Comparison of Different Cooling Schemes for AlGaN/GaN High-Electron Mobility Transistors

Abstract

:1. Introduction

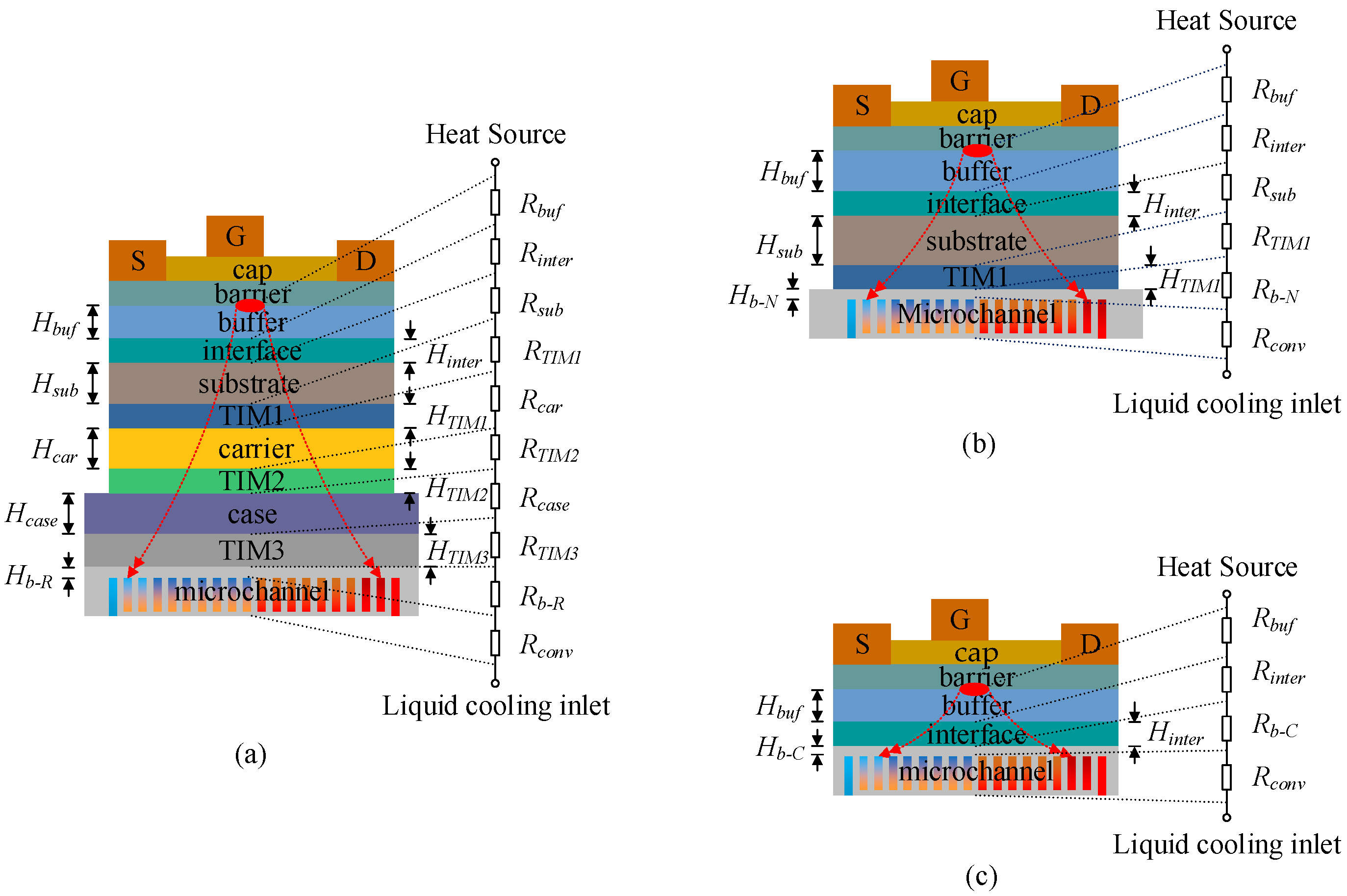

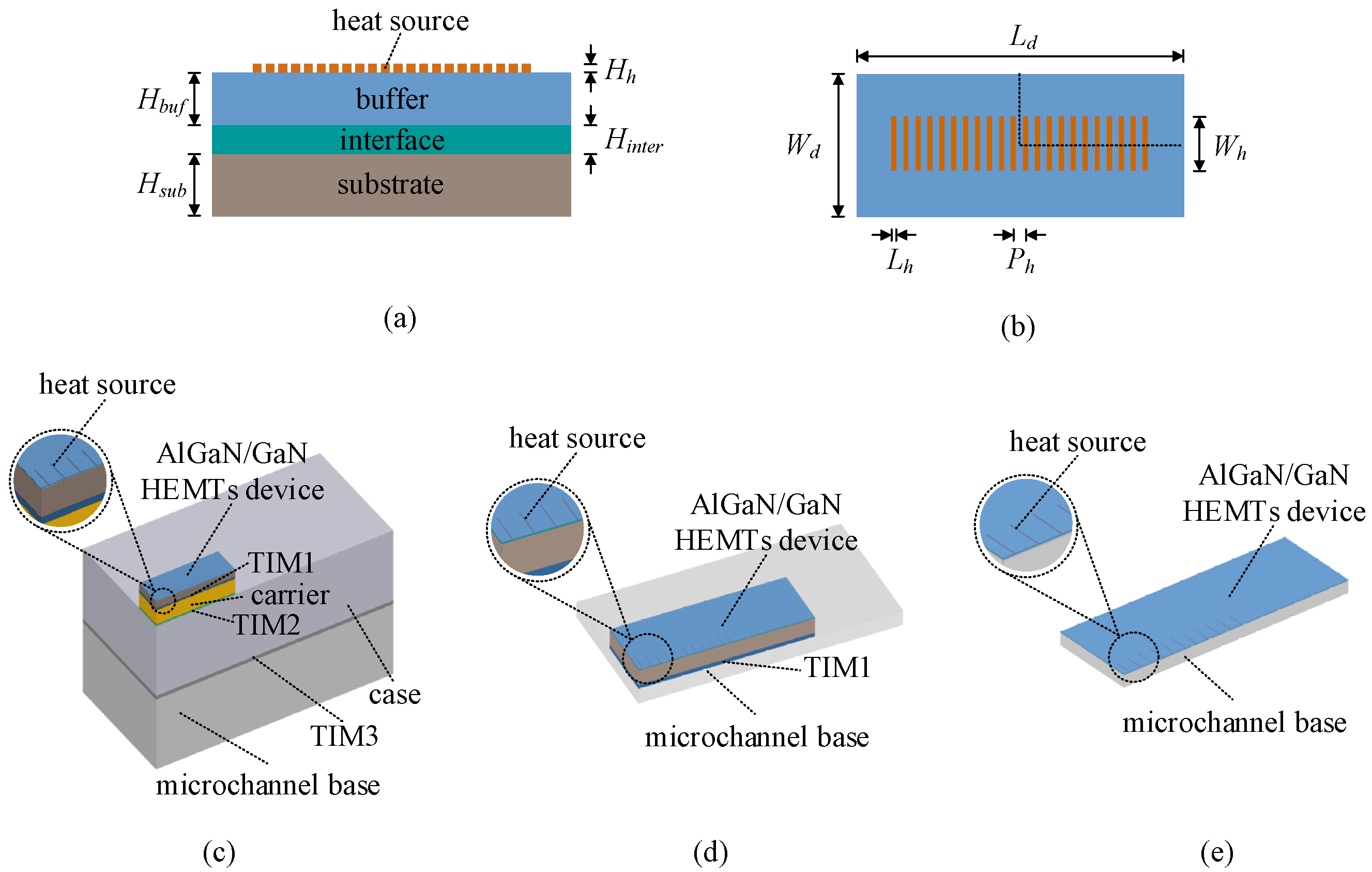

2. Modeling and Simulation

2.1. Model and Materials

- (1)

- (2)

- (3)

- The TBR of the heterogeneous interface between GaN and SiC significantly affects the overall thermal resistance of GaN devices [33], which cannot be ignored. In order to generate a smoother mesh and save computational resources, it is equivalent to a thicker anisotropic material in this model, and the thermal conductivity is set to be λinter in the direction of thermal conduction and 0 in the other directions. λinter is calculated as follows,

- (4)

- Other interface thermal resistances are ignored.

