Attitude Algorithm of Gyroscope-Free Strapdown Inertial Navigation System Using Kalman Filter

Abstract

1. Introduction

2. Fundamentals

2.1. GFSINS Principles

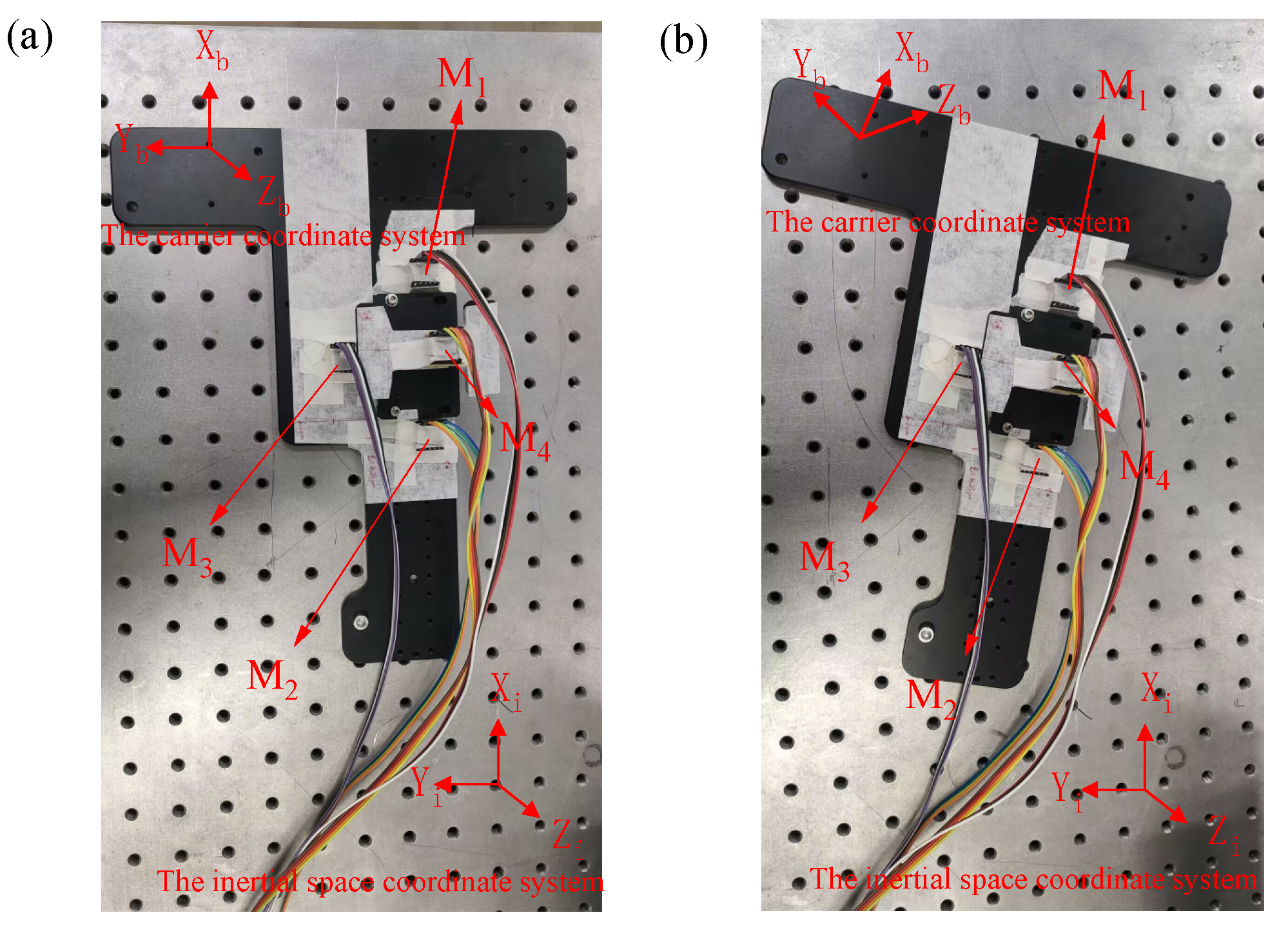

2.2. Configuration Scheme

3. Attitude Algorithm

3.1. Angular Velocity Calculation

- Integral algorithm:

- Integral algorithm:

3.2. Improved Extraction Algorithm

- Determining the sliding window size.

- Defining the Window Function.

- Detecting Anomalies.

- Correcting Angular Velocity Sign.

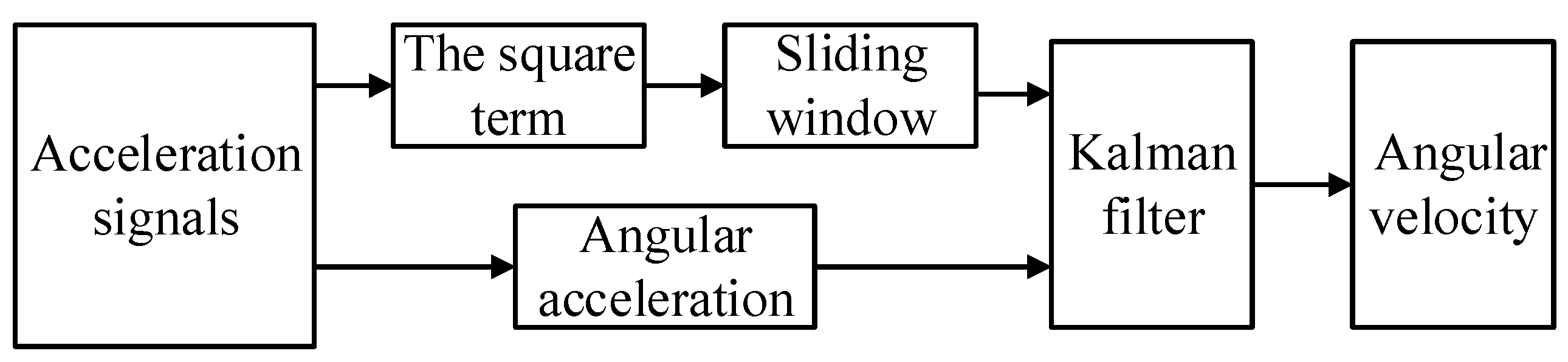

3.3. Kalman Filter Fusion Algorithm

- Discretizing Equation (7), the system’s state prediction equation is obtained:

