Application of Amorphous and Nanocrystalline Soft Magnetic Materials in Balanced-Force-Type Electromagnetic Relay

Abstract

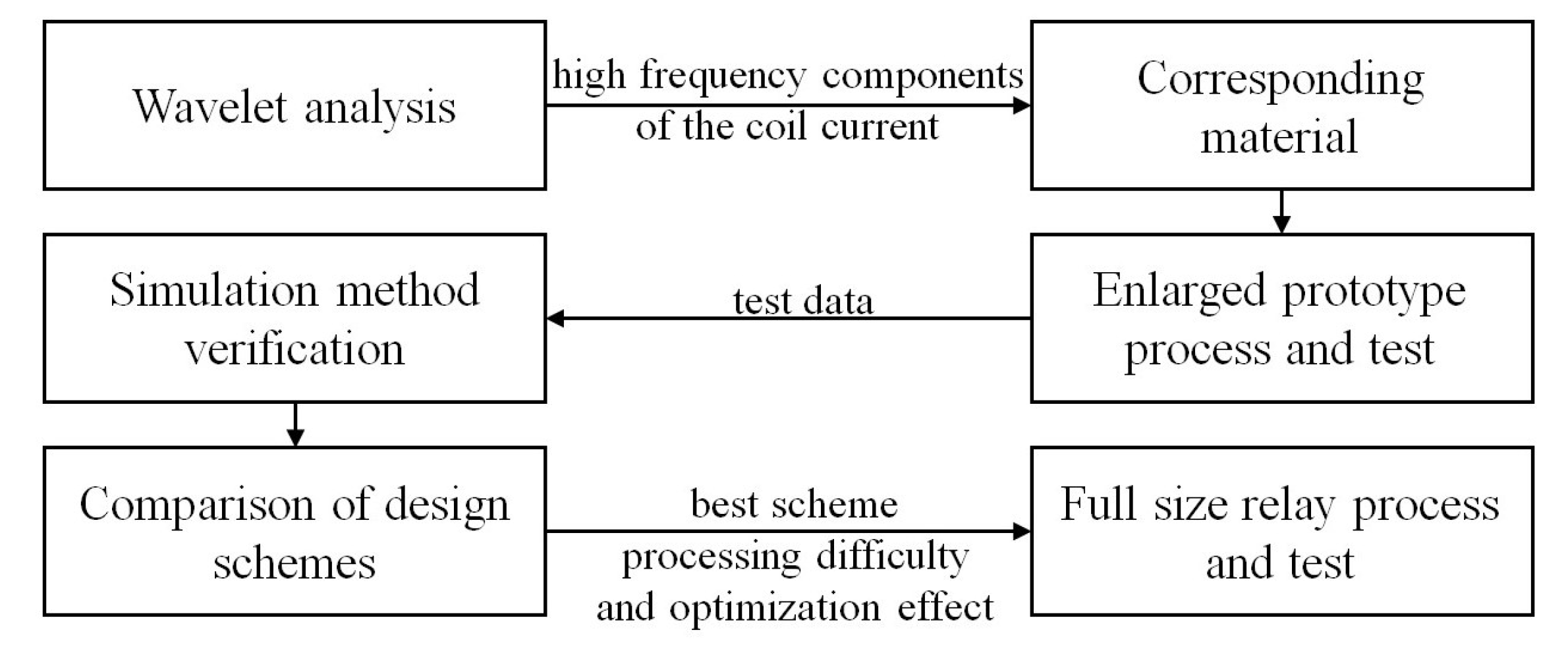

1. Introduction

2. Magnetic Material Selection

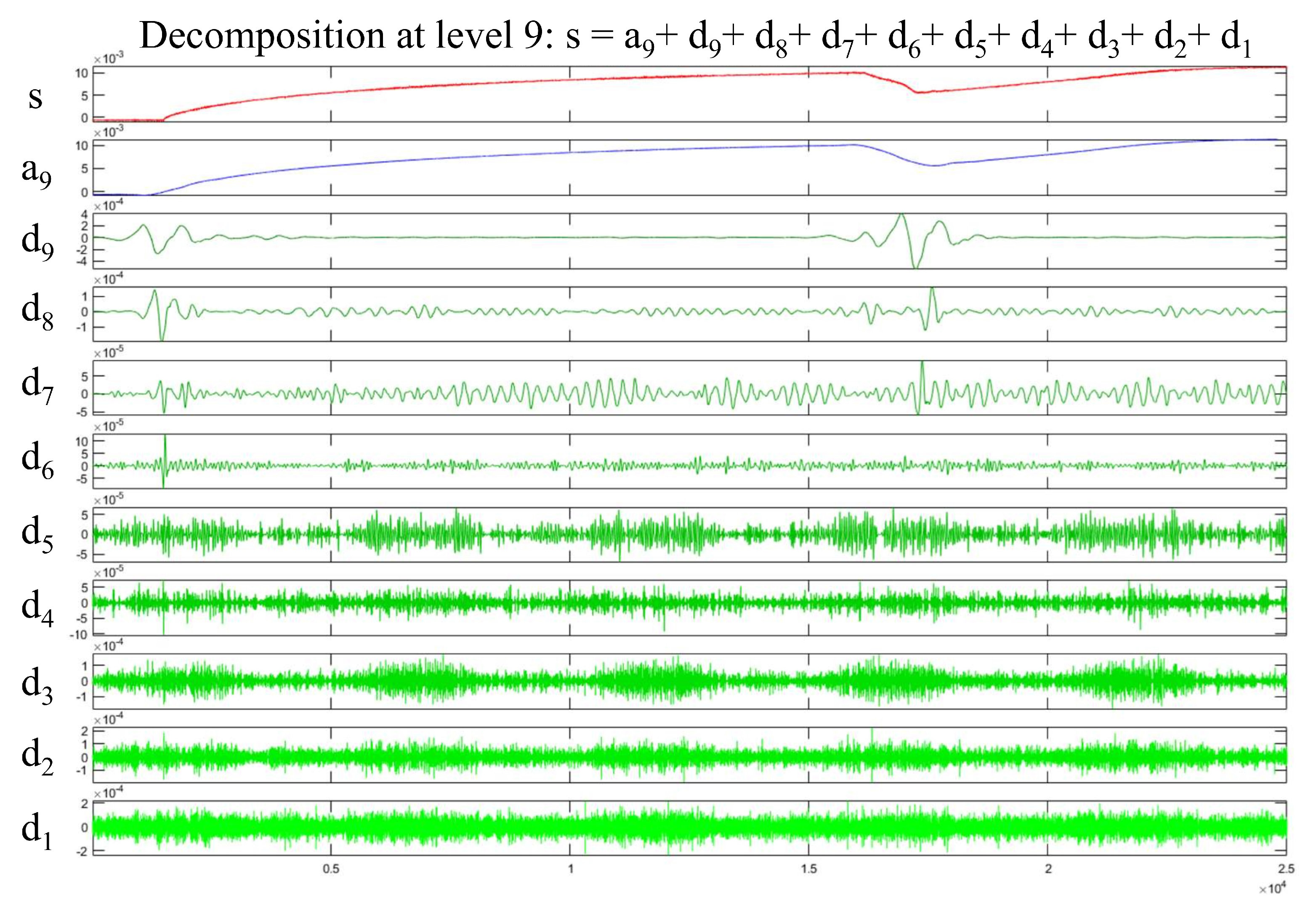

2.1. Wavelet Analysis Method

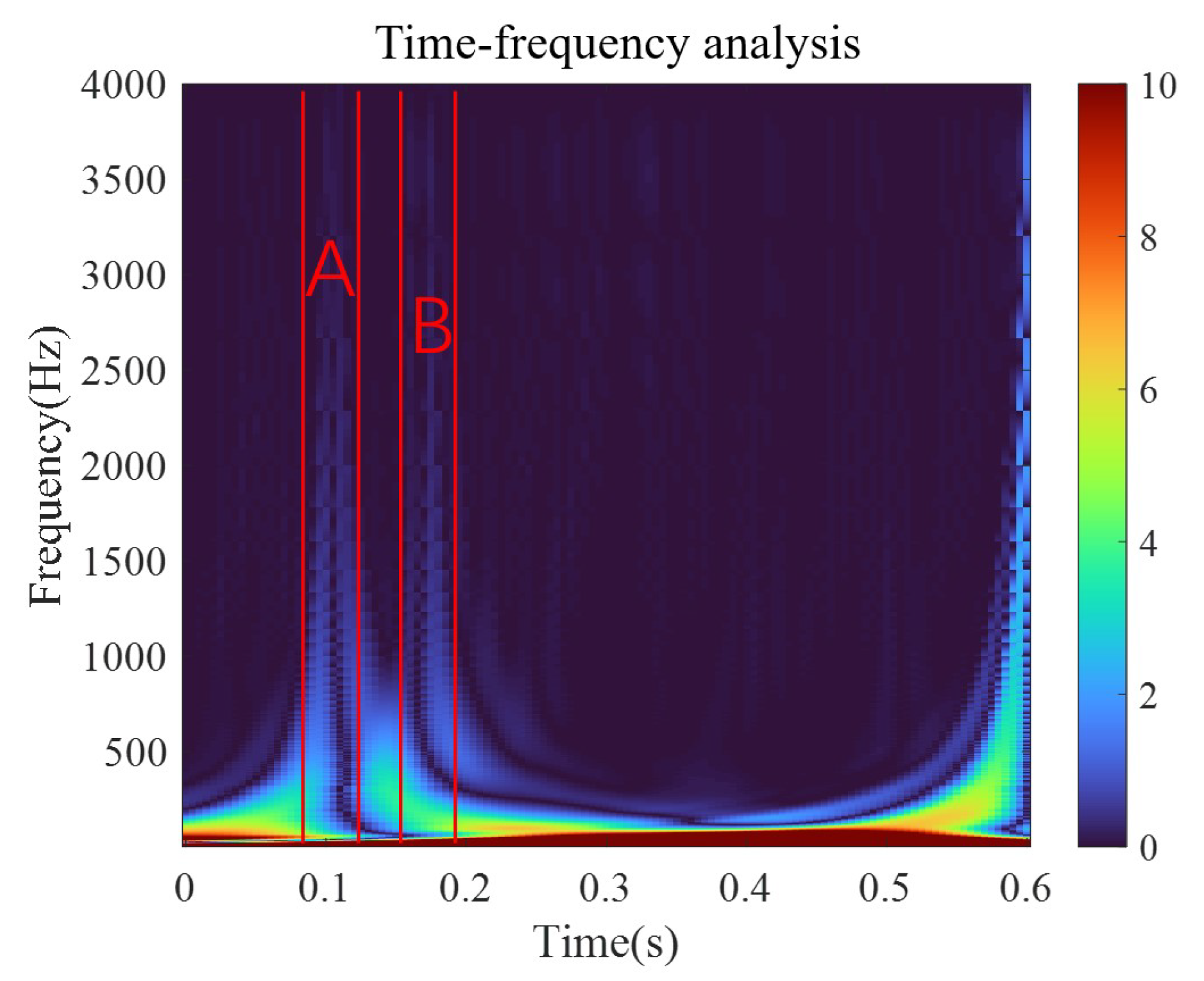

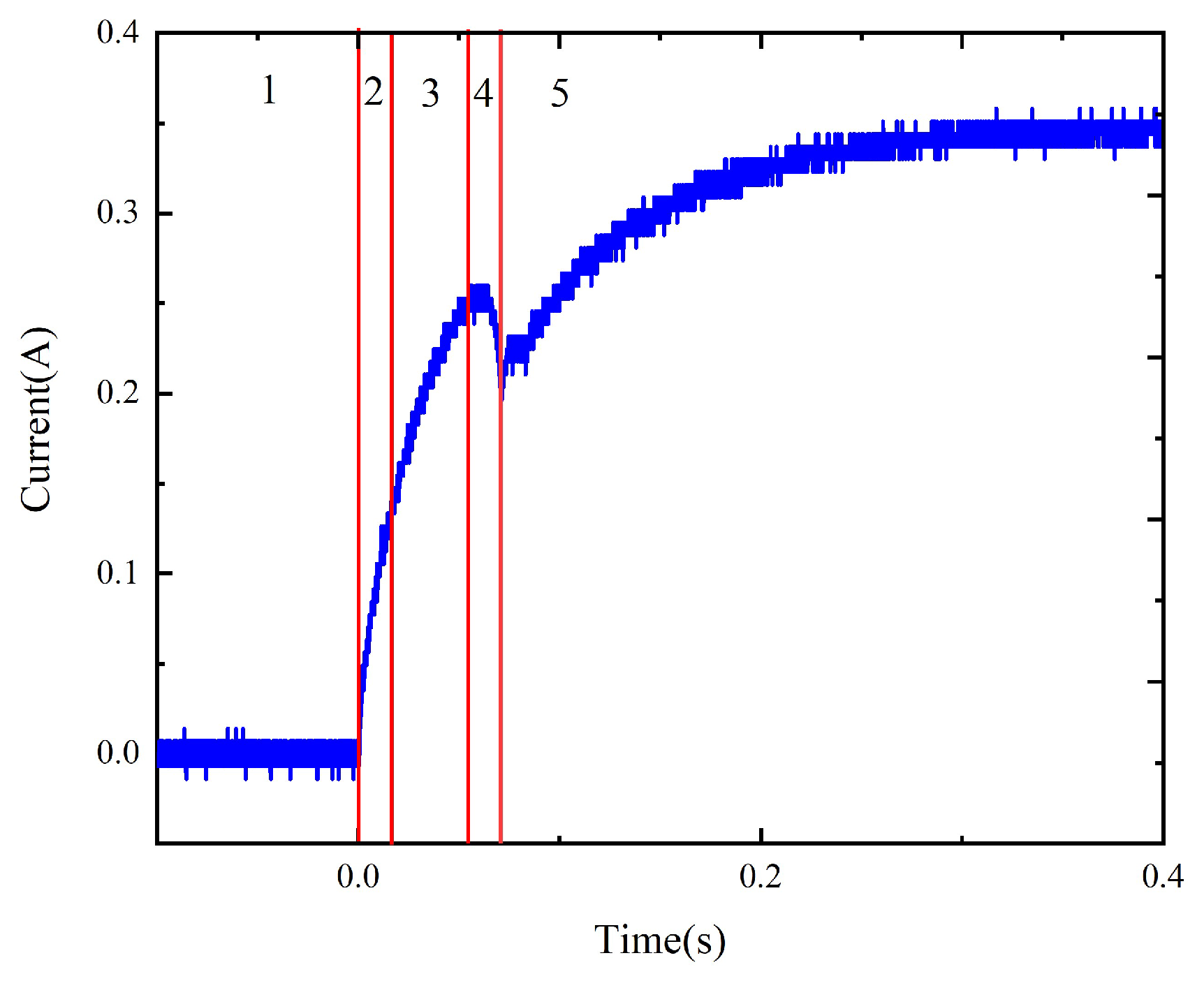

2.2. Coil Current Wavelet Analysis

2.3. Nanocrystalline Material Selection

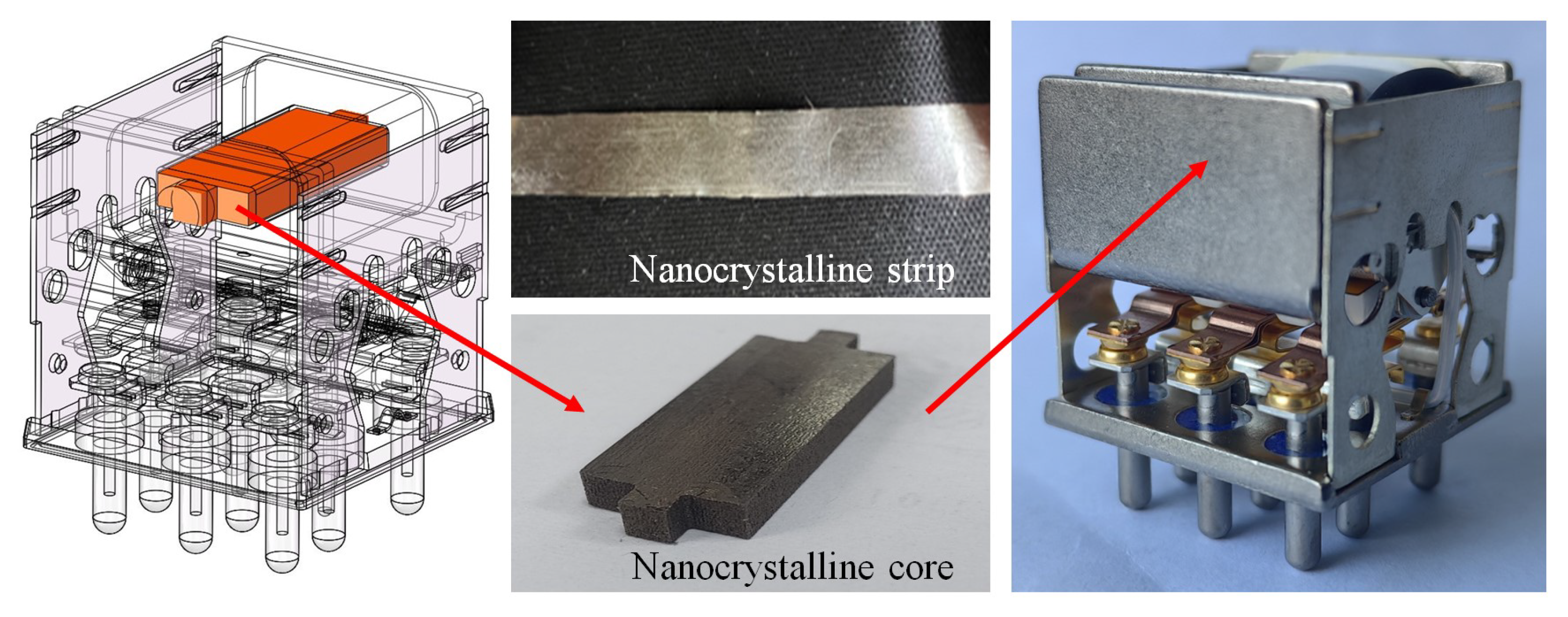

3. Prototype and Testing

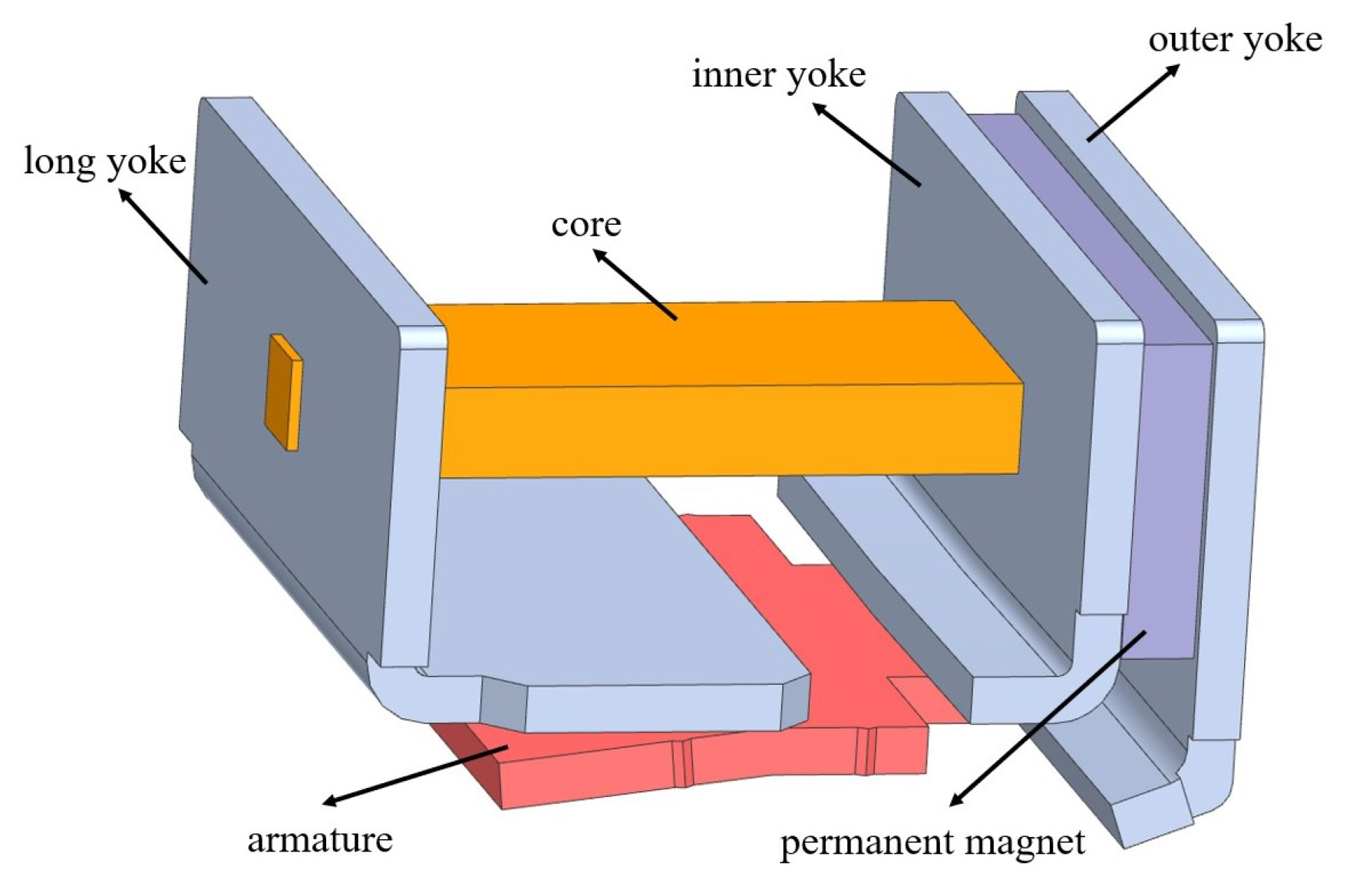

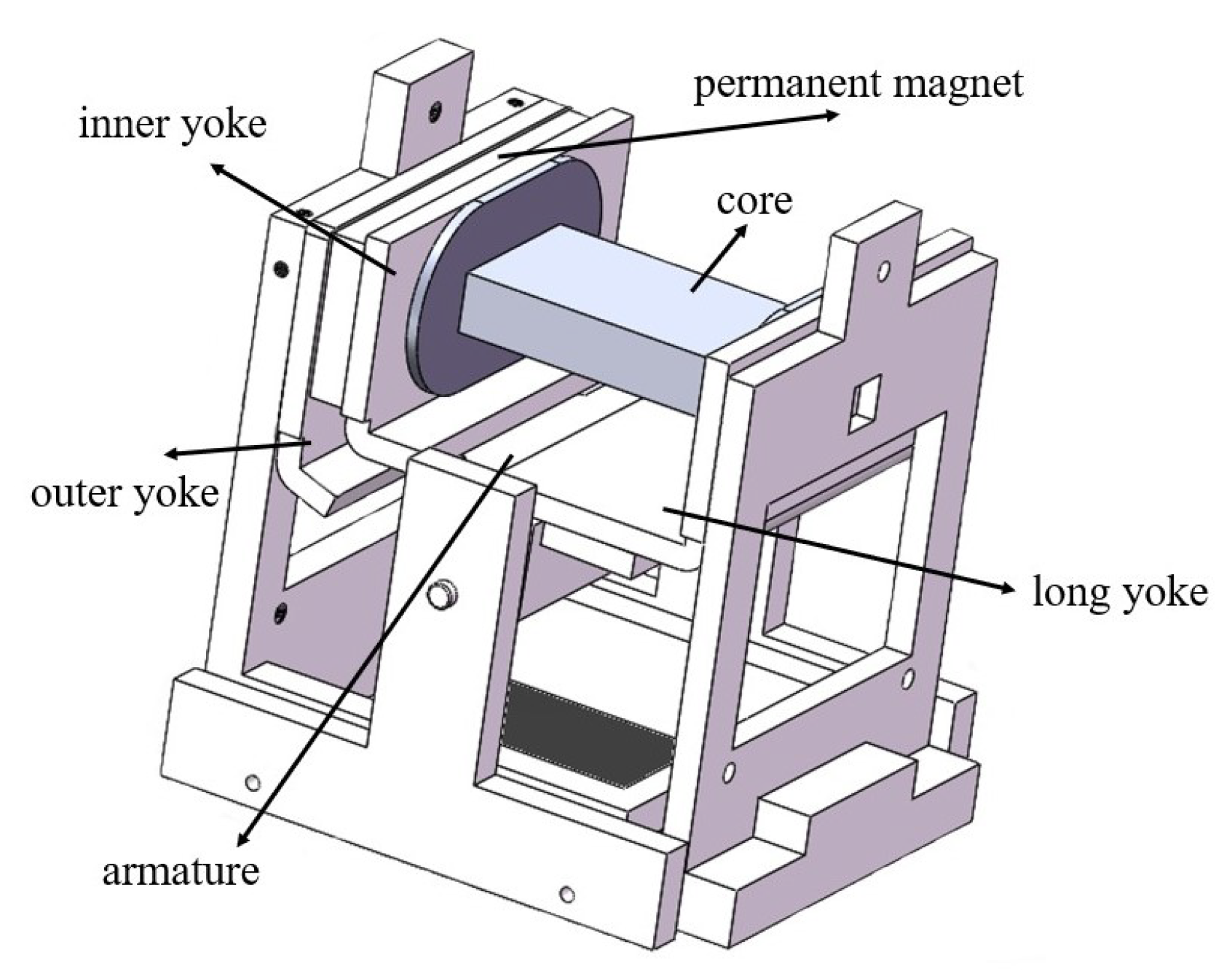

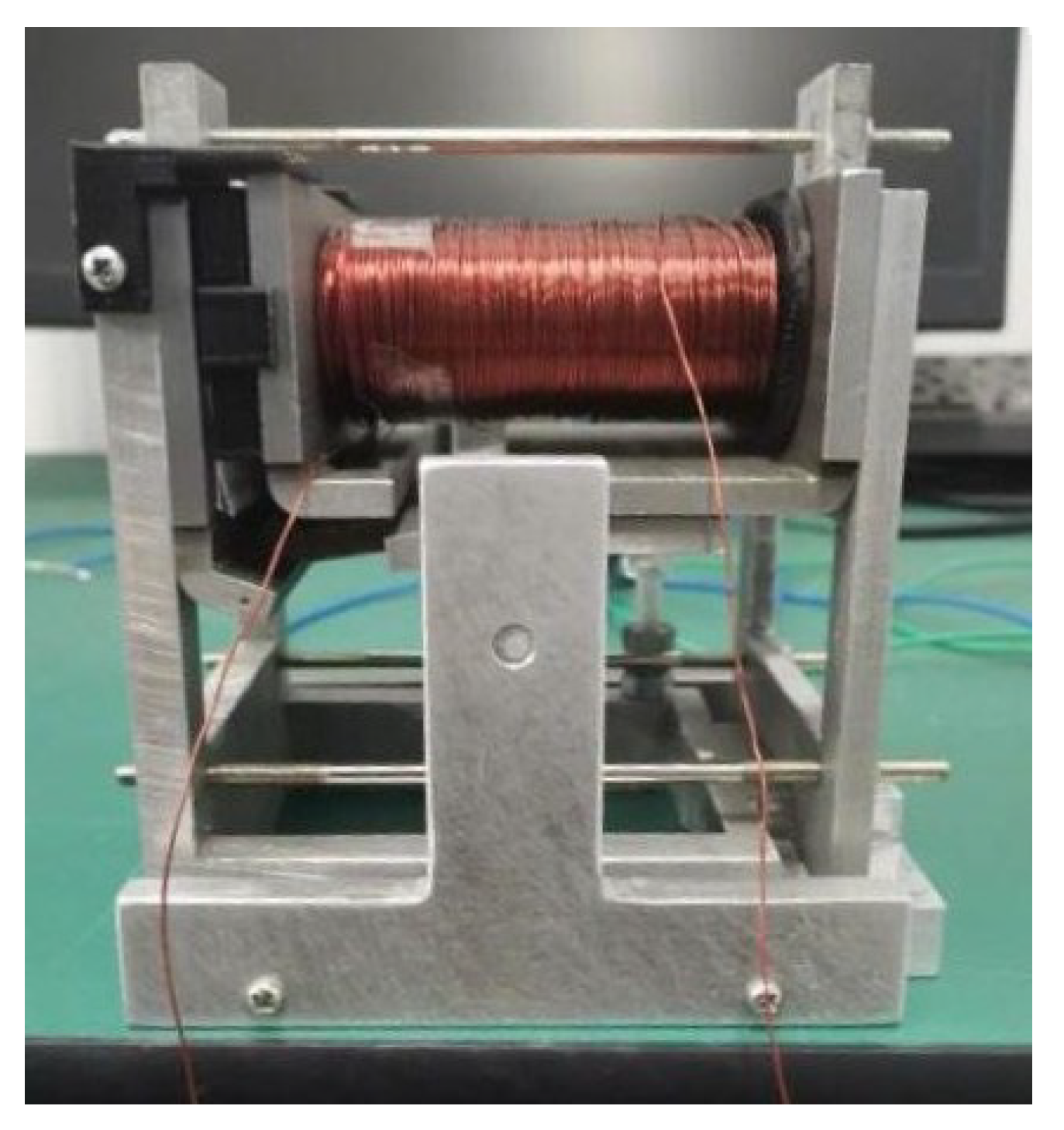

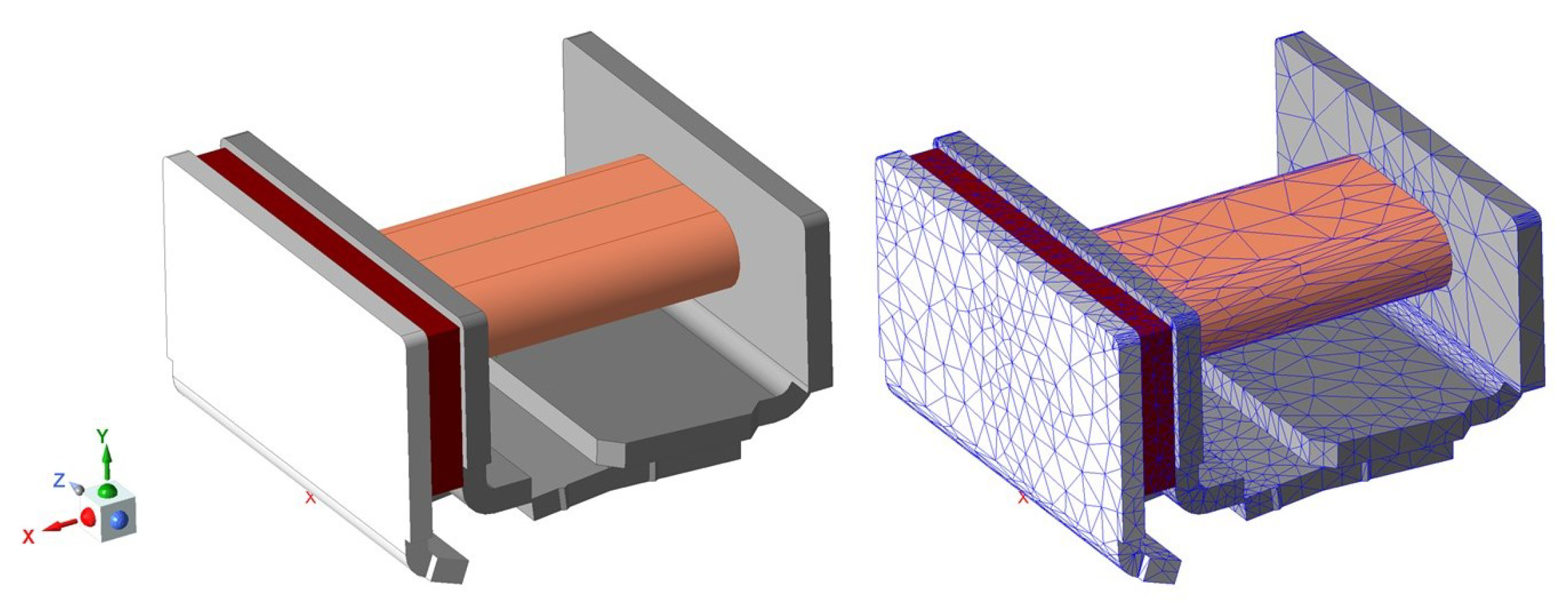

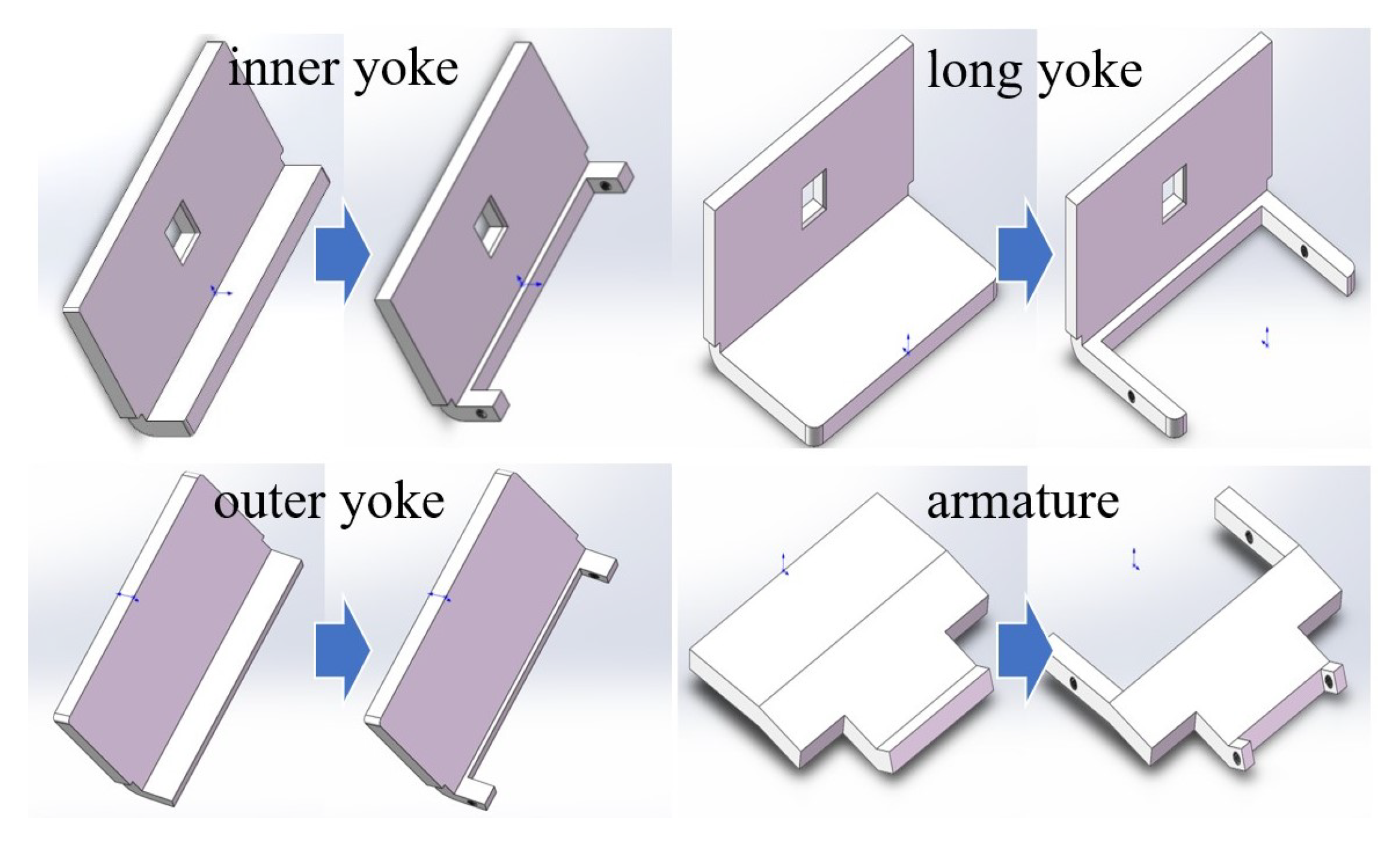

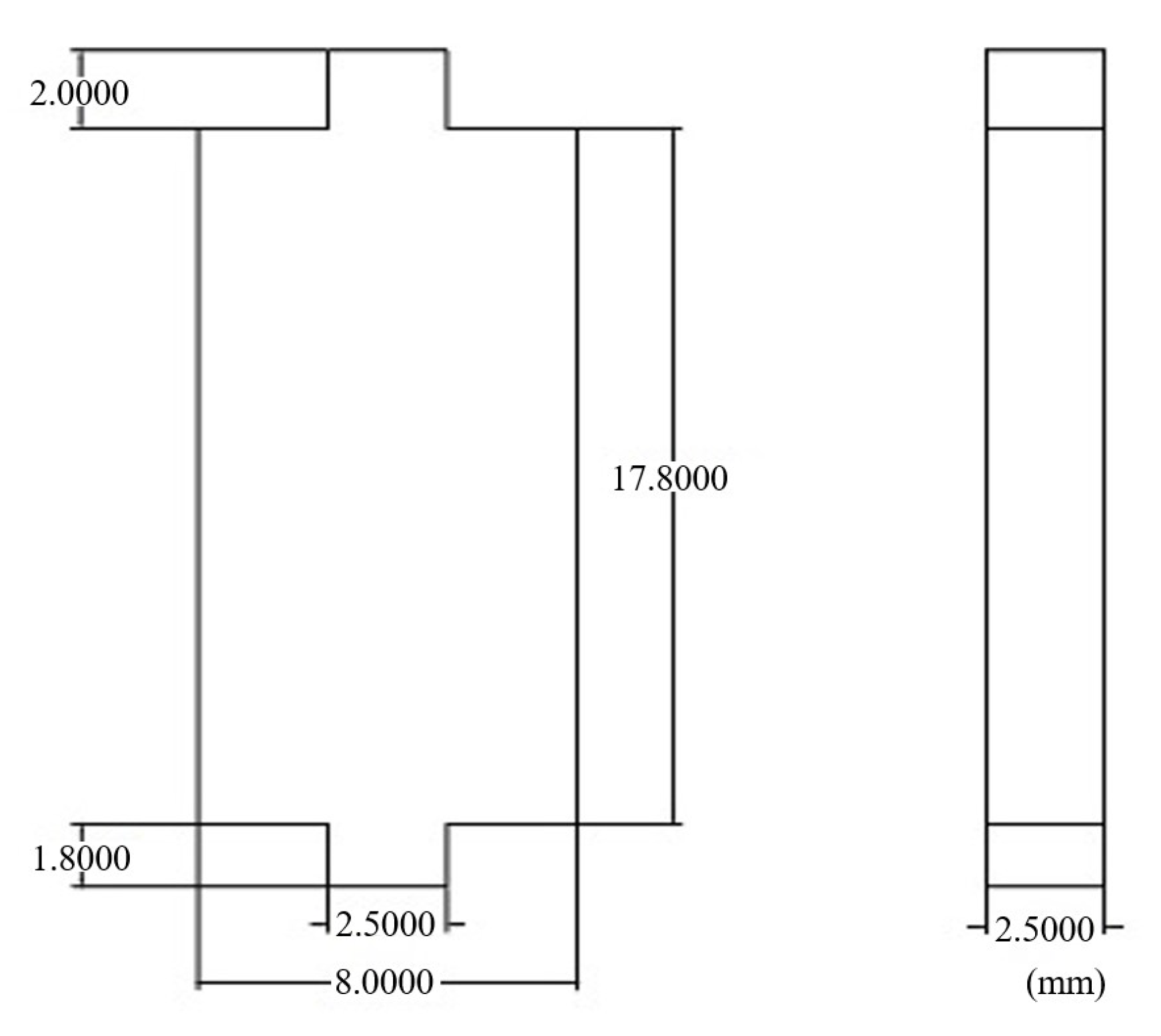

3.1. Scaled-Up Model Design

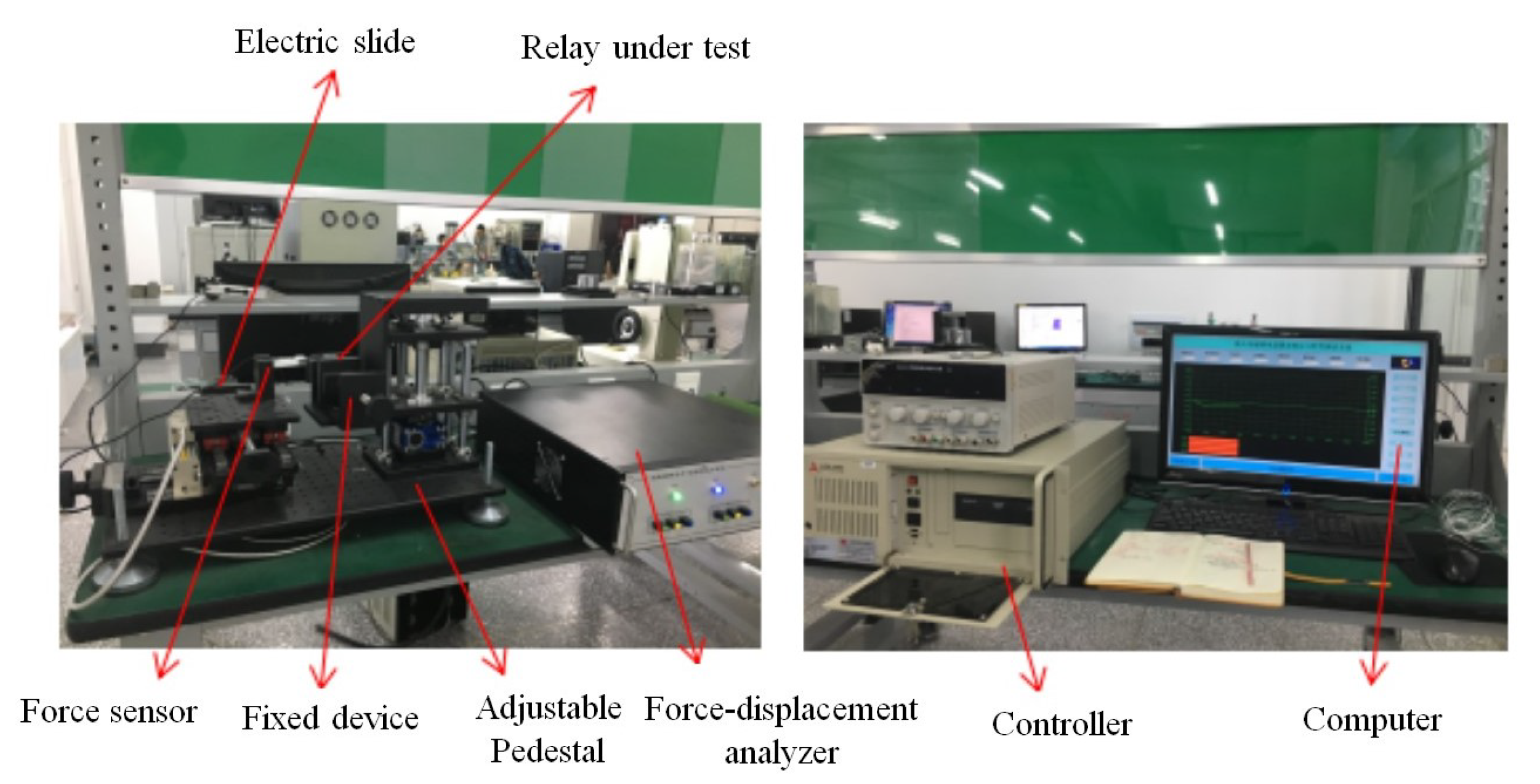

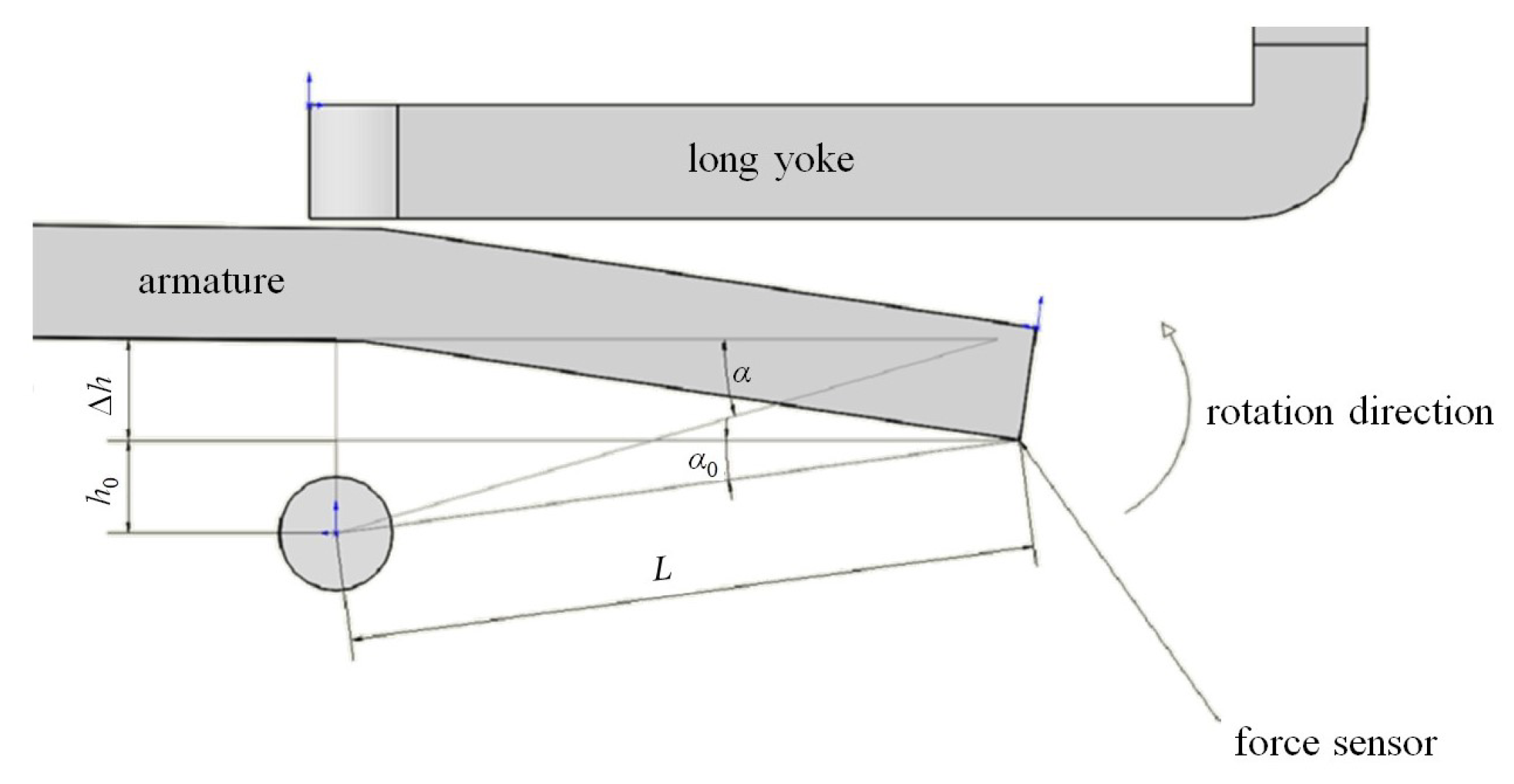

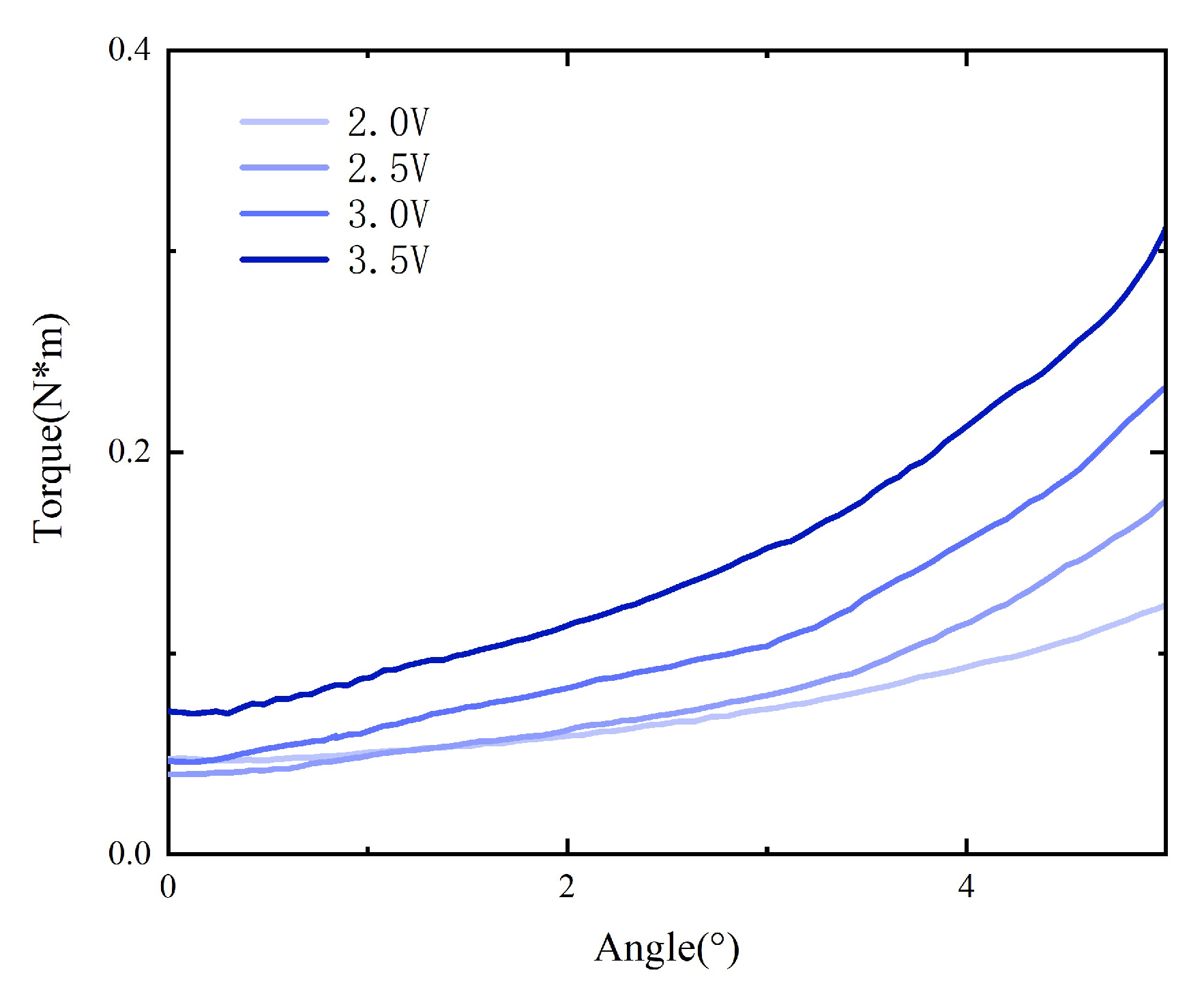

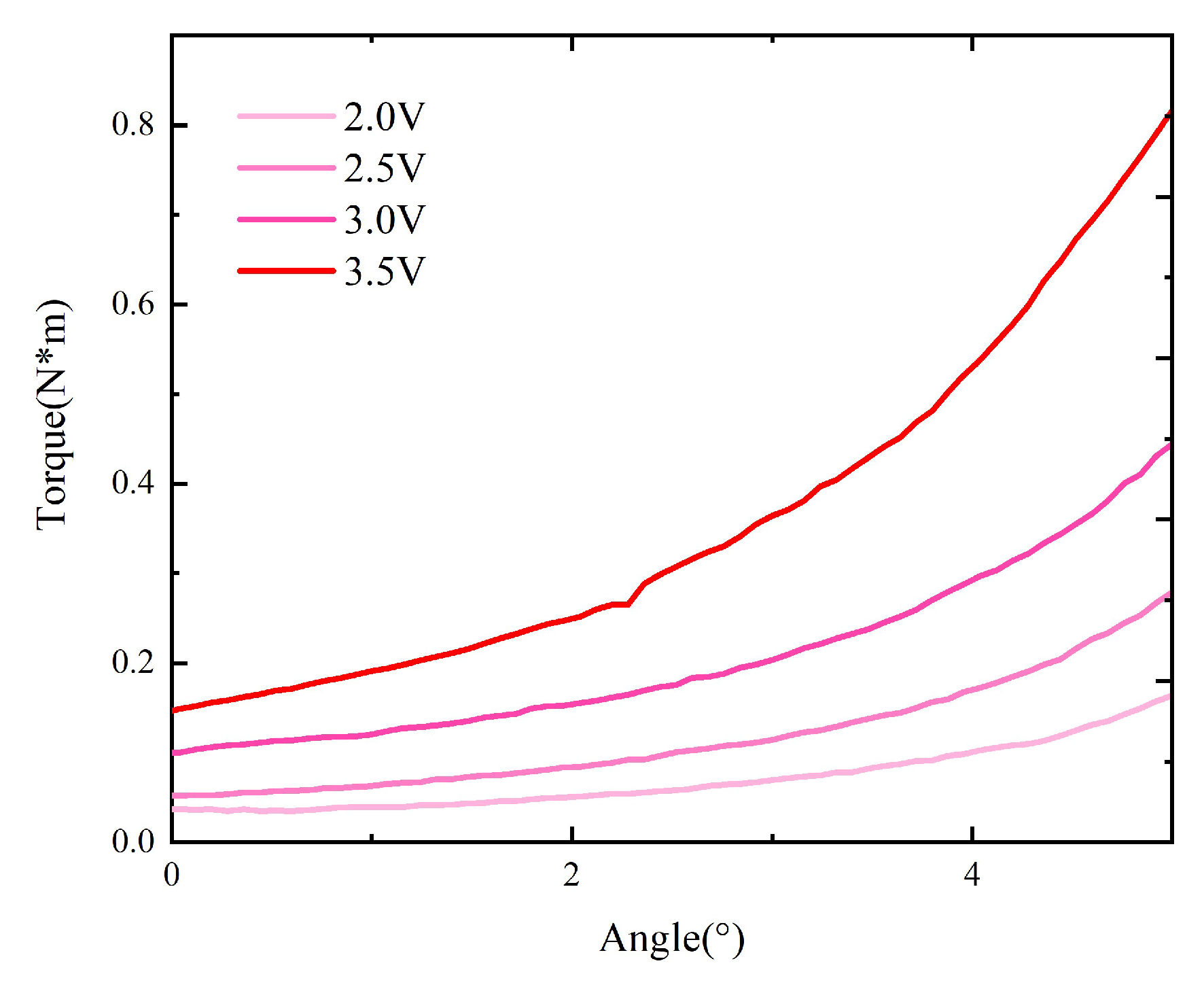

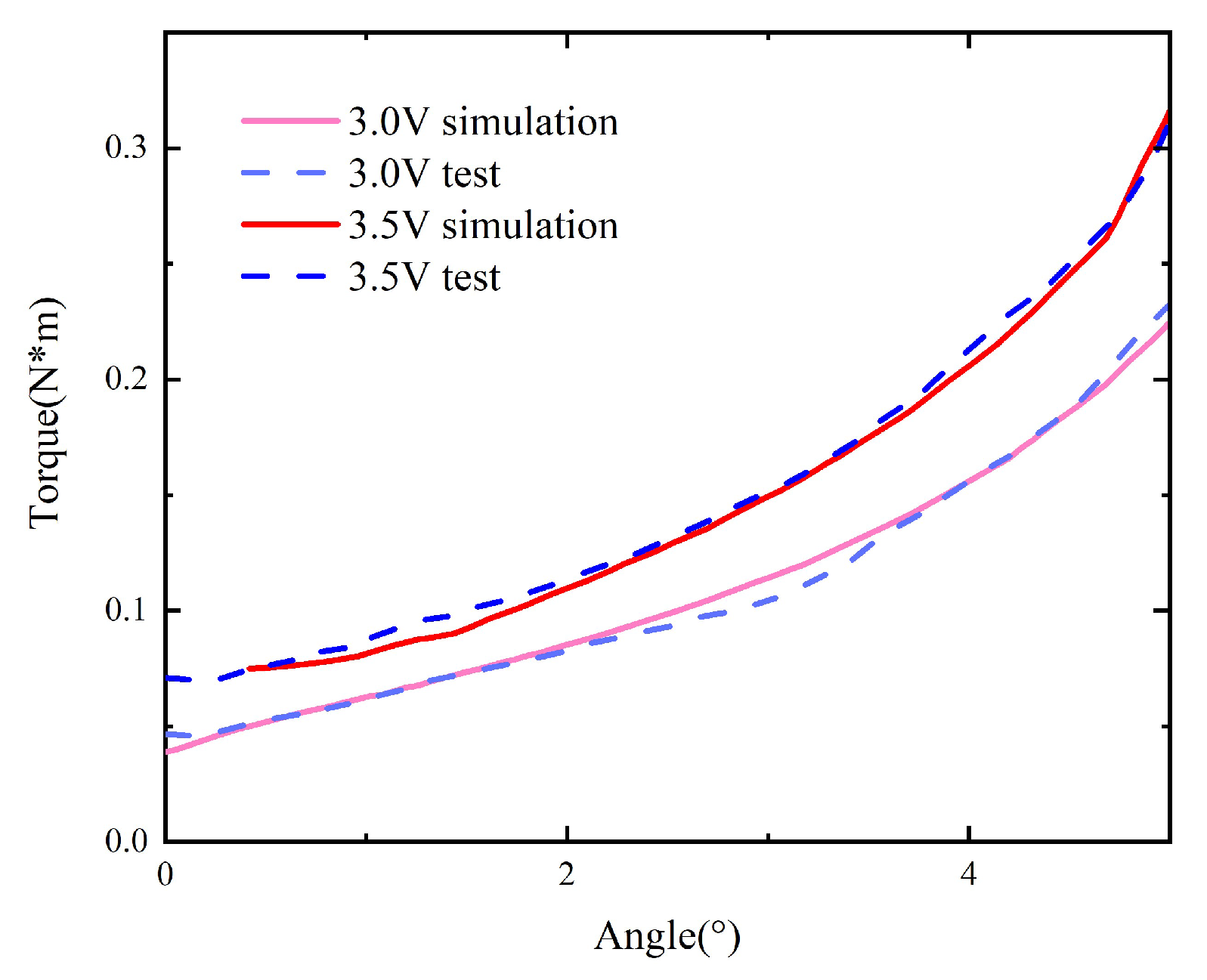

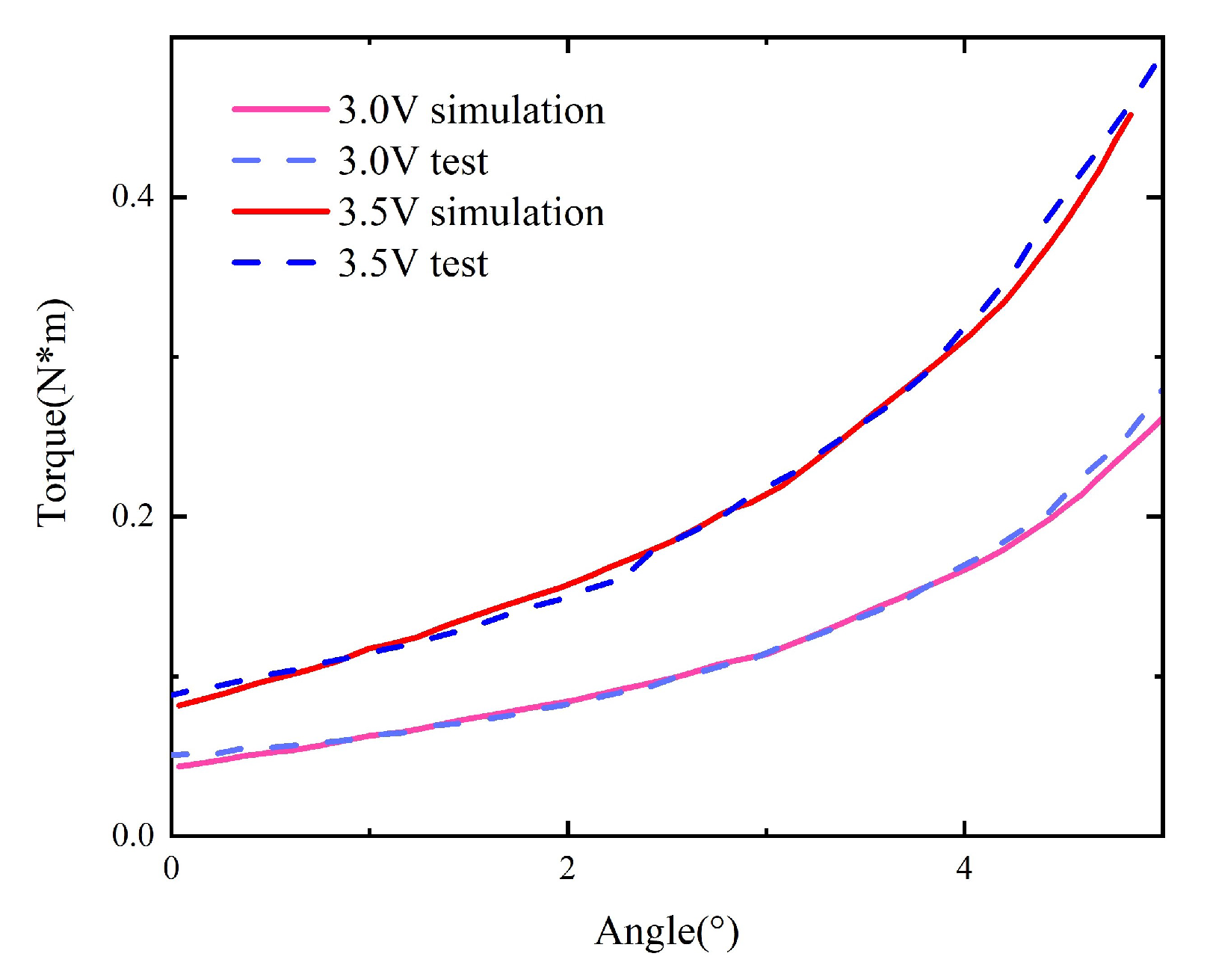