- (5)

- The change in thermal conductivity of the material with temperature and the influence of thermal radiation are not considered.

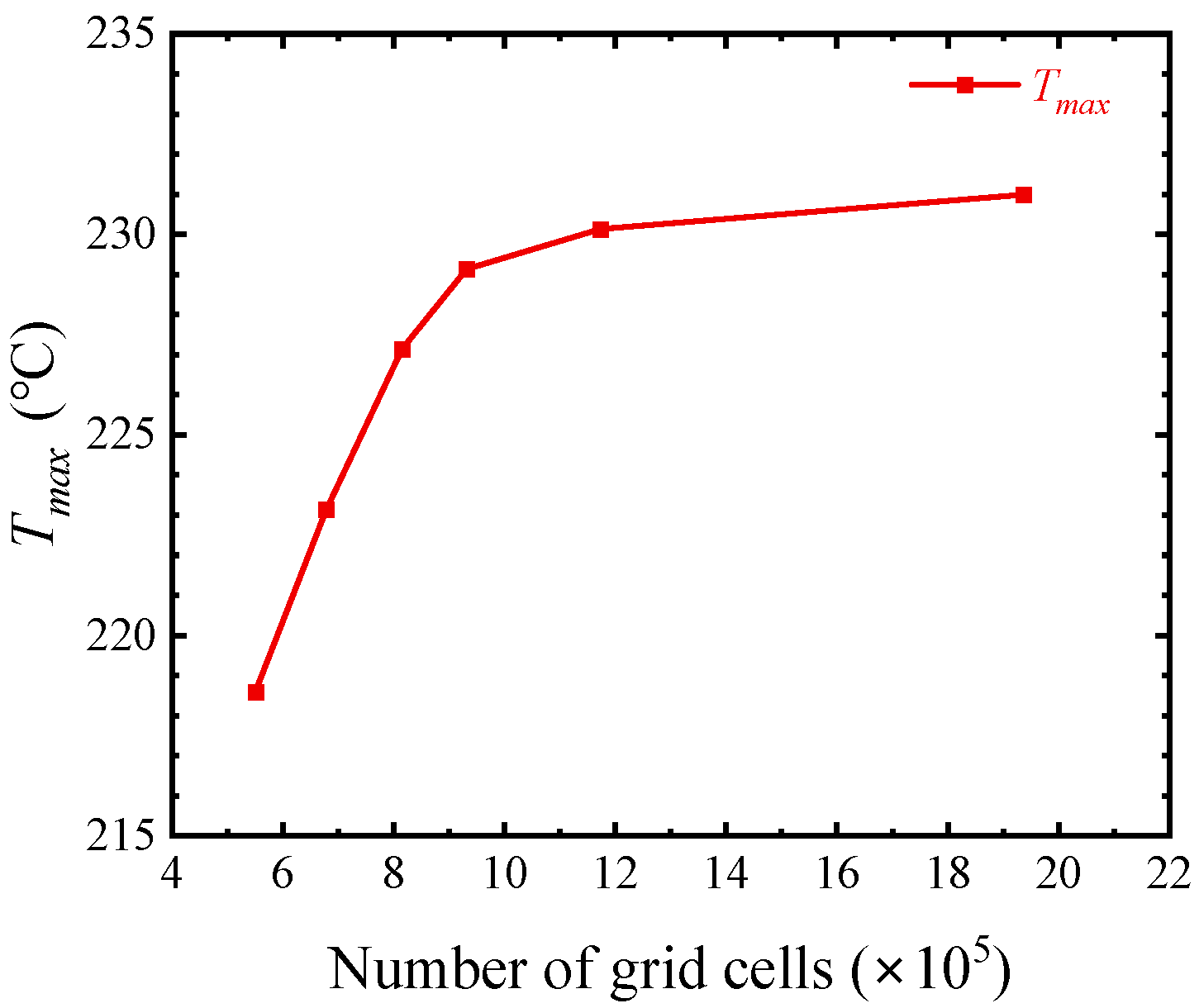

2.2. Mesh Size and Boundary Conditions

2.3. Data Processing

3. Results and Discussion