- The observation equation for the system is established as follows:

- Update the state variable estimates:

- Predict the error covariance array:

- Calculate the Kalman gain matrix:

- Update the error covariance array:

3.4. Fuaternion Mean

4. Simulation

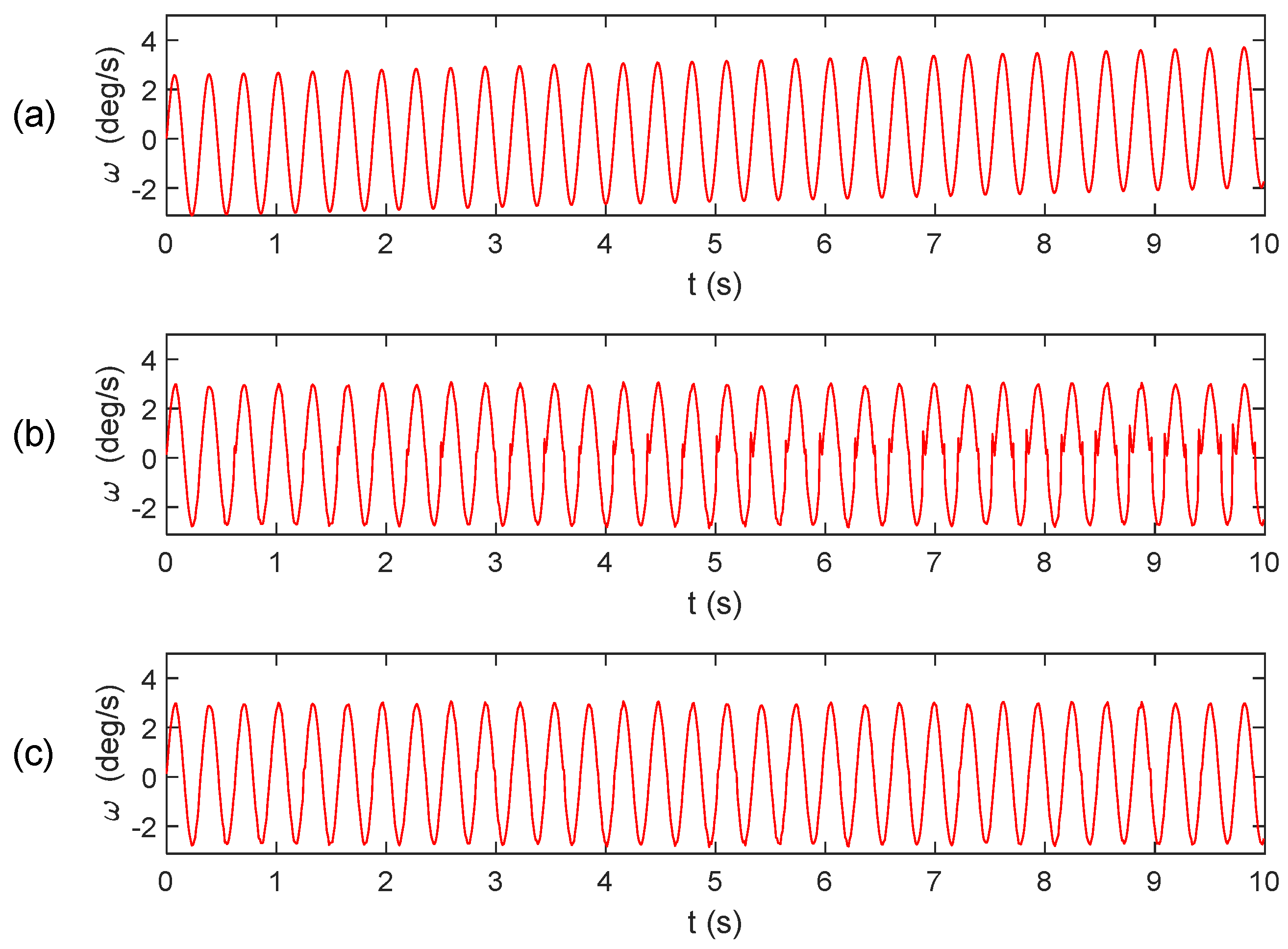

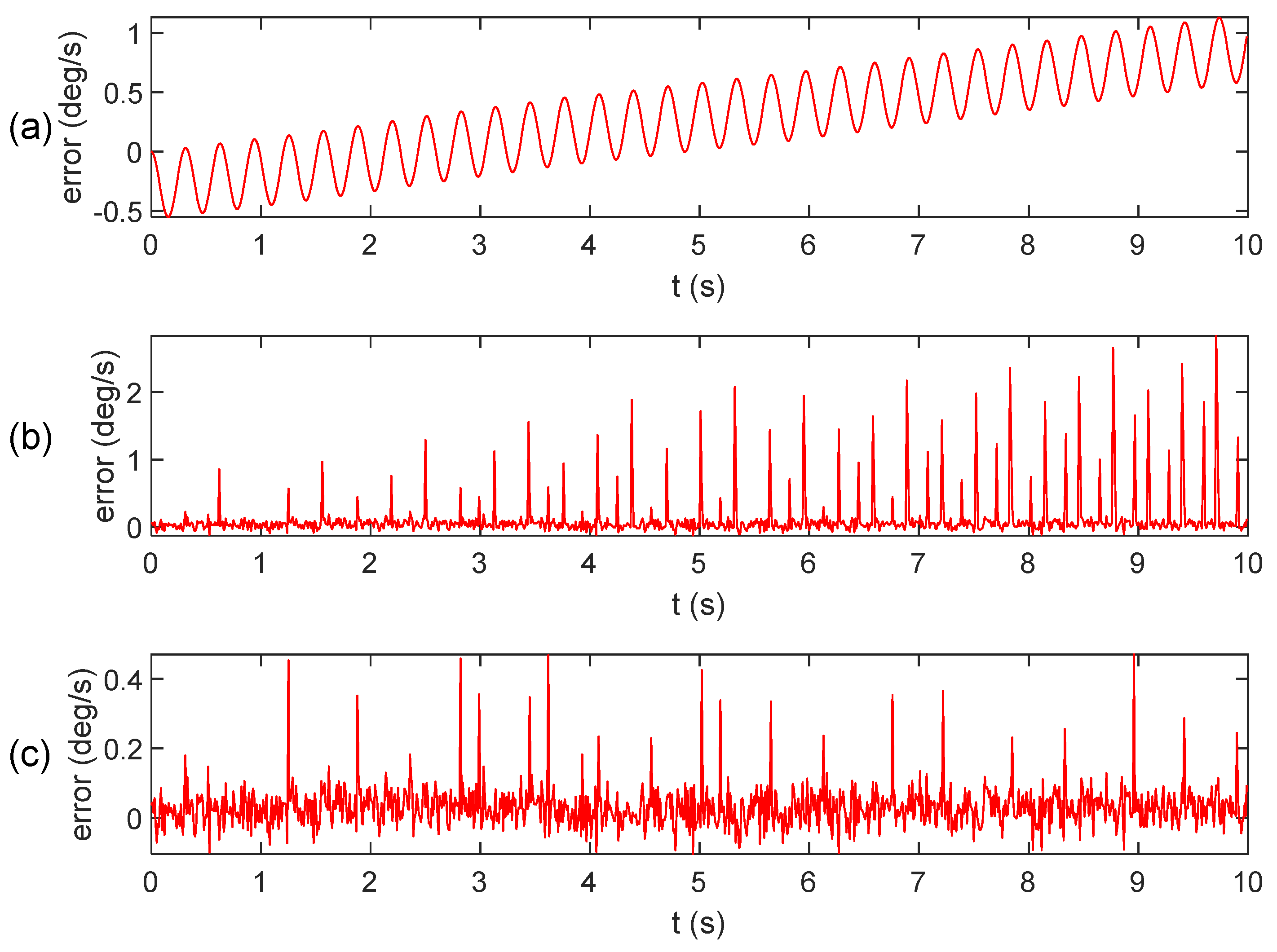