3.2. Static Characteristic Test

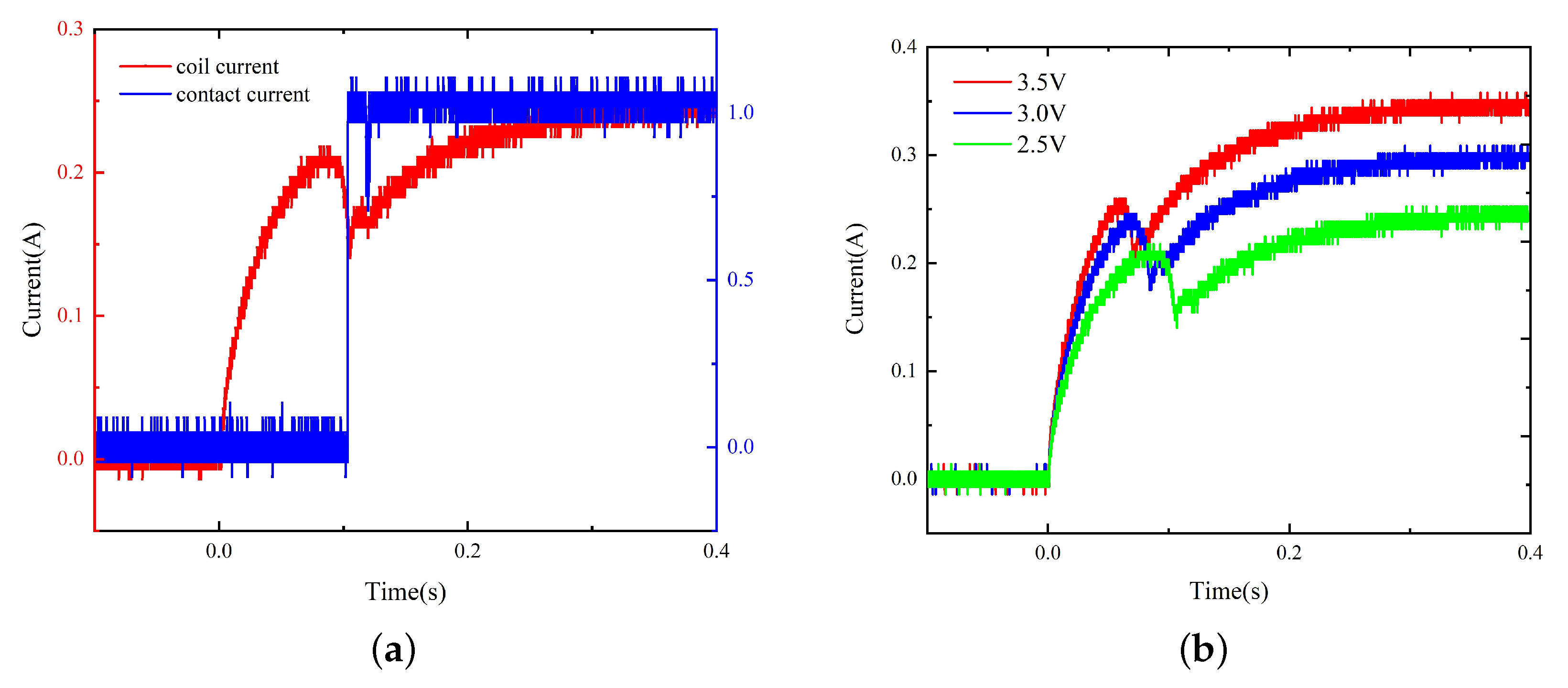

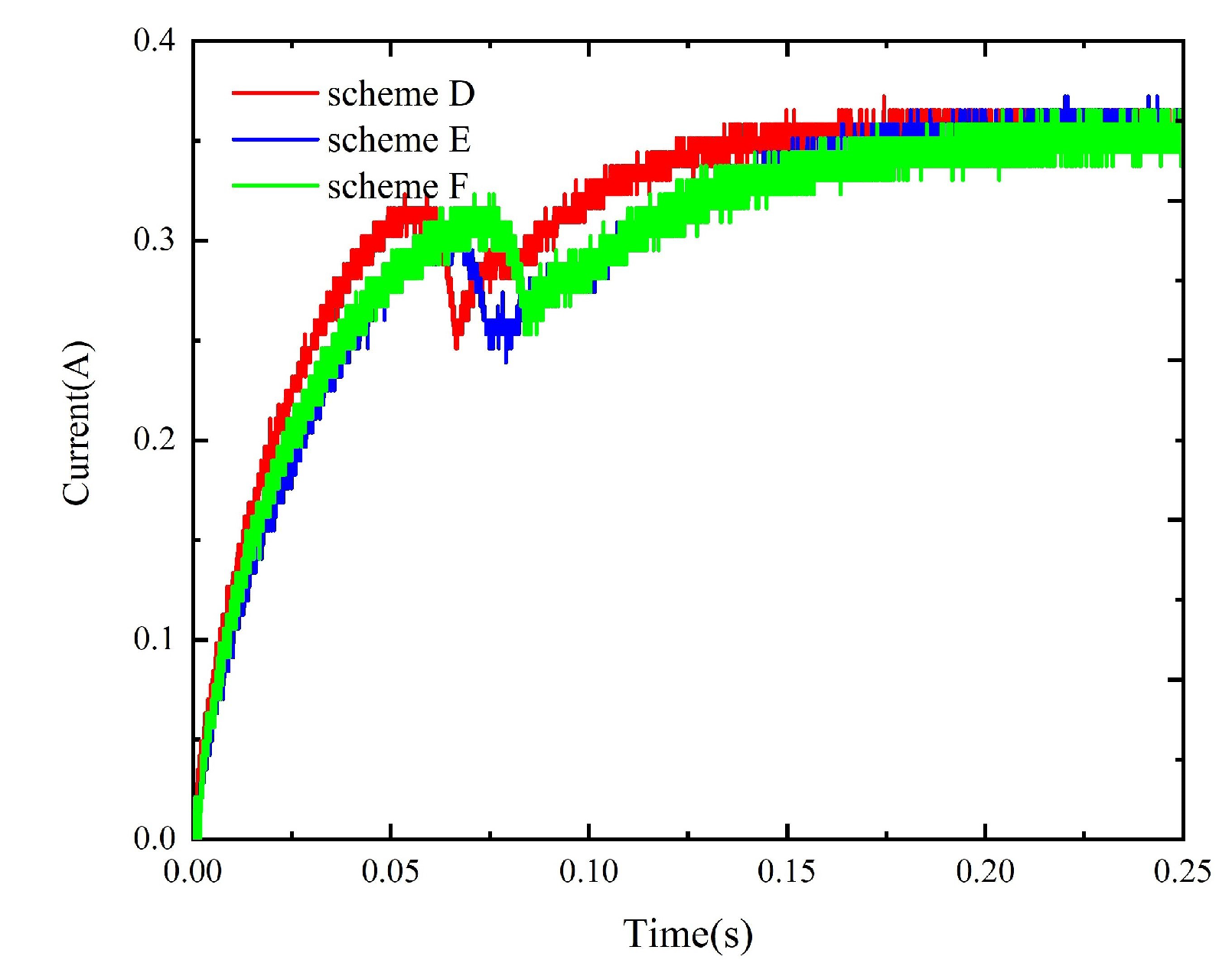

3.3. Dynamic Characteristic Test

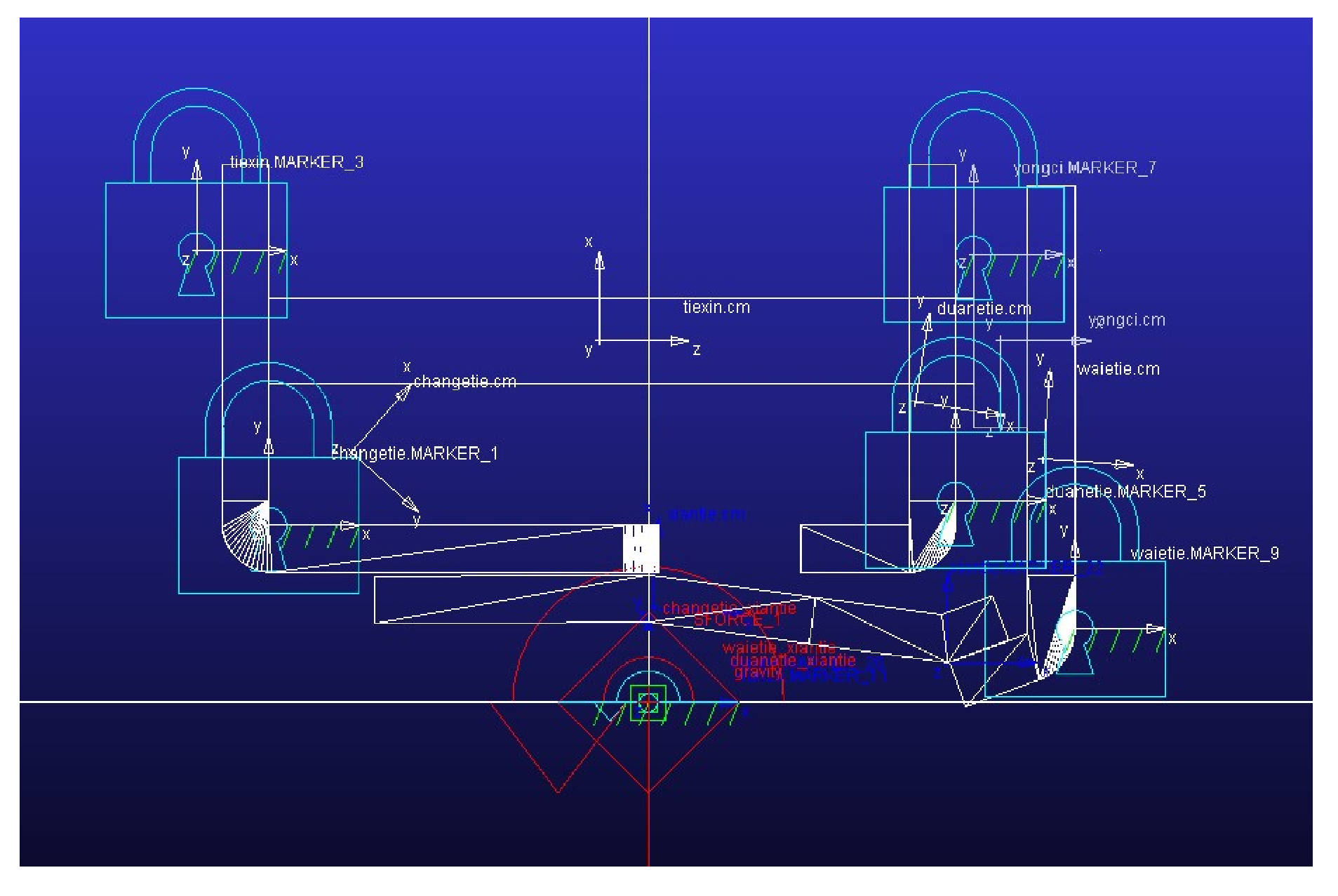

4. Simulation and Verification

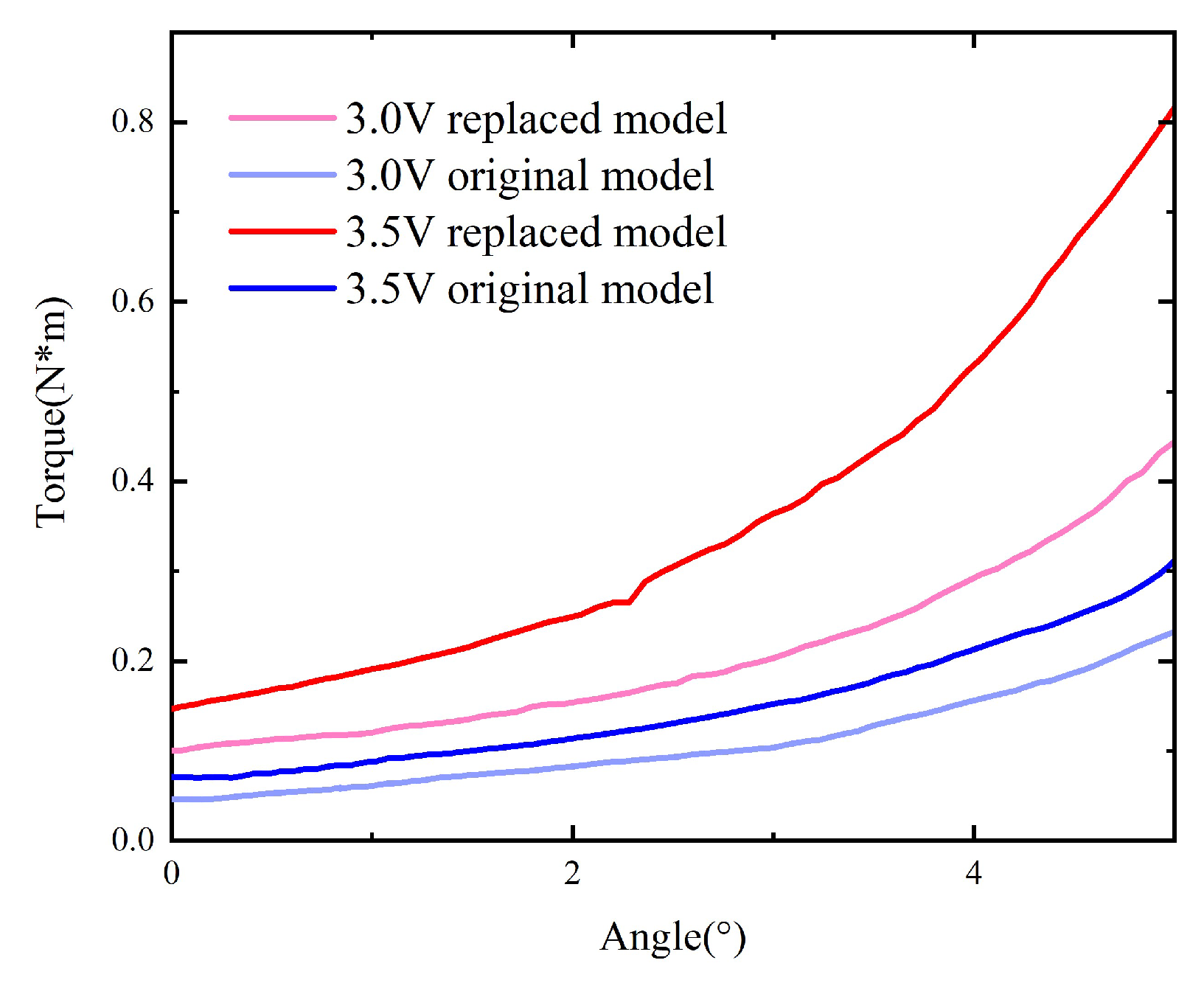

4.1. Static Characteristic Simulation

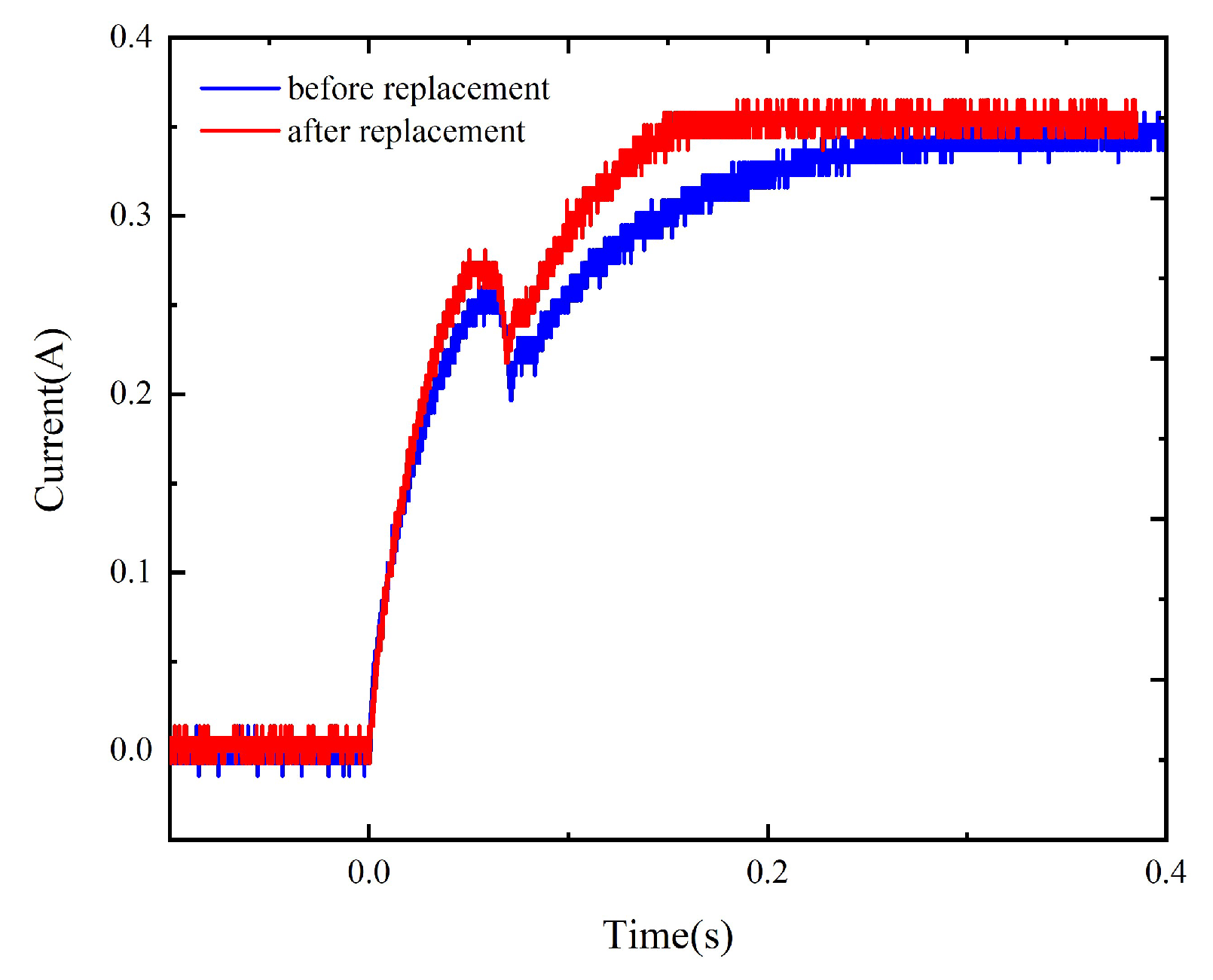

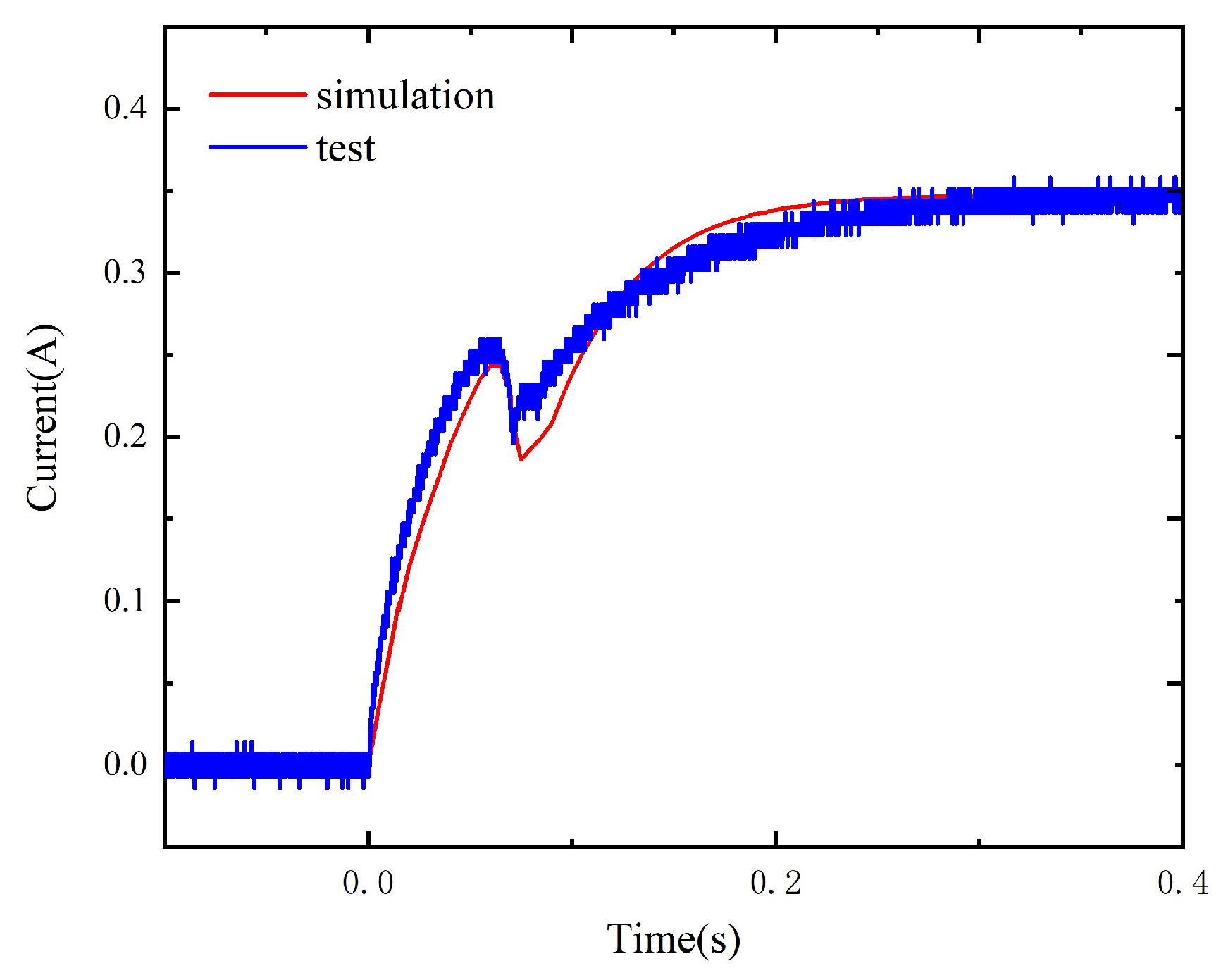

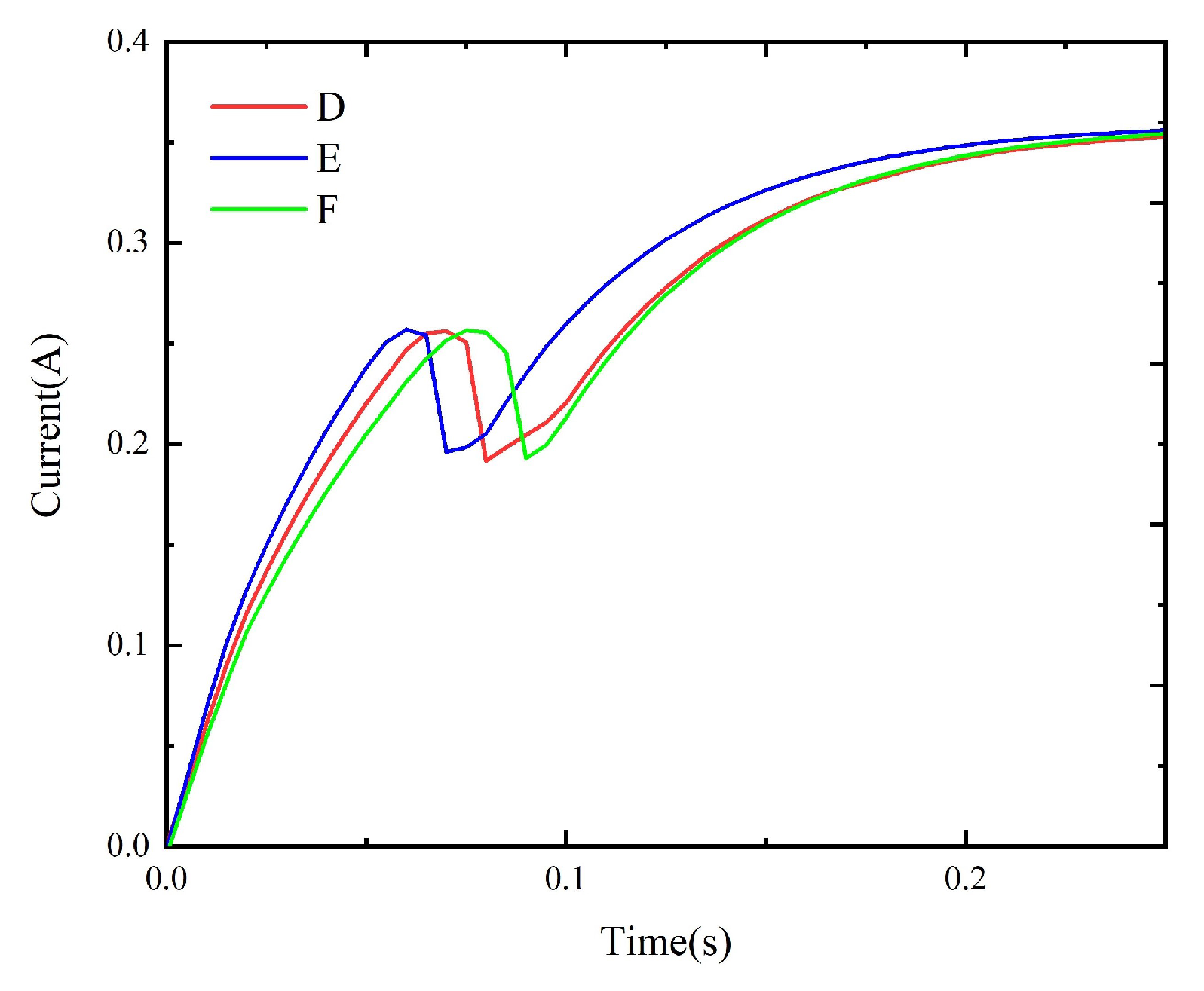

4.2. Dynamic Characteristic Simulation

5. Results and Discussion

5.1. Replacement Design and Schemes

5.2. Prototype Test and Simulation Results

5.3. Full-Size Relay Test and Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qiao, Y.; Zhai, G.; Ding, D.; Du, X.; Zhang, H.; Zhou, C. Robust design of dynamic characteristics consistency of Busbar-Mounted Electromagnetic Contactor based on a fast calculation surrogate model. In Proceedings of the 2022 IEEE 67th Holm Conference on Electrical Contacts (HLM), Tampa, FL, USA, 23–26 October 2022; pp. 1–7. [Google Scholar]