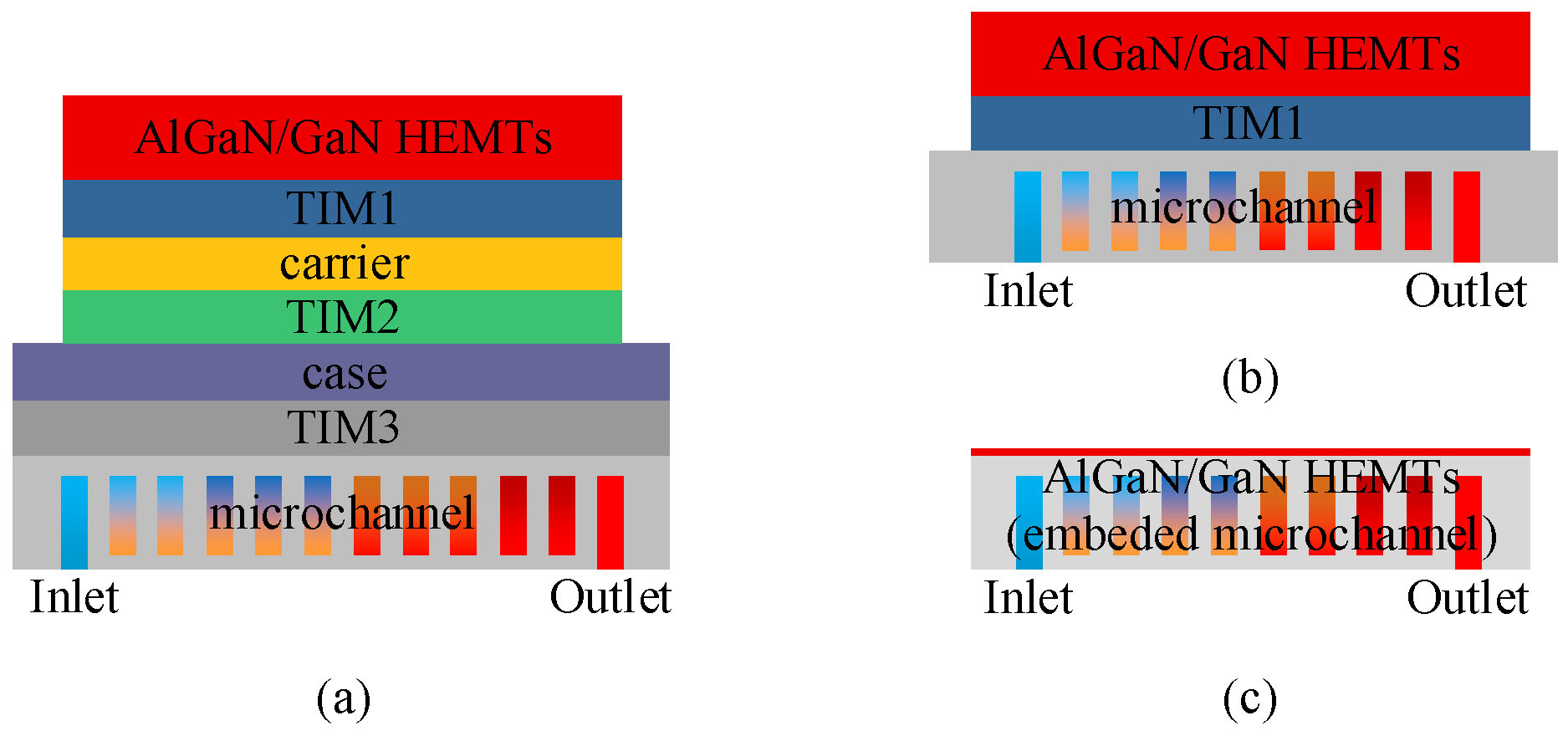

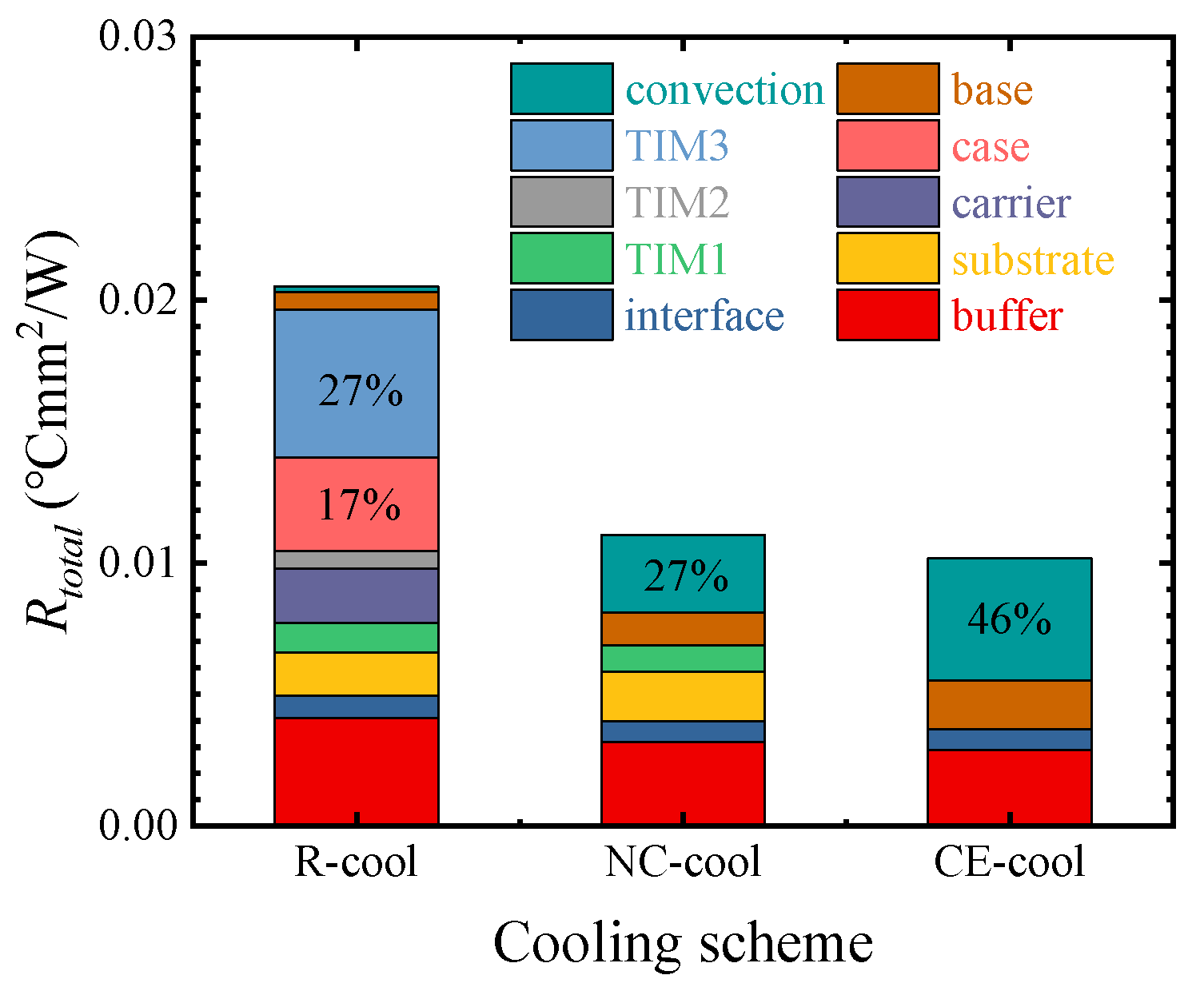

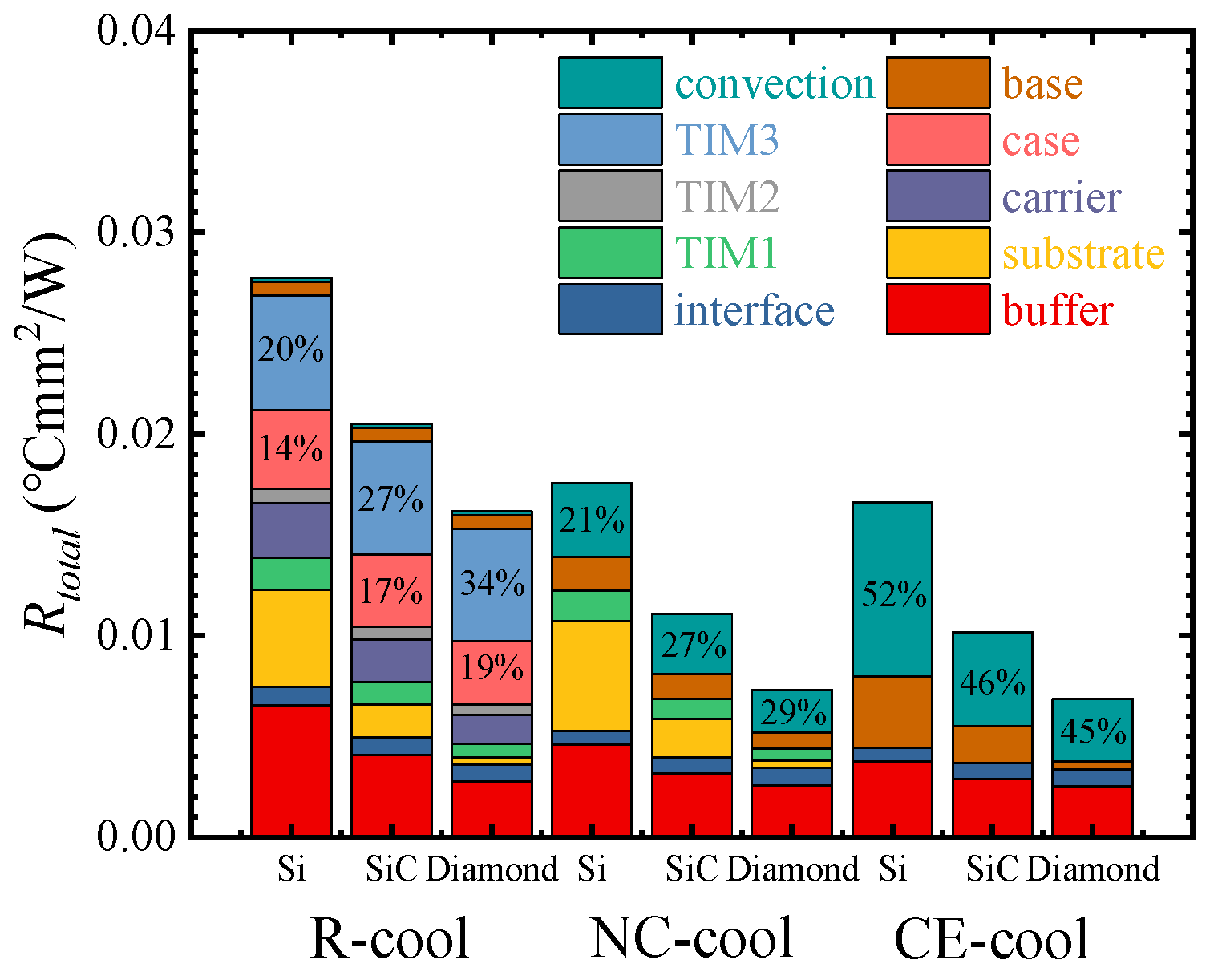

3.1. Cooling Scheme

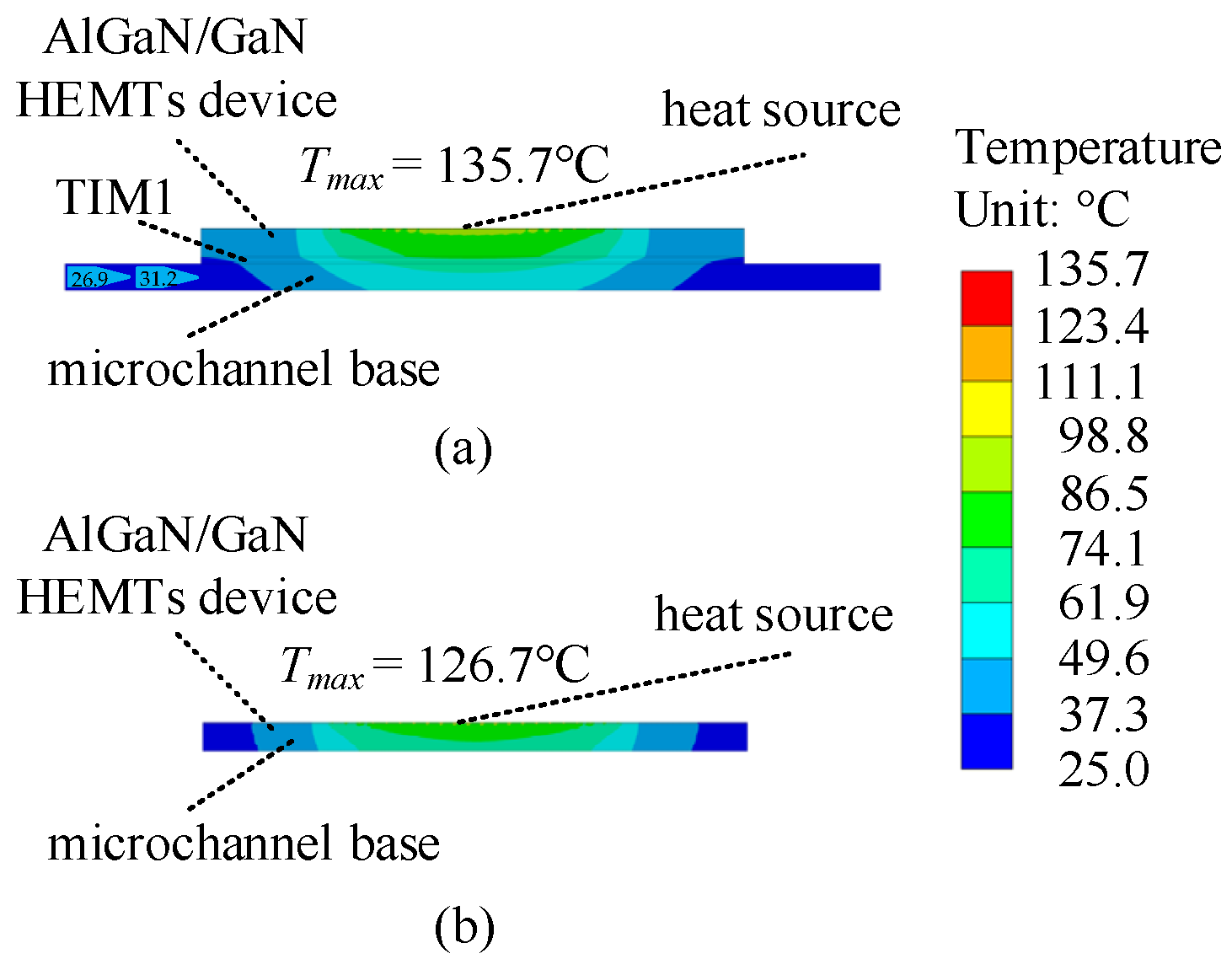

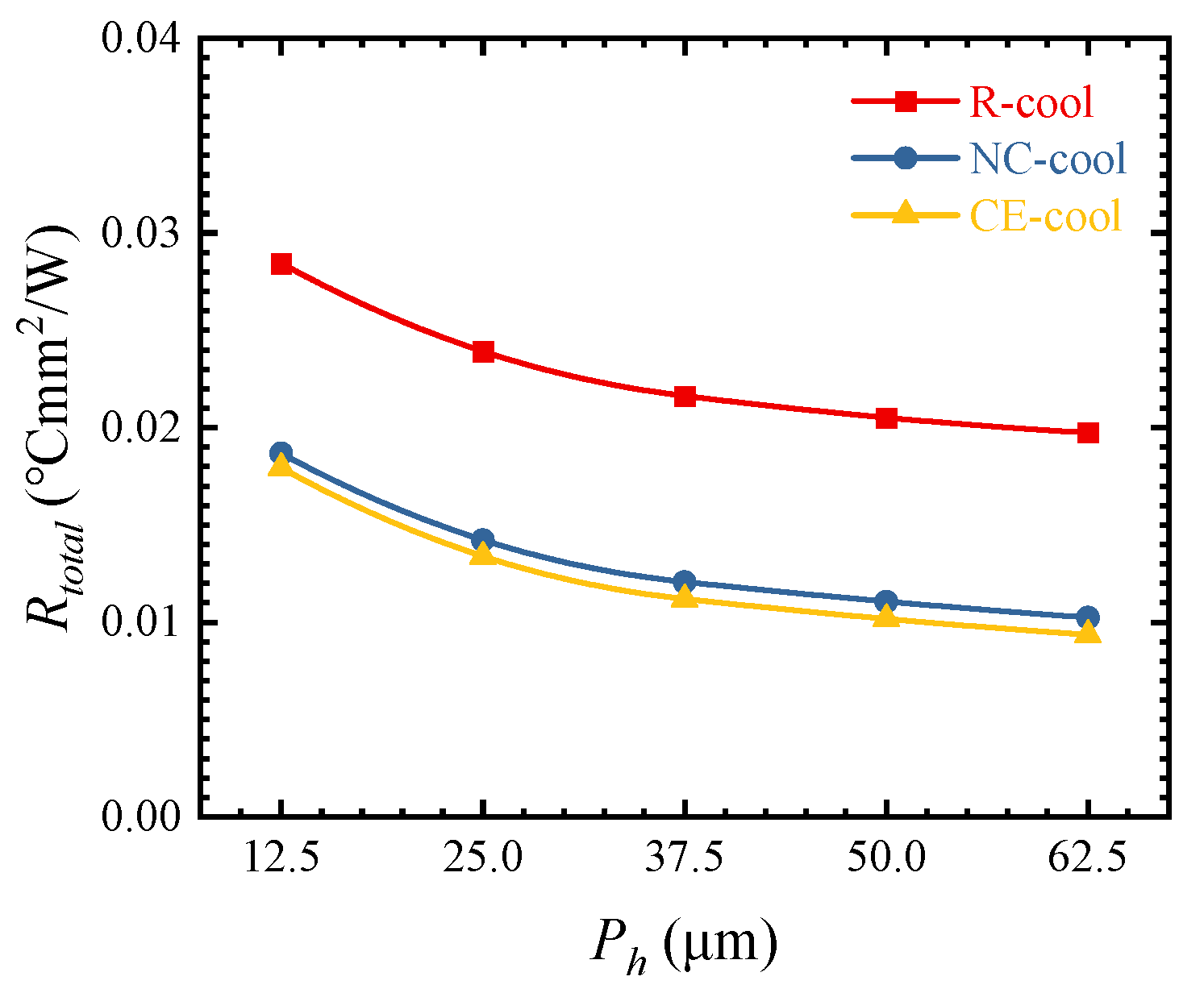

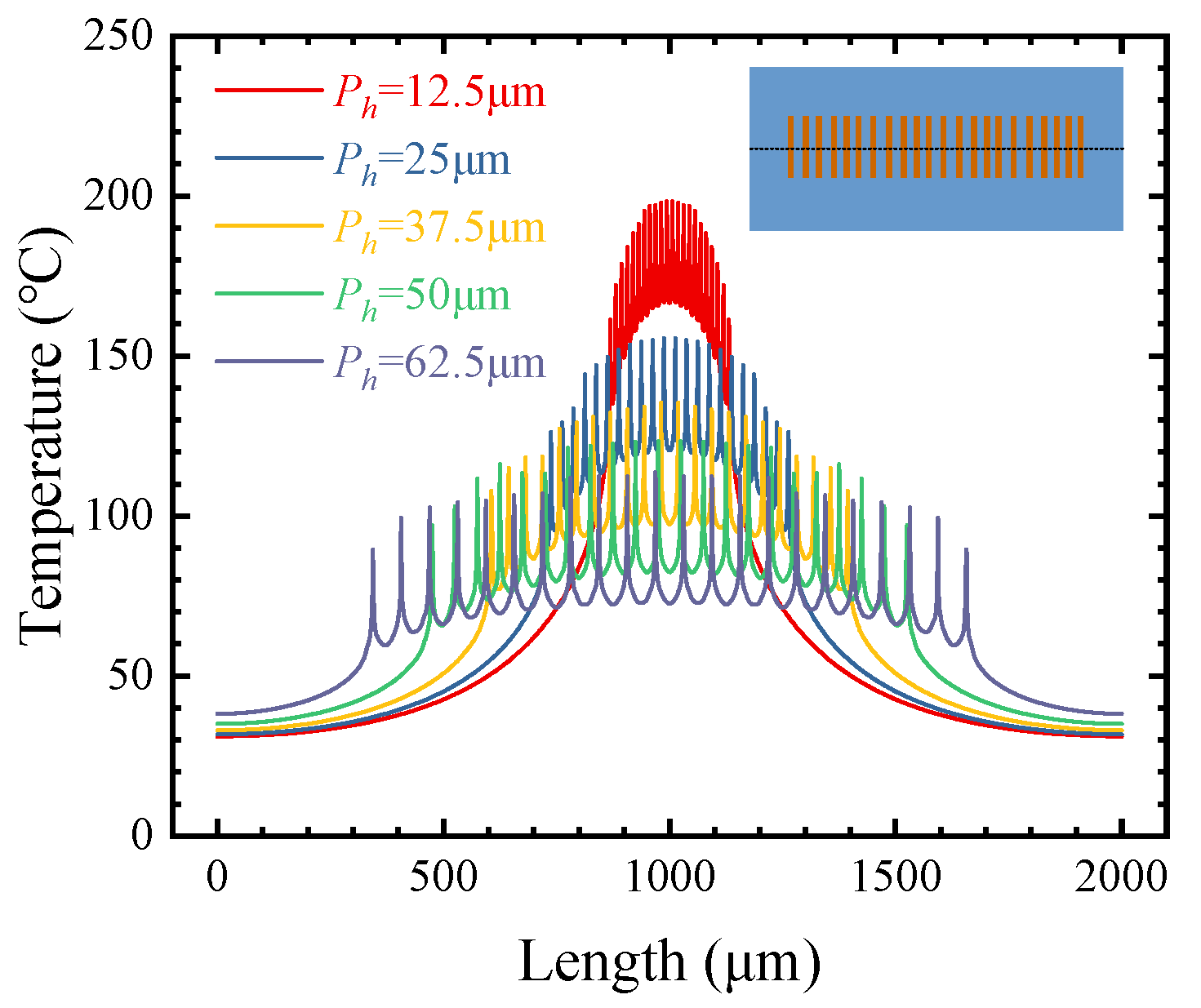

