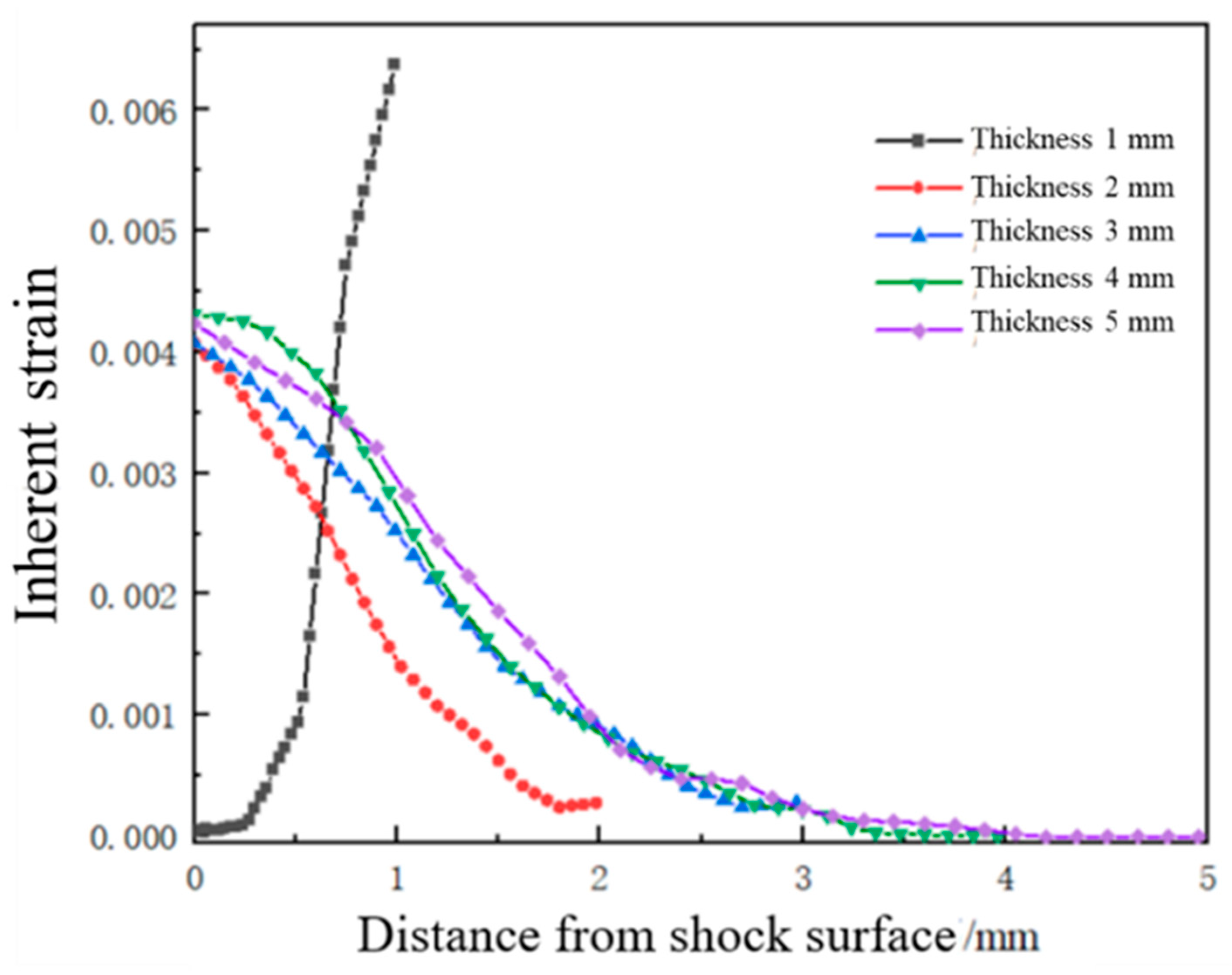

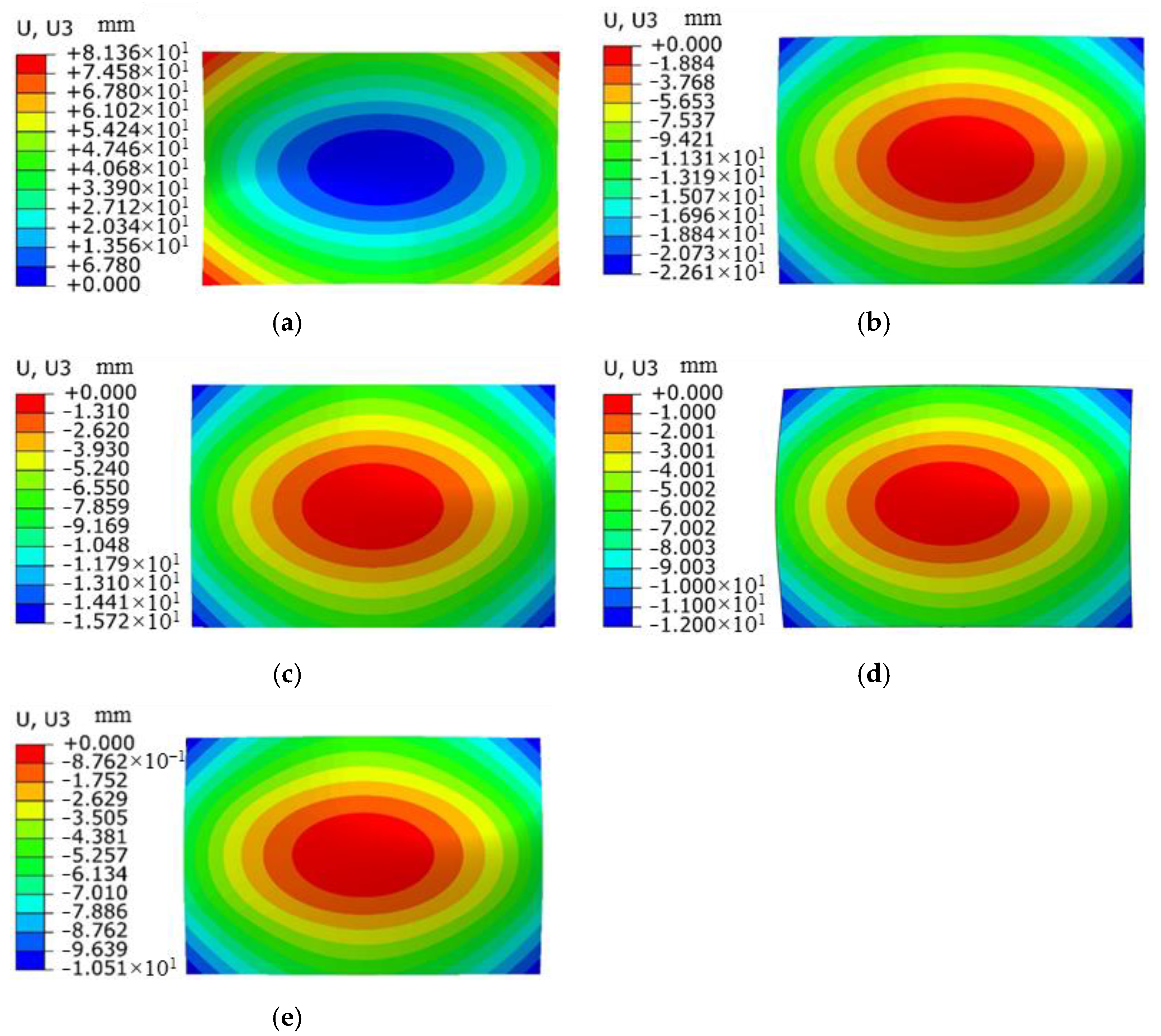

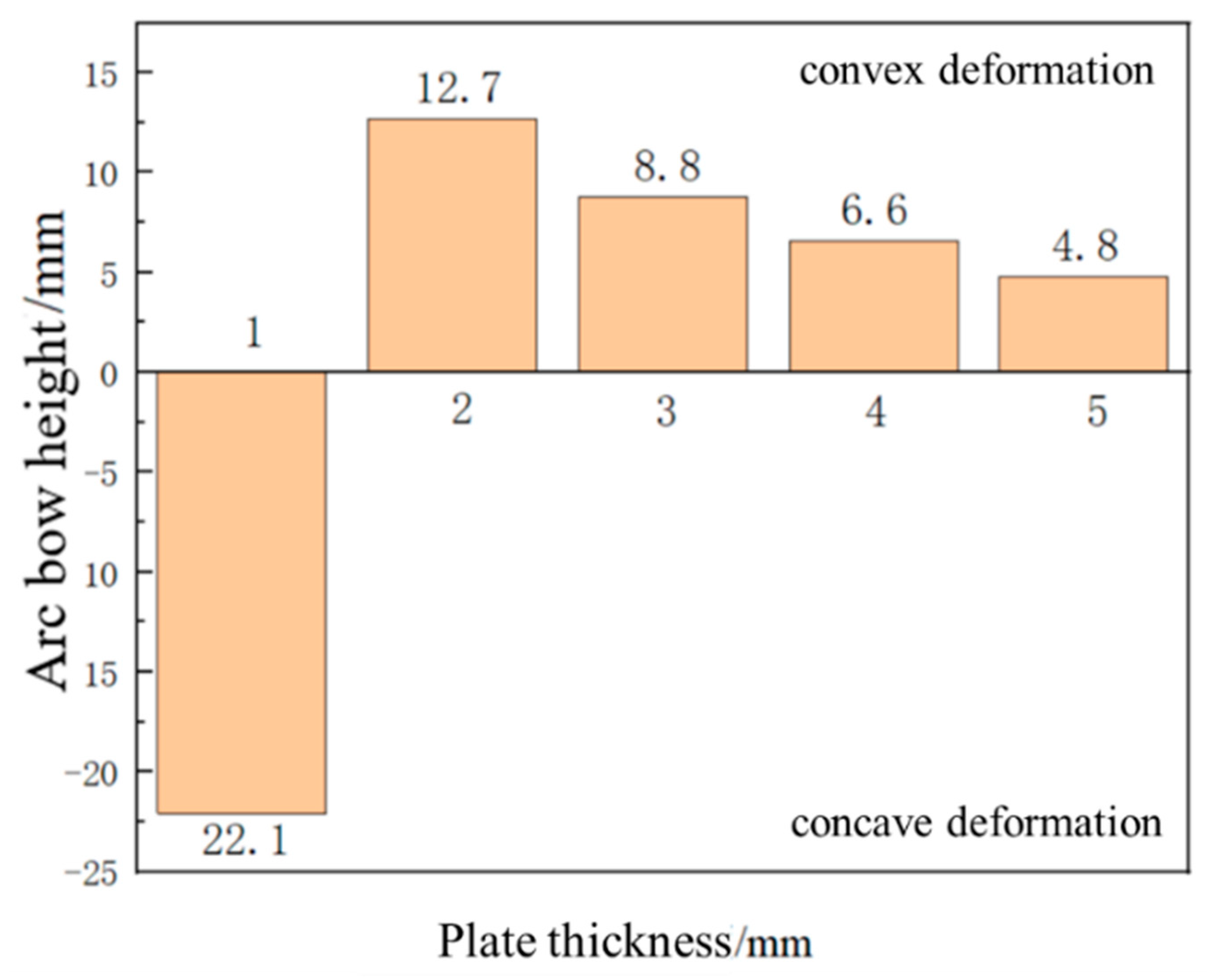

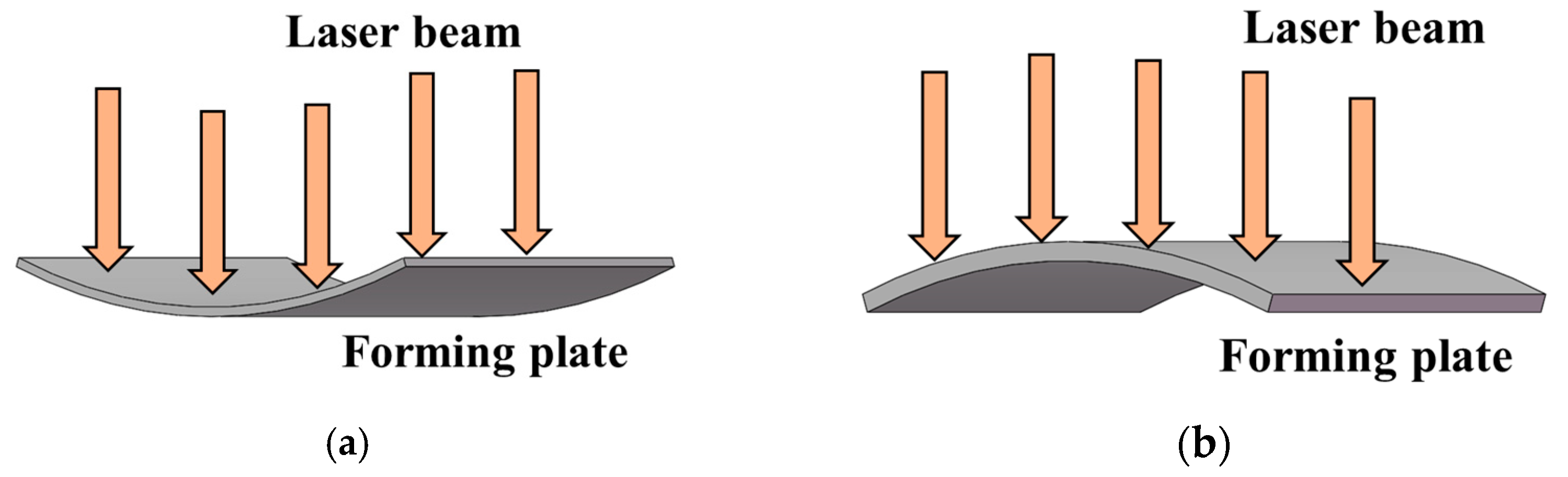

3.2. Effect of Plate Thickness on Forming Quantity of the Plate

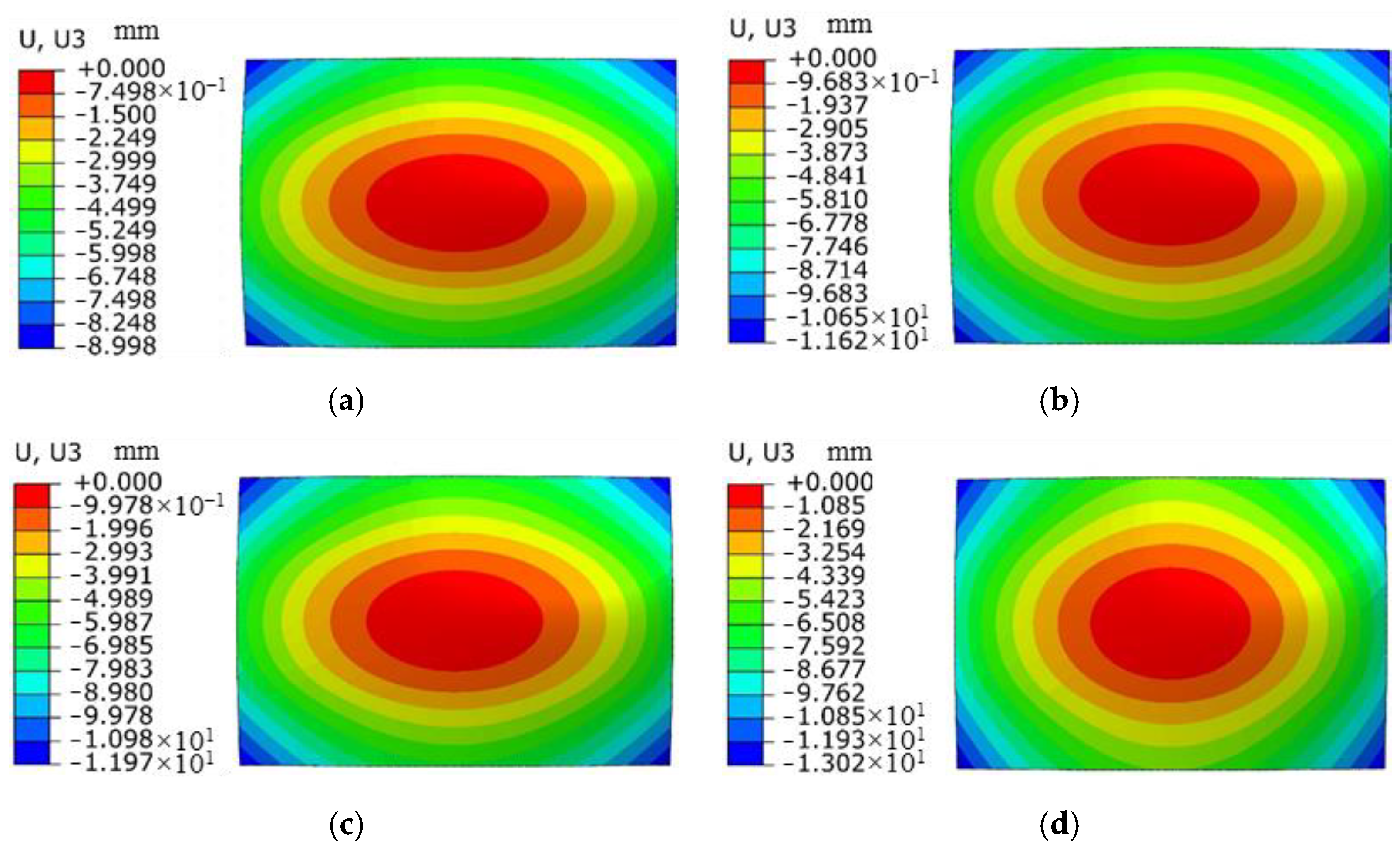

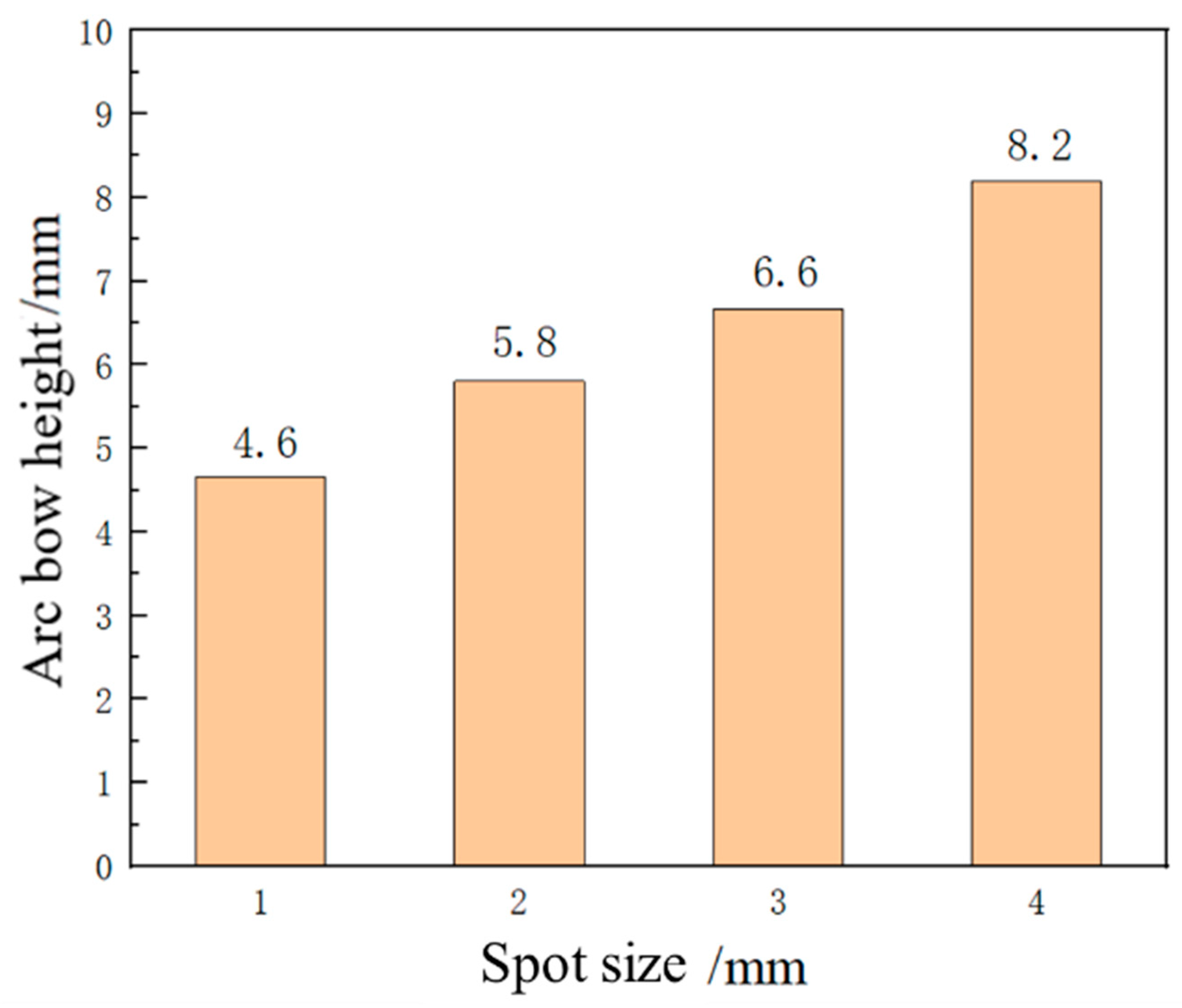

3.3. Effect of Spot Size on Forming Quantity of the Plate

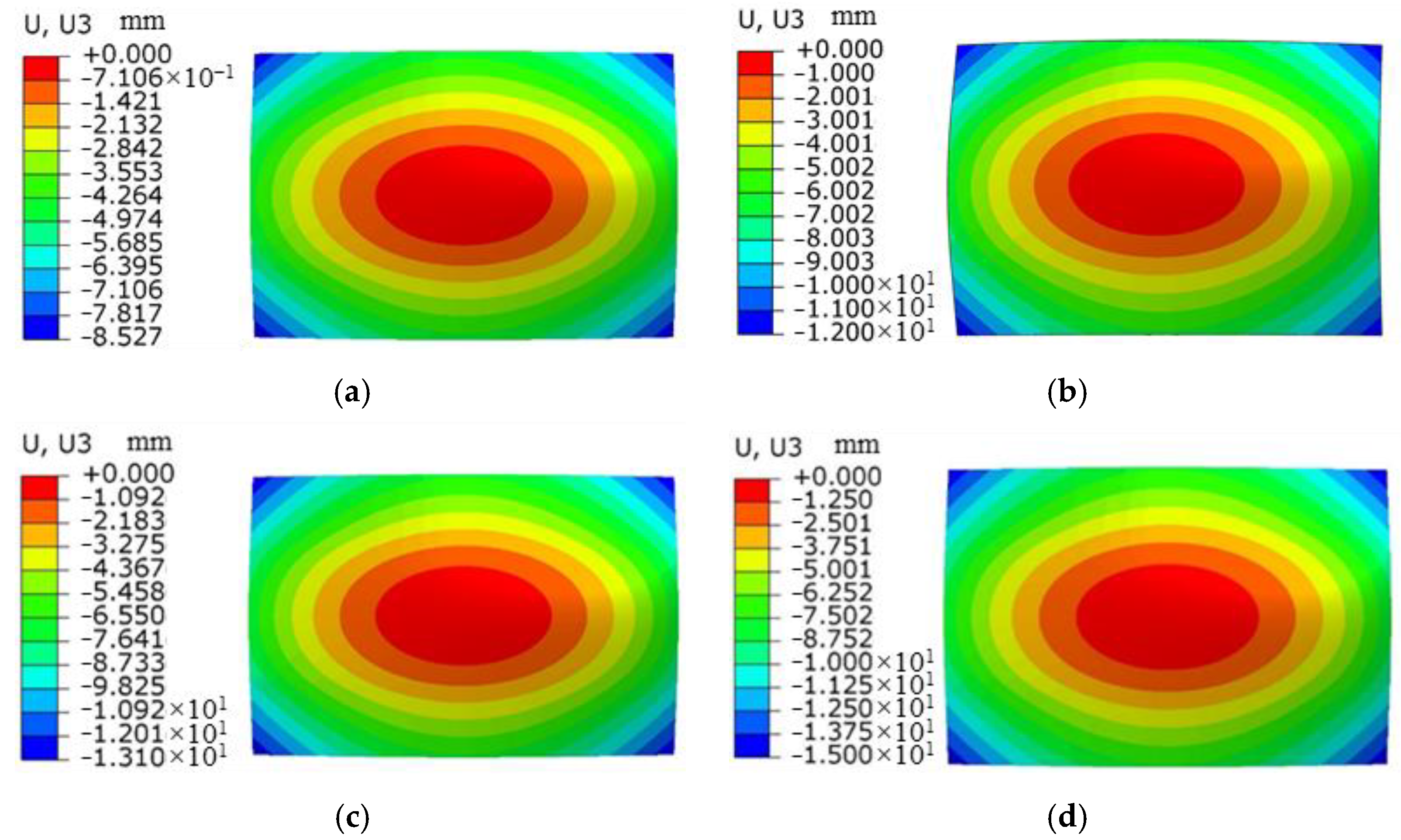

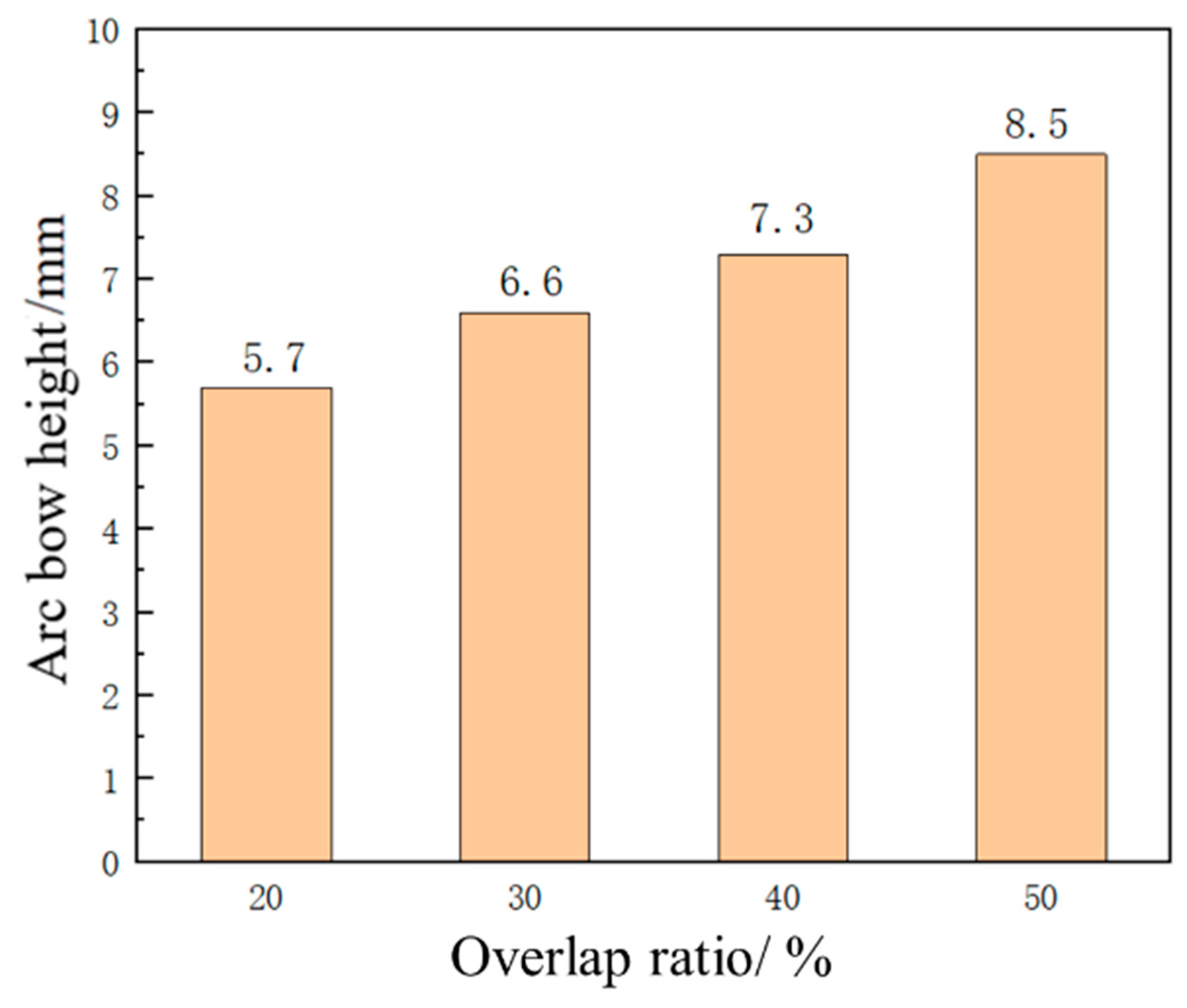

3.4. Effect of Overlap Ratio on Forming Quantity of the Plate

4. Conclusions

- (1)