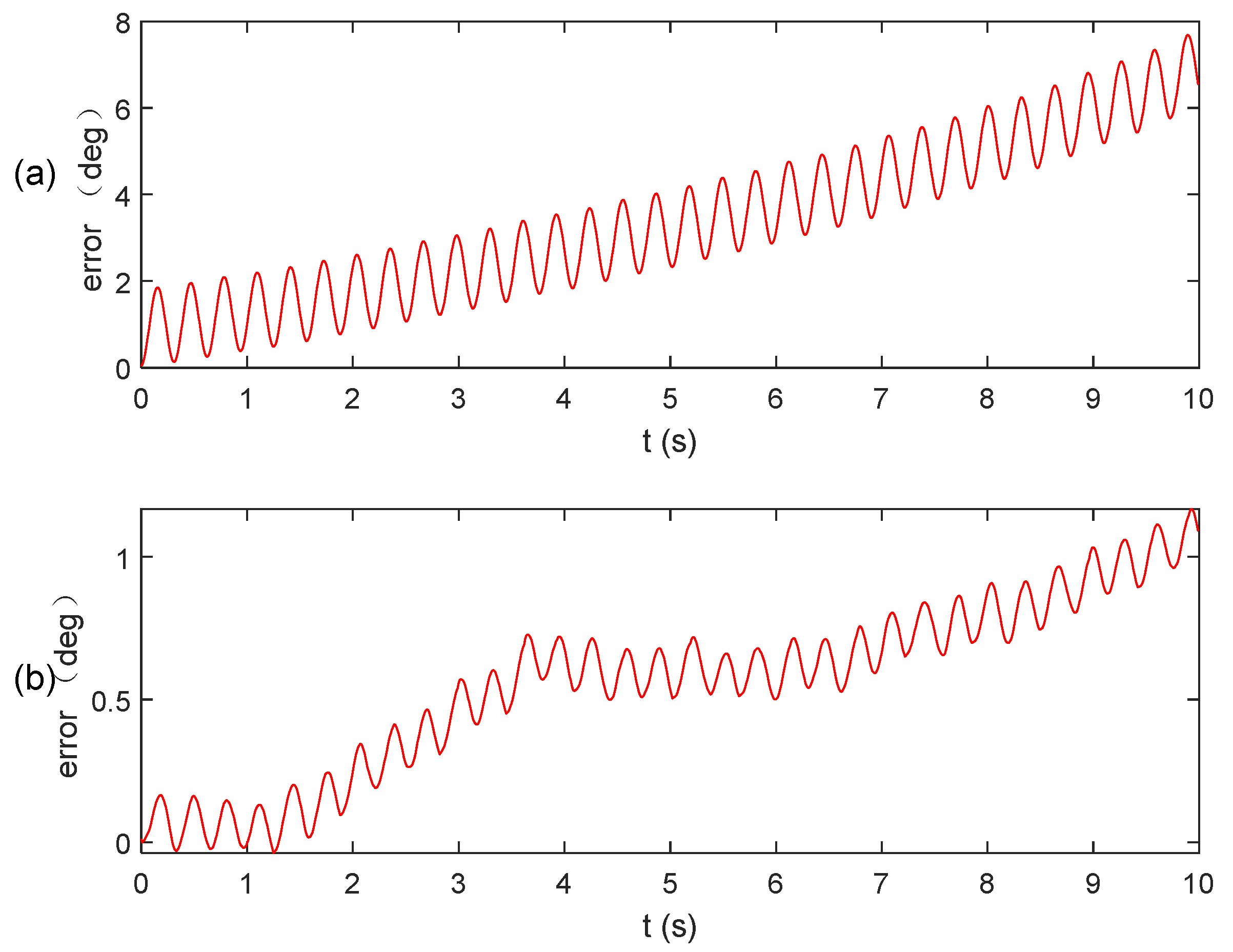

4.1. Simulation of the Basic Algorithm

4.2. The Fusion Algorithm

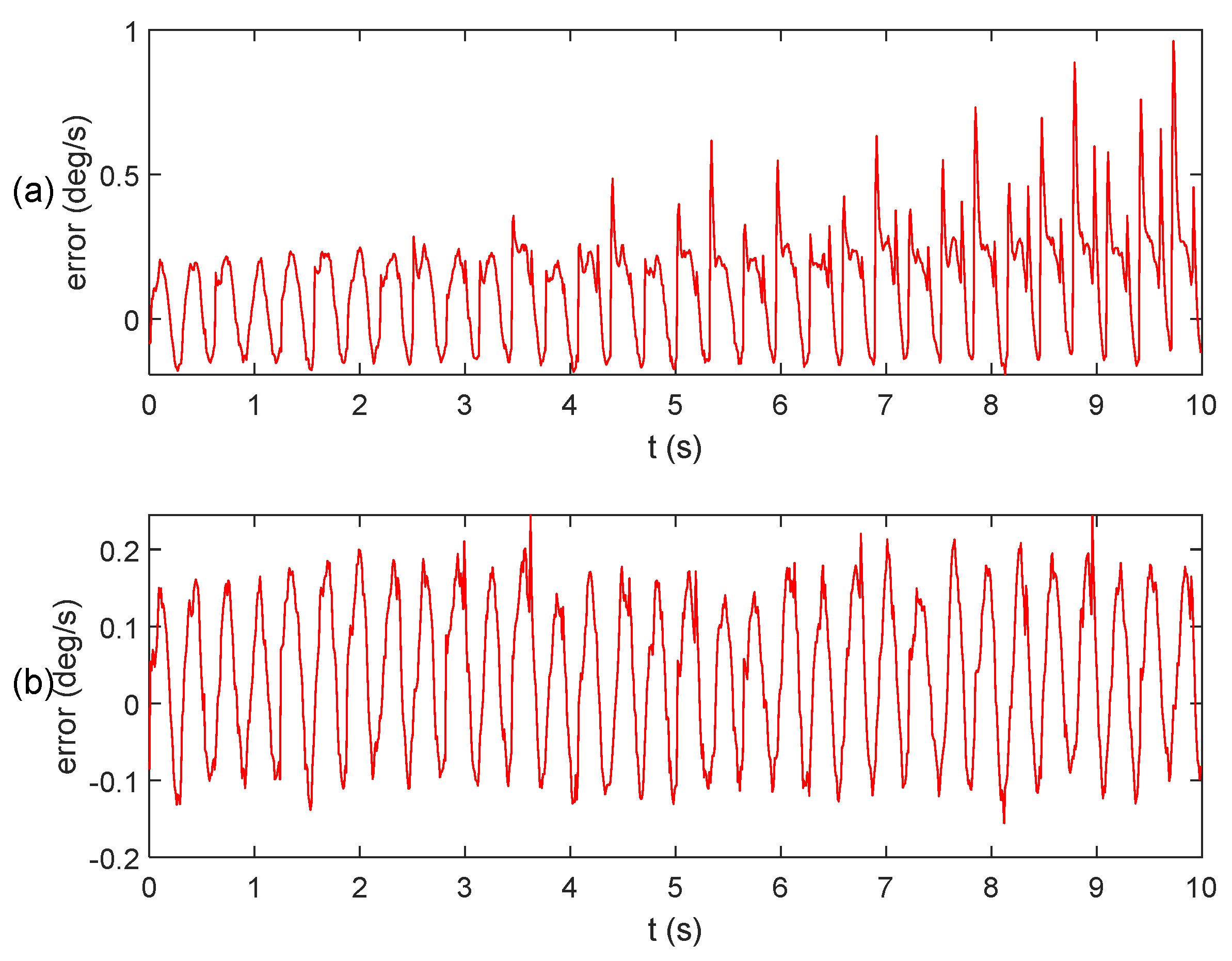

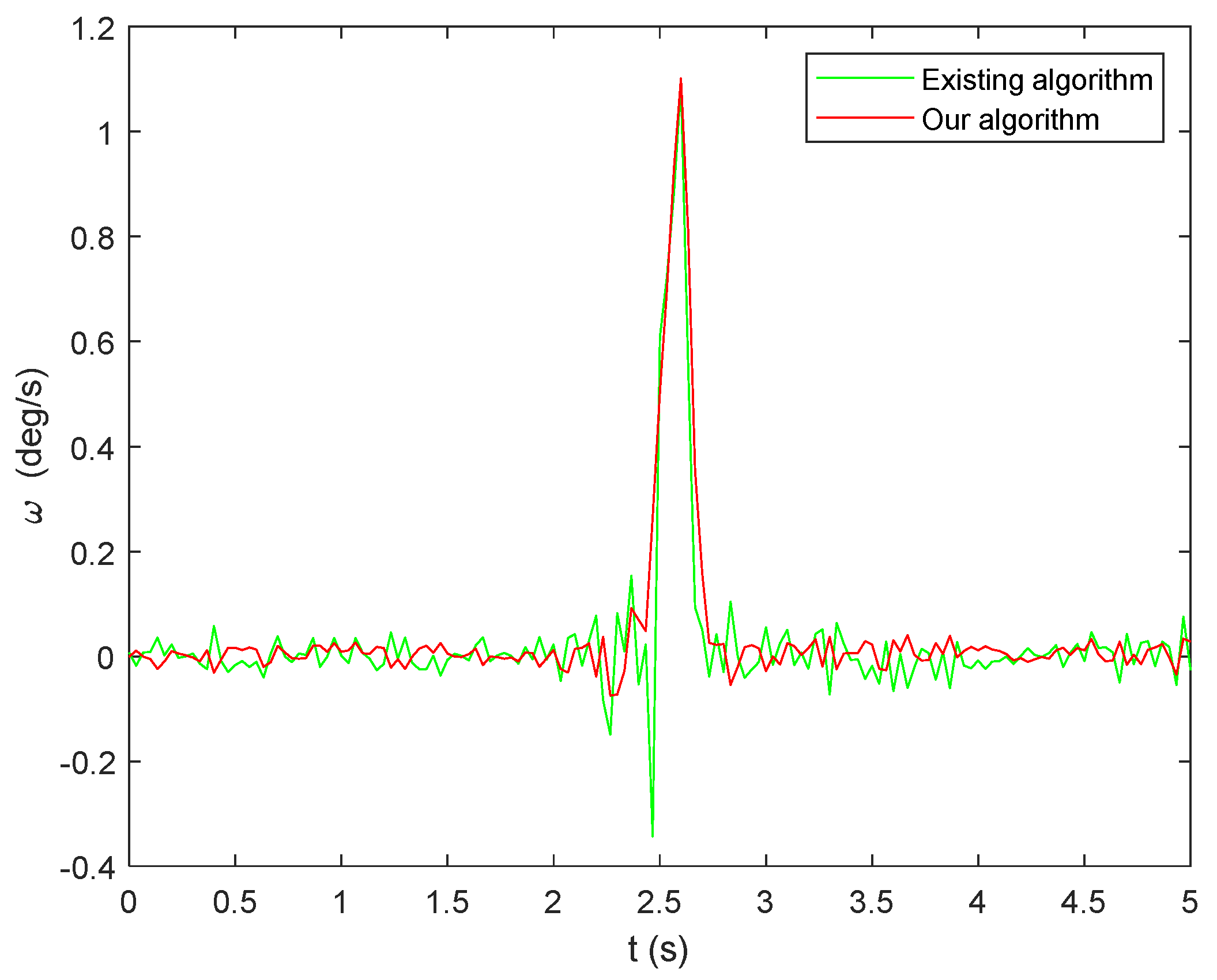