3.2. Heat Source Pitch

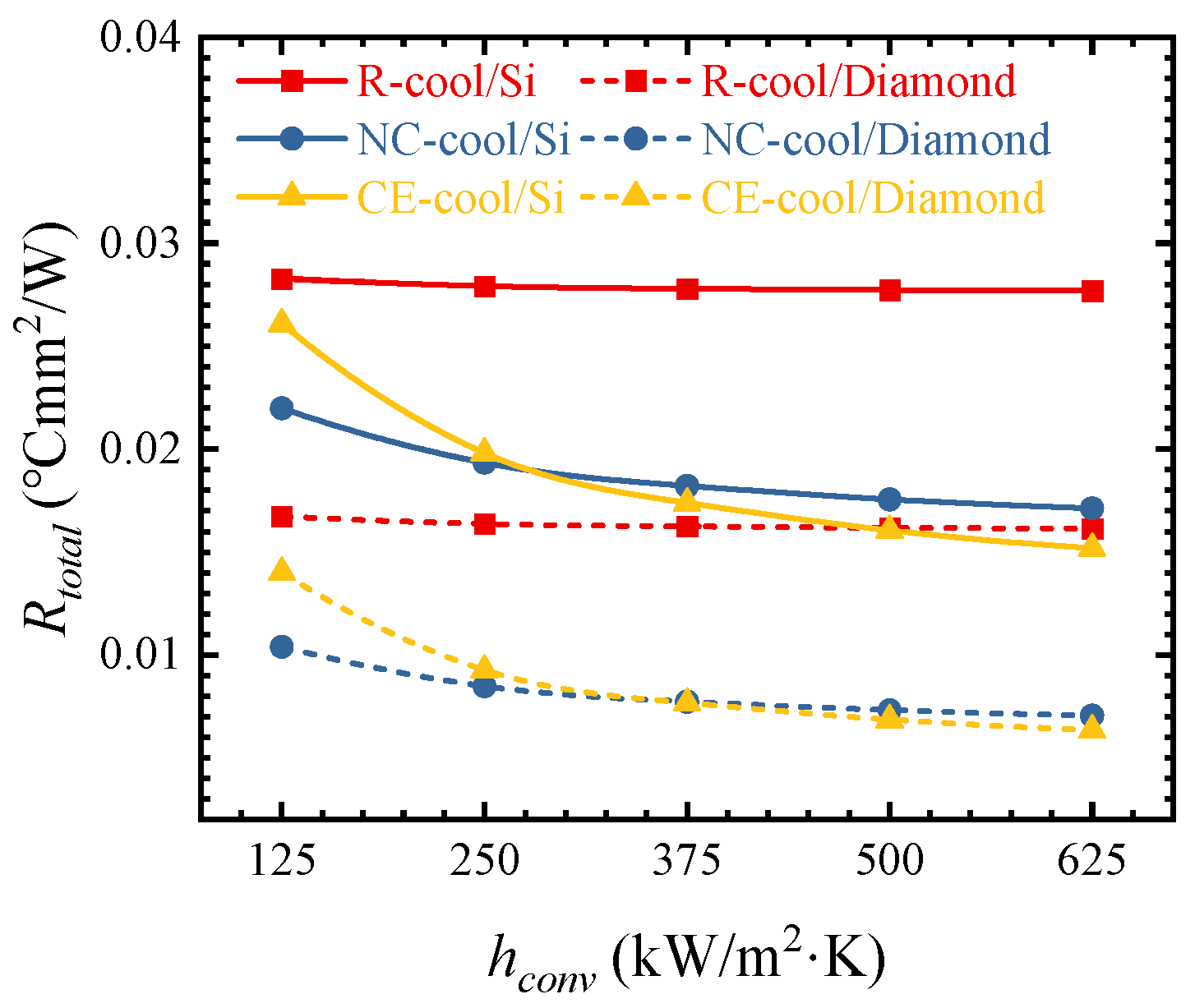

3.3. Substrate and the Convective Heat Transfer Coefficient

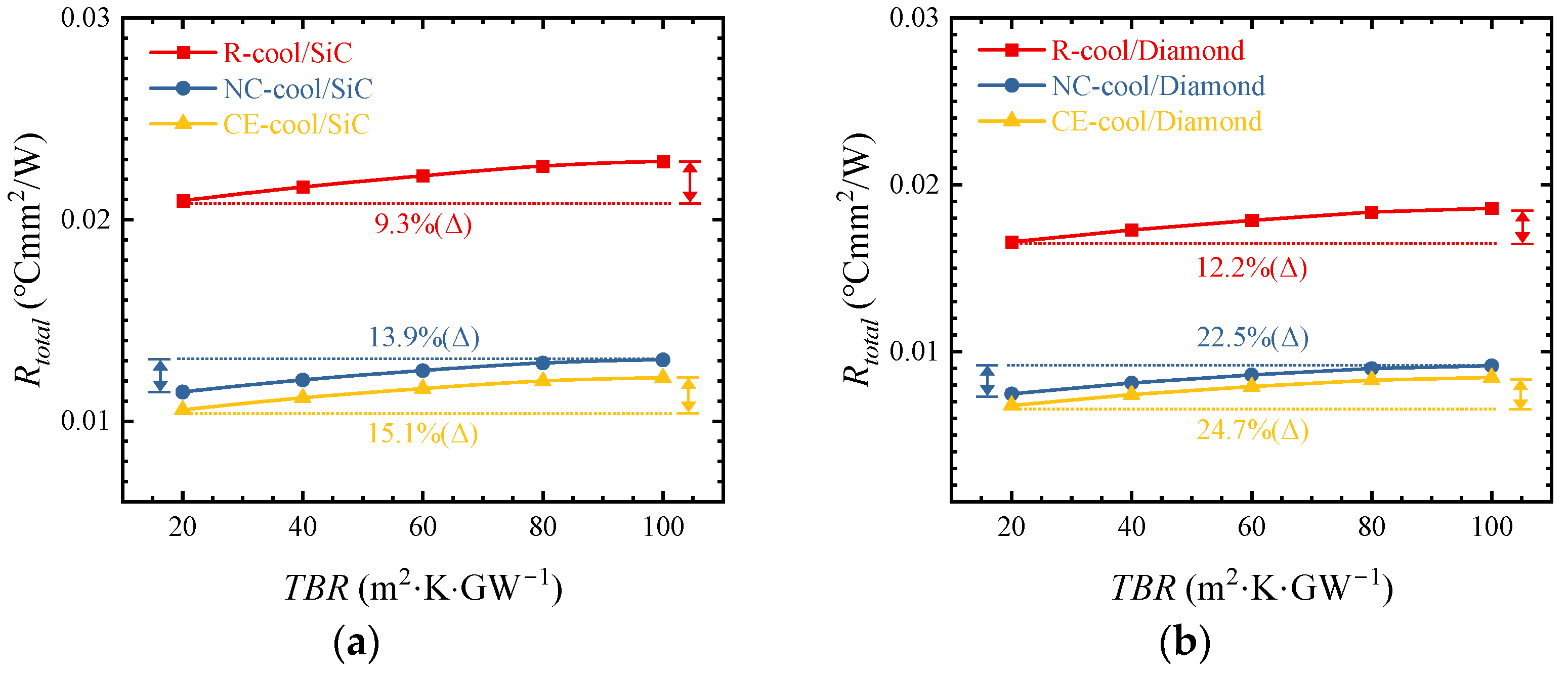

3.4. Boundary Thermal Resistance

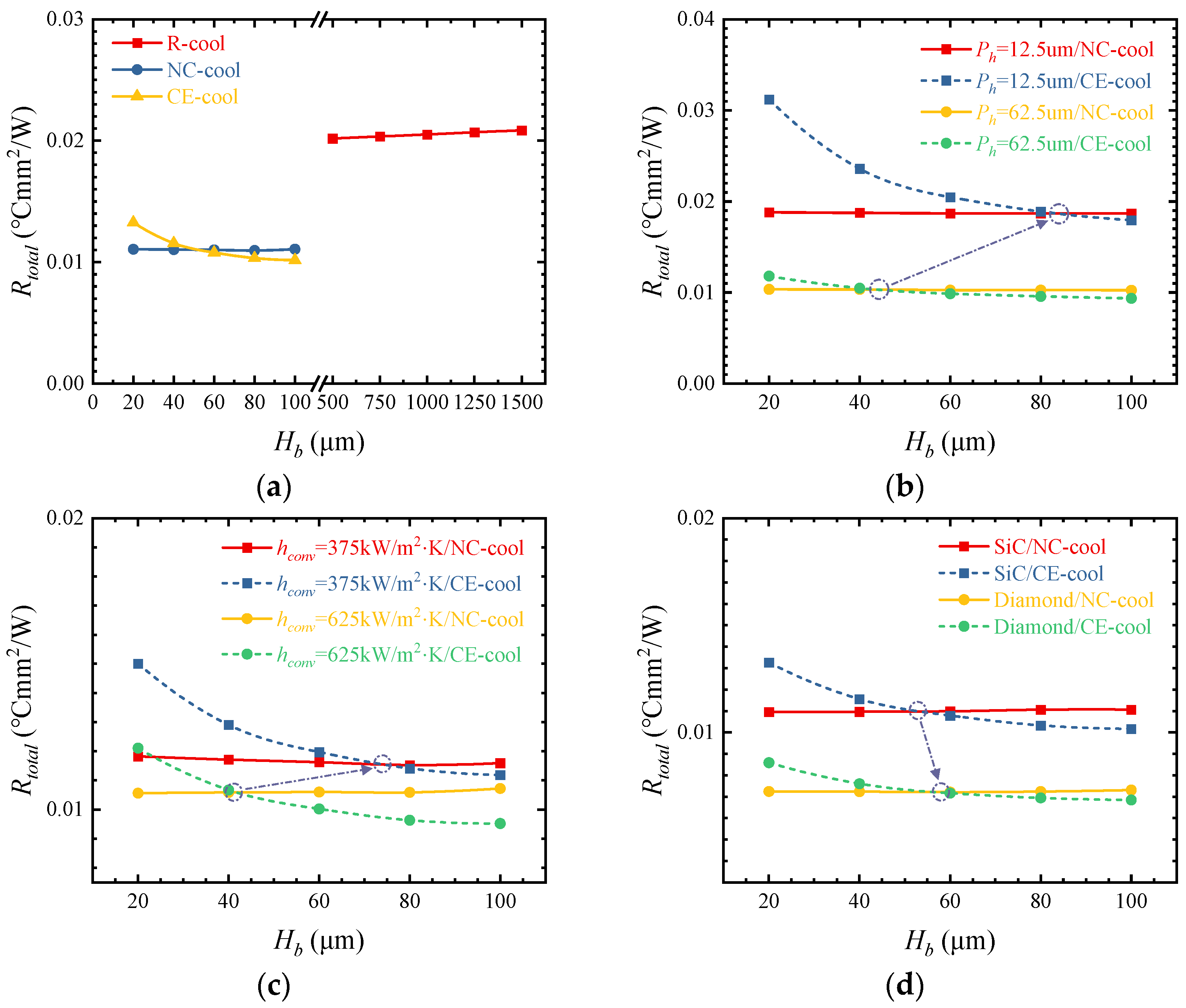

3.5. Height of the Microchannel Base

4. Conclusions

- (1)

- Compared with R-cool, NC-cool and CE-cool exhibit significantly lower thermal resistance, and the thermal resistance of NC-cool and CE-cool are almost the same. The decrease in Hb significantly increases the thermal resistance of CE-cool, and there exists a critical thickness. When the thickness is less than the critical value, NC-cool can obtain superior cooling performance than CE-cool. The critical thickness decreases with increasing Ph and hconv or decreasing λsub.