- Zhai, G.; Wang, Q.; Ren, W. An Output Space-Mapping Algorithm to Optimize the Dimensional Parameter of Electromagnetic Relay. IEEE Trans. Magn. 2011, 47, 2194–2199. [Google Scholar] [CrossRef]

- Lankenau, T.; Graf, M. Simulation of mechanical relays under coupled electromagnetic physics and structural dynamics. Int. J. Multiphysics 2022, 16, 67–80. [Google Scholar]

- Zhai, G.; Wang, Q.; Ren, W. Research on electromagnetic relay’s dynamic characteristics disturbed by uniform static magnetic field. Zhejiang Univ. Sci. 2008, A 9, 577–582. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, F.; Liu, Y.; Guo, Q. A dynamic simulation of the circuit breaking electromagnetic system with a drive circuit. Adv. Mech. Eng. 2019, 11, 1687814019828564. [Google Scholar] [CrossRef]

- Nobuyuki, N.; Kenji, A.; Akihisa, I. Bulk Metallic Glasses for Industrial Products. Mater. Trans. 2004, 45, 1245–1250. [Google Scholar]

- Liu, D.; Li, J.; Noubissi, R.K.; Wang, S.; Xu, X.; Liu, Q. Magnetic properties and vibration characteristics of amorphous alloy strip and its combination. IET Electr. Power Appl. 2019, 13, 1589–1597. [Google Scholar] [CrossRef]