- The plugin can quickly establish an explicit dynamic model and extract the distribution of intrinsic strain along the depth direction of the characteristic unit. Then, it is applied to an implicit static model, and the bending forming amount of the sheet after laser impact forming is predicted through elastic analysis. The simulation results have small errors.

- (2)

- The laser energy has a large effect on the amount of plate formed, which increases as the laser energy increases.

- (3)

- When the thickness of the sheet is 1 mm, the sheet undergoes concave deformation in the direction of the impact. With the increase in thickness, the bending forming amount of the sheet decreases, and the sheet exhibits convex deformation.

- (4)

- Under the same laser power density, the forming amount of the sheet increases with the increase in spot size.

- (5)

- With the increase in the overlap ratio, the arc height of the sheet gradually increases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Qiao, H.; Lu, Y.; Zhao, J.; Sun, B. The plastic flow mechanism and precise forming method of 7075 aluminum plate in laser shock forming. Opt. Laser Technol. 2023, 167, 109823. [Google Scholar] [CrossRef]

- Yan, Z.; Xingquan, Z. Effect of Sheet Thickness on Forming Precision in Single Laser Shock Forming with Mold. J. Phys. Conf. Ser. 2023, 2617, 012013. [Google Scholar] [CrossRef]

- Wanli, M.; Changzhi, J. Effect Analysis of Laser Shock Peening on Nickel-based Alloys by Laser Solid Forming. J. Phys. Conf. Ser. 2021, 1865, 022049. [Google Scholar]

- Correa, C.; De Lara, L.R.; Diaz, M.; Porro, J.A.; García-Beltran, A.; Ocana, J.L. Influence of pulse sequence and edge material effect on fatigue life of Al2024-T351 specimens treated by laser shock processing. Int. J. Fatigue 2015, 70, 196–204. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, C.F.; Lu, Y.F.; Nastasi, M.; Cui, B. Laser shock processing of polycrystalline alumina ceramics. Am. Ceram. Soc. 2017, 100, 911–919. [Google Scholar] [CrossRef]

- Rao, X.; Ye, Y.; Zhao, L.; Ren, X.; Li, L. Experimental research on nanosecond laser shock forming of 2024 aluminum alloy shaped parts. Laser Optoelectron. Prog. 2018, 55, 301–308. [Google Scholar]

- Yu, Q.; Dong, Z.; Miao, R.; Deng XChen, L. Bending deformation of laser peened aluminium alloy with uniform rectangular spots. Mater. Sci. Technol. 2016, 32, 45–49. [Google Scholar] [CrossRef]

- Morales, M.; Porro, J.A.; Garcia Ballesteros, J.J.; Molpeceres, C.; Ocana, J.L. Effect of plasma confinement on laser shock microforming of thin metal sheets. Appl. Surf. Sci. 2011, 257, 5408–5412. [Google Scholar] [CrossRef]

- Hu, Y.; Grandhi, R.V. Efficient numerical prediction of residual stress and deformation for large-scale laser shock processing using the eigenstrain methodology. Surf. Coat. Technol. 2012, 206, 3374–3385. [Google Scholar] [CrossRef]

- Luo, M.S.; Hu, Y.X.; Hu, L.; Yao, Z.Q. Efficient process planning of laser peen forming for complex shaping with distributed eigen-moment. J. Mater. Process. Technol. 2020, 279, 116588. [Google Scholar] [CrossRef]

- Gachegova, E.A.; Sikhamov, R.; Ventzke, V.; Kashaev, N.; Plekhov, O.A. Influence of laser shock peening on low- and high-cycle fatigue of an OT4-0 titanium alloy. J. Appl. Mech. Tech. Phys. 2022, 63, 335–342. [Google Scholar] [CrossRef]

- Chen, F.; Wang, C.; Li, W.; Yang, J. Application of ABAQUS secondary development in simulation of shot peening strengthening of aerospace arch structures. Comput. Aided Eng. 2020, 29, 55–60. [Google Scholar]