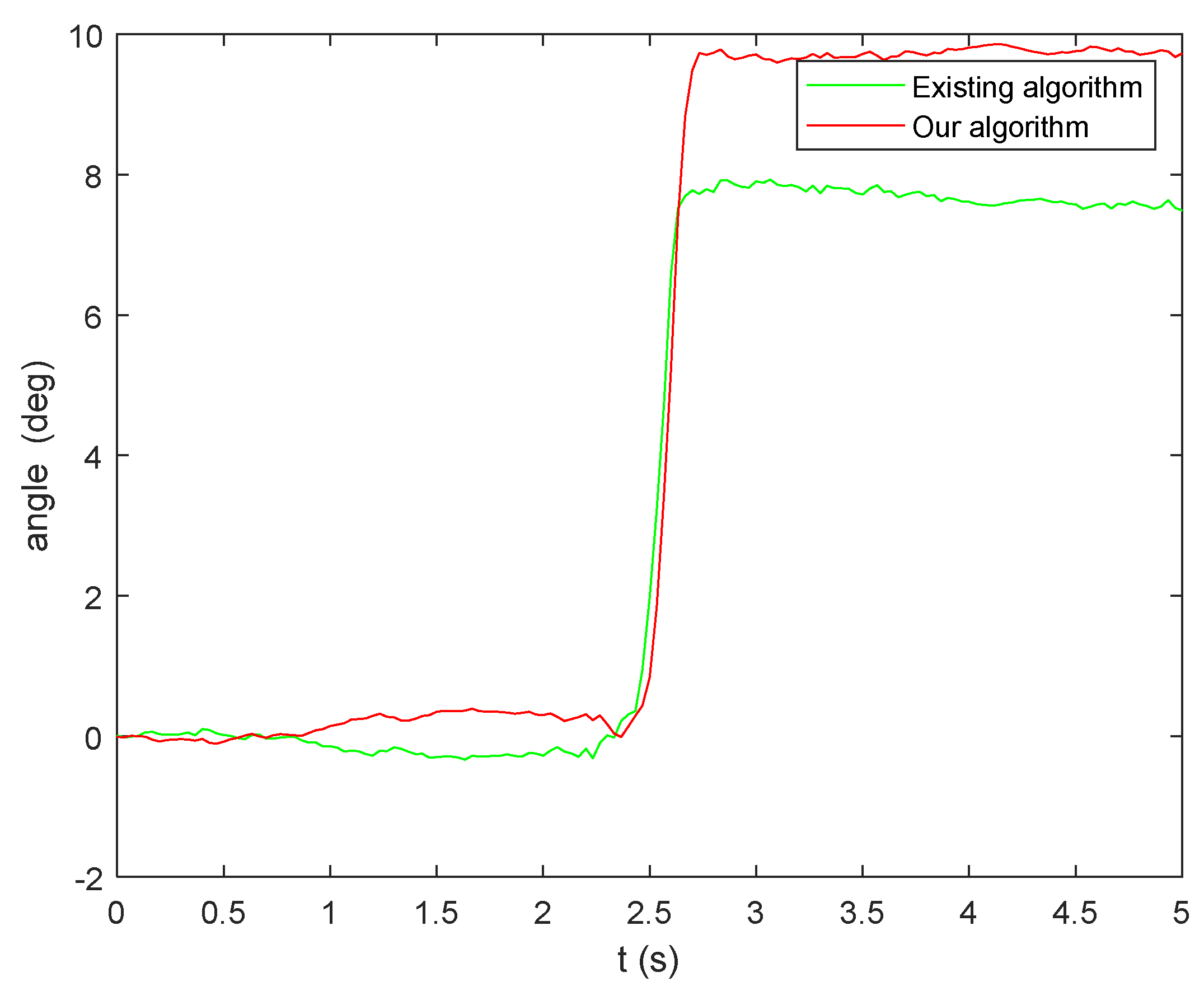

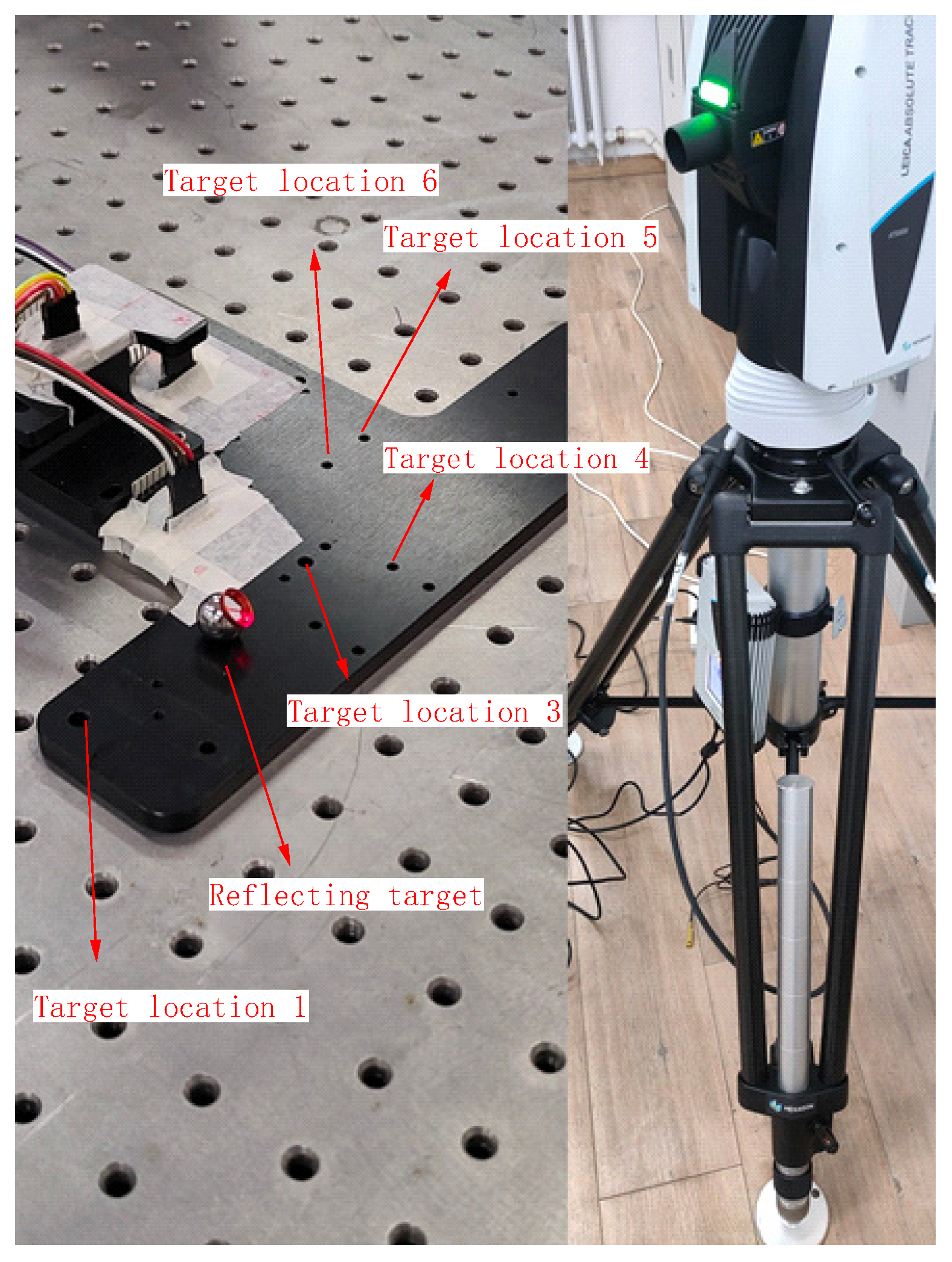

5. Experiment

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hou, M.; Liu, J.; Liu, D.; Chen, Y.; Zhang, X.; Fan, C. Research on calibration technology of laser scanning projection system based on laser ranging. China Laser 2019, 46, 237–245. [Google Scholar]