- Takagi, M.; Yamamoto, H.; Yamaji, K. An Evaluation of Amorphous Transformers Using the Load Curve Pattern Model for a Pole Transformer. Electr. Eng. Jpn. 2009, 169, 1–9. [Google Scholar] [CrossRef]

- Chai, F.; Li, Z.; Chen, L.; Pei, Y. Effect of Cutting and Slot Opening on Amorphous Alloy Core for High-Speed Switched Reluctance Motor. IEEE Trans. Magn. 2021, 57, 1–5. [Google Scholar] [CrossRef]

- Yuji, E.; Mamoru, K.; Yasuhiro, M.; Hirohisa, S. Distributed Winding IPM Motor with an Amorphous Metal Stator Core. IEEJ J. Ind. Appl. 2022, 11, 730–736. [Google Scholar]

- Guo, L.; Wang, C.; Zhi, S.; Feng, Z.; Lei, C.; Zhou, Y. Wide Linearity Range and Highly Sensitive MEMS-Based Micro-Fluxgate Sensor with Double-Layer Magnetic Core Made of Fe–Co–B Amorphous Alloy. Micromachines 2017, 8, 352. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.-H. Effect of Local Annealing on Magnetic Flux Distribution and Noise in a Micro-Generator with Amorphous Shell. Micromachines 2022, 13, 2086. [Google Scholar] [CrossRef]