- (2)

- Increasing Ph or λsub significantly improves the thermal resistance of the three cooling schemes. When Ph increases from 12.5 to 62.5 μm, the thermal resistance of R-cool, NC-cool, and CE-cool decreases by 30.59%, 45.18%, and 47.81%, respectively. When the substrate is Diamond, compared with the Si substrate, the thermal resistance for R-cool, NC-cool, and CE-cool decreases by 41.68%, 58.36%, and 57.23%, respectively.

- (3)

- hconv has little influence on the thermal resistance of R-cool, whereas it has a significant influence on the thermal resistance of NC-cool and CE-cool. When hconv increases from 125 to 625 kW/m2 K, the thermal resistance of AlGaN/HEMTs on the Diamond substrate decreases by 32.32% and 54.68% in the NC-cool and CE-cool schemes, respectively.

- (4)

- The influence of TBR on thermal resistance increases significantly at higher λsub and larger hconv. Under the Diamond substrate with an hconv of 625 kW/m2 K, when TBR increases from 20 to 100 m2·K·GW−1, the thermal resistances of NC-cool and CE-cool increase by 22.5% and 24.7% respectively, while the thermal resistance of R-cool increases by only 12.2%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bar-Cohen, A.; Maurer, J.J.; Felbinger, J.G. DARPA’s IntraInterchip Embedded Cooling (ICECool) Program. In Proceedings of the 2013 International Conference on Compound Semiconductor Manufacturing Technology, New Orleans, LA, USA, 13–16 May 2013; pp. 171–174. [Google Scholar]

- Back, D.; Drummond, K.P.; Sinanis, M.D.; Weibel, J.A.; Garimella, S.V.; Peroulis, D.; Janes, D.B. Design, Fabrication, and Characterization of a Compact Hierarchical Manifold Microchannel Heat Sink Array for Two-Phase Cooling. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 1291–1300. [Google Scholar] [CrossRef]

- Garimella, S.V.; Persoons, T.; Weibel, J.A.; Gektin, V. Electronics Thermal Management in Information and Communications Technologies:Challenges and Future Directions. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 1191–1205. [Google Scholar] [CrossRef]

- Bar-Cohen, A.; Maurer, J.J.; Altman, D.H. Embedded Cooling for Wide Bandgap Power Amplifiers: A Review. J. Electron. Packag. 2019, 141, 040803. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Moore, M.; Saxler, A.; Wisleder, T.; Parikh, P. 40W mm Double Field-plated GaN HEMTs. In Proceedings of the 2006 64th Device Research Conference, State College, PA, USA, 26–28 June 2006; pp. 151–152. [Google Scholar]

- Ditri, J.; Pearson, R.R.; Cadotte, R.; Hahn, J.W.; Fetterolf, D.; McNulty, M.; Luppa, D. GaN Unleashed: The Benefits of Microfluidic Cooling. IEEE Trans. Semicond. Manuf. 2016, 29, 376–383. [Google Scholar] [CrossRef]

- Upadhya, G.; Pullins, C.; Freitag, K.; Hall, G.; Marthinuss, J. State of the Art of Electronics Cooling for Radar Antenna Applications. In Proceedings of the ASME 2017 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, San Francisco, CA, USA, 29 August 2017; p. IPACK2017-74080. [Google Scholar]

- Ditri, J.; Cadotte, R.; Fetterolf, D.; McNulty, M. Impact of Microfluidic Cooling on High Power Amplifier RF Performance. In Proceedings of the 2016 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 1501–1504. [Google Scholar]

- Nam, H.; Kim, J.; Jeon, J.; Jhon, H.; Kim, J. High-Performance RF Power Amplifier Module Using Optimum Chip-Level Packaging Structure. IEEE Trans. Ind. Electron. 2022, 69, 5660–5668. [Google Scholar] [CrossRef]

- Guo, H.; Kong, Y.; Chen, T. Thermal simulation of high power GaN-on-diamond substrates for HEMT applications. Diam. Relat. Mater. 2016, 73, 260–266. [Google Scholar] [CrossRef]

- Gerrer, T.; Pomeroy, J.; Yang, F.; Francis, D.; Carroll, J.; Loran, B.; Witkowski, L.; Yarborough, M.; Uren, M.J.; Kuball, M. Thermal Design Rules of AlGaN/GaN-Based Microwave Transistors on Diamond. IEEE Trans. Electron Devices 2021, 68, 1530–1536. [Google Scholar] [CrossRef]

- Kim, T.; Song, C.; Park, S.I.; Lee, S.H.; Lee, B.J.; Cho, J. Modeling and analyzing near-junction thermal transport in high-heat-flux GaN devices heterogeneously integrated with diamond. Int. Commun. Heat Mass Transf. 2023, 143, 106682. [Google Scholar] [CrossRef]

- Lian, T.; Xia, Y.; Wang, Z.; Yang, X.; Fu, Z.; Kong, X.; Lin, S.; Ma, S. Thermal property evaluation of a 2.5D integration method with device level microchannel direct cooling for a high-power GaN HEMT device. Microsyst. Nanoeng. 2022, 8, 119. [Google Scholar] [CrossRef]

- Yu, M.; Zhang, H.; Huang, M.; Zhang, H.; Zhu, J. Microfluidic silicon interposer for thermal management of GaN device integration. Appl. Therm. Eng. 2023, 230, 120681. [Google Scholar] [CrossRef]

- Ditri, J.; McNulty, M.K.; Igoe, S. Embedded Microfluidic Cooling of High Heat Flux Electronic Components. In Proceedings of the 2014 Lester Eastman Conference on High Performance Devices (LEC), Ithaca, NY, USA, 5–7 August 2014; pp. 1–4. [Google Scholar]

- Ditri, J.; Hahn, J.; Cadotte, R.; McNulty, M.; Luppa, D. Embedded cooling of high heat flux electronics utilizing distributed microfluidic impingement jets. In Proceedings of the ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, San Francisco, CA, USA, 6–9 July 2015; p. IPACK2015-48689. [Google Scholar]

- Jung, K.W.; Kharangate, C.R.; Lee, H.; Palko, J.; Zhou, F.; Asheghi, M.; Dede, E.M.; Goodson, K.E. Embedded cooling with 3D manifold for vehicle power electronics application: Single-phase thermal-fluid performance. Int. J. Heat Mass Transf. 2019, 130, 1108–1119. [Google Scholar] [CrossRef]

- Jung, K.W.; Cho, E.; Lee, H.; Kharangate, C.; Zhou, F.; Asheghi, M.; Dede, E.M.; Goodson, K.E. Thermal and Manufacturing Design Considerations for Silicon-Based Embedded Microchannel-3D Manifold Coolers (EMMCs): Part 1—Experimental Study of Single-Phase Cooling Performance With R-245fa. J. Electron. Packag. 2020, 142, 031117. [Google Scholar] [CrossRef]

- Jung, K.W.; Hazra, S.; Kwon, H.; Piazza, A.; Jih, E.; Asheghi, M.; Gupta, M.P.; Degner, M.; Goodson, K.E. Thermal and Manufacturing Design Considerations for Silicon-Based Embedded Microchannel-Three-Dimensional Manifold Coolers—Part 2: Parametric Study of EMMCs for High Heat Flux (∼1 kW/cm2) Power Electronics Cooling. J. Electron. Packag. 2020, 142, 031118. [Google Scholar] [CrossRef]