- Nocerino, A.; Opromolla, R.; Fasano, G.; Grassi, M.; Balaguer, P.F.; John, S.; Cho, H.; Bevilacqua, R. Experimental validation of inertia parameters and attitude estimation of uncooperative space targets using solid state LIDAR. Acta Astronaut. 2023, 210, 428–436. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, X.; Lu, Z.; Liao, W. An improved central difference Kalman filter for satellite attitude estimation with state mutation. Int. J. Robust Nonlinear Control 2022, 32, 3442–3468. [Google Scholar] [CrossRef]

- Abdelaziz, N.; El-Rabbany, A. INS/LIDAR/Stereo SLAM Integration for Precision Navigation in GNSS-Denied Environments. Sensors 2023, 23, 7424. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Zhan, X.; Zhang, X. Nonlinear Complementary Filter for Attitude Estimation by Fusing Inertial Sensors and a Camera. Sensors 2020, 20, 6752. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, H.; Xu, G.; Liu, H.; Liu, X. Attitude anti-interference federal filtering algorithm for MEMS-SINS/GPS/magnetometer/SV integrated navigation system. Meas. Control 2020, 53, 46–60. [Google Scholar] [CrossRef]

- Abdelaziz, N.; El-Rabbany, A. An Integrated INS/LiDAR SLAM Navigation System for GNSS-Challenging Environments. Sensors 2022, 22, 4327. [Google Scholar] [CrossRef]

- Jiao, J.C. New scheme for vibration test by applying 3-axis acceleration. China Meas. Test. 2012, 38, 109–112. [Google Scholar]

- Barbour, N.; Schmidt, G. Inertial sensor technology trends. IEEE Sens. J. 2001, 1, 332–339. [Google Scholar] [CrossRef]

- Kraft, M. Micromachined Inertial Sensors: The State-of-the-Art and a Look into the Future. Meas. Control 2000, 33, 164–168. [Google Scholar] [CrossRef]

- Algrain Marcelo, C. Accelerometer-based platform stabilization. SPIE Acquis. Track. Pointing 1991, 148, 367–382. [Google Scholar]

- Chen, J.; Lee, S.; DeBra, D. Gyroscope Free Strapdown Inertial Measurement Unit by Six Linear Accelerometers. J. Guid. Control Dyn. 1994, 17, 286–290. [Google Scholar] [CrossRef]

- Sanjuan, J.; Sinyukov, A.; Warrayat, M.F.; Guzman, F. Gyro-Free Inertial Navigation Systems Based on Linear Opto-Mechanical Accelerometers. Sensors 2023, 23, 4093. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.T.; Chen, S.Y.; Li, Y.M.; Zhang, H.X. Strapdown Inertial Navigation System without Gyros. Acta Aeronaut. Astronaut. Sin. 1997, 101–105. [Google Scholar]

- Zappa, B.; Legnani, G.; Van Den Bogert, A.J.; Adamini, R. On the Number and Placement of Accelerometers for Angular Velocity and Acceleration Determination. J. Dyn. Syst. Meas. Control-Trans. Asme 2001, 123, 552–554. [Google Scholar] [CrossRef]

- Xiao, C.; Hao, Y.P.; Wang, L. Research on Inertial Measurement Unit Combination in High-Speed Guided Munitions. Foreign Electron. Meas. Technol. 2008, 10, 35–38. [Google Scholar]

- Buhmann, A.; Peters, C.; Cornils, M.; Manoli, Y. A GPS aided Full Linear Accelerometer Based Gyroscope-free Navigation System. In Proceedings of the IEEE/ION PLANS 2006, San Diego, CA, USA, 25–27 April 2006; pp. 622–629. [Google Scholar]

- Park, S.; Hong, S.K. Angular Rate Estimation Using a Distributed Set of Accelerometers. Sensors 2011, 11, 10444–10457. [Google Scholar] [CrossRef]

- Zhang, H.X.; Wang, S.C.; Yang, Y.L.; Ma, Y.H.; Qin, L.; Zhang, X.X. Optimization of the Angular Velocity Solution Method for All-Accelerometer Inertial Measurement Systems. J. Chin. Inert. Technol. 2008, 16, 672–675. [Google Scholar]

- Wang, X.N.; Wang, S.Z.; Zhu, H.B. Study on algorithm of angular velocity of GFSINS. J. Nav. Univ. Eng. 2008, 15–19+76. [Google Scholar]

- Zhao, L.; Chen, Z. A New Method for Improving the Angular Velocity Calculation Precision of Gyroscope-Free Strapdown Inertial Navigation System. J. Syst. Simul. 2003, 579–580+603. [Google Scholar]

- Wang, C.; Dong, J.X.; Yang, S.H.; Kong, X.W. Hybrid algorithm for angular velocity calculation in a gyroscope-free strapdown inertial navigation system. Chin. J. Chin. Inert. Technol. 2010, 18, 401–404+409. [Google Scholar]