- Herzer, G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Roc’h, A.; Leferink, F. Nanocrystalline Core Material for High-Performance Common Mode Inductors. IEEE Trans. Electromagn. Compat. 2012, 54, 785–791. [Google Scholar] [CrossRef]

- Richerzhagen, M.; Hopgood, J. Construction and testing of a common mode choke for cryogenic detector pre-amplifiers. J. Astron. Telesc. Instruments Syst. 2023, 9, 1–9. [Google Scholar] [CrossRef]

- Shen, W.; Wang, F.; Boroyevich, D.; Tipton IV, C. High-Density Nanocrystalline Core Transformer for High-Power High-Frequency Resonant Converter. IEEE Trans. Ind. Appl. 2008, 44, 213–222. [Google Scholar] [CrossRef]

- Somkun, S.; Sato, T.; Chunkag, V.; Pannawan, A.; Nunocha, P.; Suriwong, T. Performance Comparison of Ferrite and Nanocrystalline Cores for Medium-Frequency Transformer of Dual Active Bridge DC-DC Converter. Energies 2021, 14, 2407. [Google Scholar] [CrossRef]

- Yao, A.; Sugimoto, T.; Odawara, S.; Fujisaki, K. Core Loss Properties of a Motor With Nanocrystalline Rotor and Stator Cores Under Inverter Excitation. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Xiong, M.; Wei, X.; Huang, Z.; Luo, Z.; Dai, H. Research on Novel Flexible High-Saturation Nanocrystalline Cores for Wireless Charging Systems of Electric Vehicles. IEEE Trans. Ind. Electron. 2021, 68, 8310–8320. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Hou, X.; Ke, H.; Fan, X.; Luan, J.; Peng, H.; Zeng, Q.; Lou, H.; Wang, J.; et al. Ultrahigh Permeability at High Frequencies via A Magnetic-Heterogeneous Nanocrystallization Mechanism in an Iron-Based Amorphous Alloy. Adv. Mater. 2023, 35, 2304490. [Google Scholar] [CrossRef]

- Nonaka, T.; Zeze, S.; Makino, S.; Ohto, M. Research on motor with nanocrystalline soft magnetic alloy stator cores. Electr. Eng. Jpn. 2020, 139, 873–879. [Google Scholar]

- Gaona, D.E.; Long, T. Feasibility Analysis of Nanocrystalline Cores for Polarize and Non-Polarized IPT Charging Pads. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019; pp. 1539–1546. [Google Scholar]