- van Erp, R.; Soleimanzadeh, R.; Nela, L.; Kampitsis, G.; Matioli, E. Co-designing electronics with microfluidics for more sustainable cooling. Nature 2020, 585, 211–216. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Donmezer, F.N.; Kumar, S.; Graham, S. A Numerical Study on Comparing the Active and Passive Cooling of AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2014, 61, 4056–4061. [Google Scholar] [CrossRef]

- van Erp, R.; Kampitsis, G.; Matioli, E. Efficient Microchannel Cooling of Multiple Power Devices With Compact Flow Distribution for High Power-Density Converters. IEEE Trans. Power Electron. 2020, 35, 7235–7245. [Google Scholar] [CrossRef]

- Ye, Y.; Wu, M.; Kong, Y.; Liu, R.; Yang, L.; Zheng, X.; Jiao, B.; Ma, X.; Bao, W.; Hao, Y. Active Thermal Management of GaN-on-SiC HEMT With Embedded Microfluidic Cooling. IEEE Trans. Electron Devices 2022, 69, 5470–5475. [Google Scholar] [CrossRef]

- Shoemaker, D.C.; Song, Y.; Kang, K.; Schuette, M.L.; Tweedie, J.S.; Sheppard, S.T.; McIlwaine, N.S.; Maria, J.-P.; Choi, S. Implications of Interfacial Thermal Transport on the Self-Heating of GaN-on-SiC High Electron Mobility Transistors. IEEE Trans. Electron Devices 2023, 70, 5036–5043. [Google Scholar] [CrossRef]

- Tang, D.-S.; Cao, B.-Y. Phonon thermal transport and its tunability in GaN for near-junction thermal management of electronics: A review. Int. J. Heat Mass Transf. 2022, 200, 123497. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, Z. Near-junction microfluidic cooling for GaN HEMT with capped diamond heat spreader. Int. J. Heat Mass Transf. 2022, 186, 122476. [Google Scholar] [CrossRef]

- Gupta, M.P.; Vallabhaneni, A.K.; Kumar, S. Self-Consistent Electrothermal Modeling of Passive and Microchannel Cooling in AlGaN/GaN HEMTs. IEEE Trans. Compon. Ackaging Manuf. Technol. 2017, 7, 1305–1312. [Google Scholar] [CrossRef]

- Anderson, T.J.; Hobart, K.D.; Tadjer, M.J.; Koehler, A.D.; Feygelson, T.I.; Pate, B.B.; Hite, J.K.; Kub, F.J.; Eddy, C.R. Nanocrystalline Diamond for near Junction Heat Spreading in GaN Power HEMTs. ECS Trans. 2013, 61, 45–49. [Google Scholar] [CrossRef]

- Han, Y.; Lau, B.L.; Zhang, X.; Leong, Y.C.; Choo, K.F. Thermal Management of Hotspots With a Microjet-Based Hybrid Heat Sink for GaN-on-Si Devices. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1441–1450. [Google Scholar] [CrossRef]

- Bertoluzza, F.; Delmonte, N.; Menozzi, R. Three-dimensional finite-element thermal simulation of GaN-based HEMTs. Microelectron. Reliab. 2009, 49, 468–473. [Google Scholar] [CrossRef]

- Cho, J.; Li, Z.; Bozorg-Grayeli, E.; Kodama, T.; Francis, D.; Ejeckam, F.; Faili, F.; Asheghi, M.; Goodso, K.E. Improved Thermal Interfaces of GaN–Diamond Composite Substrates for HEMT Applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 79–85. [Google Scholar] [CrossRef]

- Chu, K.K.; Yurovchak, T.; Chao, P.C.; Creamer, C.T. Thermal Modeling of High Power GaN-on-Diamond HEMTs Fabricated by Low-Temperature Device Transfer Process. In Proceedings of the 2013 IEEE Compound Semiconductor Integrated Circuit Symposium (CSICS), Monterey, CA, USA, 13–16 October 2013; pp. 1–4. [Google Scholar]

- Song, C.; Kim, J.; Lee, H.; Cho, J. Fundamental limits for near-junction conduction cooling of high power GaN-on-diamond devices. Solid State Commun. 2019, 295, 12–15. [Google Scholar] [CrossRef]

- Bagnall, K.R.; Muzychka, Y.S.; Wang, E.N. Analytical Solution for Temperature Rise in Complex Multilayer Structures With Discrete Heat Sources. IEEE Trans. Compon. Ackaging Manuf. Technol. 2014, 4, 817–830. [Google Scholar] [CrossRef]

- Sarua, A.; Ji, H.; Hilton, K.P.; Wallis, D.J.; Uren, M.J.; Martin, T.; Kuball, M. Thermal Boundary Resistance Between GaN and Substrate in AlGaN/GaN Electronic Devices. IEEE Trans. Electron Devices 2007, 54, 3152–3158. [Google Scholar] [CrossRef]

- Babić, D.I. Optimal AlGaN/GaN HEMT Buffer Layer Thickness in the Presence of an Embedded Thermal Boundary. IEEE Trans. Electron Devices 2014, 61, 1047–1053. [Google Scholar] [CrossRef]

| Parameter | Definition | Value (μm) |

|---|---|---|

| Ld, Wd | Length and width of device | 2000, 700 |

| Lh, Wh, Hh | Length, width, and height of heat source | 0.5, 150, 0.1 |

| Ph | Heat source pitch | 50 |

| Hbuf, Hinter, Hsub, HTIM1, Hcar, HTIM2, Hcase, HTIM3 | Height of buffer, interface, substrate, TIM1, carrier, TIM2, case, and TIM3 | 2, 3, 100, 25, 300, 25, 1000, 50 |

| Lb-R, Wb-R, Hb-R | Length, width, and height of the microchannel base (R-cool) | 6000, 3000, 1000 |

| Lb-N, Wb-N, Hb-N | Length, width, and height of the microchannel base (NC-cool) | 3000, 1500, 100 |

| Lb-C, Wb-C, Hb-C | Length, width, and height of the microchannel base (CE-cool) | 2000, 700, 100 |

| Layer | Meterial | Thermal Conductivity (W/m·K) |

|---|---|---|

| heat source, buffer | GaN | 150 |

| interface | AlN | X, Y, Z: 0, 0, 300 |

| substrate, carrier, case | 4H-SiC, Mo80Cu20, Al50Si50 | 420, 170, 140 |

| TIM1, TIM2, TIM3 | Au80Sn20, Sn63Pb37, silicon grease | 57, 51, 1 |

| microchannel base of R-cool, NC-cool, and CE-cool | 6061Al, Si, 4H-SiC | 155, 148, 420 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Chen, C.; Wang, Q.; Feng, J.; Fu, R.; Zhang, X.; Cao, L. Comparison of Different Cooling Schemes for AlGaN/GaN High-Electron Mobility Transistors. Micromachines 2024, 15, 33. https://doi.org/10.3390/mi15010033

Song Y, Chen C, Wang Q, Feng J, Fu R, Zhang X, Cao L. Comparison of Different Cooling Schemes for AlGaN/GaN High-Electron Mobility Transistors. Micromachines. 2024; 15(1):33. https://doi.org/10.3390/mi15010033

Chicago/Turabian StyleSong, Yunqian, Chuan Chen, Qidong Wang, Jianyu Feng, Rong Fu, Xiaobin Zhang, and Liqiang Cao. 2024. "Comparison of Different Cooling Schemes for AlGaN/GaN High-Electron Mobility Transistors" Micromachines 15, no. 1: 33. https://doi.org/10.3390/mi15010033

APA StyleSong, Y., Chen, C., Wang, Q., Feng, J., Fu, R., Zhang, X., & Cao, L. (2024). Comparison of Different Cooling Schemes for AlGaN/GaN High-Electron Mobility Transistors. Micromachines, 15(1), 33. https://doi.org/10.3390/mi15010033