- Fu, Q.; Dai, X.B. Research on calibration technology of multi-axial vibration table based on accelerometer array. Struct. Environ. Eng. 2018, 45, 10–16. [Google Scholar]

- Wu, J.W.; Wang, X.; Li, M.W. Research on GF-IMU angular velocity calculation method. J. Syst. Simul. 2009, 21, 3194–3198. [Google Scholar]

- Morozov, A.Y.; Reviznikov, D.L. Sliding Window Algorithm for Parametric Identification of Dynamical Systems with Rectangular and Ellipsoid Parameter Uncertainty Domains. Differ. Equ. 2023, 59, 833–846. [Google Scholar] [CrossRef]

- Wang, K.; Wu, P.; Li, X.; He, S.; Li, J. An adaptive outlier-robust Kalman filter based on sliding window and Pearson type VII distribution modeling. Signal Process. 2024, 216, 109306. [Google Scholar] [CrossRef]

- Tang, Z.; Ma, J.; Liu, W.; Zhang, P.; Lv, F. Sliding Window Dynamic Time-Series Warping Based Ultrasonic Guided Wave Temperature Compensation and Defect Monitoring Method for Turnout Rail Foot. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2022, 69, 2681–2695. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Fan, Y.; Jiang, P.; He, Z.; Xu, P.; Li, X.; Yang, W.; Zhou, W.; Ma, S. Vehicle platform attitude estimation method based on adaptive Kalman filter and sliding window least squares. Meas. Sci. Technol. 2021, 32, 035007. [Google Scholar] [CrossRef]

- Wang, W.; Dai, Y.J.; Chen, H.L. Application of Kalman filter to calculate angular velocity of complicated vibration by full acceleration sensor. China Meas. Test. 2017, 43, 105–109+119. [Google Scholar]

- Bernardes, E.; Viollet, S. Quaternion to Euler angles conversion: A direct, general and computationally efficient method. PLoS ONE. 2022, 17, e0276302. [Google Scholar] [CrossRef]

- Sarabandi, S.; Shabani, A.; Porta, J.M.; Thomas, F. On Closed-Form Formulas for the 3-D Nearest Rotation Matrix Problem. IEEE Trans. Robot. 2020, 36, 1333–1339. [Google Scholar] [CrossRef]

- Gołąbek, M.; Welcer, M.; Szczepański, C.; Krawczyk, M.; Zajdel, A.; Borodacz, K. Quaternion Attitude Control System of Highly Maneuverable Aircraft. Electronics 2022, 11, 3775. [Google Scholar] [CrossRef]

| Accelerometer Serial Number | Installation Position L = [Lx, Ly, Lz] | Sensitive Direction θ = [θx, θy, θz] |

|---|---|---|

| M1 (A1x, A1y, A1z) | [l, 0, 0] | [1 0 0; 0 1 0; 0 0 1] |

| M2 (A2x, A2y, A2z) | [−l, 0, 0] | [1 0 0; 0 1 0; 0 0 1] |

| M3 (A3x, A3y, A3z) | [0, l, 0] | [1 0 0; 0 1 0; 0 0 1] |

| M4 (A4x, A4y, A4z) | [0, 0, l] | [1 0 0; 0 1 0; 0 0 1] |

| Method | Maximum Absolute Error | Average Relative Error | Standard Deviation |

|---|---|---|---|

| Existing algorithm | 7.8823 | 3.4295 | 1.8103 |

| Our algorithm | 1.1435 | 0.5534 | 0.2978 |

| Parameter (Unit) | Input Range (g) | Digital Resolution (µg/LSB) | Noise Density (μg/√Hz) | Bias Instability (μg) | Constant Bias (mg) |

|---|---|---|---|---|---|

| Value | ±1 | 1 | 9 | 3 | 0.5 |

| Method | Rotation Matrix | Angle Change/(°) |

|---|---|---|

| Existing algorithm | ||

| Our algorithm |

| Experiment Number | Angle Measured by Laser Tracker | Existing Algorithm | Our Algorithm | Minimum Absolute Error |

| 1 | 10.1317 | 7.6893 | 9.6705 | 0.4612 |

| 2 | 7.4615 | 8.1204 | 7.1427 | 0.3188 |

| 3 | 11.0265 | 8.6521 | 10.5531 | 0.4734 |

| 4 | −4.3621 | −6.2212 | −4.0082 | 0.3539 |

| 5 | −7.4342 | −6.1290 | −6.9908 | 0.4434 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X.; Liu, T.; Duan, J.; Hou, M. Attitude Algorithm of Gyroscope-Free Strapdown Inertial Navigation System Using Kalman Filter. Micromachines 2024, 15, 346. https://doi.org/10.3390/mi15030346

Jiang X, Liu T, Duan J, Hou M. Attitude Algorithm of Gyroscope-Free Strapdown Inertial Navigation System Using Kalman Filter. Micromachines. 2024; 15(3):346. https://doi.org/10.3390/mi15030346

Chicago/Turabian StyleJiang, Xiong, Tao Liu, Jie Duan, and Maosheng Hou. 2024. "Attitude Algorithm of Gyroscope-Free Strapdown Inertial Navigation System Using Kalman Filter" Micromachines 15, no. 3: 346. https://doi.org/10.3390/mi15030346

APA StyleJiang, X., Liu, T., Duan, J., & Hou, M. (2024). Attitude Algorithm of Gyroscope-Free Strapdown Inertial Navigation System Using Kalman Filter. Micromachines, 15(3), 346. https://doi.org/10.3390/mi15030346