| Coil Voltage/V | Original Model/ms | Model with Replacement/ms |

|---|---|---|

| 2.5 | 107.8 | 100.7 |

| 3 | 80.9 | 74.8 |

| 3.5 | 71.4 | 65.7 |

| Number | Schemes |

|---|---|

| A | The core is replaced with nanocrystals. |

| B | The core, yoke, and armature are replaced with nanocrystals. |

| C | The yoke and armature are replaced with nanocrystals. |

| D | The core is replaced with an amorphous alloy. |

| E | The core, yoke, and armature are replaced with an amorphous alloy. |

| F | The yoke and armature are replaced with an amorphous alloy. |

| Scheme | Operation Time/ms | ||

|---|---|---|---|

| 2.5 V | 3.0 V | 3.5 V | |

| A | 100.7 | 74.8 | 65.7 |

| B | 103.1 | 92.3 | 77.3 |

| C | 99.3 | 91.2 | 80.2 |

| D | 85.6 | 78.4 | 64.3 |

| E | 116.6 | 100.2 | 76.2 |

| F | 108.7 | 90.6 | 83.4 |

| Original model | 107.8 | 80.9 | 71.4 |

| Number | Operation Time/ms | Pick-Up Voltage/V | Release Time/ms | Drop-Out Voltage/V |

|---|---|---|---|---|

| Relay with replacement | 5.96 | 16.0 | 1.98 | 2.5 |