- Rong, G.; Peng, Y.; Tian, K. Application of ABAQUS finite element strength reduction method program based on Python in slope stability analysis. J. North Univ. 2021, 42, 332–339. [Google Scholar]

- Li, S.; Jeanmeure LF, C.; Pan, Q. A composite material characterisation tool: UnitCells. J. Eng. Math. 2015, 95, 279–293. [Google Scholar] [CrossRef]

- Zhang, S.F.; Wang, X.M.; Lv, G.M.; Li, J.; Liu, Y. Application of Python-based secondary development in the simulation of 3D profile stretch bending forming. In Proceedings of the 2021 IEEE International Conference on Electrical Engineering and Mechatronics Technology (ICEEMT), Qingdao, China, 2–4 July 2021. [Google Scholar]

- Bellet, M.; Tematio, K.J.; Zhang, Y. The inherent strain method for simulation of additive manufacturing–A critical assessment based on a new variant of the method. Int. J. Numer. Methods Eng. 2023, 125, e7378. [Google Scholar] [CrossRef]

- Guo, K.; Huang, Z.; Tu, Y.; Qie, Y.; Qiao, L.; Anwer, N. Improved inherent strain extraction algorithm based analytical surface modeling for Ti-6Al-4V and SS316L selective laser melting part. J. Manuf. Processes 2023, 101, 618–638. [Google Scholar] [CrossRef]

- Xue, Z.; Qu, W.; Chai, P.; Zhang, Y. Research progress on welding deformation prediction technology. Weld. J. 2003, 24, 87–90. [Google Scholar]

- Fabbro, R.; Fournier, J.; Ballard, P. Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Correa, C.; Lara, L.R.D.; Díaz, M.; Gil-Santos, A.; Porro, J.A.; Ocaña, J.L. Effect of advancing direction on fatigue life of 316L stainless steel specimens treated by double-sided laser shock peening. Int. J. Fatigue 2015, 79, 1–9. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, W.; Wang, C. Numerical simulation study on residual stress of laser shock strengthening. Laser Technol. 2016, 41, 1–5. [Google Scholar]

- Zerilli, F.J. Dislocation mechanics-based constitutive equations. Metall. Mater. Trans. A 2004, 35, 2547–2555. [Google Scholar] [CrossRef]

- Liang, R.; Khan, A.S. A critical review of experimental results and constitutive models for BCC and FCC metals over a wide range of strain rates and temperatures. Int. J. Plast. 1999, 15, 963–980. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rate and high temperatures. Eng. Fract. Mech. 1983, 21, 541–548. [Google Scholar]

- Mocko, W.; Radziejewska, J.; Sarzynski, A.; Strzelec, M.; Marczak, J. Analysis of the plastic deformation of AISI 304 steel induced by the nanosecond laser pulse. Opt. Laser Technol. 2017, 90, 165–173. [Google Scholar] [CrossRef]

- Peng, C.; Xiao, Y.Z.; Wang, Y.Z.; Guo, W. Effect of laser shock peening on bending fatigue performance of AISI 9310 steel spur gear. Opt. Laser Technol. 2017, 94, 15–24. [Google Scholar] [CrossRef]

- Xiao, Y.; Fang, Q.; Wu, H.; Gong, Z.; Kong, X. Sensitivity analysis of parameters of Johnson-Cook principal model. Appl. Math. Mech. 2015, 36, 21–28. [Google Scholar]

| Material | ρ g/cm3 | E/GPa | Poisson’s Ratio | A/MPa | B/MPa | n | C |

|---|---|---|---|---|---|---|---|

| 6082-T6 | 2.7 | 70 | 0.3 | 274.65 | 169.98 | 0.2806 | 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Zhang, T.; Kong, C.; Sun, B.; Zhu, R. Application of Python-Based Abaqus Secondary Development in Laser Shock Forming of Aluminum Alloy 6082-T6. Micromachines 2024, 15, 439. https://doi.org/10.3390/mi15040439

Yang J, Zhang T, Kong C, Sun B, Zhu R. Application of Python-Based Abaqus Secondary Development in Laser Shock Forming of Aluminum Alloy 6082-T6. Micromachines. 2024; 15(4):439. https://doi.org/10.3390/mi15040439

Chicago/Turabian StyleYang, Junru, Tongle Zhang, Chuijiang Kong, Boyu Sun, and Ran Zhu. 2024. "Application of Python-Based Abaqus Secondary Development in Laser Shock Forming of Aluminum Alloy 6082-T6" Micromachines 15, no. 4: 439. https://doi.org/10.3390/mi15040439

APA StyleYang, J., Zhang, T., Kong, C., Sun, B., & Zhu, R. (2024). Application of Python-Based Abaqus Secondary Development in Laser Shock Forming of Aluminum Alloy 6082-T6. Micromachines, 15(4), 439. https://doi.org/10.3390/mi15040439