| Original relay | 8.61 | 14.0 | 2.45 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, D.; You, J.; Cui, X.; Xue, Y.; Tan, X.; Zhai, G. Application of Amorphous and Nanocrystalline Soft Magnetic Materials in Balanced-Force-Type Electromagnetic Relay. Micromachines 2024, 15, 368. https://doi.org/10.3390/mi15030368

Ding D, You J, Cui X, Xue Y, Tan X, Zhai G. Application of Amorphous and Nanocrystalline Soft Magnetic Materials in Balanced-Force-Type Electromagnetic Relay. Micromachines. 2024; 15(3):368. https://doi.org/10.3390/mi15030368

Chicago/Turabian StyleDing, Ding, Jiaxin You, Xiangqian Cui, Yutong Xue, Xu Tan, and Guofu Zhai. 2024. "Application of Amorphous and Nanocrystalline Soft Magnetic Materials in Balanced-Force-Type Electromagnetic Relay" Micromachines 15, no. 3: 368. https://doi.org/10.3390/mi15030368

APA StyleDing, D., You, J., Cui, X., Xue, Y., Tan, X., & Zhai, G. (2024). Application of Amorphous and Nanocrystalline Soft Magnetic Materials in Balanced-Force-Type Electromagnetic Relay. Micromachines, 15(3), 368. https://doi.org/10.3390/mi15030368